#Scale Model Maker

Explore tagged Tumblr posts

Text

scale model maker

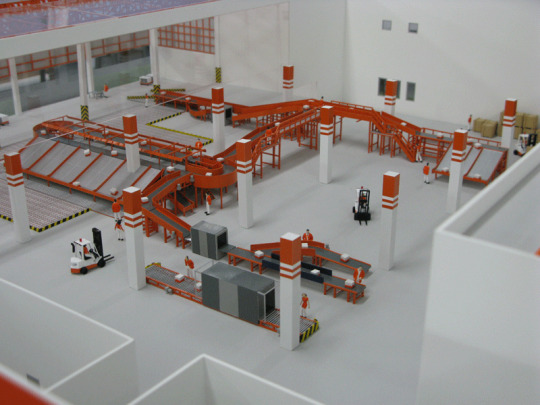

Scale model making is an art that involves creating precise and detailed replicas of real-world objects or structures on a smaller scale. These models are used for various purposes, including architectural visualization, engineering prototypes, industrial designs, and educational demonstrations. Scale model makers are skilled artisans with exceptional engineering knowledge, creativity, and craftsmanship. In India, one name stands out in this field: Engg Model.

Understanding Scale Model Makers:

Scale model makers are professionals who meticulously craft scaled-down versions of objects, buildings, vehicles, and machines, among other things. In their creations, they use various materials and techniques to achieve accuracy and attention to detail. Their work often involves precision measurements, complex calculations, and the ability to interpret technical drawings or specifications.

The Art of Scale Model Making:

Scale model makers play a crucial role in various industries. In architecture and urban planning, they create miniature representations of buildings and landscapes, helping architects visualize their designs better and enabling clients to get a realistic preview of the final project. Engineers and product designers also rely on scale models to prototype and test their concepts before moving to the actual production phase. Scale models are used for aerodynamics testing and design validation in the automotive and aerospace industries.

Engg Model: India's Best Scale Model Maker:

Engg Model has earned a stellar reputation as India's best scale model maker, with an unwavering commitment to excellence and innovation. Their team of highly skilled and passionate artisans combines engineering expertise with artistic flair to deliver outstanding scale models that exceed client expectations.

Exceptional Craftsmanship:

Engg Model's scale model makers are masters of their craft, each with years of experience and expertise in their respective fields. They are adept at using cutting-edge technologies and traditional handcrafting techniques, ensuring that every detail is accurately replicated in the scale model. Engg Model's craftsmanship is unmatched, from the minutest components to intricate surface textures.

Unrivalled Accuracy:

One of the distinguishing features of the Engg Model is its unwavering commitment to precision. Their scale models are not mere replicas but accurate representations of the original objects. The team meticulously studies technical drawings, architectural plans, or engineering specifications to ensure that every dimension and proportion is faithfully captured.

Versatility and Innovation:

Engg Model has a diverse portfolio, catering to a wide range of industries and projects. Whether it's a towering skyscraper, an intricate machine, a sprawling industrial complex, or a sophisticated product prototype, Engg Model's artisans have the expertise to handle it all. Moreover, they continually push the boundaries of innovation, incorporating the latest technologies and materials to enhance the quality and realism of their scale models.

Client-Centric Approach:

At Engg Model, clients' satisfaction is the topmost priority. They collaborate closely with their clients, understanding their specific requirements and objectives. This client-centric approach allows them to deliver tailor-made scale models that precisely meet the client's vision and purpose.

Conclusion:

Scale model makers play an indispensable role in various industries, bringing designs to life and helping stakeholders visualize projects before execution. Engg Model has emerged as India's premier scale model maker, delivering exceptional craftsmanship, accuracy, and innovation in every project they undertake. Their commitment to excellence and client satisfaction makes them the go-to choice for scale models in India. Engg Model is the name you can trust if you seek perfection and finesse in scale model making.

0 notes

Text

What Materials Are Used for Making Scale Models and Miniature Models?

