#SCADA development software provider

Explore tagged Tumblr posts

Text

SCADA Development Software: The Backbone of Industrial Automation

If you’re in the industrial automation space, you already know how crucial SCADA (Supervisory Control and Data Acquisition) systems are. They’re the unsung heroes behind manufacturing plants, power grids, water treatment facilities—you name it. But here’s the thing: a SCADA system is only as good as the software powering it. That’s why choosing the right SCADA development software provider is a game-changer.

Why SCADA Development Software Matters

Think of SCADA software as the brain of an industrial operation. It collects real-time data, monitors equipment, and even triggers alerts when something goes wrong. Whether it’s tracking temperature levels in a food processing plant or managing an entire oil refinery, SCADA software gives operators the power to make informed decisions quickly.

But not all SCADA solutions are created equal. A clunky, outdated system can slow down operations and cause unnecessary headaches. That’s why modern SCADA development software focuses on intuitive interfaces, cloud integration, and advanced analytics.

What to Look for in a SCADA Development Software Provider

So, how do you find the right provider? Here are a few things to consider:

Customization – No two industries have the same needs. A good provider will offer flexibility to tailor solutions to your specific requirements.

Scalability – Your business will grow (hopefully!), and your SCADA system should be able to grow with it.

Security – Cybersecurity threats are real. A strong SCADA provider prioritizes data protection.

At the end of the day, investing in a high-quality SCADA development software provider means smoother operations, better efficiency, and fewer surprises. And in the industrial world, that’s worth its weight in gold.

0 notes

Text

Automation and Integration Needs Power Robust Growth in System Integrator Market

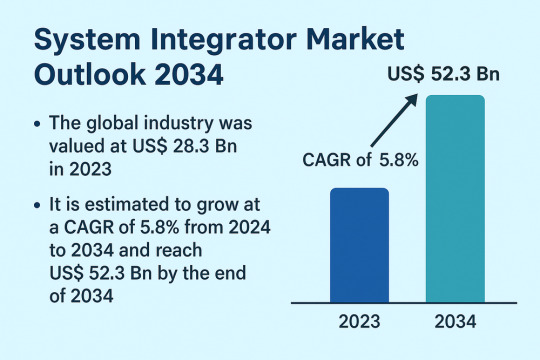

The global System Integrator Market is poised for significant growth, projected to rise from US$ 28.3 Bn in 2023 to US$ 52.3 Bn by 2034, growing at a CAGR of 5.8% from 2024 to 2034. This growth is driven by the widespread adoption of industrial robots, technological advancements, and a pressing need among businesses to optimize operational efficiencies through connected systems.

System integrators play a pivotal role in designing, implementing, and maintaining integrated solutions that bring together hardware, software, and consulting services. These services support organizations in unifying internal and external systems, such as SCADA, HMI, MES, PLC, and IIoT, to enable seamless data flow and system interoperability.

Market Drivers & Trends: One of the primary market drivers is the rise in adoption of industrial robots. As industries accelerate automation, robotic system integrators have become vital in delivering customized, scalable, and high-performing solutions tailored to complex manufacturing needs.

Another major catalyst is the surge in technological advancements. Integrators are deploying cloud-based tools and platforms that provide real-time data insights, improve developer productivity, and support hybrid architectures. The increasing use of Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) in integration solutions is fostering innovation and growth.

Latest Market Trends

Several emerging trends are shaping the system integrator landscape:

Cloud modernization platforms such as IBM’s Z and Cloud Modernization Center are enabling businesses to accelerate the transition to hybrid cloud environments.

Modular automation platforms are gaining popularity, allowing companies to rapidly deploy and scale integration solutions across multiple industry verticals.

Edge computing and cybersecurity solutions are increasingly being integrated to support secure, real-time decision-making on the production floor.

Digital hubs and scalable workflow engines are being adopted by integrators to support multi-specialty applications with high adaptability.

Key Players and Industry Leaders

The system integrator market is characterized by a strong mix of global leaders and regional specialists. Key players include:

ATS Corporation

Avanceon

Avid Solutions

Brock Solutions

JR Automation

MAVERICK Technologies, LLC

Burrow Global, LLC

BW Design Group

John Wood Group PLC

TESCO CONTROLS

These companies are actively investing in next-generation technologies, enhancing their product portfolios, and pursuing strategic acquisitions to strengthen market presence. For instance, in July 2023, ATS Corporation acquired Yazzoom BV, a Belgian AI and ML solutions provider, expanding their capabilities in smart manufacturing.

Recent Developments

Olympus Corporation launched the EASYSUITE ES-IP system in July 2023 in the U.S., offering advanced visualization and integration solutions for procedure rooms.

IBM introduced key updates in 2021 and 2022 to streamline mission-critical application modernization using cloud services and hybrid IT strategies.

Asia-Pacific companies have led the charge in deploying advanced integrated systems, reflecting the rapid industrial digitization in countries such as China, Japan, and South Korea.

Market Opportunities

Opportunities abound in both mature and emerging markets:

Smart factories and Industry 4.0 transformation offer immense potential for integrators to offer comprehensive solutions tailored to real-time analytics, predictive maintenance, and remote monitoring.

Government-led infrastructure modernization projects, particularly in Asia and the Middle East, are increasing demand for integrated control systems and plant asset management solutions.

The energy transition movement, including renewables and electrification of industrial processes, requires new types of integration across decentralized assets.

Future Outlook

As industries pursue digital transformation, the role of system integrators will evolve from traditional project implementers to long-term strategic partners. The future will see increasing demand for intelligent automation, cross-domain expertise, and real-time adaptive solutions. Vendors who can provide holistic, secure, and scalable services will dominate the landscape.

With continued advancements in AI, IoT, and robotics, the system integrator market will continue to thrive, transforming operations across diverse sectors, from automotive and food & beverages to oil & gas and pharmaceuticals.

Review critical insights and findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82550

Market Segmentation

The market is segmented based on offering, technology, and end-use industry.

By Offering:

Hardware

Software

Service (Consulting, Design, Installation)

By Technology:

Human-Machine Interface (HMI)

Supervisory Control and Data Acquisition (SCADA)

Manufacturing Execution System (MES)

Functional Safety System

Machine Vision

Industrial Robotics

Industrial PC

Industrial Internet of Things (IIoT)

Machine Condition Monitoring

Plant Asset Management

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

By End-use Industry:

Oil & Gas

Chemical & Petrochemical

Food & Beverages

Automotive

Energy & Power

Pharmaceutical

Pulp & Paper

Aerospace

Electronics

Metals & Mining

Others

Regional Insights

Asia Pacific leads the global system integrator market, holding the largest market share in 2023. This leadership is attributed to:

Rapid industrialization and digital transformation in China, Japan, and India.

Strong investments in smart manufacturing and Industry 4.0 initiatives.

Government support for infrastructure modernization, especially through Smart City programs and cybersecure IT frameworks.

North America and Europe also show strong demand, driven by the presence of established manufacturing facilities and a robust focus on sustainable operations and green automation.

Why Buy This Report?

Comprehensive Market Analysis: Deep insights into market size, share, and growth across all major segments and geographies.

Detailed Competitive Landscape: Profiles of leading companies with analysis of their strategy, product offerings, and key financials.

Actionable Intelligence: Understand technological trends, regulatory developments, and investment opportunities.

Forecast-Based Strategy: Develop long-term strategic plans using data-driven forecasts up to 2034.

Frequently Asked Questions (FAQs)

1. What is the projected value of the system integrator market by 2034? The global system integrator market is projected to reach US$ 52.3 Bn by 2034.

2. What is the current CAGR for the forecast period 2024–2034? The market is anticipated to grow at a CAGR of 5.8% during the forecast period.

3. Which region holds the largest market share? Asia Pacific dominated the global market in 2023 and is expected to continue leading due to rapid industrialization and technology adoption.

