#manufacturing robots

Text

Revolutionizing Manufacturing: The 30% Productivity Leap

Unlocking Efficiency: How the Industrial Metaverse Can Boost Manufacturing Productivity by 30%

The industrial metaverse is the next big thing in manufacturing, combining VR/AR with AI, IoT, and blockchain. While exciting, it also brings challenges like tech integration, cost, security, and workforce training. This article explores both sides to help manufacturers navigate the future.

Defining the Industrial Metaverse

The Evolution of Digital Twinning

Digital twins revolutionized manufacturing by creating virtual replicas. Now, the industrial metaverse takes it further. It builds on these models, integrating them into a dynamic 3D platform that reflects the entire value chain in real time.

Integrating the Physical and Virtual

The industrial metaverse merges physical and virtual worlds. Real-time data fuels smarter decisions, boosting efficiency and reducing costs. Industries like aerospace leverage this for faster development and less waste.

The Combinatory Nature of Technologies

Extended Reality (XR): XR bridges the physical-digital gap with immersive interfaces. These go beyond visualization, enabling real-time interaction and complex assembly tasks.

Robotics and Sensors: Advanced robots with sensors perform precise virtual and physical actions. They collect real-time data for adjustments and optimizations within the metaverse.

Artificial Intelligence (AI): AI analyzes vast data streams within the metaverse. It provides insights, automates decisions, and optimizes operations. AI can predict machine failures, preventing downtime and revolutionizing manufacturing.

Blockchain: Blockchain secures data sharing across the metaverse. This is crucial for complex supply chains with multiple stakeholders, ensuring data integrity and traceability.

Technological Foundations

Cutting-edge technologies like AI, XR, and blockchain form the backbone of the industrial metaverse, driving integration, efficiency, and innovation in manufacturing.

Extended Reality (XR): Bridging the Gap between Virtual and Real

VR, AR, and MR combine to create immersive training and guide complex assembly with AR overlays.

Statistical Insight: A report from PwC predicts that VR and AR could boost the global economy by $1.5 trillion by 2030, with $294 billion of that impact in the manufacturing sector alone.

Real-World Application: Automakers like BMW use AR to cut errors by 50% and improve training during assembly.

Artificial Intelligence (AI): The Brain Behind Automation

AI in the industrial metaverse goes beyond automation, enabling predictive maintenance, production optimization, and real-time decision-making.

Statistical Insight: AI in Manufacturing: Up to 20% production increase and 4% less material consumption (McKinsey & Company)

Real-World Application: AI in Action: Tesla uses AI and machine learning to optimize production, improving quality and speed.

Internet of Things (IoT): The Connectivity Fabric

IoT in the industrial metaverse connects machines and sensors for real-time data flow and system-wide visibility.

Statistical Insight: The IoT in manufacturing market size is projected to reach $136.83 billion by 2026, growing at a CAGR of 10% from 2021, as reported by Fortune Business Insights.

Real-World Application: General Electric has leveraged IoT to create its Predix platform, which monitors industrial machinery to predict failures before they happen, significantly reducing downtime and maintenance costs.

Robotics: Precision and Efficiency in Physical Operations

AI-powered robots with sensors automate complex tasks in the industrial metaverse, ensuring precision and flexibility.

Statistical Insight: The industrial robotics market will likely grow by 10.4% before 2027, driven by increased adoption in manufacturing sectors.

Real-World Application: In the electronics sector, companies like Foxconn have deployed thousands of robots, dramatically increasing production rates and consistency by automating repetitive tasks previously performed by humans.

Blockchain: Securing the Industrial Metaverse

Blockchain secures data in the industrial metaverse for reliable transactions and multi-party exchanges.

Statistical Insight: Blockchain's application in manufacturing, particularly in supply chain management, is expected to generate a market value of $30 billion by 2030.

Real-World Application: Aerospace manufacturer Boeing uses blockchain to track and record thousands of parts throughout the lifecycle of its aircraft, enhancing traceability and security.

Opportunities in the Industrial Metaverse

This section dives into the exciting opportunities of the industrial metaverse, showcasing real-world examples. From boosted efficiency and cost savings to groundbreaking innovation and deeper customer connections, the potential to revolutionize manufacturing is immense.

