#Robotic End-Effector Market

Text

Analyzing the Market Dynamics of Robot End Effector Market

The global robot end effector market size is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%.

Growing demand for modular end effectors, increasing adoption of cobots, penetration of automation in SMEs, and increasing adoption in the warehousing, pharmaceutical, and food industry are the main drivers for the growth of the robot end effector market.

The robot end-effector market will grow significantly due to its various applications in several industries, such as automotive, electrical & electronics, food & beverage, and pharmaceutical. Various key players in the market adopt different strategies such as acquisitions, product launches, collaborations, and partnerships to grow in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Driver: Increasing demand for modular end effectors by various industries.

Due to the fast-changing nature of industries, the demand for modular end effectors is increasing. This scenario is observed in the consumer goods industry, specifically packaging, where the shape, size, surface, or weight of the packaging is constantly changing. This shortens the life cycle of an end effector to 1 to 2 years and thereby increases the cost of replacement for the company. Modular end effectors have the capability to accommodate and handle a large variety of objects as required. A modular vacuum bar from Schmalz (Germany) can perfectly seal and lift objects regardless of their size; Zimmer Group (Germany) and Schunk (Germany) introduced a modular gripping system – MATCH with an unlimited range of uses from production and assembly to warehouse logistics, shipping, and even laboratory automation. This modularity ensures that the grippers do not have to be changed from time to time, thereby reducing the cost of redesigning and downtime associated with its change and replacement.

Restraint: High cost of deployment, especially for SMEs.

Small and medium-sized enterprises (SMEs) differ from large-scale industries such as automotive or electronics manufacturing in various ways. SMEs typically have a low threshold for capital expenditure, a low-risk appetite, and limited time to generate returns on their investment. Additionally, their applications are often specific and on a case-by-case basis. For instance, Saint-Gobain, a glass manufacturing company in France, required automation of its glass polishing process that was previously carried out manually. Robotiq successfully automated the process by programming its torque sensor to replicate the hand movements and pressure applied by a human. Unlike large industries, many SMEs have not built their infrastructure around deploying robots, and must often integrate them into their existing floor space at a later stage.

Opportunity: Advancement in robotics has surged the demand for soft grippers.

Advances in soft robotics, coupled with the increasing need to handle delicate items, have enabled rapid progress in soft grippers. Unlike traditional grippers that are made of rigid materials, these end effectors are fabricated from soft and flexible components. Earlier, most end effectors were able to only manipulate objects of fixed size and shape. However, industry requirements are slowly shifting toward the use of components that can grasp and manipulate a large variety of objects. Due to the material softness of the gripper arms, they can be used for sensitive applications such as in the food & beverage or glass manufacturing industries that can handle objects without damaging them. Fruits or vegetables have varying sizes, making soft grippers ideal due to their consistent clamping force irrespective of slight differences in size and shape. Soft grippers are mainly adopted by the food & beverage industry, one of the fastest-growing clients for soft grippers. Hence, the high penetration rate of automation in the food & beverage industry is expected to stimulate the adoption of soft grippers in the next 4 to 5 years.

Challenge: Interoperability and integration issues related to end effectors with existing facilities.

Interoperability is a very important function in any factory or manufacturing unit. There must exist a modular framework for both hardware and software to connect and coordinate various end effector systems. The focus is not only on the software side, which is used for programming, diagnosing, and monitoring but also the interchangeability of hardware between the end effector and robot arm. There have been cases in the robot end effector industry where a client has bought a robot arm and an end effector separately that were not fully compatible with each other, and the setup was a huge challenge from the onset.

0 notes

Text

Robot End Effector Market Size, Share, Growth Analysis 2024 - 2030

0 notes

Text

#RobotEndEffectorMarket#IndustrialAutomation#ManufacturingTechnology#RoboticsIndustry#EndEffectorDesign#MarketResearch#AutomationSolutions

0 notes

Text

0 notes

Text

Unlocking Precision and Performance: The Power of Hiwin Linear Bearings in Ghaziabad

Introduction: Hiwin Linear Bearings Redefining Engineering Excellence

In the bustling industrial landscape of Ghaziabad, where precision and performance are paramount, Hiwin linear bearings stand tall as the epitome of engineering excellence. As one of the leading distributors of Hiwin linear bearings in Ghaziabad, Jai Krishna Bearing House is committed to providing industries with the cutting-edge technology they need to achieve unparalleled levels of precision, efficiency, and reliability in their operations. In this blog, we delve into the world of Hiwin linear bearings, exploring their applications, benefits, and the transformative impact they have on industries across Ghaziabad.

