#Smart Factory Solutions

Explore tagged Tumblr posts

Text

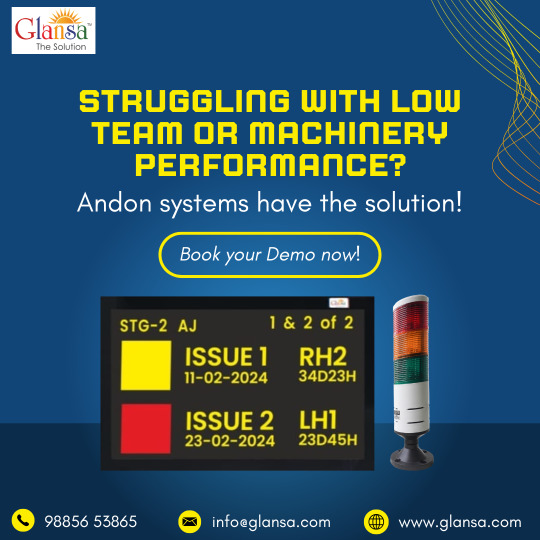

Red and Yellow Andon: Boosting Manufacturing Efficiency Through Visual Management

In today’s fast-paced industrial environment, the need for real-time communication on the shop floor is more critical than ever. Manufacturers are constantly seeking smarter ways to minimize downtime, improve safety, and ensure smooth operations. One of the most effective tools for achieving this is the Andon system, particularly using Red and Yellow Andon lights.

What is an Andon System?

An Andon system is a visual alert tool used in lean manufacturing to notify operators and managers about production line issues. It helps enhance process visibility, team coordination, and problem resolution.

At Vidgastech, we specialize in designing smart Andon systems tailored for various industrial needs. Our systems use a combination of red and yellow signals to streamline operations and promote rapid response.

Understanding Red and Yellow Andon Signals

🔴 Red Andon Light: This indicates a critical issue that requires immediate attention, such as a machine malfunction, safety hazard, or production stop.

🟡 Yellow Andon Light: A warning signal to show non-critical issues, such as material shortages, minor defects, or preventive maintenance alerts.

These signals help teams act quickly and effectively, reducing downtime and boosting overall productivity.

Benefits of Red and Yellow Andon in Manufacturing

✅ Faster identification and resolution of issues ✅ Improved communication between teams and supervisors ✅ Reduced downtime and higher throughput ✅ Enhanced worker safety and accountability ✅ Supports lean and Six Sigma practices

Why Choose Vidgastech’s Andon Solutions?

At Vidgastech, we understand the unique challenges of modern manufacturing. Our Red and Yellow Andon systems are designed with reliability, clarity, and scalability in mind. We offer:

High-visibility LED Andon lights

IoT integration for real-time monitoring

Custom alerts and configurations

Easy installation and low maintenance

Whether you operate in automotive, electronics, packaging, or food processing, our solutions can be adapted to your specific requirements.

Final Thoughts

Implementing a Red and Yellow Andon system is more than just installing lights—it's about building a culture of responsiveness and continuous improvement. With Vidgastech’s expertise and technology, your facility can achieve greater control, visibility, and operational efficiency.

About Vidgastech Vidgastech is a leading provider of industrial automation solutions, helping businesses transform their shop floors into smart, responsive production environments.

🔗 Learn more at: https://www.vidgastech.com

#Red Andon Light#Yellow Andon Light#Andon System#Lean Manufacturing#Visual Alerts#Production Efficiency#Vidgastech#Smart Factory Solutions

0 notes

Text

Weatherproofing Industrial Equipment: Smart Solutions for Harsh Environments

Discover practical methods and real-world advice to safeguard your machinery from rain, dust, heat, and corrosion—because downtime is never an option.

📘 Introduction

Why I Started Caring About Weatherproofing

A few years ago, I watched one of our most reliable outdoor compressors break down after a night of heavy rain. It was just one storm, but it cost us over $10,000 in repairs and halted production for 3 full days. That was my wake-up call. Since then, I’ve made it my mission to understand weatherproofing industrial equipment and implement smart, sustainable strategies.

A Costly Mistake That Taught Me a Lesson

The mistake? We assumed equipment labeled "rugged" could withstand anything. But harsh weather doesn't discriminate. Rain penetrates, UV rays degrade, and rust creeps in slowly but surely.

