#Steel Plate Weight Chart

Text

The Lifeline of Industrial Sector: Unveiling the Secrets of Steel Plate Manufacturing

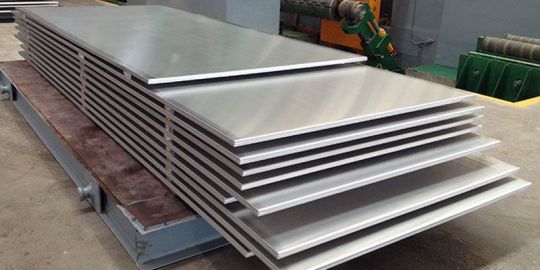

Piping Projects is one of the most trusted Steel Plate Manufacturers in USA. Steel plates function efficiently in various environments and have good corrosion resistance. The most skilled workers are hard at work, ensuring that all quality standards satisfy the customer's demands. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

Steel Plate Manufacturers metal plates using steel that can be formed into more intricate products through cutting and fabrication. Steel plates come in a range of thicknesses and may be made to any desired width or length. The alloy steel plate acquires particular constraints and qualities by adding these components. Also, We lead Welding Electrode Manufacturers in USA.

We are also a market-leading provider of carbon steel, alloy steel, and Stainless Steel Plate with ASME Quality and ISO 9001:2015 Certifications. The AS plate is alloyed with 1% to 50% elements. Steel Plates production is necessary for a structure to be dependable and long-lasting. Because of their extreme robustness and durability, these plates are crucial for manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

The Significance of Steel Plate Manufacturing

The production of steel plates is essential to many different sectors. Its importance is seen in some ways:

Infrastructure Development: Steel Plate Suppliers, which are frequently used in the construction of buildings, bridges, and roads, provide the framework for the development of infrastructure. Steel plates' durability and adaptability guarantee the lifetime and safety of these kinds of constructions.

Automotive Industry: The transportation sector uses steel plates extensively because they give transport structure and body parts the strength and crash resistance they need. Steel plates' low weight and strength combination helps improve passenger safety and fuel economy.

Shipbuilding: Steel plates are a significant component of ships built in the marine industry. Because of their superior structural integrity and immunity to corrosion, these plates are perfect for withstanding opposing marine conditions and preserving sailors' safety.

Energy Sector: In the energy industry, steel plates are crucial, especially for offshore oil rigs, pipelines, and power plants. Their great tensile strength and tolerance to high temperatures and pressure make energy production efficient and dependable.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

These plates are thicker than foils but thinner than ordinary steel plates. Stainless steel plates are widely known for their strong resistance to corrosion and work very well in various challenging conditions. Texas's top steel plate supplier, PipingProjects.us, offers premium plates for various commercial and construction applications.

Steel Plate Manufacturer in California

Our experts are dedicated to maintaining the highest quality standards, making us a leading Steel Plate Supplier in California. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. The welding process used to join these plates is standard.

Steel Plate Manufacturer in Florida

We produce seamless and welded steel plates under stringent quality control guidelines and standards that provide good surface and near-dimensional tolerances. We are a market-leading Steel Plate Manufacturer in Florida, offering solutions on a worldwide scale, with ASME Quality and ISO 9001:2015 Certifications.

Steel Plate Manufacturer in New York

As among the best Steel Plate Suppliers in New York, we have experienced staff members dedicated to maintaining the best calibre requirements. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. These plates are welded using standard welding techniques.

Common Uses For Stainless Steel Plate

The planning and constructing a building's external features, such as the exterior, roof, railings, doors, and windows, is called architecture.

Equipment for meal preparation, sinks, and appliances are all part of the food service setup.

Oil and gas, chemical processing, medical, and shipping equipment.

Application, Energy Management, and Manufacturing Automation.

Producing steel plates is a multi-step, specialised procedure to provide high-quality plates appropriate for various industrial uses. Identifying the best raw materials determines the quality of Steel Plate Supplier in USA. Based on the intended use, manufacturers carefully evaluate strength, durability, and corrosion resistance when selecting the steel alloy.

To Know More, Visit us,

Product: Steel Plate Manufacturers USA

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Welding Electrode Manufacturers in USA#Stainless Steel Plate#Steel Plate Weight Chart#Steel Plate Suppliers#Steel Plate Manufacturer in Texas#Steel Plate Manufacturer in California#Steel Plate Manufacturer in Florida#Steel Plate Manufacturer in New York#Steel Plate Supplier in USA

0 notes

Text

WEIGHT CHART FOR STEEL SHEETS AND PLATES IN MM, KG, AND PDF

Do you need a Steel Plate Weight Chart? There is an easily available Verified Steel Plate Weight Chart in kilos and millimeters. Below is a weight table in kilograms per meter (kg/m) for steel plates of various diameters and wall thicknesses. It should be noted that the weights supplied are simply estimates and may vary based on the type of steel and manufacturing procedures employed.

A steel sheet plate weight chart in kg is a steel that has the same thickness all the way around. Because of its high mechanical qualities, strength, and durability, it is a versatile and frequently utilized material in a variety of industries. If you want to get high-quality Steel Plates, go to: steel plates manufacturer & supplier.

Product source:Steel Plate Weight Chart in mm

0 notes

Text

Choosing the Right Steel Plate: How Weight Impacts Your Project

For any construction or engineering project, selecting the proper materials is paramount to its success and safety. Steel plates are popular choices among engineers for various uses but did you know their weight may have an effectful influence? This Steel Plate Weight Chart in kg, mm provides you with a handy reference for various steel plate sizes and their corresponding weights in kilograms (kg) per millimeter (mm) of thickness. In this guide we explore how steel plate weight affects decision-making processes and ultimately impacts project outcomes.

Understanding Steel Plates

Before discussing weight concerns, let's quickly review what steel plates are: flat sheets made of steel ranging in thickness and dimension which are used across industries in construction, manufacturing and transportation due to their strength, durability and versatility.

Why Does Weight Matter in Steel Plate Construction?

