#Steel Plate Manufacturer in Texas

Text

The Lifeline of Industrial Sector: Unveiling the Secrets of Steel Plate Manufacturing

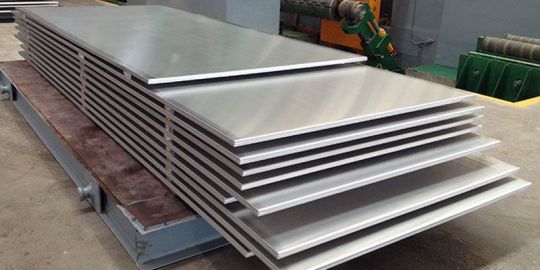

Piping Projects is one of the most trusted Steel Plate Manufacturers in USA. Steel plates function efficiently in various environments and have good corrosion resistance. The most skilled workers are hard at work, ensuring that all quality standards satisfy the customer's demands. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

Steel Plate Manufacturers metal plates using steel that can be formed into more intricate products through cutting and fabrication. Steel plates come in a range of thicknesses and may be made to any desired width or length. The alloy steel plate acquires particular constraints and qualities by adding these components. Also, We lead Welding Electrode Manufacturers in USA.

We are also a market-leading provider of carbon steel, alloy steel, and Stainless Steel Plate with ASME Quality and ISO 9001:2015 Certifications. The AS plate is alloyed with 1% to 50% elements. Steel Plates production is necessary for a structure to be dependable and long-lasting. Because of their extreme robustness and durability, these plates are crucial for manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

The Significance of Steel Plate Manufacturing

The production of steel plates is essential to many different sectors. Its importance is seen in some ways:

Infrastructure Development: Steel Plate Suppliers, which are frequently used in the construction of buildings, bridges, and roads, provide the framework for the development of infrastructure. Steel plates' durability and adaptability guarantee the lifetime and safety of these kinds of constructions.

Automotive Industry: The transportation sector uses steel plates extensively because they give transport structure and body parts the strength and crash resistance they need. Steel plates' low weight and strength combination helps improve passenger safety and fuel economy.

Shipbuilding: Steel plates are a significant component of ships built in the marine industry. Because of their superior structural integrity and immunity to corrosion, these plates are perfect for withstanding opposing marine conditions and preserving sailors' safety.

Energy Sector: In the energy industry, steel plates are crucial, especially for offshore oil rigs, pipelines, and power plants. Their great tensile strength and tolerance to high temperatures and pressure make energy production efficient and dependable.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

These plates are thicker than foils but thinner than ordinary steel plates. Stainless steel plates are widely known for their strong resistance to corrosion and work very well in various challenging conditions. Texas's top steel plate supplier, PipingProjects.us, offers premium plates for various commercial and construction applications.

Steel Plate Manufacturer in California

Our experts are dedicated to maintaining the highest quality standards, making us a leading Steel Plate Supplier in California. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. The welding process used to join these plates is standard.

Steel Plate Manufacturer in Florida

We produce seamless and welded steel plates under stringent quality control guidelines and standards that provide good surface and near-dimensional tolerances. We are a market-leading Steel Plate Manufacturer in Florida, offering solutions on a worldwide scale, with ASME Quality and ISO 9001:2015 Certifications.

Steel Plate Manufacturer in New York

As among the best Steel Plate Suppliers in New York, we have experienced staff members dedicated to maintaining the best calibre requirements. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. These plates are welded using standard welding techniques.

Common Uses For Stainless Steel Plate

The planning and constructing a building's external features, such as the exterior, roof, railings, doors, and windows, is called architecture.

Equipment for meal preparation, sinks, and appliances are all part of the food service setup.

Oil and gas, chemical processing, medical, and shipping equipment.

Application, Energy Management, and Manufacturing Automation.

Producing steel plates is a multi-step, specialised procedure to provide high-quality plates appropriate for various industrial uses. Identifying the best raw materials determines the quality of Steel Plate Supplier in USA. Based on the intended use, manufacturers carefully evaluate strength, durability, and corrosion resistance when selecting the steel alloy.

To Know More, Visit us,

Product: Steel Plate Manufacturers USA

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Welding Electrode Manufacturers in USA#Stainless Steel Plate#Steel Plate Weight Chart#Steel Plate Suppliers#Steel Plate Manufacturer in Texas#Steel Plate Manufacturer in California#Steel Plate Manufacturer in Florida#Steel Plate Manufacturer in New York#Steel Plate Supplier in USA

0 notes

Text

Automated Cleaning Systems: Revolutionizing Industrial Efficiency

In the realm of industrial processes, efficiency, precision, and reliability are paramount. Automated cleaning systems have emerged as a vital component in achieving these goals, transforming how industries manage their cleaning and maintenance operations. Quintessential Systems, formerly known as Process Design Group, has been at the forefront of this technological evolution since its inception in 2003. With a rich history of innovative solutions, Quintessential Systems has established itself as a leader in providing cutting-edge automated cleaning systems tailored to meet the diverse needs of modern industries.

The Genesis of Quintessential Systems

Quintessential Systems was born as Process Design Group (PDG) in 2003, founded by Richard Hall, the eldest son of Ken Hankinson, the founder of KCH Services Inc. The company’s journey began with a notable project in 2004 when Gray Construction approached Richard Hall for the design, build, and installation of automated cleaning, degrease, and paint strip lines for the Corpus Christi Army Depot (CCAD) in Texas. This project marked the beginning of PDG's reputation for excellence in creating automated systems that enhance operational efficiency and reduce costs.

Breakthrough Projects and Innovations

One of the significant milestones for PDG, now Quintessential Systems, was the successful completion of the CCAD project in 2005. The installation included five automated cleaning lines with 440’ stainless steel tanks, automatic hoists, and parts baskets. A notable feature of this project was the integration of automated tank covers that synchronized with the hoist instructions. These covers significantly reduced unnecessary exhaust and energy consumption, showcasing the company’s commitment to sustainability and cost-efficiency.

In the same year, Precision Machine of Savannah sought PDG's expertise for an anodizing line. PDG not only met their requirements but also introduced semi-automatic tank covers operated by push buttons. This innovation allowed Precision Machine of Savannah to control their anodizing processes more effectively, bringing operations in-house and enhancing workflow efficiency.

Expanding Horizons and Expertise

Quintessential Systems continued to expand its horizons by taking on challenging projects across various industries. In 2009, the company was awarded a contract by the Department of Defense (DOD) to supply and install a small arms plating facility at Camp Taji, Iraq. The successful execution of this project further cemented PDG's reputation for reliability and expertise in automated systems.

Subsequent projects included the installation of a semi-automatic chemical etch line for a DOD contractor in 2012 and an automated anodizing line for a large aerospace vendor in Orangeburg, SC, in 2015. These projects demonstrated the company’s versatility and ability to deliver customized solutions that meet specific industrial needs.

The Quintessential Systems Difference

Quintessential Systems’ success is built on a foundation of experienced industry professionals, engineers, craftsmen, and draftsmen. The company’s unique approach involves assembling a hand-picked team for each project, ensuring that every client receives the best possible service and expertise. This customer-centric approach has been instrumental in building long-lasting relationships and delivering projects that exceed expectations.

The company’s commitment to innovation is evident in its use of the build-to-print process, which ensures that every system is manufactured to precise specifications and assembled on-site. This approach minimizes overhead costs and maximizes efficiency, providing clients with reliable, high-quality automated systems.

