#Lined Swing Check Valve manufacturers

Text

The Ultimate Guide to Choosing the Best Hydraulic Check Valve Manufacturer in India

Hydraulic check valves play a crucial role in many hydraulic systems, ensuring the smooth and safe operation of machinery. Whether you’re working in manufacturing, automotive, or construction, the right hydraulic check valve can make all the difference. Today, we spotlight Pedlock, a leading manufacturer renowned for its quality and innovation in hydraulic check valves manufacturer in Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India.

Understanding Hydraulic Check Valves

What are Hydraulic Check Valves?

Hydraulic ball valves and check valves are devices that allow fluid to flow in one direction while preventing backflow. They are essential components in hydraulic systems, ensuring that the flow of fluid is controlled and directed as needed.

Key Functions and Applications

These valves are used in various applications, from industrial machinery to automotive systems. They help maintain pressure, prevent contamination, and protect equipment from damage caused by reverse flow.

Types of Hydraulic Check Valves

There are several types of hydraulic check valves, including ball check valves, swing check valves, and lift check valves. Each type has its specific applications and advantages, depending on the system’s requirements.

Why Quality Matters in Hydraulic Ball Valves & Check Valves

Impact on System Efficiency

A high quality hydraulic Ball valve and check valve ensures that your system operates efficiently. Poor-quality valves can lead to leaks, pressure drops, and overall system inefficiencies.

Long Term Cost Savings

Investing in quality valves from a reputable manufacturer like Pedlock can save you money in the long run by reducing maintenance costs and preventing expensive system failures.

Safety Considerations

Safety is paramount in any hydraulic system. Reliable check valves help prevent accidents and ensure the safe operation of your equipment.

Pedlock: A Pioneer in Hydraulic Check Valve Manufacturing

Company History and Background

Pedlock has been a trusted name in the hydraulic check valve industry for decades. Founded with a commitment to quality and innovation, Pedlock has grown to become a leader in the field.

Core Values and Mission

Pedlock’s mission is to provide the best hydraulic solutions with a focus on quality, reliability, and customer satisfaction. Their core values include integrity, innovation, and excellence.

Innovation and Technology

Pedlock invests heavily in research and development, ensuring that their products incorporate the latest technologies and innovations in hydraulic engineering.

Product Range Offered by Pedlock

Overview of Different Hydraulic Check Valves

Pedlock offers a wide range of hydraulic check valves manufacturer Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India to suit various applications. Their product line includes ball check valves, swing check valves, and more.

Special Features and Benefits

Each Pedlock valve is designed with unique features that enhance performance and durability. For example, their ball check valves are known for their robust construction and reliable sealing.

Customization Options

Pedlock understands that every system is unique. They offer customization options to tailor their valves to your specific needs, ensuring optimal performance and compatibility.

Manufacturing Excellence at Pedlock

State of the Art Facilities

Pedlock’s manufacturing facilities are equipped with the latest machinery and technology, allowing them to produce high-quality valves with precision and efficiency.

Quality Control Processes

Every valve undergoes rigorous testing and quality control processes to ensure it meets Pedlock’s high standards. This commitment to quality ensures reliable and long-lasting products.

Certifications and Standards

Pedlock is certified by various industry standards organizations, reflecting their commitment to quality and safety. These certifications give customers confidence in the reliability of Pedlock’s products.

The Pedlock Advantage

Superior Materials and Durability

Pedlock uses only the best materials in their valves, ensuring they can withstand harsh conditions and heavy use. This durability translates to longer lifespans and fewer replacements.

Advanced Design and Engineering

Pedlock’s team of engineers is dedicated to designing valves that meet the highest performance standards. Their advanced designs help improve system efficiency and reliability.

Customer Support and Service

Pedlock prides itself on providing excellent customer service. Their knowledgeable support team is always ready to assist with any questions or concerns, ensuring a smooth experience from purchase to installation.

Case Studies and Success Stories

Real-World Applications

Pedlock’s valves are used in a variety of industries, from automotive to industrial machinery. Real-world case studies demonstrate how their products have improved system performance and reliability.

How to Choose the Right Hydraulic Check Valve

Factors to Consider

When choosing a hydraulic check valve, consider factors such as the type of fluid, pressure requirements, and the specific application. Pedlock offers a range of options to meet different needs.

