#Static Var Generator

Explore tagged Tumblr posts

Text

Enhance Your Electrical and Energy Efficiency with Venus Technocrafts’ Advanced Solutions

In today’s rapidly evolving industrial and commercial sectors, ensuring energy efficiency and maintaining power quality is vital for reducing operational costs and protecting valuable equipment. At Venus Technocrafts, we offer a range of innovative solutions designed to optimize your electrical systems and enhance energy efficiency. Our products, including APFC Panels, Active Harmonics Filters, Static Var Generators, and Heat Pumps, are engineered to meet the growing demands of industries and businesses, providing reliable performance and long-term savings.

In this blog, we’ll explore how these advanced solutions can transform your power systems for better energy management and operational success.

1. APFC Panels – Optimizing Power Factor for Better Efficiency

One of the most crucial aspects of electrical system performance is maintaining an optimal power factor. A low power factor can result in higher energy consumption, increased electricity bills, and unnecessary strain on equipment. The Automatic Power Factor Control (APFC) Panels by Venus Technocrafts are designed to automatically manage and correct power factor levels, improving the overall efficiency of your electrical system.

These APFC Panels monitor the power factor in real-time and automatically control capacitor banks to keep the power factor at an optimal level. By improving the power factor, businesses can reduce electricity costs, avoid penalties from utility companies, and extend the lifespan of electrical equipment.

Key Benefits of APFC Panels:

Improved energy efficiency by maintaining an optimal power factor.

Cost savings on electricity bills.

Compliance with industry standards and utility requirements.

Protection of electrical equipment from overloads and damage.

2. Active Harmonics Filters – Maintaining Power Quality

Harmonic distortion in electrical systems is caused by non-linear loads such as variable frequency drives, computers, and industrial machinery. This distortion can lead to overheating, equipment malfunction, and increased energy consumption. To combat this issue, Active Harmonics Filters (AHFs) are designed to eliminate harmonics and maintain power quality in your electrical system.

Our Active Harmonics Filters offer a dynamic solution to real-time harmonic compensation. These advanced devices continuously monitor harmonic frequencies and adjust accordingly, ensuring minimal distortion and optimal power quality at all times.

Key Benefits of Active Harmonics Filters:

Real-time harmonic compensation for clean and stable power.

Protection of sensitive equipment from damage caused by harmonics.

Reduced energy losses and increased system efficiency.

Compliance with IEEE 519 standards for harmonic limits.

3. Static Var Generators – Ensuring System Stability and Power Quality

Maintaining a stable and reliable electrical supply is vital for the smooth operation of any business. Static Var Generators (SVGs) are cutting-edge solutions that automatically provide reactive power compensation to stabilize voltage levels and improve power factor. SVGs play a crucial role in ensuring power system stability, especially in environments with fluctuating loads, such as industrial plants and data centers.

Venus Technocrafts’ Static Var Generators offer fast, efficient, and precise voltage regulation, enhancing the stability and reliability of your electrical system. By automatically adjusting reactive power in real-time, SVGs ensure that your system performs optimally, reducing voltage fluctuations and preventing equipment failure.

Key Benefits of Static Var Generators:

Improved voltage regulation and system stability.

Reduced risk of equipment damage from voltage fluctuations.

Fast and precise reactive power compensation.

Increased overall system efficiency and reduced operational costs.

4. Heat Pumps – Sustainable and Energy-Efficient Heating and Cooling

When it comes to heating and cooling, heat pumps are an excellent energy-efficient solution. Unlike traditional heating systems that rely on burning fuel, heat pumps transfer heat from the air, water, or ground to provide both heating and cooling in a sustainable and energy-efficient manner.

Venus Technocrafts’ heat pumps are ideal for residential, commercial, and industrial applications. They are designed to provide consistent indoor comfort while minimizing energy consumption. By using renewable energy sources, heat pumps significantly reduce carbon footprints and operating costs.

Key Benefits of Heat Pumps:

Energy-efficient heating and cooling solutions that reduce energy costs.

Sustainability through the use of renewable energy sources.

Reduced carbon footprint compared to traditional heating and cooling methods.

Long-term savings through reduced operating costs.

Conclusion:

At Venus Technocrafts, we are committed to helping businesses optimize their electrical systems and reduce operational costs through cutting-edge technologies. From APFC Panels that ensure power factor correction to Active Harmonics Filters that maintain power quality, Static Var Generators that enhance system stability, and Heat Pumps that provide sustainable heating and cooling, we offer a comprehensive range of solutions designed to improve energy efficiency, protect equipment, and reduce energy wastage.

