#Roofing Sheet Roll Forming Machine

Explore tagged Tumblr posts

Text

#roof roll forming machine#roll forming machine#cold roll forming machine#forming machine#machine#roofing sheet machine#steelmama#roof sheet making machine#building machine#china forming machine#roll forming machine for sales

0 notes

Text

It’s Alive!

Summary: After losing you beloved husband You seek out the help of the renowned doctor; Satoru Frankenstein, to bring him back, With some upgraded ‘equipment’!

Pairing: Kenjaku!Geto Suguru x AFAB!Reader

Warning: Frankenstein themes, language, size kink, monster sex, unprotected sex, cream pies, ( it’s monster sex—kinda)

Word Count: 2.1K

A/N: Kinktober day Twenty-Six: Frankenstein! I kind of struggled with this one I had like three versions going. But this one was The one I was most happy with.

He was cold. Too cold.

Your eyes watered as you remembered how your husband Suguru’s remains were rolled past yours on a cold steel table a week ago. A white sheet shielding your eyes from the irrevocable damage done to his body. This felt wrong on so many levels. But you needed him; you couldn’t lose him.

That’s what brought you to this old rickety castle, hoping Dr. Satoru Frankenstein could get your beloved husband back to life. He, of course, agreed, with no cost either, all because he was eager to test his new equipment. It almost seemed too good to be true.

“Missus.” A deep, smooth voice drew you out of your spiraling anxiety. “Missus, it’s time.” You turned to look at the young man before you. A black arrow tattoo crossed the bridge of his nose, while two additional arrows went down his cheeks, one under each eye.

“Choso.” You greeted, fingers gripping the front of your gown. “I-I’m ready.”

He led you up the stairs to the tower. You gripped the railing, climbing higher and higher until Choso opened the door to Satoru’s lab. Lightning flashed, machines hummed, and Satoru ran around his lab, round black goggles shielding his eyes from the flashing machines and whirling wind from the open hatch in the ceiling. His prestigious white hair and lab coat whirled around as he glanced toward you and his assistant.

“Ah! Mrs. Geto, Choso, hurry, it's almost time!”

Choso nodded, ushering you to the side before rushing to help Satoru. Your eyes fixed on the clothes body they were lifting into the opened hatch—your beloved husband. You clasped your hands together, bottom lip quivering, as you prayed for this to work, for him to be okay.

Lightning flashed, and thunder roared as Satoru jumped down from the stairs he was on, rushing towards a wall of valves and electronic machines. “On my word, Choso!” He shouted as his assistant ran to the room's other side, grabbing a lever. Satoru’s attention was transfixed on the flashing lightning strikes in the dark skies above. He was focused like the mad scientist he was. “Steady—steady!” A giant lightning bolt striped the mechanical structure. He had set up outside the tower on the roof. “Now!!”

Choso flipped the lever, and as he did, electricity sparked, flowing down towards the table. You screamed, covering your eyes and ears as the machines cried out screaming. Gojo laughed maniacally as the sparks continued to spark until they died down. It was only then that Gojo lifted his goggles before grinning.

“Choso! Bring him down!”

You felt a swell of anxiety as Choso began lowering the table, and you rushed forward, watching as the form underneath it began to twitch. You swallowed, watching as Satoru rushed forward, yanking the sheet off of your husband. Stitches ran along his forehead and different body parts that had been stitched back together. As your eyes roamed over his body, he suddenly blinked. One violet eye, one brown, stared up at Satoru before darting towards you.

“Oh!” You gasped, placing your hand over your chest with wide eyes. “Suguru?”

Your husband slowly sat up, looking down at his hands before his attention focused on you. You stared at one another in shock and hope. Your breathing hitched as you stepped forward, gently, taking him much larger on your own. Your husband looked puzzled at the gesture for the briefest moments before his fingers curled, clasping your hand and his.

“It’s alive,” Satoru announced to Choso. “It’s alive! It’s alive!” He laughed madly as Suguru pulled your hand up to his mouth, pressing a kiss against it.

“O-Oh Suguru!” You chirped out as your relief and joy overflowed like a fountain.

Suguru kicked the rest of the sheet off before standing before you. His frame is much larger than you remembered it before. He towered over you with a sly smirk before cupping your cheek. You learned into it, fighting a sob as Satoru cleared his throat.

“I have made several improvements to your husband. Please take the time to get reacquainted with him.”

Without another word, the two men left you and your husband alone. You listen until the door shuts behind them, and when it does, you finally allow yourself to look up at Suguru. He smiled fondly before lifting you by the hips and carrying you to the nearest wall.

“Suguru?” You swallowed, staring up at his tall, muscular form. “Darling, what are you—“ you gasped, recoiling as he bunched your skirts up, lifting it to your hips. “O-Oh!”

“Wife~” he cooed, growling as he towered over you. His large muscles pulsed as he leaned down next to your ear. “You’re so small~ I can easily lift you.” You gasped as he ran his hands down, groping your thighs as he forced you to wrap them around his waist. “So cute~ so small, I’ll protect you.”

And you knew he meant every single word he said. Because you wanted him to protect you, he was tall, muscular, and strong. Your body shivered against his thick form, making you drip with need as he reached his hands up, tugging your lacy undergarments to the side. You couldn’t remember the last time you were so aroused; Suguru always had that effect on you. But his newer, stronger form made you even wetter.

“Suguru~!” You cried out, wrapping your arms around his neck, pulling him down to your mouth, kissing him with a force so strong it almost knocked the wind out of his lungs.

He kissed you back, snarling as he did. He wasted no time as he reached down, stroking himself with three quick pumps before he pressed the head of his cock against your entrance. His cock was larger than you remembered causing you to hiss out in slight discomfort that slowly eased into pure pleasure. This must have been the additional upgrade Satoru had been talking about. Suguru paused momentarily, allowing you to adjust, his body as stiff and rigid as a rock.

“Are you okay?” He whispered against your lips, his two different-colored eyes examining your face.

“Yes~ I missed you so much, Sugu!” You shot out, kissing him eagerly as he continued pushing inside of you. You moaned, burying your face in the inside of his neck as he stretched your inner walls out like you had never been stretched before. He rested his stitched forehead against your shoulder, dark hair tickling your heated skin as he completely bottomed out inside of you. You never thought being fucked with such a big cock would feel good. But it felt so fucking so good, fuck it just felt so right, like he was meant to be inside of you despite the size difference.

When your body finally adjusted to the size, you pulled your head away just as he did. You lost yourself in his eyes, panting softly as you panted softly as he began rocking his hips. The head of his cock brushed right against your g-spot, drawing out a shaky breath from you as you dug your nails into his back. Suguru hissed against your skin, leaning back to plant kisses along your sensitive neck. Each roll and rock he pushed into you had his cock moving deeper inside of you. Until the head of it brushed against your cervix. The sensation was almost electrifying, making you arch off the wall.

“Fuck, fuck, holy fuck!” His grip on your hips tightened as he began pounding into you. You grabbed a handful of black silky locks, pulling at it.

“Princess,” he roared, “you’re so wet and tight for me.” His finger dug into your flesh, making you rock them faster. “You have no idea how fucking good you feel.” Suguru mewled as his cock throbbed deep within you.

The coil deep within you began to tighten; you were growing close to your release. Suguru grunted and growled in your ear, his cock sliding in and out of your slickened folds as he thrust his hips up, nearly causing the wall behind you to crack. One robust and large arm held you in place while his free hand reached up, gently choking you. His huge fingers squeezed around your delicate neck as he let out an animalistic sound as you rocked your hips against his faster and harder.

“Haah! Suguru!” You gasped, your erect nipples rubbing against his bare stitched skin. “Nngh fuck yes!.”

“Princess, I-I’m gonna cum, fuck, I’m so close.”

“M-Me too!”

He didn’t need to be told a second time; his thrusts became erratic as he cut off your airway just a bit. That left you desperate. Your eyes rolled back as you continued moving, trying to push each other over the edge, and everything continued to build until you both came simultaneously. Your body stilled as Sugurue growled as his cum came out in ropes painting your walls. Your pussy clenched tightly around him, cumming harder than you had ever come before. You both stayed there gasping and panting roughly until the waves of pleasure died down. You grinned as he leaned back to look at you; his cheeks were faintly flushed as he smiled back. The two of you leaned in for another kiss, only to jump as someone bangs on the door.

