Welcome to THM Huade Hydraulics Pvt Ltd, a trusted name in the hydraulics industry since 1994. Born in Ludhiana, India, as Tania Hydraulic Machines (THM), we’ve grown into a global leader, combining the legacy of THM and Beijing Huade. Our journey took a transformative leap in 2006 when THM partnered with Beijing Huade, creating a powerhouse of innovation and reliability.Today, we specialize in designing and delivering cutting-edge hydraulic solutions tailored to meet the unique needs of our customers. With a team of skilled engineers and a commitment to excellence, we pride ourselves on providing top-quality products and services that drive success across industries.At THM Huade Hydraulics, we’re not just shaping the future of hydraulics—we’re powering it. Explore our story and discover how we can help you achieve your goals with precision and reliability.Know More - https://thmhuade.com/

Don't wanna be here? Send us removal request.

Text

The Comprehensive Guide to Hydraulic Cylinder Repair: Maximizing Equipment Efficiency in the USA

Hydraulic systems are the backbone of numerous industrial applications, powering everything from construction equipment to manufacturing machinery. Among the most crucial components in these systems are hydraulic cylinders, which convert hydraulic energy into mechanical force. When these cylinders begin to fail, it’s essential to address the issue promptly to avoid costly downtime and prevent further damage to your equipment. This is where hydraulic cylinder repair comes into play.

As a user of hydraulic machinery, it’s crucial to understand the signs of failure, the components that are often responsible, and the steps involved in repairing these cylinders. In this guide, we will explore hydraulic cylinder repair in detail, focusing on components like the hydraulic cylinder piston, hydraulic cylinder seals, and more, providing you with the knowledge to make informed decisions.

Understanding the Role of Hydraulic Cylinders

Before diving into repair details, let’s first understand what hydraulic cylinders do. A hydraulic cylinder is a mechanical actuator used to give a unidirectional force through a unidirectional stroke. These cylinders are used in many applications where heavy lifting or pushing is necessary.

The cylinder consists of a barrel, piston, and rod. Fluid pressure moves the piston, which is attached to the rod, causing it to extend or retract. This movement provides linear force and motion. Hydraulic cylinders are a key component in various machines like excavators, lifts, presses, and more.

However, despite their importance, hydraulic cylinders are prone to wear and tear over time. Factors like contamination, excessive pressure, and improper maintenance can lead to damage, resulting in a loss of performance.

Identifying Common Hydraulic Cylinder Failures

When hydraulic cylinders begin to malfunction, the signs can be subtle at first, but they often lead to more severe issues if not addressed. Recognizing the early signs of failure is key to extending the life of your equipment and avoiding expensive repairs. Here are some common symptoms:

Read More:- The Evolution of DC Power Units in Hydraulic Systems

1. Leaks in the Hydraulic Cylinder Seals

The hydraulic cylinder seals are designed to keep fluid contained within the cylinder and prevent contaminants from entering. If the seals become damaged or worn, hydraulic fluid may leak, causing a loss of pressure and efficiency.

2. Sluggish or Inconsistent Operation

If you notice that your machinery is operating slower than usual or is not moving with the same force, the hydraulic cylinder may not be functioning at full capacity. This could be due to problems with the piston or the seals, or it could be a sign of low hydraulic fluid.

3. Unusual Noises

Hydraulic cylinders should operate quietly and smoothly. If you hear unusual sounds like grinding or popping, it could indicate internal damage, possibly to the piston or seals, or even air trapped in the hydraulic fluid.

4. Visible Physical Damage

Sometimes, the issue is obvious. A bent or damaged rod, worn-out piston, or cracked cylinder housing can all lead to poor performance. This type of damage is usually the result of external forces or contamination in the hydraulic fluid.

The Importance of Hydraulic Cylinder Piston and Seals in the Repair Process

Two of the most critical components in a hydraulic cylinder are the piston and seals. If either of these parts is damaged, the entire system can fail, which is why paying close attention to their condition is essential.

Hydraulic Cylinder Piston: The Heart of the System

The piston inside a hydraulic cylinder is responsible for converting fluid pressure into mechanical movement. The force from the hydraulic fluid moves the piston, which, in turn, moves the rod. The piston must be durable, as it is subjected to immense pressure. Over time, the piston can become damaged due to high loads, contaminants in the fluid, or simply wear and tear.

When performing a repair, it’s important to inspect the piston thoroughly. Signs of damage may include scoring, pitting, or cracks. A damaged piston can result in poor performance, reduced force, and potential failure of the cylinder.

Hydraulic Cylinder Seals: Protecting the Integrity of the System

Seals play a vital role in ensuring the hydraulic fluid stays inside the cylinder while preventing contaminants like dirt, dust, and water from entering. If the seals degrade or become damaged, the hydraulic fluid may leak, reducing pressure and efficiency. Leaking seals can also introduce contaminants into the hydraulic system, which can damage internal components like the piston.

There are different types of seals used in hydraulic cylinders, including:

Rod Seals: These seals prevent the hydraulic fluid from leaking out of the cylinder through the rod. They are exposed to harsh conditions and are prone to wear.

Piston Seals: These seals ensure that the hydraulic fluid stays within the cylinder and prevents contaminants from entering. They are critical in maintaining pressure.

Wiper Seals: Wiper seals prevent dirt and debris from entering the cylinder by wiping the rod as it moves.

