#SaltSprayTest

Explore tagged Tumblr posts

Text

Why Every USA Manufacturer Is Switching to Premium Salt Fog Test Chambers

Discover why salt fog test chambers are becoming essential for corrosion testing in every major US manufacturing sector. Learn how Testron’s Basic and Cyclic Salt Spray Test Chambers deliver precision, compliance, and performance.

#SaltFogTestChamber#CorrosionTesting#MaterialTestingUSA#SaltSprayChamber#QualityControlUSA#DurabilityTesting#ManufacturingStandards#SaltSprayTest#IndustrialTesting#PremiumTestEquipment

0 notes

Text

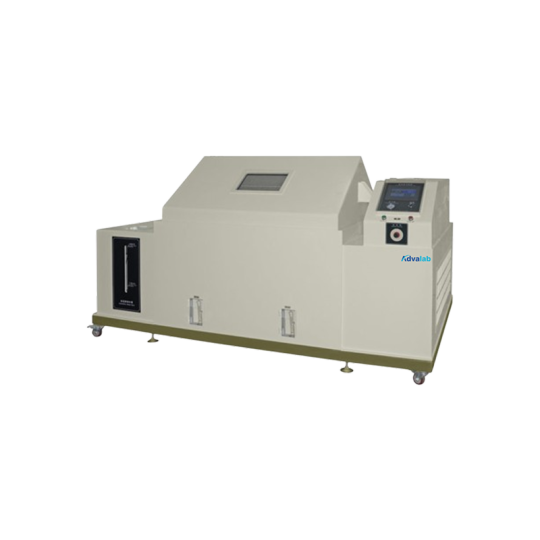

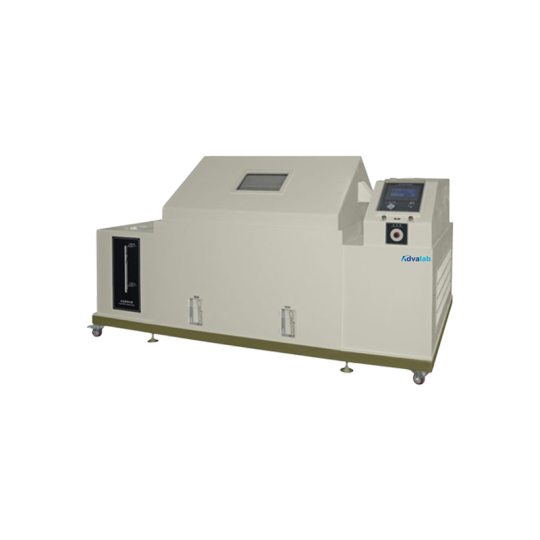

Salt Spray Test Chamber ADST-501

Advalab Salt Spray Test Chamber has a 108L capacity, with a temperature range of ensuring accurate thermal testing and reliable results. It offers minimal temperature fluctuations 5 °C ,fuse protection, and flexible spray modes for reliable, efficient testing.

0 notes

Text

What are the Benefits Salt Spray Chamber?

The operation of a Salt Spray Chamber involves creating a highly corrosive environment by spraying a solution of salt and water onto test specimens, typically made of metal, plastic, or other materials. This process, known as the Salt Spray or Corrosion Test, uses a 5% sodium chloride (NaCl) solution, mimicking the salt content of seawater, under controlled temperature, humidity, and pH levels.

The duration of the test can vary, allowing for the evaluation of the specimen's corrosion resistance over time. After testing, specimens are inspected for corrosion signs, which help in assessing the material's or coating's durability.

The application of Salt Spray Chambers spans multiple industries, including automotive, aerospace, coatings, electronics, marine, and military, to test components such as automotive parts, aircraft structures, coatings, electronic components, and materials used in marine structures. This testing helps ensure that these materials can withstand harsh conditions and corrosive substances, thereby ensuring reliability and extending the lifetime of products.

What is a Salt Spray Chamber?