How AR Model Makers Choose Materials for Stunning Scale Models

When it comes to crafting precise and eye-catching scale models, the materials used can make or break the final product. Whether it��s an engineering model, a marine model, an industrial model, or an architectural model, the team at AR Model Makers knows that selecting the right materials is key to delivering quality. In this article, we’ll explore the materials commonly used by expert miniature model makers like AR Model Makers, how they enhance different types of models, and why they matter to clients across industries. From house models to complex industrial designs, you’ll discover what goes into creating these miniature masterpieces.

Why Material Choice Matters in Scale Model Making

Common Materials Used by Miniature Model Makers

Miniature models come in all shapes and sizes, and so do the materials used to create them. Here’s a breakdown of the most popular choices at AR Model Makers and how they’re applied.

Wood – The Timeless Classic

Acrylic and Plastics – Precision and Durability

Metal – Strength for Industrial and Marine Models

Foam and Cardboard – Lightweight and Cost-Effective

https://armodelmakers.com/wp-content/uploads/2025/03/Foam-and-Cardboard.jpg

3D Printing Resins – The Future of Model Making

How AR Model Makers Tailor Materials to Your Project

Every project at AR Model Makers is unique, and material choices reflect that. For a marine model, they might combine metal for the hull with acrylic for water effects, creating a lifelike display. An industrial model could blend 3D-printed parts with metal accents to highlight machinery. By understanding the project’s purpose—whether it’s a trade show display or a client presentation—AR Model Makers ensures the materials align with both budget and vision.

For instance, a recent house model project in Delhi used a mix of wood and foam to craft a realistic neighborhood layout, earning praise from clients and establishing AR Model Makers as one of the best model makers in Delhi.

The Role of Craftsmanship in Material Selection

Materials alone don’t tell the full story—expert craftsmanship brings them to life. As one of the best model makers in Mumbai and beyond, AR Model Makers combines cutting-edge tools with hands-on expertise. Their team knows how to sand wood to a perfect finish, weld metal seamlessly, or paint acrylic for a polished look. This dedication elevates every engineering model, marine model, or architectural model they produce.

Interested in the process? Learn more about their approach on the AR Model Makers About Us page.

Why Choose AR Model Makers for Your Next Model?

With a reputation as top model makers in India, AR Model Makers stands out for their material expertise and client-focused approach. Whether you need a detailed marine model for a maritime expo or a sleek industrial model for a product pitch, their use of high-quality materials ensures stunning results. Plus, their presence in cities like Delhi and Mumbai makes them accessible to businesses nationwide.

Ready to start your project? Reach out via the AR Model Makers Contact Us page to discuss your vision.

External Resources for Further Reading

To dive deeper into scale model materials, check out these authoritative sources:

The Spruce Crafts: Guide to Model Making Materials

Material Properties for 3D Printing by Formlabs

If you have a project In mind just give us a Call

Have a project in mind? Let AR Model Makers bring it to life with the perfect materials! Drop a comment below with your thoughts, share this post with fellow model enthusiasts, or reach out to the team at AR Model Makers Contact Us to get started.

FAQ

What materials are best for an engineering model?

Materials like acrylic, metal, and 3D printing resins are ideal for engineering models due to their precision and durability, as used by best engineering model makers like AR Model Makers.

How long does it take to build a marine model with AR Model Makers?

Depending on complexity, a marine model can take anywhere from a few days to weeks, with AR Model Makers using metals and acrylics for top-quality results.

#marine model#architectural model#scale model#craft#art#model makers#model making#miniature model#engineering model#scalemodel

2 notes

·

View notes

Text

Orlando Hunter Jeep Paint Work

Just got the Orlando Hunter OH35A01 Jeep. I am starting with the paint work first, while waiting for other parts to arrive in the mail for the rest of the build.

I don't paint often, so I don't have a dedication paint station ... Hahaha ... Hence, the need to setup a temporary paint station. I have an exhaust fan/hose that I use for this and also for soldering.

I went with orange for the body, and black for the roof and trims. It's been ages since I had to do masking, and it's still a pain ... lol

Overall, quite happy with how it turned out. Made some stupid mistakes while masking, but luckily, nothing too terrible ... lol ... Designed a logo for “ChrisTan Workshop” in Canva and printed some transparent decals. I think they add some nice details to the truck.