When performing a hydraulic cylinder repair, replacing damaged seals is often necessary to restore full functionality.

The Hydraulic Cylinder Repair Process

When you’re faced with a malfunctioning hydraulic cylinder, it’s essential to approach the repair systematically. Here is a step-by-step guide to repairing a hydraulic cylinder:

Step 1: Diagnose the Issue

Before making any repairs, you need to determine the exact cause of the failure. Are the piston and seals damaged? Is there a problem with the cylinder housing? Identifying the root cause will help you determine which components need to be replaced or repaired.

Step 2: Remove the Cylinder from the Equipment

Once you’ve diagnosed the issue, the next step is to remove the hydraulic cylinder from the equipment. Be sure to follow proper safety protocols when handling the cylinder and machinery.

Read More:- Buy High Quality A4VSO Variable Displacement Pumps

Step 3: Disassemble the Cylinder

With the cylinder removed, you can begin disassembling it. Carefully remove the rod, piston, and seals. As you do, inspect each component for signs of wear, damage, or contamination. Take note of the parts that need replacing.

Step 4: Inspect the Components

Thoroughly inspect the piston, seals, and cylinder housing. Look for any signs of damage like scoring, cracks, or excessive wear. Pay special attention to the seals, as they are often the first to fail. If the piston or cylinder housing is damaged, it may need to be replaced entirely.

Step 5: Clean the Components

Cleaning is an essential part of the repair process. Dirt, dust, and old hydraulic fluid can cause further damage if left on the components. Use a non-abrasive cleaner to remove contaminants and old sealant from the piston, seals, and cylinder housing.

Step 6: Replace the Seals and Damaged Components

Once the components are clean, replace the seals with new, high-quality seals. If the piston or cylinder housing is damaged, replace those components as well. Be sure to choose parts that are compatible with your specific hydraulic system.

Step 7: Reassemble the Cylinder

With the new parts in place, reassemble the hydraulic cylinder. Be sure to carefully install the piston, seals, and rod. Ensure that all parts are properly aligned and that there are no gaps or areas where fluid could leak.

Step 8: Test the Cylinder

Before reinstalling the hydraulic cylinder back into the equipment, it’s important to test it. Pressurize the cylinder and check for any leaks. Ensure that the piston moves smoothly and that the seals are functioning properly.

Step 9: Reinstall the Cylinder

Once you’ve confirmed that the cylinder is functioning correctly, reinstall it into the equipment. Make sure all connections are secure and that the cylinder is properly aligned.

Step 10: Monitor the System

After the repair is complete, continue to monitor the hydraulic system to ensure that the repair was successful. Regular maintenance and inspections can help prevent future issues and extend the lifespan of your equipment.

Preventing Hydraulic Cylinder Failures

While hydraulic cylinder repair is often necessary, the best way to avoid expensive repairs is through preventive maintenance. Here are some tips for prolonging the life of your hydraulic cylinders:

Regular Inspections: Perform routine inspections of your hydraulic cylinders to catch any issues early. Look for signs of wear, leaks, or unusual noises.

Maintain Proper Fluid Levels: Ensure that the hydraulic fluid is at the correct level and is clean. Contaminated fluid can cause damage to the piston and seals.

Check for Contaminants: Prevent dirt, dust, and debris from entering the hydraulic system. Use filters and wiper seals to keep contaminants out.

Follow Manufacturer Guidelines: Always follow the manufacturer’s recommendations for maintenance, fluid type, and operating conditions.

Proper Handling: Ensure that the hydraulic system is not exposed to excessive pressure, heat, or other conditions that could cause premature wear.

Conclusion: The Importance of Timely Hydraulic Cylinder Repair

In industries that rely on heavy machinery, hydraulic cylinder failure can cause costly downtime and damage to equipment. By understanding the role of components like the hydraulic cylinder piston and hydraulic cylinder seals, you can make more informed decisions about maintenance and repair. Proper hydraulic cylinder repair, when done correctly and on time, can significantly improve the performance and lifespan of your machinery.

Remember, hydraulic systems are complex, and repairs should be handled with care. Regular maintenance, early diagnosis of issues, and prompt repairs will ensure that your hydraulic cylinders continue to perform optimally, helping you keep your equipment running efficiently and your operations smooth.

By following the steps outlined in this guide, you can approach hydraulic cylinder repair with confidence, knowing that you have the knowledge to make the right decisions and maximize the lifespan of your equipment.

#hydraulictechnology#motioncontrol#smarthydraulics#hydraulicsystems#excavatorparts#engineeringsolutions#thmhuade#industrialautomation#hddindustry#excavatorpartsindia

0 notes

Text

Hydraulic Motors for Sale: What You Need to Know Before Purchasing

If you're in the market for hydraulic motors, you know how essential these components are for efficient machinery operation. Hydraulic motors are at the heart of systems in industries like construction, agriculture, and manufacturing. But how do you ensure you're making the right purchase when searching for hydraulic motors for sale?

Let’s break down the key factors to consider before buying and how hydraulic pumps and motors work together to maximize performance.

What Are Hydraulic Motors and Why Do They Matter?

Hydraulic motors convert hydraulic energy into mechanical energy to drive machinery components like wheels, arms, or conveyors. They're crucial in systems that need powerful and consistent movement. Whether you're dealing with large equipment like cranes or smaller machines, hydraulic motors provide the precision and power necessary for reliable operation.

