#Supplier of PTFE Lined Ball Check Valve

Text

Important Steps to Troubleshoot and Fix the Most Common Problems with AODD Pumps

Because of their simplicity, air operated double diaphragm pumps (AODD Pumps)are great for transfer applications. To achieve maximum performance, it is important to properly install and operate your pump. These six easy fixes will help you troubleshoot and fix common problems when your AODD is not working properly during installation and operation.

1.To Check The Air Inlet Size And Pressure.

A small airline is the most common error with AODD pumps. To operate at its best, the pump requires compressed air. An airline that is too small will deprive it of the fuel it needs. Larger AODD pumps (one-inch and more) require more compressed and longer air lines than their smaller counterparts. For the correct size air line for your pump, refer to the manufacturer's instructions and operation manual. It is a good rule of thumb to match the size of the air line hose to the size of the inlet port on AODD pumps. Explore the latest AODD Pumps at Antlia Engineering Works. They are the AODD Pump Suppliers Globally.

Your pump's performance can also be optimized by adjusting the inlet pressure. Diaphragm pumps work in a 1:1 ratio. The pump's inlet pressure is directly proportional to the pump's outlet pressure. 100 psi is the target outlet pressure for a 50 gpm 1 inch pump. The pump's inlet pressure must also be greater than or equal to 100psi.

The outlet fluid pressure is affected by fluid viscosity, system back pressure, and fluid viscosity. Too little back pressure can cause the pump to run slower and the ball checks may not be as quick. If the fluid pressure exceeds the air pressure, the pump may stall. An air regulator is required to regulate the incoming pressure to ensure that an AODD pump performs at its best. An air regulator and the correct size air line will resolve most of the problems associated with AODD pump installation.

2.Check for Muffler Icing and Restrictions

Mufflers can be installed on AODD pumps and are recommended because they can produce high decibel levels at full speed. To operate the pump's air motor, compressed air is needed. Rapid temperature changes are caused by the compressed air entering the valve. It is then channeled through the pump's center section and exhausts through the muffler. The muffler exhaust temperature is below freezing and can lead to icing issues. This is more prevalent in environments with high humidity. Looking for AODD Pump Manufacturers In India.

Visit Antlia Engineering works, they manufacture all types of AODD Pumps.

If your pump is acting erratically, your inlet air contains high levels of moisture, or you can see the front of your muffler, these are indicators that your pump has icing issues. These solutions can help you eliminate icing issues and improve your pump's efficiency.

Pump the air pressure down

To operate at a lower speed (i.e.,. lower air pressure)

An exhaust port tube allows you to exhaust the air to remote locations

To collect condensation, add an air filter and a water catcher to your system.

To raise exhaust air temperature above freezing, install an air heater

To adjust the pressure dew point temperature, use an air compressor dryer

3.Checking Sealing Surfaces for Leaking

Leakage issues can occur with all types of pumps. These tips will ensure that your fluids remain in the pump and not the ground.

Follow the bolting pattern's illustration and torque the pump to the manufacturer's specifications.

When servicing your AODD pump, replace all PTFE o rings. Although PTFE can be used in many applications, it is not capable of returning to its original form after being compressed.

You can reduce the risk of leakage by properly torquing your pump according to the manufacturer's specifications and ensuring that sealing o-rings are replaced during service.

4. Ensure proper tubing and piping sizes

The flow rate of fluid required will determine the diameters of the pump's inlet and outlet ports. The size of the outlet and inlet hoses must be equal. This is a major concern because of the potential for cavitation, as well as the higher repair frequency and increased maintenance costs.

A pump that is 1 inch tall has a 1/2-inch inlet hose attached. The pump will not be capable of operating at its maximum capacity without cavitation. As the fluid viscosity increases, this risk is greater. To avoid cavitation, a pump of 1 inch should have an outlet and inlet hose of 1 inch. This will prevent costly and frequent repairs.

AODD pumps should have flexible inlet and outlet connections. This is preferable to hard plumbed installations. As the pump speed increases, vibration increases. Vibration increases with pump speed. This increases the possibility of hard-plumbed connections being loosened, which can lead to leakage.

5. PRIME - LOWER THE PUMP

AODD pumps are a popular choice for applications that require self-priming. The AODD pumps draw fluid by creating a low-pressure zone within the fluid bowls. This is less than the atmospheric pressure (14.7 psi). If the air pressure is too high, the pump will not changeover quickly enough to allow the fluid to flow into it.