A Salt Spray Chamber is an essential tool used in the industrial testing of materials and coatings for corrosion resistance. By simulating a highly corrosive environment, typically through the dispersion of a salt-laden mist, it allows researchers and manufacturers to predict how materials will perform under harsh conditions.

How Does a Salt Spray Chamber Work?

The chamber works by atomizing a salt solution, usually sodium chloride, into a fine mist within a sealed testing compartment. The concentration of salt in the solution, the temperature, and the humidity within the chamber can be precisely controlled to replicate various corrosive environments. Test specimens are exposed to these conditions for predetermined periods to assess corrosion resistance.

What are the Benefits of Using a Salt Spray Chamber?

Predictive Analysis: Provides valuable data on how materials and coatings will withstand corrosive environments.

Quality Control: Ensures products meet required corrosion resistance standards.

Material Selection: Helps in choosing the right materials and coatings for specific applications.

Research and Development: Aids in the development of new, more corrosion-resistant materials and coatings.

What Types of Tests Can Be Performed in a Salt Spray Chamber?

Neutral Salt Spray (NSS) Test: The most common and involves a neutral (pH 6.5-7.2) salt solution.

Acetic Acid Salt Spray (AASS) Test: Introduces acetic acid into the salt solution, simulating more aggressive conditions.

Copper-Accelerated Acetic Acid Salt Spray (CASS) Test: Further accelerates corrosion through the addition of copper chloride, used for testing decorative chrome plating.

How Long Do Tests Typically Last?

Test duration can vary significantly depending on the standards being followed and the materials being tested. Some tests last a few hours, while others can extend for more than a thousand hours.

How Do I Maintain My Salt Spray Chamber?

Regular maintenance includes:

Cleaning the chamber and nozzles to prevent clogging.

Checking and calibrating the temperature and humidity controls.

Ensuring the salt solution concentration remains consistent.

Regularly inspecting for any signs of wear and tear.

What Are Common Issues with Salt Spray Chambers?

Nozzle Blockage: Salt build-up can block the nozzles, disrupting the mist.

Humidity and Temperature Fluctuations: Faulty sensors or heating elements can affect test conditions.

Corrosion of the Chamber Itself: Proper materials and maintenance are required to prevent the chamber from corroding.

Can Salt Spray Chambers Simulate All Types of Corrosive Environments?

While highly effective for many applications, Salt Spray Chambers cannot replicate every corrosive environment, such as those with UV exposure or mechanical wear. They are best used as part of a comprehensive testing program.

Where Can I Find Standards for Salt Spray Testing?

Standards are provided by organizations such as ASTM International, ISO, and specific industry bodies. These documents outline the specific conditions and procedures for various types of salt spray tests.

Conclusion

Salt Spray Chamber play a crucial role in ensuring the durability and reliability of materials and coatings in corrosive environments. By understanding their operation, benefits, and maintenance requirements, you can significantly enhance your product's quality and longevity. Whether you're in the early stages of research and development or ensuring your final product meets quality standards, a Corrosion Test Chamber is an invaluable tool in your arsenal.

Read More

Facebook: https://www.facebook.com/pacorrtestinginstruments

Twitter: https://twitter.com/Pacorr_testing

Instagram: https://www.instagram.com/pacorrtestingLinkedin: https://www.linkedin.com/in/pacorr

0 notes

Video

tumblr

Salt Spray Test Chamber could evaluate the anti-corrosion ability of material and material coating, make a comparsion about the product techniques and quality of similar coating and products, It be used to test the electronic elements, and metal materials and industrial products.

For more Information Visit -

Or Call/WhatsApp - +91 82919 71983, 022 49706073.

0 notes

Photo

Qingdao Tianwei Casting (beläget i Qingdao, Shandong, Kina) är mycket specialiserat på investeringsgjutning, precisionsgjutning och sandgjutning för att producera alla typer av teknik / metalldelar. Vi kan gjuta mer än 100 slags legeringar.

När det gäller investeringsgjutning (gjutningsmetod för förlorat vax) har vi två produktionslinjer: kiselgel och vattenglas så att vi kan möta olika kunders olika behov.

