#fused deposition modeling

Text

#custom 3d printing near me#custom 3d printing services#custom 3d printing#3d print service near me#3d printing companies near me#3d printing cost#online 3d printing#3d printing online services#3d print vase#fused deposition modeling#3d printer service near me#large 3d printing services#sls 3d printing service#fused deposition modeling 3d printer#large industrial 3d printer#rapid prototyping 3d printing#3d scanning services cost#3d scale model maker#High resolution 3d scanning#Industrial 3d scanning#Reverse engineering services#Rapid Prototyping#Scale modeling#3d printing services#large 3d printing#best 3d printing service#large format 3d printing#3d model printing service#sls printing service#large scale 3d printing service

0 notes

Text

What on earth is 3D printing?

That's... a big one. Sorry in advance. It also gets a little technical. Folx, if you want to chime in in the notes what we forgot or missed, have at it, just be polite. Discussion is great. Being a jerk is not.

So you know that we sell 3D print planters (and some other stuff coming out soon), but we saw a lot of comments in our first post introducing ourselves that were curious about what 3D printing was, if it was resin printing, and how it worked.

We also didn't realize our ask box wasn't turned on until we saw a note after the post was up for several hours. Sorry! It's open now if you have questions or comments or whatever. Just be polite.

Well. We are not experts. We're going to share our own experience and understanding of what 3D printing is, most common methods, and why we do the kind of 3D printing we do.

So.

What is 3D printing?

In its all-encompassing definition, 3D printing (also called additive manufacturing if you want to get STEM-y about it) is basically creating a 3D object using a digital 3D model. The programs engineers use, like Fusion360, AutoCAD, FreeCAD, and others? Yeah. Those. Exactly.

If you're an artist, don't despair, you can create models in Blender (or whatever 3D modeler you use) and work with those for 3D printing.

If you're us, who only started modeling a few months ago, you use the program geared for children and young adults, and that's TinkerCAD. There's nothing wrong with it, it's just limited in what it can do compared to other programs. The massive benefit is it's free and the learning curve is also much more gentle than the sheer cliff we ran face-first into trying to learn the CAD programs or Blender.

If anyone has good sources to learn them (esp with Blender's new updates) we would be happy to try them. Because as much as we love 3D printing, modeling still gives us a headache.

So that's the most basic definition of 3D printing.

So, what's the most COMMON form of 3D printing?

Well, we'd say there are two:

Resin printing. There's several different methods, but the most common today still is SLA, or stereolithography. Basically, a UV laser marks a cross-section of part of an object on a layer of liquid resin. When it's exposed to the UV light it's cured and solidifies. Another layer of resin is put down, the laser process is repeated, and it continues until an object is made. What's nice about it is it lets you get high detail in very small objects, like minis for Warhammer or other games. There's also Digital Light Processing (DLP), which is like SLA but uses digital projection to expose more parts of resin to light. It can cure an entire layer at once, instead of only part. If you see a Warhammer figurine being sold, or any miniature, especially stuff for DnD or other tabletop games, it's probably resin printed.

FDM (fused deposition modeling). It's also known as FFF, or fused filament fabrication). This is what you probably think of for 3D printers if you ever saw one, where things are printed in one tiny layer at a time where a heated print head is pushing out filament in layers on a build plate. FDM is more common for practical prints, like car parts or manufacturing pieces. To us it reminds us of icing a cake. You can print with stuff like carbon fiber and nylons or flexible material like TPU. FDM is good for prototyping and larger objects, like our planters (last product plug, we swear) to. You know.

Houses.

We use FDM printing.

Why?

Most everything we're going to make doesn't need the detail that a resin printer provides. The smallest, jewelry, still isn't to the level where we'd need a resin printer -- FDM printers work in fractions of milimeters, and resin printers can go even smaller. That's not necessary for us.

Everything we make is going to be larger prints, which means more material. Filament (which we'll explain in another post) costs less than resin.

Resin is more toxic than PLA filament, which is what we use. We can handle PLA filament spools without gloves or protective goggles. Resin? Absolutely not. They ARE making plant-based resin which is less irritating, but we have no experience with it. If you do, chime in in the comments.

Resin involves cure time. You also have to wash your print after. That can add to the process time too.

So that's the extreme basics of what 3D printing is, the two most common types, and why we do FDM printing. We hope you found it helpful! We're going to try to make this a series to explain more about 3D printing in general so it's less mysterious for non-printers. What do you want us to talk about next? Let us know! Like...what different materials you can print with? What are they made of? Maybe some example pictures with different finishes? Would that be interesting? We'd love to hear from you. And we look forward to seeing the comments in the notes/tags! We couldn't go as in-depth as we wanted without turning it into a novel, so have at it in the notes. We can't wait to follow the discussion!

We're Planterful Pieces, a small business focused on offering made-to-print products that cater to the planty people of the world, whether that means you OWN plants or simply just LOVE nature. We also want to share with you all cool designs that aren't easily accessible to people who DON'T 3D print, and there's a LOT!

If you're not interested in our planters but ARE interested in future products, like our upcoming art collection, jewelry, and more, subscribe to our email newsletter on our website here (you'll have to scroll down a little). We promise we'll only email you once a month with sneak peeks, product updates, deals, or if there's an upcoming launch. Frankly, we don't have time to spam you with emails, since we'd rather be designing and printing.

Instagram

TikTok (We're bad at this but will be working on it)

Facebook

Thanks for reading!

(PS: We haven't forgotten about those interested in international shipping! If you sign up on the newsletter we can let you know as soon as it's available! We'll make posts here of course and our other socials but that's always hit or miss. This way it goes right in your inbox.)