However, choosing the right hydraulic motor for your specific application is critical for optimal performance. It must be able to handle the required torque, speed, and pressure for your system to operate efficiently.

Key Factors to Consider When Searching for Hydraulic Motors for Sale

When looking for hydraulic motors for sale, here are the essential points to keep in mind:

Torque and Speed Needs: Hydraulic motors come in various configurations, offering different torque and speed outputs. Determine your specific requirements—whether high torque at low speeds or faster speeds with moderate torque—and select a motor accordingly.

Motor Type: Common hydraulic motor types include gear motors, piston motors, and vane motors. Gear motors are generally more cost-effective for consistent torque, while piston motors offer higher efficiency and are ideal for variable displacement needs. Your application should guide your choice.

Compatibility with Hydraulic Pumps: Hydraulic motors depend on hydraulic pumps for pressure and flow. Ensure that the pump and motor are compatible to avoid inefficiencies or system damage. Incorrect pressure or flow rates can result in performance issues or even failure of both components.

Size and Mounting: The motor’s size and the available mounting options are essential. Make sure the motor fits within your machinery's design, whether you're replacing an existing motor or installing a new one.

Durability and Maintenance: Consider the motor's durability and the level of maintenance it will require. Look for motors designed for your operating conditions, including factors like temperature, exposure to contaminants, and expected operational hours.

Hydraulic Pumps and Motors: Working in Tandem

The hydraulic motor is only one part of a complete hydraulic system. To operate efficiently, it needs a hydraulic pump to supply the necessary pressure and flow. The pump’s specifications—such as pressure and flow rate—must match the motor’s capabilities to ensure smooth operation.

If your pump and motor aren't properly matched, your system will be inefficient, leading to potential wear, energy waste, and even breakdowns. Therefore, selecting compatible hydraulic pumps and motors is crucial for system longevity and performance.

Conclusion: Make the Right Investment

Choosing the right hydraulic motor requires careful consideration. By understanding your application’s torque, speed, pressure, and flow needs, as well as the compatibility between your motor and pump, you can make a well-informed decision. Prioritize quality and ensure your motor can handle the demands of your equipment to maximize performance and minimize costly repairs.

#hydraulictechnology#motioncontrol#engineeringsolutions#thmhuade#industrialautomation#smarthydraulics#hydraulicsystems#excavatorpartsindia#hddindustry#excavatorparts

0 notes

Text

Precision in Motion: The Importance of Linear Position Sensors in Hydraulic Cylinders

In hydraulic systems, power is nothing without control. Whether it’s lifting, pushing, or positioning, the ability to monitor the exact location of a cylinder’s piston rod can be the difference between smooth operation and costly inefficiency. That’s where linear position sensors come in—a technology that has become essential in applications demanding real-time feedback, safety, and motion accuracy.

At THM Huade, we understand that for today’s machinery to perform at its best, it must also think—monitoring itself and adjusting on the fly. Integrating linear position sensors into hydraulic cylinders is one of the most effective ways to achieve this.

What Does a Linear Position Sensor Actually Do?

A linear position sensor is designed to measure the position of a piston or rod within a hydraulic cylinder and transmit that data to a controller or interface. This allows a system to “know” exactly where the rod is in its stroke—helping manage speed, force, and response in real-time.

These sensors come in a range of formats, including:

Magnetostrictive sensors for high precision and durability

Potentiometric sensors for cost-sensitive applications

Inductive and LVDT types for rugged, contactless performance

Regardless of the technology, the goal is the same: deliver continuous, accurate position feedback under tough industrial conditions.

Why Hydraulic Systems Need Real-Time Position Sensing

Hydraulic cylinders are workhorses. They generate immense force and are used in everything from heavy construction to aerospace. But without position sensing, they’re effectively “blind”—relying only on pressure changes or end-limit switches for control.

Here’s how linear position sensors add value:

Improved accuracy in stroke movement

Feedback for automated or closed-loop systems

Enhanced safety with position-aware operations

Reduced downtime via diagnostics and predictive maintenance

Energy savings by optimizing fluid delivery to actual load requirements

For OEMs and system designers, adding a sensor turns a standard hydraulic cylinder into a smart actuator, capable of adapting to changing loads, sequences, and safety logic.

Built to Endure: Sensor Technology from THM Huade

THM Huade offers sensor-integrated hydraulic solutions built for industries where failure is not an option. Our sensors are designed for:

Shock and vibration resistance in off-road and industrial settings

IP-rated protection against dust, water, and extreme temperatures

Long service life, with solid-state and contactless options for minimal wear

We work closely with OEMs to embed these sensors directly into the cylinder housing or mount them externally, depending on system requirements and maintenance preferences.

Use Cases: From Automation to Heavy Machinery

The adoption of linear position sensors is growing rapidly in:

Agricultural machinery (e.g., smart tractors, sprayers)

Construction equipment (e.g., excavators, cranes, lifts)

Industrial automation (e.g., material handling, robotic arms)

Energy and marine sectors (e.g., dam gates, drilling platforms)

In each application, precise position feedback helps operators and systems execute movements more efficiently, safely, and reliably.

The Future: Smart Hydraulics and Industry 4.0

As machines become more intelligent, the demand for real-time feedback loops grows. Position sensors play a central role in enabling predictive maintenance, adaptive controls, and remote diagnostics—pillars of Industry 4.0.

At THM Huade, we’re not just building components; we’re engineering intelligent hydraulic solutions that fit seamlessly into the future of connected machinery.