4. What are the key growth drivers? Key drivers include the rise in adoption of industrial robots and continuous advancements in integration technologies like IIoT, AI, and cloud platforms.

5. Who are the major players in the system integrator market? Prominent players include ATS Corporation, JR Automation, Brock Solutions, MAVERICK Technologies, and Control Associates, Inc.

6. Which industries are adopting system integrator services the most? High adoption is seen in industries such as automotive, oil & gas, food & beverages, pharmaceuticals, and electronics.

Explore Latest Research Reports by Transparency Market Research:

Multi-Mode Chipset Market: https://www.transparencymarketresearch.com/multi-mode-chipset-market.html

Accelerometer Market: https://www.transparencymarketresearch.com/accelerometer-market.html

Luminaire and Lighting Control Market: https://www.transparencymarketresearch.com/luminaire-lighting-control-market.html

Advanced Marine Power Supply Market: https://www.transparencymarketresearch.com/advanced-marine-power-supply-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Top Ranked Commercial RO Plant Manufacturer In Noida

A sudden increase in the demand & requirement fulfilments for clean water solutions in Noida, which is an industrial hub in a well-located geographic location that has given way for Commercial RO plants to be installed & operated to resolve all water-related issues. Now leading this water purification revolution, Netsol Water is the leading & most significant commercial RO plant manufacturer in Noida. Modern commercial RO plant systems from Netsol Water are implemented in a variety of industrial or residential settings, including small enterprises & major manufacturing plants.

The manufacturer of commercial RO plants in Noida along with other water treatment industries will be thoroughly discussed. We will discuss about these modern advanced technological innovations that Netsol Water offers with world-class facilities, along with all the benefits of our systems, as well as provide information on how we are changing the history of water treatment in this specific area.

The steady & strong development of commercial RO plants, particularly those made by Netsol Water

The industrial atmosphere within the surroundings of Noida has been changed significantly in the last several decades. More effective water treatment technologies, such as these commercial RO plants, are being installed as a result of increased legal requirements & public awareness of environmental protection along with water quality issues.

When they are performing at their best, Netsol Water experts have witnessed this change on their own. Order lists are more comprehensive than ever before as commercial enterprises, especially those in the fabric textile, eateries, & pharmaceutical industries, have come to understand the value of having high-quality purified water. Because RO technology is configurable & customizable, it can be applied to eliminate impurities while decreasing total dissolved solids while maintaining a high standard of water quality.

Netsol Water Description

The team under Netsol Water of highly skilled engineers & technician at organizations like Netsol Water puts in continuous effort to craft designs along with constructing commercial RO systems that meet the unique requirements of our clients.

Owing much more to our flexibility, we can provide our best services to a variety of commercial businesses, ranging from big power plants to smaller processing firms. Being the top noble commercial RO plant manufacturer in Noida has gained itself a national reputation; Netsol Water has significantly earned recognition for its unwavering dedication to quality & innovation through numerous accolades.

Crucial Features Netsol Water designs & manufactures commercial RO plants.

1) Better Membrane Integration: The most advanced thin-film membranes available, known for their long lifespan & significant rejection rate, are commonly employed by Netsol Water or any other branches.

2) Automated Software Control Systems: Control panels built on SCADA Programmable Logic Controllers (PLC) ensure smooth functioning with real-time live data monitoring.

3) Systems for Pre-treatment: The purpose of the pre-treatment modules is to maintain & extend the life of the RO membranes.

4) Various Additional Treatments available with many options: In addition to various treatment methods for a variety of purposes, Netsol Water provides restoration or many mineral contents & pH balancing systems, depending on the particular characteristics of the water.

The principal sequence of events that must be followed by for fabricating commercial RO plants are as follows:

Procedures implemented in the manufacturing process to provide all of its customers with the highest quality of commercial RO plants:

1) Design Development Stage: Our engineers collaborate directly with clients to learn about their needs, then figure out distinctive designs for RO plants.

2) Purchasing Parts or Other Related Components for the RO Plants: Netsol Water buys instruments, pumps, including valves from reputable suppliers in addition to other premium parts.

Various Applications of Commercial RO Plants

Industries such as textiles, manufacturing of medicines, food & beverage production, power plants, along with other medical facilities including hospitals or hotels are just a few of the Noida industries that depend on our RO plant systems.

The advantages of utilizing Netsol Water as commercial RO plant manufacturer In Noida consist of:

We approach each assignment with an unmatched expertize due to our extensive knowledge in the water treatment sector.

1) Flexibility in the Event of Change Depending on what the client expects: We can offer distinctive solutions that meet client requirements thanks to our most recent creative designs along with revisions or modifications.

2) Helps with the ultimate buying decision: We provide thorough maintenance agreements along with rapid technical assistance.

3) Economical: Reduced operating costs are the direct result of energy-efficient structures along with enhanced processes.

4) Enforcement & Implementation by Regulatory Terms: By ensuring that our methods meet & exceed regulatory requirements, we provide our clients with stability by meeting their needs.

Conclusion

The commercial RO plant manufacturer in Noida is proliferating quickly as a result of growing industrial demand & worries about water quality. The top exporter or supplier in this rapidly changing industry, Netsol Water, has been consistently pushing the boundaries of quality & innovative thinking.

Netsol Water is totally dedicated to providing the most specialized, reliable, as well as successful commercial RO solutions, which might have propelled this business to the top of Noida's water treatment facilities.

#commercial ro plant#commercial ro plant manufacturer#water treatment plant#save water#water is life#netsol water#noida#greater noida

0 notes

Text

Implementation of Digital Twin Technology: Bridging the Physical and Digital Worlds

Digital Twin technology is transforming industries by creating dynamic digital replicas of physical assets, systems, and processes. By integrating real-time data with simulation and analytics, digital twins enable better decision-making, predictive maintenance, and operational efficiency. The implementation process requires strategic planning, technological infrastructure, and a clear understanding of desired outcomes.

What Is a Digital Twin?

A digital twin is a virtual representation of a physical object or system across its lifecycle. It uses real-time data to simulate the performance and behavior of the asset. Unlike static 3D models, digital twins are dynamic and continuously updated through inputs from IoT sensors, enterprise systems, and environmental data.

Industries such as manufacturing, aerospace, healthcare, energy, and smart cities are leveraging digital twins to reduce costs, increase productivity, and drive innovation.

Key Steps in Implementing Digital Twin Technology

1. Define Objectives and Scope

Start by identifying the business problems or goals the digital twin is meant to address. These could include:

Predicting equipment failures

Optimizing operations

Enhancing product design

Improving customer experiences

Clearly defining the scope—whether it’s a single machine, an entire facility, or a supply chain—helps align resources and expectations.

2. Establish Data Infrastructure

Reliable data is the foundation of an effective digital twin. This includes:

Historical data for modeling

Real-time sensor data for monitoring

Operational data from ERP, MES, or SCADA systems

Cloud-based platforms are commonly used to integrate, store, and process this data at scale.

3. Select the Right Technologies

A successful implementation requires a combination of technologies:

IoT sensors: Collect physical asset data

Cloud computing: Offers scalability and remote access

Simulation tools: Enable virtual testing and modeling

AI/ML algorithms: Analyze trends and make predictions

AR/VR platforms: Provide immersive visualization and interaction

Selecting technologies that can be integrated smoothly into existing systems is crucial.

4. Develop the Digital Model

Create a digital replica of the physical object using CAD tools and simulation software. Incorporate real-world physics and operational parameters to mirror actual performance.

At this stage, accuracy is vital. A precise model ensures reliability when forecasting behavior or optimizing performance.

5. Enable Real-Time Integration

The true power of a digital twin comes from real-time synchronization. This involves:

Integrating sensors and devices

Using APIs and middleware to connect systems

Enabling feedback loops between the digital and physical environments

This step transforms the model from a static replica into a living, breathing digital twin.