You blinked, looking at the door, and several people came running in with torches and pitchforks. But they—weren't people, they were vegetables? The fuck? They yelled and screamed, not seeming to care that Suguru was balls deep inside of you. Your husband didn’t even mind them as he stared at you.

“Princess?” Your vision began to fade as Suguru called out your name several times. “Hey, wake up.” When you blinked again, you found Suguru’s violet eyes on you. “Hey, sleepy head, we're home.”

He was wearing all black, bolts sticking out of his neck. Stitches had been drawn across his forehead, smeared here and there. Huh, you glanced around before looking down at yourself. You were in a white dress and could feel the sticky, tacky face paint on you.

Oh yeah, you went to Satoru’s Halloween party. You had too many shots, and getting home was a bit of a blur. But your tall, large husband was anything but blurry. He was all muscle and kind. He agreed to be the DD for you both so you could have a fun time! And you had a fun time but were craving a different kind of fun now.

“Mmm, I had the craziest dream.” You yawned as Suguru unbuckled your seatbelt before carefully scooping you into his large arms. “You were Frankenstine’s monster, and we had hot monster sex.”

Your husband gave you a judgmental look with a laugh before shaking his head as he carried you inside. “Hot monster sex?” He shook his head. “So that’s why you were moaning and squirming the whole ride home. Because I was fucking you as a monster?”

“I was not!”

“Yes, you were, Little Monster Fucker; I bet when you get into the room, those panties are gonna be soaked.”

You pouted, crossing your arms over your chest. “They are not.” You stuck your bottom lip out. “And I’m not a monster fucker!” Suguru gave you an incredulous look.

“Says the person who dreamt of me as a reanimated man fucking her.”

You open your mouth to babble, shut it as a thought, and roam over your mind. “Wait, does that count as necrophilia?” Your husband stopped dead in his tracks, turning his head slowly to stare down at you.

“You know what, I was gonna fuck your brains out against the wall, but that was the least sexiest thing you could’ve said.”

“Wait! Please fuck me. I’m sorry!”

Suguru rolled his eyes. “Only because you said please, you little necrophiliac.” You grimaced, shaking your head in disgust.

“Eww, no, I would much rather be a monster fucker.” You sighed dramatically, going slightly slack in his arms. “Oooh, please, Mr. Monster, don’t do the nastiest things to meet Daddy!”

“Oh my god,” Suguru laughed softly, shaking his head as he carried you into the bedroom. “I want you to remember this moment when I get you a T-shirt that says: ‘Proud Monster Fucker’ on it for Christmas.”

“It’s better than ‘Proud Necrophiliac’!”

Sugar dropped you on the bed, sighing deeply. “Stop saying that damn word.” He turned his jeans down, freeing his monster-sized thick hard cock out, rubbing the tip over your bottom lip. “And put your mouth to better usage.” You grinned slowly, taking his thick, monster-like length into your mouth. Maybe you were a monster fucker, but you were proud to be one for him!

Forever Tag List:

@darkstarlight82 @pandoness @nealeart @simp-plague @sugurubabe @chilichopsticks @reap3erslov3 @wil10wthetree @msniks @lana18918 @draculemon

Kinktober Tag List:

@candy-s72

#jjk x reader#jjk x you#jjk#jjk smut#jjk reader smut#jjk reader insert#jjk y/n#jjk men#jjk geto suguru#suguru geto smut#geto smut#getou suguru x reader#geto suguru smut#geto x reader#jjk geto#jujutsu kaisen geto#geto suguru#jjk kinktober#marie’skinktober#jjk reader insert smut#reader jjk#jjk reader#jjk suguru geto#jujutsu geto#geto x you#jjk geto smut#jujutsu kaisen reader#jujutsu kaisen x reader#jjk men x you#jjk men x reader smut

180 notes

·

View notes

Text

Found/Fated/Forever

Part 1 Part 2 Part 3

Pairing: BTS OT7 x Reader Genre: Fantasy, eventual smut, porn with plot, slow burn, hurt/comfort Characters: Supernatural!BTS, Vampire!Jungkook, Supernatural!Reader Content Warning: Y/N in danger, medical scene & terminology Word Count: 3k

Jungkook held your body, cool, clammy, and lifeless in a state of panic. He didn’t mean to go that far, he thought desperately. He put his head on your chest and prayed to any gods that would listen that he hadn’t killed out outright, and a tiny blip of relief washed over him when he hurt the faint, slow beating of a heart. It wasn’t too late.

“What am I supposed to do?” He said, anxiously pacing. The idea hit him suddenly. If there was someone that could help, it was Namjoon.

Jungkook picked up your body, handling and cradling it like it was the most delicate flower. Standing in the middle of your apartment, in a puff of dark smoke, Jungkook willed the two of you to disappear, then reappear again on the roof of the largest general hospital in your city. At this time, the morning sun had begun cresting over the horizon, its warm rays falling onto the two of you. Jungkook for the first time felt his grip on you weaken and his muscles begin to strain and ache under your weight. Where you were weightless to him before, the sunlight was weakening him considerably. He wasted no further time dashing into the rooftop access door and into the hospital proper.

If Jungkook knew Kim Namjoon, and he was certain he did, he knew that it was almost certain that Namjoon hadn’t yet gone home from his shift as an emergency room attending. Jungkook hadn’t been to the hospital often, the stench of alcohol, death, blood, and other bodily fluids was overwhelming to his heightened senses and churned his stomach. Looking to blend in, he used the glamour magic afforded to him, disguising both of your forms as he navigated the halls, appearing to be just another doctor carrying a box of medical equipment. He paused, closing his eyes and concentrating, mentally pulling and tugging at the bond he shared with the older man.

Where are you? I am here.

Office. The bond answered back.

It wasn’t long until he was in front of the office of Dr. Kim Namjoon. Taking a deep breath, he opened the door.

Inside was a tired-looking, young man, busily typing and scratching down notes on a piece of paper. As Jungkook entered, he looked up, his expression initially pleased at seeing his mate quickly turned to one of shock and horror at what he was carrying.

“Hello Jungk-” Namjoon cut himself and stood suddenly from his desk, seeing the body he carried in his arms. “What the hell is this?”

“Help her, please,” Jungkook begged. “I can explain more later.”

Namjoon walked over, feeling for a pulse. “Did you do this to her?” He asked, his voice grave.

“Yes,” Jungkook replied, ashamed.

“Well you didn’t kill her,” Namjoon stated with a sigh. “She needs urgent treatment. Disguise yourself and bring her up to the 8th floor, B corridor, last room on the left. We will have a bit more privacy that way. I will be up right behind you.”

With a simple nod of solemn understanding, Jungkook turned on his heel, and made haste out of the office, following Namjoon’s instructions carefully. The B corridor on the 8th floor was sparsely populated, it appeared to be mostly storage for patient care monitors and machines, Jungkook noted passively. He tried the door of the aforementioned room, finding it unlocked, before letting himself in. The room was minimal, with a bed made up with only a pillow and a single fitted sheet, a bedside monitor, and a chair. Jungkook quickly laid you down on the bed before drawing the blinds to prevent any additional sunlight from getting in, it was making him feel like shit enough as it was.

It wasn’t much longer after Jungkook entered that Namjoon entered as well. He came, backpack slung over a shoulder and pushing a rolling table. Wordlessly, he unpacked the supplies and began setting you up on the monitors.

“Her pulse is thready, weak, and slow, but it's there. Regular rythm.” Namjoon noted out loud to no one in particular. “Her blood pressure is really low so I’m going to have to start her on a blood transfusion and fluids. Is that going to bother you, or do I have to kick you out?”

Jungkook shook his head emphatically. Namjoon nodded in understanding, but stood in place, unmoving.

“DO something!” Jungkook insisted, anxiously.

“I can count the number of times I’ve placed an IV on one hand and as for the IV pumps, they might as well be set to a foreign ancient language. I promise I am the last person you want handling this stuff. I’ve already paged my nurse, Clara. She should be here any moment.”

As if divinely timed, the door handle jiggled and opened, and a short, stout, human walked in. Clara was the veteran nurse of veteran nurses. She had been working since she graduated at the age of 22, she could place an IV in your forehead, she could run a code blue better than most of the resident doctors, and she was wise enough to know when to not ask too many questions.

“I got your page, Dr. Kim,” Clara said, walking in, and quickly assessing the situation.