Upgrade your hydraulics with smart sensing. Learn more about linear position sensor solutions from THM Huade.

#LinearPositionSensor#HydraulicCylinders#SmartHydraulics#IndustrialSensors#AutomationEngineering#THMHuade#MotionControl#HydraulicSolutions#PrecisionInMotion

0 notes

Text

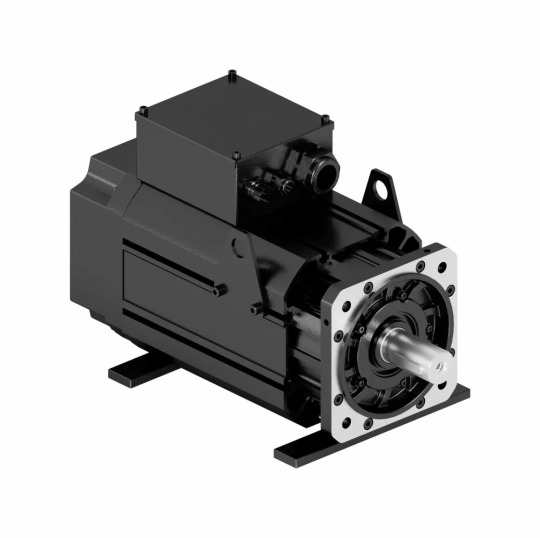

Small Servo Motors and Drives: Big Performance in a Compact Package

When you think of high-precision motion systems, it's easy to imagine large, complex machines operating in sprawling factories. But what about applications where space is limited, yet the demand for performance remains sky-high? This is where small servo motors and drives come into play—offering the same precision and control as their larger counterparts, in a much smaller footprint.

At their core, small servo systems provide closed-loop motion control using a servo motor and a dedicated drive. The combination ensures that position, speed, and torque are tightly managed, which is essential in applications like robotics, medical equipment, lab automation, and compact assembly lines.

1. Miniature Size, Maximum Accuracy

Don’t let their size fool you—small servo motors are engineered to deliver incredible accuracy. With high-resolution encoders and fast feedback loops, these motors can achieve micron-level precision. For industries where detail matters—like electronics, 3D printing, or optical manufacturing—this is a critical advantage.

2. Space-Saving, Cost-Saving

One of the biggest advantages of small servo motors and drives is their ability to save valuable space. Compact control cabinets, lightweight end-of-arm tools, and portable machines benefit greatly from these scaled-down systems.

But space isn’t the only thing saved—costs come down too. Smaller systems typically consume less power, generate less heat, and require fewer support components, making them more efficient both operationally and financially.

3. Highly Responsive for Delicate Tasks

In precision operations such as dosing, cutting, or delicate part manipulation, speed without control is useless. THM Huade’s small servo motors and drives are built for fast, intelligent response to changing loads or commands. Whether you’re operating a miniature conveyor belt or a robotic gripper, every movement is smooth and predictable.

4. Plug-and-Play Integration

Small servo drives from THM Huade come with user-friendly interfaces and are compatible with popular industrial control systems like EtherCAT and Modbus. The drives support both position and torque modes and offer configuration flexibility, so you can adapt them easily to a wide variety of compact machinery.

5. Built for Versatility

These small systems might be designed for tight spaces, but their capabilities are expansive. From lab automation to packaging equipment, and from laser cutters to textile machines—small servo motors and drives prove themselves in virtually any application where precision and footprint matter.

Why Choose THM Huade?

At THM Huade, we understand the challenges of fitting high-performance automation into limited space. Our small servo motors and drives are designed with engineers and integrators in mind—offering powerful functionality, long-term reliability, and seamless integration with your existing systems.

Backed by technical support and decades of industry experience, our solutions are built to help you scale precision, not just machinery.

💡 Interested in upgrading your compact motion system with intelligent servo technology? Visit THM Huade to discover small servo motors and drives that deliver big results in tight spaces.

#SmallServoMotors#ServoDrives#THMHuade#PrecisionAutomation#CompactMachinery#MiniServoSystems#SmartManufacturing#MotionControlTech#IndustrialAutomation#HighPrecisionDrives

0 notes

Text

Why the World Is Turning to Small Servo Motors for Big Industrial Challenges

You’ve probably never looked twice at a small servo motor. It’s compact, quiet, and almost too unassuming to be a game-changer. But if you’re working in robotics, automation, or fluid power systems, that little motor might just be your secret weapon.

In this post, you’re going to explore how small servo motors are transforming industries—from precision manufacturing to energy-efficient hydraulics—and why your next system upgrade might be a lot more compact than you imagined. Whether you're designing a robotic arm or looking for smarter ways to power a hydraulic motor pump, this read will equip you with real insights and modern thinking.

Let’s dive in.

1. The Big Potential in a Small Servo Motor

Imagine needing precise control in a small space—like a robotic gripper, a micro CNC machine, or a medical automation device. That’s where the small servo motor thrives. These motors offer:

Compact size

High torque-to-weight ratio

Precise control over motion, speed, and position

What’s fascinating is how industries that once relied on bulky systems are now turning to miniaturized alternatives. This isn’t just about saving space—it’s about smarter control and energy savings.

If you’ve dealt with complex motion systems before, you know the headaches that come from bulky motors that lack finesse. With a small servo motor, those problems shrink, quite literally.