Operational Efficiency and Productivity

The integration of metaverse technologies significantly enhances manufacturing operations, making them more efficient and less prone to error.

Statistical Insight: Digital twins + IoT boost efficiency by 35% and cut maintenance costs by 20% (Deloitte).

Real-World Application: Siemens' digital twins in electronics manufacturing lead to 25% higher productivity and 30% faster development (Siemens).

Cost Reduction and Resource Optimization

AI predictions and real-time IoT data empower manufacturers to slash waste and optimize resource use.

Statistical Insight: AI cuts costs 40% and downtime 50% through predictive maintenance (Capgemini).

Real-World Application: Chevron saves $1 billion annually with AI and IoT for equipment optimization (Chevron).

Enhanced Innovation and Product Development

The industrial metaverse accelerates innovation by facilitating rapid prototyping, testing, and development through virtual simulations.

Statistical Insight: Companies using AR and VR for product development can see a time-to-market improvement of up to 50%.

Real-World Application: Ford uses VR in design to prototype vehicles virtually, saving millions in physical modeling costs.

New Business Models and Customer Engagement

The industrial metaverse fosters new customer engagement and business models like virtual factories and digital marketplaces.

Statistical Insight: IBM studies show businesses using digital twins as a service see revenue grow 10-15% in the first year.

Real-World Application: Adidas uses a digital twin of its Speedfactory to offer virtual shoe customization, boosting customer engagement and mass customization.

Challenges Facing the Industrial Metaverse

The industrial metaverse's potential is undeniable, but challenges like technological integration and security concerns can hinder adoption. Manufacturers must navigate these hurdles to fully utilize its potential.

Technological Integration and Complexity

Integrating diverse technologies requires significant time and resources.

Statistical Insight: 75% of organizations struggle to choose the right technologies and vendors for IoT due to its complexity (Gartner survey).

Real-World Application: A major automaker faced delays in deploying digital twins due to challenges synchronizing data across VR, AI, and IoT platforms.

High Initial Costs

Expensive tech (AI, IoT, VR/AR) can be a barrier for SMEs.

Statistical Insight: Industrial IoT setup over $100,000 (IoT Analytics).

Real-World Application: Small manufacturer struggles with AR adoption due to cost (Midwest).

Skills Gap and Workforce Adaptation

Emerging tech requires upskilling the workforce.

Statistical Insight: Deloitte: 45% of executives see lack of skilled workers as a hurdle;

Real-World Application: Electronics company delays IoT rollout due to employee training difficulties

Data Security and Privacy Concerns

Increased connectivity raises cybersecurity threats, demanding robust data protection.

Statistical Insight: Cyberattacks surge 300% (IBM Security), making data protection in manufacturing crucial (average data breach cost: $5 million).

Real-World Application: Major energy company suffers data breach from compromised IoT devices.

Regulatory and Compliance Issues

Complexities arise for global manufacturing in the evolving metaverse regulatory landscape.

Statistical Insight: Compliance costs for global manufacturers can reach 10% of sales (Manufacturing Institute).

Real-World Application: Multinational pharmaceutical company faces regulatory challenges with blockchain for supply chain (data handling variations).

Strategic Directions for Stakeholders

This section offers a roadmap for manufacturers, outlining actionable steps and strategies to successfully integrate metaverse technologies and capitalize on its potential.

Developing a Comprehensive Technology Integration Plan

Given the complexity of integrating various technologies, a structured plan is essential for successful deployment.

Action Steps:

Conduct a thorough technology audit to understand existing capabilities and gaps.

Develop a phased integration plan that starts with pilot projects to gauge effectiveness before full-scale implementation.

Invest in middleware solutions that can seamlessly connect disparate systems and platforms.

Investing in Skills Development and Change Management

Continuous learning and effective change management are critical to mitigate the skills gap and prepare the workforce for new technological paradigms.

Action Steps:

Establish partnerships with educational institutions and tech companies to develop training programs tailored to the needs of the industrial metaverse.

Create internal upskilling and reskilling initiatives to enhance employee capabilities in AI, VR/AR, IoT, and data security.

Implement a change management strategy that includes communication plans, support structures, and incentives for adoption.

