#Slitter Rewinder Machine

Explore tagged Tumblr posts

Text

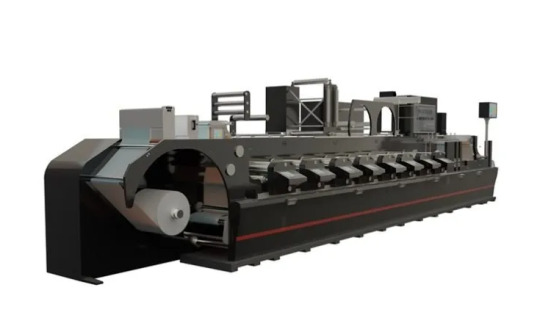

A Heavy-Duty slitter rewinder machine is an integral part of converting wide rolls into smaller widths of material with high accuracy. The heavy-duty type is meant to deal with tougher materials, processing those smoothly while maintaining the best quality.

the Heavy-Duty Slitter Rewinder Cylinder Machine cuts and rewinds materials such as paper, plastic films, laminates, and foils with unmatched precision. Krishna Engineering Works the reputed name worldwide as a manufacturer and exporter of industrial machinery-supplies the best Slitter Rewinder Machines with excellent durability, precision, and ease of operation.

#krishnaengineeringworks#slitter rewinder machine#machine#manufacturer#machinemanufacturer#industry#export#supplier#machinery#industrial#heavy duty slitter rewinder machine#packaging industry#paper machinery#paper industry

2 notes

·

View notes

Text

Label stock Kraft Paper Lamination Film Jumbo Roll Release Paper slitter

This model jumbo roll slitter rewinder machine mainly use for converting pressure sensitive material, such as self adhesive paper, sublimation paper, BOPP, OPP, PVC film. Differential friction rewinding shaft for better control tension.

sonia wei E-mail: [email protected] whatsapp: 008613306265137

#slitter machine#slitting machine#rewinder machine#slitter rewinder machine#labelstock slitter machine#paper roll slitter machine#roll slitter machine#film rewinder machine#filmslitter rewinder machine#release paper#self adhesive paper#lamination film#jumbo roll#kraft paper

0 notes

Text

Jandu PPM - Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a leading Slitting and Rewinding Machine manufacturer and offers an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper. Key Features of Slitting and Rewinding Machines Latest in Design Good Performance Simple in Operating Easy Maintenance High Speed Contact for Slitter and Rewinder…

0 notes

Text

KEW ENGG. & MFG. PVT. LTD., we specialize in manufacturing cutting-edge Heavy Duty Drum Slitter Machine designed to meet diverse industrial requirements. Whether it’s for paper, plastic, textile, or packaging applications, our machines deliver unparalleled precision and durability.

#kewengg#machine#machinery#industry#machinemanufacture#industrial#exporter#supplier#manufacturer#manufacturing#Heavydutydrum#heavyduty#slittermachine#paper industry#papermachinery

2 notes

·

View notes

Text

A paper slitter is a slitting device that cuts a wide roll of paper on a paper machine into a narrower width of paper while rewinding it onto a receiving reel.

2 notes

·

View notes

Text

0 notes

Text

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Bopp / Paper Tape Coating Machine

Mohindra is recognized as one of the top manufacturers of Doctoring Slitting Machines in India. Although we are located in Delhi, we supply our wide range of products across the country. We use premium quality raw materials in the production of all our machines. As you may know, the demand for Doctoring Slitting Machines is increasing daily, driven by the rising consumption of paper bags in India. Mohindra Machine stands out as a leading manufacturer of Doctoring Slitting Machines. We are dedicated to producing and supplying these machines to potential customers in the market. The Doctoring Slitting Machine is designed to cut and convert large sheets of paper, foil, and film materials into narrower rolls. These machines consist of three main components: the slitter, unwind, and rewind.

#Bopp paper tape coating machine price#Bopp paper tape coating machine price in india#Bopp paper tape coating machine in india#Bopp paper tape coating machine for sale

1 note

·

View note

Text

Jandu PPM - Printing and Packaging Machines Manufacturer

Jandu Printing and Packaging Machines Company is a professional Slitting and Rewinding Machine manufacturer and supplier in Delhi, India. We are manufacturing an exclusive range of slitter and rewinder machines, which are widely used for cutting and rewinding paper.