Conclusion

Automated cleaning systems are transforming industries by enhancing efficiency, reducing costs, and promoting sustainability. Quintessential Systems, with its rich history and proven track record, stands at the forefront of this technological revolution. From its early projects to its current status as an industry leader, the company continues to innovate and deliver solutions that meet the evolving needs of modern industries. For businesses looking to optimize their operations and achieve new levels of efficiency, Quintessential Systems offers unparalleled expertise and a commitment to excellence. Contact us today to learn how we can help take your industrial processes to the next level.

1 note

·

View note

Text

How to Choose a CNC Machine Shop

How to Choose a CNC Machine Shop

Whether you need tons of tiny metal plates bent to a precise angle or a large panel punched to order, CNC precision machining is the way to go. The right shop can handle it all.

Owens Industries in Lexington, KY specializes in machining complex components for medical manufacturers and oil & gas industry applications. They machine a wide variety of materials, including stainless steel and brass.

1. High Precision

The manufacture of precision parts requires a high level of accuracy. CNC machining is used to cut materials with an encoded computer program directing the movement of machines that are capable of performing a variety of tasks like cutting, grinding, drilling, milling and turning.

Companies such as Bates Machine and Mfg. in Dallas have the capabilities to meet your cnc machine shop manufacturing needs. They offer a variety of services including CNC machining, welding and custom assembly. Their customers include medical manufacturers and automotive manufacturers. They have the capability to machine a variety of materials including stainless steel, carbon steel and aluminum alloys.

2. Fast Turnaround

A machine shop that takes pride in their work will ensure they are always able to provide a timely delivery of the finished product. They will also have a quality control and management system to prevent delays due to equipment failure or human error.

Machined products can require precision tolerances that the human eye cannot discern. Medical devices are a good example of a complex product that requires precise CNC milling.

Medical manufacturers can count on Owens Industries for precision machined parts. Their services include machining, prototyping, custom fabrication, heat treating and assembly. They work with materials such as aluminum, low and high carbon steel, brass and bronze as well as plastics like delrin.

3. Economical

When choosing a CNC machine shop, look for long-term value. Avoid companies with outdated equipment that will only lead to costly mistakes and delays in production. Instead, choose a company that has invested in the latest machinery to ensure high-quality results.

Medical manufacturers and food processing plants often require CNC machines to meet specific health codes and industry standards. Owens Industries provides precision CNC machining services to these clients.

Moreover, the city hosts several Fortune 500 companies, including American Airlines Group, Exxon Mobil, Texas Instruments, Dean Foods, Tenet Health Care and Lockheed Martin Aeronautics Co.

4. Customer Satisfaction

If you want to ensure that your customers will return to your business, you need to provide excellent customer service. This includes making sure that your parts are accurate and meeting your expectations. Choosing a CNC machine shop with updated equipment can help you achieve this goal.

The quality of the CNC machines in a machine shop plays an important role in determining the finished product. You should look for a shop that has multiple styles of machines, such as turning and milling. They should also have two to five-axis shaping capabilities, which can make a big difference in the accuracy of your products.

5. Innovation

The complexities of modern electronic parts require high-precision machining. CNC machines are able to produce detailed PCBs and delicate connectors that meet the exact specifications of customers.

For medical devices and instruments, CNC machining can produce a variety of contours, shapes, carvings, joints and inlay that are difficult to create manually. Furniture makers can also use this technology to shape wood components according to customer specifications.

Moreover, 5-axis machining capabilities enable shops to achieve accurate and smoother parts with less time and effort than traditional 3-axis machines. This makes them ideal for manufacturing aerospace applications and other industries that demand a high degree of precision.

6. Flexibility

It’s important to choose a CNC machine shop that offers flexibility. For example, a company that has multiple styles of machines can produce parts with different shapes. Moreover, they can adjust their equipment to accommodate new requirements or to address issues that occur with older machines. This ensures that the parts produced are high quality and fit well.

Precision CNC machining is an ideal solution for industries that need custom components. This process is fast and leaves little room for errors. This is why medical manufacturers rely on this technology for products like MRI machines and safe enclosures. In addition, auto companies use it to make prototypes before adding them to the production line.

7. Experience

Choosing a CNC machine shop with extensive experience can save you money in the long run. Unlike some cheaper shops, quality ones invest in updated equipment and work closely with clients to understand their needs. This helps to avoid mistakes that could cost you in the future.

Whether you need to meet industry standards or create prototypes, precision CNC machining can provide the exact results you require. From lathes to milling machines, look for a company that has a range of capabilities to ensure your project is completed accurately and within budget.

Read the full article

0 notes

Text

Chequered Plate Prices Trend, Monitor, News & Forecast | ChemAnalyst

Chequered Plate Prices: During the Quarter Ending December 2023

In North America, particularly in the USA, the Chequered Plate market witnessed a slight decline during the fourth quarter of 2023, influenced by several significant factors impacting prices. Initially, Chequered Plate prices surged in the US due to heightened demand from the chemical and automotive industries, coupled with limited upstream material supply. Despite robust economic indicators, the unresolved steel dispute between the EU and the US, along with global increases in metallurgical coke and non-coking coal prices, added pressure.

However, by December, Chequered Plate prices in the US began to decline due to increased production, reduced consumption, and a rise in supply from key producer Outokumpu. Surpluses in Nickel and Chequered Plate Scrap persisted, while disruptions in the Australian coal industry further influenced market dynamics. Additionally, the anticipation of the wind power sector surpassing coal in electricity generation by 2026 impacted market sentiments. Low inventory levels, reduced downstream demand, and winter-related disruptions contributed to the continuation of low Chequered Plate prices in the US market. The latest settled prices of Chequered Plate (6 mm) DEL Texas in the USA by the end of December 2023 were recorded at USD 10660/MT.

Get Real Time Prices of Chequered Plate: https://www.chemanalyst.com/Pricing-data/chequered-plate-1490

In the Asia-Pacific region, the fourth quarter of 2023 presented challenges for the Chequered Plate market. Initially, Chequered Plate prices in the Chinese spot market declined in October due to a shift in demand towards the southern direction, influenced by Anti-dumping and Countervailing duties in the US and European markets. Uncertainties in upstream Steel scrap and Nickel availability in Chinese warehouses added to the market complexities. Chinese steelmakers sought iron ore, resulting in the lowest Chinese iron ore stocks in 7 years. However, as the quarter progressed, Chequered Plate prices decreased due to increased Nickel supply and reduced global consumption. Despite decreased demand globally, Chequered Plate prices in the Chinese spot market remained steady in December, influenced by adverse weather conditions, increased Nickel supply, and trade disruptions in the Red Sea route. The latest price for SS Chequered Plate (304-6 mm) Ex Tangshan in China at the end of the quarter stood at USD 2318/MT, marking an overall decline throughout the fourth quarter.

In Europe, the Chequered Plate market encountered various factors impacting prices during the fourth quarter of 2023. In October, the German spot market observed an increase in Chequered Plate prices driven by heightened demand from the automotive and chemical sectors, alongside a decrease in upstream material supply. However, Chequered Plate prices in the German spot market declined in November due to reduced demand from downstream industries and surplus supply. By the end of 2023, Chequered Plate prices in the German spot market continued to decline due to surplus supply and decreased demand in manufacturing industries. Rising production costs and concerns about decreased demand further impacted the sector. The latest price of SS Chequered Plate (304-5mm) Ex Ruhr in Germany for the last quarter was recorded at USD 3269/MT.