Understanding Hiwin Linear Bearings and Their Applications

Introduction to Hiwin Linear Bearings: Hiwin linear bearings are designed to facilitate smooth and precise linear motion in various industrial applications. These bearings consist of a carriage mounted on a linear guide rail, allowing for frictionless movement along a predetermined path. From machine tools and robotics to automation systems and aerospace applications, Hiwin linear bearings find extensive use across diverse industries due to their exceptional accuracy, rigidity, and durability.

Applications in Machine Tools: In the realm of machine tools, where precision is paramount, Hiwin linear bearings play a critical role in ensuring the smooth and accurate movement of cutting tools, spindles, and workpieces. Whether it's milling, drilling, grinding, or turning operations, Hiwin linear bearings provide the stability and repeatability necessary for achieving tight tolerances and superior surface finishes, thereby enhancing the overall productivity and quality of machined components.

Advancements in Robotics and Automation: The adoption of robotics and automation is rapidly transforming industries in Ghaziabad, driving efficiency, productivity, and competitiveness. Hiwin linear bearings serve as the backbone of robotic systems, enabling precise movement and positioning of robotic arms, grippers, and end effectors. With features such as high load capacity, low friction, and minimal maintenance requirements, Hiwin linear bearings empower manufacturers to optimize their production processes and adapt to changing market demands with ease.

Precision in Aerospace and Aviation: In the aerospace and aviation sector, where safety and reliability are paramount, Hiwin linear bearings play a crucial role in critical applications such as aircraft landing gear, flight control systems, and aerospace instrumentation. The exceptional precision and repeatability of Hiwin linear bearings ensure smooth and stable operation even in the most demanding environments, contributing to the safety and efficiency of aerospace operations in Ghaziabad and beyond.

Benefits of Hiwin Linear Bearings in Ghaziabad Industries

Unrivaled Precision and Accuracy: Hiwin linear bearings are renowned for their exceptional precision and accuracy, enabling industries in Ghaziabad to achieve tight tolerances and maintain consistent performance across a wide range of applications.

Enhanced Rigidity and Stability: With features such as preloaded ball circuits and rigid construction, Hiwin linear bearings offer enhanced rigidity and stability, minimizing deflection and ensuring reliable operation even under heavy loads and high-speed conditions.

Longevity and Reliability: Built to withstand the rigors of industrial environments, Hiwin linear bearings are engineered for longevity and reliability, reducing downtime and maintenance costs for businesses in Ghaziabad.

Versatility and Adaptability: From standard linear guides to custom-engineered solutions, Hiwin linear bearings offer unmatched versatility and adaptability to meet the unique requirements of different industries and applications in Ghaziabad.

Conclusion: Elevating Industries with Hiwin Linear Bearings in Ghaziabad

In conclusion, the widespread adoption of Hiwin linear bearings in Ghaziabad reflects their indispensable role in driving innovation, efficiency, and competitiveness across various industrial sectors. As the demand for precision engineering solutions continues to grow, Jai Krishna Bearing House remains at the forefront, providing businesses in Ghaziabad with access to the latest advancements in Hiwin linear bearing technology. With their unparalleled performance, reliability, and versatility, Hiwin linear bearings are poised to continue shaping the future of industrial automation and manufacturing in Ghaziabad, empowering businesses to reach new heights of success and excellence

0 notes

Text

0 notes

Text

Revolutionizing Robotics: Exploring the Explosive Growth of the Articulated Robot Market to Reach $31.89 Billion by 2033

Overview and Scope

The articulated robot refers to a robot that has rotational joints and up to 10 or more axes. The rotary joints enable a full range of motion and significantly expand the robot's capabilities, as they can rotate over many planes. The accuracy and movement pattern nearly resemble a human arm.

Sizing and Forecast

The articulated robot market size has grown rapidly in recent years. It will grow from $15.69 billion in 2023 to $18.26 billion in 2024 at a compound annual growth rate (CAGR) of 16.4%. The growth in the historic period can be attributed to manufacturing sector growth, automotive industry adoption, rise of electronics and semiconductors, focus on efficiency, medical and healthcare applications..

The articulated robot market size is expected to see rapid growth in the next few years. It will grow to $31.89 billion in 2028 at a compound annual growth rate (CAGR) of 15.0%. The growth in the forecast period can be attributed to regulatory support and safety standards, smart factory growth , automotive industry evolution , energy efficiency and sustainability, smes embracing robotics.

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/articulated-robot-global-market-report

Segmentation & Regional Insights

The articulated robot market covered in this report is segmented –

1) By Type: 4-Axis Or Less, 5-Axis, 6-Axis Or More

2) By Payload: Upto 16 Kg, 16 To 60 Kg, 60 To 225 Kg, More Than 225 Kg

3) By Function: Handling, Welding, Dispensing, Assembly, Processing, Other Functions

4) By Component: Controller, Arm, End Effector, Drive, Sensor, Other Components

5) By End Industry: Automotive, Electrical And Electronics, Chemicals, Rubber And Plastics, Metal And Machinery, Food And Beverages, Precision Engineering And Optics, Pharmaceuticals And Cosmetics, Other End-Users

Asia-Pacific was the largest region in the articulated robots market share in 2023. The regions covered in the articulated robot market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8340&type=smp

Major Driver Impacting Market Growth

The increase in demand for industrial robots is expected to propel the growth of the articulated robots market. Industrial robots are mechanical systems or machines programmed to perform production-related activities autonomously in industrial settings. Articulated robots are industrial robots with a human resemblance and are used in various industrial applications.