2. The Rise of Compact Power: How It’s Reshaping Automation

Let’s say you’re developing a lightweight industrial robot or building a portable device that requires high accuracy. Large motors just won’t cut it.

That’s why the demand for small servo motors has spiked in areas like:

Electronics assembly

Medical robotics

Portable packaging systems

Drones and inspection bots

Even in the hydraulic world—traditionally dominated by size and force—you’re now seeing a shift. Smart engineers are integrating small servo motors with small hydraulic pumps to get the best of both worlds: precision and power.

In companies like THM Huade, engineers often explore such hybrid solutions—melding servo control with hydraulics to meet modern demands without compromising on reliability.

3. Integrating Small Servo Motors with Small Hydraulic Pumps

Now, here’s where things get interesting.

You’ve got a small servo motor on one hand, and a small hydraulic pump on the other. Together, they create a system that is:

Energy-efficient (thanks to variable-speed control)

Space-saving (essential for mobile equipment)

Exceptionally responsive (ideal for dynamic load changes)

This is particularly valuable in applications like:

Injection molding machines

Servo-hydraulic presses

Construction machinery

AGVs (Automated Guided Vehicles)

When you combine electronic precision with hydraulic muscle, you're no longer choosing between finesse and force—you get both. This approach is at the heart of innovation at forward-thinking motion companies like THM Huade.

4. What Makes These Setups So Valuable?

Let’s walk through the benefits from your perspective as a system designer, plant operator, or maintenance engineer.

✅ Size Matters (In a Good Way)

A small servo motor can fit into tight spaces. When integrated with compact hydraulic components, you reduce machine footprints—perfect for OEMs targeting mobile or modular designs.

✅ Reduced Energy Waste

Older hydraulic systems often run continuously. With servo-driven pumps, you only power what you need. The result? Lower energy bills and reduced system heat.

✅ Precise Feedback Loops

Need to hold a load mid-cycle or change directions quickly? Servo control offers real-time feedback—critical in applications like testing systems or forming machines.

✅ Simplified System Architecture

Modern industrial servo drives support multi-protocol control (EtherCAT, CANopen, etc.), which makes integration with PLCs and IoT platforms smoother.

This is especially true in THM Huade’s servo-hydraulic system designs, where precision, modularity, and performance converge.

5. Looking Ahead: What the Future Holds

The trend is clear—systems are getting smarter, smaller, and more connected. You’ll see more machines built with embedded intelligence, real-time diagnostics, and plug-and-play modules.

In that context, small servo motors aren’t just filling a niche—they’re setting the stage for the next wave of industrial automation. Paired with compact hydraulic systems and sophisticated industrial servo drives, the applications are endless.

From flexible manufacturing lines to autonomous maintenance systems, the drive toward smarter machines is gaining momentum. Companies like THM Huade are responding by designing systems that are adaptable, efficient, and intelligent at every scale.

Conclusion:

You started this read wondering what role a small servo motor could play in your big-picture system. Now you know—it could be the very component that simplifies your design, cuts your energy usage, and enhances your performance.

And when paired with modern hydraulic motor pumps or industrial servo drives, the possibilities are even broader. These compact solutions are no longer just for lightweight robots or medical tools—they're reshaping the future of industrial control and motion systems across the board.

If you're in the research or design phase of your next industrial project, take a closer look at the power of small servo motors and servo-hydraulic systems. Explore how compact control could be the smartest move you make this year.

#SmallServoMotor#IndustrialAutomation#SmartHydraulics#ServoDriveTechnology#MotionControl#CompactPower#ServoHydraulicSystem#HydraulicInnovation#FutureOfIndustry#THMHuade

0 notes

Text

Hydraulic Flow Control Valves: The Real Key to System Stability, Safety, and Precision

In any hydraulic system, control is everything. Without accurate flow control, you risk inefficient energy use, unstable operations, or even costly equipment failure. This is where the hydraulic flow control valve becomes more than just a component—it becomes a key system enabler.

But what exactly is a hydraulic flow control valve, and why should it matter to system designers, plant operators, or maintenance teams?

Let’s break it down in simple, real-world terms.

🔧 What Does a Hydraulic Flow Control Valve Actually Do?

At its core, a hydraulic flow control valve regulates the rate of fluid flow within a system. That might sound simple, but it plays a critical role in controlling actuator speed, system pressure, and response timing.

These valves help ensure:

A cylinder extends at a predictable rate.

A motor rotates at a steady speed.

The system avoids shock loading or pressure spikes.

By managing how fast hydraulic fluid moves through the system, flow control valves allow machines to perform smooth, repeatable motions—which is essential in industrial automation, mobile hydraulics, or construction equipment.

🚜 Where Are They Used?

You’ll find hydraulic flow control valves in industries like:

Agriculture: controlling cylinder stroke on harvesters or sprayers.

Manufacturing: regulating fluid speed in molding presses or assembly lines.

Construction: managing the flow rate in excavator arms or loaders.

Material handling: ensuring smooth conveyor and lift operations.

In systems with variable load conditions, these valves help keep flow constant despite pressure fluctuations—crucial for machines that operate in dynamic environments.

🧩 Types of Flow Control Valves

Not all flow control valves are created equal. Here are some common types and where they shine:

Needle Valves: Simple, adjustable flow control; ideal for low-pressure applications.

Pressure-Compensated Valves: Keep flow constant regardless of load or pressure changes.