Get Real Time Prices of Chequered Plate: https://www.chemanalyst.com/Pricing-data/chequered-plate-1490

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

5 Facts You Should Know About Machined Parts

Machined parts are integral components in manufacturing and engineering processes, contributing to the creation of precise and intricate components used in various industries. Understanding the critical aspects of machined parts is essential for design, production, and quality control professionals. This article will elaborate broadly on the five crucial facts about machining parts in Texas, shedding light on their significance and the considerations involved in their production.

Machining Processes and Techniques:

Machining is a manufacturing technique that removes material from a workpiece to gain the desired shape, size, and surface finish. Several machines are employed, each suited for specific applications. Standard machining parts techniques include milling, turning, drilling, grinding, and electrical discharge machining (EDM).

Milling: Comprises rotating cutting tools to remove material from a stationary workpiece.

Turning: The workpiece rotates, and a cutting tool removes material to create cylindrical shapes.

Drilling: Creates holes in the workpiece using a rotating drill bit.

Grinding: Achieves high-precision surface finishes through abrasive cutting.

EDM: Uses electrical discharges for intricate and precise shaping of conductive materials.

The choice of machining process depends on factors such as material properties, part geometry, and production volume.

Materials for Machining Parts:

Turned components can be produced from various materials, including metals, plastics, and composites. Typical metals used in machining include aluminium, steel, stainless steel, and titanium. Each material has distinct properties that impact the machining process, such as hardness, thermal conductivity, and machinability. For example, aluminium is known for its excellent machinability, making it suitable for applications where lightweight and corrosion resistance is essential.

The preference for materials is a critical element of machining, as it directly influences the tool selection, cutting speeds, and overall machining strategy.

Tolerances and Precision:

One of the defining characteristics of machining parts in Texas is the high level of precision that can be achieved. Tolerances relate to the allowable deviation from a specified dimension, and machining processes can achieve tight tolerances, often measured in micrometers. Precision is crucial in aerospace, automotive, and medical industries, where components must fit together seamlessly and meet strict performance criteria.

Achieving precise tolerances requires careful planning, tool selection, and monitoring of machining parameters to ensure consistent and accurate results.

CNC Machining:

Computer Numerical Control (CNC) machining has revolutionized the production of machined parts. CNC machines use computer agendas to control the movement of cutting tools and workpieces, enabling highly automated and precise machining. This technology creates complex shapes and intricate details efficiently and repeatably.

CNC machining offers advantages such as increased productivity, minimizing human error, and the ability to produce prototypes and small batches quickly. The versatility of CNC machining components makes it a cornerstone of modern manufacturing.

Surface Finishes and Treatments:

Machining components often undergo additional processes to achieve specific surface finishes or enhance their properties. Depending on the application requirements, surface finishes can range from rough to mirror-like. Procedures such as polishing, anodizing, plating, and coating are commonly employed to improve aesthetics, corrosion resistance, and wear resistance.

Polishing: Enhances surface smoothness and appearance.

Anodizing: Forms a protective oxide layer on the surface of aluminium parts.

Plating: Deposits a metal layer onto the surface for improved corrosion resistance.

Coating: Applies a protective layer to enhance properties such as hardness or lubricity.

These additional treatments are crucial for ensuring that machined parts meet the functional and aesthetic standards of the final product.

The Bottom Line

Turned components are fundamental in manufacturing and pivotal in creating precise and intricate components across diverse industries. Understanding the various machining processes, material considerations, tolerances, the impact of CNC machining, and post-machining treatments is crucial for professionals involved in designing and producing these components. The ability to make high-precision machined parts is a critical factor in the success of industries that demand accuracy, reliability, and performance in their end products.

#machining parts#machine parts manufacturer texas#machining parts texas#turned components#machining components

0 notes

Text

Harold B. Burdick House

2424 Stratford Rd.

Cleveland Heights, OH

Cleveland native Harold B. Burdick was known for designing 28 houses in Shaker Heights. Although he was best known for his English Tudor designs, Burdick stands out for his eclectic designs in Colonial, French, and Neoclassical styles. Born in 1895 to Halbert and Mariette Bennet Burdick, he graduated from Cornell University School of Architecture and served as a second lieutenant in the U.S. Army during World War I, where he became interested in aviation and served as an instructor for the U.S. Army Air Service at Love Field in Dallas and Barron Field near Eberman, Texas.

After the war, Burdick returned to Cleveland and joined Walker & Weeks—a firm known for its Neoclassical, Italian Renaissance, Moderne, and Art Deco architectural styles over four decades. While with the firm, he helped in 1919 with the design of the Federal Reserve Building on the corner of Superior Avenue and East 6th Street, and then worked with Meade & Hamilton before starting his own practice. Burdick’s first major design came in 1924 with a 4,571-square-foot French Provincial home on 19000 South Woodland Road in Shaker Heights. Many of his Shaker Heights designs can be found on Shelburne Road and Shaker Boulevard.

Perhaps Burdick’s most unique design was his own Cleveland Heights home at 2424 Stratford Road. He designed and built the glass block International Style home in 1938. He designed the house as a prototype for an economical, quality house. Its streamlined 1,688-square-foot design features some pioneering first for the 1930s—an electric kitchen, the first domestic use of fluorescent lighting, open spaces, and walls made of glass and mahogany panels. The home was added to the National Register of Historic Places on September 17, 1974, was a 2013 winner of the Cleveland Heights Historic Preservation Award, and is a featured home on the Heights Heritage Tour. Burdick died at the age of 51 on May 24, 1947. He left behind his wife, Marjorie, and two children. He is buried in Lake View Cemetery.

Harold Burdick not only designed and built this house for his own family, but also as an example of an International Style, mass-produced home. By using modern architectural concepts and manufactured materials, he hoped to create a prototype for a mass-produced house for middle income living. The later years of the Depression in the United States saw a blossoming of the International Style – the style of Gropius and his group at the Bauhaus in Germany, and of Corbusier in France. Built in 1938 for an estimated cost of $12,000, the Burdick House is a very rare example of a Midwest residence designed according to the principles of this short lived but interesting architectural mode.

The International style shows itself in the use of glass block walls and ceiling-to-floor plate glass windows, thus proclaiming its steel frame construction. No masonry or wood construction could do this. The second floor deck over the garage with its slim curved railing is suggestive of an ocean liner, as well as the esthetic Corbusier set up in his 1923 Vers Un Architecture. Burdick used modern manufactured materials for his construction in an effort to link home construction with mass production, thus reducing costs. There is no hardwood in the house. Stucco and flooring are laid on Masonite board and the ceilings are Celotex. All interior walls are paneled to avoid having to maintain plaster. The entire frame is supported on steel beams and the interior walls are movable.

In this American version of a “machine for living,” cabinets are built in and all doors slide into the walls on ball bearing tracks. The rooms wrap around a vertical core that contains the stairs, chimney and utilities. Yet there is ample space where it is needed, and a feeling of spaciousness for the activities of the family. The Burdick house was built in 1938-39 as a prototype for an economical middle-income house. Modern materials not commonly used in domestic architecture at that date were used in the construction, such as Armenite (a masonite board) and linoleum, plywood and plywood veneer walls, and stainless steel. Curved deck railings and some curved interior walls suggest the modernistic aesthetic of the ocean liner and streamlined vehicles. The house is framed of steel, and its most characteristic feature is the large expanses of plate glass and glass-block windows. The house also incorporated one of the earliest uses of fluorescent lighting and had an all-electric kitchen. Located in a typical neighborhood of traditional houses in Cleveland Heights, the house stands out because of its simple rectangular shape, bare stucco walls, and large windows. Burdick lived in the house from 1939 until his death in 1947.