#3d#3d printing#garden#planters#plants#shop small#small business#tech#technology#houseplant#hopefully this is interesting?#I find my writing on a computer versus mobile I have different tones#so depending on how this one goes versus my first#i might use one or the other#house plants#houseplants#warhammer#resin printing#resin#houses#3d print house#3d print construction#miniatures#minis#decor#home decor#FDM printing#SLA printing#crown#diamond

12 notes

·

View notes

Text

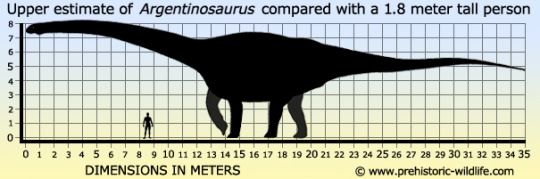

Argentinosaurus huinculensis

(temporal range: 96.2-92.19 mio. years ago)

[text from the Wikipedia article, see also link above]

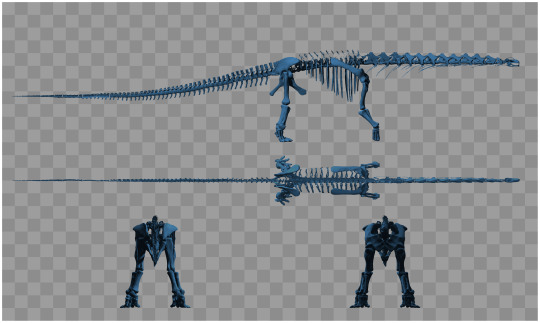

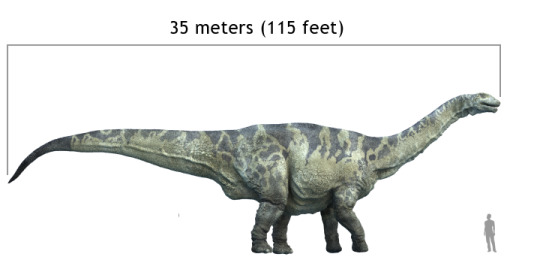

Argentinosaurus is a genus of giant sauropod dinosaur that lived during the Late Cretaceous period in what is now Argentina. Although it is only known from fragmentary remains, Argentinosaurus is one of the largest known land animals of all time, perhaps the largest, measuring 30–35 metres (98–115 ft) long and weighing 65–80 tonnes (72–88 short tons). It was a member of Titanosauria, the dominant group of sauropods during the Cretaceous. It is widely regarded by many paleontologists as the biggest dinosaur ever, and perhaps lengthwise the longest animal ever, though both claims have no concrete evidence yet.

The first Argentinosaurus bone was discovered in 1987 by a farmer on his farm near the city of Plaza Huincul. A scientific excavation of the site led by the Argentine palaeontologist José Bonaparte was conducted in 1989, yielding several back vertebrae and parts of a sacrum—fused vertebrae between the back and tail vertebrae. Additional specimens include a complete femur (thigh bone) and the shaft of another. Argentinosaurus was named by Bonaparte and the Argentine palaeontologist Rodolfo Coria in 1993; the genus contains a single species, A. huinculensis. The generic name Argentinosaurus means "Argentine lizard", and the specific name huinculensis refers to its place of discovery, Plaza Huincul.

The fragmentary nature of Argentinosaurus remains makes their interpretation difficult. Arguments revolve around the position of the recovered vertebrae within the vertebral column and the presence of accessory articulations between the vertebrae that would have strengthened the spine. A computer model of the skeleton and muscles estimated this dinosaur had a maximum speed of 7 km/h (5 mph) with a pace, a gait where the fore and hind limb of the same side of the body move simultaneously. The fossils of Argentinosaurus were recovered from the Huincul Formation, which was deposited in the middle Cenomanian to early Turonian ages (about 96 to 92 million years ago) and contains a diverse dinosaur fauna including the giant theropod Mapusaurus.

6 notes

·

View notes

Text

FTM and FDM are also things I accidentally mix up when talking.

Yeah, I'm a fused deposition modeling transgender, and I love operating my female to male machine.

4 notes

·

View notes

Text

POLY CONDENSED FUSED-POLYNUCLEAR AROMATICS

IMPUL PCF BRAKE PAD

New concept of braking power

IMPUL PCF BRAKE PAD is a breakthrough new concept brake pad that uses a new material called PCF. has overturned the conventional concept of pads using asbestos and metals. Eliminates the lack of efficacy in low temperature ranges, which is common in conventional sports pads, and achieves stable and extremely high braking power in a wide temperature range. In addition, it suppresses squealing and dirt on the wheel due to pad shavings, and has dramatically improved durability compared to asbestos pads. IMPUL PCF BRAKE PAD with many other new performances. It demonstrates its true value as a strong ally for high safety on the street and sporty driving.

*Poly Condensed Fused-polynuclear Aromatics

Features Uses PCF, a new material that is neither metal nor asbestos Reduced squeal Low rotor aggression that makes the wheel less likely to get dirty Dramatically improved durability compared to conventional asbestos materials Constant resistance to temperature changes Ensures stable effectiveness Fade point is set high for hard use Extremely high braking performance High control performance

Applicable models Cedric Gloria Cima Y31, Y32 Cedric Gloria Y32 Infiniti Q45 Fairlady Z32 Skyline GTR R32 Price For each model Front 30,000 yen Rear 29,000 yen (with aluminum case)

Garage IMPUL

GARAGE IMPUL, MITAKA SHOWROOM, MITAKA DEPOSIT 6-1-7 SHIMORENJAKU, MITAKA-SHI, TOKYO, 181, JAPAN TEL.0422-49-6484 HEAD OFFICE, SHOWROOM 5-32-3 SAKURAGAOKA, SE TAGAYA KU TOKYO, 156, JAPAN TEL 03-3439-1122

4 notes

·

View notes

Text

Technologies revolutionizing 3D Dental sector

Additive manufacturing has reached a significant number of sectors and industries, subsequently offering important advantages in terms of productivity, costs, customization and lead times. In the field of dentistry the technology creates solutions adapted to the needs of each patient. It is also a flourishing industry, not too long ago the consulting firm QY Research announced that dental 3D printing was expected to reach $930 million by the end of 2025. In other words, the market is expected to grow at an annual rate of 17%, which can be explained by the constant development of 3D technologies and their materials. Indeed, dental 3D printing includes different processes such as stereolithography or direct metal sintering and therefore a variety of materials: resins, plastics, metals, etc. The application of 3D printing in dental is wide, it is possible to make surgical guides, crowns, trays and dentures and each solution is adapted to each patient with high precision.