What I’ll Share With You

Proven ways to protect machines from harsh weather

Smart solutions for weather damage

Maintenance tips and materials that work

How to extend machinery life outdoors

10 FAQs, product tips, and real stories

Let's dive in.

⚙️ 1. The Hidden Dangers of Unprotected Industrial Equipment

Rain, Snow, and Humidity Issues

Moisture is one of the biggest threats to any type of industrial equipment. From short circuits in control panels to rust forming in gearboxes, unprotected machines are vulnerable.

UV Degradation of Materials

Plastic parts, rubber seals, and even paint coatings can break down under prolonged exposure to sunlight. This weakens structural integrity and invites faster deterioration.

Rust, Corrosion, and Rot

Without anti-corrosion solutions for heavy-duty gear, rust can silently destroy machines. I've seen whole outdoor cranes deteriorate within months in coastal areas.

Case Study: A Mining Site's Loss

A mining operation lost over $250,000 worth of conveyor equipment in under a year simply due to lack of adequate industrial equipment rain protection.

🌞 2. Understanding Your Local Environment and Threats

Know Your Climate Zone

Coastal/Marine: Salt accelerates rust and corrosion.

Desert: High UV exposure and sand erosion.

Polar: Freezing can cause hydraulic lines to burst.

Tropical: High humidity means nonstop rust risk.

Use Data and Sensors for Localized Protection

Install humidity sensors inside enclosures.

Monitor temperature extremes.

Use data to automate smart HVAC systems or deploy alerts.

🧰 3. My Go-To Smart Solutions for Weatherproofing

Waterproof Enclosures and Shelters

IP66-rated boxes for control panels

Steel-framed sheds for compressors

Custom Industrial Covers

PVC or vinyl-based

Tailored to specific machine profiles

Ventilated and UV-resistant

Rustproof Coatings and Anti-Corrosion Sprays

Zinc-rich primers

Spray-on hydrophobic coatings

Airflow and Humidity Control Tools

Desiccant dryers

Smart ventilators

Automatic Weather Sensors

Used to trigger protective systems

Ideal for automation-driven industries

Smart HVAC and Temperature Regulators

Regulate internal cabinet temperatures

Prevent freeze-thaw cycles

🛡️ 4. Must-Have Materials That Really Work

PVC-Coated Polyester

Flexible, waterproof, resistant to UV rays

Industrial-Grade Tarpaulins

Often multi-layered for maximum insulation

Corrosion-Resistant Metals

Galvanized steel, stainless steel, or anodized aluminum

Powder Coating

Durable, aesthetic, and protective

Hydrophobic Coatings

These repel water and prevent buildup on surfaces

💡 5. How to Plan a Weatherproofing Strategy from Scratch

Assess Equipment Vulnerabilities

Exposed electrical components?

Stationary vs mobile?

Ingress protection (IP) ratings?

Calculate ROI of Weather Protection

Investing $2,000 in protective covers saved me from a $12,000 gearbox replacement.

Long-Term Maintenance Budgeting

Plan for yearly coating touch-ups, cover replacements, and inspections.

Smart Inventory and Spare Part Planning

Weather exposure speeds up wear—keep backups handy.

🧪 6. Real-World Case Study: How I Protected My Outdoor Compressor Units

The Challenges I Faced

Constant rain exposure

UV damage cracking rubber hoses

Failing electrical panels

What Worked

Installed sloped shelters

Used anti-corrosion solutions for heavy-duty gear

Weekly manual checks

What Didn’t

Generic plastic covers (they tore in wind)

Ignoring early signs of rust

Cost vs Savings

Spent: $3,200 | Saved: Over $25,000 in downtime and repairs

📏 7. Maintenance Tips That Make a Difference

Weekly Checks

Look for cracks, rust spots, pooling water

Cleaning Routines

Remove dirt, salt, and debris

Rotate and Air Out Covers

Prevent mold buildup

Spot-Treat Rust and Wear

Immediate intervention = long life

💼 8. How to Convince Your Boss (or Yourself) to Invest in Weatherproofing

Downtime Cost Calculation

Calculate hourly loss per machine and multiply by average outage duration.

Insurance and Compliance Considerations

Some insurers offer discounts for weatherproofed assets.