This is solved by using the air regulator to reduce the air pressure entering an air valve and slow down the pump. The pump speed can be reduced to ensure that the fluid supplied has sufficient time to reach the pump. After this, the pump can operate at a faster speed by increasing the air pressure.

6. CLEAR ALL FLUID LINE RESERVATIONS

Clearing any fluid line restrictions is the final step in ensuring optimal pump performance. Limitations can lead to increased maintenance, pressure loss and potential cavitation. This issue can be fixed by removing the following:

Valves that are partially or fully closed

Line kinks or clogs

Too many hoses or too long a distance

These six steps will resolve most of the problems associated with AODD pumps. This will allow you to produce more and not spend time trying to fix it. If you need more help troubleshooting and repairing your AODD pump contact one of our experts.

For more details visit Antlia Engineering Works and know in detail about AODD Pumps as they are the Peristaltic Pump Manufacturers and supplier of the Pumps worldwide.

#AODDPumps#AODDPumpManufacturers#AODDPumpSuppliers#AODDPumpManufacturersInIndia#PeristalticPumpManufacturers

0 notes

Text

Do You Have These Products?

The industry type we are talking about will never do anything with our requirement.

Thus, it becomes a deal that we learn through and expect the things to go the way expected.

Thus, have you ever needed Lined Pipes, Fittings, Valves and other such customized products?

Do share your thoughts, and now – We are going to share the product types you should have in place for the operations to get going.

Below are the products you can directly get out from AblazeLining!

Ball Valve

Ball Check Valve

Butterfly Valve

Lined Globe Valve

Diaphragm Valve

Flush Bottom Valve

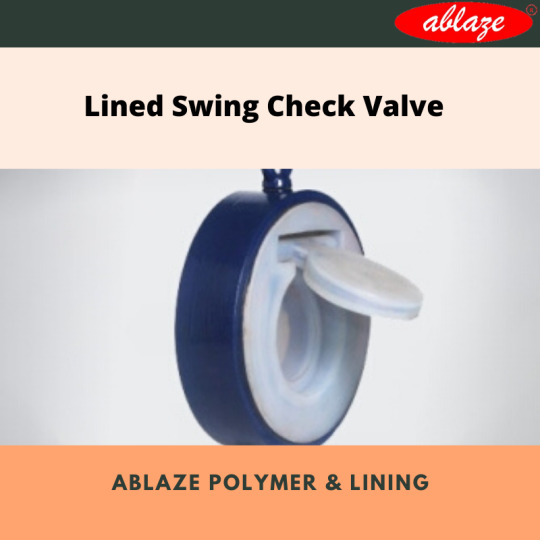

Lined Swing Check Valve

Plug Valve

Full View Sight Glass

Double Window Type Sight Glass

Dip Pipe

PTFE Stirrer & Agitators

Feed Pipe

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined EQUAL TEE

Lined Concentric Reducer

Lined Equal Cross

Lined Unequal Cross

Lined Blind Flanges

Solid Spacer

Lined Spacer

If you are the person and need these products to conducting business operations at an ease, just make sure that you are switching to Ablaze Lining! They have been a leading and trustworthy Lined Pipes, Fittings, Valves and Customized Products’ manufacturer and supplier. They will also manage to serve you as per your requirement and needs. Make sure that you are filling in their contact form, and get to the every detail they have mentioned on their website. It will ensure you are having everything you need to have reasonable decision in place. On top of everything – They have served countless customers and always ensure the requirements clients use their products for taking on everything in the best possible manner. So, visit the recommendation for sure!

Final Thoughts

Thus, in case you are still looking for the Lined Swing Check Valve Manufacturer, the recommendation we talked about will do the best.

Just ensure to stick with the guide and take it as a reference.

These are the products we shared are what Ablaze Lining offers!

On a sweeter note – Thanks for the read, though!

0 notes

Text

Advantages of Shopping with a Reputed Check Valve Manufacturer

The multitude of valve types available on the market makes it difficult for customers to choose the best alternative for their systems. When shopping for butterfly valves, ball valves, check valves, globe valves and other similar products, customers feel overwhelmed with the high number of alternatives and have the tendency to make uninspired shopping decisions. If you are looking for quality valves for your commercial or industrial applications, you should resort to the services of a long-standing Butterfly Valve Manufacturer that will offer you specialized advice, as well as quality products. By shopping with a reputed Check Valve Manufacturer, you can rest assured that your valves will perform without error for a long time.