Contact us today to learn more about how these advanced solutions can benefit your business and help you achieve greater efficiency, cost savings, and sustainability. Together, we can create a more efficient and sustainable future for your operations.

0 notes

Text

Dynamic Energy Solutions: Leading Static Var Generator Manufacturer

Are you tired of power fluctuations disrupting your operations? Say goodbye to voltage sags and surges with Inventum Power's cutting-edge Static Var Generator Technology! As pioneers in the field, we pride ourselves on delivering the best-in-class solutions to keep your systems running seamlessly.

In a world where uninterrupted power supply is paramount, Inventum Power stands tall as the beacon of reliability and innovation. As a premier manufacturer of Static Var Generators (SVGs), we at Inventum understand the critical role that stable power plays in the success of businesses across industries. With our unwavering commitment to excellence and cutting-edge technology, we have established ourselves as leaders in the field, providing top-of-the-line solutions to meet the dynamic needs of our customers.

Why choose Inventum? It's simple. We offer unparalleled reliability, efficiency, and performance. Our Static Var Generators are engineered with precision to ensure optimal power factor correction, safeguarding your equipment and maximizing energy utilization.

Experience the difference with Inventum Power. Trust in our expertise to elevate your power management strategy and take control of your electrical infrastructure like never before. Don't settle for less when it comes to power stability. With our unwavering commitment to quality, innovation, and customer satisfaction, we are revolutionizing the way businesses manage their power infrastructure. Whether you're looking to improve power quality, enhance energy efficiency, or future-proof your operations, Inventum Power has the solution you need to succeed. Contact us today and discover the difference that Inventum can make for your business.

0 notes

Text

https://heyjinni.com/read-blog/231501_static-var-technology-market-outlook-for-svg-and-svc-solutions.html

#Static Var Generator (SVG) and Static Var Compensator (SVC) Market Scope#Static Var Generator (SVG) and Static Var Compensator (SVC) Market Growth#Static Var Generator (SVG) and Static Var Compensator (SVC) Market Report

0 notes

Text

0 notes

Text

#Active Harmonic Filter in UAE#Capacitor Bank in UAE#Voltage Optimizer in UAE#Power Quality Solutions in Dubai#Harmonic Studies in UAE#Sinexcel Distributor in UAE#Heat Pump System in Dubai#Energy Audit in Dubai#Power Quality Analyze in dubai#Smart Metering & Lighting in UAE#Static VAR Generator in UAE#Smell Removal in UAE#Air Purification System in Dubai#Uninterrupted Power Supply in UAE#Building Management System in UAE#Automation solution in UAE#Energy Management System In UAE#A-eberle Distributor in UAE#Siemens WinCC in UAE#Siemens System Integrator in Dubai#Siemens SCADA#Helmholz Distributor in Dubai#Sustainability solutions provider in Dubai#Demand Control Kitchen Ventilation System in UAE#EV Charger in Dubai

0 notes

Note

forgive me for the questions & any possible inconsistencies or malformations:

how do we compile our symbolic high/low level code into machine language, and how do we find the most efficient method of conversion from symbolic to machine code?

is it possible to include things from asm in C source code?

why do any of the abstractions in C mean anything? how does the compiler translate them?

would it be possible to write and compile a libc in C on a machine which didn't have a precompiled libc? i think the answer is no, so how much peripheral stuff would you need to pull it off?

are these things i could have figured out by just reading the one compiler book with the dragon on the cover?

thanks and apologies.

these are uhh. these are really good questions. like if you're asking these then i think you know way more than you think you do

how do we compile our symbolic high/low level code into machine language?

we do it the natural (only?) way, using parsers, although a bit more technically involved than just a parser. all programming languages are comprised of just keywords (e.g. int, static, enum, if, etc) and operators(+, -, *, %), those are the only reserved terms. everything between them is an identifier (name of variable, struct, etc), so at some level we can just search for the reserved terms and match them, and match whatever is between them as identifiers (var names or whatever). with this, we can tokenize the raw input put it in the context of a defined grammar.

lex is the name of the program that does this. you have simple, defined keywords, and defined operators, and you group them together a few categories (e.g. int, float, long might all fall under the same "variable qualifier" category"). this is tokenization.

those tokens are given to another program, yacc, which deals with it in the context of some context-free defined grammar you've also provided it. this would be a very strict and unambiguous definition of what C code is, defining things like "qualifiers like int and float always proceed an identifier, the addition (+) operator needs two operands, but the ++ (increment by 1) operator only needs one". yacc processes these tokens in the context of the defined grammar, and since those tokens are defined in broad categories, you can start to converge on a method of generating machine code for them.