We also find metal additive manufacturing as a process in dentistry. Mainly used to produce implants, stellites, or nickel-chromium screeds. Oliver Bellaton comments, “This technology requires sustained production to absorb investments of up to several hundred thousand euros with skills coming from the industrial world rather than the dental sector.” Metal printers are much more expensive than other technologies and will sometimes require more post-processing work reducing productivity for some. After talking with a dental technician, he explained that a crown made by machining requires 15 minutes of work, however a 3D printed metal one requires 5 hours of printing. On the other hand, in terms of cost per unit, additive manufacturing is much more interesting, 75 cents for the latter against more than 7 euros.

Dental 3D Printing Technologies and their Materials

When we talk about dental additive manufacturing, it is important to understand that several technologies are involved, whether it is fused deposition modeling, photopolymerisation or laser sintering, the choice will depend on the type of application at stake. For example, the FDM process will manufacture pieces “at a cost of a couple of pennies and no post-processing after printing. However, speed, accuracy and biocompatibility are not present.” Generally, the latter technology will be used to create orthodontic dental models for thermoform gutters, whether for alignment, bleaching or restraint. On the other hand, 3D printed dental solutions using PEEK are emerging. The 3D printer manufacturer, IEMAI3D said, “There are many advantages to making partial prostheses with PEEK. It is a strong and lightweight material that will improve patient comfort. The frame of the prosthesis is produced without metal and is completely neutral in terms of taste.”

Another additive manufacturing process used in the dental sector and probably the main one is photopolymerisation. Whether we are talking about stereolithography (SLA) or DLP, this process offers a much higher resolution, and most importantly biocompatible materials. In this case, liquid resins. Anton Lopez, Channel Sales Manager France at EnvisionTEC told us, “Combined with CE/FDA approved materials, photopolymerisation and especially DLP, gives more accurate printing which allows more accurate devices to be created. The finishing is much less complex, which reduces manufacturing time. Also, it is very easy to change materials and print for different applications. This is very beneficial for the dental industry because professionals can treat their patients more quickly”. In terms of applications, this technology offers more possibilities due to its precision; we are talking about surgical guides, temporary crowns and bridges, calcinable elements such as dental stellites, etc.

For more details on our products and services, please feel free to visit us at: Clear retainer package Idaho, dental 3d printing Idaho, digital bracket removal, dental 3d printer & orthodontic lab.

Please feel free to visit us at: https://www.3ddentalprints.com/

2 notes

·

View notes

Text

The Revolution Of 3D-Printed Batteries: Pioneering The Future Of Energy Storage

In recent years, 3D printing technology has surged to the forefront of innovation, revolutionizing various industries from healthcare to aerospace. One of the most groundbreaking applications of this technology is in the development of 3D-printed batteries. These batteries promise to transform energy storage by offering enhanced design flexibility, improved performance, and the potential for customizability. 3D-printed batteries explores the world of batteries, delving into their fabrication, advantages, current applications, and future prospects.

The Fabrication Process:

The fabrication of 3D-printed batteries involves using additive manufacturing techniques to layer materials in precise geometries, creating intricate battery architectures. This process typically includes the following steps:

Design and Modeling: The first step involves designing the battery’s structure using computer-aided design (CAD) software. Engineers can optimize the shape and size to enhance performance characteristics such as energy density and thermal management.

Material Selection: Suitable materials for the anode, cathode, electrolyte, and current collectors are selected. Common materials include lithium-based compounds for lithium-ion batteries while emerging materials like graphene and nanomaterials are also being explored for their superior properties.

Printing Process: Various 3D printing technologies, such as fused deposition modeling (FDM), stereolithography (SLA), and direct ink writing (DIW), are employed to print the battery components layer by layer. Each technology offers distinct advantages in terms of precision, material compatibility, and production speed.

Testing and Optimization: The fabricated battery undergoes rigorous testing to evaluate its performance metrics, such as capacity, energy density, cycle life, and thermal stability. Based on the results, the design and fabrication processes can be refined to achieve optimal performance.

Advantages of 3D-Printed Batteries:

Printed batteries offer several significant advantages over traditional manufacturing methods:

Design Flexibility: Traditional battery manufacturing is limited by the constraints of conventional fabrication techniques. 3D printing allows for the creation of complex geometries and custom designs, enabling batteries to be tailored to specific applications and form factors.

Enhanced Performance: By optimizing the internal architecture of the battery, 3D printing can improve energy density, power density, and thermal management. This leads to batteries that are more efficient, have longer cycle lives, and perform better under various conditions.

Material Efficiency: Additive manufacturing is inherently a material-efficient process, as it builds components layer by layer, minimizing waste. This not only reduces material costs but also supports sustainable manufacturing practices.

Rapid Prototyping and Production: 3D printing enables rapid prototyping, allowing researchers and engineers to quickly iterate and test new battery designs. This accelerates the development cycle and brings innovative battery technologies to market faster.

Customization and Integration: Batteries can be customized to fit specific devices or integrated directly into products during the manufacturing process. This is particularly advantageous for applications requiring non-standard battery shapes or integrated energy storage solutions.

Current Applications:

The unique advantages of 3D-printed batteries make them suitable for a wide range of applications across various industries:

Consumer Electronics: The miniaturization and customization capabilities of printed batteries are ideal for consumer electronics, where space is at a premium, and devices require high energy density and long battery life. Examples include smartphones, wearable devices, and portable gadgets.

Medical Devices: In the medical field, 3D-printed batteries can be designed to fit the specific requirements of implantable devices, such as pacemakers and neurostimulators. Their ability to conform to unique shapes and provide reliable power is crucial for patient safety and device performance.

Aerospace and Defense: In aerospace and defense applications, where weight and reliability are critical, 3D-printed batteries offer significant advantages. They can be integrated into the structure of drones, satellites, and other equipment, providing efficient and lightweight energy solutions.

Renewable Energy Storage: Batteries are being investigated for use in renewable energy storage systems, such as solar panels and wind turbines. Their ability to store and deliver energy efficiently is essential for maximizing the output of renewable energy sources.

