#ServoDriveTechnology

Explore tagged Tumblr posts

Text

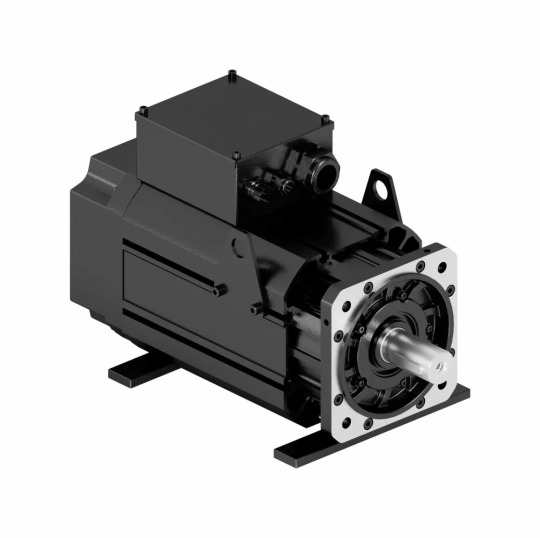

Why the World Is Turning to Small Servo Motors for Big Industrial Challenges

You’ve probably never looked twice at a small servo motor. It’s compact, quiet, and almost too unassuming to be a game-changer. But if you’re working in robotics, automation, or fluid power systems, that little motor might just be your secret weapon.

In this post, you’re going to explore how small servo motors are transforming industries—from precision manufacturing to energy-efficient hydraulics—and why your next system upgrade might be a lot more compact than you imagined. Whether you're designing a robotic arm or looking for smarter ways to power a hydraulic motor pump, this read will equip you with real insights and modern thinking.

Let’s dive in.

1. The Big Potential in a Small Servo Motor

Imagine needing precise control in a small space—like a robotic gripper, a micro CNC machine, or a medical automation device. That’s where the small servo motor thrives. These motors offer:

Compact size

High torque-to-weight ratio

Precise control over motion, speed, and position

What’s fascinating is how industries that once relied on bulky systems are now turning to miniaturized alternatives. This isn’t just about saving space—it’s about smarter control and energy savings.

If you’ve dealt with complex motion systems before, you know the headaches that come from bulky motors that lack finesse. With a small servo motor, those problems shrink, quite literally.

2. The Rise of Compact Power: How It’s Reshaping Automation

Let’s say you’re developing a lightweight industrial robot or building a portable device that requires high accuracy. Large motors just won’t cut it.

That’s why the demand for small servo motors has spiked in areas like:

Electronics assembly

Medical robotics

Portable packaging systems

Drones and inspection bots

Even in the hydraulic world—traditionally dominated by size and force—you’re now seeing a shift. Smart engineers are integrating small servo motors with small hydraulic pumps to get the best of both worlds: precision and power.

In companies like THM Huade, engineers often explore such hybrid solutions—melding servo control with hydraulics to meet modern demands without compromising on reliability.

3. Integrating Small Servo Motors with Small Hydraulic Pumps

Now, here’s where things get interesting.

You’ve got a small servo motor on one hand, and a small hydraulic pump on the other. Together, they create a system that is:

Energy-efficient (thanks to variable-speed control)

Space-saving (essential for mobile equipment)

Exceptionally responsive (ideal for dynamic load changes)

This is particularly valuable in applications like:

Injection molding machines

Servo-hydraulic presses

Construction machinery

AGVs (Automated Guided Vehicles)

When you combine electronic precision with hydraulic muscle, you're no longer choosing between finesse and force—you get both. This approach is at the heart of innovation at forward-thinking motion companies like THM Huade.

4. What Makes These Setups So Valuable?

Let’s walk through the benefits from your perspective as a system designer, plant operator, or maintenance engineer.

✅ Size Matters (In a Good Way)

A small servo motor can fit into tight spaces. When integrated with compact hydraulic components, you reduce machine footprints—perfect for OEMs targeting mobile or modular designs.

✅ Reduced Energy Waste

Older hydraulic systems often run continuously. With servo-driven pumps, you only power what you need. The result? Lower energy bills and reduced system heat.

✅ Precise Feedback Loops

Need to hold a load mid-cycle or change directions quickly? Servo control offers real-time feedback—critical in applications like testing systems or forming machines.

✅ Simplified System Architecture

Modern industrial servo drives support multi-protocol control (EtherCAT, CANopen, etc.), which makes integration with PLCs and IoT platforms smoother.

This is especially true in THM Huade’s servo-hydraulic system designs, where precision, modularity, and performance converge.

5. Looking Ahead: What the Future Holds

The trend is clear—systems are getting smarter, smaller, and more connected. You’ll see more machines built with embedded intelligence, real-time diagnostics, and plug-and-play modules.

In that context, small servo motors aren’t just filling a niche—they’re setting the stage for the next wave of industrial automation. Paired with compact hydraulic systems and sophisticated industrial servo drives, the applications are endless.

From flexible manufacturing lines to autonomous maintenance systems, the drive toward smarter machines is gaining momentum. Companies like THM Huade are responding by designing systems that are adaptable, efficient, and intelligent at every scale.

Conclusion:

You started this read wondering what role a small servo motor could play in your big-picture system. Now you know—it could be the very component that simplifies your design, cuts your energy usage, and enhances your performance.

And when paired with modern hydraulic motor pumps or industrial servo drives, the possibilities are even broader. These compact solutions are no longer just for lightweight robots or medical tools—they're reshaping the future of industrial control and motion systems across the board.

If you're in the research or design phase of your next industrial project, take a closer look at the power of small servo motors and servo-hydraulic systems. Explore how compact control could be the smartest move you make this year.

#SmallServoMotor#IndustrialAutomation#SmartHydraulics#ServoDriveTechnology#MotionControl#CompactPower#ServoHydraulicSystem#HydraulicInnovation#FutureOfIndustry#THMHuade

0 notes