how do we find the most efficient method of conversion from symbolic to machine code?

ehehehe. ill save this one for later

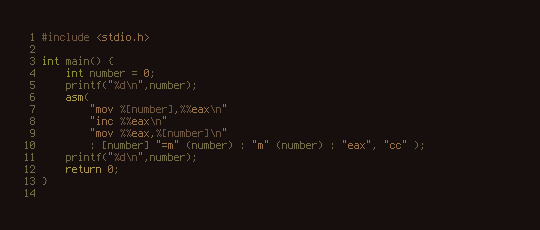

is it possible to include things from asm in C source code?

yes:

assembly (which translates directly 1-to-1 to machine code) is the only thing a CPU understands, so there has to be a link between the lowest level programming language and assembly at some point. it works about as you'd expect. that asm() block just gets plopped into the ELF right as it appears in the code. there are some features that allow passing C variables in/out of asm() blocks.

why do any of the abstractions in C mean anything? how does the compiler translate them?

hoping above answers this

would it be possible to write and compile a libc in C on a machine which didn't have a precompiled libc? i think the answer is no, so how much peripheral stuff would you need to pull it off?

yes, and in fact, the litmus test that divides "goofy idea some excited kid thought up and posted all over hacker news" and "real programming language" is whether or not that language is bootstrapped, which is whether or not its compiler is written in "itself". e.g. gcc & clang are both C compilers, and they are written in C. bootstrapping is the process of doing this initially. kind of a chicken-and-egg problem, but you just use external things, other languages, or if it is 1970s, direct assembly itself, to create an initial compiler for that language, and the write a compiler for that language in that language, feed it to the intermediate compiler, and bam.

its really hard to do all of this. really hard. lol

are these things i could have figured out by just reading the one compiler book with the dragon on the cover?

idk which one that is

finally...

how do we find the most efficient method of conversion from symbolic to machine code?

so this is kind of an area of debate lol. starting from the bottom, there are some very simple lines of code that directly map to machine code, e.g

a = b + c;

this would just translate to e.g. sparc

add %L1,%L2,%L3 !

if statements would map to branch instructions, etc, etc. pretty straightforward. but there are higher-order optimizations that modern compilers will do, for example, the compiler might see that you write to a variable but never read from it again, and realize since that memory is never read again, you may as well not even bother writing it in the first place, since it won't matter. and then choose to just not include the now-deemed-unnecessary instructions that store whatever values to memory even though you explicitly wrote it in the source code. some of the times this is fine and yields slightly faster code, but other times it results in the buffer you used for your RSA private key not being bzero'd out and me reading it while wearing a balaclava.

34 notes

·

View notes

Text

How we created the ideal water system for Wildmender

Over the last 4 years of work, we've created a gardening survival game in a desert world that let people create massive and complex oasis where each plant is alive. At the heart of a system-driven, procedurally generated ecology is a water simulation and terraforming system, and this post is to share a bit of how we built it.

We knew early on that the game would include some level of soil and water simulation, just as an outgrowth of wanting to simulate an ecosystem. The early builds used a simple set of flags for soil, which plants could respond to or modify, and had water present only as static objects. Each tile of soil (a 1x1 “meter” square of the game world) could be rock or sand, and have a certain level of fertility or toxicity. Establishing this early put limits on how much we could scale the world, since we knew we needed to store a certain amount of data for each tile.

Since the terrain was already being procedurally generated, letting players shape it to customize their garden was a pretty natural thing to add. The water simulation was added at first in response to this - flat, static bodies of water could easily create very strange results if we let the player dig terrain out from under them. Another neat benefit of this simulation was that it made water a fixed-sum resource - anything the player took out of the ground for their own use wasn’t available for plants, and vice versa. This really resonated well with the whole concept of desert survival and water as a critical resource.

The water simulation at its core is a grid-based solution. Tiles with a higher water level spread it to adjacent tiles in discrete steps. We broke the world up into “simulation cells” (of 32 by 32 tiles each) which let us break things like the water simulation into smaller chunks that we could compute in the background without interrupting the player. The amount of water in each tile is then combined with the height of the underlying terrain to create a water mesh for each simulation cell. Later on, this same simulation cell concept helped us with various optimizations - we could turn off all the water calculations and extra data on cells that didn’t have any water, which is most of the world.