#maker#rc cars#crawler#microrc#micro crawler#rc crawler#diy#Orlandoo hunter#OH35A01#Jeep Wrangler#scale model

3 notes

·

View notes

Text

Why Choose a Professional 3D Scale Model Maker?

When it comes to presenting architectural projects or industrial prototypes, the expertise of a 3D Scale Model Maker is invaluable. These professionals transform your blueprints into tangible representations that capture every intricate detail.

At C3D, we pride ourselves on being a trusted partner for delivering high-quality scale models. Our commitment to precision and attention to detail ensures that every model we create meets the highest standards. Whether for construction projects, product design, or exhibitions, our models provide clarity and insight.A reliable 3D Scale Model Maker like C3D employs advanced technology and materials, ensuring durability and accuracy. Partner with us to enhance your presentations and showcase your vision effectively.

0 notes

Text

Miniature Scale Model Maker in Mumbai

In the world of architecture, design, and planning, precision and detail are everything. When it comes to bringing intricate ideas to life, a Miniature Scale Model Maker in Mumbai is an invaluable asset. These experts in miniature modeling transform concepts into tangible, scaled-down versions, offering a visual and tactile experience that digital renderings often can’t match.

More Information

Click Here :-

0 notes

Text

How is technology transforming the field of miniature model making?

In the ever-evolving world of engineering and design, miniature model making has long been a specialized craft where precision, artistry, and technical skill converge. From architectural models depicting future skyscrapers to intricate miniatures for tabletop games, miniature model making has always been a blend of art and science. However, as we move into the 21st century, technology is transforming this traditional craft in unprecedented ways. In this blog post, we will explore how modern innovations are reshaping the field of miniature model making, with a special focus on the impact of these changes on the role of Miniature Model Makers.

The Traditional Craft of Miniature Model Making

Before we delve into the technological advancements, let’s take a moment to appreciate the traditional techniques that have defined miniature model making for decades. Historically, miniature model makers used handcrafting techniques, including sculpting, painting, and assembling intricate parts to create detailed and accurate representations of real-world objects.

Miniature Model Makers were often skilled artisans who utilized manual tools such as X-Acto knives, precision pliers, and hand drills. These tools allowed them to cut, shape, and assemble plastic, wood, and metal materials. Each model was painstakingly crafted with attention to detail, resulting in stunning creations that could convey complex ideas and visions in a compact form.

Scale model makers

The Rise of Digital Tools in Miniature Model Making

3D Modeling Software One of the most significant technological advancements in miniature model making is the advent of 3D modelling software. Programs like Autodesk Fusion 360, SketchUp, and Blender have opened up new possibilities for Miniature Model Makers. These tools allow creators to design intricate models with precision and efficiency.

With 3D modelling software, Miniature Model Makers can:

Visualize Designs: Create detailed 3D representations of their ideas before starting the physical construction process.

Experiment with Variations: Easily modify designs, explore different configurations, and see real-time outcomes.

Generate Technical Drawings: Produce accurate blueprints and schematics that can be used for further development or manufacturing.

3D Printing 3D printing technology has been a game-changer in miniature model making. Also known as additive manufacturing, 3D printing allows Miniature Model Makers to produce complex geometries that were previously impossible or too labour-intensive to create by hand.

Key advantages of 3D printing include:

Rapid Prototyping: Quickly turn digital designs into physical models, allowing faster iterations and refinements.

Customization: Produce bespoke models tailored to specific requirements or preferences.

Complex Structures: Advanced printing techniques like SLA (stereolithography) and FDM (fused deposition modeling) allow you to create intricate details and structures with high precision.

Laser Cutting and Engraving Laser cutting and engraving technology offer another significant advancement for Miniature Model Makers. Laser cutters use high-powered lasers to precisely cut and etch acrylic, wood, and cardboard.

Benefits of laser cutting and engraving include:

Precision: Achieve intricate designs with exact measurements and clean edges.

