#slitting

Text

Me cuz i can just cut myself in peace when im home alone

#menhera#desperate for attention#mentally insane#cute#jirai danshi#jirai lifestyle#obsessed#cutting#self h@rm#slitting#home aline#kawaii angel#kangel

4 notes

·

View notes

Text

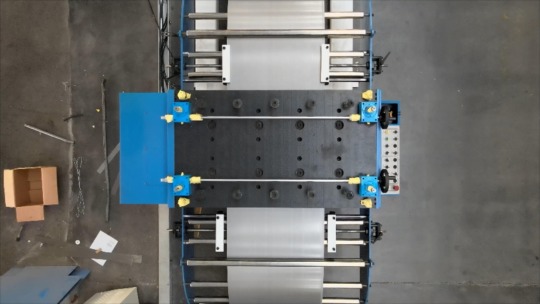

How to Choose Steel Slitting Machine?

Selecting the appropriate steel slitting machine for your industry is crucial for optimizing production efficiency and ensuring quality output. Here are some essential considerations:

Assess Your Needs: Determine the specific requirements of your production line, including material type, thickness, and width.

Evaluate Machine Features: Look for machines that offer precision cutting, adjustable speed settings, and easy maintenance.

Consider Production Volume: Choose a machine that aligns with your expected output to avoid bottlenecks in production.

Research Manufacturers: Opt for reputable manufacturers known for their reliability and customer support.

For more insights on choosing the right slitting machine, explore our resources!

+86-13814241007

[email protected]

#SteelSlitting#SlittingMachine#SteelProcessing#SlittingLineProcess#PrecisionCutting#Howtochooseaslittinglinemachine#SteelSlittingLineProcess#SteelCoilSlittingMachine#WhatisCoilSlittingLineMachine#ChoosingtheRightCuttingMachine#SlittingLineMachine#SlittingLineParts#slittinglinesProcess#slittinglinesTechnology#MetalCoilSlittingMachine#SlittingLineSetup#CoilSlittingProcess#Metalworking Machinery#IndustrialSlittingMachine#SteelCoilSlitting#SlittingMachineOperation#MetalCoilProcessing#SlittingLineTroubleshooting#slitting#slitting line#lotosslitting#high speed slitting line#slitting machine#industrialmachinery#precisionengineering

0 notes

Video

youtube

We are looking for a Slitting & Rewinding service provider company in th...

0 notes

Text

बदायूं में नाई ने उस्तरे से गला काटकर की दो मासूम भाइयों की हत्या, गुस्साए लोगों ने चौकी के सामने की आगजनी

बदायूं में नाई ने उस्तरे से गला काटकर की दो मासूम भाइयों की हत्या, गुस्साए लोगों ने चौकी के सामने की आगजनी

Uttar Pradesh News: युपी के बदायूं से एक दिल दहला देने वाला मामला सामने आया है। जहां एक नाई ने उस्तरे से 2 मासूम बच्चों की गला रेतकर हत्या कर दी तीसरा बच्चा उसके चंगुल से भागने मे कामयाब रहा। वारदात को अंजाम देने के बाद नाई मौके से भाग गया।

इस घटना से गुस्साए लोगों ने इलाके में स्थित नाई की दुकानों में तोड़फोड़ की वह दुकाने जला दी। वहीं देर रात पुलिस ने आरोपी को एनकाउंटर में मार गिराया। पुलिस के…

View On WordPress

0 notes

Text

got thinking about gerard way tour outfit predictions that never came 2 be… bloody wedding dress…

#they’ve got legs and a slit throat!#this is one i believed 2 be totally out of the question bc it would be too bulky restrictive etc#but then i was doing my research and i discovered The 60s Wedding Mini Dress and i was like oh my god she would#kind of a mod vibe but w more gothic detail so it still reads as bridal out of context yk yk. perhaps#mcr#gerard way#digital art#x

11K notes

·

View notes

Photo

BIRTHDAY DAN AND PHIL CHARITY STREAM TOMORROW - DO NOT MISS THIS MONUMENTAL EVENT IN POP CULTURE HISTORY

6K notes

·

View notes

Text

Metal Slitters Unveiled: Slitting, Cutting, or Fracturing? Which Should You Choose?