6. Test and Validate the Twin

Before full deployment, rigorously test the digital twin to ensure it matches real-world behavior. Use known scenarios and real-time inputs to confirm accuracy. Identify and resolve any discrepancies between the digital and physical systems.

7. Deploy and Continuously Improve

Once validated, the digital twin can be deployed to monitor and optimize operations. However, it must evolve alongside its physical counterpart. Continuous updates, machine learning enhancements, and sensor recalibrations are essential for long-term effectiveness.

Benefits of Digital Twin Implementation

Predictive Maintenance

By monitoring machinery in real time, digital twins detect early signs of wear or failure. Maintenance can be scheduled before issues escalate, minimizing downtime.

Operational Efficiency

Simulating different scenarios helps organizations identify bottlenecks, streamline workflows, and increase output without additional resources.

Cost Reduction

Digital prototyping reduces the need for physical models, lowering R&D expenses. Operational savings also arise from reduced breakdowns and energy optimization.

Faster Innovation

Virtual testing accelerates product development cycles. Engineers can iterate quickly, explore multiple configurations, and bring innovations to market faster.

Enhanced Customer Experiences

In retail, automotive, and real estate sectors, digital twins provide immersive virtual interactions, enabling personalized and engaging customer experiences.

Challenges and Considerations

Data Security Risks

Integrating real-time data streams and cloud systems increases exposure to cyber threats. Strong encryption, access controls, and compliance frameworks are necessary.

Data Quality and Availability

Accurate, timely data is essential. Incomplete or incorrect data can mislead simulations and produce poor decisions.

High Initial Investment

Upfront costs for hardware, software, and expertise can be significant. However, long-term gains in efficiency and cost savings often justify the investment.

Skilled Workforce Requirements

Digital twin implementation requires cross-functional expertise, including data scientists, engineers, and IT professionals. Upskilling and hiring may be necessary.

The Future of Digital Twin Technology

Digital twins are evolving rapidly. Integration with generative AI, 5G, and edge computing will unlock new levels of autonomy and intelligence. Soon, entire ecosystems such as smart cities, autonomous supply chains, and connected healthcare systems may function as networks of interconnected digital twins.

This shift represents a move toward real-time, data-driven decision-making at scale—a foundation for the next generation of digital transformation.

Conclusion

The implementation of digital twin technology is a strategic leap toward smarter, more resilient operations. While the process requires planning and investment, the long-term benefits—ranging from cost savings to innovation acceleration—make it a compelling choice for forward-thinking organizations. By merging the physical and digital worlds, digital twins unlock a powerful pathway to future-ready enterprise systems.

0 notes

Text

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

BL335: The Industrial-Grade ARM Computer Built for Node-Red - Perfect Balance of Performance and Cost!

In the fields of industrial automation and IoT, Node-Red has become the go-to tool for rapid development of data acquisition, protocol conversion, and edge computing, thanks to its visual programming and low-code features. However, not all hardware is perfectly suited for Node-Red—some are over-spec’d and wasteful, while others lack the necessary resources for smooth operation.

Beilai Technology' s ARMxy BL335 Industrial Computer, with its Node-Red-optimized hardware design, is the ideal choice for industrial users! It delivers smooth performance, rock-solid reliability, and competitive pricing to meet diverse industrial needs.

Why is the BL335 the Best Industrial Computer for Node-Red?

1. Dual-Core A7 Processor – Just the Right Performance

2× ARM Cortex-A7 @1.2GHz, optimized for lightweight applications—Node-Red runs smoothly without lag.

Unlike overpowered quad/octa-core processors, the dual-core A7 design avoids wasted resources, balancing performance and cost efficiency.

2. RAM & ROM Perfectly Matched for Node-Red

512MB/1GB DDR3 RAM, fully meeting Node-Red’s long-term stability requirements (recommended ≥512MB).

4GB/8GB eMMC storage, ensuring ample space for the OS, Node-Red, and data storage without bottlenecks.

3. Pre-Installed Node-Red, Ready Out of the Box

Comes with Ubuntu/Linux + Node-Red pre-installed—power it up and start developing immediately.

Pre-configured system images enable rapid deployment, significantly shortening project timelines.

4. Dedicated Node-Red Technical Support Team

Bairen Technology provides Node-Red application examples, development guides, and customized support to help users get started quickly.

Stuck with protocol conversion or data collection? Our expert team offers real-time remote assistance!

5. Rich Serial & Network Ports for Easy Data Acquisition

Optional 4-8x RS485/RS232 ports, supporting Modbus RTU, DL/T645, and other industrial protocols.

Dual Ethernet (Gigabit + Fast Ethernet), compatible with TCP/IP, MQTT, OPC UA, and more for flexible device integration.

6. Industrial-Grade Stability for 24/7 Reliability

Fully isolated serial ports & independent hardware watchdog prevent crashes, ensuring long-term stable operation.

Wide-temperature design (-40℃~85℃), built to withstand harsh industrial environments.

7. Flexible Expansion for Diverse Needs

Optional DI/DO, CAN, GPIO, AI/AO modules for seamless connectivity with PLCs, sensors, actuators, and more.

4,000+ I/O combinations—customize your setup without overspending.

8. Optimized Hardware, Unbeatable Value

A refined hardware design that perfectly balances performance, stability, and cost.

Priced at just 60%~70% of comparable solutions, making industrial IoT more accessible than ever!

BL335 + Node-Red = The Ultimate Industrial IoT Combo!

✅ Data Acquisition: Easily connect PLCs, meters, and sensors with support for Modbus, CAN, MQTT, and more.

✅ Edge Computing: Local data processing reduces cloud dependency and network costs.

✅ Protocol Conversion: Use BLIoTLink software to quickly integrate with SCADA, Alibaba Cloud, Huawei Cloud, and other platforms.

✅ Remote Maintenance: BLRAT tool enables remote debugging, cutting on-site service costs.

Experience the Power of BL335 for Node-Red Today!

Website: www.BLIIoT.com

Free technical evaluations & industry solutions available!

Let BL335 be your ultimate Node-Red partner—low cost, high efficiency, and the perfect engine for industrial IoT! 🚀

0 notes

Text

PLC SCADA Programming

Madox Malaysia is a leading automation solutions provider specializing in HMI development in Malaysia and PLC software development in Malaysia. We deliver user-centric Human-Machine Interface designs that enhance control, monitoring, and efficiency in industrial processes. Our PLC software development services are tailored to ensure seamless communication between machines and systems, enabling intelligent automation. With deep expertise in major platforms like Siemens, Allen-Bradley, and Omron, we build robust, scalable, and reliable automation systems. Our team focuses on precision programming, system integration, and real-time performance. Madox Malaysia supports industries such as manufacturing, energy, and process automation with customized, high-performance solutions. We are committed to delivering innovation, quality, and operational excellence. Choose Madox Malaysia for advanced HMI and PLC solutions that drive productivity and growth.

For more info please click the link:

0 notes

Text

Weathering the Storm: Challenges and Solutions in Solar Drone Panel Inspection

While solar drone panel inspection offers undeniable advantages in efficiency, accuracy, and safety, the technology is not without its challenges. Operating unmanned aerial vehicles (UAVs) in diverse environmental conditions and managing complex data streams presents unique hurdles. Understanding these challenges and the innovative solutions being developed is crucial for maximizing the effectiveness of drone-based solar O&M.

Solar farms are often located in open, exposed areas, making them particularly vulnerable to environmental factors. Overcoming these obstacles is key to ensuring consistent and reliable solar drone panel inspection.

Key Challenges in Solar Drone Panel Inspection:

Weather Dependency:

Wind: High winds can destabilize drones, making accurate flight paths difficult and compromising image clarity. Strong gusts can even lead to crashes.

Rain and Moisture: Most commercial drones are not fully waterproof, and rain can damage sensitive electronics. Moisture can also affect thermal camera readings.

Temperature Extremes: Very high or low temperatures can impact battery life and drone performance.