Enhancing Cybersecurity Measures

With increased connectivity, ensuring the security of data and systems is paramount.

Action Steps:

Develop a comprehensive cybersecurity strategy specific to the industrial metaverse, incorporating advanced threat detection, incident response, and recovery plans.

Regularly update and patch systems and software to protect against new vulnerabilities.

Train employees on cybersecurity best practices and the importance of data security.

Engaging with Regulatory Bodies and Industry Groups

Active engagement with regulatory bodies and industry groups can help navigate compliance challenges and shape industry standards.

Action Steps:

Participate in industry consortia focused on the industrial metaverse to stay updated on best practices and regulatory developments.

Collaborate with regulatory bodies to understand and influence policies that affect the industrial metaverse.

Ensure compliance with international data protection regulations, such as GDPR, and industry-specific standards.

Exploring New Business Models and Revenue Streams

The industrial metaverse opens opportunities for new business models and revenue streams, such as virtual factories and digital twins as a service.

Action Steps:

Identify opportunities for service-based models, such as offering digital twin services to other companies.

Explore the potential for cross-industry collaborations that leverage the industrial metaverse for shared services and facilities.

Develop customer engagement platforms using VR and AR to offer unique, immersive experiences.

Looking Ahead in the Industrial Metaverse

As the industrial metaverse evolves, it reshapes the manufacturing sector with its potential and complexities. Advancements in AI and machine learning will enhance predictive analytics and decision-making capabilities, while the integration of sophisticated robotics and automation technologies poses new challenges and opportunities. Cybersecurity becomes crucial as systems interconnect, necessitating new protections against evolving threats.

The rapid pace of technological change also challenges workforce management, requiring manufacturers to ensure their workforce remains skilled and adaptable. Developing regulatory frameworks for global data exchanges within the industrial metaverse is another critical area for exploration. Ongoing dialogue among manufacturers, technology providers, and regulators is essential to navigate these challenges and realize the full benefits of the industrial metaverse.

Connect with us to ensure your business is ready to harness the full potential of the industrial metaverse and stay competitive in an increasingly complex landscape. Connect with Coditude.

#Industrial metaverse#future of manufacturing#smart factories#manufacturing innovation#manufacturing industries#industry 4#manufacturing process#automation industry#manufacturing robots#industrial manufacturing companies#ai in automation

1 note

·

View note

Text

Revolutionizing Automotive Assembly: The Power of Collaborative Robots

Boosting Productivity and Quality on Automotive Assembly Lines with Collaborative Robots

In the rapidly evolving landscape of the automotive industry, manufacturers are continually seeking ways to enhance productivity, efficiency, and quality. One of the most transformative technologies being integrated into automotive assembly lines today is collaborative robots or cobots. These robots are not just reshaping production techniques but are also setting new standards for operational excellence. Svaya Robotics, a leader in the field, exemplifies how advanced collaborative robots are paving the way for a more dynamic and responsive manufacturing environment.

Introduction to Collaborative Robots in Automotive Manufacturing

Collaborative robots in automotive manufacturing are designed to work alongside human operators, combining the precision and consistency of robotic automation with the cognitive and adaptive skills of humans. This synergy is particularly valuable in automotive production, where flexibility and meticulousness are paramount. Cobots are equipped to handle tasks ranging from assembly to inspection, all while ensuring safety and enhancing ergonomics on the shop floor.

The Role of Cobots in Automotive Industry

Cobots in the automotive industry are not just tools for automation; they are partners in production. These robots are uniquely capable of adapting to varied tasks without the need for extensive reprogramming. This adaptability makes them ideal for automotive manufacturers who deal with multiple models and configurations in their product lines. From assisting with intricate wiring harnesses to handling heavy components like windshields, cobots provide a versatile solution that can adjust to the complexities of automotive assembly.

Enhancing Productivity with Cobots in Manufacturing

The integration of cobots in manufacturing extends beyond simple task execution. They enhance productivity by enabling continuous production cycles and reducing downtime. For instance, cobots can operate safely alongside humans during intricate assembly operations, allowing for a seamless blend of tasks that optimize the assembly line. Furthermore, their precision reduces the occurrence of errors and defects, significantly improving overall product quality.