When you're building the towering skyscrapers, the colossal bridges, or even the luxurious condos that give our cities their unique skylines, the last thing you probably think about is the humble metal slitter. But today, we're about to shine a light on this overlooked hero.

When it comes to professional construction projects, choosing the right metal services can make a world of difference. Slitting, cutting, or fracturing metal? What's the difference? Which is best for your project? Buckle up, because we're about to dive into the metallic maze and emerge as experts on the other side.

Metal Slitters: The Quiet Champions of Construction

Ah, the thrill of a towering skyscraper. The magic of a sprawling bridge. And amid all this architectural grandeur? Enter the modest metal slitter, often overlooked, yet indispensable.

Picture this: a diligent worker, efficiently and quietly slitting away, ensuring that the beams, frames, and railings all fit together in harmony. Now, I know what you're thinking: "It's just a machine, right?" But metal slitters are like the rhythm section in a band. They might not always be the lead guitarists grabbing the attention. But without them, the song just doesn’t feel right.

Just imagine if the metals weren’t cut with precision. Those perfectly aligned windows or that flawless balustrade? They wouldn’t exist. These machines, operating in the backdrop of metal services, make all those intricacies possible in construction. They make sure that each piece fits just right, making the entire construction process smoother and easier. And honestly, isn't that what we all want in life? A little smoothness and ease?

The Art of Slitting: Where Craftsmanship Meets Technology

Slitting isn't just about splitting metal; it's a delicate dance of craftsmanship and technology. Picture a painter meticulously creating fine brush strokes on a canvas. That's what slitting feels like in the world of metal services.

Using a series of sharp, circular knives, the slitter slices through metal sheets or rolls, almost like how a master chef dices vegetables. Each slice, each strip, made with precision and consistency. What's truly fascinating is how uniform these strips are, making them absolutely perfect for those construction projects where even a millimeter can make a world of difference.

And here’s a little secret for you: the efficiency of slitting can be a lifesaver. Especially when you're racing against time to meet project deadlines. The quicker the slitting, the faster the building goes up. It's like magic, but better because it's real.

Cutting Metal: The Swiss Army Knife of Metal Manipulation

Now, if slitting is the fine brush stroke, cutting is like sculpting a masterpiece from a block of stone. Cutting is versatile, flexible, and, dare I say, a tad adventurous.

While slitting is all about those long, slender strips, cutting is where you get to play with shapes. Circles, triangles, funky custom designs: you name it, cutting can achieve it. Ever wondered how those intricate metal designs in fancy lobbies or exquisite gardens come to life? Yep, you guessed it: the marvel of cutting techniques, like laser or plasma cutting.

Of course, with great power comes great responsibility. While cutting offers versatility, it demands precision. It’s a bit like fitting the pieces of a puzzle together; each piece has to be just right. But when done right, the results are simply awe-inspiring.

Fracturing Metal: The Powerhouse of Endurance

Imagine the core strength of a gymnast, flexing and bending without breaking. That's exactly what fracturing, or bending, does to metals. It’s a show of sheer endurance. Unlike cutting or slitting, where the aim is to separate, fracturing molds the metal, giving it a new shape without splitting it apart.

Why is this bending without breaking so crucial, you ask? Think about the backbone structures in our buildings. Those metals need to be sturdy, withstanding not only the weight of the structure but also the external forces of nature. By bending the metal at certain angles, we create components that can shoulder this heavy responsibility.

Cost Considerations: Navigating the Financial Landscape

Money talks, especially in construction. But here's the thing: while we all love a bargain, it's crucial to understand the true value of our choices in metal services.

Let’s break it down. Slitting, with its swift and efficient ways, often comes out as the budget-friendly champ. It's like grabbing that early-bird discount – quality results, but easier on the pocket.

Cutting, with its artsy flair and custom designs, can be a bit more lavish. It’s akin to ordering a bespoke suit: unique and tailored to perfection, but with a slightly heftier price tag.