Thermal Turbulence/Atmospheric Conditions: Air currents can affect thermal readings, leading to inaccuracies, especially during mid-day inspections.

Battery Life Limitations:

Commercial drones typically have limited flight times (20-40 minutes on average). For large solar farms, this necessitates frequent battery changes and landing/re-launching, which can add to inspection time and logistical complexity.

Data Accuracy and Interpretation:

Reflective Surfaces: Solar panels are highly reflective, which can cause glare and distort thermal or visual readings, making it difficult to accurately identify defects.

Flight Parameters: Inconsistent flight altitude, speed, or camera angle can lead to variations in data quality and make comparative analysis challenging.

False Positives/Negatives: AI algorithms, while powerful, can sometimes misinterpret data, leading to false alarms or missing genuine issues if not properly trained or calibrated.

Data Volume: Drones generate vast amounts of data (terabytes for large farms), requiring robust storage, processing, and analytical capabilities.

Regulatory and Compliance Issues:

Drone regulations vary significantly by country and even within regions. Navigating airspace restrictions, obtaining necessary permits, and adhering to privacy concerns can be complex and time-consuming.

The need for skilled, certified pilots further adds to the regulatory burden.

Cost and Scaling Concerns:

While cost-effective in the long run, the initial investment in high-quality drones, thermal cameras, and advanced software can be substantial, especially for smaller operators.

Scaling operations to inspect an entire portfolio of solar farms requires significant logistical planning and investment in multiple drone units and skilled personnel.

System Integration:

Integrating drone inspection data with existing solar farm monitoring systems (SCADA, asset management software) can be challenging due to differing data formats and platforms.

Innovative Solutions and Future Outlook:

Despite these challenges, the solar drone panel inspection industry is rapidly innovating to provide robust solutions:

Weather-Resistant Drones: Manufacturers are developing more ruggedized and weatherproof drones capable of operating in a wider range of environmental conditions.

Extended Battery Life & Swappable Systems: Improvements in battery technology and the development of intelligent battery management systems, along with hot-swappable battery designs, are increasing effective flight times. Some advanced solutions even explore drone-in-a-box systems with autonomous charging.

Advanced Sensors & Algorithms:

Radiometric Thermal Cameras: These cameras capture absolute temperature values, providing more precise and reliable thermal data, less susceptible to environmental noise.

Anti-Glare Technology: Improved camera lenses and software algorithms are being developed to mitigate glare issues on reflective panel surfaces.

Sophisticated AI & Machine Learning: Continuous improvement in AI models for defect recognition, false positive reduction, and predictive analytics, trained on vast datasets.

Automated Flight Planning: Software that optimizes flight paths to ensure comprehensive coverage and consistent data capture, minimizing human error.

Streamlined Regulatory Compliance: Industry bodies are working with regulators to develop clearer and more standardized guidelines for commercial drone operations, making it easier for businesses to comply.

Integrated Platforms: Development of comprehensive software platforms that manage drone operations, data processing, analysis, and seamlessly integrate with existing solar O&M software, providing a unified view of asset health.

Drone Swarms & Autonomous Operations: The future envisions coordinated fleets of autonomous drones working together to inspect vast areas, significantly increasing speed and efficiency while reducing human intervention.

While challenges remain, the rapid advancements in drone technology, AI, and software are continuously pushing the boundaries of what's possible in solar drone panel inspection. As these solutions mature, drones will become even more indispensable for ensuring the efficiency, reliability, and long-term viability of solar power generation, making the future of renewable energy brighter and more resilient.

0 notes

Text

Buraq Integrated Solutions

Buraq Integrated Solutions is a premier system integration, professional services, and software development company, offering cutting-edge technology solutions across multiple industries. Specializing in Industrial Automation, Automatic Weather Stations, Flood Early Warning Systems, PLC/SCADA, and IT Consultancy, Buraq Integrated Solutions provides tailored services to government bodies, financial institutions, telecom providers, energy sectors, healthcare, and educational institutions. With a commitment to delivering reliable, rapid, and robust solutions, Buraq Integrated Solutions has established itself as a trusted partner for businesses and government organizations seeking to enhance efficiency through automation and advanced technology. Comprehensive Solutions for Various Industries As a technology-intensive company, Buraq Integrated Solutions offers a diverse portfolio of services designed to meet the evolving needs of its clients. The company specializes in: 1. Industrial Automation & Control Systems - PLC Programming & SCADA Systems – Advanced industrial automation solutions for seamless control and monitoring. - HMI (Human-Machine Interface) – Intuitive systems for process control and operational efficiency. - Telemetry Systems – Real-time data acquisition and remote monitoring solutions. 2. Automatic Weather Stations & Flood Early Warning Systems - Environmental Monitoring Systems – Providing accurate weather data for improved forecasting. - Flood Early Warning Systems – Enhancing disaster preparedness through real-time flood detection technology. - GIS Survey & Mapping – Geographic Information Systems (GIS) for land and infrastructure analysis. 3. IT Consultancy & Software Development - Custom Software Solutions – Tailored applications for financial services, government institutions, and enterprise operations. - Cybersecurity & Data Protection – Ensuring the integrity and security of IT infrastructure. - Cloud-Based Solutions – Scalable and efficient cloud computing services for businesses. Industries We Serve Buraq Integrated Solutions delivers advanced technological solutions to a broad range of industries, ensuring efficiency, security, and automation in key sectors: Government (Local & Central): We provide digital transformation solutions that enhance the efficiency and effectiveness of local and central government operations. Financial Services: Our solutions help banks, insurance companies, and clearing houses streamline operations, reduce risks, and improve customer service. Telecommunications: We enable telecom companies to optimize their networks, improve service delivery, and stay competitive in a rapidly evolving industry. Energy & Utilities: Our solutions help energy providers and utilities improve operational efficiency, reduce costs, and enhance sustainability. Healthcare: We deliver technology solutions that improve patient care, streamline operations, and ensure compliance with regulatory requirements. Education: Our solutions help educational institutions enhance learning experiences, improve administrative efficiency, and prepare students for the future. Why Choose Buraq Integrated Solutions? ✔ Proven Expertise – A team of highly skilled professionals with vast industry experience. ✔ Innovative Technology – Implementation of the latest advancements in industrial automation and IT solutions. ✔ Custom-Tailored Solutions – Designed to meet the unique needs of each client. ✔ Reliable & Scalable Systems – Ensuring long-term efficiency and adaptability. ✔ Commitment to Excellence – Delivering quality-driven solutions that maximize performance. Get in Touch Buraq Integrated Solutions is your trusted partner for advanced technology solutions. Whether you need automation, IT consultancy, or environmental monitoring, we have the expertise to deliver state-of-the-art solutions that work. For inquiries, consultations, or collaborations, contact us today! Read the full article

0 notes

Text

How Greenbeam Delivers End-to-End EPC Excellence for Solar EPC Projects ?

In today’s energy landscape, Solar EPC (Engineering, Procurement, and Construction) services are crucial for businesses and utilities aiming to transition to renewable energy. Greenbeam stands at the forefront of this transformation, offering turnkey solar EPC services that drive efficiency, innovation, and long-term sustainability. As a trusted partner for solar infrastructure, Greenbeam ensures that every project is executed with precision from concept to commissioning.

What is a Solar EPC Project?

A Solar EPC project encompasses the complete scope of services needed to plan, procure, construct, and maintain a solar power plant. This model allows clients to outsource the entire development and implementation process to a single vendor. Greenbeam’s EPC model guarantees efficiency, cost-effectiveness, and technical expertise.