Future Prospects:

The future of printed batteries holds immense promise, driven by ongoing advancements in materials science, printing technologies, and design methodologies. Some key trends and future directions include:

Multi-Material Printing: The integration of multiple materials in a single printing process allows for the creation of multifunctional batteries with improved performance characteristics. This approach can lead to batteries that combine high energy density with flexibility and robustness.

Scaling Up Production: Efforts are underway to scale up the production of printed batteries for commercial applications. This involves optimizing printing processes for mass production, reducing costs, and ensuring consistent quality and performance.

Hybrid Energy Storage Systems: Combining printed batteries with other energy storage technologies, such as supercapacitors and fuel cells, can create hybrid systems that offer enhanced energy storage and delivery capabilities. These systems are particularly promising for applications requiring both high power and long-duration energy supply.

Integration with IoT and Smart Devices: The Internet of Things (IoT) and smart devices are driving the demand for compact, efficient, and customizable energy storage solutions. 3D-printed batteries can be seamlessly integrated into these devices, enabling new functionalities and improving overall performance.

Conclusion:

3D printed batteries represent a transformative innovation in the field of energy storage, offering unparalleled design flexibility, enhanced performance, and the potential for rapid prototyping and customization. As the technology continues to evolve, 3D-printed batteries are poised to revolutionize a wide range of industries, from consumer electronics and medical devices to electric vehicles and renewable energy storage. With ongoing advancements in materials, printing technologies, and integration methods, the future of 3D-printed batteries holds immense promise, paving the way for a new era of energy storage solutions tailored to the demands of modern technology and sustainable development.

0 notes

Text

ACLE 2024: Illustration of Folktales at 3D Printing, tinuro online

Tenshi Bedico, Arwen Chanliongco, at Rima Millora

Mayo 30, 2024

Kabilang sa mga itinurong paksa ang Illustration of Folktales at 3D Printing sa ACLE 2024 o Alternative Classroom Learning Experience, pinamamagatang BUKAL, na isinagawa noong Mayo 7, 2024 sa Zoom.

Pinamunuan nina Billy John T. Adonis at Eduardo DC. Bustamante ng Folklore Pilipinas ang Illustration of Folktales, habang pinamunuan ni Voltaire Gaviola ng Makerlab Electronics at 3D Printing Community of the Philippines ang klase para sa 3D Printing.

Nagpakita ang parehong paksa ng paliwanag ng kani-kanilang mga paksa gamit ang presentation slides at demonstrasyon ng mismong mga proseso.

Pinamunuan ng mga miyembro ng Sangguniang Pangwika ang pagho-host at pagpapakilala ng mga guro sa Illustration of Folktales.

Nagpakita sina Sir Adonis at Sir Bustamante ng halimbawa ng mga animation, tulad ng “Datu Pat I Mata﹕ Tudtudlan atag sa Pulangi”, isang proyekto ng Folklore Pilipinas tungkol sa folklore mula sa Maguindanao, na gumagamit ng digital at tradisyonal na sining upang bumuo ng maikling pelikula.

Animasyon ng aso gamit ang pintura sa Illustration of Folktales noong Mayo 7, 2024 sa Zoom (Kuha ni Rima Millora)

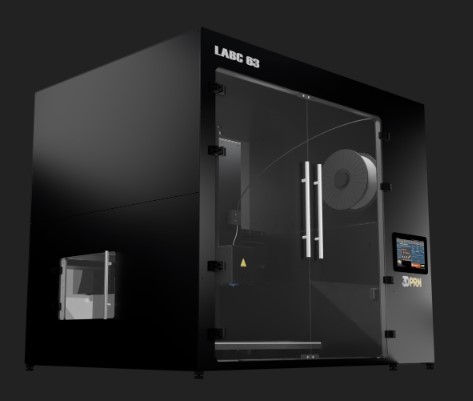

Ipinaliwanag ni Sir Gaviola ang maikling kasaysayan at mga benepisyo ng 3D printing. Maraming uri ng 3D printers sa merkado, ngunit fused deposition modeling (FDM) ang karaniwang ginagamit, at ito ang ipinakita niya sa mga estudyante. Natuklasan ng mga mag-aaral ang proseso sa 3D printing at ang iba’t ibang mga bahagi ng printer. Tinuro rin ni Sir Gaviola kung paano gamitin ang mga aplikasyon para sa 3D printing tulad ng Creality Print.

Ang ELEGOO 3D printer, isa sa mga printer na ipinakita ni Voltaire Gaviola noong Mayo 7, 2024 sa Zoom. (Kuha ni Arwen Chanliongco)

Ginanap online ang BUKAL﹕Buksan ang Kaalaman matapos ang ilang pagbabago sa UPIS Days bunsod ng init ng panahon. Bago maging mapanganib ang heat index, Abril 17 ang orihinal na petsa nito.

Sa paglipat sa remote, nabawasan ang mga klaseng maaaring kuhanin ng mga estudyante — noong una, dapat 28 ang mga paksa ngunit nakaltasan ito sa 18 sapagkat hindi lahat ng tagapagsalita ay maaaring makadalo sa bagong iskedyul.

Kabilang ang Illustration of Folktales at 3D Printing sa mga paksa na hindi napalitan sa kabila ng biglaang online setup.

Upang maatasan lahat ng mag-aaral sa isang klase, kinailangang ilipat ang ilan. Ayon kay Kate Papa, ang nag-organisa ng ACLE at Tagapamayapa ng Pamunuan ng Kamag-aral (PKA), “isa ito sa mga naging problema ng council dahil nagkaroon ng hindi pagkakaintindihan ukol sa paglipat ng mga estudyante.”

Sa kabila nito, mabilis na tumugon ang mga guro ng iba’t ibang departamento. “Maganda ang kooperasyon ng mga homeroom advisers,” pahayag niya.

Naniniwala rin si Papa na matagumpay ang ACLE ngayong taon sa kabila ng maraming pagbabago. “Nangyari lamang ito dahil sa kooperasyon ng lahat,” dagdag niya.