“Clara, we are running a hypovolemic protocol on this patient. She needs bilateral peripheral IVs, 1-liter Lactated ringers at 120 milliliters an hour, packed red blood cells should run at 200 milliliters an hour, and platelets at 400. Take whatever blood you can and run a CBC, Jane Doe, stat. I have all the supplies here.”

“Yes, doctor,” Clara responded before quickly getting started. Clara worked fast and efficiently, with a work ethic born from years in the emergency room. Sliding the IVs in place, she expertly set up the fluids and blood products to transfuse and finally drew a vial of blood for testing. “I am going to run this to the lab. Will you be doing the transfusion monitoring, Doctor?”

“Yes. Thank you, Clara, for your work and your discretion,” Namjoon said, dismissing her. She excused herself with a simple head nod, and the two men were again alone in the room.

“She’s going to get better now, right?” Jungkook asked, bouncing his leg anxiously.

“She should,” Namjoon said, seriously. “But this is not over, and we will be discussing what the hell happened here because if I am doing some of the mental math here, I suspect this…” he said gesturing to you, “is an everyone problem.”

Jungkook looked away. The older man wasn’t usually so serious or harsh with him, and if he was honest with himself it definitely hurt on top of everything else that was going on, not that he didn’t deserve it.

The pair sat in silence for some time. Namjoon stood at your bedside carefully monitoring your vital signs. As the minutes passed, steadily your vital signs improved, and steadily Namjoon was able to relax.

“It was good you got here when you did,” Namjoon finally broke the silence. “She would have certainly died if you hadn’t.”

Jungkook swallowed hard at that. The last words you had said to him before this all started echoed in his mind, swallowing him with guilt. Please don’t hurt me.

After about 30 minutes, Namjoon received a message on his phone, your lab results. Confusingly, almost all the values were low. Did you even have any blood in your body, no one can survive this kind of low. Namjoon knitted his eyebrows together in confusion, and just as he was about to look up and question Jungkook, the monitoring alarms started blaring.

“Fuck!” Namjoon cursed. “She’s having a reaction to the blood. That should be impossible it’s O- blood, no one reacts to that! I checked it 5 times, FUCK! He cursed again.

“What do we do?” Jungkook stood now, panicked.

“Stay here, I need to get some medications I will be back as fast as I can.” Namjoon typically tapered his mannerisms and movements to the human world he worked in. He moved deliberately slowly, but at this moment, he allowed himself to use the maximum of his powers. Truly in a flash, he had gone and come back with armfuls of different medications he wasted no time in administering.

“This is really bad, Jungkook,” Namjoon said, looking over your body anxiously. “Her blood levels are so low, no human should have survived, and now she’s reacting to the one type of blood that everyone should be able to tolerate. I can give her some medications to encourage her body to make more blood cells faster, but I’m not sure she’ll survive that long.”

Jungkook stood, running his hands through his hair pacing. “She asked me not to hurt her, Joon. She asked me and I did this to her. She trusted me.” His voice waivered, boarding on tears.

“If I am right about what I suspect, you couldn’t control yourself, Kook,” Namjoon said, attempting to be comforting.

Jungkook continued to pace, chewing on his nails as he watched Namjoon attempt to resuscitate you.

“What if she wasn’t human?” Jungkook suddenly asked.

“What?” Namjoon asked, spinning around.

“What if she wasn’t human? She does crazy magic and her blood tasted weird. Different. I’ve drank a lot of human blood and it was never like that.”

Namjoon drew in a breath, answering in a cool, measured way. “You mean to tell me this woman can do magic and it’s only now occurring to you she’s probably not human? What human have you ever met that possesses anything resembling magic? Never mind the fact that her blood was completely unlike any other humans you’ve tasted, now I’m thinking the next thing we should be testing is your head because I’m desperately concerned that it is entirely empty!”

Jungkook looked down, ashamed, at the older man’s chiding.

“No wonder she had a reaction to the blood I gave her! Explains the impossibly low lab values too, she’s a bit more durable than the average human. Don’t be mistaken, these medications will likely have limited effect on her, and she is still gravely ill.”

“What can we do?” Jungkook asked, eyes misty.

“We,” Namjoon said emphasizing the word. “Can’t do a whole lot. You can teleport to Baba Yena and hope she’s feeling charitable today.”

Jungkook groaned internally. Baba Yena was known to be exceptionally powerful, but exceptionally apathetic. Legend states that she was older than time, older than the gods and the powers that created them. She possessed incredible powers, but was, in a word, incredibly stingy to whom she blessed with them. Jungkook’s run-ins with the woman had been scarce, but the few times he had, were certainly memorable. At all costs, he had wanted to avoid being around her, but on the other hand, it was the least he owed you after nearly taking your life.

With a heavy sigh and crossed fingers, Jungkook walked to the center of the room, and in yet another puff of black smoke instantly disappeared, leaving Namjoon alone with your body.

He sat next to your bedside, going between monitors, checking medication flow rates, and staring at you.