0 notes

Text

Free Search the Asia Pacific Steel Plate Prices

North America

Steel Plate prices in the North American region upsurged during the first quarter of 2023. Initially, demand picked up moderately, reflecting lower stock levels following the holiday season. Service centers reported increased customer inquiries and shipments, but few were interested in stocking up on steel products, especially with lead times not extending any further than they had. In mid-Q1, the domestic steelmakers kept prices elevated owing to the rising raw material costs. As per the buyer, major players were raising costs to compete with the import offers. In March, mills continued to raise spot market offers, but demand remained steady as buyers continued to review their order books. Lead times increased to 7-8 weeks from 6-7 weeks. Confirmed orders were agreed upon and protected until the order was completed and shipped. Therefore, prices of the Steel plate for Ex-Work Texas were assessed at USD 1702/MT on March 31.

Asia- Pacific

In the first quarter of 2023, the Steel Plate prices showcased an upward momentum in the Asia- Pacific region. In January, demand picked up with a rise in downstream inquiries on the back of stabilized global inflation and China's reopening. However, China's production cuts and the Russia-Ukraine war resulted in tighter supply. Following the Spring Festival holiday, the steel market strengthened more in February, and the steel price continued to rise, signaling a promising start. Steel mills stopped production for more maintenance due to high costs, and output continued to fall, which was good for steel prices. With the arrival of the traditional peak season in March, domestic production was increased due to tight spot supply. Also, the costs of iron ore and coking coal rose due to inventory replenishment and Beijing's tightening control over crude steel production. Steel Wire Rod Prices were under a lot of cost pressure, so the ex-factory price was raised. Therefore, the price of the Steel plate for Ex Shanghai was assessed at USD 648/MT on March 31.

Europe

In the European region, the price trend of Steel Plate followed an upward price trajectory during the first quarter of 2023. The hikes in Steel Plate prices were due to increasing prices of the slab, improved demand, and short supply due to longer plate delivery times. Major manufacturers claimed that big buyers who had avoided restocking in December began to place orders in this quarter. The anticipated rise in import slab prices from Asia following the Lunar New Year holidays in China, as well as good order books at European plate producers, also contributed to the market's bullishness. Sales volumes picked up significantly due to limited inventory and higher downstream demand, and buyers were willing to pay higher prices. Some automotive steel demand revival had also contributed to the upbeat mood. Therefore, the price of the Steel plate for Ex Ruhr was assessed at USD 1165/MT on March 31.

ChemAnalyst tackles the primary difficulty areas of the worldwide chemical, petroleum, pharmaceutical, and petrochemical industries, empowering decision-makers to make informed decisions. It examines and analyses geopolitical risks, environmental concerns, raw material availability, supply chain functioning, and technological disruption. It focuses on market volatility and guarantees that clients manage obstacles and hazards effectively and efficiently. ChemAnalyst's primary expertise has been data timeliness and accuracy, benefiting both local and global industries by tuning in to real-time data points to execute multibillion-dollar projects internationally.

0 notes

Text

What is special about the corten steel bar?

Weathered steel, also known as corten steel, is an alloy of steel commonly used outdoors. Corten steel was designed to eliminate the need to paint. If left outside in the elements, it will develop a rusty appearance within just a few months.

Coal wagon manufacturers in America in the 1930’s noticed certain steel alloys developed a layer of rust that instead of corroding the steel, protected it. With the brand name Cor-Ten – an abbreviation for corrosion resistance, and tensile strength – these alloys soon gained popularity among architects (possibly the best example being the John Deere World Headquarters in Illinois, designed by Eero Saarinen) which persists to this day.

Speaking of Corten Steel, specialized Corten Steel is used for proper functioning. Cortensteeltube.com Is one leading Manufacturer, Supplier & Stockist Of S355JOWP Corten Steel Plates And Sheets.

Alloys continued to be developed to increase their strength and durability. In time, the name lost its hyphen and became a generic term. A corten steel wall is also known as weathering steel or weathered steel.

COR-TEN is a trademark owned by U.S. Steel. COR-TEN refers to two of this type of steel’s distinguishing properties: corrosion resistance and tensile strength. USS sold its discrete plate business to International Steel Group (now ArcelorMittal) in 2003, but it still sells COR-TEN branded material in strip-mill plates and sheets.

The original COR-TEN received the standard designation A242 (COR-TEN A) from the ASTM International standards group. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheets. All alloys are in common production and use.

Why is Corten Steel popular?

CorTen is popular with architects and sculptors because of the exterior layer of rust that forms on its surface when conditions are right. The mute-reddish brown color of CorTen makes it stand out like the red rock faces of Utah, Texas, and South America. These naturalistic steel patinas look stunning on large, imposing surfaces.

Using this steel, certain design styles are possible because conjoined joints will fuse together as a result of surface rust. Because of this, steel is popular with sculptors, who can use it to create new shapes. However, even ordinary structures can benefit from the fusing quality of CorTen. If you were to build a steel structure from this material, it would become one solid piece within a year or two, ceiling to floor, making it extremely rigid and durable.

We explored some of the most famous Corten Steel Structures Around the World. As there are so many creative examples of how the alloy has been used in architectural projects the world over, we decided to put the spotlight on a few more eye-catchingCorten steel projects.

Tap here to read more about this article:

0 notes

Text

Rectangular Connectors : D-sub Connectors

The rectangular connectors provide flexibility in design and ease of use. This is an advantage over other connector types.

Air Electro is an authorized stocking distributor for Positronic Souriau-Sunbank from Eaton, Radiall, Amphenol, Glenair, TE Connectivity Deutsch and ADI Electronics as far as connectors with rectangular shapes are concerned.

Rectangular connectors are commonly utilized in robotics, automation for industrial use machines, machine building, transportation rail and power generation.

Today, we're taking a deep dive into D-SUB CONNECTORS.

D-Sub Connectors

D Sub connectors, commonly referred to as D Subminiature or D-type connectors, are tiny light connectors perfect for industrial instruments, ground support devices, and computers. They are also used in consumer electronics, telecommunications, medical equipment, and Local Area Networks (LANs).

D Subminiature connectors can be found in various pin-out and shell sizes. The standard sizes of shells are 9, 15, 25, 37, and 50. Shells are made of steel that can be plated with zinc-nickel or cadmium to ensure ROHS compliance. D sub connectors are certified to MIL-DTL-24308 specifications and use standard size 20 pins and socket contacts as per AS39029. Size 22 contacts can also be utilized in the more dense connectors. Contacts can be either non-removable or removable with the option of solder cup, crimp and PC tail.

Air Electro is a franchised distributor of ADI Electronics, a leading QPL manufacturer of MIL-DTL-24308 connectors based in Dallas, Texas. Air Electro is also an approved distributor for Amphenol PCD and Positronic D-Sub connectors.

Every D Sub product is "off the shelf" and available for shipment on the same day. We carry a range of shell sizes and pin-outs, plating options and pin-outs. In addition, we maintain an inventory of required AS39029 contacts and the locking hardware to secure connectors.