Lastly, fracturing is the solid investment. Think of it as buying that timeless, durable watch. It might seem like a splurge upfront, but its longevity and robustness make it worth every penny in the long run.

In the end, it's all about balance. Weigh your project's needs against your budget, and remember: sometimes, spending a bit more upfront can save costs down the line.

Environmental Concerns: Building with a Conscience

In today’s age, it's not just about building; it's about building responsibly with Quantify North America. The environment is a shared inheritance, and the choices we make in construction today will shape the world for generations to come.

Slitting, for instance, has an eco-friendly edge. With its straight, clean cuts, it minimizes waste, much like using every bit of fabric when sewing a garment. Less waste means a happier planet.

Cutting and fracturing, while offering their unique advantages, might produce more material leftovers. But here's where innovation steps in. Many metal services providers are now adopting sustainable practices, recycling the residues or repurposing them for other projects.

If the environment holds a special place in your heart (as it should), always inquire about the green credentials of your metal services. Because constructing responsibly doesn't just build structures; it builds a legacy.

Conclusion

In the bustling cacophony of construction, metal slitters are your unsung heroes. They silently chip away at those big metal sheets, turning them into the perfect pieces for your architectural masterpieces.

Slitting, cutting, or fracturing: each has its pros and cons, and the choice boils down to what suits your project best. So, the next time you consult with your metal services provider, you'll be armed with all the information you need to make an informed decision.

Learn More:

Custom Metal Fabrication

Metal Painting

0 notes

Text

The sheet coil slitting machine is widely applied in steel furniture, electrical cabinets, elevator, etc. industries, which can be combined with laser cutting, cnc panel bender, Robert loading and unloading system, which can realize the 24 hours unmanned processing and the electricity consumption only need 1 degree/hour. This sheet metal coil line machine is the complete solution for coil sheets. Including a de-coiling system, levelling system, thick turret punching and slitting system.If you need the higher productivity, less electric consumption and less cost on materials and labors. REMCOR sheet metal slitting machine is your best choice. Contact us and get steel coil slitting machine price now!

REMCOR coil-sheet fed punching or shearing line is a fully automated punching solution for metallic coils. Which can realize the 24 hours unmanned production. It is capable of handling coils of 300 – 1500 mm in width, up to 9 ton in weight.

Features of Coil-Fed Punching Machine

24 hours unmanned processing, From the de-coiling, feeding, leveling, feeding, thick turret punching, slitting the whole process can be done with our system continuously. Realize the real 24 hours unmanned processing. The traditional processing needs different systems and a numeral labor to handle the machine together with loading and unloading. Different devices have different beats and lead a lot of waste on labors.

Higher productivity, only need to monitor the system, can realize the 24 hours continuous automatic manufacturing. Continous processing from the raw coil material to the final profile, there is no waste of time in loading and blanking compared with traditional forming lines. 2 times faster than traditional technologies.

Higher Flexibility, Multiple combination with standard die bases and diverse die tools, one-to-one correspondence between products and molds. Shorter mold changing time.

More chances for automation, It is available for combining with laser cutting system, panel bender system, and Robert loading and unloading system, which can leave more space for automation. With punching station unworking, and the other station working, it is equivalent to a leveling line, can provide plates for turret punching, single platform laser cutting machines, automatic panel benders, etc.

Parameter Details of Coil-Fed Punching Machine

Feeding system

1000mm/ Precision Ball Screw

Die base

2 sets of standard thick turret plug-in box molds 4 sets of Remcor standard mold bases

Punch frequency

200cp/min

Die changing trolley

2

Number of servo axes

8+1+2

Material width

300-1000mm

Feed roller

2sets

Correction roller

Up 5/Down 4

Output speed

16m/min

Coil weight

7T/8T

Coil inner hole

φ508mm

Coil outer hole

φ1300mm

Rack expansion

Hydraulic

Max thickness

2mm

Forth

300KN

Maximum punching

90*180mm

Number of modules

There are 8 stations in B and 4 stations in D, which can hold 4 large squares or 8 small squares

Punching accuracy

±0.1mm

Diagonal accuracy

±0.5mm

Coil loading - Trolley - Decoiler

The Coil-sheet fed system starts with loading. The process can automatically change from one material to another in under 2 minutes. The hydraulic expansion is applied in decoiling station. After the decoiling station, the strip is straightened and the coiling tensions are removed.