0 notes

Photo

The LaFigures Digimon Izzy and Tentomon 3D model beautifully captures the beloved characters from the popular Digimon series. This detailed model showcases Izzy, the tech-savvy DigiDestined, alongside his loyal Digimon partner, Tentomon. Designed for both FDM (Fused Deposition Modeling) and SLA (St... https://freestl.3d-fx.net/2024/05/28/lafigures-digimon-izzy-and-tentomon/?feed_id=1896&_unique_id=665622428f423

0 notes

Text

Innovative Uses of 3D Printing Applications in 2024

3D Printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. It has gained immense popularity in recent years due to its ability to create complex shapes and structures that were once impossible to manufacture. This article will provide an overview of 3D Printing, its importance in various industries, and its applications. Additionally, the article will focus on the 3D Printing services available in India.

What is 3D Printing or Additive Manufacturing?

Additive manufacturing is a process of creating a physical object from a digital model by adding layers of material on top of each other. The process involves slicing the digital model into multiple layers and then printing each layer one by one until the object is complete. The types of 3D Printing techniques include Fused Deposition Modeling (FDM), Stereo lithography (SLA), and Selective Laser Sintering (SLS). The materials used in 3D Printing include plastic, metal, ceramics, and even food.

The benefits of additive manufacturing include the ability to create complex shapes and structures, reduce waste, and decrease the time and cost of production. However, the drawbacks of Additive manufacturing include limited material options, the need for post-processing, and the potential for copyright infringement.

Importance of Additive manufacturing

3D Printing has significant importance in various industries such as healthcare, manufacturing, and aerospace. In healthcare, It is used to create customized medical implants, prosthetics, and surgical instruments. In manufacturing, It is used for rapid prototyping and product development. In aerospace, 3D Printing is used to create lightweight and complex parts for aircraft.

Moreover, 3D Printing has a positive impact on the economy and the environment. It reduces the cost and time of production, increases customization, and decreases waste. Additionally, reduces the carbon footprint of manufacturing by decreasing transportation and material waste.

Applications of 3D Printing

The applications of 3D Printing the applications of Additive manufacturing are vast and varied. In product development, It is used for rapid prototyping, allowing designers to quickly create and test new products. In architecture, 3D Printing is used to create scale models of buildings and structures. In fashion, It is used to create unique and customized clothing and accessories.

In healthcare, 3D Printing is used for creating customized prosthetics, dental implants, and surgical instruments. In education, 3D Printing is used to teach engineering and design concepts. In art, 3D Printing is used to create sculptures and other forms of artwork.

The potential of Additive manufacturing in the future is enormous. It has the potential to revolutionize manufacturing, reduce waste, and increase customization. Moreover, 3D Printing has the potential to create new industries and new jobs.

Advantage of Additive Manufacturing

3D printing technology has several advantages over traditional manufacturing methods.

According to TWI Global, some of the benefits of 3D printing technology include:

Flexible design: Allows for the design and print of more complex designs than traditional manufacturing processes.

Faster production: Quicker than conventional manufacturing, including injection molds and subtractive production.

Reduced waste: Generates less waste than traditional manufacturing methods.

Cost-effective: Cost-effective for low-volume production runs, and it eliminates the need for expensive tooling used in traditional manufacturing processes.

Customization:Allows for customization of parts and products, which is not possible with traditional manufacturing methods.

3D Printing Services in India

There are several 3D Printing services available in India. These services offer a range of materials, colors, and finishes. The pricing of these services varies depending on the complexity of the object, the material used, and the delivery time.

Some of the popular 3D Printing services in India include 3Dexter, Fracktal Works, and think3D. These services offer a range of materials, including plastic, metal, and ceramics. They also offer a range of delivery options, including home delivery and pickup.

Various industries use additive manufacturing technology. According to the 3D Printing Industry, some of the industries that use these technologies include:

Aerospace and defense

Architecture and construction

Automotive

Dental and medical

Education

Fashion

Jewelry

Manufacturing

Product design

Research and development

Best websites to learn about 3D printing

There are several websites available for learning about 3D printing. Here are some of the best websites to learn about 3D printing:

Tinkercad: Tinkercad is a free web-based 3D design and modeling tool that is easy to use and perfect for beginners. It offers a range of tutorials and projects to help users learn the basics of 3D printing.

Instructables: Instructables is a website that offers step-by-step instructions on how to build and make things. It has a dedicated section for 3D printing and offers a range of tutorials on how to design, print, and finish 3D printed objects.

Make: Make is a website that offers tutorials, projects, and news related to 3D printing and other DIY projects. It has a dedicated section for 3D printing that covers everything from design to post-processing.

3D Printing Industry: 3D Printing Industry is a news website that covers the latest developments and trends in the 3D printing industry. It offers a range of articles, reviews, and tutorials that are useful for both beginners and experts in the field.

Simplify3D: Simplify3D is a website that offers software for 3D printing. It has a dedicated section for learning about 3D printing that covers everything from the basics of 3D printing to advanced techniques.

These websites provide a wealth of information for anyone looking to learn about 3D printing, from beginners to experts.

Conclusion

In conclusion, 3D Printing is a revolutionary technology that has significant importance in various industries. It has the potential to change the way we manufacture, reduce waste, and increase customization. Additionally, 3D Printing services are available in India, providing a range of materials, colors, and finishes. As 3D Printing technology continues to evolve, it will create new opportunities and new industries.

Sources:

https://www.tinkercad.com/

https://www.instructables.com/

https://makezine.com/

https://3dprintingindustry.com/

https://www.simplify3d.com/

#3dprinting#mold manufacturing#compression molding#3d printing services#3d printing for plastic#product 3d printing

0 notes

Text

Transforming Ideas into Reality: The Impact of 3D Printers

In the ever-evolving landscape of technology, few innovations have captured the imagination and practical applications of both individuals and industries as profoundly as 3D printing. This transformative technology, which allows for the creation of three-dimensional objects from digital designs, has not only revolutionized manufacturing but also redefined creativity, prototyping, and production across various sectors. This blog delves into the multifaceted impact of 3D printing, exploring its history, technological advancements, applications, and the future it heralds.