“If you keep fighting, I will fight for you,” Namjoon said. “Welcome to the family.”

~~~~~~~~~~~~~~~~~~~~

Jungkook appeared suddenly and to his relief in front of a large, dome-shaped house. Baba Yena’s house was located in a pocket dimension, and without the proper talismans or magic symbols, teleportation here was… unreliable. The house itself seemed to be made out of packed dirt or fired brick, the roof overgrowing with moss. The house was seemingly the only thing in the pocket dimension, and aside from Baba Yena’s home and overgrown yard, a black abyss stretched on in all directions seemingly endlessly.

Jungkook steeled his nerves, walking up the short, rough stone walkway to the large, wooden front door. There was no door knob, Jungkook suddenly realized, but as he raised his hand to knock, the door flung itself open. Taking it as an open invitation, he let himself in.

The inside smelled fairly pleasant of wood, and for good reason. Betraying the fired brick exterior, the interior of the home seemed that of a log cabin or other wood-inspired architecture. In the entryway, there was a single spiral staircase going up, and corridors leading to who knows where on the left and right. If Jungkook focused his hearing, from the right direction he could hear a female voice humming and mumbling to herself. He decided to follow.

The corridor was plain with wood paneling, but most bizarrely seemed to stretch on for much, much longer than it had first appeared. Jungkook found himself walking first for 1 minute, then 5, and when 10 minutes passed and he still hadn’t reached the room he was walking towards, his anxiety heightened. He stopped, thinking.

“I seek your help, Baba Yena!” He called out. He waited a few seconds, and when nothing changed he thought of a new approach. Baba Yena was also called the Knowing Mother, and to her, information was worth its weight in favors. “A girl of an unknown race lies dying in a hospital bed, and without your gracious help, she will perish an unknown, and her secrets will die with her.” Jungkook waited a few more seconds. He felt a rush suddenly and was nearly knocked off his feet as a large, invisible force picked him up, and shot him forward, dropping him off at the threshold of the room once impossibly far away.

Jungkook entered the room which he quickly assessed to be a kitchen of sorts with black and white floor tiling, scuffed with age, a dark wood table covered in various ingredients, tubes, flasks, and other unrecognizable equipment, a ceiling littered with drying herbs and meats, and a sink next to a counter, on which is something that was clearly freshly butchered. On the side closest to him, there was a forge of sorts, a large stone pit full of red-hot coals, perched over which was a large, black cauldron, the depth of which was at least half of Jungkook’s height. Standing over the cauldron on a step stool was Baba Yena, a diminutive old woman. Hair silver and white was wild and long, her face a map of wrinkles and liver spots, and her hands, gnarled, twisted, and bony. If she noticed Jungkook enter, she didn’t show it and continued stirring whatever concoction bubbled loudly in the kettle.

Jungkook cleared his throat and shifted uncomfortably, attempting to get Baba Yena’s attention to no avail.

“Baba Yena,” Jungkook began, taking a tentative step forward. “I bring you information in exchange for some of your magic.”

Baba Yena didn’t look up from her work but finally spoke. “The Liar Boy comes to me asking for favors, tell me Liar Boy, how does that pendant serve you?”

“It serves me well, Baba,” Jungkook said holding it in his hand instinctually. “There is a girl, not human, not demon, not fae, not angel. She is dying.”

“I see…” Baba Yena stirs her pot more aggressively now, reaching up, plucking a dried herb from the ceiling, and mixing it in. “You, Liar Boy are the one who almost killed the girl…”

“I was compelled by the Smoke. It is my fault nonetheless, and I have come to beg for your mercy.”

“I have saved you once, Liar Boy. Many who come to my doorstep don’t have even that many chances.”

“The girl is unusual and powerful. She could be of interest to you.”

“You again offer the girl as a sacrifice, and yet nothing of personal sacrifice, how peculiar.” Baba Yena said with a small cackle.

“I have nothing left to give,” Jungkook replied, forlorned.

“I see the girl,” Baba Yena said, staring into her cauldron. “The horned one cares for her well, but she is as ill as you say and- ah! She is mated to you, she holds your final Fragment, I see. No wonder the Liar Boy again finds himself on my doorstep.”

“You understand why I humbly bring myself to your home. Allowing her to die would be a punishment too heavy for someone innocent, she is guilty of only trusting me. I intend to earn her trust in earnest, and I only ask for the opportunity to do so.”

“So it would seem…” Baba Yaga said, half listening. She stares intently at something, the light from the cauldron giving her an even more menacing look. Her eyes dart around as if watching something intently, and Jungkook watches as her face twists into a wolfish smile.

“I ought to sever your bonds and cast your soul to wander the Astral Sea for being such a pain in my side, Liar Boy. I will help this girl, but not without sacrifice from you.”

“Anything,” Jungkook said earnestly.

“Oh, I have something in mind,” Baba Yaga said, climbing down from the step stool and waddling across the kitchen before phasing through a portion of the wall, disappearing from view. Jungkook could still hear the sound of items being shuffled, glass clinking against glass, however. After a minute or so, Baba Yaga returned, a dusty, palm-sized, green potion in hand.

“Drink this and we will be on our way.” She said, handing him the bottle.

Jungkook took it from her, turning it in his hand, examining the liquid inside. It was a sickly lime green color, and he noticed, to the dismay of his stomach, that the texture of the liquid was actually quite viscous and grainy. He wondered if it was a poison, naturally, perhaps one meant to weaken him severely but never kill him outright. He had a mind to ask, but understanding how fickle Baba Yena was, he knew better. He lifted the cork out of place with a solid thunk, closed his eyes, and focused on not vomiting as he poured the potion down his throat. He didn’t fight the wave of magical something that passed through his body, bracing himself for pain or weakness. He opened his eyes and checked his body, felt his face, but somehow, he felt completely fine.

“You’ll know what it does in time, Liar Boy. Now come, let's go save this girl.”

#bts#bangtan#bts x reader#jungkook x reader#ot7 x reader#namjoon x reader#bts x reader angst#bts smut#bts x reader smut#bts x y/n#bts x you#bts x fem!reader#bts x oc#ot7 x reader smut#ot7 x you#poly ot7#foundfatedforever#foundfatedforever part 3

168 notes

·

View notes

Text

Discover the Power of Aluminium Sheets: Lightweight, Durable, and Sustainable—Inox Steel

Inox Steel is a trusted name among Aluminium Sheet Manufacturers in India, delivering top-quality aluminium products for a wide range of industrial and commercial applications. As a leading Aluminium Sheet Supplier, we understand the growing demand for lightweight, corrosion-resistant, and durable materials across sectors such as construction, transportation, electronics, packaging, and more. Our aluminium sheets combine innovation with excellence to meet the highest quality standards and performance expectations.

Understanding Aluminium Sheet

Aluminium Sheets are flat-rolled products created by passing aluminium slabs through heavy rollers to achieve the desired thickness. They typically range from 0.2 mm to 6 mm in thickness, with variations above 6 mm classified as plates and below 0.2 mm as foils. Available in various grades, finishes, and tempers, aluminium sheets are suited for a wide range of functional and aesthetic applications.

Leading Aluminium Sheet Manufacturers in India offer products that comply with global standards, catering to different industrial needs. Common alloys such as 1100, 3003, 5052, and 6061 are used by almost every Aluminium Sheet Manufacturer to ensure high strength, formability, and corrosion resistance.

Advantages That Make a Difference

Durability Meets Versatility Aluminium sheets are built to last. They resist rust, environmental damage, and chemical exposure, making them ideal for outdoor and high-wear applications. Despite their durability, these sheets are easy to form, cut, and weld.

Weight Efficiency That Delivers Weighing significantly less than steel, aluminium sheets reduce structural load and transportation costs. Using an Aluminium Sheets Weight Chart helps engineers and fabricators calculate loads and plan for structural efficiency without compromising strength.

Visual Appeal with Functional Design With a range of finishes—such as anodised, brushed, or mirror-like polish—Aluminium Sheet not only serves a functional purpose but also offers a modern appearance. Architects and designers often use it in interior decor and facade systems.

Excellent Formability for Custom Solutions Aluminium sheets can be bent, rolled, or shaped without losing structural integrity. This makes them ideal for customised components in machinery, signage, packaging, and consumer products.

Eco-Friendly and Fully Recyclable Aluminium is among the most recycled materials in the world. Using recycled aluminium saves up to 95% of the energy required to produce it from raw ore, making Aluminium Sheet a sustainable choice for green manufacturing practices.

Where Aluminium Sheets Make an Impact

1. Industrial Manufacturing Used in equipment housings, panels, and machine parts, aluminium sheet provides a dependable material that balances strength and formability in factory settings.

2. Building and ConstructionAluminium Sheet Suppliers provide sheets for cladding, insulation panels, roofing systems, and more. Their weather resistance and aesthetic flexibility make them ideal for modern infrastructure projects. Builders often rely on the Aluminium Angles Weight Chart to select the right materials.

3. Automotive and TransportationFrom vehicle body panels and trailer sides to train and aircraft skins, aluminium sheet helps manufacturers reduce vehicle weight, improve fuel efficiency, and meet emissions targets. Weight estimation using tools like the Aluminium Pipe Weight Chart is critical in this sector.