ADI Electronics D-Sub MIL-DTL-24308 Connectors

ADI Electronics MIL-DTL-24308 D-Sub connector has a variety of shell sizes and pin-outs. The standard shell sizes are 9,15, 25, 37, and fifty positions. Contacts come in 20 AWG solder-pot, crimp, or printed circuit contacts. They can also be interconnected using MIL DTL-24308 connectors.

Amphenol D-Sub Connectors - MIL-DTL-24308

The rack and panel subminiature connectors have polarized shells. The D-Sub connectors of Pcd are MIL-DTL-24308 certified. They deliver the highest density and security by utilizing socket and pin-machined contact points. The most common use is in applications where weight and dimension are crucial. D-Sub Series include a variety of PCB solder, crimp and wire-wrap connections. All Amphenol D Subs have thermoplastic housings that are flame-resistant and UL-94 compliant.

Air Electro stocks and offers same-day shipping on many Amphenol Pcd D connectors. Our technical team can assist you with any questions.

Positronic D-Sub Connectors

D-sub connectors are utilized in a range of applications. D-sub connectors are typically utilized on communication ports, which allow connections between various devices like copiers, CPUs, printers, as well as other power supply devices.

DB9 connectors are utilized for token rings, other computer networks, and the controller area networks (CAN). D-sub connectors are also utilized for video output from computer ports for games controllers' multi-channel analogue ports and AES digital audio within recording studios. Many of the Positronic D-Sub connectors meet the NASA GSFC S-311 certification.

1 note

·

View note

Text

Az Custom Truck Bodies Van Our Bodies Modifications Repairs

With a Supreme truck physique, you’ll be confident that you and your customers are using one of the best high quality products on the road. The Company's solutions include rentals, gross sales, aftermarket parts, tools, accessories and repair, gear production, manufacturing, financing options and asset disposal. Custom Truck One Source Inc., previously generally recognized as Nesco Holdings Inc., relies in KANSAS CITY, Mo. Located in Downey, California, California Trucking Co. is one of the largest service body manufacturers in the state of California. Located in Birmingham, Alabama, Altec manufacturers a broad range of service our bodies to be used in a quantity of industries, together with forestry our bodies, crane our bodies, service bodies, enclosures, toppers and capsules, and trailers.

Highly specialized technicians commonly require customized truck bodies that match their particular utility. Your truck physique is your workshop on wheels, so constructing it to suit exactly what you do and how you work will present productivity and safety advantages. You can make adjustments before the manufacturing phase of your service physique begins. Customers who see their body drafted on paper before the construct begins discover this to be a major benefit.

That is why we offer a limited-lifetime guarantee on the truck physique structure of utility body we produce. “One of the things we wished to do is be a one-stop shop for our customers,” he explains. Since 2001, Custom Concessions has built meals vehicles, concession trailers, and mobile kitchens for thousands custom truck manufacturers of satisfied and profitable clients. Based in Houston, Texas, Trailer King Builders build trailers from scratch and supply a chance for entrepreneurs to visualise and design their perfect cell kitchen and make their dream a reality.

Browse our selection of dump vehicles in Phoenix as nicely as Curry Supply Houston dump trcuks. Experience and Focus are what set Sutphen aside from the competitors. Over one hundred thirty years of experience go into each equipment that we construct, and our Company focus is to build the most secure and best product obtainable. Quality, craftsmanship, and household values have been our ardour for over a century.

Dump truck leases are in excessive demand amongst transportation and transferring corporations. Sutphen Aerial Apparatus are built to do work, and to back that up, we now provide a 30-year Aerial Structural and Corrosion guarantee on all Aerial Apparatus. We additionally supply crane inspections, full hydraulic repairs, and equipment to install. Each crane extends totally different mounting-configurations, control options, and increase custom truck manufacturers fashion backed by our commonplace 10-year guarantee. Every cupboard is outfitted with premium pneumatic door closers and stainless-steel door hinges, as well as a quantity of latch choices. It begins with understanding the workflow means of the person, and growing a solution that enables them to maximize their output and reduce the time they achieve this.

From highly customized bumpers to material racks to lighting, custom options can add much more worth to that custom body. Similar to the custom body, custom options can be tailored to your particular application. We’re eager to accommodate specific wants for custom truck our bodies. With each custom utility truck bed we produce, we strive to make your job in the area simpler. Our custom truck beds provide a standard, diamond plated wrap alongside the storage cupboards, providing yet one more layer of protection. SH Truck Bodies is a pacesetter within the fabrication of truck our bodies – from pickup truck our bodies, to large dump vans, and everything in between.

Manufacturer of normal and custom truck cabs for off-highway OEMs. Construction, mining, agriculture, forestry, utilities, airport floor assist, government/military, turf care, recycling/waste management/refuse and leisure car industries served. Mechanical and hydraulic pressing, milling, CAD/CAM, plotting, laser printing and cutting, CMM checking, prototyping, welding, stamping and machining services out there. Theheavy duty vehicles in our provide are equipped with a convenient swing-away tailgate for a complete access to the truck rear, as well as dent-resistant tubular side rubrails , amongst other options. Whether clients are shopping for, leasing, or renting, Custom Truck has the applications and gear to meet highly particular performance and budgetary necessities while including value at every step. For example, when a piece of apparatus has reached its limit of usefulness or is not wanted, Custom Truck will take it back, commerce it in, or make it out there for consumers via its in-house auction company.

According to these new guidelines, businesses must ensure that the compartments of their vehicles that the meals is held in are properly pre-cooled and cleaned. They also need to be able to show that they have maintained temperature conditions during transport. Whether you’re a veteran of the trade or a food truck dreamer simply wading in, we’re right here with helpful suggestions and insights to help and encourage you. All told, WTF employs about 50 individuals, with the bulk working in production.

Definitely do your analysis, but I assure you'll be back talking with them when you're done. At Douglass Truck Bodies, we believe in building the greatest utility bodies attainable. We strive custom truck manufacturers to search out the most effective supplies, to provide you with essentially the most efficient designs, and to craft our beds with the very best level of workmanship.

0 notes

Text

The Authority of Steel Plate Manufacturing - Pipingprojects.us

Piping Projects follow strict quality control procedures and standards that guarantee good surface and near dimensional tolerances. We manufacture Steel plates using top-quality materials. Steel Plate Manufacturers is a metal plate which uses steel, that can be cut and fabricated into a more complex product. Steel plates offer a variety of thicknesses and can be produced to whatever length or width you desire. We are also a leading Coated Pipes Manufacturer in USA

Piping Projects is one of the leading Steel Plate Manufacturers in USA. We are a market-leading provider of carbon steel, alloy steel, and stainless steel plate solutions on a global scale, having obtained ASME Quality and ISO 9001:2015 Certifications. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

The Importance of Steel Plate Manufacturing

For a construction to be reliable and durable overall, Steel Plates manufacturing is essential. These plates are highly durable and robust, making them essential in manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

Steel Plates in Construction:

Steel plates provide the required strength to support buildings, bridges, and other infrastructure, serving as the basis for the construction sector.

The stability and durability of buildings against external factors like wind, earthquakes, or large loads are guaranteed by the high tensile strength of these plates.

Steel plates also provide better resistance to corrosion, which keeps structures intact and guarantees longevity.

Steel Plates in Automotive:

Steel plates are used in the automobile industry to produce car bodywork, construction, and other essential parts.