Knowing the Steel Plate Weight Chart is crucial for several reasons, Weight of Steel Plate is an integral factor when purchasing steel products for many different reasons:

Structural Integrity: Steel plate weight has an immense effect on its load-bearing capability and choosing one too lightweight can compromise structural integrity of projects, leading to failure or safety hazards.

Transportation and Handling: Steel plates can be extremely heavy. Transporting them requires special equipment and careful consideration; heavier plates could incur higher transportation costs or require extra safety precautions during installation.

Cost Estimation: The weight of steel plates has an impactful influence on project costs. Heavier plates tend to incur additional material and transport-related fees that increase overall project expenses.

Environmental Benefit: Projects that incorporate lighter steel plates can have a beneficial environmental effect by decreasing energy usage during transport, leading to lower greenhouse emissions and carbon emission reductions.

Steel Plate Weight Chart in kg, mm Calculation

Here is Steel Plate Weight Calculation Formula in kg:

Weight (kg) = Length (mm) × Width (mm) × Thickness (mm) × Density of Steel (7.85 g/cm³)

Here, the density of steel is taken as 7.85 grams per cubic centimeter (g/cm³), which is the approximate density of mild steel.

Factors Influencing Steel Plate Weight

Multiple factors play a part in determining the weight of a steel plate:

Thickness: Thicker plates tend to weigh more, so selecting an appropriate thickness for your project's load-bearing requirements.

Material Types: Mild steel, stainless steel and high-strength alloy steel each possess different densities which affects its weight when placed onto plates.

Plate Sizes: When choosing plate sizes for installation purposes, take into consideration any available installation space when choosing them. Larger plates tend to weigh more.

Additional Features: Some steel plates feature additional features like coatings or treatments which may add weight.

Selecting an Appropriate Steel Plate

Follow these steps in selecting an appropriate steel plate for your project:

Assess Load Requirements: Evaluate the load-bearing needs for your project to identify its minimum thickness and strength requirements.

Consider Material Types: Select an ideal steel material based on factors like corrosion resistance, strength and cost considerations.

Size Is Everything: Select the plate size which best meets the project requirements and available space. This chart should help you quickly determine the approximate weight of a steel plate based on its dimensions like Steel Plate Weight per meter.

Consult With Experts: If in doubt, seek assistance from steel experts or engineers who are highly experienced. Their advice could prove invaluable!

Cost Analysis: Carefully consider all costs related to your selection, such as material, transportation and handling expenses when making decisions that impact costs.

Environmental Considerations: Take environmental considerations and sustainability goals into account when selecting plate weight for your project.

Conclusion

For construction and engineering projects, selecting the appropriate steel plate should not be made lightly. piping projects is a top stainless steel plate suppliers in middle east. Weight can have far-reaching repercussions for project success, safety and budget considerations - by understanding all factors which impact steel plate weight as well as your project requirements, it will allow for informed decisions that lead to optimal outcomes - whether building skyscrapers or bridges! Choosing a great plate is integral in making sure success lies ahead!

0 notes

Text

A GUIDE TO WEATHERING STEEL PLATES

A Guide to Weathering Steel Plates

Understanding Weathering Steel: Weathering steel is composed of specific alloys that form a protective layer of rust-like appearance when exposed to weathering. This layer acts as a barrier to further corrosion, thus protecting the underlying steel. It typically contains elements such as copper, chromium, nickel, and phosphorus.

Initial Weathering Period: Weathering steel undergoes an initial period of weathering where it develops the protective patina. During this period, its essential to avoid washing or disturbing the surface as it may disrupt the formation of the protective layer. Depending on the environmental conditions, this period can last several months to a few years.

Cleaning: Once the protective patina has formed, cleaning weathering steel is generally not required. The protective layer prevents further corrosion, and cleaning can sometimes disturb this layer. However, if cleaning becomes necessary due to heavy soiling or contaminants, its essential to use gentle methods. Avoid abrasive cleaners or tools that could scratch the surface and compromise the protective layer.

Maintenance: Weathering steel requires minimal maintenance compared to other materials like painted steel. Regular inspection for damage or signs of corrosion is recommended, especially in areas prone to moisture accumulation or salt exposure. Any damaged areas should be addressed promptly to prevent corrosion from spreading.

Repairs: If localized corrosion occurs or if theres damage to the protective layer, repairs may be necessary. This typically involves removing the affected area and allowing it to weather naturally to develop a new protective layer. Specialized coatings or treatments may also be applied to accelerate the formation of the protective patina.

Avoidance of Ponding Water: Standing water or prolonged exposure to moisture can accelerate corrosion in weathering steel. Proper design and installation of structures should ensure adequate drainage to prevent water accumulation on the surface of the steel.

Compatibility with Other Materials: When using weathering steel in conjunction with other materials, its essential to consider compatibility to prevent galvanic corrosion. Consult with a materials engineer or corrosion specialist to ensure proper design and compatibility with adjacent materials.

Environmental Considerations: Environmental factors such as salt exposure, industrial pollutants, and high humidity can affect the performance of weathering steel. Regular inspections and appropriate maintenance can help mitigate potential issues caused by these factors.

Professional Consultation: For complex projects or if you are unsure about the best practices for maintaining weathering steel, consider consulting with professionals experienced in working with this material. They can provide guidance tailored to your specific application and environmental conditions.

By understanding the characteristics of weathering steel and following these guidelines for maintenance and care, you can ensure the longevity and aesthetic appeal of structures made from this durable material.

0 notes

Text

aluminum pipe weight chart

1 note

·

View note

Text

How To Select A Good Stainless Steel Round Bar Using Weight Chart

Stainless steel round bars are commonly used in the industrial sector in conditions involving high as well as low pressure work. They are either made seamless or in welded nature. The material used in manufacturing these pipes has to go through different procedures like melting, casting and hot rolling. Following is a detailed explanation of this procedure:

Melting: the stainless steel material is composed of iron, chromium, nickel, etc and it is melted in Electric Arc Furnace (EAF) for further steps.

Casting: the molten steel is then emptied into a cast to form billets or large slabs which will be used to make the round bars.