Versatility: Work with a wide range of materials and thicknesses.

Efficiency: Produce high-quality cuts and engravings quickly, ideal for creating complex models or multiple copies of a design.

The Impact of Technology on Miniature Model Making

Increased Efficiency One of the most noticeable impacts of technology on miniature model making is the increase in efficiency. Digital tools streamline the design and production processes, allowing Miniature Model Makers to complete projects faster and more precisely. The ability to quickly prototype designs and make adjustments has revolutionized how models are developed and refined.

Enhanced Creativity Technology also opens up new avenues for creativity. Miniature Model Makers can explore more innovative design concepts with advanced software and tools. Digital simulations and virtual reality offer new ways to visualize and interact with models before they are built, leading to more creative and ambitious projects.

Broader Accessibility Modern technology has made miniature models more accessible to a wider audience. Where traditional methods required specialized skills and equipment, today’s tools lower the barrier to entry. Online resources, tutorials, and affordable software enable hobbyists and aspiring model makers to experiment with new techniques and develop their skills.

Collaborative Opportunities Technology has also facilitated collaboration among Miniature Model Makers. Digital platforms and online communities allow creators from around the world to share ideas, offer feedback, and work together on projects. This global knowledge exchange and expertise enriches the field and fosters a vibrant community of miniature model enthusiasts.

Conclusion Technology has undeniably transformed the field of miniature model making, offering Miniature Model Makers a wealth of new tools and techniques to explore. From 3D modeling and printing to laser cutting and digital collaboration, these advancements have made the craft more efficient, creative, and accessible.

As we look to the future, it’s exciting to imagine how new technologies will continue to shape the world of miniature model making. Whether you are a seasoned professional or a hobbyist just starting, embracing these technological advancements can open up new opportunities and elevate your craft to new heights.

The future of miniature model making is bright, and technology is at the heart of this transformation. So, if you’re passionate about creating intricate models and exploring new possibilities, there has never been a better time to dive into this fascinating field.

Stay tuned to the Engg Model website for more insights, updates, and tips on the latest in miniature model making technology!

0 notes

Text

Architectural Model Making in Dubai

#3d model#model making#architectural model#model makers#model making dubai#scale model#3d model making#building model

1 note

·

View note

Text

How to Find the Best Scale Model Maker for Your Project

Introduction

When bringing your engineering projects to life, scale models are crucial in visualizing concepts, identifying potential issues, and presenting ideas to stakeholders. Choosing the right scale model maker is essential to ensure accuracy, attention to detail, and overall quality. This blog post will guide you through finding the best scale model maker for your project. At Engg Model, a leading provider of scale models, we combine expertise, craftsmanship, and state-of-the-art technology to deliver exceptional results for clients in India and beyond.

Expertise and Experience

One of the most critical factors in selecting a scale model maker is their expertise and experience in the field. Look for a company with a proven record of creating high-quality scale models. Assess their portfolio, client testimonials, and case studies to gauge their capabilities. An experienced scale model maker will deeply understand engineering principles, materials, and techniques required to create accurate and visually stunning models. Engg Model boasts a team of skilled professionals with extensive experience creating various scale models.

Customization and Specialization

Consider the customization options and specialization offered by the scale model maker. Every project is unique, and the ability to tailor the scale model to your specific requirements is essential. A reliable scale model maker should offer a range of customization options, including scale, materials, finishes, and level of detail. They should also specialize in creating models for your specific industry or sector. Engg Model specializes in engineering scale models and offers a comprehensive range of customization options to meet your project needs.

Quality and Attention to Detail

The quality and attention to detail in a scale model can make a significant difference in effectively conveying your project's concept and design. Look for a scale model maker emphasizing precision, accuracy, and fine craftsmanship. The models should showcase intricate details, realistic textures, and accurate scaling. Ask for sample models or visit their showroom to assess the quality of their work firsthand. Engg Model is committed to delivering top-notch quality and pays meticulous attention to detail in every scale model we create.