Key Industry Players

Major companies operating in the articulated robot market report are ABB Ltd., FANUC Corporation, Kawasaki Heavy Industries Ltd., KUKA AG, Omron Adept Technology Inc., Mitsubishi Electric Corporation, Seiko Epson Corporation, Denso Wave Incorporated, Nachi-Fujikoshi Corp., Yaskawa Electric Corporation, Aurotek Corporation, Stubli International, ST Robotics, Toshiba Machine Co. Ltd.

The articulated robot market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

How are Modular Robotics Systems Revolutionizing Factory Operations?

The ballooning utilization of collaborative modular robotics systems is one of the biggest factors responsible for the expansion of the global modular robotics market. Cobots, as they are popularly called, are revolutionizing robot and human relationships in the logistics and manufacturing industries. These systems allow operators to directly provide parts and components to robots for performing the rest of the operation, which leads to reduced requirement for floor space, lower costs, and shorter process time.

Additionally, the highly versatile nature of these systems allows them to perform various tasks and operations with the help of several suitable end-effectors. In the logistics industry, cobots are used for inspecting fragile goods and transporting loads and machine parts. Because of these reasons, the sales of collaborative modular robotics systems are rising rapidly across the world. Besides this, the growing requirement for automation in the manufacturing industry is also fueling the demand for these robots around the world.

Due to the aforementioned factors, the modular robotics market is growing rapidly all over the world. The valuation of the market is predicted to rise from $5.6 billion to $15.1 billion from 2019 to 2030. Furthermore, the market is expected to progress at a CAGR of 9.9% between 2020 and 2030. Depending on robot type, the market is categorized into cartesian modular robots, articulated modular robotics systems, SCARA modular robotics systems, parallel modular robots, and collaborative modular robots.

Out of these, the articulated modular robotics systems category recorded the highest growth in the market in the past years and this trend is likely to continue in the coming years as well. This would be due to the large-scale usage of these robots for handling and managing heavy automotive components and parts in the automotive industry. In addition to this, these robots are extensively used for handling heavy metal parts and sheets in the metal and machinery industry.

The growing sales of these robots are boosting the demand for services, software, and hardware. Out of these, the demand for hardware will be the highest in the future, as per the forecast of the market research company, P&S Intelligence. Sensors, manipulators, driver modules, and controllers are the most commonly used types of hardware. Amongst these, the usage of controllers is currently the highest, because of the utilization of robot controllers in various industrial robots for accomplishing point-to-point repetitive tasks.

Geographically, the modular robotics market registered the highest growth in the Asia-Pacific (APAC) region in the years gone by. This was because of the huge investments that were made in automation in electricals, electronics, and automotive industries, particularly in countries such as India, China, and South Korea. In addition to this, the high usage of collaborative modular robotics systems by various manufacturers further propelled the advancement of the market in the region in the past.

Hence, it can be said with full surety that the sales of modular robotics systems would shoot-up all over the world in the forthcoming years, mainly because of the rising requirement for automation in various industries such as automotive, logistics, electricals, and electronics and also, in the manufacturing sector.

Source: P&S Intelligence

#Modular Robotics Market Share#Modular Robotics Market Size#Modular Robotics Market Growth#Modular Robotics Market Applications#Modular Robotics Market Trends

1 note

·

View note

Text

Robot End Effector Market is Register to Grow at a CAGR of 13.5% during 2023-2028

The global robot end effector market is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%. Increasing demand for modular end effectors and the growing adoption of collaborative robots due to the fast-changing nature of industries are among a few major factors driving the growth of the robot end effector market.

Key players operating in the robot end effector market include Schunk (Germany), Schmalz (Germany), Zimmer Group (Germany), Tünkers (Germany), and Destaco (US) are the top five players in the robot end effector market.

Download PDF Brochure:

https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Grippers is expected to register a higher CAGR during the forecast period.

The market for grippers is largely driven by their handling application in a wide range of workpieces considering their various shapes and size. The increasing application of soft grippers and vacuum grippers in different varieties of handling and assembly applications across several industries would present several growth opportunities to players operating in the gripper segment.

Collaborative industrial robots to record the highest CAGR during the forecast period.