Early on, we were mostly concerned with just communicating what was happening with simple blocks of color - but once the basic simulation worked, we needed to decide how the water should look for the final game. Given the stylized look we were building for the rest of the game, we decided the water should be similarly stylized - the blue-and-white colors made this critical resource stand out to the player more than a more muted, natural, transparent appearance did. White “foam” was added to create clear edges for any body of water (through a combination of screen depth, height above the terrain, and noise.)

We tweaked the water rendering repeatedly over the rest of the project, adding features to the simulation and a custom water shader that relied on data the simulation provided. Flowing water was indicated with animated textures based on the height difference, using a texturing technique called flowmaps. Different colors would indicate clean or toxic water. Purely aesthetic touches like cleaning up the edges of bodies of water, smooth animation of the water mesh, and GPU tessellation on high-end machines got added over time, as well.

The “simulation cell” concept also came into play as we built up the idea of biome transformations. Under the hood, living plants contribute “biomass” to nearby cells, while other factors like wind erosion remove biomass - but if enough accumulates, the cell changes to a new biome, which typically makes survival easier for both plants and players. This system provided a good, organic feel, and it fulfilled one of our main goals of making the player’s home garden an inherently safe and sheltered place - but the way it worked was pretty opaque to players. Various tricks of terrain texturing helped address this, showing changes around plants that were creating a biome transition before that transition actually happened.

As we fleshed out the rest of the game, we started adding new ways to interact with the system we already had. The spade and its upgrades had existed from fairly early, but playtesting revealed a big demand for tools that would help shape the garden at a larger scale. The Earthwright’s Chisel, which allowed the players to manipulate terrain on a larger scale such as digging an entire trench at once, attempted to do this in a way that was both powerful and imprecise, so it didn’t completely overshadow the spade.

We also extended the original biome system with the concept of Mothers and distinct habitats. Mothers gave players more direct control over how their garden developed, in a way that was visibly transformative and rewarding. Giving the ability to create Mothers as a reward for each temple tied back into our basic exploration and growth loops. And while the “advanced” biomes are still generally all better than the base desert, specializing plants to prefer their specific habitats made choosing which biome to create a more meaningful choice.

Water feeds plants, which produce biomass, which changes the biome to something more habitable that loses less water. Plants create shade and block wind-borne threats, which lets other plants thrive more easily. But if those plants become unhealthy or are killed, biomass drops and the whole biome can regress back to desert - and since desert is less habitable for plants, it tends to stay that way unless the player acts to fix it somehow. The whole simulation is “sticky” in important ways - it reinforces its own state, positive or negative. This both makes the garden a source of safety to the player, and allows us to threaten it - with storms, wraiths, or other disasters - in a way that demands players take action.

38 notes

·

View notes

Text

Empowering Modern Industry: A Look into Static VAR Generator Manufacturers

In the age of automation and smart infrastructure, maintaining power quality has become essential for industries and utilities alike. One of the most effective solutions for managing reactive power and improving power factor is the Static VAR Generator (SVG). As the demand for reliable and efficient electrical systems grows, manufacturers around the world are stepping up with cutting-edge SVG solutions to support this transformation.

What is a Static VAR Generator?

A Static VAR Generator is an advanced power electronic device designed to provide real-time reactive power compensation. Unlike traditional capacitor banks or synchronous condensers, SVGs respond instantly to changes in load, maintaining voltage stability, reducing harmonics, and improving overall power quality. They are widely used in industries such as manufacturing, steel, renewable energy, commercial complexes, and more.

Importance of SVGs in Power Management

Improved Power Factor – Reduces penalties from utilities and optimizes energy usage.

Voltage Stability – Maintains steady voltage levels despite load fluctuations.

Reduced Harmonics – Minimizes distortion and protects sensitive equipment.

Energy Efficiency – Lowers energy loss and improves overall operational performance.

What to Look for in an SVG Manufacturer

When choosing a Static VAR Generator manufacturer, consider these key factors:

Technical Expertise: A good manufacturer will have deep knowledge of power electronics and system integration.

Customization: Solutions should be tailored to specific industry needs and site conditions.

After-Sales Support: Reliable service, installation, and maintenance support are crucial.

Compliance: Products should meet international and local electrical standards (like IEC, IEEE, etc.).

Innovation: Look for companies investing in R&D and offering IoT-enabled, smart-grid-ready devices.

Leading SVG Manufacturers Globally

While several companies worldwide manufacture SVGs, a few notable names include:

Schneider Electric – Known for modular, scalable SVG systems.

Siemens – Offers high-performance reactive power compensators for industrial and grid use.

ABB (Hitachi Energy) – Provides advanced grid-tied and industrial SVGs with a global presence.

Eaton – Known for compact and flexible SVG solutions.