Due to its strength-to-weight ratio, steel plates reduce weight and provide a strong foundation, which improves vehicle safety.

These plates also provide impact resistance, which safeguards individuals in the event of an accident.

The Manufacturing Process

The manufacturing process of steel plates involves several stages, each contributing to the final product's quality and reliability.

Raw Material Selection:

The initial material is usually high-quality steel, usually in the shape of slabs or coils. The plate's features primarily depend on this steel's composition and qualities.

Steel comes in various grades, each designed for a particular use, such as wear resistance, corrosion resistance, or structural strength.

Material Composition:

Generally, materials with specific ratios of iron, carbon, and other elements like manganese, silicon, and nickel make high-quality steel plates.

The alloy's structure impacts properties like hardness, strength, and corrosion resistance.

Manufacturing Process:

Quality steel plates are produced using advanced manufacturing processes such as hot rolling, cold rolling, or forging.

Stringent quality control measures are implemented throughout production to ensure consistent thickness, flatness, and surface finish.

Surface Finish and Cleanliness:

The texture is defect-free surfaces devoid of rust, scale, or surface contaminants that characterize excellent steel plates.

To confirm its quality and performance attributes, steel plates go through extensive testing.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

Steel Plate Manufacturer in California

Steel Plate Manufacturer in Florida

Steel Plate Manufacturer in New York

Steel Plate Manufacturer in Los Angeles

Common Uses For Steel Plate

Architecture includes designing and constructing building exteriors, such as facades, roofs, railings, doors, and windows.

Foodservice includes tables, countertops, sinks, appliances, and food preparation equipment.

Industrial: Chemical processing equipment, pharmaceutical equipment, marine equipment, oil and gas equipment.

Other: Manufacturing Automation, Energy Management, and Application.

To Know More Visit,

Website: pipingprojects.us

Source: Steel Plate Manufacturers USA

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers USA#Steel Plate Manufacturers#Steel Plate#Steel Plates

0 notes

Text

Wellbeing Meets Luxury with Armored Civilian Vehicles

With regards to car wellbeing, the majority of us consider airbags and electronically monitored slowing mechanisms. Be that as it may, envision kicking it up a couple of indents with a protected non military personnel vehicle.

Envision yourself in a definitive safe vehicle. It can withstand bomb impacts and gunfire. It even produces a helpful distraction to battle off aggressors. Coincidentally, your driver is driving. You're sitting in a delicate Italian calfskin seat in the traveler compartment, tasting champagne from your scaled down bar.

It might seem like a scene from a James Bond film, however extravagance reinforced vehicles are genuine, and their utilization among U.S. regular citizens is developing.

Military work force, law implementation, banks and heads of state have utilized shielded vehicles for quite a long time. However, developing security concerns have extended the market to incorporate corporate initiative, lawmakers, famous people, proficient competitors and other chauffeured VIPs – especially in the U.S.

Five years prior, International Armored Corporation, a protected vehicle maker, sent out around 95 percent of its U.S.- based vehicles to nations confronting common war, psychological oppression, and sorted out wrongdoing. Presently, around 80% go to U.S. customers who favor modified Cadillac Escalades, Range Rovers and Mercedes Sprinter vans.

Who Makes Luxury Armored Civilian Vehicles?

Shielded extravagance vehicles originate from either OEMs or organizations that modify existing models.

Among the extravagance automakers, Jaguar Land Rover creates the Range Rover Sentinel, a steel-plated traveler vehicle equipped with projectile safe glass. The SUV can withstand shield penetrating combustible rounds, TNT blasts, and projectile impacts. BMW's Security Vehicles Division plans its models to withstand expanding levels of assault: road wrongdoing, composed wrongdoing, and blasts. Mercedes offers an exceptionally reinforced Maybach S600 Pullman Guard.

INKAS Armored Vehicle Manufacturing, situated in Toronto, changes over existing extravagance models into a definitive in heavily clad assurance. Its 2019 Armored Cadillac Escalade ESV Chairman Package, valued somewhere in the range of $300,000 and $500,000, holds a leader office in the traveler compartment with Italian cowhide seats, outlandish wood framing, a smaller than expected bar, shrewd TV and significantly more.

While the SUV offers the bustling chief an agreeable, completely working office space, it's intended to secure against assault. The vehicle includes a 360-degree surveillance camera and shield that ensures against 7.62 x 51mm or .308 Winchester full-metal coat ammo. It can likewise withstand the explosion of two hand projectiles all the while.

INKAS sells the Escalade generally in South America, Africa, the Middle East and South Asia where chauffeured heads not just need insurance, they have to complete work as they travel in serious gridlock. The organization likewise alters limousines, estimated at $1 million each, and fabricates shielded bank trucks, law authorization vehicles and cannabis transport vans for states, for example, Michigan and Colorado where maryjane is presently lawful.

Custom Security Options for Armored Civilian Vehicles That Rival Action Films

Shielded vehicle organizations value giving significant level assurance while keeping up the look and execution of the first extravagance vehicle. Also, security highlights can regularly oppose creative mind.

INKAS, for instance, can alter a Mercedes-Benz S600 with an impact verification underside and night vision capacities. Texas Armoring Corporation does likewise and can equip vehicles with glimmering strobe lights and self-fixing fuel tanks. For presidential sorts, Texcalibur Armor will change over a Mercedes SUV into a popemobile.

In case you're yearning for that Mission Impossible experience, International Armoring Company offers an assortment of reasonable choices, including:

Bomb Blankets – ingest the effect and diminish shrapnel from an assortment of touchy gadgets

Electric Shock Handles – a 12-volt battery takes care of a 120-volt flow legitimately to the entryway handles

Oil spill Systems – foil followers with a tricky wreck dispatched from the back of the vehicle

Street Tacks – discharge tire-harming tacks from the back of the vehicle with the flick of a flip switch

Run-Flat Tires – drive the vehicle with punctured tires for 50 miles at 70 mph

Weapons – a rooftop unit or tag compartment can house attack rifles, mine launchers, and so on.

Maybe the ejector seat alternative isn't a long ways behind.

Inkas Armored Russia is one spot where you can find top luxury vehicles.

2 notes

·

View notes

Text

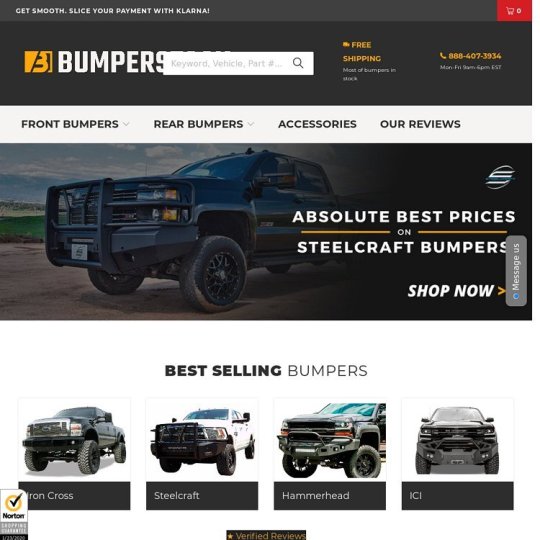

Hammerhead bumpers

If you own a truck, you probably want to protect that baby as best you can. And one protective accessory you should never skimp on is your bumper.