Hot rolling: this process involves passing the billets obtained in the casting process through rollers to achieve round bars. The diameter and the thickness of the bars is also decided in this stage.

After this, the bars are given cold drawing or heat treatment to provide enhanced strength or to relieve stress.

These bars are either seamless or welded. The seamless round bars are made by piercing a heated billet, thereby leaving no weak areas on the surface, while welded round bars are made by joining two ends of a steel plate by performing welding on it.

There are at least 5 different grades of stainless steel round bar namely austenitic, ferritic, martensitic, duplex and Precipitation-Hardening grades.

It becomes very hard for someone to select a good stainless steel round bar which fit into their specific preference and requirement due to availability of so many grades.

Hence following are some pointers one should remember while selecting a round bar using a weight chart:

Knowing the specification requirement:

Stainless steel round bars have a variety of grades like austenitic, ferritic, duplex, etc while contain more standard specifications like 304, 316, 310, etc, which are used in demanding environments. Hence, before selecting a material, one should know the requirements of the machinery like corrosion resistance, durability, weldability, etc. this helps in proper functioning of the machinery.

Selecting based on requirement:

One should be familiar with the conditions of the working environment, this helps in selection process regarding the material grade. many factories have extreme heat zones, high pressure work, high exposure to corrosion or low temperature zone as well. Hence because of this, there are different standard specified grades available in the market and one should carefully examine them as per the need before selecting.

Use of weight chart:

The weight chart contains very valuable information of the material related to its size, dimensions and weight.

The size of rod is an important variable as the rod should be able to cover the required area without falling short.

The dimensions are an important aspect as well because the diameter or thickness of different materials should be compatible otherwise it may lead to accident.

The weight of the material is directly proportional to its capability to handle pressure while maintaining its stability hence, one should calculate the weight requirement of the project and select the bar accordingly.

0 notes

Text

[ad_1]

Poster printing is a dynamic and impactful solution to convey data, promote occasions, or add visible curiosity to any house. Whether or not you are a enterprise proprietor trying to promote, an occasion planner making ready for an enormous day, or an artist showcasing your work, understanding the nuances of poster printing may also help you obtain excellent outcomes. This information delves into the varied facets of poster printing, from selecting the best kind and materials to efficient design methods.

Understanding Poster Sorts

Promotional Posters: These are designed to market merchandise, providers, or particular provides. They usually characteristic daring visuals and compelling messages to draw consideration and drive gross sales.

Occasion Posters: Crafted to offer particulars about upcoming occasions comparable to live shows, exhibitions, or neighborhood gatherings. They need to embody important data like date, time, venue, and ticket particulars in a transparent and interesting format.

Informational Posters: Utilized in academic settings, workplaces, or public areas to offer data or directions. These posters usually embody charts, infographics, or step-by-step guides.

Ornamental Posters: Created for aesthetic functions, these posters would possibly characteristic art work, motivational quotes, or lovely pictures. They're sometimes used for private or workplace ornament.

Printing Strategies Defined

Offset Printing: This conventional methodology makes use of steel plates to switch ink onto paper. It is extremely appropriate for giant runs resulting from its cost-effectiveness and constant prime quality. Offset printing is right for promotional and occasion posters the place colour accuracy and element are essential.

Digital Printing: Straight prints from digital information, making it preferrred for brief runs and fast turnaround occasions. Digital printing is flexible, permitting for personalization and high-resolution output. It’s excellent for small portions of occasion posters or customized designs.

Display screen Printing: Includes making a stencil and utilizing it to use ink onto the printing floor. This method is well-suited for posters on unconventional supplies or for designs that require vibrant colours. It is generally used for customized and specialty posters.

Inkjet Printing: Makes use of inkjet expertise to use ink droplets onto the paper. This methodology is favored for its capacity to provide detailed, high-quality prints with wealthy colours, making it appropriate for inventive and ornamental posters.

Selecting the Proper Supplies

Paper Sorts: The selection of paper can considerably have an effect on the look and sturdiness of your poster. Choices embody shiny paper for a vibrant end, matte paper for a extra subdued look, and heavyweight paper for a premium really feel.

Vinyl: Preferrred for out of doors use, vinyl is weather-resistant and sturdy. It’s generally used for banners and posters that want to face up to the weather.

Canvas: Offers a textured, high-quality end that’s nice for artwork prints and ornamental posters. Canvas posters add a contact of magnificence and are appropriate for framing.

Foam Board: This materials is light-weight and inflexible, making it a sensible choice for shows and shows. It’s simple to mount and sturdy sufficient for numerous settings.

Design Rules for Efficient Posters

Outline Your Goal: Perceive the first purpose of your poster. Are you selling an occasion, promoting a product, or just adorning an area? Your design ought to align with this goal.

Visible Hierarchy: Arrange your design components to information the viewer’s eye by way of the poster. Use dimension, colour, and placement to spotlight necessary data and create a transparent visible path.

Excessive-Decision Photographs: To make sure your poster seems skilled, use high-resolution photos and graphics. Low-quality photos can seem pixelated and detract from the general influence.

Typography: Select fonts which might be legible and acceptable in your poster’s message. Keep away from utilizing too many alternative fonts, which might create visible litter. Persist with a most of two or three fonts and guarantee they complement one another.

Colour Schemes: Colours play an important function in grabbing consideration and conveying temper. Use contrasting colours for textual content and background to reinforce readability, and select a colour scheme that aligns together with your model or message.

Whitespace: Don’t overcrowd your poster with textual content and pictures. Permit for ample whitespace to create a balanced, uncluttered design. This helps necessary components stand out and makes the poster simpler to learn.

Name to Motion: In case your poster goals to immediate a particular motion (e.g., visiting a web site, attending an occasion), make sure that the decision to motion is obvious and outstanding. Use actionable language and supply all vital particulars.

Finalising Your Poster

Earlier than sending your poster design to print, fastidiously evaluation it for any errors or inconsistencies. Take into account requesting a proof to make sure that colours and particulars seem as anticipated. Moreover, take into consideration how your poster can be displayed. The situation and methodology of show can affect how your poster is perceived and its effectiveness.