Environmental Safety and Sustainability

Less breakdown = less waste = greener operations

🔧 9. Tools, Vendors, and Products I Swear By

Tool/ProductUse CaseNotesPVC Covers from CoversAndAllCustom fit for machinesUV & water-resistantRust-Oleum Cold Galvanizing CompoundAnti-corrosion paintIdeal for steel partsFluke 971 Temp-Humidity MeterClimate monitoringHighly accurate

📉 10. What Happens When You Don’t Weatherproof

Real Industry Stats and Consequences

$1B+ annually in machinery losses due to weather (U.S. manufacturing)

Stories of Unplanned Shutdowns and Losses

A logistics hub shut down 3 days due to rusted chain lifts

Environmental Impact and Fines

Oil leaks from weathered machines = EPA violations

❤️ Heartfelt Conclusion: Why I Care So Much About This

My Personal “Aha” Moment

Watching a $40,000 pump die because of moisture made me realize: prevention is cheaper than repair.

Why This Topic Matters

In a world battling climate unpredictability, weatherproofing isn’t optional—it’s responsible engineering.

How Weatherproofing Changed My Business

From unpredictable breakdowns to reliable uptime, it’s made us leaner, safer, and more productive.

❓ Top 10 Frequently Asked Questions (FAQ)

What is the best material to weatherproof outdoor equipment? PVC-coated polyester or industrial-grade tarps.

Can I use regular plastic covers for my machinery? No—they degrade quickly and offer little UV protection.

How much does a professional weatherproofing system cost? Anywhere from $1,000 to $50,000+ depending on scale.

What’s the easiest DIY weatherproofing method? Use tailored waterproof covers and apply rust-preventive sprays.

How do I protect electronics and control panels outdoors? Use IP66+ rated enclosures with desiccant inserts.

Does rust-proof paint actually work long-term? Yes, especially zinc-rich and powder-coated options.

Can heat also damage industrial equipment? Absolutely. Overheating degrades lubricants and seals.

What are the signs my equipment is weather-damaged? Rust spots, discoloration, insulation cracking, sensor failure.

How do I maintain my covers and enclosures? Clean monthly, inspect quarterly, replace annually if worn.

Should I invest in smart weather sensors? Yes—they prevent damage through early alerts and automation.

❤️🔥 Touch

❝I’ve watched rust slowly eat away at machines I once trusted. I’ve learned that nature doesn’t care about your deadlines or budgets. But we can care—and we can act. Protecting your equipment isn’t just a task, it’s a commitment to safety, sustainability, and success. Don’t wait for the storm to act. Start weatherproofing today—and give your machines the future they deserve.❞

👉 Share this guide with your maintenance team or save it for your next facility audit. If this helped you, leave a comment or message me. Let’s build smarter, together.

⚠️ Disclaimer

This article is based on my personal experience and industry knowledge. Always consult with a certified industrial maintenance expert before implementing new systems in high-risk environments.

#Industrial Equipment Maintenance#Heavy Equipment Protection#Outdoor Machinery Care#Industrial Engineering#Smart Factory Solutions#Equipment Longevity#Industrial Asset Management#Plant Maintenance Best Practices#Manufacturing Safety Tips#Facility Management Insights#Weatherproofing Industrial Equipment#Protect Machines from Harsh Weather#Outdoor Equipment Weather Protection#Dust and Rust Prevention Solutions#Rain Protection for Machinery#UV Protection for Equipment#Heat Resistant Industrial Covers#Snow and Ice Protection for Machines#Anti-Corrosion Coating for Equipment#Smart Weather Sensors for Factories

0 notes

Text

Manufacturing IoT in the Automotive Industry - Key Companies and Trends to Know

Explore how top companies are using IoT in automotive manufacturing to boost efficiency and reduce costs. Learn how Theta Technolabs, a leading IoT app development company in Dallas, builds smart IoT solutions to power innovation in the automotive industry.

#IoT Solutions#IoT in automotive manufacturing#IoT app development company#smart factory solutions#industrial IoT solutions#Technology

0 notes

Text

The Role Of Robotics And Automation In Smart Factory Solutions

As manufacturing continues to evolve, robotics and automation have become integral to creating smart factories. These technologies are not just transforming factory floors but are driving significant improvements in efficiency, precision, and overall production. Let’s explore the critical role robotics and automation play in smart factory solutions and how they contribute to manufacturing excellence.