Robot end effector market for collaborative industrial robots is to grow at the highest CAGR during the forecast period. This is due to the adoption of collaborative robots, especially for small and medium-sized companies, to easily adapt to different tasks and enable a faster return on investment (ROI). These robots are witnessing widespread adoption in small and medium-sized enterprises and large-scale, traditional industries such as automotive. With the growing adoption of cobots in many new use cases, such as remote monitoring and remote manufacturing are being enabled, this factor is expected to propel the growth of the end effector market for collaborative industrial robots.

China is expected to account for the largest market share in Asia Pacific market from 2023 to 2028.

China accounted for the largest share of the robot end effector market in Asia Pacific in 2022 and is expected to remain the largest market throughout the forecast period. As many Asian countries are highly populated, and the geriatric population is becoming a concern for the future, the aging population, especially in China, is prompting companies toward automation and industrial robots to reduce costs. With the rise in industrial robots for automation, the demand for their associated end effectors is also expected to increase.

0 notes

Text

Robot Tool Changers Market Recent Developments Study Analysis By 2033

A Robot Tool Changer (RTC) is a device used to quickly and easily change the tool or end-effector attached to a robot arm. This allows the robot to perform multiple tasks without the need to stop and change tools manually.

RTCs typically consist of two parts: a gripper that attaches to the robot arm and a tool-changing mechanism that is mounted on the robot. The gripper is opened and closed using a pneumatic or hydraulic cylinder, and the tool-changing mechanism is operated using an electric motor.

RTCs can be used with a variety of different robot types, including articulated, SCARA, and delta robots. They are often used in applications where the robot needs to perform multiple tasks, such as pick-and-place, welding, and assembly. For example, a robot that assembles cars might need to change its tool from a screwdriver to a wrench.

To Know More: https://www.globalinsightservices.com/reports/robot-tool-changers-market/?utm_id=Snehalkast

Market Outlook

In the current market scenario, there are various factors which are driving the growth of Robot Tool Changers market. Some of the key drivers are as follows:

Increasing demand for automation in various industries: With the increasing competition and need for efficiency and accuracy, there is a growing demand for automation in various industries such as automotive, food & beverage, pharmaceuticals, etc. This is one of the key drivers for the growth of Robot Tool Changers market as these devices help in increasing the productivity and efficiency of the manufacturing process.

Rising labor costs: The rising labor costs across the globe is another key driver for the growth of Robot Tool Changers market. These devices help in reducing the dependence on manual labor, thus leading to lower production costs.

Increasing adoption of collaborative robots: Collaborative robots are becoming increasingly popular in various industries as they offer several advantages over traditional robots such as being safe to work with, easy to program and operate, and cost-effective. This is leading to the increasing adoption of collaborative robots which in turn is driving the growth of Robot Tool Changers market.

Request Sample: https://www.globalinsightservices.com/request-sample/GIS10229/?utm_id=Snehalkast

Major Players

Some of the key players of Robot Tool Changers Market are ATI Industrial Automation Inc. (US), SCHUNK GmbH & Co. KG (Germany), Applied Robotics Inc. (US), Nitta Corporation (Japan), Carl Kurt Walther GmbH & Co. KG (Germany), DESTACO (US), Stäubli International AG (Switzerland), A Dover Company (US), American Grippers Inc (US), and PTM Präzisionstechnik GmbH (Germany).

0 notes

Text

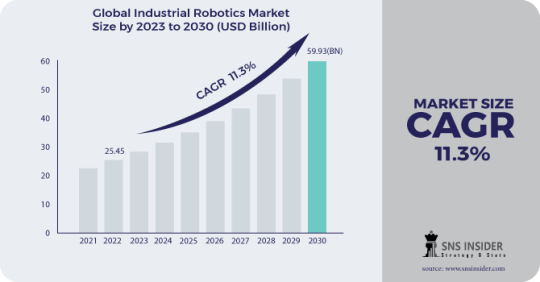

New Research Report On Industrial Robotics Market is Going to Boom by Size, Share, Scope and Forecast-2030

Industrial Robotics Market is going to reach USD 59.93 billion by 2030 and grow at a CAGR of 11.3% over the forecast period 2023-2030.

The most recent Industrial Robotics study evaluates global and regional market estimates and forecasts for all research segments. This study examines market trends, leading companies, supply chain trends, technological advances, key breakthroughs, and future strategies. Market figures were compiled using a combination of primary and secondary sources. Sales revenue from all of the study's specified segments and sub-segments are used to calculate market size. The market sizing analysis employs both top-down and bottom-up approaches for data validation and accuracy checks.

The study uses historical market data to estimate revenue. Other aspects of the industry, such as the supply chain, downstream buyers, and sourcing strategy, have been investigated in order to provide a complete and in-depth picture of the market. Customers who purchase the Industrial Roboticsmarket report will also be subjected to a market positioning analysis, which will take into account factors like target consumer, brand strategy, and pricing strategy. In addition, the study report computes current and prior market values in order to forecast possible market management over the forecast period.