Svaya Robotics: At the Forefront of Cobot Integration

As a leading manufacturer and supplier of collaborative robots for the automobile industry, Svaya Robotics is at the cutting edge of this technological revolution. Their cobots are designed with an emphasis on simplicity, convenience, and reliability, making them accessible for various applications within the automotive sector. Whether it’s assembly, painting, or inspection, Svaya’s robots are engineered to enhance both productivity and quality.

The Impact of Cobots on Automotive Assembly Lines

The introduction of collaborative robots into automotive assembly lines has led to a remarkable transformation in how vehicles are assembled. With cobots, manufacturers can achieve a higher degree of customization and flexibility, which is crucial in today’s market where consumer preferences are constantly changing. Additionally, cobots contribute to a safer workplace by taking on hazardous tasks, thereby reducing the risk of injuries and enhancing worker satisfaction.

Conclusion

The integration of collaborative robots in the automotive industry represents a significant leap towards more efficient and adaptable manufacturing processes. With companies like Svaya Robotics leading the charge, the potential for cobots to revolutionize automotive production is immense. As this technology continues to evolve, the synergy between human workers and robots is expected to unlock new levels of productivity and quality on assembly lines, making the vision of truly collaborative manufacturing a reality.

#collaborative robots#industrial automation#cobots#robotics#automationrobotics#industrial robot manufacturers#manufacturing robots#business

0 notes

Text

Barcode Scanner Supplier In Pune, India | Aeron Automation

In the era of fast-paced business operations, reliability is key. Elevate your business efficiency with Aeron Automation, your trusted Barcode Scanner Supplier in Pune, India. We are committed to delivering not just products but solutions that redefine reliability and productivity. Our barcode scanners are precision-engineered to meet the diverse needs of modern businesses. Whether you're managing inventory, improving customer service, or enhancing data accuracy, our scanners offer the reliability you can count on. Choose Aeron Automation as your partner in efficiency and reliability. Discover how our barcode scanners can streamline your operations and elevate your business to new heights.

#barcode scanner supplier#Human Machine Interface in India#human-machine interface manufacturers#programmable logic controller manufacturers in India#Industrial Power Suppliers India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#industrial robots manufacturers in India#industrial ethernet solutions services providers in India#CNC machine suppliers#CNC machine manufacturers#cnc supplier#manufacturing robots#robot manufacturing companies#industrial sensor manufacturers

0 notes

Text

Songstress robot model UTA-3305, assigned to entertain guests at a high-end restaurant. Currently slowly going out of order due to lacking maintenance, and the presence of foreign biological material growing inside it.

Though it is a robot, it wishes to come to understand the human emotions it's been made to sing about all its "life". Please do entertain it with your stories while you pass by.

#oc#original character#my art#artists on tumblr#my artwork#drawing#digital art#a proper introduction for my sad robo!#the name for her model is the UTA-33 part#she was the 5th robot of her kind of be manufactured. thus you can call her 'five' or '05' for short#basically the world ended and pretty much the only humanlike creatures left are the robots they built#fives restaurant stage was well built so it gets various survivors dropping by to shelter every once in a while#her only possible charging port for hundreds of kilometres is in the restaurant so she cant go too far#thankfully for her she is solar powered! as long as the charging station stays somewhat functional she can hang out :)

201 notes

·

View notes

Text

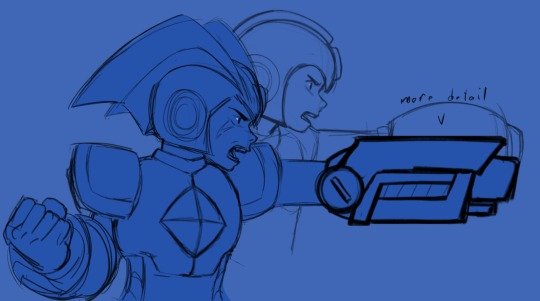

A small handful of things I drew last month, haven’t felt like finishing anything lately

#mega man#megaman#rockman#megaman classic#megaman au#robot master#megaman manufactured#megaman x command mission#megaman x#bass megaman#megaman bass#megaman fanart

154 notes

·

View notes

Text

industrial robots

#KUKA#robot#industrial robot#manufacturing#heavy industry#automotive#FIAT#Italy#Torino#Turin#FIAT 500