Why Greenbeam Leads in Solar EPC Solutions

Greenbeam has successfully executed numerous Solar EPC projects across industrial, commercial, and utility-scale segments. Here’s what makes Greenbeam a leader in this domain:

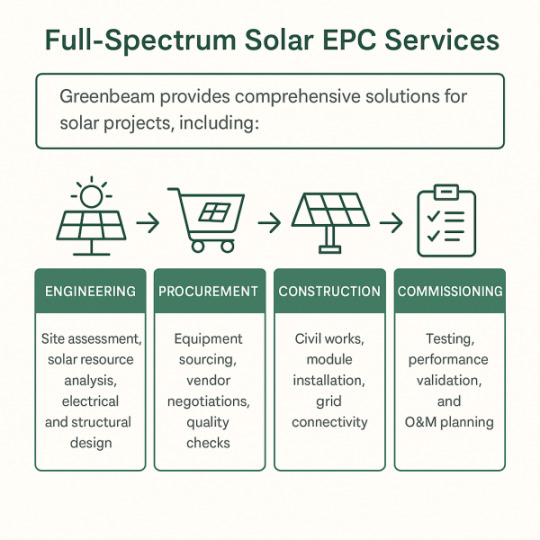

Full-Spectrum Solar EPC Services

Greenbeam provides comprehensive solutions for solar projects, including:

Engineering: Site assessment, solar resource analysis, electrical and structural design

Procurement: Equipment sourcing, vendor negotiations, quality checks

Construction: Civil works, module installation, grid connectivity

Commissioning: Testing, performance validation, and O&M planning

Proven Technical Expertise

Greenbeam’s in-house engineering team uses advanced design tools and simulation software to deliver optimal solar layouts. Each Solar EPC project is engineered for maximum energy yield and long-term performance.

Timely Execution and Quality Assurance

Time-bound execution is critical in the solar industry. Greenbeam’s project management framework ensures that each milestone in a Solar EPC project is met without compromising on safety and quality standards.

End-to-End Project Management

Clients benefit from:

A single point of accountability

Agile issue resolution

Transparent progress tracking

Strict compliance with local and international standards

Greenbeam’s Key Differentiators in Solar EPC

Strong supplier and OEM network

Custom project solutions for rooftop, ground-mount, and floating solar

Smart monitoring systems and SCADA integration

Robust after-sales support

Sustainability & Compliance

Sustainability is core to Greenbeam’s value system. Each Solar EPC solution is designed to meet or exceed regulatory guidelines while minimizing environmental impact. This includes:

Use of Tier-1 solar modules and inverters

Eco-friendly site practices

Waste and water management during construction

Future-Proof Energy with Solar EPC

As the world transitions toward clean energy, a Solar EPC project offers a sustainable, low-carbon alternative to traditional energy sources. With the Indian government’s increasing push for renewable capacity, now is the time for industries to invest in dependable solar infrastructure.

Greenbeam ensures every Solar EPC installation is scalable, efficient, and ready for integration with future technologies such as battery storage and green hydrogen.

Conclusion: Trust Greenbeam for Your Solar EPC Journey

If you’re looking to build a reliable solar power system, Greenbeam is your go-to Solar EPC partner. With a proven track record, expert teams, and a commitment to excellence, Greenbeam delivers solar solutions that power a cleaner, greener tomorrow.

Connect with Greenbeam today to begin your journey toward sustainable solar energy.

0 notes

Text

Rising Momentum: How Anaerobic Digestion Systems Are Shaping a Greener Future

Market Overview

The anaerobic digestion systems market is seeing remarkable growth, driven by the rising global demand for renewable energy sources, strong government support for sustainable technologies, the urgent need for safe waste disposal solutions, and a growing public awareness about the environmental benefits of anaerobic digestion. Additionally, the increasing application of these systems in sewage and wastewater treatment, along with the adoption of advanced technologies, is expected to unlock new opportunities for market stakeholders.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=5522?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=29-04-2025

Anaerobic Digestion Systems Market Growth Drivers

Rising Demand for Renewable Energy Sources

The world’s growing need for cleaner, more sustainable energy sources is undeniable. Environmental, economic, and technological shifts are pushing governments, businesses, and individuals to seek alternatives that reduce carbon emissions and help tackle climate change. According to the IEA’s Renewables 2023 report, renewable energy capacity additions grew by 50% in 2023, totaling nearly 510 gigawatts worldwide—three-quarters of which came from solar PV.

The increasing shift towards renewable energy is a major driver for the adoption of anaerobic digestion systems. These systems produce biogas, a renewable energy form that can power electricity generation, heating, and even serve as vehicle fuel. With their ability to provide reliable, local, and carbon-neutral energy, anaerobic digestion systems are becoming a key solution in reducing dependence on fossil fuels. As the demand for clean energy continues to soar, the popularity of biogas and anaerobic digestion systems is following closely behind.

Anaerobic Digestion Systems Market Growth Opportunities

Integration of Advanced Technologies into Anaerobic Digestion Systems

Technological innovation is reshaping the landscape of anaerobic digestion. Breakthroughs in digitalization, automation, data analytics, and material science are enhancing the efficiency, scalability, and sustainability of biogas plants. With the development of newer, more efficient anaerobic digestion systems, industry players are finding opportunities to increase both performance and profitability.

The use of Internet of Things (IoT) devices enables real-time monitoring and performance optimization. Artificial intelligence and machine learning help analyze large datasets, predict biogas yields, and automate operations for maximum output. Meanwhile, advanced bioreactor designs and pretreatment technologies are allowing the digestion of more diverse waste streams and boosting biogas production. These technological integrations are creating exciting opportunities, making anaerobic digestion systems more effective, profitable, and widely adoptable.

Anaerobic Digestion Systems Market Analysis: Key Findings

The Hardware Segment to Dominate the Market in 2024

In terms of offerings, the anaerobic digestion systems market is segmented into hardware, software, and services. In 2024, hardware is expected to dominate with a market share of 46.7%. This dominance can be attributed to the rising demand for digesters, compressors, gas storage tanks, generators, pumps, and other essential equipment required for the anaerobic digestion process.

However, the software segment is forecasted to register the highest CAGR of 11.7% during the period, driven by the increased integration of SCADA systems, heightened strategic collaborations among software providers, and rising industrial adoption.

The Industrial Waste Segment to Lead by Feedstock Type

When considering feedstock types, the market is divided into industrial waste, municipal waste, agricultural waste, sewage waste, and others. The industrial waste segment is projected to hold the largest share of 25.6% in 2024. Factors such as stringent environmental regulations promoting green technologies and the high organic waste generation from industries support this trend.

The agricultural waste segment, however, is poised to grow the fastest, with a predicted CAGR of 12.4%, spurred by the surge in organic waste generation from farms and the push to convert such waste into renewable energy, helping to reduce emissions and enhance soil health.

Get Full Report @ https://www.meticulousresearch.com/product/anaerobic-digestion-systems-market-5522?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=29-04-2025

Medium-scale Systems to Dominate by Capacity

Based on capacity, the anaerobic digestion systems market is segmented into small-scale, medium-scale, and large-scale categories. In 2024, medium-scale systems are expected to capture the largest market share at 41.4%. These systems, typically ranging from 500KW to 3MW, are increasingly being adopted for commercial and industrial applications due to their ability to process large amounts of organic waste efficiently.

Moreover, the medium-scale segment is projected to record the highest growth rate, with a CAGR of 11.1%, reflecting the rising need for efficient waste-to-energy solutions for mid-sized operations.

Agricultural & Industrial Waste Management Segment to Dominate Applications

Applications of anaerobic digestion systems span across power generation, fuel production, agricultural & industrial waste management, and other uses. In 2024, the agricultural & industrial waste management segment is expected to hold the largest share at 42.1%. The growing demand for managing agricultural residues, food processing waste, and industrial organic waste through anaerobic digestion underpins this dominance.

Additionally, this application segment is forecasted to witness the highest CAGR of 11.4%, driven by increasing sustainability efforts in key industries and agriculture.

The Energy & Utilities Sector to Lead by Sector

Sector-wise, the market includes energy & utilities, automotive, commercial & residential, agriculture, and industrial. In 2024, the energy & utilities sector is expected to account for the largest share of 32.2%. The sector’s shift toward low-carbon energy sources, adoption of biofuels, and stricter emission reduction mandates are major factors fueling this growth.