In abstract, poster printing is a flexible and highly effective medium for communication and ornament. By understanding completely different poster sorts, printing strategies, supplies, and design ideas, you possibly can create posters that not solely look nice but in addition obtain your required influence. Whether or not for private use or skilled functions, a well-designed poster could make a big impression.

[ad_2]

Supply hyperlink

0 notes

Text

From Factories to Frontlines: Exploring India's Premier Bolt Manufacturers

Introduction

The overlooked leaders of industrial applications are bolts, holding together everything from massive structures to tiny gadgets. In India, the bolt manufacturing industry has grown significantly, providing high-quality products for both domestic and international markets. This article delves into the intricacies of bolt manufacturing in India, highlighting its history, types, materials, top manufacturers, and future prospects.

History of Bolt Manufacturing in India

The journey of bolt manufacturing in India began in the early 20th century with small-scale operations. Over the decades, the industry evolved, driven by increasing industrialization and technological advancements. Today, India is a prominent player in the global bolt manufacturing sector.

Types of Bolts Manufactured in India

Indian manufacturers produce a wide range of bolts to meet diverse industrial needs. Here are some of the key types:

Hex Bolts: Known for their hexagonal heads, these bolts are commonly used in construction and machinery.

Carriage Bolts: Featuring a rounded head and square neck, these bolts are used in wood and metal applications.

Anchor Bolts: Essential for securing structures to concrete, these bolts are crucial in construction.

Eye Bolts: With a looped end, these bolts are used for lifting and securing cables.

Other Specialized Bolts: Customized bolts for specific applications in various industries.

Key Materials Used in Bolt Manufacturing

The choice of material is crucial for bolt performance. Indian manufacturers use a variety of materials:

Stainless Steel: Known for its corrosion resistance and strength.

Carbon Steel: Commonly used due to its affordability and versatility.

Alloy Steel: Offers enhanced mechanical properties for high-stress applications.

Non-Ferrous Metals: Used for specialized bolts requiring unique properties.

Manufacturing Process of Bolts

Bolt manufacturing is a meticulous process involving several stages:

Raw Material Selection: High-quality materials are chosen based on the bolt's intended use.

Forging and Shaping: The material is heated and forged into the desired shape.

Heat Treatment: Bolts undergo heat treatment to enhance strength and durability.

Threading: Threads are cut or rolled onto the bolt shaft.

Finishing: The bolts are coated or plated for protection against corrosion.

Quality Standards and Certifications

Ensuring quality is paramount in bolt manufacturing. Indian manufacturers adhere to various standards:

ISO Certifications: International standards ensuring consistent quality.

ISI Mark: Indian standard mark for product quality.

International Quality Standards: Compliance with global benchmarks.

Superior High-Quality Bolt Manufacturer In India

One of the largest bolt manufacturer in India is Bhansali Fasteners. Bolts are an excellent choice for fluid transfer in a variety of sectors, including construction, culinary, chemical, oil and gas, and pharmaceuticals. They also provide sustainability advantages and cheap maintenance. They offer dependability and security.

We provide low-cost, high-quality bolts that promote efficient and successful work. Our bolts meet numerous standards, including ASTM, ASME, ANSI, UNS, and DIN. Our collection, which includes various sizes, thicknesses, bars, and grades, meets a wide variety of demands. In addition, we are one of leading screw manufacturer in India.

Bhansali Fasteners is one of the leading Bolt Manufacturers in India. Bolts are polished to the specifications provided by the customer, including wall thickness and size. For more demanding applications, heat treatment is also available. At the lowest possible price, we manufacture, provide, and stock a wide variety of bolts in all sizes. Check the bolt weight chart as well.

We are also a Bolt Manufacturers in UAE, Bolt Manufacturer in Bangladesh.

The bolt manufacturing industry in India is a dynamic and growing sector, contributing significantly to various industrial applications. With advancements in technology, government support, and a focus on quality and sustainability, Indian bolt manufacturers are well-positioned for future success.

For More Detail

Website: bhansalibolt.com

Product: SS Bolt Manufacturer

Other Product: Fasteners Manufacturers In Saudi Arabia.

#Bolt Manufacturers In India#Bolt Manufacturers#SS Bolt Manufacturer#Bolt Suppliers#Fasteners Manufacturers In Saudi Arabia

0 notes

Text

15 Essential Crane Hire Safety Tips

Cranes are indispensable in various industries, from construction to logistics, thanks to their ability to lift and transport heavy loads. However, operating these powerful machines comes with significant risks. Ensuring safety when hiring and using crane hire is paramount to prevent accidents, injuries, and damage.

Choose the Right Crane for the Job

Selecting the appropriate crane for your specific task is the first step in ensuring safety. Consider factors such as the weight and size of the load, the height the crane needs to reach, and the working environment. Using the wrong type of crane can lead to dangerous situations and inefficiencies.

Inspect the Crane Thoroughly

Before any lifting operation, conduct a thorough inspection of the crane. Check for any signs of wear and tear, such as cracks, corrosion, or other damage. Ensure that all components, including cables, hooks, and booms, are in good working condition. Regular maintenance and inspections are crucial to identify potential issues before they become hazardous.

Verify Operator Qualifications

Crane operators must be adequately trained and certified. Verify that the operator has the necessary qualifications and experience to handle the specific crane being used. Proper training ensures that the operator is familiar with the crane's controls, safety procedures, and emergency protocols.

Conduct a Risk Assessment

Perform a comprehensive risk assessment of the job site before beginning any crane operations. Identify potential hazards such as power lines, unstable ground, and adverse weather conditions. Develop a plan to mitigate these risks and ensure that all personnel are aware of the safety measures in place.

Ensure Proper Ground Conditions

Cranes require stable ground to operate safely. Assess the ground conditions to ensure they can support the weight of the crane and the load. Avoid setting up cranes on soft or uneven ground, and use mats or steel plates if necessary to provide additional stability.