1. Boosting Production Efficiency

One of the main advantages of integrating robotics and automation in smart factories is enhanced production efficiency. Automated machines can work continuously without breaks, increasing the output rate compared to manual labor. Robots can perform repetitive tasks with consistent speed and accuracy, which reduces downtime and accelerates the manufacturing process. This enables manufacturers to meet higher production targets without sacrificing quality or introducing errors.

2. Ensuring Precision and Consistency

Robotics plays a crucial role in achieving precision in manufacturing processes. Robots can perform tasks like assembly, welding, and painting with high precision and repeatability, ensuring that each product meets stringent quality standards. Whether it’s micro-welding in electronics or assembling complex automotive parts, robotics provides the accuracy that humans may not be able to match. This leads to reduced defects and higher consistency in product quality.

3. Reducing Labor Costs and Human Error

By automating labor-intensive and repetitive tasks, businesses can reduce labor costs and decrease the potential for human error. Automation frees up human workers to focus on more strategic roles like system management, innovation, and quality assurance, leading to better resource allocation. Additionally, robots can work in hazardous environments where human workers may face safety risks, thus improving workplace safety.

4. Improving Flexibility and Scalability

One of the standout features of robotics and automation in smart factories is their flexibility. Automated systems can quickly adapt to new products or changes in manufacturing processes. Robots can be reprogrammed for different tasks, while automation systems can easily scale production up or down to meet market demand. This agility is essential for manufacturers in today’s fast-paced, consumer-driven markets.

5. Enabling Data-Driven Decision-Making

Robotics and automation in smart factories are often connected to IoT sensors and cloud-based systems, which collect real-time data. This data is used for predictive maintenance, quality control, and performance optimization. Automated systems can analyze data to make adjustments on the fly, ensuring optimal performance and minimizing the risk of machine breakdowns or production delays.

Conclusion

Robotics and automation are central to the success of smart factory solutions. By enhancing production efficiency, ensuring precision, reducing labor costs, and improving safety, these technologies drive manufacturing excellence. As industries continue to embrace automation, the future of smart factories looks increasingly promising, with robotics at the core of innovation and productivity.

0 notes

Text

Conveyor Systems for OEM Machine Builder Partners

Our capacity to provide process advancements to our OEM partners and apply process improvements to their customers go hand in hand. Every project we work on demonstrates our dedication to fulfilling new criteria and hygienic design. This not only helps the initiatives of our OEM partners, but it also fosters trust, which strengthens our relationship.

#Solutions for OEMs and Machine Builders Pune#Conveyors India#PLC Automation Pune#PLC and SCADA Service Provider India#Automators Industrial Projects#Let’s Get in Touch#Company Automators Industrial Project#Smart Factory Solutions#Energy

0 notes

Text

CNC Machine Manufacturer in India

Looking for a reliable CNC machine manufacturer in India? Discover high-quality, precision-engineered CNC machines that power industries across automotive, aerospace, electronics, and more. Indian CNC machine manufacturers have quickly emerged as global leaders, offering advanced, affordable, and durable solutions for both small businesses and large-scale industries.

One of the standout names in the Indian CNC sector is Sahil Machines. Known for their innovation and commitment to quality, Sahil Machines provides a wide range of CNC solutions, including CNC turning centers, vertical machining centers (VMC), and custom-built systems. Their machines are designed for accuracy, speed, and longevity—making them ideal for high-demand applications.

With strong after-sales service, installation support, and training, Indian CNC machine manufacturers ensure that your production lines stay efficient and productive. Whether you're a startup or an established industry player, choosing a trusted Indian manufacturer helps reduce costs without compromising on performance.

Many manufacturers now also offer smart features like IoT integration, real-time monitoring, and automated production capabilities—ensuring you stay ahead in a competitive market.

Bookmark this page if you’re planning to invest in reliable CNC machinery made in India. Experience engineering excellence, world-class support, and unbeatable value with top CNC brands from India.

0 notes

Video

youtube

Telescopic Sliding Gates | Automatic & Industrial Gate Systems by Secure...