Download Sample Copy of Report: https://www.snsinsider.com/sample-request/1058

Market Segmentation

The Industrial Robotics market segment analysis will assist in determining how each segment will affect market growth in the coming years. In order to determine the market's true potential, the research report also examines all market classifications and sub-segments. In today's global economy, the dynamic nature of the corporate environment is increasing demand for business experts who can keep up with current market conditions.

By Application

Palletizing

Assembling

Welding

Material Handling

Painting

By Types

6-Axis Robots

SCARA

Cartesian

Articulated

Redundant

Delta

Dual-Arm and Parallel

By End-user

Entertainment

Electronics

Automotive

Rubber & Plastic

Food & Beverage

Pharmaceuticals

By Component

Robotic Arms

End Effectors

Drive Units

Robot Accessories

Controllers

Vision Systems

Sensors

Get Exclusive Discout on this Report: https://www.snsinsider.com/discount/1058

Major Questions Answered in the Report

What are the key trends influencing the Industrial Robotics market's growth?

What are the primary strategies used by leading organizations to control a sizable portion of the global market?

How has the rapidly changing business environment of the market influenced growth?

What are the primary macroeconomic factors driving market growth?

Competitive Outlook

For each of the market's top competitors, the research includes current business profiles, gross margins, selling price, sales income, sales volume, product specs with images, and contact information. In the report's conclusion, a descriptive section highlights the feasibility of new projects that may succeed in the global market in the near future, as well as the overall scope of the global market in terms of investment feasibility in various segments of the Industrial Robotics market.

Top Keyplayers:

ABB, DÜrr, FANUC, YASKAWA, KUKA, Denso Corporation, Mitsubishi Electric, Kawasaki Heavy Industries, Universal Robots A/S, NACHI-FUJIKOSHI, Panasonic Corporation, Rockwell Automation, Inc., Bosch GmbH, Yaskawa Electric Corporation, Toshiba Corporation, Seiko Epson

About US:

SNS Insider is a frontrunner in global market research and consulting. We empower clients with the insights they need to navigate evolving landscapes.

Our team leverages a global network to deliver cutting-edge market data, consumer trends, and actionable insights. Through surveys, focus groups, and video discussions, we provide the information you need to make confident decisions.

We are committed to delivering reliable data across a wide range of industries. Recognized as a global leader, we have the expertise to design and implement tailored research programs, from surveys to focus groups, catering to virtually any sector.

Key improvements:

Stronger verbs and adjectives: uses words like "frontrunner," "empower," "navigate," "cutting-edge," to create a more dynamic and confident tone.

Focus on benefits: emphasizes how SNS Insider helps clients make confident decisions and navigate change.

Conciseness: streamlines the text while maintaining key information.

Actionable language: highlights the "tailored" research programs offered by SNS Insider.

Contact Us:

Akash Anand – Head of Business Development & Strategy

[email protected]

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

𝐅𝐫𝐨𝐦 𝐂𝐨𝐧𝐜𝐞𝐩𝐭 𝐭𝐨 𝐑𝐞𝐚𝐥𝐢𝐭𝐲: 𝐓𝐡𝐞 𝐂𝐨𝐛𝐨𝐭 𝐄𝐧𝐝 𝐄𝐟𝐟𝐞𝐜𝐭𝐨𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐄𝐱𝐩𝐥𝐚𝐢𝐧𝐞𝐝

𝑮𝒆𝒕 𝒂 𝒇𝒓𝒆𝒆 𝒔𝒂𝒎𝒑𝒍𝒆 𝑷𝑫𝑭 𝒓𝒆𝒑𝒐𝒓𝒕: https://www.nextmsc.com/cobot-end-effector-market/request-sample?utm_source=debashree_linkedin&utm_medium=debashree_gp&utm_campaign=debashree_cobot_end_effector&utm_id=debashree_mar&utm_term=debashree_gp&utm_content=debashree_gp

𝑨𝒓𝒆 𝒚𝒐𝒖 𝒓𝒆𝒂𝒅𝒚 𝒕𝒐 𝒘𝒊𝒕𝒏𝒆𝒔𝒔 𝒕𝒉𝒆 𝒇𝒖𝒕𝒖𝒓𝒆 𝒐𝒇 𝒄𝒐𝒍𝒍𝒂𝒃𝒐𝒓𝒂𝒕𝒊𝒗𝒆 𝒓𝒐𝒃𝒐𝒕𝒊𝒄𝒔?

The 𝐂𝐨𝐛𝐨𝐭 𝐄𝐧𝐝 𝐄𝐟𝐟𝐞𝐜𝐭𝐨𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 is here, and it's set to revolutionize industries worldwide!