Technology and Innovation

Technology plays a significant role in scale model making in today's digital age. A reputable scale model maker should leverage advanced tools and techniques to enhance the accuracy and efficiency of the model creation process. Look for a company that utilizes cutting-edge technology, such as 3D printing, CNC machining, laser cutting, and computer-aided design (CAD). These technologies enable precise prototyping, faster production, and intricate detailing. Engg Model stays at the forefront of technological advancements, incorporating innovative tools and techniques into our scale model production process.

Timely Delivery and Project Management

Meeting project deadlines is crucial in any engineering endeavour. Ensure that the scale model maker has a reputation for delivering projects on time and managing multiple tasks efficiently. Inquire about their project management processes, communication channels, and ability to handle complex projects with tight timelines. Engg Model prides itself on timely delivery and effective project management, ensuring that your scale model is ready when needed.

Local Presence and Support

If you are looking for scale model makers in India, consider the advantage of working with a company that has a local presence and support. This allows for accessible communication, site visits, and prompt assistance. Engg Model, headquartered in India, provides comprehensive support and services to clients nationwide.

Conclusion

Finding the best scale model maker for your engineering project requires carefully considering their expertise, experience, customization options, quality standards, technological capabilities, and project management skills. Engg Model, a trusted scale model maker in India, ticks all these boxes, ensuring we deliver unprecedented scale.

0 notes

Text

Tiny towers, big imagination.

There’s something beautifully poetic about miniature worlds built with such detail.

AR Model Makers turns architectural dreams into palm-sized realities—where creativity meets craftsmanship.

Let’s create something artful, one scale model at a time.

#ArtOfModelMaking #MiniatureWorld #DesignAesthetic #CreativeCraft #ARModelMakers

#miniature model#architectural model#marine model#scalemodel#scale model#engineering model#model makers#model making

1 note

·

View note

Text

Why Choose a 3D Scale Model Maker for Your Next Project?

When planning a new project, visualization is critical. A 3D scale model maker provides the perfect solution by creating a tangible representation of your concept. Whether you're in architecture, engineering, or product design, these models bring your vision to life like never before.

By partnering with experts like C3D, you can leverage state-of-the-art technology to produce detailed and accurate models. These models not only help in refining the design but also act as an excellent tool for presentations and client approvals. The ability to see and feel the design gives stakeholders confidence in the project's direction.Dubai, with its reputation for innovation, has seen a surge in demand for professional 3D scale model makers. Companies like C3D are leading the charge, offering reliable and customizable solutions for projects of any scale.

0 notes

Text

#Interior Model Maker in Mumbai#Architectural Scale Model Makers in Mumbai#Best 3D Printing Services in Mumbai

0 notes

Text

How is technology transforming the field of scale model making?

Today, we're diving into an exciting topic shaping the future of scale model making. As technology continues to evolve, it's profoundly impacting how scale model makers approach their craft. From advanced design software to 3D printing and beyond, technology is expanding the possibilities for model builders and bringing innovations to the field. In this blog post, we'll explore several ways technology transforms scale model making and how these advancements are helping scale model makers achieve incredible results.

The Evolution of Scale Model Making Before we discuss the specifics, let's examine the history of scale model making. Traditionally, scale models were crafted by hand from materials such as wood, plastic, and metal. Model makers meticulously sculpted, painted, and assembled components to create detailed representations of real-world objects, such as vehicles, buildings, or miniature figures.

Over the years, this art form has evolved, driven by advancements in materials and techniques. However, the pace of change has accelerated dramatically in recent years with the advent of new technologies. Today, scale model makers can access many tools and technologies to produce unprecedented precision and detailed models.

3D Modeling and CAD Software One of the most significant technological advancements in scale model making is the development of 3D modelling and Computer-Aided Design (CAD) software. These tools allow scale model makers to create highly detailed and accurate digital representations of their models before any physical work begins.

Precision and Accuracy 3D modelling software provides a platform for scale model makers to experiment with designs, test different components, and visualize the end product in a virtual environment. Programs like SolidWorks, AutoCAD, and Blender offer a range of features that enable precise measurements, detailed textures, and complex geometries. This digital approach allows model makers to make adjustments easily, saving time and resources compared to traditional trial-and-error methods.