Investeringsgjutning (gjutning av förlorat vax): rostfritt stål, kolstål, legerat stål, duplex rostfritt stål, gjutjärn. ISO9001: 2000 certifierat.

Sandgjutning: fläckar stål 304,316; duplex rostfritt stål 17-4ph, 630; värmebeständigt stål, höglegerat stål.

Delnamn: Bildelar, överflödesventildelar, Rörmontering, fläns, pumpkropp, pumpkåpa, ventilhus, ventilkåpa, pumphjul (primär, HP), lager, växel, växellåda, bultuttag, konsol, tee-koppling, gaffel, bränsleledning, knock, bränslepåfyllning, anslutningsaxel, hölje, monteringsfäste, stålarmbåge, styrskovel, golfputthuvud, vakuumpumpdelar, avloppspumphölje, axiell flödespumphjul, dragfläktfodral, tanklock, kompressorhölje, dubbel sughjul, ringdrift; union M / F, hexagonlock, hexagon plugg, sockelböjd, koppling, hexagon nippel, fyrkantig plugg, reducerande tee, hexagon bussning, tvärrör, reducerande armbåge, slangnippel.

Bearbetning: svarvning / svarvning, fräsning, borrning, slipning,

Tappgängor, 5-axlig CNC-bearbetning; CMM-inspektion; spektrometer för kontroll av kemiska kompositioner; testning av mekaniska egenskaper; trycktestning under vatten, antirostolja, saltspraytest.

Värmebehandling: lösningsglödgning, normalisering, kylning och härdning,

karburiserande behandling, fallhärdande, nitriderande behandling.

Ytbehandling:

zinkbeläggning, nickelplätering, svartfärgning, spegelpolering, satinpolering, E-polering.Dacromet ytbehandling.

Vi vill bli din kinesiska produktionsbas!

Hoppas uppriktigt att samarbeta med dig!

vänliga hälsningar

Maria Li

E-post: [email protected]

Webbplats : www.tianweicasting.com www.chntianwei.com

0 notes

Photo

Salt Spray Testing lab in Delhi

#saltspraytesting #saltspraylab

0 notes

Text

Combat Corrosion with Confidence – Discover Testron’s Salt Spray Test Chamber

In industries where material durability defines performance, corrosion testing is nonnegotiable. Testron’s Salt Spray Test Chamber is engineered to deliver unmatched precision, repeatability, and real world simulation of the harshest salt-laden environments.

Built for Industry Experts Who Can’t Afford to Compromise:

Advanced temperature and salt fog control for precise corrosion testing

Periodic or continuous spray cycles with uniform distribution

Transparent lid for uninterrupted sample monitoring

Compatible with standard and custom sample holders

Certified to CE mark and ISO17025 calibration standards

Ideal for Corrosion-Intensive Applications:

From automotive and aerospace components to marine equipment, oil & gas pipelines, consumer appliances , and electronic housings-this chamber supports every sector where corrosion resistance is mission-critical.

Testron empowers industries to validate their materials, extend product lifespan, and meet global durability standards with confidence.

Rethink reliability in your corrosion testing protocol.

#SaltSprayTest#CorrosionTesting#MaterialTestingEquipment#QualityControl#SaltSprayChamber#EnvironmentalTesting#LabTestingEquipment#TestronGroup#SaltFogTest#CorrosionResistance

0 notes

Text

Protect Your Materials from Corrosion – The Perfect Salt Spray Test Solution

Corrosion is a quiet destructor, undermining the strength and integrity of materials across various industries. The Testron Composite Salt Spray Test Chamber allows manufacturers to subject metals, coatings, and components to rigorous corrosion tests in controlled conditions, replicating real-world environments with precise accuracy.

Why Industry Leaders Rely on Testron

Advanced Corrosion Simulation – Ongoing and regular salt spray testing guarantees proper evaluation of material endurance.

Accurate Environmental Control – Includes temperature control, salt fog measurement, and hydrostatic hood seal for uniform test conditions.

Real-Time Observation – A transparent lid facilitates easy observation of samples under test.