Bumpers are designed to absorb shocks and prevent damage to your grille, hood, and fuel system in the event of a crash. But when it comes to ultimate protection, standard stock bumpers just don’t cut it. What you need is a good, heavy-duty bumper.

But how do you pick the right manufacturer when there are so many brands to choose from? Not to worry, we’ve already done the homework. Below is our top 5 selection of aftermarket bumper manufacturers that offer great service and high-quality products:

Top 5 Heavy-Duty Bumper Manufacturers

Steelcraft

Quick Facts:

Headquarters: Southern California

Year founded: 1998

Material of choice: Diamond plate and schedule 40 pipe

Warranty: 2-year warranty on all heavy-duty bumpers

If you’re struggling to find an expertly crafted bumper to go with your newer model truck, then Steelcraft is your guy. With more than 20 years’ experience in the automotive aftermarket, Steelcraft’s team is dedicated to be the first to develop accessories for newly released vehicles.

To ensure maximum strength and durability, they offer one-piece designs that are all E-coated and protected with a black powder coat finish, which has a limited 3-year warranty. They also offer a 2-year warranty on their heavy-duty products, and their stainless-steel products carry a limited lifetime warranty. This earns them extra brownie points as they have the longest warranty when compared to other suppliers.

Hammerhead

Quick Facts:

Headquarters: Bay Springs, Mississippi

Year founded: 2008

Material of choice: A36 Carbon Steel

Warranty: 12-month warranty on all Hammerhead products

Though Hammerhead bumpers ram 1500 has only been around for about 12 years, its founders come from a very knowledgeable background. Back in 2008, a few Hol-Mac employees were inspired by the corporation’s high-strength steel, and decided to venture out on their own to develop the best possible aftermarket bumper.

Not only does Hammerhead pride itself on using industrial-grade materials and highly certified craftsmen, it also aims to create strong, durable accessories that bolt straight onto your vehicle’s existing frame. That means you don’t need to cut, weld, or drill into your truck to accommodate your new bumper.

All Hammerhead Armor products carry a 1-year warranty, and if you’re not entirely satisfied with your bumper, you can return it within 10 business days. They also offer free shipping to any commercial US continental address.

If you want a custom-colored bumper, Hammerhead gives you the option to order raw, unpainted products. However, they don’t recommend this as extensive prep work will be required to ensure a smooth finish.

Ranch Hand

Quick Facts:

Headquarters: Shiner, Texas

Year founded: 1986

Material of choice: Industrial-grade steel

Warranty: 1-year warranty on all Ranch Hand products

Another proudly American manufacturer that puts its heart and soul into its aftermarket bumpers is Ranch Hand. As a subsidiary of Kaspar Companies, which has been around since the late 19th century, Ranch Hand understands what it takes to keep customers satisfied.

Nothing matters more to them than you and your vehicle’s safety. They even claim that their bumper pipe is 90% thicker than that of their competitors!

They also put effort into adapting their designs to match the make and model of your vehicle, and offer a 12-month warranty for each and every product that leaves their factory.

Iron Cross

Quick Facts:

Headquarters: Tulsa, Oklahoma

Year founded: 2003

Material of choice: All-steel, fully welded

Warranty: Shipped with product

If you invest in an Iron Cross bumper, you can rest assured that your vehicle is protected. These guys take the safety of their customers very seriously - which is not only conveyed by their Maltese Cross-inspired logo, but also in their top-quality workmanship.

They source only the finest grade of materials to bring you replacement bumpers that not only look good, but are strong and durable to boot.

Fab Fours

Quick Facts:

Headquarters: Lancaster, South Carolina

Year founded: 2005

Material of choice: Premium steel

Warranty: Varies across different products

Fab Fours is driven by passion and the vision to be different. You won’t find any standard, plain-looking accessories in this shop - they strive to be innovative, which is what afforded them a spot in our top 5 list. Not only do they take great care in crafting bumpers that complement each vehicle’s unique design, they even add a personal touch by doing away with mass-production and hand-finishing each product instead.

They also offer varying warranties on all their different products, so be sure to ask us about that when you place your order.

2 notes

·

View notes

Photo

Gustave Young engraved Colt “Millikin Dragoon”.

Sold at Rock Island Auctions for $1,450,000.

The Millikin Dragoon is a virtual superstar even amongst an elite category of antique firearms recognized by the collector fraternity by its nickname and, in the words of noted Colt historian R.L. Wilson, is “one of the classics of Colt collecting.” It is a type of revolver with an unprecedented level of historical pedigree, ownership pedigree, artistic merit and condition that collectors usually can only fantasize about owning. A one gun tour de force which transcends fine arms collecting in way that it has the ability to instantaneously reveals itself as fine art, a steel canvas by definition. This historic revolver (serial number 16477) falls into a known serial number range of presentation grade Dragoons. These sister revolvers include serial numbers 16474 and 16476, a matched pair, no presentation, shipped by Colt in April 1864, recipient unknown (Lee Collection); 16480, 16481, and 16482 which were presented by Samuel Colt to Russian Czar Alexander II and his two brothers (State Hermitage Museum, St. Petersburg Russia); 16461 which was presented by Samuel Colt to his chief engineer E.K. Root (Autry Museum of the American West, Studio City California) ; and 16467 which was presented by Colt employees to Secretary of War John B. Floyd (whereabouts unknown, condition is reported "fair"). Manufactured in 1857, this revolver showcases Gustave Young’s abilities on an unrivalled surface and combination of finishes. The profuse engraving consists of Young’s signature tight and immaculate floral scrollwork featured on all major components. Note the engraving extends to the rear of the cylinder, a flourishment reserved for only the most important presentation specimens. Amongst the scrollwork is an eagle head and dog head on the barrel lug, a dog head on the frame and a wolf head on the hammer. The screw heads and barrel wedge are also engraved. Young’s attention to detail is astonishing. The Colt barrel address (“ADDRESS SAML COLT NEW YORK CITY”) and frame marking (“COLT/PATENT”) are hand engraved rather than the standard roll die impression. The inscription, which is flanked by scrollwork at each end, appears on the silver plated back strap. The inscription reads “Colonel P.M. Milliken.” The misspelling of the surname “Millikin” was an engraver’s error. The cylinder has the Ranger and Indian scene, and the left side of the trigger is marked with the letters “V” and “M.” Matching numbers are found on the barrel, frame, trigger guard, back strap, cylinder, loading lever and wedge, and the cylinder pin is unnumbered. The revolver originally belonged to a heroic Union Army officer, Colonel John Minor Millikin, Jr. (1834-1862) of the 1st Ohio Volunteer Cavalry. The colonel went by his middle name Minor, and before the Civil War, he attended Harvard Law School, worked for his father's former law partner for a short time, married his college sweetheart, and co-owned the Hamilton Intelligencer Newspaper. At the outbreak of the Civil War, Minor assisted in outfitting the Captain Burdsall's Cincinnati Company with horses and saddles and helped to recruit men for the regiment. He started his war service as a sergeant, then lieutenant and was promoted to major in the 1st Ohio Volunteer Cavalry after several months of war. In 1862 he was promoted to the rank of colonel. On December 31,1862, Minor was killed in action while leading a saber charge against Confederate forces at Stones River near Murfreesboro, Tennessee. Cited for gallantry by General Rosecrans, and noted in the field report of General John A Wharton, CSA- “Colonel Milliken was killed by private John Bowers, Company K, Texas Rangers, in single Combat”. Fought from December 31, 1862, to January 2, 1863, the Battle of Stones River or the Second Battle of Murfreesboro was a Union victory which deterred the Confederacy from controlling Middle Tennessee. Minor along with a small group of his men became cut off from the rest of the regiment but refused to surrender to the rebel cavalry. The fight evolved into hand to hand combat. Minor was killed by a Texas Rangers private, John Bowers, who, from a distance, shot the colonel in the neck. For his actions and ultimate sacrifice, Minor was cited for gallantry. Minor's college friend and future New York Times editor Whitlaw Reid eulogized the fallen colonel, stating with great pride "I cannot feel that I have done justice to the memory of my dead friend, without adding the conviction that by no single blow during the war did the Country lose, among her younger officers, one braver, more devoted, more unselfish, more cultured, purer in character, or loftier in honorable ambition...he was in some respects of too sensitive and peculiar an organization for the rough ways of common life. But in the fire of our great struggle his true character shone out; and in the halo from Stone River that now surrounds the name, none, even of his enemies, fail to do tender justice to his worth, or to cherish as a sacred possession the memory of Minor Millikin." At the time of his death, Minor’s son, Paul Minor (1858-1934), was four years old. Paul inherited his father’s Dragoon and went on to have a military career. Paul was a colonel during the Spanish-American War, served as chief of the Cincinnati police force from 1903 to 1911, saw additional military service in World War I and was an accomplished insurance businessman until his death in 1934. It is Paul’s name with military rank that is inscribed on the back strap of this revolver. The included partitioned case is lined in blue velvet, has a Blunt & Syms trade card on the interior of the lid and contains lead rounds, rare “COLTS/PATENT” marked high gloss blued steel double cavity bullet mold, double face Colt Dragoon powder flask and Eley Brothers cap tin. Throughout the decades the Dragoon has been pictured in numerous publications which include R.A. Dow and R.L. Wilson’s “The Art of American Arms” in the July/August 1986 issue of "The American West Magazine" on page 41 and in "Outdoor Life Guns and Shooting Yearbook, 1988" on page 137 (copy included) and R.L. Wilson’s Japanese edition of “Colt Handguns” on page 6, “The Book of Colt Engraving” on page 49, “Samuel Colt Presents” on page 56, “The Colt Heritage” on pages 22 and 59, “Colt an American Legend” on page 22 and 59 and “Colt Engraving” on page 50. Wilson confessed that the revolver had “long been a favorite and thus it’s prominence in so many of his published works.” Note the included Outdoor Life publication features a handwritten salutation from R.L Wilson congratulating noted collector Al Cali for owning the Millikin Dragoon. The revolver was also part of the “Samuel Colt Presents” exhibition at Wadsworth Atheneum in 1961. An accompanying letter from R.L. Wilson documents the revolver’s significance as stated above and correspondence from Robert Nelson to Al Cali identifies this dragoon as once being part of Cali’s collection, John S. duMont and Larry Shrerin, all legends in their own right.