4. Electrical and Electronics Due to its conductivity and thermal dissipation properties, aluminium sheet is used in casings, heat sinks, and enclosures for electronic equipment.

5. Packaging and Consumer Products Aluminium sheets are used in the production of beverage cans, cosmetic containers, and food trays. They offer excellent hygiene, non-toxicity, and recyclability.

Choosing the Right Aluminium Sheet for Your Needs

When selecting aluminium sheet, consider:

Application environment (indoor, marine, structural)

Required strength and formability

Surface finish needs

Alloy and temper specifications

Trusted sourcing from an experienced Aluminium Sheet Supplier

If you're located in Gujarat, working with an Aluminium sheet supplier in Ahmedabad can ensure faster delivery and personalised service. Many regional manufacturers offer tailored solutions to meet construction and industrial demands efficiently.

Conclusion:

Aluminium sheets from Inox Steel India offer the perfect combination of strength, lightness, and sustainability, making them an essential material across industries. With a strong presence as an Aluminium Sheet Supplier in India, we are committed to delivering superior-quality products that meet diverse application needs. Whether you're building infrastructure, manufacturing equipment, or designing consumer goods, our aluminium sheets provide unmatched performance and reliability.

#AluminiumSheetManufacturersinIndia#AluminiumSheetManufacturer#AluminiumSheet#AluminiumSheetSupplier

0 notes

Text

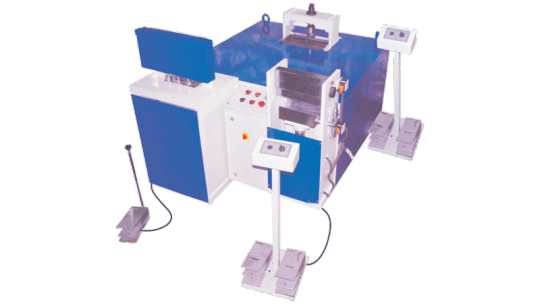

Roofing to Racking – Jugmug’s Versatile Top Hat Profile Machines

In today’s fast-evolving construction and manufacturing industries, versatility, speed, and precision are not just desirable—they’re essential. Jugmug RollForming, a renowned name in India’s metal forming machinery sector, continues to redefine industry standards with its Top Hat Section Roll Forming Machines. From roofing frameworks to industrial storage systems, Jugmug’s top hat profile machines offer unmatched versatility, enabling businesses to streamline production and ensure high-strength, consistent metal profiles for diverse applications.

What is a Top Hat Section?

A Top Hat Section is a type of cold-formed steel profile characterized by its ‘hat’-like cross-section. Typically used in roofing battens, wall studs, racks, cable trays, automotive parts, and structural frameworks, this shape offers:

High strength-to-weight ratio

Load-bearing capacity

Easy integration into modular systems

Aesthetic simplicity and functionality

These sections are vital across industries including construction, HVAC, storage, solar mounting structures, and automotive components—making efficient and precise manufacturing crucial.

Jugmug RollForming: Setting the Standard in Profile Precision

Jugmug RollForming has built a reputation for delivering cutting-edge roll forming machinery with robust design and long-term performance. Their Top Hat Roll Forming Machines are engineered to handle varying material gauges and dimensions with exceptional accuracy.

Key highlights include:

Fully Automated Lines: From decoiling to punching and cutting, Jugmug machines provide seamless automation to reduce labor and errors.

Custom Profile Flexibility: Whether you're producing narrow top hat profiles for cable trays or wider sections for roofing purlins, Jugmug’s systems are adaptable.

High-Speed Production: Speeds up to 20–40 meters per minute ensure rapid output without sacrificing quality.

Material Compatibility: Suitable for GI, CR, HR, SS, aluminum, and pre-painted steel coils.

Applications: From Roofing to Racking

Jugmug’s Top Hat Roll Forming Machines cater to a broad spectrum of industries and use cases:

1. Roofing Frameworks

Top hat sections are widely used as roof battens to support metal sheeting or tiles. Jugmug machines can produce consistent battens with pre-punched holes for quick installation, saving time and labor at construction sites.

2. Cable Trays & Electrical Channels

Precision is critical in cable management systems. Jugmug’s machinery ensures smooth edges and accurate profiles that support safe and efficient cable routing.

3. Storage Racks & Shelving

Industrial racking demands profiles that are both strong and uniform. Jugmug’s machines offer roll forming solutions with customizable hole punching and profile depths for heavy-duty shelving systems.

4. HVAC & Duct Framing

Top hat channels serve as structural frames in HVAC systems. Jugmug ensures clean, sharp profiles that are easy to assemble and provide long-term stability.

5. Solar Panel Mounting Structures

For solar farms and rooftop systems, corrosion-resistant and structurally sound profiles are a must. Jugmug machines can handle galvanized and coated materials, providing solar-grade quality.

Design, Engineering & Build Quality

Jugmug RollForming machines are built with a focus on:

Modular Tooling Setup – Quick changeover between different sizes and profile types

Heavy-Duty Construction – Ensures stability during high-speed operations

Hydraulic/Servo Cutting Units – For clean, burr-free profile ends

In-Line Punching – Custom punching patterns integrated into the roll forming line

Each machine is tested under industrial load conditions and meets ISO standards, reflecting Jugmug’s commitment to quality and safety.

Customization at its Core

Jugmug understands that no two manufacturers are the same. That’s why their Top Hat Roll Forming Machines offer:

Variable roll stand configuration (12 to 24+ stations)

Adjustable width and depth

Interchangeable tooling for multi-profile setups

Integration with PLC and HMI for real-time monitoring and control

This adaptability means Jugmug machines are suitable for batch production, just-in-time manufacturing, or mass production lines.

Why Choose Jugmug RollForming?

1. Industry Experience With decades of engineering excellence, Jugmug has supplied machines across India and abroad, earning the trust of OEMs and infrastructure giants alike.

2. After-Sales Support Their dedicated service team offers on-site commissioning, training, and lifetime technical assistance—ensuring your operations never halt.

3. Custom Engineering Jugmug works closely with clients to design machine setups that meet exact application needs, offering true “concept to commissioning” solutions.

4. Competitive Pricing Despite their world-class quality, Jugmug machines are affordably priced, giving Indian manufacturers a strong ROI and global manufacturing edge.

Conclusion: The Right Machine for the Right Profile

Whether you're building a skyscraper’s roofing system or setting up an industrial racking warehouse, Jugmug RollForming offers the precision, durability, and support needed to stay ahead of the curve. Their Top Hat Profile Roll Forming Machines bring versatility and performance under one roof—making Jugmug a trusted name in India’s metal forming sector.

Ready to Scale Your Metal Profile Production?

Contact Jugmug RollForming today to get a custom quote or schedule a demo of their top hat section roll forming line.

1 note

·

View note

Text

What Is Brass Sheet, Copper Sheet & the Best Metal for Reliable Performance?

Introduction: The Backbone of Quality Fabrication

From industrial workshops to architectural design studios, choosing the right sheet metal determines the quality, functionality, and longevity of your work. Whether you're crafting durable components, elegant fixtures, or high-precision parts, materials like the brass sheet, copper sheet, and globally trusted imported products stand out for their reliability.

In this blog, we’ll explain what each material is, where it’s best used, and how to select the best sheet metal for reliable performance in any project.

What Is a Brass Sheet?

A brass sheet is a flat-rolled alloy of copper and zinc, appreciated for its durability, corrosion resistance, and decorative appeal. It is used in both engineering and design contexts due to its strength and golden finish.

✔ Features of Brass Sheet:

Visual Appeal: Bright, gold-like appearance perfect for design

High Workability: Easily bent, cut, or engraved

Corrosion Resistance: Withstands moisture and salt air

Smooth Surface: Ideal for etching or engraving

✔ Best Uses:

Architectural hardware and design panels

Plumbing components and valves

Marine applications and instruments

Engraved nameplates and display boards

Choose from premium Brass Sheet options ideal for aesthetic and industrial-grade applications.

What Is a Copper Sheet?

A copper sheet is made from high-purity copper and is known for its excellent thermal conductivity, electrical properties, and antimicrobial capabilities.

✔ Why It’s Preferred:

Unmatched Conductivity: Ideal for electrical applications

Thermal Efficiency: Used in cooling and heating systems

Antimicrobial Surface: Makes it hygienic for healthcare and kitchens

Aging Gracefully: Forms a beautiful patina for weathered looks

✔ Best Applications:

Switchboards, wiring plates, and PCB boards

Copper roofs, domes, and flashings

Countertops, wall claddings, and kitchen surfaces

Renewable energy units and HVAC systems

Get certified and versatile Copper Sheet trusted across electrical and sanitary industries.

What Are Imported Products in Sheet Metal?

Imported products refer to high-grade metal sheets sourced from international manufacturers, known for their tight tolerance, premium finish, and global certifications like ISO, ASTM, and DIN.

✔ Advantages of Imported Sheets:

Global Compliance: Meets international quality standards

Superior Surface Quality: Available in mirror, matte, brushed, or coated

Specialty Materials: Includes bronze, nickel silver, and other alloys

Perfect for Automation: Ready for CNC, laser, and hydraulic presses

✔ Best Industrial Uses:

Aerospace components and instrumentation

Luxury architectural interiors and elevators

Medical equipment, enclosures, and consoles

High-end export products requiring consistent quality

Explore globally compliant Imported Products for quality that meets international demand.

What Is the Best Sheet for Reliable Results?

Here’s a quick guide comparing your three material options for performance: CategoryBrass SheetCopper SheetImported ProductsVisual AppealElegant Gold FinishRich Reddish ToneCustomizable (Mirror, Matte)Electrical UseModerateExcellentDepends on grade/alloyMechanical StrengthHighHighExtremely HighCertificationsIS/BISBIS/ASTMISO, ASTM, JIS, DINWeather ResistanceHighVery HighVaries (coated or alloy-based)