Follow Load Limits

Adhere strictly to the crane's load limits as specified by the manufacturer. Overloading a crane can lead to catastrophic failures, including tipping or structural damage. Use load charts to determine the maximum safe lifting capacity for different configurations and boom lengths.

Use Appropriate Rigging

Select the correct rigging equipment for the load, including slings, shackles, and hooks. Inspect all rigging gear for wear and damage before use. Ensure that the load is properly balanced and secured to prevent it from shifting or falling during the lift.

Establish Clear Communication

Effective communication is vital during crane operations. Use standard hand signals or radios to maintain clear and concise communication between the crane operator and ground personnel. Miscommunication can lead to accidents and injuries, so ensure everyone understands the signals and protocols.

Implement Safety Zones

Establish and enforce safety zones around the crane's operating area. Keep unauthorised personnel out of these zones to reduce the risk of injuries from swinging loads or moving parts. Use barriers and signage to mark these areas clearly.

Monitor Weather Conditions

Adverse weather conditions, such as high winds, rain, and lightning, can significantly impact crane operations. Monitor the weather closely and suspend operations if conditions become unsafe. Wind can cause loads to sway, and wet or icy conditions can affect ground stability and traction.

Regularly Review and Update Safety Protocols

Safety protocols should be dynamic and regularly reviewed to incorporate new safety standards, technologies, and learnings from previous operations. Ensure that all personnel are updated on any changes to the safety procedures.

Utilise Technology for Monitoring and Control

Advanced technologies like anti-collision systems, load moment indicators, and crane monitoring software can provide real-time data on crane operations. These technologies can help prevent accidents by alerting operators to potential issues before they become critical.

Implement a Lift Plan

Create a detailed lift plan for each crane operation, outlining every aspect of the lift, including the load weight, crane configuration, rigging method, and communication plan. Ensure that all team members understand the lift plan and their specific roles within it.

Conduct Pre-Lift Meetings

Hold pre-lift meetings with all personnel involved in the crane operation. Use these meetings to review the lift plan, discuss potential hazards, and ensure everyone understands their responsibilities and the communication protocol.

Prepare for Emergencies

Have a comprehensive emergency response plan in place. This should include procedures for different types of emergencies, such as crane malfunctions, accidents, and severe weather conditions. Train all personnel on emergency procedures and conduct regular drills to ensure preparedness.

Crane hire safety is a critical aspect of any lifting operation. By following these ten essential tips, you can help ensure a safe and efficient work environment. Remember that safety is a collective responsibility, and everyone on the job site must be vigilant and proactive in adhering to safety protocols. Regular training, thorough inspections, and clear communication are key components in preventing accidents and maintaining a safe workplace.

0 notes

Text

What is Inconel 690 Sheet & Plate ?

Chhajed Steel & Alloy Pvt Ltd. is a stockiest and trader of high-temperature Inconel 690 Sheet & Plate. We stock an unrivaled range of sheets and plates in different thickness, standards, designation, specifications, and custom lengths. One can enquire for too large and small quantities. We will gladly discuss any specific requirement of the clients that may fall outside from our inventory. We offer sheets and plates in multitude size and thickness supported by laser cutting, profiling, shearing and punching that cuts strips as exact specifications.

The Inconel 690 Sheet & Plate is a high chromium-nickel alloy having excellent resistance to many oxidizing media and elevated temperatures. These sheet and plates have the capacity to function in hoists or moderate temperatures. It also works where high surface stability is required. In addition to resistance property, these have high strength, favorable fabrication properties, and metallurgical stability. It is known for its high chromium nickel base composition with superior pitting and stress cracking resistance.

Inconel grade plates are extensively used because of its high-temperature strength, magnetic feature, and thermal expansion feature. These sheets are the versatile element and will be welded to other metals. Moreover, it has good hardenability and also toughness. These sheets have also the good tendency of formability and machinability that is ideal for constructing any complex design. Moreover, these come with tolerance limit and machining allowance for different types of applications. It is available in tempered and quenched states.

Inconel 690 Sheet & Plate is rolled with the hot and cold working process. Extra hardening is provided by heat treatment process and annealing process. The surface is refined by grinding or brushing process so the dimensions become more precise and finished. However, the bright black polish and SATIN coat prevents atmospheric eruption mostly at reducing environments.

Testing performed by us-

Following are the tests- flaring test, flattening test, Mechanical test, hardness test, tensile test, positive material test, micro and macro test, chemical test/ spectral analysis. Also, intergranular corrosion test, ultrasonic test, radiographic test, pitting corrosion test and visual inspection are also performed.

The entire test performed in our LAB is certified by national and international norms under the supervision of experts. Additionally, last stage inspection is performed by third parties for top-notch quality.

Certificate that assures our quality-

We provide MTC report as per EN 10204 3.1 or 3.2, marketable invoice, specification guide, fumigation certificates, packing list like the net and gross weight, quantity and marks and number, NABL test report, and guarantee letter. Apart from this, Certificate origin by legalized manufacturers/ embassy, attested certificate by suppliers, raw material test report, mill test report, quality assurance plan, and heat treatment charts are also provided to our clients.

Delivery options-

Our Concise logistic service delivers your product within time also in a safe mode. We use standard packing so as to remove damages while exporting to global clients. In addition to providing extra protection from oxidation these are coated with the plastic film.

Purchase Inconel 690 Sheet & Plate at low rates from here for long-term engineering applications.

Standard Specification

SpecificationASTM B168 / ASME SB168Length2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm.Width1000mm / 1219mm /1250mm / 1500mm / 2000mmThicknessRanging from 0.3mm to 20mmHardnessAs per ASME A & NACE MR 175FinishHot rolled plate (HR), Cold rolled sheet (CR)

Inconel 690 Sheet & Plate Manufacturers in Mumbai, Inconel 690 Sheet & Plate Suppliers in Mumbai, Inconel 690 Sheet & Plate Stockists in Mumbai, Inconel 690 Sheet & Plate Exporters in Mumbai

0 notes

Text

Supreme Quality Steel Plate Manufacturer in USA

Piping projects is one of the leading Steel Plate Manufacturers in USA. Steel plates have strong corrosion resistance properties and perform well in various situations. We have the most skilled professionals working hard to ensure that all quality standards meet the client's requirements. The AS plate is alloyed with 1% to 50% elements.