212 notes

·

View notes

Text

Leggie

#alycia debnam carey#the girl is like 85% Leg™#baby's first podcast was also surprisingly good 👀#not in a bad sense but just that it wasn't so ultra manufactured that it was like listening to a robot#and they actually - ya know - let her speak

63 notes

·

View notes

Text

mera for @hrokkall

#artfight 2024#robot#q#using my knowledge of shipping for tech manufacturers for GOOD and ART and FIGHT!#my

18 notes

·

View notes

Text

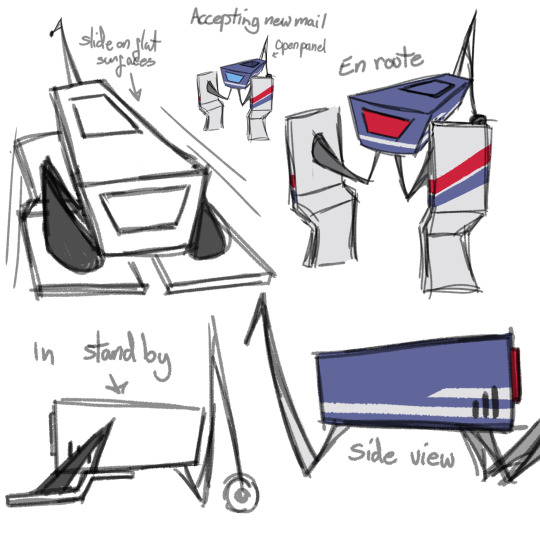

Thinking more about my little robot

#al art#al ocs#so ya it is a courier^^#i think theres different types of mail robots this is like the standard letters + medium parcels carrier#theyre probably like big dog sized i think msybe a bit bigger#theyre fun cause you can tell when one is freshly manufactured because its front legs wont be scuffed to shit#their chunky board legs give them pretty loud footsteps so they dont usually need to ring doorbells#But if they do the back leg is extra flexible so they lie down on their front legs and the back bends back over top of them to hit the bell#so ya! i just think theyre fun#also i need help naming them

17 notes

·

View notes

Text

thoughts on sound design and Divinity in ultrakill

#listening to things like#the sounds the virtues and their heavenly beam attacks make#or the hum of gabriel's light weapons#it's not the sound of an angelic choir. it's warbly and distorted and inorganic#almost like a synthesized imitation of more traditionally heavenly sound#and i don't remember if i've talked about it here. but that ties into the mechanical nature of heaven and its heirarchy#reading what the game has to say about gabriel. the wording very Very badly wants you to think of gabriel as a machine#as a weapon#the way the terminal talks about him and the way the council does#it's dehumanizing commodification#and that brings to mind the contrast the game sets up between angels and machines#because angels are counterpart to Robots in ultrakill's story. not demons#the game sets up conflict between Heaven and Earth. with hell just serving as a backdrop#and that shows in the way the game handles angels and machines#where the structure of heaven's forces is rigid and the sound of divinity is a synthetic growl#looking at ultrakill's scripture on machines on the other hand. you'll find that every robot described in the terminal has a story involving#some kind of deviation from originally manufactured purpose. form. design. aesthetic#they're really Wild Animals#they fight. they Live#they evolve and they mutate#they do whatever the hell they need to#and i find that fascinating. perfect contrast#again my fingers are crossed tighter than hell that the Violence layer plays with that animalism#or that machinekind is at least explored further somewhere else in the story#either way. can't wait#no one does hell like hakita#make it this far down i'd love to hear what you think

76 notes

·

View notes

Text

Gambling Apocalypse Tenma AU

As I rewatch Kaiji I inevitably end up wanting to combine show I like with other show I like and stuffing fav characters into show. So here we are.

This was uh going to be a short summary type thing but I accidentally wrote a novella about it sorry

This AU starts off with a much more depressive Tenma. After Tobio's death, rather than immediately pour his grief into developing a robot version of his son, he recedes into himself, psychologically paralyzed, likely turning to alcohol to drown out his anguish.

His mental state is taken as an opportunity within the Ministry of Science to have him ejected from his position; Tenma was never the most well-liked director, and there were those with ambition to usurp him that would jump at the chance. Not that he especially cares in his state.