Jandu PPM offers highly versatile Roll To Sheet Cutting Machine and centre drum slitting and rewinding machines suitable for slitting plastic films, paper, and metal foils. This machine comes with slitting.

Contact Jandu Printing and Packaging Machines

Company: Jandu PPM

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#ReelToSheetCuttingMachine#RollToSheetCuttingMachine#JanduPPM

1 note

·

View note

Text

The flexible packaging industry is undergoing a revolution, driven by innovative technologies that prioritize precision, efficiency, and versatility. Among these advancements, the Slitter Rewinder Machine stands as a cornerstone of modern converting solutions.

#krishnaengineeringworks#flexible packaging#packaging#packagingindustry#machines#machine#manufacturer#slitterrewindermachine#machinery#export#supplier#industrial#packaging machine

2 notes

·

View notes

Text

#conpaptex#machine#manufacturers#flexible packaging#packagingmachinery#packaging industry#plastic#plastic slitter rewinder machine#industry#slitter rewinder machine

1 note

·

View note

Text

Slitting and Rewinding Machine Manufacturer

Jandu Printing and Packaging Machines Company is a professional slitting and rewinding machine manufacturer and supplier in Delhi, India.

Key Features of Slitting and Rewinding Machines

Latest in Design

Good Performance

Simple in Operating

Easy Maintenance

High Speed

Contact for Slitter and Rewinder Machine

Company: Jandu Printing and Packaging Machines

Call: +91-9811100842, 9811510842

Address: 25/18, Gali No.6, Master Mohalla Libaspur, Delhi-110042

#SlittingandRewindingMachine#SlitterandRewinderMachine#CentreDrumSlittingAndRewindingMachine#janduppm

1 note

·

View note

Text

Slitter Rewinder Machine Manufacturers

1.Special designed machine depend on customer’s request.

2.It can instill CCD camera, splicing table, ink, welding.

3.SIEMENS servo or Inovance(China)syste

Tel:0086-571-88813010 Email:[email protected]

0 notes

Text

Roll Slitting Machine Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The Roll Slitting Machine Global Market Report 2024 by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Roll Slitting Machine Market: https://www.thebusinessresearchcompany.com/report/roll-slitting-machine-global-market-report

According to The Business Research Company’s Roll Slitting Machine Global Market Report 2024, The roll slitting machine market size is expected to see strong growth in the next few years. It will grow to $2.95 billion in 2028 at a compound annual growth rate (CAGR) of 5.1%. The growth in the forecast period can be attributed to expansion of the renewable energy sector, expansion of the printing and converting industry, growth in flexible packaging, and increased use of flexible packaging materials, development of e-commerce. Major trends in the forecast period include development of advanced automation and control systems, precision cutting technologies, development of energy-efficient and waste-reducing slitting technologies, customization and versatility, and digital control systems.

The growing e-commerce industry is expected to propel the growth of the roll-slitting machine market going forward. The e-commerce industry encompasses online platforms where goods and services are bought and sold electronically, facilitating transactions between businesses, consumers, and suppliers worldwide. The growth is supported by increased internet penetration, the convenience of online shopping, broader product availability, and evolving consumer preferences towards digital transactions. Roll slitting machines are required in the e-commerce industry for efficiently processing and packaging various materials, like packaging films and labels used in shipping and product packaging. For instance, in October 2021, according to a report published by the International Trade Administration, a US-based agency, it is anticipated that e-commerce for consumer goods will constitute approximately 22% of global retail sales in 2024, with a projected average annual growth rate exceeding 1%. Additionally, global retail e-commerce sales are expected to maintain a steady increase of 8% annually through 2024. Therefore, the growing e-commerce industry is driving the growth of the roll-slitting machine market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=17250&type=smp

The roll slitting machine market covered in this report is segmented –

1) By Type: Roll Or Log Slitters, Slitter Rewinders 2) By Material: Paper, Polymers, Foil, Other Materials 3) By Slitter Blade: Large Circular Blade, Fixed Band Blade 4) By Distribution Channel: Direct Sales (Original Equipment Manufacturer (OEM)), Indirect Sales 5) By Industry: Paper And Pulp, Textile, Packaging, Other Industries