#youtube#telescopic sliding gate#AutomaticGatesIndia#industrial sliding gates#SecureIndiaGates#AutomaticTelescopicGate#HeavyDutyGates#IndustrialGateAutomation#sliding gate system#automatic swing gate#SecurityGatesManufacturer#Automatic Gate Installation#Industrial Entrance Gates#Smart Gate Solutions#Automatic Gate for Factory#Motorized Gate Systems#Commercial Sliding Gate#Automatic Gate Supplier India#Gate Automation Ahmedabad#Entrance Control Solutions#Secure India Security Products#Automated Entry Gates#Perimeter Security Solutions

0 notes

Text

#Industrial Automation Training kits in Pune#Hydraulics and Pneumatics Manufacturer in Pune#Hydraulic Training Kit Supplier in Pune#Pneumatic Training Kit Exporter in Pune#PLC Training Kit Manufacturer#Robotics Equipment Exporter#Smart Factory Systems Trader#Mechatronics Training Kit Supplier#Industrial Automation Equipment Manufacturer#CNC Simulators Exporter#Technical Training Solutions Manufacturer#Didactic Equipment Supplier in Pune#Robotics Training kits in Pune#PLC Training kits in Pune#HMI Training kits in Pune#SCADA Training kits in Pune

0 notes

Text

Top Companies for Automation Services in Naperville, IL

Naperville, Illinois, stands out as a technology-driven city with a thriving industrial and commercial sector. As the demand for smarter, more efficient systems continues to grow, companies automation services in Naperville are becoming essential for businesses aiming to stay competitive in today's digital age.

Automation is no longer just an advantage—it’s a necessity for businesses looking to scale operations, reduce labor-intensive tasks, and increase efficiency across various departments. Whether in manufacturing, logistics, commercial buildings, or process industries, automation technologies are transforming how companies in Naperville operate, manage resources, and deliver value.

Why Automation is Crucial for Businesses in Naperville

Automation is revolutionizing the way Naperville-based companies handle their day-to-day operations. Here are several reasons why local businesses are investing in automation:

Increased productivity: Automation reduces the need for manual labor, leading to faster production cycles and reduced downtime.

Cost savings: Automated systems can significantly lower operational expenses over time.

Accuracy and consistency: Automated machines and software ensure precise execution of tasks with minimal errors.

Real-time data and analytics: Intelligent systems provide insights that help improve decision-making.

Workforce optimization: Employees can focus on high-value tasks rather than repetitive or dangerous duties.

Compliance and safety: Automation helps meet strict regulatory standards and safety requirements.

For Naperville’s growing tech and industrial scene, these benefits position automation as a long-term strategic asset.

Key Industries Leveraging Automation in Naperville

Naperville businesses across multiple industries are adopting automation technologies to streamline their operations:

Manufacturing: Robotics, CNC machinery, and industrial automation are optimizing production lines.

Warehousing and logistics: Automated conveyors, barcode scanners, and inventory systems ensure smooth supply chain operations.

Healthcare: Automation helps in diagnostics, lab testing, and administrative workflows.

Retail and service sectors: POS automation, customer service chatbots, and order tracking systems are improving customer experiences.

Building management: Building automation systems (BAS) regulate lighting, HVAC, and security systems for commercial properties.

As Naperville continues to attract diverse business investments, the demand for reliable automation companies is on the rise.

Types of Automation Services Offered by Naperville Companies

Automation companies in Naperville, Illinois offer a broad range of services tailored to specific business needs. These include:

PLC Programming and Integration: Custom logic programming for industrial control systems.

SCADA and HMI Design: Supervisory control systems with user-friendly interfaces.

Robotics Integration: Installation and configuration of robotic arms for precise and repetitive tasks.

IoT and Smart Systems: Device interconnectivity for real-time monitoring and control.

Building Automation Solutions: Energy-efficient systems for HVAC, lighting, and building access.

Custom Software Development: Development of automation software for scheduling, reporting, and analytics.

Each service is designed to help companies improve their workflows and align with modern operational standards.

Choosing the Right Automation Partner in Naperville

Not all automation companies offer the same level of expertise. When selecting a provider in Naperville, consider the following factors:

Experience and specialization: Choose companies with a proven track record in your specific industry.

Technical capabilities: Ensure they can handle the level of system complexity required.

Scalability: Look for solutions that can grow with your business.

Customer support: Strong post-installation service is key to long-term success.

Customization: Your business needs a partner that can tailor solutions to your workflow.

Certifications and compliance: Check for relevant industry certifications like UL, ISO, or OSHA compliance.