He's eventually dragged out of his stagnation by Ochanomizu - who, inadvertently, becomes the very catalyst pushing Tenma to develop a robot replacement to his child. This was not what he meant by encouraging Tenma to fill the void left by his son.

...But, well, he is no longer the director of the Ministry of Science. His access to limitless government funds and resources for "scientific research" has been cut off, and this is a project he cannot finance on his own. He can't ask Ochanomizu for help, but...interestingly...a representative of a certain shady organization known as the Teiai Corporation reaches out to him, offering to finance and support his project. A sane and well-minded Tenma might think better of it, but grieving and desperate, Tenma accepts their offer and is able to create a robot in the image of his beloved Tobio. For a while, there's joy in his life.

But the bill, as ever, comes due: Tenma must pay up, and the very resources that had been at his disposal will certainly ensure that he will, or else. Of course, he doesn't have the money; instead, he is given a choice. He can relinquish the robot Tobio in order to wipe out his debt - the child is a sophisticated and powerful robot, after all - or he can participate in a certain illicit event hosted by the Teiai Corporation.

It's nothing major...just a four-hour gambling cruise with a collection of desperate, damned souls that were also swept into debt with Teiai. The conditions are simple: Those who choose to participate are given a chance to clear their debts wholesale should they win. And should they lose...?

Well...no one really knows what happens to the losers seized by Teiai. It's said that they labour away their debts under Teiai's watchful eye and are freed once their work has covered their debts, though it's rumoured that most perish before they reclaim freedom.

There's only one answer Tenma can give, of course; he's not willing to lose Tobio again.

Thus is Tenma's debut into the Gambling Apocalypse, where he must become cutthroat in order to survive; if he wants to see his son again, he must make choices that will doom the hapless to miserable servitude, with a nonzero chance it ends in their death.

He survives the cruise, but of course, it was hardly enough to clear his debt; the cruise was never going to be the end of it. Teiai doesn't let go of its victims that easily. He will be called on again: this is a weight that hangs over him, all while he returns to his son Tobio. The same hands that have pushed innocents into hell must now be the hands that can embrace his child.

He wants to protect Tobio from the truth and enjoy what peaceful moments he's allowed with his son, but it's difficult. It's difficult to be the parent of a child who cannot understand the danger that looms ahead; this "happy" home is not to last. Tenma angers quickly and easily. He turns that anger onto Tobio.

As Teiai's games become more and more vicious and unrelenting, as his conscience holds onto the last vestiges of thread that remain, Tenma even threatens, once, to give the boy in: it would all end, then; the debt would be clear and no longer would he have to endure Tobio's childish annoyances, his ungratefulness.

The next time that Tenma is beckoned, Tobio takes matters into his own hands. He does understand, now; and he would have, if only Tenma had bothered to explain sooner. If it's a debt that needs clearing, he will work. He will help his father clear his debts however he can. Of course, it's difficult to find work as a child; but a circus troupe finds amusement in the idea of a child robot, and takes him in. He is whisked into a certainly unpleasant working situation, but he remembers his father, and what he must be enduring. Tobio, also, will endure.

When Tenma returns, Tobio is gone.

All that held Tenma back from becoming something monstrous has disappeared. All that kept him going has disappeared. When he is called upon by Teiai, there is no knowing what sort of person might come out the other end; whether a monster clawing his way to freedom regardless of what actions he must take, or a desolate husk surrendering defeat.

There is still a light, however dim: Found by Professor Ochanomizu and rescued from the circus, Tobio - now Atom - is able to shed light on the situation which Tenma took great pains to keep hidden from his old friend. With time running out, Ochanomizu and Atom must do what they can to save Tenma - from Teiai, and from himself.