𝑾𝒉𝒂𝒕 𝒆𝒙𝒂𝒄𝒕𝒍𝒚 𝒊𝒔 𝒂 𝑪𝒐𝒃𝒐𝒕 𝑬𝒏𝒅 𝑬𝒇𝒇𝒆𝒄𝒕𝒐𝒓, 𝒚𝒐𝒖 𝒂𝒔𝒌?

Well, it's the innovative solution that bridges the gap between human workers and robotic automation. These cutting-edge tools are designed to enhance efficiency, productivity, and safety in various work environments.

𝑺𝒐, 𝒘𝒉𝒂𝒕 𝒎𝒂𝒌𝒆𝒔 𝒕𝒉𝒆 𝑪𝒐𝒃𝒐𝒕 𝑬𝒏𝒅 𝑬𝒇𝒇𝒆𝒄𝒕𝒐𝒓 𝑴𝒂𝒓𝒌𝒆𝒕 𝒔𝒐 𝒄𝒂𝒑𝒕𝒊𝒗𝒂𝒕𝒊𝒏𝒈?

Here are just a few highlights:

Versatility: From gripping to welding, painting to assembly, cobot end effectors can handle a wide range of tasks with precision and ease.

Collaboration: Say goodbye to the days of robots working in isolation. Cobots are built to work alongside human counterparts, creating a seamless synergy that maximizes output and minimizes downtime.

Innovation: With advancements in AI, machine learning, and sensor technology, cobot end effectors are continuously evolving, pushing the boundaries of what's possible in automation.

Cost-Effectiveness: Investing in cobot end effectors isn't just about embracing the latest technology; it's also about making smart financial decisions. These tools offer a high return on investment by streamlining processes and reducing operational costs.

𝐀𝐜𝐜𝐞𝐬𝐬 𝐟𝐮𝐥𝐥 𝐫𝐞𝐩𝐨𝐫𝐭: https://www.nextmsc.com/report/cobot-end-effector-market?utm_source=debashree_linkedin&utm_medium=debashree_gp&utm_campaign=debashree_cobot_end_effector&utm_id=debashree_mar&utm_term=debashree_gp&utm_content=debashree_gp

0 notes

Text

Surgical Robots Market 2023 Trend, Segmentation and Opportunities Forecast To 2030

The surgical robots market is expected to continue growing rapidly as advancements in technology and robotics revolutionize the field of surgery. These robots offer increased precision, accuracy, and control during procedures, leading to better outcomes for patients. Additionally, they can help reduce the risk of human error and minimize the invasiveness of surgeries, resulting in shorter recovery times and reduced hospital stays. As more healthcare providers adopt surgical robots into their practices, the market is projected to expand even further, making this a promising area for investment and innovation in the medical industry.

The global surgical robots market is on an upward trajectory, projected to reach USD 18.46 billion by 2030. This signifies a significant increase from its 2022 valuation of USD 4.52 billion, with a robust Compound Annual Growth Rate (CAGR) of 19.2% anticipated over the forecast period (2023-2030), according to a recent market analysis.

Driving Forces Behind the Rise of Surgical Robots:

Several key factors are contributing to the flourishing surgical robots market:

Minimally Invasive Surgery Advantages: Surgical robots offer numerous advantages for minimally invasive procedures, including improved precision, enhanced dexterity, and potentially faster patient recovery times.

Growing Adoption in Diverse Surgical Fields: The application of surgical robots is expanding beyond urology, with increasing adoption in general surgery, gynecology, orthopedics, neurosurgery, and other specialties.

Aging Population and Rising Chronic Conditions: The growing geriatric population and the rising prevalence of chronic conditions are expected to lead to a higher demand for complex surgical procedures, potentially driving the use of surgical robots.

Technological Advancements: Continuous advancements in robotics technology, artificial intelligence, and machine learning are leading to the development of more sophisticated and user-friendly surgical robots.

Get Free PDF Sample Copy of Report @ https://www.snsinsider.com/sample-request/1791

Some of the major key players are: Stryker Corporation, Intuitive Surgical, Smith & Nephew, TransEnterix Surgical Inc., Medrobotics, Zimmer Biomet, Renishaw plc., THINK Surgical Inc., Medtronic, and other players.

Market Segmentation: A Closer Look

The press release can be enhanced by including a section on market segmentation, providing a more comprehensive picture:

Components: The market is segmented by components, including robotic surgical systems, accessories (disposable instruments, end-effector devices), and related services (maintenance, training, and support).

Surgery Type: The market caters to a diverse range of surgical procedures, with a growing focus on general surgery, gynecology, urology, orthopedic surgery, neurosurgery, and other specialized procedures.

Regions: The report explores the surgical robots market across different regions, providing valuable insights for geographically focused strategies.