Compliance & Quality – Certified with CE marking and ISO 17025 calibration for international industry standards.

Multi-purpose Usage – Suitable for automotive, aerospace, marine, oil & gas, electronics, and construction industries to improve the performance and longevity of materials.

Industries Dependent on Testron

Automotive & Aerospace – Preventing corrosion protection of structural members, frames, and coatings.

Electronics & Electricals – Testing the toughness of housings and circuit boards.

Oil & Gas – Putting pipelines and valves through harsh environments.

Marine & Construction – Testing metal and coating resistance in extreme saltwater conditions.

Be at the forefront of material quality assurance. Guarantee long-term performance with accurate salt spray testing.

𝗙𝗼𝗿 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻:

Email: [email protected]

Product: https://testrongroup.com/product/basic-salt-spray-corrosion-test-chamber/

Website: https://testrongroup.com/

#SaltSprayTest#CorrosionTesting#MaterialTesting#QualityControl#SaltSprayChamber#TestingEquipment#CorrosionResistance#LabTesting#IndustrialTesting#TestronGroup

0 notes

Text

Guard Your Products Against Corrosion with Testron's Advanced Salt Spray Test Chamber

Testron's Basic Salt Spray Corrosion Test Chamber Defends Your Products Against Corrosion

Corrosion is one of the biggest enemies of durability, but not for your products anymore! Testron has the ultimate tool to simulate corrosive environments and help your materials stand the test of time.

Top Features for Precision Testing:

Display unit with temperature control

Continuous/periodic salt spraying

Hydrostatic hood seal for reliable operations

Standard & custom sample holders.

Applications Developed for Any Industry:

Automotive: Resistance to corrosion of crucial parts such as frames and coatings.

Construction: Testing the endurance of metals used in construction products.

Electronics: Ensuring that connectors and casings withstand corrosion in harsh conditions.

Marine: Testing components exposed to salt environments.

Manufacturing: Validating materials for the endurance of industrial equipment.

Get the Edge Over Corrosion!

Protect your products, build trust with your clients, and comply with international standards.

Contact us today for a demo and ensure corrosion resistance like never before!

For more information:

Email: [email protected]

Product: https://testrongroup.com/product/basic-salt-spray-corrosion-test-chamber/

Website: https://testrongroup.com/

#SaltSprayTest#CorrosionTesting#MaterialTesting#QualityControl#SaltSprayChamber#CorrosionResistance#TestingEquipment#LabTesting#SaltFogTest#TestronGroup

0 notes

Text

Best Salt Spray Test Chamber Manufacturers in the UK You Should Know About

Looking for reliable salt spray test chamber manufacturers in the UK? This post covers the top names you should check out for quality and performance. Perfect for businesses that need dependable corrosion testing equipment.

Follow us for more updates on quality control and testing equipment suppliers.

0 notes

Text

Salt Spray Test Chamber

Advalab Salt Spray Test Chamber has a 108L capacity, with a temperature range of RT to 55°. and ensuring accurate thermal testing and reliable results. It offers minimal temperature fluctuations 5 °C ,fuse protection, and flexible spray modes for reliable, efficient testing.

0 notes

Text

The Future of Corrosion Resistance: Innovations in Salt Spray Chamber Technology

Introduction

In the relentless pursuit of quality and durability, industries worldwide turn to rigorous testing methods to ensure their products withstand the test of time and environment. Among these methods, salt spray testing stands out as a critical procedure for assessing corrosion resistance. Pacorr’s Salt Spray Chambers epitomize the pinnacle of testing technology, offering unparalleled precision in simulating harsh environments to guarantee your products' longevity and reliability.

Features

Advanced Corrosion Testing Technology: Our Salt Spray Chambers are equipped with state-of-the-art features to accurately simulate a variety of corrosive environments. From adjustable spray nozzles to precisely controlled temperature and humidity settings, our chambers are designed to meet and exceed ASTM B117 and ISO 9227 standards.