Levelling station

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

Punching unit

The levelling station principle is using upper and down rolls to staigthen the strip. After this station the tensions for the strip are removed. The rolls and drive motors will be choosen according to the material thickness. The straightener settings can be imported from the controller system, we also add the manual wheel for the special condition

FAQ of Coil-Fed Punching Machine

1. How can I know if your system workable for my factory

Our metallic coil-sheet feed punching line is widely applied in steel furniture industry, the electric cabinets. the elevator shells, the kitchen and bathroom facilities, etc. Pls kindly share with your profile drawings and material type, width, thickness, weight. We will offer you suitable proposals

2. Can I come to your factory to check the real working process?

Yes and before travelling, pls also kindly share with us your profiles drawings, material type and thickness and weight. We welcome the global business partners to visit us.

3. What's your system punching process, and are they same as turret punching?

Our system Punching is done by tools set in two traversing tool cassettes, with the punching stroke done by a single ram plate. The dies quantity for our punching unit is at least 6 stations more than turret punching. And our system support the customerized square dies. The system starts with the raw coil material, which is different as turret which need to be cut-to-length square sheets that have been processed. The completly efficiency for our system is much higher than turret punch.

0 notes

Text

couldn’t even focus on the rest of the dialogue because this sent me into hysterics

#bg3#dark urge#durge#sceleritas voice. my dear genderless champion…perhaps you ought to start slitting the throats of those who do not respect your pro-nouns#sceleritas fel

6K notes

·

View notes

Text

Idk why no one has done this for the phour. Here’s Dan and Phil as tits.

#phan#danisnotonfire#amazingphil#dnp#dan and phil#phour#terrible influence tour#hey Phil look at this#grace.png#why has this popped off?#dan and phil games#🥥🥥#I FORGOT TO GIVE THEM SLITS

2K notes

·

View notes

Text

another seb screenshot redraw between work

(credit to yukihon_d on twitter!)

#that glare......that damn glare#hey seb watcha casting?? probs just killing someone for clora nbd 😇😇😇#no dark arts allowed but slitting someones throat with diffindo?? all good!!😍😍#such a good screenshot tho......the pose is cool and the expression and his hair like okkkkk??? model#actually now that i look it kinda reminds me of that one classical painting ppl always redraw that i forget the name of#you know the one#sebastian sallow#choccyart#hogwarts legacy

1K notes

·

View notes

Text

Steel Slitting Line Components

The efficiency of your slitting machine depends significantly on the quality and performance of its individual parts. From cutting components to specialized slitting machine parts, we ensure that all elements meet industry standards for optimal operation.

+86-13814241007

[email protected]

#SteelSlittingLine#MetalSlittingMachines#SlittingMachineParts#CuttingComponents#slittingmachineparts#Componentsslittingmachine#SteelCoilSlittingLine#SLITTINGLINEPARTS&SERVICES#WUXICHINA#SlittingLineMachine#SlittingLineParts#slittinglinesProcess#slittinglinesTechnology#MetalCoilSlittingMachine#SlittingLineSetup#CoilSlittingProcess#Metalworking Machinery#IndustrialSlittingMachine#SteelCoilSlitting#SlittingMachineOperation#MetalCoilProcessing#SlittingLineTroubleshooting#slitting#slitting machine#lotosslitting#high speed slitting line#slitting line#precisionengineering#industrialmachinery#slittingline

0 notes

Text

I may die before I can draw them consistently

#cotl art#narilamb#I’m liking how my lamb is slowly turning out but Narinder staying mostly the same forever with his fruity slit dress as a staple asdfgjkl

2K notes

·

View notes