What Is the Best Thickness for Industrial Use?

Sheet thickness determines mechanical strength, weight capacity, and application suitability.

0.3 mm – 1 mm: Ideal for electronic panels, art, and interior cladding

1 mm – 3 mm: Best for furniture hardware, roof sheets, machine covers

3 mm – 6 mm+: Used in structural, load-bearing, or high-voltage systems

Imported sheets offer tight tolerance precision, making them excellent for robotic and automated use.

What Is the Best Surface Finish for Reliable Results?

Surface finish affects corrosion resistance, appearance, and post-fabrication effort. Finish TypeIdeal ForMirror PolishInteriors, nameplates, hotel lobbiesBrushed FinishKitchens, signage, elevatorsMatte FinishIndustrial or minimalist architectural stylesEmbossed/LaminatedDecorative and outdoor-use sheets

Imported products come pre-finished, which saves cost and ensures factory-grade consistency.

What Is the Best Way to Maintain Sheet Metal Performance?

✔ Storage Tips:

Keep flat with protective layers in low-humidity environments

Separate sheets with foam or plastic to prevent scratches

Avoid contact between dissimilar metals to prevent galvanic corrosion

✔ Maintenance Tips:

Brass Sheet: Clean with brass polish or a lemon-vinegar mixture

Copper Sheet: Let natural patina develop or use copper polish

Imported Sheets: Follow specific finish guidelines; avoid abrasive cleaning

Final Thoughts: Choose Materials That Stand the Test of Time

Choosing between a brass sheet, copper sheet, or imported products isn’t just about price—it’s about long-term performance, safety, and visual appeal. Brass offers beauty and corrosion resistance. Copper brings conductivity and hygiene. Imported materials offer global standards, precision, and versatility.

0 notes

Text

Quality That Rolls Forward – Trusted Roll Forming Machines by Jugmug RollForming

In today’s rapidly evolving industrial landscape, precision, reliability, and innovation are the cornerstones of success. When it comes to metal forming, Jugmug RollForming stands tall as a beacon of engineering excellence. With decades of expertise and a relentless commitment to quality, Jugmug has redefined what roll forming means for manufacturers around the globe. Their machines are not just tools—they're solutions built to roll industries forward.

What Is Roll Forming and Why Does It Matter?

Roll forming is a continuous bending operation in which sheet metal is passed through a series of rollers to create desired cross-sections. The process is fast, efficient, and capable of producing high-strength components with tight tolerances. Industries ranging from construction to automotive, infrastructure to energy, rely on roll forming for their structural and precision part needs.

Whether it's roofing sheets, door frames, cable trays, solar panel structures, or highway guardrails, roll forming offers unmatched consistency, speed, and material utilization. And Jugmug RollForming ensures these advantages are delivered with industry-leading precision.

Why Choose Jugmug RollForming?

1. Commitment to Quality

At the heart of Jugmug’s philosophy lies a simple yet powerful idea—quality never goes out of style. Every machine is designed, engineered, and tested with stringent quality checks to ensure it meets both national and international standards. From raw material selection to final assembly, Jugmug leaves no stone unturned in delivering machines that last long and perform consistently.

2. Customization and Flexibility

One size does not fit all in industrial manufacturing. Jugmug RollForming understands this deeply and offers customized roll forming solutions tailored to specific requirements. Whether it’s a unique profile, a specific gauge range, or automation integration, Jugmug delivers solutions that fit your production goals perfectly.

3. State-of-the-Art Technology

Jugmug RollForming is at the forefront of technological advancement. From PLC and HMI control panels to servo-driven feeding systems and automatic stackers, their machines reflect the best in modern manufacturing. This not only ensures faster setup and changeover but also helps clients achieve higher throughput and efficiency.

4. Superior After-Sales Support

Jugmug’s commitment doesn’t end with the sale. They offer comprehensive support, including installation, training, troubleshooting, and maintenance. Their expert team is available to ensure your operations stay smooth and productive, helping you get maximum ROI from your investment.

Wide Range of Applications

Jugmug RollForming caters to an expansive list of industries, offering roll forming machines for a variety of applications:

Construction Industry: Roofing sheets, wall panels, purlins (C/Z/U shapes), door and window frames.

Energy Sector: Solar panel mounting structures, cable trays, and enclosures.

Infrastructure Projects: Highway guardrails, metal crash barriers, and road sign supports.

Storage and Racking: Shelving profiles, pallet racking systems.

Automotive & Transport: Bus body profiles, container parts, structural reinforcements.

Their machines are designed to handle various metals including galvanized steel, stainless steel, aluminum, and pre-painted materials—ensuring flexibility across product lines.

Engineering That Sets the Standard

Jugmug RollForming doesn’t just build machines—they build trust through engineering excellence. Their roll forming lines come equipped with:

High-precision rollers crafted from hardened steel for longer life

Hydraulic or pneumatic cutting systems for clean and accurate cuts

Decoilers and recoilers for seamless coil management

In-line punching and notching to reduce post-processing time

Optional automation features to scale up production

Each element of the roll forming machine is engineered with longevity and performance in mind, ensuring minimal downtime and consistent production.

Made in India, Trusted Worldwide

While Jugmug RollForming proudly manufactures its machinery in India, its reputation transcends borders. Their roll forming solutions have found customers in multiple countries thanks to their commitment to quality, cost-efficiency, and customer satisfaction.

By combining world-class engineering with localized support, Jugmug is helping businesses both big and small modernize their manufacturing processes.

Sustainability and Cost Efficiency

In addition to performance, Jugmug’s machines are built with a keen eye on energy efficiency and material optimization. Reduced waste, optimized forming speeds, and low maintenance needs help businesses stay sustainable and profitable.

Their machines also support modular upgrades, allowing businesses to add capabilities as they grow—making it a smart investment for startups and established industries alike.

The Future is Rolling – With Jugmug

As demand for faster, leaner, and smarter production rises, Jugmug RollForming is ready to meet the challenge. With ongoing R&D, customer-focused engineering, and a robust service network, Jugmug continues to be a trusted name in roll forming.

Their motto—“Quality That Rolls Forward��—is more than a tagline. It’s a reflection of the values that drive them every day: precision, reliability, and customer success.

Conclusion

In a competitive industrial environment, the tools you choose can define your growth. With Jugmug RollForming, you’re not just investing in a machine—you're partnering with a company that puts your success at the center of everything they do. From the first coil to the last cut, Jugmug ensures that quality keeps rolling forward.

0 notes

Text

Best Quality Metro sheet manufacturers in India

Metro Sheet Manufacturers in India: Powering the Growth of PEB Construction

India’s construction industry is experiencing rapid evolution, driven by the increasing demand for fast, durable, and cost-effective building solutions. One of the key innovations shaping this transformation is the rise of Pre-Engineered Buildings (PEBs)—steel structures that are pre-designed, factory-fabricated, and assembled on-site. As the backbone of PEB cladding and roofing systems, Metro sheet manufacturers in India are playing a pivotal role in enabling this shift toward modern infrastructure development.

What Are Metro Sheets?

Metro sheets refer to high-quality, profiled metal sheets commonly used for roofing and wall cladding in industrial, commercial, and residential buildings. These sheets are typically made from galvanized steel, Galvalume, or aluminum, and often come with protective coatings and attractive color finishes. Their durability, light weight, and corrosion resistance make them ideal for a wide range of construction applications—particularly in pre-engineered steel structures.

Metro sheets are available in various profiles, including trapezoidal, corrugated, and standing seam, offering versatility in design while ensuring strength and weather protection. These sheets serve as both functional and aesthetic elements in PEB construction.

Role of Metro Sheet Manufacturers in the PEB Industry

In the context of PEBs, metro sheets act as the external skin of the building, providing structural protection, insulation, and visual appeal. PEB manufacturers rely on metro sheet suppliers to provide high-precision, quality-controlled materials that align with the specific dimensions and performance requirements of their projects.

Key contributions of metro sheet manufacturers to the PEB sector include:

Customization: Sheets are produced to exact sizes, thicknesses, and finishes as per PEB design requirements.

High Production Standards: Use of advanced roll-forming machines and automated production lines ensures consistent quality and precision.

Durability and Protection: Coated sheets protect steel frames from weather elements, enhancing the lifespan of the building.

Speed of Construction: Pre-fabricated sheets enable quick installation, reducing project timelines and labor costs.

By offering reliable supply chains and consistent quality, metro sheet manufacturers support the seamless execution of PEB projects across India.

Market Demand and Industrial Applications

The Indian PEB market is growing rapidly due to increased demand in sectors like logistics, warehousing, manufacturing, agriculture, aviation, and commercial development. With this growth, the demand for superior roofing and cladding materials has also surged—placing metro sheet manufacturers in a critical position.