A trusted partner can help you navigate technology decisions, integrate systems, and train staff effectively.

Automation Trends Transforming Naperville Businesses

The landscape of automation is constantly evolving. Here are some top trends influencing Naperville’s commercial and industrial environments:

AI-Powered Automation: Machine learning algorithms enhance predictive maintenance and production optimization.

Edge Computing: Local data processing reduces latency and improves response time in real-time systems.

Cloud-Based Control Systems: Enables remote access, monitoring, and updates.

Green Automation: Energy-efficient solutions aligned with sustainability goals.

Cybersecurity for Automation Networks: Enhanced protection of control systems from cyber threats.

Staying ahead of these trends is key for companies looking to maintain a competitive edge in the Naperville market.

Benefits of Automation for Small and Medium Enterprises (SMEs)

Automation is not exclusive to large corporations. In Naperville, small and medium businesses are increasingly investing in automation technologies for:

Inventory management and procurement

Workflow automation in administrative tasks

Customer relationship management (CRM) systems

Automated billing and invoicing

Smart energy control in small office buildings

The accessibility and affordability of modern automation tools make them an excellent investment for SMEs aiming to scale without hiring extensively.

Automation and Economic Development in Naperville

Automation is playing a key role in Naperville’s economic growth. As companies become more efficient and competitive, they attract more business and create high-skill job opportunities. Local schools and training institutions are also responding by offering specialized programs in automation, robotics, and engineering—helping to create a talent pipeline that supports long-term innovation.

With Naperville’s continued investment in infrastructure and technology parks, the city is well-positioned to be a hub for automation excellence in Illinois.

Empowering Naperville Through Smart Automation

From small businesses to large enterprises, the ability to implement smart automation systems is critical for long-term success. The right automation partner can help you optimize operations, increase profits, and stay agile in an ever-changing market. As demand for precision, speed, and efficiency increases, Naperville businesses are finding automation to be one of their most strategic investments.

Partner with a Trusted Automation Company in Naperville

If you're seeking high-quality automation solutions tailored for your Naperville business, Xtreme Automation LLC delivers the expertise and support needed to elevate your operations. Whether you require industrial controls, building automation, or full-system integration, their team is committed to delivering scalable, efficient, and customized automation solutions. Learn more at xtremeautomationllc.com.

#automation companies Naperville IL#industrial automation Naperville#automation engineering Naperville Illinois#smart factory solutions Naperville#Naperville automation systems

0 notes

Text

Transform with SAP Industry 4.0 Solutions for Smart Factories

Explore SAP Industry 4.0 Solutions' impact on manufacturing. Unlock intelligent products, and factories with Web Synergies' expertise in SAP technologies.

1 note

·

View note

Text

Vidgastech is a leading innovator in Industrial Automation, delivering smart, scalable, and cutting-edge automation solutions to enhance manufacturing efficiency and precision. Our team of experts specializes in PLC programming, SCADA systems, IoT integration, robotics, and turnkey automation projects tailored to your industrial needs.

We help industries reduce downtime, boost productivity, and transition into Industry 4.0 with seamless automation technologies. With a strong commitment to quality, innovation, and customer satisfaction, Vidgastech is your trusted partner for transforming industrial operations.

Services:

PLC & SCADA Development

Industrial IoT (IIoT) Integration

Robotics & Machine Automation

Process Control & Monitoring Systems

Custom Industrial Software Development

Maintenance & Support Services

#Industry Automation#Industrial Automation Company#PLC SCADA Automation#Factory Automation#Smart Manufacturing#IIoT Solutions#Industrial Robotics#Vidgastech Automation#Industry 4.0 Solutions

0 notes

Text

Smart Factory with 7 Axes Robot and Digital Twin Manufacturer in Pune India

Manufacturer and Supplier of Smart Factory solutions with 7 Axes Robots and Digital Twin technology in Pune. We provide flexible manufacturing systems (MPS), connected machines, and SCADA training.