Toshiba – Offers large-scale SVGs for power plants and utilities.

Rising Demand for Local Manufacturers

With the global shift towards energy efficiency and smart grids, regional manufacturers are gaining traction. Many local companies now offer quality SVGs that are cost-effective and suited to specific climatic and grid conditions. Countries like India, China, Brazil, and others have seen a surge in domestic SVG manufacturing to support growing industrialization and renewable energy integration.

Industries That Benefit Most

Steel & Metallurgy Plants

Renewable Energy Farms (Solar & Wind)

Textile & Pharmaceutical Units

Data Centers & IT Parks

Automotive Manufacturing Units

Airports & Metro Rail Systems

Final Thoughts

Static VAR Generators are no longer a luxury — they are a necessity for modern power systems. Choosing the right SVG manufacturer can significantly impact your energy efficiency, operational reliability, and cost savings. Whether you're upgrading an existing system or building from scratch, investing in a trusted SVG solution is a step toward smarter, more resilient infrastructure.

0 notes

Text

0 notes

Text

0 notes

Text

Strategic Growth Drivers in the Global Static VAR Compensator Market

The Static VAR Compensator (SVC) market is poised for significant growth, projected to increase from $1,020.2 million in 2024 to $1,667.0 million by 2034, reflecting a 5.0% CAGR . This expansion is primarily driven by the escalating demand for grid stability and the integration of renewable energy sources.

Key Market Drivers:

Grid Modernization Initiatives: The global shift towards smart grid technologies necessitates advanced solutions like SVCs to manage reactive power and ensure voltage stability, especially with the increasing penetration of renewable energy sources.

Industrial Expansion: Rapid industrialization, particularly in regions like Asia-Pacific, is driving the need for reliable power systems. SVCs play a crucial role in maintaining voltage levels and improving power quality in sectors such as steel, mining, and electric utilities .

Renewable Energy Integration: The intermittent nature of renewable energy generation requires dynamic voltage control. SVCs facilitate the smooth integration of renewable sources like wind and solar into the grid by compensating for reactive power fluctuations.

Regional Insights:

Asia-Pacific: Expected to witness the highest growth rate, driven by substantial investments in grid infrastructure and renewable energy projects in countries like China and India .

North America: A mature market characterized by ongoing grid modernization efforts and a strong emphasis on renewable energy integration.

Europe: Growth fueled by stringent regulations promoting energy efficiency and the adoption of smart grid technologies.

Conclusion:

The Static VAR Compensator market is set for robust growth, underpinned by the global transition towards more resilient and sustainable power systems. Stakeholders are encouraged to monitor developments in grid infrastructure and renewable energy policies to capitalize on emerging opportunities.

For more detailed insights and market forecasts, visit: DataString Consulting

0 notes

Text

Heat Pumps – Energy-Efficient Heating Solutions by Venus Technocrafts Discover energy-efficient heat pumps from Venus Technocrafts. Ideal for heating and cooling applications with advanced technology. Contact us for details!

#active harmonics filter#Energy saving Heat Pump#APFC - Automatic Power factor control Panel#Automatic Power Factor#Static Var Generator

0 notes

Text

0 notes

Text

#Active Harmonic Filter in UAE#Capacitor Bank in UAE#Voltage Optimizer in UAE#Power Quality Solutions in Dubai#Harmonic Studies in UAE#Sinexcel Distributor in UAE#Heat Pump System in Dubai#Energy Audit in Dubai#Power Quality Analyze in dubai#Smart Metering & Lighting in UAE#Static VAR Generator in UAE#Smell Removal in UAE#Air Purification System in Dubai#Uninterrupted Power Supply in UAE#Building Management System in UAE#Automation solution in UAE#Energy Management System In UAE#A-eberle Distributor in UAE#Siemens WinCC in UAE#Siemens System Integrator in Dubai#Siemens SCADA#Helmholz Distributor in Dubai#Sustainability solutions provider in Dubai#Demand Control Kitchen Ventilation System in UAE#EV Charger in Dubai

0 notes

Text

Power Control Centre Panels, MCC Panels, Manufacturer, Kolhapur, India

We are Manufacturer, Supplier, Exporter of Power Control Centre Panels, MCC Panels, APFC Panels, PCC Panels, SVG Panels, PDB Panels from Kolhapur, India.

Power Control Centre Panels, MCC Panels, SVG Panels, PDB Panels, Static Var Generator Panels, PCC Panels, APFC Panels, Power Distribution Board Panels, Motor Control Center Panels, Manufacturer, Supplier, Exporter, Kolhapur, Maharashtra, India.

0 notes