The Genesis of 3D Printing: A Brief History

The concept of 3D printing, also known as additive manufacturing, dates back to the 1980s. Dr. Hideo Kodama of the Nagoya Municipal Industrial Research Institute is credited with the first attempt to develop a rapid prototyping system. However, it was Charles Hull who invented stereolithography (SLA) in 1984, laying the groundwork for modern 3D printing. Hull’s invention involved using ultraviolet light to cure photopolymer resin layer by layer, creating solid objects from digital models.

In 1986, Hull founded 3D Systems, a company that remains a leader in the 3D printing industry. The development of fused deposition modeling (FDM) by Scott Crump in 1988 further advanced the field, making it more accessible and versatile. Over the decades, 3D printing technology has evolved from a niche tool for rapid prototyping to a versatile solution employed in various industries, including healthcare, aerospace, automotive, fashion, and construction.

Technological Advancements in 3D Printing

3D printing technology has undergone significant advancements, leading to improvements in speed, precision, and material diversity. Here are some key technological breakthroughs:

1. Materials and Composites

Early 3D printers were limited to plastics, but today, a wide array of materials can be used, including metals, ceramics, resins, and even biological materials. This diversity enables the production of complex and functional parts for various applications. For example, metal 3D printing, or direct metal laser sintering (DMLS), allows for the creation of strong, lightweight components used in aerospace and automotive industries. Visit the following site:

2. Speed and Efficiency

Advancements in printing speed and efficiency have made 3D printing more viable for mass production. Technologies like Continuous Liquid Interface Production (CLIP) and Multi Jet Fusion (MJF) offer faster print times and higher resolution, reducing the time from design to finished product.

3. Precision and Detail

Improved precision and layer resolution have expanded the possibilities for 3D printing. High-resolution printers can produce intricate details and fine features, making them suitable for applications in jewelry, dental implants, and custom prosthetics.

4. Software and Design Tools

The evolution of CAD (Computer-Aided Design) software and design tools has streamlined the process of creating and modifying digital models. Advanced software allows for complex simulations, stress testing, and optimization, ensuring that the printed objects meet exact specifications.

Applications of 3D Printing

The versatility of 3D printing has led to its adoption across a wide range of industries. Here are some notable applications:

1. Healthcare and Medicine

3D printing has made significant inroads in the medical field, transforming patient care and treatment options.

Prosthetics and Orthotics: Customized prosthetic limbs and orthotic devices can be tailored to individual patients, improving fit and functionality. This personalization enhances comfort and usability, leading to better patient outcomes.

Surgical Models and Implants: Surgeons can use 3D-printed models of patients’ anatomy to plan complex surgeries, reducing risks and improving precision. Additionally, 3D-printed implants and bone grafts can be created to match the exact specifications of the patient’s body.

Bioprinting: The future of 3D printing in medicine lies in bioprinting, where living cells are printed to create tissues and organs. While still in the experimental stage, this technology holds the promise of revolutionizing organ transplants and regenerative medicine.

2. Aerospace and Automotive

The aerospace and automotive industries have embraced 3D printing for its ability to produce lightweight, durable, and complex parts.

Lightweight Components: 3D printing allows for the creation of parts with complex geometries that are both strong and lightweight. This is particularly valuable in aerospace, where reducing weight can lead to significant fuel savings.

Rapid Prototyping: 3D printing enables rapid prototyping, allowing engineers to quickly iterate on designs and test new concepts. This accelerates the development process and reduces costs associated with traditional manufacturing.

3. Fashion and Jewelry

In the world of fashion and jewelry, 3D printing has opened up new avenues for creativity and customization.

Custom Jewelry: Designers can create intricate and personalized jewelry pieces that would be impossible or prohibitively expensive to produce using traditional methods.

Fashion Innovation: 3D printing allows designers to experiment with new materials and structures, leading to innovative and avant-garde fashion pieces. The ability to print on demand also reduces waste and supports sustainable fashion practices.

4. Construction

3D printing is poised to revolutionize the construction industry by enabling the rapid and cost-effective production of building components.

Printed Homes: 3D-printed homes and structures are becoming a reality, offering a solution to housing shortages and providing affordable, sustainable housing options. Companies are exploring the use of concrete and other materials to print entire houses on-site.

Architectural Models: Architects can use 3D printing to create detailed scale models of their designs, allowing for better visualization and communication with clients.

5. Education and Research

3D printing is a powerful tool in education and research, providing hands-on learning experiences and enabling advanced research projects.

STEM Education: Schools and universities use 3D printers to teach students about engineering, design, and manufacturing. This hands-on experience fosters creativity and innovation among students.

Research and Development: Researchers use 3D printing to develop prototypes and conduct experiments in fields ranging from materials science to biotechnology.

The Future of 3D Printing

The future of 3D printing is brimming with possibilities, driven by ongoing advancements and expanding applications. Here are some trends and potential developments:

1. Mass Customization

As 3D printing technology continues to improve, it will enable mass customization on a scale previously unimaginable. Consumers will be able to order products tailored to their exact specifications, from clothing and footwear to electronics and furniture.

2. Sustainable Manufacturing

3D printing has the potential to make manufacturing more sustainable by reducing waste and minimizing the need for transportation. On-demand production can reduce excess inventory, and the ability to recycle and reuse materials will contribute to a circular economy.

3. Medical Breakthroughs

The future of bioprinting holds the promise of creating functional tissues and organs for transplantation. Advances in this field could address the shortage of donor organs and revolutionize regenerative medicine.

4. Space Exploration

NASA and other space agencies are exploring the use of 3D printing for space exploration. The ability to print tools, spare parts, and even habitats on-site in space or on other planets could reduce the need for costly and logistically challenging resupply missions.

5. Integration with Other Technologies

The integration of 3D printing with other technologies such as artificial intelligence, robotics, and the Internet of Things (IoT) will open up new possibilities. For example, AI algorithms can optimize designs for 3D printing, while IoT devices can monitor and control the printing process in real-time.