Steel Plate Manufacturers is a metal plate manufacturer that uses steel that can be cut and fabricated into a more complex product. Steel plates offer a variety of thicknesses and can be produced to whatever length or width you desire. Incorporating these elements into the alloy steel plate imparts unique properties and tolerances to the material.

With ASME Quality and ISO 9001:2015 Certifications, we are also a market-leading supplier of carbon steel, alloy steel, and Stainless Steel Plate solutions on a global scale. Also, We lead Welding Electrode Manufacturer in USA.

To Know More In Detail, Visit: Steel Plate weight chart

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Stainless Steel Plate#Welding Electrode Manufactures in USA#Steel Plate weight chart

0 notes

Text

STEEL PLATE WEIGHT CHART

Do you need a Steel Plate Weight Chart? It is simple to find a Verified Steel Plate Weight Chart in kilos and millimeters. The weight of steel plates with various diameters and wall thicknesses, given in kilograms per meter (kg/m), is shown in the table below. It's vital to understand that the weights given are simply estimates and could change depending on the type of steel and manufacturing methods employed.

A flat, rectangular steel sheet having a consistent thickness throughout its whole surface is called a steel plate. As a result of its exceptional mechanical qualities,strength, and durability, it is a flexible and often used material in many industries. Visit STEEL PIPE WEIGHT CHART if you want to buy steel plates of the highest quality.

Product source:Steel Plate Weight Chart

1 note

·

View note

Text

The Most Important Guide to Picking the Best Flanges Manufacturer

Trimac Piping Solutions is a prominent Flanges Manufacturers in India.

We offer our customers reliable, cost-effective, and high-quality superior Mild Steel Flanges Supplier products according to international specification ASTM and dimensional specification ANSI/ASME. Trimac Piping Solutions ASTM Flange Manufacturer are premiere value solution for all of your flanges & forged flanges needs. We are one of the premier Quality Carbon Steel Flange Manufacturer in India. Trimac Piping Solutions has been a trusted vendor as a Steel Flanges distributor & dealer in your country. To know more - Flange Weight chart and dimensions, Flanges Weight Chart in kg, mm, PDF.

Cities Where We Supply our Flanges Manufacturer

Flanges Manufacturer In Mumbai

Flanges Manufacturer In Pune

Flanges Manufacturer In Ahmedabad

Flanges Manufacturer In Vadodara

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Delhi

Flanges Manufacturer In Raipur

Flanges Manufacturer In Coimbatore

Flanges Manufacturer In Kanpur

Flanges Manufacturer In Nashik

These are Some Best Types of Flanges

Flanges are essential components in various industrial and mechanical systems. They play a crucial role in connecting pipes, valves, and other equipment while providing structural support and sealing.

Weld Neck Flanges: One of the most popular forms, weld neck flanges are renowned for their high-strength construction. They are welded to the pipe and feature a long, tapered neck that offers great structural support and stress distribution. In high-pressure and high-temperature applications, such as the oil and gas industry, the flange's circular shape and smooth transition from the neck to the pipe aid decrease turbulence and erosion.

Slip-On Flanges: In low-pressure applications, slip-on flanges are frequently utilized because they are simple to install. They are made to slide over the end of the pipe and have a diameter that is just a little bit larger. After being put in position, they are kept in place by welding the perimeter. These flanges are affordable and appropriate for systems that do not need significant structural integrity.

Blind Flanges: When repair or inspection are necessary, blind flanges are utilized to close off the end of a pipe system. They are solid discs without a bore, usually fastened in place by bolts. When working on pipelines or boats, blind flanges are crucial for stopping leaks and guaranteeing worker safety.

Threaded Flanges: The internal bore of threaded flanges has threads, enabling them to be screwed into pipes having complementary external threads. In low-pressure and low-temperature applications, they are frequently utilized. For systems that need routine maintenance, threaded flanges offer a secure connection and are simple to install and disassemble.

Socket Weld Flanges: A socket or recess on socket weld flanges fits over the pipe's end. They form a solid and dependable connection since they are welded to the socket's outer edge. These flanges are perfect for use in applications involving high pressure and temperature because the socket weld joint increases structural stability.

We have Many Types of Flanges Like, Companion Flanges, Studding Outlet Flanges, ANSI B16.47 Series A Flanges, ANSI B16.47 Series B Flanges & Mild Steel Plate Flange.

The Key Factors to Consider When Choosing the Right Flanges Manufacturer

Quality Assurance and Certification: The commitment to quality and adherence to industry standards is the most important factor to take into account when choosing a flange manufacturer. Make that the manufacturer has the appropriate certifications to create flanges that adhere to international standards like ASME, ANSI, API, or ISO. Find certifications that attest to a dedication to quality management systems, such as ISO 9001:2015.

Material Selection: Carbon steel flanges, stainless steel flanges, and other materials are used to make flanges. The material you choose will depend on your application's particular needs, including temperature, pressure, and the kind of fluid or gas being conveyed. A dependable manufacturer has to offer a variety of material choices and be able to offer knowledgeable advice on material choice.

Product Range: Flanges of various varieties, including welding neck, slip-on, socket weld, and blind flanges, are needed for various tasks. To satisfy your unique requirements, confirm that the manufacturer offers a wide variety of flange types, sizes, and pressure classes. Another benefit is the ability to customize flanges to meet your specific needs.

Production Capacity: Analyze the lead times and production capacity of the firm. Take into account elements like the number of flanges you require and the project's urgency. Working with a manufacturer who can meet your manufacturing requirements and deliver on time is crucial.

Customer Reviews and References: Examine the reputation of the manufacturer by reading customer feedback. Additionally, to learn more about prior clients' opinions of the manufacturer's goods and services, get references and chat with them directly.