#Flexible Manufacturing Systems Manufacturer Pune#Smart Factory with 7 Axes Robot Pune#Smart Factory Manufacturer Pune#Flexible Manufacturing System Pune#MPS Manufacturing System Pune#Connected Machines Pune#SCADA Training Pune#Digital Twin Pune#Flexible Manufacturing Systems Pune#Digital Twin for Manufacturing Pune#SCADA Solutions Pune

0 notes

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

Face mask appearance inspection machine, Intsoft Tech machine vision solution

#face mask making machine#integrated machine vision solutions for the smart factory#custom automated mechanical machines#optical inspection#deep learning for vision systems#computer system validation in pharmaceutical industry

1 note

·

View note

Text

Conveyor Systems for OEM Machine Builder Partners in pune | India

Our capacity to provide process advancements to our OEM partners and apply process improvements to their customers go hand in hand. Every project we work on demonstrates our dedication to fulfilling new criteria and hygienic design. This not only helps the initiatives of our OEM partners, but it also fosters trust, which strengthens our relationship.

#Solutions for OEMs and Machine Builders Pune#Conveyors India#PLC Automation Pune#PLC and SCADA Service Provider India#Automators Industrial Projects#Let’s Get in Touch#Company Automators Industrial Project#Smart Factory Solutions#Energy

0 notes

Text

Smart Factory and Industrial Automation Market - Forecast(2024 - 2030)

Overview

The smart factory and industrial automation market is expected to be valued at $187.8 billion in 2018 and is expected to grow at a CAGR of 7.2% between 2019 and 2025. This market growth is due to the impact of evolution and adoption of the Internet of Things (IoT), industrial robots, smart automation solutions, and increasing emphasis on regulatory compliances. Industrial and commercial developments in the growing economies are also responsible for the growth of this market.

Industrial automation is defined as the automation of industrial processes through computers, communication systems, and process operators. Industrial automation minimizes human intervention in the industry and ensures a superior performance as compared to humans. Moreover, whereas, smart factory connects people, processes, and machines to enable advanced manufacturing with the optimized process reduced errors, improved quality, and eliminate waste.

Both smart factory and industrial automation enhance the productivity and quality of products and simultaneously decrease the production cost. Smart factory and industrial automation meet the demand for mass production with providing nominal human intervention, better quality, and less labor expenses, significantly reduce overall operational cost.

Report Coverage

The report: “Smart Factory and Industrial Automation Market – Forecast (2019-2025)”, by IndustryARC covers an in-depth analysis of the following segments of the Smart Factory and Industrial Automation Market

Request Sample

Key Takeaways

· Key drivers of the market are; reduction of energy consumption and increasing factory efficiency. All the Industries are adopting smart factory concept to ensure that every component of the value chain is connected for providing informed manufacturing with no-time lags and zero defects.

· The automotive manufacturing sector has been one of the largest adopters of automated robots and is the largest the revenue-generating end-user in the market. Smart factory and industrial automation play an important role in connecting and automating the operations of these robots.

· Industrial Automation in China has increased the uptake of smart manufacturing. As per the Ministry of Industry and Information Technology, China initiated around 100 smart manufacturing pilot projects in 2018.

By Application - Segment Analysis

Material handling application generated 38% of the smart factory and industrial automation market revenue in 2018. Robotics and automation system is helping in business according to their growing demands and making it cost-efficient, and these advances in technology are a material handling system more affordable and effective. This high-speed automation technology can load and unload the truck at the pallet and cartoon level. Over the next decade, material handling is expected to immerse with the automated system highly.

Various advancements have been made in the automation of the multiple activities that were formerly carried out manually (particularly in the labor-intensive manufacturing industry), with most of these being almost fully automated, with the help of the latest technologies. This has led to improved efficiency, high-quality products, and attendant savings in labor and costs.

Inquiry Before Buying

By End-User - Segment Analysis

Automotive industry end-use accounted for the highest market share in the smart factory and industrial automation market in 2018. Smart factory solutions play a key role in the development and production of quality automobiles. The automobile manufacturing industry is the largest adopter of robots in 2018 (according to the international federation of robotics {IFR}). For enhance quality and increase factory productivity, while using these robots, smart factory and industrial automation solutions play a major role.

The fastest-growing end-use in the forecasted period is the energy and power sector. The sector consists of the gas industry, petroleum industry, coal industry, power industry, among others. The adoption rate of smart factory technology is expected to be the highest in the oil & gas industry due to the growing need for safety in oil and gas plants. The automation market has penetrated the energy sector in developed economies.