Enhanced Design Capabilities With 3D modelling software, scale model makers can explore intricate designs that were previously difficult or impossible to achieve by hand. For example, they can create complex structures with interlocking parts or experiment with advanced aerodynamic shapes for model aircraft. The ability to simulate various conditions and scenarios in the virtual world also allows for more rigorous testing and refinement of designs.

3D Printing Technology 3D printing, also known as additive manufacturing, has revolutionized how scale model makers produce physical models. This technology allows for creating complex parts and assemblies with a level of precision previously unattainable with traditional manufacturing methods.

Rapid Prototyping One key benefit of 3D printing for scale model makers is the ability to rapidly produce prototypes. With a 3D printer, model makers can quickly turn their digital designs into physical models, test their ideas, and iterate on their designs with minimal lead time. This iterative process is invaluable for refining details and achieving the best possible result.

Customization and Complexity 3D printing also enables a high degree of customization. Whether it's a unique one-off model or a limited production run, 3D printing can accommodate a variety of design specifications. Scale model makers can produce intricate details, such as tiny gears or delicate structures, which would be challenging to achieve with traditional methods. Furthermore, 3D printers can use various materials, from standard plastics to more specialized filaments, depending on the project's needs.

Laser Cutting and Engraving Laser cutting and engraving technologies are another major advancement in scale model making. These tools use laser beams to precisely cut or etch materials, enabling model makers to achieve detailed designs with high accuracy.

High Precision Cuts Laser cutting machines offer exceptional precision for creating intricate parts and designs. Whether cutting out components for a model or engraving detailed patterns, laser technology ensures that every piece fits perfectly. This precision is particularly useful for producing parts with fine details or working with materials that require careful handling.

Versatility in Materials Laser cutting technology is versatile, allowing model makers to work with various materials, including wood, acrylic, metal, and cardstock. This flexibility opens up new possibilities for creating diverse models and experimenting with different textures and finishes.

Digital Fabrication Tools In addition to 3D printing and laser cutting, several other digital fabrication tools are transforming the field of scale model making.

CNC Machining Computer Numerical Control (CNC) machining is a process where a computer controls machine tools to create precise parts. CNC machines can accurately mill, cut, or drill materials, making them ideal for producing complex model components. Scale model makers can use CNC machines to create parts from various materials, including metals and plastics, with consistent quality.

Vinyl Cutting Vinyl cutting technology allows model makers to create detailed decals, stickers, and graphics. This technology adds realistic markings to scale models, such as aircraft insignias or vehicle logos. Vinyl cutters use a blade to cut designs from sheets of vinyl, which can then be applied to model surfaces.

Augmented Reality (AR) and Virtual Reality (VR) Emerging technologies like Augmented Reality (AR) and Virtual Reality (VR) are beginning to find applications in scale model making, offering new ways for model makers to interact with their creations.

Enhanced Visualization AR and VR technologies allow scale model makers to visualize their models in a virtual space. For example, AR applications can overlay digital models onto real-world environments, helping model makers see how their designs will look in various settings. VR can provide immersive experiences where model makers can explore their creations from different angles and perspectives.

Interactive Prototyping These technologies also support interactive prototyping, where users can manipulate digital models in real time. This capability is useful for evaluating design features, exploring configurations, and presenting models to clients or collaborators.

Online Communities and Resources The rise of online communities and resources has also been a transformative force in scale model making. Digital platforms offer model makers opportunities to share their work, seek feedback, and access tutorials and guides.

Knowledge Sharing Online forums, social media groups, and dedicated websites provide spaces for scale model makers to exchange ideas, showcase their projects, and learn from one another. These communities foster collaboration and help model makers stay up-to-date with the latest techniques and trends.

Access to Tutorials and Tools The internet is a treasure trove of resources for scale model makers. From video tutorials and step-by-step guides to downloadable templates and design files, model makers have access to a wealth of information that can help them improve their skills and expand their capabilities.