Conclusion

The success and safety of your projects might be affected by your choice of flange dimensions, which is a crucial decision. You can make an informed decision that protects the dependability and lifespan of your plumbing systems by carefully weighing criteria like quality, material selection, technological prowess, and customer service. When picking flanges, keep in mind that reliability and quality should always take precedence above price because the long-term effects of selecting inferior products can be expensive and dangerous.

0 notes

Text

The Comprehensive Guide of Steel Plate Weight Chart in kg, mm

When it comes to construction and engineering projects, steel plates are a common material choice due to their strength and durability. To ensure that steel plates are used effectively in any project, it's essential to have accurate information about their weight in different dimensions. This Steel Plate Weight Chart in kg, mm provides you with a handy reference for various steel plate sizes and their corresponding weights in kilograms (kg) per millimeter (mm) of thickness.

Steel Plate Weight Chart in kg, mm Calculation

Here is Steel Plate Weight Calculation Formula in kg:

Weight (kg) = Length (mm) × Width (mm) × Thickness (mm) × Density of Steel (7.85 g/cm³)

Here, the density of steel is taken as 7.85 grams per cubic centimeter (g/cm³), which is the approximate density of mild steel.

Importance of Knowing Steel Plate Weight Chart

Knowing the Steel Plate Weight Chart is crucial for several reasons:

Structural Integrity: It ensures that the structure is designed to bear the expected load without compromising its integrity.

Material Cost: Accurate weight calculations help in estimating material costs, which is essential for budgeting and project planning.

Safety: Proper weight distribution is crucial for the safety of the structure and the people working on or around it.

Transportation: Understanding the weight of steel plates is vital for transportation and logistics planning, as it affects the choice of equipment and methods used for moving the plates.

Environmental Impact: Accurate weight calculations contribute to reducing waste and minimizing the environmental impact of a project.

Types of Steel Plates

Steel plates come in various types and grades, each designed for specific applications. Here are some common types of steel plates and their typical uses:

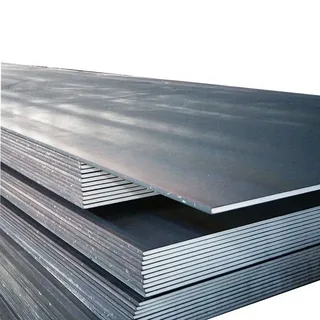

Mild Steel Plates: These are the most common type of steel plates, known for their versatility and affordability. They are used in general construction, manufacturing, and fabrication.

High-Strength Low-Alloy (HSLA) Steel Plates: HSLA plates offer higher strength and improved corrosion resistance compared to mild steel. They are used in structural applications where weight savings and durability are important.

Abrasion-Resistant Steel Plates: These plates are designed to withstand wear and abrasion, making them suitable for applications like mining equipment, conveyor systems, and industrial machinery.

Boiler and Pressure Vessel Steel Plates: These plates are specially designed to withstand high-pressure and high-temperature conditions, making them ideal for use in boilers, pressure vessels, and heat exchangers.

Shipbuilding Steel Plates: Shipbuilding plates are used in the construction of ships and marine structures. They are chosen for their strength, corrosion resistance, and weldability.

Weathering Steel Plates: Weathering steel, also known as corten steel, is designed to develop a protective rust-like surface when exposed to the elements. It's commonly used in outdoor structures and artistic sculptures.

Standard Steel Plate Sizes

In addition to thickness, steel plates come in standard sizes, typically measured in millimeters. Common plate sizes include:

1000x2000 mm

1250x2500 mm

1500x3000 mm

2000x4000 mm

Custom sizes can also be ordered to meet specific project requirements.

Steel Plate Weight Chart in kg, mm

Below is a comprehensive chart that lists common steel plate sizes and their respective weights per millimeter of thickness. Please note that the values provided are approximate and can vary depending on the specific grade and composition of the steel plate.

This chart should help you quickly determine the approximate weight of a steel plate based on its dimensions like Steel Plate Weight per meter. Keep in mind that these values are for mild steel plates and may not be accurate for plates made from different types of steel.

Handling and Storage

Proper handling and storage of steel plates are essential to maintain their quality and prevent accidents. Consider the following tips:

Lifting Equipment: Use appropriate lifting equipment, such as cranes or forklifts, to move heavy steel plates safely.

Stacking: When stacking plates, ensure they are supported evenly and secured to prevent shifting.

Storage: Store steel plates in a dry, well-ventilated area to prevent rust and corrosion. Use appropriate racks or pallets to keep them off the ground.

Labeling: Clearly label plates with their dimensions, weight, and material grade for easy identification.

Weight Tolerance

It's important to note that steel plate weights can have a tolerance, which may vary based on manufacturing standards and specifications. Be sure to check with your supplier or manufacturer for the specific weight tolerance applicable to your steel plates.

Conclusion

This Steel Plate Weight Chart in kg, mm serves as a valuable resource for engineers, architects, and project managers involved in construction and engineering projects. It provides a quick reference to estimate the weight of steel plates, facilitating efficient project planning and execution. However, it's important to verify the accuracy of the weight with the specific steel grade and composition being used for your project.

Understanding the weight of steel plates and their various types and applications is fundamental for any construction or engineering project. Accurate weight calculations, proper handling, and knowledge of steel plate types and sizes contribute to the success and safety of these projects.

0 notes

Text

Steel pipes Weight Calculator

Steel pipes Weight Calculator

Follow the link for Calculator--

0 notes

Text

“Captain, you should have never taken Evangeline through that typhoon,” Jamestown barked as soon as I came down the stair. The engineer continued to growl through his white beard as he led me through the lower decks, “The winds ripped one of the screws (propellers) clean off. Number 3 engine is just dead weight now. But that’s nothing compared to this problem,” Jamestown gestured to one of the ballast tanks. There was a tear in the side big enough for a man to put his hand through, and silvery inertium was dripping up from it and pooling on the ceiling.

“How could this have happened?” I gasped, then, more practically, “how bad’s the loss?”