130 notes

·

View notes

Text

Ranch hand bumper f250

If you own a truck, you probably want to protect that baby as best you can. And one protective accessory you should never skimp on is your bumper.

Bumpers are designed to absorb shocks and prevent damage to your grille, hood, and fuel system in the event of a crash. But when it comes to ultimate protection, standard stock bumpers just don’t cut it. What you need is a good, heavy-duty bumper.

But how do you pick the right manufacturer when there are so many brands to choose from? Not to worry, we’ve already done the homework. Below is our top 5 selection of aftermarket bumper manufacturers that offer great service and high-quality products:

Top 5 Heavy-Duty Bumper Manufacturers

Steelcraft

Quick Facts:

Headquarters: Southern California

Year founded: 1998

Material of choice: Diamond plate and schedule 40 pipe

Warranty: 2-year warranty on all heavy-duty bumpers

If you’re struggling to find an expertly crafted bumper to go with your newer model truck, then Steelcraft is your guy. With more than 20 years’ experience in the automotive aftermarket, Steelcraft bumpers team is dedicated to be the first to develop accessories for newly released vehicles.

To ensure maximum strength and durability, they offer one-piece designs that are all E-coated and protected with a black powder coat finish, which has a limited 3-year warranty. They also offer a 2-year warranty on their heavy-duty products, and their stainless-steel products carry a limited lifetime warranty. This earns them extra brownie points as they have the longest warranty when compared to other suppliers.

Hammerhead

Quick Facts:

Headquarters: Bay Springs, Mississippi

Year founded: 2008

Material of choice: A36 Carbon Steel

Warranty: 12-month warranty on all Hammerhead products

Though Hammerhead has only been around for about 12 years, its founders come from a very knowledgeable background. Back in 2008, a few Hol-Mac employees were inspired by the corporation’s high-strength steel, and decided to venture out on their own to develop the best possible aftermarket bumper.

Not only does Hammerhead pride itself on using industrial-grade materials and highly certified craftsmen, it also aims to create strong, durable accessories that bolt straight onto your vehicle’s existing frame. That means you don’t need to cut, weld, or drill into your truck to accommodate your new bumper.

All Hammerhead Armor products carry a 1-year warranty, and if you’re not entirely satisfied with your bumper, you can return it within 10 business days. They also offer free shipping to any commercial US continental address.

If you want a custom-colored bumper, Hammerhead gives you the option to order raw, unpainted products. However, they don’t recommend this as extensive prep work will be required to ensure a smooth finish.

Ranch Hand

Quick Facts:

Headquarters: Shiner, Texas

Year founded: 1986

Material of choice: Industrial-grade steel

Warranty: 1-year warranty on all Ranch Hand products

Another proudly American manufacturer that puts its heart and soul into its aftermarket bumpers is Ranch Hand. As a subsidiary of Kaspar Companies, which has been around since the late 19th century, Ranch Hand understands what it takes to keep customers satisfied.

Nothing matters more to them than you and your vehicle’s safety. They even claim that their bumper pipe is 90% thicker than that of their competitors!

They also put effort into adapting their designs to match the make and model of your vehicle, and offer a 12-month warranty for each and every product that leaves their factory.

Iron Cross

Quick Facts:

Headquarters: Tulsa, Oklahoma

Year founded: 2003

Material of choice: All-steel, fully welded

Warranty: Shipped with product

If you invest in an Iron Cross bumper, you can rest assured that your vehicle is protected. These guys take the safety of their customers very seriously - which is not only conveyed by their Maltese Cross-inspired logo, but also in their top-quality workmanship.

They source only the finest grade of materials to bring you replacement bumpers that not only look good, but are strong and durable to boot.

1 note

·

View note

Text

In the final quarter of 2022, the Steel Plate prices plunged in the US market owing to the limited inquiries from the downstream segment. In October, major manufacturers were curtailing production activity to fill the supply-demand gap. The Mississippi River's water level had dropped so low that barges had become stuck, resulting in costly dredging and traffic congestion. According to manufacturers, Steel Plate fell as the market remains concerned about logistics. As shippers cannot load as much weight on a barge at low water levels, barges became much more expensive, causing shipping delays. Towards the quarter's end, the inventory level dropped, and Steel Plate manufacturers started raising prices, anticipating a higher demand outlook before the Christmas holiday. Buyers had opted wait-and-watch outlook as the market slowed ahead of the holidays. Thus, Steel Plate (20 mm) prices for Ex Works Texas (USA) settled at USD 1605/MT.

0 notes