-----

UHHH and that's a wrap!!!! I couldn't quite decide which way Tenma would go after hitting Rock Bottom in this AU, and tbh it would really depend on the kind of mental state he's in at the time. On the one hand I like the narrative of Ochanomizu and Tobio racing to prevent Tenma from crossing a line (actual outright murder probably) - or having to pull him back into humanity (and yknow, his ensuing penance)

But on the other hand having him get sent to Teiai Evil Hell Prison would be interesting because a) there's a lot of narrative potential having Tenma faced with what Teiai is doing with the people that lose the games and b) need him to decimate the foreman at chinchirorin Kaiji style

Tenma's whole character is definitely a much different guy in this AU, he starts off pretty sympathetic, the guy you wanna root for, he just ends up having an inverse character arc where he gets worse instead of better. His conflict with "Tobio" is also kind of reversed, less about being unsatisfied with Tobio as a son and more not being able to handle the fact that he probably has intense PTSD now and isnt capable of coping with it in a way conducive to being a parent (or like, coping at all)

Anyway that's gambling apocalypse tenma!!!

#umataro tenma#long post#well that became a novel. sorry lmao#in my mind teiai's evil hell prison in astro boy verse would probably be quite a bit different than regular kaiji#like. fuckin. weapons manufacturing for teiai or something like that. or scary bad danger robots. horrifying concept#Tenma would be a valuable asset to them whether by giving up Atom or by losing in death game hell and being forced to work for em#and if he dies? they can just take atom#get him out of there.#I'm also thinkin of who Teiai would be represented by.....the snakey loan sharks u could easily put skunk in there.#but who is an evil fucked up sadist billionaire. theres probably someone who could be fucked up enough I just dont know offhand#and im allergic to mischaracterizing in AUs lol im not gonna make a slightly bad guy into an evil freakguy. so. Hyoudou is just himself.#if you squint this could be considered an 80s astro boy AU..has a cruise arc & not actually giving atom away#but man. that tenma LEAST of all deserves this fate lmao#do I want to write fic of this? yes. will I? not likely!#I can just smell it dude this would be some crazy fuckoff 100k shit I am not ready brother#also it would just be soooooo so so so so so edgy. I dont really enjoy writing intensely grim stuff w/ little to no respite#also tbh. I am too stupid. LOL. I cannot write clever gambles alas

12 notes

·

View notes

Text

I don’t think any of you understand the sheer tidal wave of objectum nonsense that I have been fighting off for the last week. My drafts can never see the light of day. This job was a terrible mistake. For reasons I doubt HR is prepared to handle.

#it is hit after hit in this fucking factory#I’d say ‘if y’all saw the welding robot you’d understand’ but you wouldn’t. I know this.#car manufacturing plants are a sinner’s paradise if you have the right cocktail of diagnoses#objectum

8 notes

·

View notes

Text

The Synergy of Steel and Skill: How Collaborative Robots Are Transforming Manufacturing

Collaborative Robots

In the contemporary landscape of industrial production, the integration of Collaborative Robots, often referred to as Cobots, signifies a pivotal shift towards more dynamic and versatile manufacturing environments. These sophisticated automatons are not just tools of automation; they are becoming integral partners in the craft of manufacturing, bringing a harmonious blend of precision and flexibility to assembly lines worldwide.

The Evolution of Collaborative Robots in Industry

Historically, robots in manufacturing settings were isolated from human operators, designated to perform monotonous, repetitive tasks within confined spaces. However, the advent of Cobots has disrupted this norm. Engineered to work alongside humans, these robots are equipped with advanced sensors and control systems that ensure safety and enhance human-machine interaction.

A Cobot's ability to learn and adapt to different tasks makes it an invaluable asset. For example, in automotive manufacturing, Cobots are used to assist with intricate assembly processes that require a high degree of precision. Their deployment reduces the ergonomic strain on human workers and increases the overall quality of production.

Strategic Implementation of Cobots by Manufacturers

The shift to Cobots does not merely represent a technological upgrade but a strategic transformation within factories. The role of a Cobots manufacturer is not only to produce these machines but also to tailor them to integrate seamlessly into existing workflows. This bespoke adaptation is crucial as it allows for minimal disruption and maximizes the efficiency gains from the robot's deployment.

One of the most significant advantages of Cobots is their flexibility. Unlike their predecessors, Cobots can be reprogrammed and redeployed for different tasks within the same facility. This versatility is particularly beneficial for small to medium-sized enterprises (SMEs) that require production lines to switch between products more frequently.

Economic Impact of Cobots in Manufacturing

The economic implications of integrating Cobots into manufacturing are profound. Initially, the investment might seem substantial; however, the return on investment (ROI) is accelerated by the substantial gains in productivity and reduction in operational costs. Cobots contribute to a decrease in production downtime and maintenance costs, as their precision and reliability prevent the frequent errors that human operators might make.