Challenges and Considerations

While 3D printing offers numerous advantages, it also presents challenges that need to be addressed:

1. Material Limitations

Despite the advancements in material diversity, there are still limitations in terms of strength, durability, and performance. Continued research is needed to develop new materials that meet the demands of various applications.

2. Quality Control

Ensuring consistent quality and reliability in 3D-printed products can be challenging. Variability in printing conditions and materials can lead to defects and inconsistencies. Standardization and quality control measures are essential to address these issues.

3. Intellectual Property and Legal Issues

The ability to easily replicate designs raises concerns about intellectual property theft and copyright infringement. Clear legal frameworks and protections are needed to safeguard the rights of designers and manufacturers.

4. Cost and Accessibility

While the cost of 3D printers has decreased, high-quality printers and materials can still be expensive. Making 3D printing more accessible to individuals and small businesses will require further cost reductions and support.

Conclusion

3D printing is a transformative technology that is reshaping industries and unleashing creativity in ways previously unimaginable. From healthcare and aerospace to fashion and construction, its applications are diverse and far-reaching. As the technology continues to evolve, it promises to bring even more innovations and opportunities, transforming ideas into reality with unprecedented speed and precision.

The journey of 3D printing from its inception to its current state is a testament to human ingenuity and the relentless pursuit of progress. As we look to the future, it is clear that 3D printing will play a pivotal role in shaping the world, making it a technology worth watching and investing in. Whether you are a designer, engineer, entrepreneur, or enthusiast, the impact of 3D printing is undeniable, offering a glimpse into a future where the only limit is our imagination.

#3D_printers_Elegoo#Buy_3D_printer_in_Moscow#Photopolymer_3D_printer#FDM_3D_printer#Printers_Elegoo_Mars#Neptune#Saturn#Accessories_for_3D_printer

0 notes

Text

Best 3D Printer in Dubai, UAE – Inoventive 3D

3D Printer Dubai - Inoventive 3D, known for its best 3D Printing services is the largest 3D Printing company in Middle East and Africa.

Inoventive 3D: Leading the 3D Printing Revolution in Dubai

In the bustling metropolis of Dubai, where innovation meets luxury and futuristic design is a hallmark, finding a reliable and cutting-edge 3D printing service is crucial. Inoventive 3D stands out as the premier 3D printing service provider in the region, setting new standards in the industry with its state-of-the-art technology, exceptional customer service, and a wide range of applications.

Unmatched Technological Prowess

Inoventive 3D is at the forefront of the 3D printing revolution in Dubai, offering an array of advanced 3D printing technologies that cater to various industries. Whether it’s for architectural models, automotive parts, medical devices, or bespoke art pieces, Inoventive 3D has the equipment and expertise to deliver top-notch results.

Their portfolio includes cutting-edge techniques such as:

Fused Deposition Modeling (FDM): Ideal for creating durable and functional prototypes.

Stereolithography (SLA): Perfect for high-resolution prints that require fine details.

Selective Laser Sintering (SLS): Suitable for producing robust and complex geometries.

MultiJet Printing (MJP): Offers precise and smooth surface finishes for intricate designs.

By leveraging these diverse technologies, Inoventive 3D ensures that clients receive the best possible solution tailored to their specific needs.

Comprehensive Service Offerings

What sets Inoventive 3D apart from other service providers in Dubai is its comprehensive range of services that extend beyond just printing. They offer end-to-end solutions that include:

3D Modeling and Design: Expert designers work closely with clients to bring their visions to life through meticulous 3D modeling.

Prototyping and Production: From initial concept to final product, Inoventive 3D manages the entire process, ensuring quality and precision.

Post-Processing: Services such as painting, finishing, and assembly ensure that the final product is ready for immediate use or display.

Customer-Centric Approach

Inoventive 3D prides itself on its customer-centric approach, which has earned it a stellar reputation in the industry. Their team of professionals is dedicated to understanding and fulfilling the unique requirements of each client. By providing personalized consultations and maintaining open communication throughout the project, they ensure that the final output not only meets but exceeds expectations.

Moreover, their commitment to fast turnaround times without compromising on quality has made them a preferred partner for many businesses in Dubai. Whether it’s a tight deadline or a complex project, Inoventive 3D has consistently demonstrated its ability to deliver exceptional results promptly.

Diverse Applications

The versatility of Inoventive 3D's services is reflected in the wide array of industries they serve. Some notable applications include:

Architecture: Creating detailed scale models that help architects and developers visualize projects.

Healthcare: Producing custom medical devices and anatomical models for educational and practical applications.

Education: Providing educational institutions with models and tools that enhance learning experiences.

Automotive: Manufacturing parts and components for both prototype and final production vehicles.

Art and Design: Collaborating with artists and designers to create unique and intricate pieces.

Commitment to Sustainability

Inoventive 3D is also committed to sustainability, utilizing eco-friendly materials and processes wherever possible. By reducing waste and optimizing resource use, they contribute to a greener and more sustainable future, aligning with Dubai’s vision of becoming a leader in sustainable development.

Please feel free to contact us for any further assistance. Call/WhatsApp: +971 52 595 9616 | +971 58 658 6675 | Email: [email protected] | https://3dprintingdubai.ae/

0 notes

Text

L'Innovazione delle Stampanti 3D: Una Rivoluzione Tecnologica

Introduzione

Le stampanti 3D stanno rivoluzionando il modo in cui produciamo oggetti, consentendo la creazione di componenti complessi con una precisione e una velocità senza precedenti. Questa tecnologia, che è stata sviluppata negli anni '80, ha subito una rapida evoluzione, diventando uno strumento fondamentale in settori che spaziano dalla medicina all'ingegneria, dall'arte alla moda. In questo articolo esploreremo le basi delle stampanti 3D, i loro usi, i vantaggi e le sfide associate, nonché le prospettive future di questa straordinaria tecnologia.

Cos'è una Stampante 3D?

Una stampante 3D è un dispositivo che crea oggetti tridimensionali depositando materiale strato dopo strato secondo un modello digitale. Questi modelli digitali vengono progettati utilizzando software di modellazione 3D e possono essere creati da zero o scansionati da oggetti esistenti. Le stampanti 3D utilizzano diversi materiali, tra cui plastica, resina, metallo e persino biocompatibili come il tessuto umano.