Proportional Flow Valves: Offer electronically controlled, variable flow rates—great for automation.

Flow Dividers: Distribute flow equally between two outputs—used when synchronizing actuators.

Choosing the right type isn’t just about specs—it’s about the application environment, duty cycle, and control strategy.

💡 Why the Right Flow Control Valve Matters

Selecting an undersized or poorly matched valve can lead to:

System overheating due to throttling losses

Jerky actuator movement

Inconsistent response under varying loads

Increased wear on pumps and cylinders

On the other hand, a properly sized and well-positioned flow control valve ensures better machine control, reduced energy consumption, and longer component life.

And with many modern systems moving toward smart hydraulics, it’s increasingly common to see flow valves integrated with sensors or electronics for closed-loop control.

🔍 What to Look for in a Good Hydraulic Flow Control Valve

When evaluating or replacing a valve, consider:

Pressure rating and flow capacity

Material compatibility (especially with fluids like HLP or bio oils)

Temperature resistance

Mounting configuration (in-line, cartridge, or manifold-mounted)

Response characteristics (especially for dynamic or proportional valves)

Reliable manufacturers typically offer modular valves that allow for easy integration into existing systems—and support customization for niche requirements.

✅ Final Thoughts

In a world where efficiency, control, and reliability drive success, the humble hydraulic flow control valve plays a crucial behind-the-scenes role. It’s not just a passive component; it’s a strategic one—impacting everything from energy savings to operational safety.

If you’re reviewing your system’s performance, don’t overlook this valve. Upgrading or correctly sizing it can yield outsized results for a relatively small investment.

#HydraulicSystems#FlowControlValve#FluidPowerEngineering#IndustrialHydraulics#HydraulicTechnology#PrecisionHydraulics#ValveControl#HydraulicComponents#EngineeringSolutions#THMHuade

0 notes

Text

Hydraulic Cylinder Seals: Small Components, Big Impact on System Performance

In the world of hydraulics, where heavy lifting and precise movement are part of daily operations, it’s easy to overlook the small components that hold the system together. Among these unsung heroes, hydraulic cylinder seals play an especially critical role. Though compact and inexpensive compared to larger parts, seals are fundamental to the performance, efficiency, and lifespan of any hydraulic system. A single worn or improperly installed seal can result in fluid leaks, pressure drops, contamination, and ultimately system failure—costing valuable time and resources.

At their core, hydraulic seals are designed to contain pressurized fluid within the cylinder, separate internal chambers, and prevent external contaminants from entering the system. Each seal is precisely engineered to handle specific operating conditions such as temperature fluctuations, pressure levels, motion speed, and exposure to chemicals or abrasive materials. That’s why not all seals are interchangeable. The wrong material or shape can quickly lead to accelerated wear or mechanical breakdown, particularly in demanding environments like construction, mining, or heavy industrial applications.

There are generally two types of seals used in hydraulic cylinders—static and dynamic. Static seals are positioned in areas where no motion occurs, such as between cylinder end caps and tubes. Dynamic seals, on the other hand, are located in areas involving movement, like along the piston rod or between the piston and cylinder wall. The latter must withstand constant motion and pressure changes, making them more prone to wear. This is where material science and design precision really matter. Seals must maintain tight tolerances, adapt to pressure shifts, and resist extrusion, all while minimizing friction.

When hydraulic systems fail due to seal-related issues, the signs are often subtle at first. Small external leaks, slight reductions in system pressure, or increased heat generation can all be early indicators. Unfortunately, these early warnings are often missed until the problem escalates into a full-blown failure. Preventive maintenance, including regular inspection and timely replacement of seals, is essential to avoiding costly repairs and unplanned downtime.

In high-performance or custom hydraulic systems, many equipment operators rely on trusted manufacturers who understand the delicate balance between seal design and system performance. Companies like THM Huade, known for their precision-engineered hydraulic components, approach seals not as accessories but as integral elements of cylinder design. When seal geometry, material composition, and installation clearances are aligned perfectly, the cylinder operates at peak performance with lower risk of leaks and extended service intervals.

What often separates average hydraulic performance from exceptional reliability is attention to the smallest details—like how seals respond to pressure spikes, how they interact with hydraulic fluid, and how they wear over time. Replacing seals isn’t just about swapping out rubber parts; it requires choosing the right specifications, ensuring proper groove sizing, and sometimes upgrading to advanced materials like PTFE, polyurethane, or Viton to match the operating demands.

More industries are now prioritizing component compatibility and long-term maintenance planning. With modern machinery becoming more compact and efficient, the margin for error is shrinking. This has pushed manufacturers and service providers to invest in better seal technology and more accurate manufacturing standards. It’s also why the sourcing of seals—whether for repair or OEM assembly—should come from specialists who understand the real-world dynamics of hydraulic systems.

Ultimately, hydraulic cylinder seals are quiet enablers of system efficiency. Their job may go unnoticed when everything’s running well, but when a seal fails, the entire operation feels the impact. So whether you’re maintaining a fleet of construction equipment or operating precision-controlled industrial systems, giving proper attention to your seals isn’t just smart—it’s essential.

0 notes

Text

Hydraulic Valve Seals: Why Small Components Make a Big Difference

In hydraulic systems, it’s often the smallest components that carry the heaviest responsibility. Hydraulic valve seals are a perfect example. Though they may seem minor compared to pumps, valves, or actuators, their role in maintaining system efficiency and reliability is crucial.