Some common applications of metro sheets in PEBs include:

Warehouses and distribution centers

Cold storage and agro-processing units

Airports and hangars

Manufacturing plants and workshops

Commercial and institutional buildings

Residential roofing and farm structures

The ability of metro sheets to withstand harsh environments, including heat, rain, and wind, makes them especially suitable for diverse Indian climatic conditions.

Conclusion

Metro sheet manufacturers in India are integral to the success of the growing PEB industry. By delivering high-quality, customizable, and durable roofing and cladding solutions, they empower PEB manufacturers to construct modern, efficient, and sustainable buildings across the country. As demand for rapid and resilient infrastructure continues to grow, the collaboration between metro sheet and PEB manufacturers will remain a cornerstone of India’s construction future.

Visit:- https://www.pebmanufacturers.in/metro-sheet.html

0 notes

Text

What is Steel Coil? Application and Classification of Steel Coil

In today’s fast-evolving industrial landscape, steel coil is one of the most essential raw materials that powers sectors like construction, automotive, manufacturing, and infrastructure. Its versatility, strength, and ability to be fabricated into countless forms make it a core component in modern engineering. But what exactly is a steel coil, and how is it classified and used across industries?

In this blog, we’ll explore the definition, applications, and classifications of steel coils, with a special focus on stainless steel coil, and discuss how Kinetic Industries, a leading Steel Coil, Plate, Sheet & Spool Wire Manufacturer, plays a key role in supplying premium-quality products.

What is a Steel Coil?

A steel coil is a finished steel product such as sheet or strip which has been wound or coiled after rolling. These coils are manufactured through a process of hot or cold rolling and are then formed into long, continuous lengths of steel wound into large rolls. This format makes handling, storage, and transportation efficient and cost-effective.

Depending on the production process and application, coils can be made from various types of steel including carbon steel, galvanized steel, and stainless steel coil.

Key Characteristics of Steel Coils:

High strength-to-weight ratio

Flexibility for shaping, cutting, and welding

Resistant to corrosion (especially in stainless steel variants)

Available in different grades, finishes, and thicknesses

At Kinetic Industries, a trusted steel coil manufacturer in India, you’ll find a comprehensive range of coils catering to both standard and customized industrial requirements.

Applications of Steel Coil

Thanks to their adaptability, steel coils are used in nearly every industry that relies on metal components. From structural engineering to precision manufacturing, their applications are wide-ranging and impactful.

1. Construction Industry

Steel coils are used extensively in constructing buildings, bridges, tunnels, and infrastructure components. They are often used in roofing sheets, wall panels, and steel framing due to their structural integrity and ease of fabrication.

2. Automotive Manufacturing

In the automotive sector, both hot rolled and cold rolled steel coils are utilized for body parts, chassis, and components. Stainless steel coil is especially valued for its resistance to corrosion, which is crucial in vehicle manufacturing.

3. Household Appliances

Appliances such as refrigerators, washing machines, ovens, and microwaves often have parts made from stainless steel coils. Their smooth finish, hygiene benefits, and durability make them ideal for such products.

4. Shipbuilding and Marine

Given the exposure to moisture and salt, stainless steel coils are widely used in marine applications to prevent rust and corrosion.

5. Energy and Power Plants

Steel coils are found in wind turbines, solar panels, and even in thermal and hydroelectric power plants. Kinetic Industries, known as a reliable steel coil supplier, provides components that meet these critical industry demands.

6. Fabrication of Refractory Anchors

Specialty components like refractory anchors are fabricated using high-grade steel coil materials. These anchors are used in lining systems of furnaces, kilns, and reactors in industries like cement, steel, and petrochemical.

Classification of Steel Coil

Steel coils are classified based on various factors such as the method of production, material type, and end-use. Below are the major classifications:

1. By Production Method

a. Hot Rolled Steel Coil

Produced by rolling the steel at high temperatures (over 1700°F), hot rolled coils are ideal for applications where precise shapes and tolerances are not critical. They are typically used in construction, railways, and heavy equipment.

b. Cold Rolled Steel Coil

These are produced by rolling the steel at room temperature, which improves strength and surface finish. Cold rolled coils are used in applications requiring tighter tolerances and better surface quality — such as automobile panels and precision appliances.

2. By Material Type

a. Carbon Steel Coil

This type of steel coil is composed primarily of iron and carbon. It is used where strength is required without needing resistance to corrosion. It’s cost-effective and widely used in structural applications.

b. Stainless Steel Coil

Made by adding chromium and other elements, stainless steel coil offers excellent corrosion resistance and high strength. They are used in applications demanding hygiene, durability, and a refined appearance.

Kinetic Industries, a reputable stainless steel coil manufacturer, provides a wide variety of grades and finishes to match various industrial applications.

3. By Application or Use

Structural Coils — For construction and engineering purposes

Industrial Coils — Used in machinery, tools, and equipment manufacturing

Decorative Coils — For interior design and architectural detailing

Specialty Coils — For products like refractory anchors, heating elements, etc.

Whether you need robust steel coils for heavy industry or aesthetic-grade stainless steel coils for architecture, Kinetic Industries has you covered with consistent quality and custom solutions.

Why Choose Kinetic Industries?

When it comes to sourcing reliable steel coil suppliers or stainless steel coil manufacturers, trust is everything. Kinetic Industries has established itself as a leading Steel Coil, Plate, Sheet & Spool Wire Manufacturer in India.

What Sets Kinetic Industries Apart:

Premium Quality Materials: Only certified raw materials are used to ensure longevity and performance.

Custom Solutions: From size and thickness to grades and finishes, products are tailored to fit customer needs.

Advanced Manufacturing: State-of-the-art equipment and a skilled team ensure precision manufacturing.

Broad Product Range: Besides steel coil, Kinetic also supplies plates, sheets, spool wires, and refractory anchors.

As a trusted stainless steel coil supplier, Kinetic supports industries ranging from construction and manufacturing to petrochemical and marine.

Final Thoughts

Steel coils are more than just rolled metal — they are the building blocks of modern industry. From skyscrapers and automobiles to household appliances and energy plants, their role is irreplaceable. Understanding the application and classification of steel coil can help you make informed choices in sourcing and project planning.

Whether you require high-performance stainless steel coils for corrosion resistance or heavy-duty carbon steel coils for construction, it’s important to choose a steel coil manufacturer that offers quality, reliability, and support.

Explore Kinetic Industries’ steel products to discover a comprehensive range of steel coils, plates, sheets, spool wires, and specialty items like refractory anchors — all designed to meet the demanding standards of modern industries.

Interested in sourcing top-grade steel coils for your business? Visit Kinetic Industries — Steel Products and connect with a leading steel coil supplier in India.

#Steel Coil#Steel Coil manufacturer#Steel Coil supplier#Stainless Steel Coil#stainless steel coil manufacturers#stainless steel coil supplier#Kinetic Industries. Steel Coil#Plate#Sheet & spool Wire Manufacturer#refractory anchors.

0 notes

Text

Roll Forming Machine Market to Grow on Automotive Demand

Roll forming machines are continuous bending systems designed to shape sheet metal into uniform cross-sections with high precision and consistency. These machines integrate decoilers, straighteners, roll stands, and cut-off units to deliver a seamless, automated production line that minimizes material waste, reduces labor costs, and ensures tight tolerances.

Widely used in industries such as automotive, construction, aerospace, and storage solutions, roll forming machines accommodate a variety of metals—including steel, aluminum, and copper—enabling manufacturers to produce components like roof panels, door frames, chassis parts, and cable trays. The advantages of Roll Forming Machine Market Demand include high throughput, energy efficiency, customization for complex profiles, and the ability to handle long uninterrupted runs.

As businesses seek to optimize production efficiency and meet strict quality standards, the need for advanced roll forming equipment and complementary ancillary products continues to rise. Market insights highlight that increasing investments in infrastructure projects and the shift toward lightweight, high-strength materials are further fueling product adoption. With growing interest in digital controls, Industry 4.0 integration, and flexible manufacturing, manufacturers are exploring innovative solutions to enhance their market share and boost business growth.

Get More Insights On- Roll Forming Machine Market

#Manufacturing#IndustrialMachinery#RollFormingMachine#RollFormingMachineMarket#RollFormingMachineMarketoutlook#RollFormingMachineMarketInsights#CoherentMarketInsights

0 notes

Text

Metal Manufacturing Company in India: Fueling Industrial Growth and Innovation

India is fast becoming a global hotspot for metal manufacturing, thanks to its robust infrastructure, skilled workforce, and competitive pricing. From automotive components and aerospace structures to construction-grade steel and precision-machined parts, the demand for metal products is growing rapidly. At the center of this boom are the metal manufacturing companies in India, delivering high-quality solutions for both domestic and global markets.