Tipi di Stampanti 3D

Ci sono diversi tipi di stampante 3d, ognuno con le proprie specifiche applicazioni e materiali compatibili:

Fused Deposition Modeling (FDM): Questo è il tipo più comune di stampante 3D, che utilizza filamenti di plastica fusi per costruire gli oggetti. È ampiamente utilizzato per prototipazione rapida e hobbistica.

Stereolitografia (SLA): Utilizza resine liquide che vengono solidificate strato dopo strato tramite un laser UV. È noto per la sua alta precisione e finitura superficiale liscia, ideale per applicazioni come la gioielleria e i modelli dentali.

Selective Laser Sintering (SLS): Utilizza un laser per sinterizzare polveri di materiale, come plastica o metallo, strato dopo strato. È particolarmente utile per la produzione di componenti industriali complessi.

Electron Beam Melting (EBM): Utilizza fasci di elettroni per fondere polveri metalliche, creando oggetti altamente robusti e durevoli. Viene spesso utilizzato in applicazioni aerospaziali e medicali.

Applicazioni delle Stampanti 3D

Le applicazioni delle stampanti 3D sono vaste e in continua espansione, includendo:

Medicina: Le stampanti 3D stanno trasformando il settore medico, permettendo la produzione di protesi personalizzate, impianti dentali e strumenti chirurgici. Inoltre, la bioprinting sta aprendo la strada alla creazione di tessuti e organi umani, potenzialmente risolvendo la carenza di donatori di organi.

Industria: La produzione additiva è utilizzata per creare parti complesse che sarebbero impossibili o molto costose da produrre con i metodi tradizionali. Questo include componenti per l'industria automobilistica, aerospaziale e dell'elettronica.

Educazione: Le stampanti 3D stanno diventando strumenti didattici preziosi, aiutando gli studenti a comprendere concetti di design, ingegneria e produzione attraverso l'apprendimento pratico.

Arte e Moda: Gli artisti e i designer di moda stanno sfruttando la libertà creativa offerta dalle stampanti 3D per creare pezzi unici e complessi, impossibili da realizzare con le tecniche tradizionali.

Vantaggi delle Stampanti 3D

Personalizzazione: Una delle caratteristiche più apprezzate delle stampanti 3D è la capacità di personalizzare ogni singolo oggetto prodotto. Questo è particolarmente utile in settori come la medicina, dove le protesi possono essere adattate esattamente alle esigenze del paziente.

Riduzione dei Costi: Per la produzione di piccoli lotti o prototipi, le stampanti 3D possono essere molto più economiche rispetto ai metodi di produzione tradizionali, eliminando la necessità di costosi stampi e attrezzature.

Velocità: La prototipazione rapida consente alle aziende di passare rapidamente dal design alla produzione, riducendo significativamente i tempi di sviluppo del prodotto.

Sostenibilità: Le stampanti 3D riducono gli sprechi di materiale, utilizzando solo ciò che è necessario per costruire l'oggetto. Inoltre, l'adozione di materiali riciclabili e biodegradabili sta contribuendo a rendere questa tecnologia più sostenibile.

Sfide e Limiti

Nonostante i numerosi vantaggi, le stampanti 3D presentano anche alcune sfide e limitazioni:

Costo delle Stampanti e dei Materiali: Sebbene i costi siano diminuiti, le stampanti 3D professionali e i materiali specializzati possono ancora essere costosi, limitando l'accesso alla tecnologia per le piccole imprese e i singoli.

Qualità e Affidabilità: La qualità delle stampe 3D può variare e talvolta richiede post-elaborazione per ottenere finiture adeguate. Inoltre, alcune tecnologie di stampa 3D non sono ancora affidabili per produzioni di larga scala.

Velocità di Produzione: Anche se la prototipazione è rapida, la produzione di oggetti di grandi dimensioni o complesse può richiedere molto tempo rispetto ai metodi tradizionali di produzione in serie.

Brevetti e Proprietà Intellettuale: La facilità di replicazione degli oggetti con le stampante 3d solleva preoccupazioni riguardo la violazione dei brevetti e la protezione della proprietà intellettuale.

Il Futuro delle Stampanti 3D

Il futuro delle stampanti 3D è promettente, con sviluppi tecnologici che continuano a migliorare le capacità e le applicazioni di questa tecnologia. Alcuni dei futuri sviluppi includono:

Materiali Avanzati: La ricerca su nuovi materiali, inclusi metalli avanzati, ceramiche e materiali biocompatibili, sta ampliando le possibilità applicative delle stampanti 3D.

Stampa Multimateriale: Le stampanti 3D stanno diventando sempre più capaci di stampare con materiali multipli simultaneamente, permettendo la creazione di oggetti con proprietà diverse in un'unica operazione.

Miglioramenti di Velocità e Precisione: Con il progresso della tecnologia, le stampanti 3D stanno diventando più veloci e precise, rendendo possibile la produzione di oggetti complessi in tempi ridotti.

Automazione e Integrazione: L'integrazione delle stampanti 3D nei processi di produzione automatizzati sta migliorando l'efficienza e riducendo gli errori umani, rendendo la produzione additiva una parte centrale dell'Industria 4.0.

Bioprinting: La bioprinting, o stampa di tessuti e organi umani, è una delle aree più promettenti della stampa 3D. Sebbene sia ancora in fase di sviluppo, il potenziale per la medicina rigenerativa e i trapianti di organi è enorme.

Conclusione

Le stampanti 3D rappresentano una delle tecnologie più rivoluzionarie del nostro tempo, con applicazioni che stanno trasformando numerosi settori. Nonostante le sfide, i vantaggi della produzione additiva, come la personalizzazione, la riduzione dei costi e la sostenibilità, la rendono una tecnologia fondamentale per il futuro. Con continui sviluppi e innovazioni, le stampanti 3D continueranno a spingere i confini del possibile, aprendo nuove opportunità per l'industria, la medicina, l'arte e oltre.

0 notes