“I don’t know, Skipper,” Jamestown scratched his head. “I’ve heard stories about tornadoes sticking straw inches deep in tree trunks, but never any storm that could throw a piece of debris right through the steel side of a ship and the tanks inside. We’re lucky nobody was in the way of whatever that was or they’d be all over the walls now. Getting to the point, the ceiling should hold it for a while, but it won't be long before our ballast seeps between the deck plates and planks and falls into space--while we fall in the other direction. Between that and the lost prop-screw I give us maybe thirty miles before we sink.”

I pondered for a second. “I’ll have to check our position on the charts.” I sighed and undid the top button on my uniform, then loosened my scarf, “Don't get the crew’s hopes up. We didn't know these skies even before we met that storm. There’s no telling whether we’ll be able to get to a tall mountain or sky island to anchor and make repairs. At our altitude it’s unlikely anyone will survive a crash landing.”

Jamestown put his fists on his hips, “I'd die before leaving Evangeline to wreck anyways. I say we go for it!”

I tried to lighten the situation, “Where’s that loyalty to Evangeline when I need you and your lads to scrape the rust and parasites off her?”

He chuckled, though grimly, “ if you didn't run her engines so hard we’d have more boys and girls free for her beauty treatments instead of stifling boiler explosions or pulling hurricane-blown trees out of windows. Did you know Karlsdottir has been struck by lightning three times. Three times. Normal people only get it once if they’re lucky.”

“Didn’t Karlsdottir join because she thought working a sunfish trawler was boring?” I recalled.

“Aye. Hasn’t missed it once.”

I returned to my cabin and worked out from the position of the sun and various landmarks that we were about twenty-seven miles from a nameless, uninhabited sky-island. It was small, but not so small we would worry about Evangeline sliding off the edge if we ran out of ballast. Twenty-seven miles is scary close to thirty when thirty means falling to your doom.

By the time I had come up to the pilot-house to lay in a course the sun was setting. A wall of fog had started to roll in behind the storm we had weathered--right in the direction we needed to be going to reach the island. We would have to take it slow, lest we risk hitting inertium-infused rocks or befoul the screw-props on some skyfauna. The last thing we needed at this point was to hit a hydrogen whale or get an infestation of barnacle-gremlins. The slower we went though, the more time our ballast had to leak out.

After two hours I decided to let the pilot, Bjorn, do his job in peace. I walked back to my chair and watched the floodlights sweep back and forth through the haze, both in the air and on the bridge’s unwashed windows. There was nothing to be found on our old wireless, whether because of interference from the storm or because we were so far out in uncharted skies. Bjorn looked out of place among the brass instruments and steel bulkheads of Evangeline’s bridge. With his enormous arms, bushy mustache, and fur scarf he looked like he should be steerman on a viking longship rather than a tramp steamer. That, or like a walrus trying to pass itself off as human. Another hour passed with no noise, save for the wind rushing by and the churning of the engine nacelles. An unexpected sound was the one to break the silence: Leslie Chang on spotter duty, shouting through the speaking tube, “Wreck off the starboard braces! Half a mile off, four hundred feet above us!”

I jumped to my feet and grabbed my binoculars. As I ran to the nearest window I realized that one of the lenses had come loose inside, but any difficulty was made up for by the fact that all the floodlight operators had spotted the wreck and were training their beams on it. From what I could see it was the remains of an old wooden airship, maybe a century or more old. She was hanging in the air upside-down, her masts dangling below her hull like spider legs. “If she’s still adrift, her ballast barrels must be intact. This could be our saving grace!” I tapped Bjorn on the shoulder and he grunted in annoyance, “Bring us in close, steady as she goes. I’ll head below and prepare a boarding party.

Only four able-bodied skymen had agreed to come with me, the rest being old superstitious flyers who thought it was better to try and make it with what we had than to have anything to do with a wreck. Avery had been a circus acrobat in her former life; she was tall and thin but surprisingly strong. She would be handling the Mark IX grappling hook. Jamestown Jr. was the spitting image of his father, and always up for any dangerous task that he could use to impress. He and Karlsdottir would handle the barrels of ballast. And then there was Tex, who insisted he needed to come along for our protection. The man had at least five guns on him at all times, and I remain convinced that he came on all boarding and landing parties not for our defense, but because he had vivid and enthusiastic fantasies about shooting people.

We all stood along Evangeline’s forecastle gunwales as Bjorn brought us in close. Junior sputtered excitedly, “She’s not just any old hulk, this is an old imperial ship-of-the-line!” As we came past her stern the letters of her name were still visible amidst the airplants and algae: Antipathy, the most unimpressive name for a warship I ever saw. As Evangeline came around Antipathy’s far side we saw something that interrupted Avery’s grappling and stilled the hearts in our breasts: A long jagged crack ran along her side nearly from gundeck to keel. Something had all-but torn this cruiser in half. It was a marvel in itself, and a testament to her construction, that Antipathy was still one ship, and not a smattering of timbers, planks, and inertium barrels spiraling in the deeps.

Tex, as soon as he regained his composure, took advantage of an opportunity to freak out the more junior shipmates, “Ain’t no wind that done this. This’s the work of the Ziz.”

“The what?” Karlsdottir scratched her head

Tex was in full scary-story-narration mode, “They say on the week of creation the Almighty made three rulers for all the domains of the world. The Leviathan in the Sea, the Behemoth in the Earth, and the Ziz in the Sky. Not beast, not bird, not fish, big enough to block out the sun over an entire kingdom with its wings. A thing to make all the krakens and rocs pi--”

I had had enough, “You’d think something that big could do a bit more damage than this. I’ve seen angry hydrogen whales and wyverns do all kinds of horrible things to ships, even worse than this.” I hadn’t actually, but I wasn’t going to admit that, “Don’t overexcite yourself, Tex. You’re liable to shoot your fool self in the leg.”

Avery began to line up the shot in the linegun. “This would be so much easier if someone hadn't lost the skiff in the Jade Moors,” Junior grumbled.

#short story#I couldn’t think of what should happen next#I’m a lot better at coming up with setups than endings#airship#alternate history#fantasy#dieselpunk#steampunk#tramp freighter#ship of the line#doodle

0 notes