A hydraulic valve seal’s primary function is to prevent fluid leakage, ensuring that hydraulic pressure is maintained within the system. Without effective seals, even the most powerful hydraulic systems would struggle to operate efficiently. Leaks not only cause performance drops but also lead to contamination, system overheating, and costly maintenance issues.

There are several types of hydraulic valve seals, each designed for specific system requirements. Common examples include O-rings, U-cups, and V-rings. O-rings, with their simple design, are widely used for static sealing applications. U-cups and V-rings, on the other hand, are typically used in dynamic applications where the seal must withstand movement, pressure changes, and varying temperatures.

Material choice is another critical factor. Seals are made from a range of materials like Nitrile (NBR), Fluorocarbon (Viton®), and Polyurethane. Each material offers distinct advantages. For instance, Nitrile seals are excellent for general-purpose use, offering good resistance to oil and fuel. Fluorocarbon seals are preferred when systems operate at higher temperatures or involve aggressive fluids. Selecting the right material ensures longer seal life and system reliability.

Failure of hydraulic valve seals can result from several causes — improper installation, chemical degradation, temperature extremes, or simply wear and tear over time. That’s why proper maintenance is key. Regular inspections can identify early signs of seal fatigue, like minor leaks or hardening of the material. Timely replacement of worn seals can prevent bigger problems such as major equipment downtime or system failure.

Design trends in modern hydraulics are also influencing how seals are engineered. As systems become more compact and operate under higher pressures, seals are required to perform more efficiently within tighter spaces and harsher conditions. Advanced sealing technologies now offer enhanced wear resistance, low friction characteristics, and better compatibility with synthetic fluids.

It’s easy to underestimate the importance of hydraulic valve seals because they are small, inexpensive parts. But in reality, they act as critical guardians of system integrity. A well-selected and well-maintained seal keeps hydraulic systems running at peak efficiency, reduces energy consumption, and extends the life of expensive components like valves and pumps.

At THM Huade, we recognize that quality at every level matters. That’s why our hydraulic solutions are built with a focus on durability, precision, and superior sealing performance — giving you the peace of mind that your system will perform exactly when you need it most.

#HydraulicSystems#ValveSeals#IndustrialMaintenance#EngineeringSolutions#HydraulicTechnology#SealingSolutions

0 notes

Text

Precision Without Contact: The Role of Inductive Linear Position Sensors in Modern Machinery

In the world of modern machinery, precision and reliability aren’t luxuries—they’re the baseline. Whether it’s a robotic arm, a CNC system, or a hydraulic actuator, every millimeter of movement matters. That’s why more engineers are turning to inductive linear position sensors for accurate, contactless feedback.

At THM Huade, we specialize in supplying advanced hydraulic and motion control components, and inductive sensors are a crucial part of that ecosystem.

What Is an Inductive Linear Position Sensor?

An inductive linear position sensor detects the position of a moving object—typically a piston, rod, or machine component—using non-contact electromagnetic technology. Unlike potentiometers or mechanical sensors, inductive sensors don’t require direct contact with the target, eliminating wear and increasing reliability.

They work by generating an alternating magnetic field and sensing changes in inductance as a metallic target moves within range. The result is a precise, linear signal that translates directly into position data.

Where Do They Make a Difference?

Inductive linear position sensors are the go-to choice for applications where:

High-frequency or continuous movement occurs

Harsh environmental conditions (dust, oil, vibration) are common

Mechanical wear from contact sensors is a concern

Space constraints require slim or embedded sensor designs

You’ll often find them in:

Hydraulic cylinders

Mobile equipment (cranes, lifts, dump trucks)

Factory automation systems

Metal stamping and press machines

Renewable energy installations (like wind turbine pitch control)

Why Engineers Prefer Inductive Sensing

What makes inductive sensors stand out?

Non-contact design = no mechanical wear, longer service life

Resistant to shock, oil, and temperature changes

High repeatability and linearity for precision control

Compact and robust housings suited for embedded systems

In short, these sensors are built for rugged reliability and long-term accuracy, even in environments where traditional sensors would fail.

THM Huade’s Expertise

At THM Huade, we supply inductive linear sensors that are:

Customizable in stroke length and output format

Compatible with analog and digital systems (voltage, current, PWM)

Sealed to withstand industrial environments

Designed for seamless integration into hydraulic and mechanical systems

We understand that the sensor is only as good as the system it serves. That’s why our team works with engineers to ensure proper sensor alignment, signal compatibility, and mounting precision. Whether you're integrating into a cylinder, robotic assembly, or automated press, our sensors offer plug-and-play performance with long-term stability.

A Key Component in Industry 4.0

In today’s push toward smart factories and connected systems, real-time position feedback is essential. Inductive linear sensors support this shift by offering precise data that can be fed into PLCs, monitoring systems, or predictive maintenance tools.

They’re more than components—they’re enablers of smarter control, better diagnostics, and increased automation.

Need Reliable Position Feedback? Trust THM Huade to deliver inductive sensor solutions that meet your performance and durability needs. We combine technical know-how with high-quality engineering—ensuring your systems move with confidence and control.