Moreover, Cobots enable manufacturers to maintain production within domestic markets, mitigating the need to offshore factories to low-cost countries. This not only helps in retaining jobs locally but also reduces the logistical costs associated with long-distance supply chains.

Enhancing Worker Safety and Job Satisfaction

Safety is a paramount concern in any manufacturing setting, and Cobots excel in this arena. Equipped with state-of-the-art safety features, such as collision detection and responsive stop mechanisms, Cobots ensure a safe working environment. This safety enhancement is critical in industries where human workers are at risk of injuries from repetitive tasks or heavy lifting.

Furthermore, the introduction of Cobots relieves workers from the monotony of repetitive tasks, allowing them to focus on more complex and creative aspects of production. This shift not only augments job satisfaction but also fosters a more engaging and mentally stimulating workplace.

Future Trends: Cobots and Beyond

As the technology behind Cobots continues to evolve, their capabilities are expected to become even more sophisticated. With advancements in artificial intelligence (AI) and machine learning, Cobots will be able to perform not only physical tasks but also make autonomous decisions based on real-time data. This evolution will further enhance their utility in manufacturing, making them an even more integral part of the production process.

In conclusion, the synergy between steel and skill introduced by Cobots is transforming the manufacturing sector. This transformation is not merely about automating tasks but about enhancing and augmenting the human workforce's capabilities. As Cobots become more embedded in industrial operations, their impact on productivity, safety, and innovation continues to grow, heralding a new era of manufacturing that is more efficient, safer, and more sustainable. The role of the Cobots manufacturer will be crucial in navigating this shift, ensuring that these robotic assistants are not only accessible but also adaptable to the varying needs of a rapidly evolving industry.

0 notes

Text

Industrial Ethernet Solutions Services in India | Aeron Automation

Unlock the future of industry with us, the forefront provider of advanced Motion Control Systems and cutting-edge Industrial Ethernet Solutions in India. Dive into a realm of seamless connectivity and unparalleled precision for your industrial operations. Our Motion Control Systems redefine how industries operate, offering unmatched accuracy and efficiency. Paired with our Industrial Ethernet Solutions, you'll experience a new level of interconnectedness that drives productivity and innovation. At Aeron Automation Solutions, we're not just providers; we're architects of industrial evolution. From engineering excellence to reliable connectivity, our solutions lay the foundation for a dynamic and efficient industry.

#industrial ethernet solutions services providers in India#industrial robots manufacturers in India#programmable logic controller manufacturers in India#Industrial Power Suppliers India#Human Machine Interface in India#ac variable frequency drive dealers in India#sensors manufacturers in India#photoelectric sensor suppliers India#CNC machine suppliers#human-machine interface manufacturers#barcode scanner supplier#CNC machine manufacturers#cnc supplier#manufacturing robots

0 notes

Text

The Ballad of Daktari and the Ludwig 2000

"Very well. You have both selected your weapons of choice. The duel will begin at the sound of the horn. If at any point your soul attempts to leave your body, you will not receive it back until the end of the duel."

"How dare you call yourself a doctor?"

"MeeM!"

Daktari's by @pinktrashgoblin

6 notes

·

View notes

Text

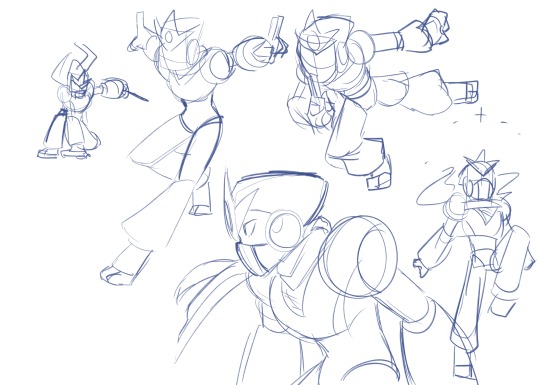

Mega Man Manufactured: File One

#mega man#megaman#rockman#megaman classic#megaman au#robot master#fan comic#megaman manufactured#cutman

66 notes

·

View notes