In this article, we take a closer look at India’s metal manufacturing sector — its strengths, services, top players, and why it’s a strategic choice for industries worldwide.

Understanding Metal Manufacturing in India

The metal manufacturing industry in India is broad and dynamic, encompassing various processes and products such as:

Steel and aluminum production

Sheet metal fabrication

Casting and forging

Precision machining

Metal forming and welding

This sector is vital to India’s economy, playing a key role in infrastructure development, automotive engineering, defense manufacturing, and more.

Government support through initiatives like Make in India and the National Steel Policy has further boosted the sector’s growth, aiming to position India as a global manufacturing powerhouse.

Why Global Companies Choose Metal Manufacturing Companies in India

Working with a metal manufacturing company in India offers multiple advantages:

1. Cost Efficiency

India offers lower manufacturing and labor costs, helping businesses reduce production expenses without sacrificing quality.

2. Advanced Capabilities

Modern manufacturing plants in India are equipped with CNC machines, robotic automation, laser cutters, and advanced inspection tools.

3. Skilled Talent Pool

India is home to a large number of experienced engineers, machinists, and technicians who specialize in high-precision metalwork.

4. Quality Certifications

Indian manufacturers often adhere to international standards such as ISO, IATF, and AS9100, making them reliable partners for global supply chains.

5. Custom Solutions

Whether it's a low-volume prototype or a high-volume production run, Indian metal manufacturers offer flexible and scalable solutions.

Industries Served by Indian Metal Manufacturers

Metal manufacturing in India supports a wide range of industries, including:

Automotive: Engine parts, frames, suspension systems

Construction: Structural steel, pipes, roofing, and scaffolding

Aerospace & Defense: Aircraft parts, enclosures, brackets

Electrical & Electronics: Housings, panels, heat sinks

Heavy Equipment: Machinery parts, chassis, and mounts

Energy: Components for wind, solar, and thermal power systems

Leading Metal Manufacturing Companies in India

Here are some of the top metal manufacturing companies in India that are setting benchmarks in quality and innovation:

1. Tata Steel

One of the largest steel producers in the world, known for its wide range of steel products and sustainability initiatives.

2. JSW Steel

Offers integrated steel manufacturing solutions and exports to over 100 countries.

3. Hindalco Industries

A global leader in aluminum rolling and copper production, part of the Aditya Birla Group.

4. Jindal Steel and Power

Produces steel, power, and infrastructure materials for industrial and commercial use.

5. Bharat Forge

Renowned for precision forging, this company supplies critical parts to the automotive, defense, and energy sectors.

6. Essar Steel

Offers a wide range of flat steel products and serves industries like automotive, engineering, and infrastructure.

7. L&T Heavy Engineering

Provides custom metal fabrication and assembly solutions for defense, aerospace, and oil & gas.

8. Godrej & Boyce - Precision Engineering

Specializes in precision sheet metal and heavy fabrication for advanced applications.

9. Amtek Auto

Manufactures forged and machined automotive components with a global footprint.

10. Metalman Auto Pvt. Ltd.

Focused on chassis parts and assemblies for two-wheelers and commercial vehicles.

Core Services Offered by Indian Metal Manufacturers

Most metal manufacturing companies in India offer end-to-end services that include:

CNC machining and turning

Sheet metal cutting and bending

Welding and assembly

Die casting and pressure molding

Laser cutting and plasma cutting

Prototyping and mass production

Surface finishing (powder coating, painting, polishing)

Quality control and testing

This comprehensive service range makes India an attractive one-stop destination for global manufacturers.

Market Trends and the Road Ahead

India’s metal manufacturing sector is evolving with modern technology and sustainable practices. Some key trends include:

✅ Smart Manufacturing & Automation

Indian manufacturers are integrating IoT, robotics, and AI to enhance productivity and precision.

✅ Sustainability Initiatives

There’s a growing emphasis on green practices, such as energy-efficient processes, recycling, and renewable energy usage.

✅ Export Expansion

India is increasing its share in global exports of fabricated metal components, especially to Europe, the US, and the Middle East.

✅ Digital Sourcing Platforms

B2B platforms like FindingMFG are making it easier for global buyers to connect with trusted Indian metal manufacturers, compare quotes, and manage orders online.

How to Choose the Right Metal Manufacturing Company in India

When selecting a metal manufacturing partner in India, consider the following:

Years of experience and industry focus

Compliance with international standards

Manufacturing capabilities and infrastructure

Testimonials and project case studies

Willingness to scale production

Location and logistics advantages

Support and communication throughout the project lifecycle

You can also use platforms like FindingMFG to discover verified and vetted suppliers across India, ensuring quality and reliability from day one.

Conclusion

India’s metal manufacturing industry is a pillar of its economic development and global manufacturing reputation. With cost advantages, skilled talent, and advanced capabilities, metal manufacturing companies in India are perfectly positioned to support international industries with high-quality, scalable, and custom solutions.

Whether you’re a startup, OEM, or global enterprise, working with Indian metal manufacturers can help you streamline your supply chain, reduce costs, and accelerate production timelines.

Looking for Trusted Metal Manufacturers in India? Let FindingMFG help you connect with verified metal manufacturing partners that match your exact project requirements. From RFQ to delivery, simplify your sourcing process today

0 notes

Text

Which Type of Steel Coil Is Right for Your Project? A Complete Buyer’s Guide

Introduction

Steel coils are an essential material used in construction, manufacturing, automotive, and many other industries. Choosing the right type of steel coil is crucial because different projects require different properties, such as strength, flexibility, or corrosion resistance. But with so many options available, how do you know which steel coil is best for your project? This guide will help you understand the different types of steel coils their uses, and how to select the right one based on your needs.

What Are Steel Coils?

Steel coils are long, continuous sheets of steel that are rolled into a coil shape. They are produced in large quantities and are then cut or shaped into different forms depending on the intended application. There are two main types of steel coils: hot-rolled steel coils and cold-rolled steel coils. Each type has unique properties and benefits that make them suitable for different industries.

Types of Steel Coils and Their Uses

1. Hot-Rolled Steel Coils

What Are Hot-Rolled Steel Coils?

Hot-rolled steel coils are made by heating steel to very high temperatures (above 1,100°C or 2,012°F) and then rolling it into thin sheets. After rolling, the steel is cooled down and coiled for storage and transport.

Key Features of Hot-Rolled Steel Coils

More affordable compared to cold-rolled steel

Has a rougher surface with scale (oxidation layer)

Less precise in terms of thickness and dimensions

Easier to work with for large structural projects

Common Uses of Hot-Rolled Steel Coils

Construction (beams, columns, steel frames)

Shipbuilding

Heavy machinery

Automotive frames

Pipelines and tubes

Hot-rolled steel coils are best for projects that do not require a smooth surface or high precision.

2. Cold-Rolled Steel Coils

What Are Cold-Rolled Steel Coils?

Cold-rolled steel coils are made by taking hot-rolled steel and rolling it again at room temperature. This process improves the surface finish, strength, and dimensional accuracy of the steel.

Key Features of Cold-Rolled Steel Coils

Smoother and more polished surface

More precise thickness and dimensions

Higher strength compared to hot-rolled steel

More expensive due to additional processing

Common Uses of Cold-Rolled Steel Coils

Automotive body parts

Appliances like refrigerators and washing machines

Metal furniture

Electrical panels

Roofing and wall panels

Cold-rolled steel coils are perfect for applications that need a fine surface finish and accurate dimensions.

3. Galvanized Steel Coils

What Are Galvanized Steel Coils?

Galvanized steel coils are coated with a layer of zinc to protect them from rust and corrosion. This coating extends the life of the steel, making it ideal for outdoor and moisture-prone environments.

Key Features of Galvanized Steel Coils

Corrosion-resistant due to zinc coating

Long-lasting and durable

Can be painted or left with a natural metallic finish

Available in different coating thicknesses for extra protection

Common Uses of Galvanized Steel Coils

Roofing and siding

Fencing and barriers

HVAC ducts

Water pipes

Outdoor structures

If your project is exposed to weather or moisture, galvanized steel coils are the best choice.

4. Stainless Steel Coils

What Are Stainless Steel Coils?

Stainless steel coils contain chromium, which gives them excellent resistance to rust and stains. They are widely used in industries that require strong, hygienic, and corrosion-resistant materials.

Key Features of Stainless Steel Coils

High resistance to rust and corrosion

Strong and durable

Heat-resistant and non-magnetic options available

More expensive than regular steel

Common Uses of Stainless Steel Coils

Kitchen equipment and utensils

Medical instruments and equipment

Chemical storage tanks

Aerospace and marine applications

High-end construction projects

Stainless steel coils are the best choice for applications that require superior corrosion resistance and hygiene.