Shopping for valves is not as easy as one may be tempted to think: for instance, customers have to know whether the valve will be used for starting/stopping or for regulating the flow, what conditions it needs to withstand, whether the valve can be easily integrated in their systems and so on. Based on their answers, the experts working for the Butterfly Valve Manufacturer will make useful suggestions, assisting the customers in purchasing the most suitable valve type for their operations. At the same type, the Check Valve Manufacturer will offer customers bespoke solutions that take into consideration the specificity of their work processes and that will fit their systems perfectly.

The butterfly valve is an excellent alternative for starting, stopping and even regulating flow. It can be efficiently used in systems that operate with chemical substances, sewage systems, beverage applications, etc. Furthermore, the butterfly valve does not require any sort of maintenance, which makes it ideal for systems positioned in places that are very difficult to reach. As for the various types of butterfly valves available, the resilient seated butterfly valve, the PTFE lined butterfly valve, the triple offset butterfly valve and the grooved butterfly valve are only a few of them. Note that it is extremely important to pay attention to the characteristics of each valve type and to identify the product that would best suit your system: for instance, the high performance butterfly valve is the best option for use in harsh conditions, where it has to withstand extreme temperatures and/or pressures. The resilient seated butterfly valve is the perfect choice for low pressure applications, being frequently used in air conditioning, mining, power plants, food and beverage lines, etc.

The check valve has a unique advantage: it can function autonomously, as it does not rely on electricity to operate. Hence, if you are looking for a valve that will perform without error in environments exposed to frequent power outages, the check valve should definitely be on your list. After doing a little research with respect to the available options, such as the cast iron check valve, the cast steel check valve, the forged steel check valve or the stainless steel check valve, you should be able to select the best type of valve for your systems. However, if you have little technical knowledge and would rather seek the advice of a specialist, you should resort to the services of a top Check Valve Manufacturers whose team of experts will provide professional advice, so that you make the right shopping decision.

Although the offer of valves is extremely varied and you can easily find lots of suppliers of such products when conducting a quick search on the Internet, you should keep in mind the fact that the quality of the ordered valves is not the same. In other words, you should do your homework and choose to work with a manufacturer that has been in this business for many years, that understands customers’ needs and that is committed to offering high quality services. Also, you should opt for a manufacturer that has acquired cutting-edge manufacturing systems to ensure the production of resilient valves of superior quality. Last but not least, you should place your order with a manufacturer that understands the fact that every customer has unique needs and that will enable you to customize valves, so as to make sure that they are the perfect match for your systems.

Resource box: If you are looking for a reliable Butterfly Valve Manufacturer with a flawless reputation, you have come to the right place. We invite you to place an order with a leading Check Valve Manufacturer and we guarantee that the end products designed, manufactured and delivered by its experts will meet all your expectations!

0 notes

Text

A Premier Supplier of PTFE Lined Products

When it comes to industrial operations, if you switch to the crappy gadgets or appliances, things won’t work the way they are expected.

That’s how managing every aspect makes sure you are aligning with what is highly sought in place.

Thus, have you been in any situation wherein you required the tool to get started any industrial operation?

In fact, are you a business owner who has to do a lot with a wide range of Lined Pipes, Fittings, Valves and other such customized products?

If this is what you are considering, this is the right guide for you.

We will do the best to ensure you have the best information available.

Do ensure to stick with the guide and let’s get started.

When it comes to manufacturing and supplying a wide range of Lined Pipes, Fittings, Valves and other such customized products, all you have got to look just at Ablaze Lining since they are a thought-leader, expert, including a leading manufacturer and supplier of Fluoropolymer Lined Pipes, Fittings and Valves. The amazing thing you will note is – They have been a successful partner with leading companies across the world. They know what it takes to working in corrosion resistant company. Therefore, whatever requirement you have got, just make sure to visit the website and fill in the contact form. This will make things a lot easier and advantageous.

Products they offer are:

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined Equal TEE

Solid Spacer

Lined Spacer

Ball Valve

Ball Check Valve

Plug Valve

Full View Sight Glass

Thus, were you looking for the products that are designed in a way that can be used in highly corrosive applications?

If yes, the recommendation will do the best.

Final Thoughts

No matter if you need High Pressure Bellow Manufacturer in India or something, the thing that separates the recommendation than the others is the level of quality product they deliver.

On a sweeter note – Thanks for the read, though!

0 notes