User-Friendly Interface: Ease of use is at the heart of our design philosophy. Our chambers come with intuitive touch-screen controls, allowing operators to easily set up tests, monitor conditions in real-time, and access historical data for comprehensive analysis.

Durability and Reliability: Constructed with high-quality materials resistant to corrosion, our chambers ensure long-term performance and reliability. The robust design minimizes maintenance requirements, ensuring continuous operation and consistent test results.

Versatile Testing Capabilities: Whether you're testing automotive components, aerospace equipment, or consumer electronics, our Salt Spray Chambers can be customized to fit your specific testing requirements. With adjustable sizes and configurations, our chambers are suitable for a wide range of industries.

Benefits

Enhanced Product Quality: By identifying potential corrosion issues early in the product development cycle, you can take corrective actions to enhance your product's quality and durability, leading to increased customer satisfaction and reduced warranty claims.

Compliance with International Standards: Our Salt Spray Chamber help you comply with international corrosion testing standards, facilitating smoother approvals and certifications for your products in global markets.

Cost-Effective Testing Solution: With their efficient operation and low maintenance design, our chambers offer a cost-effective solution for your testing needs, reducing the overall cost of quality assurance while ensuring the highest standards of reliability.

Applications

Salt Spray Chambers are indispensable tools for a variety of industries, including:

Automotive: Testing corrosion resistance of components and coatings to ensure vehicle longevity.

Aerospace: Ensuring that aircraft parts can withstand corrosive environments to maintain safety and performance.

Electronics: Assessing the corrosion resistance of electronic components for reliability in various environments.

Coatings and Metal Processing: Evaluating the effectiveness of protective coatings and treatments on metals.

FQA

What is a Salt Spray Chamber?

A Corrosion Test Chamber is a controlled environment designed to assess the corrosion resistance of materials or surface coatings. It replicates the corrosive conditions found in a marine environment by continuously spraying a saltwater solution onto the samples, allowing for accelerated corrosion testing.

How do Salt Spray Chambers work?

Salt Spray Chambers work by filling the chamber with a saltwater (usually sodium chloride) mist, which then settles on the test samples placed inside. The chambers are equipped to maintain specific conditions of temperature and humidity, which are critical for accelerating the corrosion process.

What are the types of tests performed in a Salt Spray Chamber?

The most common test performed is the Neutral Salt Spray test (NSS), which uses a neutral pH salt solution. There are also variations like the Acetic Acid Salt Spray test (AASS) and the Copper-Accelerated Acetic Acid Salt Spray test (CASS), which are designed to simulate more aggressive corrosion conditions.

Who uses Salt Spray Chambers?

Salt Spray Chambers are used by manufacturers across various industries, including automotive, aerospace, military and defense, building and construction, and metal fabrication. They are critical in R&D, quality control, and regulatory compliance processes to ensure product durability and performance.

How long do salt spray tests last?

The duration of a salt spray test can vary widely, from 24 hours to more than a month, depending on the material being tested and the specific requirements of the test standard. The purpose is to accelerate the corrosion process, so it reflects years of exposure to a corrosive environment.

Can Salt Spray Chambers predict the lifetime of a coating or material?

While Salt Spray Tester accelerate corrosion processes, they do not directly correlate to the actual lifetime of a material or coating in a real-world environment. However, they are invaluable for comparative analysis, helping to identify which materials or coatings are more resistant to corrosion.

How do you maintain a Salt Spray Chamber?

Maintenance involves regular cleaning to prevent salt accumulation, checking and refilling the salt solution, and ensuring the spray nozzles are clear and functioning properly. Calibration and validation of the chamber's conditions (temperature, humidity, and pH of the solution) are also critical for accurate test results.

What are the limitations of salt spray testing?

Salt spray testing mainly evaluates the corrosion resistance of a surface and does not account for other degradation mechanisms such as UV exposure or mechanical wear. It's also a standardized test, which means it may not replicate specific real-world corrosive environments perfectly.

Can Salt Spray Chambers be customized?