However, agriculture is predicted to be the fastest-growing sector, registering a CAGR of 12.3%. Farmers are increasingly investing in anaerobic digestion systems to manage waste, produce bioenergy, and create organic fertilizers through co-digestion methods.

Geographical Analysis

North America to Dominate the Market in 2024

In 2024, North America is expected to command 34.3% of the global anaerobic digestion systems market. This region’s dominance is largely due to its advanced waste management infrastructure, stringent environmental regulations, high levels of food waste, and an accelerating shift toward renewable energy. The presence of prominent players such as Evoqua Water Technologies Corp. further boosts market growth. For example, Evoqua’s 2022 acquisition of Smith Engineering enhanced its portfolio of high-purity water treatment systems and expanded its regional footprint.

Nevertheless, the Asia-Pacific region is set to register the highest CAGR of 11.2% during the forecast period. Factors such as rapidly increasing waste management needs, growing environmental regulations, and government incentives promoting renewable energy adoption in countries like China, India, and Japan are driving the region’s robust growth.

Anaerobic Digestion Systems Market: Key Companies

The competitive landscape of the anaerobic digestion systems market is shaped by key players with strong product portfolios and extensive geographic reach. Major companies operating in this space include Kanadevia Inova Group (a part of Hitachi Zosen Corporation), Evoqua Water Technologies Corp., EnviTec Biogas AG, Nature Energy Biogas A/S (part of Shell plc), Biokraft International AB, VWS (UK) Ltd (part of Veolia Environnement), Renewi plc, Capstone Green Energy Holdings, Bioenergy Devco, PlanET Biogas Group, Biogen (UK) Ltd, Agrinz Technologies GmbH, Zero Waste Energy, Agraferm Technologies AG, Bioquadrat Energie- und Wassertechnik Holding GmbH, and AAT Abases- und Abfalltechnik GmbH.

Anaerobic Digestion Systems Industry Overview: Latest Developments

In August 2023, Biogen (UK) Ltd. expanded its portfolio by acquiring five operational anaerobic digestion plants from Ingenious Capital Management Limited.

In April 2023, Nature Energy Biogas A/S entered a partnership with Nordion Energy AB to boost biogas production in Sweden by connecting new production facilities to the grid.

In July 2022, Evoqua Water Technologies Corp. acquired EPICOR, Inc., a leading supplier of powdered ion exchange resins primarily serving the power sector.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=5522?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=29-04-2025

0 notes

Text

Engineering Services by Servotech You Can Trust

In today's fast-paced, technology-driven world, businesses require engineering solutions that are not only innovative but also reliable and efficient. Servotech stands as a trusted name in the engineering sector, offering a wide array of services tailored to meet the unique needs of different industries. Our expertise, commitment to quality, and customer-first approach have positioned us as a leader in delivering engineering services you can depend on.

Why Choose Servotech for Engineering Services?

Choosing the right engineering partner is crucial for the success of any project. Servotech combines years of experience, technical excellence, and cutting-edge innovation to deliver unparalleled solutions. Here’s why industries across the globe place their trust in us:

Comprehensive Expertise: Our team includes seasoned engineers specializing in electrical, mechanical, civil, and automation fields.

Customized Solutions: We understand that every project is unique. We tailor our services to meet specific requirements, ensuring maximum efficiency and success.

Advanced Technology: Servotech leverages the latest tools, software, and methodologies to stay ahead of industry trends.

Commitment to Quality: Rigorous quality checks, compliance with international standards, and attention to detail are the hallmarks of our services.

Client-Centric Approach: We work closely with our clients, maintaining open communication and delivering results that align perfectly with their business objectives.

Our Range of Engineering Services

At Servotech, we offer a full suite of engineering services, designed to support projects at every stage — from ideation to final execution.

Electrical Engineering Services

Servotech provides comprehensive electrical engineering solutions, ensuring safe, efficient, and sustainable power systems. Our services include:

Electrical system design and layout

Energy audits and optimization

Control system design

Power distribution solutions

Compliance with safety and regulatory standards

Mechanical Engineering Services

Our mechanical engineering team specializes in designing, analyzing, and manufacturing mechanical systems that are robust and cost-effective. Key services include:

Product design and development

CAD modeling and drafting

Thermal and fluid system analysis

Prototyping and testing

Mechanical maintenance planning

Automation and Control Systems

Automation is at the heart of modern industry. Servotech provides intelligent automation and control solutions that increase productivity and reduce operational costs. Our expertise includes:

PLC and SCADA system development

Industrial robotics integration

IoT-based automation solutions

Process control and instrumentation

Custom software development for automation

Civil and Structural Engineering

Servotech's civil and structural engineering services are vital for building durable and resilient infrastructures. We offer:

Structural design and analysis

Site planning and development

Geotechnical investigations

Construction management support

Retrofitting and rehabilitation services

Project Management and Consulting

Beyond technical solutions, we provide project management and consulting services to ensure timely and successful project delivery. Our consulting services cover:

Feasibility studies and risk assessments

Budgeting and cost estimation

Scheduling and resource allocation

Regulatory compliance advisory

Quality assurance and control

Industries We Serve

Our multidisciplinary approach allows us to serve a wide range of industries, including:

Manufacturing

Energy and Utilities

Construction and Infrastructure

Automotive

Aerospace

Healthcare

Telecommunications

Renewable Energy

Each industry presents unique challenges, and Servotech’s adaptive solutions ensure that we meet industry-specific requirements efficiently and effectively.

Servotech’s Commitment to Sustainability

At Servotech, we recognize the importance of sustainable engineering practices. Our solutions are designed with environmental responsibility in mind. We focus on:

Reducing energy consumption

Promoting the use of renewable resources

Minimizing waste and environmental impact

Supporting sustainable manufacturing practices

By integrating green engineering principles into our services, we help our clients achieve their sustainability goals while maintaining operational excellence.

Our Engineering Process

We follow a systematic and proven engineering process to ensure that every project meets the highest standards:

Requirement Analysis: Understanding the client’s goals, challenges, and expectations.

Conceptual Design: Developing innovative solutions based on detailed analysis.

Detailed Engineering: Preparing comprehensive designs, drawings, and specifications.

Implementation Support: Assisting with manufacturing, construction, or integration.

Testing and Validation: Verifying that the solution meets all functional and safety requirements.

Ongoing Support: Offering post-project support, maintenance, and optimization services.

Each step is carried out with precision, ensuring that every project is delivered on time, within budget, and to the complete satisfaction of the client.

Conclusion

When it comes to engineering services, trust, expertise, and innovation are non-negotiable. Servotech brings all of these qualities — and more — to every project we undertake. Our client-centric approach, commitment to quality, and passion for innovation make us the ideal engineering partner for businesses aiming for success.

0 notes

Text

Why Siemens SCADA Software is the Future of Process Control

These monitoring and control functions, in combination with apt optimization of the industrial processes, are fundamental for operational efficiency and competitive edge in the current scenario marked by Industry 4.0. That is where Siemens SCADA enters the picture: a very strong and scalable solution, addressing these needs, within the Siemens SCADA paradigm. All systems relating to industrial automation can utilize Siemens SCADA. It will enable industries with visualization of data in real time, better decision-making, and dependable system control.

Learn more about, Siemens SCADA (SIMATIC WinCC): A Complete Industrial Automation Guide

What is Siemens SCADA?

Siemens SCADA is a comprehensive suite of software solutions performing the monitoring and control functions at various levels for industrial systems. Processes and building management are supervised in a centralized way for all key activities. The most well-known of products is SIMATIC WinCC, which serves as a global powerhouse SCADA platform for visualization and control of industrial processes.

Siemens SCADA ensures smooth, efficient, and safe operations across a manufacturing plant, power station, or water treatment facility.