Major companies operating in the roll slitting machine market are developing technologically advanced products, such as high-performance rewinder slitters, to better serve customers with advanced features. A high-performance rewinder slitter is a precision machine designed to efficiently slit and rewind various materials, such as paper, film, and foil, with exceptional speed and accuracy. It is often used in industrial manufacturing processes. For instance, in February 2022, Vemax, a Brazil-based machinery company, launched the Vemax VRXS STDH Rewinder Slitter. The distinctive feature of Vemax's high-performance equipment lies in its differential axles, tailored for heavy-duty operations with paper, plastic, or self-adhesive films, serving flexible packaging, labeling, and tag industries globally. These machines integrate an advanced control system, enabling direct communication via an internal network with the machine's PLC and all electronic components. This technology facilitates remote and online programming adjustments and repairs, emphasizing innovation, safety, and quality in flexible packaging machinery.

The roll slitting machine market report table of contents includes:

1. Executive Summary

2. Roll Slitting Machine Market Characteristics

3. Roll Slitting Machine Market Trends And Strategies

4. Roll Slitting Machine Market - Macro Economic Scenario

5. Global Roll Slitting Machine Market Size and Growth .............

32. Global Roll Slitting Machine Market Competitive Benchmarking

33. Global Roll Slitting Machine Market Competitive Dashboard

34. Key Mergers And Acquisitions In The Roll Slitting Machine Market

35. Roll Slitting Machine Market Future Outlook and Potential Analysis

36. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Pacific Laminates to invest Rs 50 crore over the next three years

Pacific Laminates based in Pardi in Gujarat has announced plans to invest approximately Rs 50 crore (US$ 6 million) over the next three years to triple its flexible packaging printing and converting capacity. The company’s current manufacturing capacity stands at 600 metric tons monthly, generating a revenue of Rs 70 crore.

Through strategic and concerted investments in technology, infrastructure, and talent, the aim is to increase its output capacity to 1500 metric tons monthly over two to three years. The company envisions an increase in A-grade clients and a shift to more sustainable materials and solutions to make up at least 30% of its product mix. The overall attempt is to achieve annual revenues from Rs 300 to Rs 400 crore with an EBITDA of 12 to 15% in the coming years.

The decades-old company is a supplier to domestic and global brands and markets with exports of packaging materials to the United States, Europe, and the Middle East. Its current capacity includes two multilayer LDP blown film lines, three rotogravure presses with ARC and turret winders, a pair of solventless laminators, an extrusion coater, several slitter rewinders, and a battery of 34 pouching machines.

This comprehensive setup enables Pacific Laminates to produce a wide range of flexible laminates, pouches, and packaging solutions catering to diverse industry needs. With a commitment to innovation and quality, Pacific Laminates delivers exceptional flexible packaging solutions.

The company is well known for its pouch solutions for food, FMCG, automobile, soaps, detergents, beverages, pharmaceuticals, and cosmetics, using laminates and structures with combinations of PE, PP, PET, Nylon, aluminum, BOPP, BOPA, PVC, PVDC, EVOH, and EVA. Pacific’s BOPP pouches are known for their excellent barrier properties and heat sealability and are used widely in the food, stationery, garment, and hosiery segments.

Pacific Laminates specializes in shaped and broom pouches. While unique shapes of certain products present challenges in packaging and branding the company through its experience and specialized machinery and skills can provide innovative packaging solutions for such products.

Aligned with customer’s sustainability goals

Recognizing the growing importance of sustainability in the packaging industry, the company has been actively exploring eco-friendly alternatives that it plans to extend in its projected capacity expansion. Committed to reducing its environmental footprint by using recyclable and biodegradable materials, the company is investing in research and development to develop packaging solutions compatible with sustainable practices.

These efforts include minimizing material usage and streamlining packaging processes to reduce waste and improve efficiency. The company has undertaken responsible and ethical sourcing of materials in its effort to maintain its reputation as a trusted partner of leading consumer product brands for their high and sustainable packaging solutions.

0 notes