Yes, Salt Spray Chamber can be customized in size, capacity, and functionality to meet specific testing requirements. This can include adjustments to the temperature and humidity range, integration of UV light for combined corrosion and UV testing, or modifications to accommodate large or irregularly shaped samples.

Conclusion

Pacorr’s Salt Spray Chamber represent the forefront of corrosion testing technology, offering businesses the tools they need to ensure their products stand up to the harshest conditions. With our commitment to quality, precision, and reliability, we empower industries to meet the challenges of today and tomorrow, securing the durability and integrity of their products in any environment.

0 notes

Text

Why Salt Spray Chambers are a Must-Have in Modern Manufacturing Processes

A Salt Spray Chamber, also known as a Salt Fog Chamber, is an equipment used to test the corrosion resistance of materials and surface coatings. This testing apparatus simulates a highly corrosive environment, usually by spraying a saltwater solution (typically a 5% sodium chloride solution) into a test chamber atmosphere at a controlled temperature. The main purpose of this Salt Spray Chamber is to replicate the effects of saltwater or sea spray in a controlled setting, providing rapid results on how materials will withstand such conditions over time.

What is a Salt Spray Chamber?

A Salt Spray Chamber is a testing device used to evaluate the corrosion resistance of materials and coatings. By simulating a highly corrosive environment, it allows manufacturers to predict how their products will perform under harsh conditions, extending from sea water exposure to road salts.

Why Use a Salt Spray Chamber?

Durability is key in many industries, and a Salt Spray Chamber provides a standardized method to test material resistance to corrosion. This not only helps in improving product quality but also complies with international standards.

How Does a Salt Spray Chamber Work?

Salt Spray Chambers create a controlled corrosive environment, usually by atomizing a salt solution, which then settles on the samples being tested. The conditions inside the chamber, including temperature, humidity, and salt concentration, are closely monitored to ensure consistency.

FAQ Section

Q: What types of Salt Spray Chambers does pacorr.com offer?

A: We offer a variety of Salt Spray Chamber designed to meet different industry standards and testing needs. Our range includes basic models for straightforward testing, to advanced systems with programmable features and larger capacities.

Q: How long does a salt spray test take?

A: The duration of a Salt Spray Tester can vary widely depending on the material being tested and the specific standards it needs to meet. Tests can range from a few hours to several months.

Q: Can I customize a Salt Spray Chamber to fit my specific testing requirements?

A: Yes, at pacorr.com, we understand that every industry has unique needs. We offer customizable options for our Salt Spray Chamber, including adjustable sizes, temperatures, and spray rates.

Q: What support does pacorr.com provide for Salt Spray Chambers?

A: We provide comprehensive support for all our products, including installation guidance, operational training, and maintenance tips. Our expert team is also available for any troubleshooting needs.

Q: How do I choose the right Salt Spray Chamber for my testing needs?

A: Choosing the right Salt Spray Chamber depends on several factors, including the size of your samples, the standards you need to comply with, and any specific features you require. Our team at pacorr.com is here to help guide you through the selection process to ensure you get the perfect fit for your testing needs.

Conclusion

Salt Spray Chambers are essential for industries requiring the highest standards of material durability and quality. At pacorr.com, we're committed to providing the best testing instruments to help you ensure your products stand the test of time and harsh conditions. Whether you're just starting to explore corrosion testing or looking to upgrade your Salt Spray Tester capabilities, we're here to support you every step of the way.

For More Information About Our Products And Services, Visit: - pacorr.com

0 notes

Video

tumblr

Salt Spray Test Chamber could evaluate the anti-corrosion ability of material and material coating, make a comparsion about the product techniques and quality of similar coating and products, It be used to test the electronic elements, and metal materials and industrial products.

For more Information Visit - https://www.flexitest.in/salt-spray-chambers

Or Call/WhatsApp - +91 82919 71983, 022 49706073.

Stay connected with us! ► Subscribe to Flexitest: https://bit.ly/3B6PNrj

► Like us on Facebook: https://www.facebook.com/Flexitest

► Follow us at Linkedin: https://bit.ly/3C7mBS4

0 notes