By Geography - Segment Analysis

APAC accounted for the largest share, of 34% in the smart factory and industrial automation market in 2018, due to technological innovation and adoption of automation technologies across several industries. Toyota, Honda, and Suzuki are working on developing smart factories. These smart and automated factories will be manufacturing robots, sensors, wireless technologies, and machine vision systems.

Schedule a Call

Drivers – Smart Factory and Industrial Automation Market

· GROWTH IN ADOPTION OF INDUSTRIAL ROBOTS:

The call for precision machining along with high production rates, has made use of robots an indispensable aspect of manufacturing units. Since the industrial operations are becoming complex amidst rapid technological advancements, the growth of the industrial robot is expected among such environment that is beyond the capacity of manual involvement. Smart factory and industrial automation play an essential role in connecting and automating the operations of these robots.

Almost all the processes in the production and processing plants have been automated in the past decade. This has also complemented the expansion of industrial robots integration into industrial operations.

· RISING LABOR COSTS TO BOOST THE SMART & AUTOMATED INDUSTRIAL ROBOTS DEMAND

The labor cost is significantly high in the total industrial operating cost, generally making 60%-65% of the total cost. In the majority of the cases, manual jobs typically consist of two categories of staff: direct and indirect. Direct staff is responsible for executing the procedure while the indirect staff is for the back-end support for direct staff.

The presence of both direct and indirect staff coupled along with department managers presents an essential cost in operating a warehouse.

The automation of industries has become a notable means to tackle the rising wages and workforce age. This has resulted in the industrial operators to rely upon the smart factories and automated robotics to provide a convenient and efficient way of reducing the operational costs while simultaneously maintaining the productivity at optimum levels.

Buy Now

Challenges – Smart Factory and Industrial Automation Market

· GROWTH OF CYBER ATTACKS

The history of the smart factory and industrial automation is always fascinating. Cybersecurity is one of the major issues of factory automation. Constant technological innovation has taken manufacturing processes from the Industrial Age to the information age as networking in process automation grows. These new information age factories have a great scope of cyber threats from various sources. These cyber-attacks can reduce the advantages of smart and automated factories and turn them into significant disadvantages.

For almost every minute, the global cybersecurity researchers discover threats to cybersecurity and try to solve them in real-time.

Market Landscape

Top 5 players of the smart factory and industrial automation market captured ~65% share of the market in 2018.

ABB Ltd., Mitsubishi Electric, Yokogawa, Endress+Hauser, Honeywell, Rockwell Automation, Omron, General Electric, Danfoss, FANUC, Schneider, Siemens, and Emerson Electric Company are some leading key players in the smart factory and industrial automation market.

Partnerships/Mergers/Acquisitions

Ø In July 2018, GE and Microsoft Corp. formed a partnership to bring together operational technology and information technology to eliminate hurdles in advancing digital transformation projects. In the partnership, GE Digital plans to standardize its Predix solutions on Microsoft Azure and will deeply integrate the Predix portfolio with Azure native cloud capabilities, including Azure IoT and Azure Data and Analytics.

Ø In June 2018, SAP and Endress+Hauser collaborated in the development of the Industrial Internet of Things (IIoT) applications for the process industry. The goal is to fully integrate the Endress+Hauser field instruments as digital twins into the SAP cloud platform.

Ø June 2018, PTC Inc. and Rockwell Automation Inc. formed a strategic partnership that accelerated growth for both companies and enabled them to be the partner of choice for customers around the world who want to transform their physical operations with digital technology.

R&D Investment/Fundings

Ø In July 2019, Fetch Robotics raised $46 million in a Series C round of funding led by Fort Ross Ventures. Fetch Robotics creates autonomous robots, powered by cloud-based software systems, which operate in locations such as warehouses, factories, and distribution centers. The robots can be used to transport goods and materials around warehouses, gather data automatically.

Smart Factory and Industrial Automation Market Research Scope:

The base year of the study is 2018, with forecast done up to 2025. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. These provide the key market participants with the necessary business intelligence and help them understand the future of the Smart Factory and Industrial Automation Market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the offering type, robot type, end-users, and application of Smart Factory and Industrial Automation Market.

#smart factory and industrial automation market#smart factory and industrial automation market size#smart factory and industrial automation market shape#smart factory and industrial automation market forecast#smart factory and industrial automation market analysis#smart factory and industrial automation market report#smart factory and industrial automation market growth#smart automation solutions

0 notes