👉 Learn more or request a custom solution at https://thmhuade.com

#InductiveSensor#LinearPositionSensor#NonContactSensing#SmartHydraulics#IndustrialAutomation#HydraulicSystems#MotionControl#PrecisionEngineering#SensorTechnology#Industry40#THMHuade#EngineeringSolutions#HydraulicControl#MachineSensors#PositionFeedback

0 notes

Text

Discover the Power of Internal Gear Pumps – Compact, Quiet, and Efficient

In the world of fluid power and hydraulic systems, precision and efficiency are everything. That’s why internal gear pumps are gaining widespread popularity across industries that demand quiet operation, compact design, and reliable fluid handling. Whether you're working in the food industry, chemical processing, or heavy-duty industrial systems, internal gear pumps deliver unmatched performance.

So what makes internal gear pumps such a smart choice?

They operate on a unique principle—two gears (one inside the other) rotate to create a sealed chamber that moves fluid efficiently. This design is ideal for handling high-viscosity fluids and offers a smooth, pulse-free flow, which is crucial for systems requiring precision. Additionally, these pumps are known for their quiet operation, low maintenance, and ability to function at high pressures.

At THM Huade, internal gear pump technology is taken a step further. The focus is on durability, efficiency, and compactness—without sacrificing performance. Our gear pumps are designed with advanced materials to withstand demanding environments and are ideal for applications where space and noise constraints matter.

If your operation depends on reliable hydraulic systems, switching to internal gear pumps could mean increased uptime, lower energy costs, and better control.

Looking to upgrade your hydraulic setup or source dependable components? Internal gear pumps might just be the key to enhancing system efficiency without complicating your architecture.

#InternalGearPump#HydraulicSystems#CompactHydraulics#PumpEfficiency#IndustrialAutomation#FluidPower#QuietOperationPump#PrecisionHydraulics#THMHuade#GearPumpTechnology

0 notes

Text

High-Performance Hydraulic Power Packs for Industrial Applications | THM Huade

Discover durable and energy-efficient hydraulic power packs at THM Huade. Our reliable solutions ensure seamless operation in diverse industrial applications. Contact us today to learn more!

⚙️ Unlock Efficiency with High-Quality Hydraulic Power Packs from THM Huade

When it comes to powering industrial machinery, hydraulic power packs play a critical role by converting mechanical energy into hydraulic energy. These compact yet powerful units are essential for applications that require precision, control, and high performance. At THM Huade, we offer a wide range of hydraulic power packs designed to meet the diverse demands of industries such as manufacturing, construction, and automation.

🔥 Why Choose Hydraulic Power Packs?

✅ High Efficiency: Hydraulic power packs provide a reliable and consistent power source, ensuring smooth and efficient operation of your machinery. ✅ Compact and Versatile: These systems are designed to fit into limited spaces, making them ideal for applications where space is a constraint. ✅ Precision and Control: Hydraulic power packs allow accurate control over pressure and flow, ensuring optimal performance for various industrial processes.

🛠️ Applications of Hydraulic Power Packs

Hydraulic power packs are widely used in:

Construction Equipment: To power cranes, loaders, and excavators.

Manufacturing Units: For operating presses, injection molding machines, and other industrial machinery.

Marine and Offshore Operations: Providing power for winches, lifts, and other critical systems.

💡 Why Trust THM Huade for Hydraulic Power Packs?

At THM Huade, we prioritize quality, reliability, and innovation. Our hydraulic power packs are engineered to deliver exceptional performance, ensuring seamless operation in even the most demanding environments. Our team of experts is dedicated to providing tailored solutions that align with your operational needs.

#HydraulicPowerPacks#IndustrialAutomation#PowerSolutions#HydraulicSystems#THMHuade#EnergyEfficiency#PrecisionControl#ManufacturingEquipment#HydraulicTechnology#AutomationSolutions#HydraulicPumps#ReliablePerformance#MachineryEfficiency#IndustrialSolutions#CompactPowerPacks

0 notes

Text

What is the Track Motor for HDD Machines? Features & Benefits

The Track Motor serves as a main part of HDD machines to help them move easily across different ground types. The motors deliver the required power and torque to operate HDD equipment accurately during underground drilling work. Our exploration covers the main features and advantages of track motors for HDD machines alongside their practical uses and industry specific terms including HDD machine pump, HDD pump, HDD gear pump, track motor excavator, track motor in India, and excavator track motor parts. Read More

#PumpTechnology#ExcavatorParts#HeavyMachinery#IndustrialEquipment#TrackMotorFeatures#TorqueAndPower#HDDIndustry#TrackMotorAdvantage#ExcavatorPartsIndia#PowerfulTrackMotors

0 notes

Text

What is the Track Motor for HDD Machines? Features & Benefits

The Track Motor serves as a main part of HDD machines to help them move easily across different ground types. The motors deliver the required power and torque to operate HDD equipment accurately during underground drilling work. Our exploration covers the main features and advantages of track motors for HDD machines alongside their practical uses and industry specific terms including HDD machine pump, HDD pump, HDD gear pump, track motor excavator, track motor in India, and excavator track motor parts. Read More

#TrackMotor#HDDMachines#UndergroundDrilling#TrackMotorExcavator#HDDPump#HDDGearPump#ExcavatorTrackMotor#HDDEquipment#TrackMotorsInIndia#DrillingTechnology#ConstructionMachinery#PumpTechnology#ExcavatorParts#HeavyMachinery#IndustrialEquipment#TrackMotorFeatures#TorqueAndPower#HDDIndustry#TrackMotorAdvantage#ExcavatorPartsIndia#PowerfulTrackMotors

1 note

·

View note