Primary Features of SIMATIC WinCC

SIMATIC WinCC remains a central part of the Siemens SCADA. With a scalable, flexible approach for both simple applications and complex distributed systems, some key features include:

Real-time Monitor: WinCC SCADA gives operational support for continuous monitoring and controlling processes in real time, therefore creating quick responsiveness and downtime reduction.

Scalability: The system from smaller standalone applications to complex multi-user client-server architectures grows with your operational needs.

Open Connectivity: Integration with a multitude of PLCs, databases, and third-party systems.

User-Friendly Interface: Helps an operator to quickly navigate, analyze and respond to alarms or changes in system behavior through an intuitive interface.

Comprehensive Data Logging: Logging of all processed data, alarms, and user actions for further analysis and compliance requirements.

Applications of Siemens SCADA Software

Siemens SCADA Software finds its applications in diverse industries owing to its flexibility and robustness. Some of the common applications are:

Manufacturing & Automation: Delivers superior insight into production lines with the purpose of improving efficiency and product quality.

Energy & Utilities: For power distribution management, renewable energy monitoring, and utility control centers.

Water & Wastewater: Provides real-time status reports and predictive maintenance to ensure optimum performance of water treatment facilities.

Infrastructure Management: Manages newly developed smart buildings and campuses in HVAC, lighting, and security systems.

Advantage of adopting WinCC SCADA

Adopting WinCC SCADA opens:

Increased visibility and transparency across operations

Increased uptime of the system and much maintenance cost saving

Safety through intelligent alarm systems

Industry compliance through an audit trail of the processes

Partner with the Experts – Naksh Technology Solutions LLP

Partnering with the right automation expert to implement Siemens SCADA Software makes the difference. On top of being a trusted dealer and solutions provider for Siemens automation products, Naksh Technology Solutions LLP brings deep industry knowledge and a customer-centric approach. We help operationalize clients by designing, deploying, and supporting adaptive SCADA systems tailored for operational goals.

Whether the journey has just started or someone's thinking of upgrading an existing setup, Naksh Technology is the one place one would go to find a reliable Siemens SCADA solution partner.

0 notes

Text

Designing a Basic SCADA System: A Foundational Guide

Introduction

SCADA (Supervisory Control and Data Acquisition) systems in industrial automation serve a vital purpose in monitoring and controlling processes. From manufacturing, energy management, water treatment, to infrastructure, SCADA systems offer a single platform for data collection, visualization, and control. Designing a basic SCADA system entails knowing its most important components and how they cooperate to facilitate smooth operations.

Key Components of a SCADA System

A well-structured SCADA system includes several core components:

Remote Terminal Units (RTUs) or PLCs: These collect real-time data from sensors and field devices.

Communication Infrastructure: Data from field devices is transmitted to the central system via wired or wireless communication protocols.

SCADA Software: Installed on central servers or PCs, it processes the incoming data, provides visualization through HMI screens, and allows operators to control processes remotely.

Human Machine Interface (HMI): It is the interface that presents data, alarms, and controls in an interactive form.

Steps involved in designing a basic SCADA System

Define System Requirements: Identify the process to be monitored, the number of data points, and control level needed.

Choose Hardware Components: Select suitable PLCs or RTUs, sensors, and network devices according to the needs of the process.

Develop Communication Architecture: Develop an efficient communication network through appropriate protocols (such as Modbus, Ethernet/IP, or wireless systems).

Program and Configure the System: Develop control logic in PLCs and program SCADA software to interact with field devices.

Test and Validate: Test conditions to ensure data collection, alarms, and control functionality.

Deploy and Maintain: Install the system on-site and schedule periodic updates and maintenance.

Learning SCADA Design with Real-Time Exposure

Learning how to develop a SCADA system is a skill that is best acquired in a lab-based training setup. A PLC SCADA Course in Nashik provides the future automation experts a chance to practice on live equipment and industrial-standard projects. Centers like VIATA, in the center of Nashik, have a reputation for combining theoretical knowledge with lab application.

VIATA is headed by an industrialist with more than 20 years of experience in automation. The institute's strategy involves training in Stepper & Servo Motors, Drive Technologies, DCS, and IIoT, all of which are essential for SCADA system design. Students get exposure to HMI configuration, AC motor drives, VFDs, and control panel engineering, so the training is applicable to both fresh graduates and experienced professionals.

Why opt for a PLC SCADA Course in Nashik?

Live Industrial Projects: Learners are exposed to real systems, equipping them for the challenges of the industry.

Best Automation Experts: Training experts with field experience impart real-world perspectives to the class.

Balanced Curriculum: From initial PLC logic to advanced SCADA interfaces, all aspects of control system development are included.

Guaranteed Placement Support: With career guidance and focused interview skills training, students are assisted in making the transition into the workforce.

Conclusion:

Creating a simple SCADA system isn't only about knowing software and hardware, but also real-life integration of these tools within an industrial environment. To gain a good foundation in automation, taking a hands-on PLC SCADA Course in Nashik provides the ideal combination of theory and practice. Under the tutelage of experts and real-time learning facilities such as those provided by VIATA, students are imparted the necessary skills to thrive in contemporary automation jobs.

0 notes

Text

Top Companies for Automation Services in Naperville, IL

Naperville, Illinois, stands out as a technology-driven city with a thriving industrial and commercial sector. As the demand for smarter, more efficient systems continues to grow, companies automation services in Naperville are becoming essential for businesses aiming to stay competitive in today's digital age.

Automation is no longer just an advantage—it’s a necessity for businesses looking to scale operations, reduce labor-intensive tasks, and increase efficiency across various departments. Whether in manufacturing, logistics, commercial buildings, or process industries, automation technologies are transforming how companies in Naperville operate, manage resources, and deliver value.

Why Automation is Crucial for Businesses in Naperville

Automation is revolutionizing the way Naperville-based companies handle their day-to-day operations. Here are several reasons why local businesses are investing in automation:

Increased productivity: Automation reduces the need for manual labor, leading to faster production cycles and reduced downtime.

Cost savings: Automated systems can significantly lower operational expenses over time.

Accuracy and consistency: Automated machines and software ensure precise execution of tasks with minimal errors.

Real-time data and analytics: Intelligent systems provide insights that help improve decision-making.

Workforce optimization: Employees can focus on high-value tasks rather than repetitive or dangerous duties.

Compliance and safety: Automation helps meet strict regulatory standards and safety requirements.

For Naperville’s growing tech and industrial scene, these benefits position automation as a long-term strategic asset.

Key Industries Leveraging Automation in Naperville

Naperville businesses across multiple industries are adopting automation technologies to streamline their operations:

Manufacturing: Robotics, CNC machinery, and industrial automation are optimizing production lines.

Warehousing and logistics: Automated conveyors, barcode scanners, and inventory systems ensure smooth supply chain operations.

Healthcare: Automation helps in diagnostics, lab testing, and administrative workflows.

Retail and service sectors: POS automation, customer service chatbots, and order tracking systems are improving customer experiences.

Building management: Building automation systems (BAS) regulate lighting, HVAC, and security systems for commercial properties.

As Naperville continues to attract diverse business investments, the demand for reliable automation companies is on the rise.

Types of Automation Services Offered by Naperville Companies

Automation companies in Naperville, Illinois offer a broad range of services tailored to specific business needs. These include:

PLC Programming and Integration: Custom logic programming for industrial control systems.

SCADA and HMI Design: Supervisory control systems with user-friendly interfaces.

Robotics Integration: Installation and configuration of robotic arms for precise and repetitive tasks.

IoT and Smart Systems: Device interconnectivity for real-time monitoring and control.

Building Automation Solutions: Energy-efficient systems for HVAC, lighting, and building access.

Custom Software Development: Development of automation software for scheduling, reporting, and analytics.

Each service is designed to help companies improve their workflows and align with modern operational standards.