A Global Phenomenon:

A section on the geographic landscape can be included to highlight regional trends:

The report explores the surgical robots market across different regions, providing insights for geographically focused strategies.

Looking Ahead:

The future of the surgical robots market is promising, with continued growth anticipated as technological advancements, increasing surgeon and patient acceptance, and a growing demand for minimally invasive procedures fuel market expansion.

#Surgical Robots Market#Global Surgical Robots Market#Surgical Robots Market Size#Surgical Robots Market Share#Surgical Robots Market Trends#Surgical Robots Market Growth#Surgical Robots Market Demand#Surgical Robots Market Segmentation#Surgical Robots Market Analysis#Surgical Robots Industry Analysis

0 notes

Text

Svaya Robotics: Engineering the Future of Collaborative Workspaces

Svaya Robotics: Crafting the Next Generation of Safe Cobots

In an era where the integration of robotics into the fabric of industrial production is becoming increasingly paramount, Svaya Robotics Pvt. Ltd. emerges as a vanguard, pioneering the development of the next generation of safe collaborative robots, or cobots. These innovations are not just revolutionizing manufacturing processes but are also redefining the dynamics of human-robot interaction, making it safer, more efficient, and incredibly productive.

A Vision for Safer, Collaborative Workspaces

At the core of Svaya Robotics' mission is a commitment to safety and collaboration. Traditional robots, designed for efficiency and speed, often required extensive safety measures, including cages and barriers, to protect human workers. This not only limited the robots' flexibility and utility but also kept them isolated from the human workforce. Svaya Robotics disrupts this paradigm by designing cobots that can safely work alongside humans, sharing workspace and tasks without the need for physical barriers. This approach fosters a harmonious environment where robots complement human efforts, enhancing productivity without compromising safety.

Engineering Excellence for Unparalleled Safety

Safety is an integral component of Svaya Robotics' design philosophy. Each cobot is engineered with built-in dual-channel redundant safety systems, ensuring that they can operate in close proximity to human workers without posing risks. This redundancy is crucial, as it provides an additional layer of protection, ensuring that even if one safety system fails, the other can take over, maintaining a safe operational environment at all times.

The cobots are equipped with advanced sensors and machine vision technology that enable them to be highly perceptive of their surroundings. This allows them to detect human presence and make real-time adjustments to their operations to avoid accidents, ensuring a safe collaboration space. Moreover, the intuitive design of these robots means that they can be easily controlled and programmed by the workforce, empowering employees to work alongside these machines seamlessly.

Full-Stack Technology for a Seamless Experience

Svaya Robotics stands out not just for its focus on safety but also for its comprehensive approach to robotics. By developing a full-stack technology platform, the company ensures that its cobots are equipped with the latest advancements in AI and machine learning, digital twinning, and human-robot interaction. This holistic approach enables the robots to perform a wide array of tasks with precision and reliability, from assembly and packaging to more complex processes like welding and gluing.

The integration of digital twin technology is particularly noteworthy. By creating a virtual replica of the physical robot and its operations, Svaya Robotics allows for real-time monitoring and control, enhancing the efficiency and flexibility of manufacturing processes. This virtual control layer not only improves operational visibility but also enables predictive maintenance, reducing downtime and extending the lifespan of the cobots.

Empowering Industries with Versatile Applications

The versatility of Svaya Robotics' cobots is a key factor in their appeal. Designed to be adaptable, these robots can be fitted with a variety of end-effectors, allowing them to undertake different tasks with ease. This versatility, combined with the ability to seamlessly integrate into existing ecosystems through compatibility with various industrial communication protocols, makes these cobots an invaluable asset for businesses looking to enhance their productivity and adaptability.

From assembly lines to quality control, Svaya Robotics' cobots are transforming industries by providing solutions that are not only safe and efficient but also flexible enough to meet the changing demands of the market. Their ability to work safely alongside humans opens up new possibilities for collaborative robots workflows, where the strengths of both humans and robots are leveraged to achieve optimal results.

Towards a Collaborative Future

Svaya Robotics is at the forefront of a significant shift in industrial manufacturing, where the focus is moving from automation for efficiency's sake to automation that enhances human capabilities. By crafting the next generation of safe cobots, the company is not just contributing to the evolution of robotics but is also helping shape a future where human-robot collaboration is the norm, not the exception.

This future, envisioned and brought to life by Svaya Robotics, is one where businesses can thrive in an environment that is both productive and safe. It's a future where the barriers between humans and robots are broken down, leading to workplaces that are more flexible, innovative, and efficient.

In conclusion, Svaya Robotics is not just developing robots; it's pioneering a new era of industrial production. Through its commitment to safety, versatility, and innovation, the company is crafting the next generation of cobots that promise to transform the manufacturing landscape. As we look towards this future, it's clear that the collaborative workflows enabled by these advancements will unlock new levels of productivity and creativity, heralding a new age of industrial harmony.