Conclusion Technology is undeniably transforming the scale model-making field, offering new tools, techniques, and opportunities for scale model makers to explore. From advanced 3D modeling software and 3D printing to laser cutting, CNC machining, and digital fabrication, these innovations enhance precision, enable greater creativity, and make it easier for model makers to bring their visions to life.

The integration of AR and VR technologies and the growth of online communities further enriches the field, providing new ways for scale model makers to interact with their work and connect with others in the hobby. As technology advances, we can expect even more exciting scale model-making developments.

At Engg Model, we're passionate about staying at the forefront of these innovations and helping scale model makers achieve their goals. Whether you're a seasoned professional or just starting, there's never been a better time to explore the possibilities of scale model making. Stay tuned to our blog for more insights and updates on the latest trends and technologies in the field.

0 notes

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

A little something new for our waterfront.

0 notes

Text

The Growing Demand for Engineering Model Makers & The Benefits of Using Scale-Down Model Makers in India

Global advancement in technology and the industrial revolution opened a gate for innovation that has brought demand for engineering model makers in India for various sectors. With a combination of technical advancements, knowledge in engineering, craftsmanship, and innovative thinking turning it into a newer business model.

What is the use of Engineering models?

Prototype design plays a vital role in transforming conceptual engineering into a tangible simulation model. Model making is the art of creating a scaled or miniature model of a product or a structure, that guides the engineers to visibly analyze the functionality and aesthetics of the outcome, before moving into the production or construction phase. The detailed model is the combination of both manual and digital techniques that helps the designers to visualize the product outcome after validation, testing, and evolution. A perfect model simulation completes 10% work of the overall project.

Engineering model makers are greatly needed in industries like manufacturing, architecture, automobile, robotics, Aerospace, real estate, and product designing and they may vary depending on a specific product or industry.

Model makers work along with project developers and engineers looking into project drawings, blueprints, and development platforms that help them in creating a better model by using appropriate materials like plastic, wood or metal, PVC, and acrylic boards, to meet requirements.

How are the scale down models are developed?

Scale-down models are the smaller replicas of a product or a structure. These model makers are professionally skilled in creating accurate miniature models, maintaining their actual prepositions without missing their essential features. Scale-down models are widely used for demonstration, education, and display purpose.

Benefits of using scale-down model makers

India is the fastest-growing economy in the sector of engineering, manufacturing, industries, architecture, design, and real estate that needs scale-down model makers to serve them. They design scale-down prototypes for visualization, validation, and testing of the product or a structure which helps the company to better understand the product before production.

Using scale-down model makers across various industrial sectors benefits the product or business through various aspects:

Cost effectiveness: Indian scale-down model makers offer better services when compared to international prototype-making through available resources within the country, which adds an advantage for small-scale companies with budget limitations.

Accessibility and time saving: These scale-down prototype makers are easily accessible by the clients for collaboration and communication for a better understanding of the project and its requirements. They also deliver project models on time with required modifications and changes.

Skilled workforce: India has a large scale of skilled craftsmen and artists who can create excellent models through their expertise in working with a variety of materials like wood, metal, plastics, PVC, acrylic boards, and other forms of resources in making high-quality prototype competing with international standards.

Cultural Diversity: Our rich cultural heritage and spiritual beliefs that strictly reflects in our architectural design which adds more cultural value to the structures. Scale-down model makers in India are highly qualified in making traditional and holistic design models to meet requirements.

Conclusion:

Having skilled engineering model makers in India offers numerous advantages in terms of design evaluation, cost constraints, and project visualization which will help the client for selecting a better one for their kind of business.

0 notes

Text

🏠 Tiny homes, big dreams! Our expert-crafted scale models make every architectural detail come alive—because perfection is in the details. ✨

Got a project? Let’s talk! 📩

#ArchitectureLovers #ScaleModels #MiniatureWorld #RealEstateDesign #CreativeCraftsmanship

#art#craft#miniature model#architectural model#marine model#scalemodel#scale model#engineering model#model makers#model making

1 note

·

View note