Choosing the Right Automation Partner in Naperville

Not all automation companies offer the same level of expertise. When selecting a provider in Naperville, consider the following factors:

Experience and specialization: Choose companies with a proven track record in your specific industry.

Technical capabilities: Ensure they can handle the level of system complexity required.

Scalability: Look for solutions that can grow with your business.

Customer support: Strong post-installation service is key to long-term success.

Customization: Your business needs a partner that can tailor solutions to your workflow.

Certifications and compliance: Check for relevant industry certifications like UL, ISO, or OSHA compliance.

A trusted partner can help you navigate technology decisions, integrate systems, and train staff effectively.

Automation Trends Transforming Naperville Businesses

The landscape of automation is constantly evolving. Here are some top trends influencing Naperville’s commercial and industrial environments:

AI-Powered Automation: Machine learning algorithms enhance predictive maintenance and production optimization.

Edge Computing: Local data processing reduces latency and improves response time in real-time systems.

Cloud-Based Control Systems: Enables remote access, monitoring, and updates.

Green Automation: Energy-efficient solutions aligned with sustainability goals.

Cybersecurity for Automation Networks: Enhanced protection of control systems from cyber threats.

Staying ahead of these trends is key for companies looking to maintain a competitive edge in the Naperville market.

Benefits of Automation for Small and Medium Enterprises (SMEs)

Automation is not exclusive to large corporations. In Naperville, small and medium businesses are increasingly investing in automation technologies for:

Inventory management and procurement

Workflow automation in administrative tasks

Customer relationship management (CRM) systems

Automated billing and invoicing

Smart energy control in small office buildings

The accessibility and affordability of modern automation tools make them an excellent investment for SMEs aiming to scale without hiring extensively.

Automation and Economic Development in Naperville

Automation is playing a key role in Naperville’s economic growth. As companies become more efficient and competitive, they attract more business and create high-skill job opportunities. Local schools and training institutions are also responding by offering specialized programs in automation, robotics, and engineering—helping to create a talent pipeline that supports long-term innovation.

With Naperville’s continued investment in infrastructure and technology parks, the city is well-positioned to be a hub for automation excellence in Illinois.

Empowering Naperville Through Smart Automation

From small businesses to large enterprises, the ability to implement smart automation systems is critical for long-term success. The right automation partner can help you optimize operations, increase profits, and stay agile in an ever-changing market. As demand for precision, speed, and efficiency increases, Naperville businesses are finding automation to be one of their most strategic investments.

Partner with a Trusted Automation Company in Naperville

If you're seeking high-quality automation solutions tailored for your Naperville business, Xtreme Automation LLC delivers the expertise and support needed to elevate your operations. Whether you require industrial controls, building automation, or full-system integration, their team is committed to delivering scalable, efficient, and customized automation solutions. Learn more at xtremeautomationllc.com.

#automation companies Naperville IL#industrial automation Naperville#automation engineering Naperville Illinois#smart factory solutions Naperville#Naperville automation systems

0 notes

Text

ARMxy Cortex-A53 based Computers BL340 for Wind Farm Monitoring

Hardware Support for Wind Farm Monitoring Needs

High-Performance Processor: The BL340 is equipped with the Allwinner T507-H quad-core ARM Cortex-A53 processor (up to 1.4GHz), supporting real-time data processing for monitoring wind turbine operational status and data analysis.

Flexible I/O Configuration:

(1)X and Y Series IO Boards support interfaces such as RS485, RS232, DI/DO, AI/AO, enabling connections to wind turbine sensors (e.g., vibration, temperature, rotational speed) and actuators (e.g., braking systems).

(2)For example, Y51/Y53 (PT100/PT1000) can be used for precise temperature monitoring, while Y95/Y96 (PWM output and pulse counting) are suitable for wind speed and rotor speed measurement.

Communication Interfaces:

(1)Provides 1-3 10/100M Ethernet ports, supporting networked device communication within the wind farm for centralized data management.

(2)The Mini PCIe interface supports 4G/WiFi modules, ensuring remote data transmission to cloud platforms, ideal for remote wind farms.

Environmental Durability: Certified for operation from -40°C to 85°C and with IP30 protection, it is well-suited for the harsh environments of wind farms.

Software Support for Energy Production Optimization

BLloTLink Protocol Conversion Software: Supports protocols like Modbus, MQTT, and OPC UA, enabling seamless integration with wind farm equipment, mainstream industrial SCADA systems, or cloud platforms (e.g., AWS IoT, Thingsboard) for data collection, analysis, and optimization.

BLRAT Remote Access: Facilitates remote monitoring and maintenance, reducing on-site maintenance costs and improving wind farm operational efficiency.

Real-Time Operating System: Supports Linux-RT-4.9.170, ensuring low-latency data processing for real-time turbine status monitoring.

Qt-5.12.5 GUI Tool: Enables the development of intuitive user interfaces for on-site personnel to monitor and operate the system.

Docker and Node-Red Support: Simplifies the rapid development of IoT applications for wind farm monitoring.

Typical Application Scenarios

Condition Monitoring: Collects data from sensors on vibration, temperature, and hydraulic pressure to analyze equipment health, predict maintenance needs, and extend equipment lifespan.

Energy Optimization: Leverages edge computing to analyze wind speed and power output, dynamically adjusting turbine angles or loads to maximize energy production efficiency.

Fault Diagnosis: Uses AI modules (e.g., Y31 AIN Modules) to detect abnormal vibrations or mechanical faults, providing early warnings to minimize downtime.

Cloud Integration: Uploads operational data to the cloud via 4G/WiFi for long-term trend analysis, optimizing the energy management strategy of the entire wind farm.

Customization and Scalability

Modular Design: Users can select different SOMs (e.g., SOM341: 16GB eMMC + 2GB DDR4) and IO boards (e.g., X23: 4 RS485 + 4 DI/DO) to meet specific monitoring requirements.

Development Support: Offers extensive development examples (e.g., Node-Red, MQTT, CAN) to accelerate the creation of customized monitoring applications.

Long-Term Support: Shenzhen Beilai provides customized R&D and long-term after-sales support to ensure continuous system optimization.

Practical Benefits

Enhanced Reliability: Real-time monitoring and predictive maintenance reduce wind turbine failure rates.

Optimized Energy Output: Data-driven adjustments to operational parameters improve power generation efficiency.

Reduced Operating Costs: Remote management and automated monitoring minimize manual intervention and maintenance costs.

Strong Environmental Adaptability: DIN35 rail mounting and rugged aluminum alloy casing suit the complex environments of wind farms.

Example Configuration

For wind farm monitoring, a recommended configuration is:

Model: BL342B-SOM341-X23-Y51-Y95

(1)Hardware: 3 Ethernet ports, 16GB eMMC, 2GB DDR4, 4 RS485, 4 DI/DO, 2 PT100 temperature sensors, 4 PWM outputs + pulse counters.

(2)Functions: Supports multi-device networking, temperature monitoring, wind speed measurement, and remote data transmission.

Software: Ubuntu 20.04 + BLloTLink + Node-Red for data collection, protocol conversion, and IoT application development.

Conclusion

The ARMxy BL340 series embedded industrial computer, with its high-performance hardware, flexible I/O configuration, robust software support, and industrial-grade reliability, provides an ideal solution for wind farm monitoring. It not only enables real-time management of wind turbines but also optimizes energy production through data analysis and remote maintenance, reducing operational costs. It is a core component for the intelligent operation of wind farms.

0 notes

Text

Why Control Solutions in Malaysia Are Crucial for Energy Efficiency and Sustainability

As Malaysia continues its journey toward smart industries and greener infrastructure, the demand for advanced control solutions is growing rapidly. From manufacturing plants and commercial buildings to public utilities, effective control systems are becoming essential for improving energy efficiency, operational transparency, and long-term sustainability. At the forefront of this transformation is Madox Malaysia, a trusted name in automation and intelligent engineering solutions.

Understanding Control Solutions in Malaysia