#cobots#robotics#technology#artificial intelligence#collaborative robots#manufacturing robots#business#industrial robot manufacturers#automationrobotics#industrial automation

0 notes

Text

Robotic Smart Motors Market to Reach $8.04 Billion at CAGR of 5.31% by 2033 | BIS Research

The Robotic Smart Motors Market stands at the forefront of technological innovation, driving advancements in robotics and automation. As artificial intelligence (AI) and machine learning (ML) progress, robotic systems integrated with smart motors demonstrate an ongoing enhancement in their capabilities.

Evolution of Robotic Smart Motors

Robotic smart motors represent a paradigm shift in the field of robotics, integrating intelligence, precision, and efficiency. These motors, equipped with advanced sensors and control systems, empower robots to perform tasks with unprecedented accuracy and responsiveness. As industries increasingly adopt automation, the demand for robotic smart motors is on the rise, reshaping the way machines operate.

The Robotic Smart Motors Market was valued at $4.61 billion in 2022 and is expected to reach $8.04 billion by 2033, growing at a CAGR of 5.31% between 2023 and 2033.

Industry Key Drivers of Market Growth

Industry 4.0 and Automation Trends: The advent of Industry 4.0, characterized by the integration of digital technologies into manufacturing processes, has spurred the demand for robotic smart motors. These motors play a pivotal role in the automation of tasks, enhancing productivity, and reducing manual intervention.

Efficiency and Precision: Robotic smart motors are engineered to deliver unparalleled efficiency and precision. With advanced control algorithms and real-time feedback from sensors, these motors enable robots to execute complex tasks with accuracy, making them indispensable in applications requiring intricate movements.

Emergence of Smart Factories: The concept of smart factories, characterized by interconnected and intelligent manufacturing systems, has propelled the demand for robotic smart motors. These motors contribute to the creation of agile and adaptive production environments, optimizing resource utilization and production efficiency.

Download our free Robotic Smart Motors Market Report for more detailed insights.

Robotic Smart Motors Industry Segmentation by Robot Type

Commercial

Industrial Robot

Service Robot

Medical Robot

Agricultural Robot

Inspection and Maintenance Robot

Defense

Unmanned Aerial Vehicle (UAV)

Unmanned Ground Vehicle (UGV)

Unmanned Maritime Vehicle (UMV)

Bomb Disposal Robot

Tactical Robot

Applications Across Industries

Manufacturing and Assembly: In manufacturing and assembly lines, robotic smart motors enable precise control over robotic arms and end-effectors. This application is crucial for tasks such as pick-and-place operations, welding, and assembly, contributing to streamlined production processes.

Healthcare and Medical Robotics: Robotic smart motors find applications in the healthcare sector, powering robotic surgical systems, rehabilitation devices, and diagnostic equipment. The precision and dexterity provided by these motors enhance the capabilities of medical robots, contributing to improved patient care.

Logistics and Warehousing: The logistics and warehousing industry benefits from robotic smart motors in autonomous guided vehicles (AGVs) and robotic pickers. These motors enhance the agility of robots in navigating warehouse spaces, picking and transporting goods efficiently.

Electronics and Semiconductor Manufacturing: In the electronics industry, where precision is paramount, robotic smart motors play a crucial role in the fabrication and assembly of electronic components. These motors contribute to the high-speed and precision required for semiconductor manufacturing.

Key Market Players in the Industry

The top established robotic smart motors providers hold around 79% of the presence in the market. The start-ups in the market hold around 21% as of 2022 of the global robotic smart motors industry.

ABB

Siemens

NIDEC Corporation

Yaskawa Electric Corporation

Moog Animatics

Rockwell Automation

Schneider Electric

Dunkermotoren GmbH

Future Prospects & Opportunities

As technology continues to advance, the future of the Robotic Smart Motors Industry holds exciting possibilities. Innovations in sensor technology, artificial intelligence, and connectivity are expected to further enhance the capabilities of these motors, opening up new frontiers in robotic applications.

Conclusion

The Robotic Smart Motors Market signifies a transformative era in robotics and automation, redefining how machines operate and interact with their environment. With applications spanning across industries and a relentless pursuit of technological advancements, robotic smart motors are poised to be a driving force in the ongoing evolution of smart manufacturing and robotic solutions. As industries increasingly embrace robotics and automation, these intelligent motors will continue to be at the core of enhancing efficiency, precision, and adaptability in the world of robotics.

#Robotic Smart Motors Market#Robotic Smart Motors Report#Robotic Smart Motors Industry#Robotic Smart Motors Market Report#Robotic Smart Motors Market Size#Robotic Smart Motors Market Research#Robotic Smart Motors Market Forecast#Robotic Smart Motors Market CAGR#BIS Research

0 notes