Pedlock’s Recommendations

Pedlock’s experts can help you choose the right valve for your system. Their recommendations are based on years of experience and a deep understanding of hydraulic systems.

Installation and Maintenance Tips

Best Practices for Installation

Proper installation is crucial for the optimal performance of hydraulic check valves. Follow Pedlock’s installation guidelines to ensure a secure and efficient setup.

Maintenance Guidelines to Extend Lifespan

Regular maintenance can extend the lifespan of your hydraulic check valves. Pedlock provides detailed maintenance guidelines to help you keep your valves in top condition.

Industry Trends and Future Outlook

Emerging Technologies

The hydraulic industry is constantly evolving, with new technologies emerging regularly. Pedlock stays ahead of the curve by incorporating the latest advancements into their products.

Future Developments in Hydraulic Check Valves

Looking ahead, Pedlock is committed to continuing their tradition of innovation. They are actively working on new designs and technologies to meet the future needs of the industry.

Environmental and Sustainability Efforts

Pedlock’s Commitment to Sustainability

Pedlock is dedicated to sustainability and environmental responsibility. They strive to minimize their environmental impact through eco-friendly practices and products.

Eco-Friendly Products and Practices

From using sustainable materials to implementing energy-efficient manufacturing processes, Pedlock is committed to protecting the environment while delivering high-quality products.

Conclusion

Choosing the right hydraulic check valve manufacturer Mumbai, Ahmedabad, Chennai, Delhi, Vadodara, Rajasthan, Ghaziabad, Bangalore, Gujarat in India is crucial for the efficiency and safety of your hydraulic system. Pedlock stands out as a leading manufacturer, offering high-quality, reliable, and innovative hydraulic check valves. With their extensive product range, commitment to quality, and excellent customer support, Pedlock is the go-to choice for all your hydraulic check valve needs.

#Hydraulic Check valve manufacturer in Mumbai#Hydraulic Check valve manufacturer in Ahmedabad#Hydraulic Check valve manufacturer in Chennai#Hydraulic Check valve manufacturer in Bangalore#Hydraulic Check valve manufacturer in Vadodara#Hydraulic Check valve manufacturer in Gujarat#Hydraulic Check valve manufacturer in Delhi#Hydraulic Check valve manufacturer in Ghaziabad#Hydraulic Check valve manufacturer in Rajasthan

0 notes

Text

Check Valve: Essential Component in Fluid Control Systems

A check valve, also known as a non-return valve, is a crucial component in fluid control systems. Its primary function is to allow fluid (liquid or gas) to flow through it in only one direction. This unidirectional flow is critical in various applications to prevent backflow, which could potentially damage equipment or cause system failures.

Types of Check Valves

There are several types of check valves, each suited for specific applications and operating environments:

Swing Check Valve: This type uses a swinging disc to allow or block flow. It's commonly used in water and wastewater treatment plants, as well as in fire protection systems.

Lift Check Valve: Featuring a disc that moves vertically, lift check valves are typically used in high-pressure applications. They are often found in steam and gas lines.

https://www.freture.com/site/assets/files/1238/lift-check-valve.png

Ball Check Valve: This valve uses a ball to block flow in the reverse direction. It's particularly effective in handling viscous fluids and is frequently used in pumping systems.

Diaphragm Check Valve: Utilizing a flexible diaphragm to control flow, these valves are ideal for applications where a tight seal is necessary, such as in chemical processing.

Wafer Check Valve: Compact and lightweight, wafer check valves are installed between two flanges. They are suitable for applications with limited space.

Advantages of Check Valves

Check valves offer several benefits that make them indispensable in many industries:

Prevention of Backflow: By ensuring unidirectional flow, check valves protect pumps, compressors, and other equipment from damage caused by reverse flow.

Minimal Maintenance: Most check valves are designed to operate automatically without the need for external control, reducing maintenance requirements.

Versatility: With various types and materials available, check valves can be used in a wide range of applications, from residential plumbing to industrial processing.

Cost-Effectiveness: Simple design and ease of installation make check valves an economical choice for controlling fluid flow.

Applications of Check Valves

Check valves are used in numerous applications across different industries, including:

Water Supply Systems: To prevent contamination of clean water by backflow from contaminated sources.

Oil and Gas Industry: For maintaining the integrity of pipelines and preventing reverse flow of hazardous materials.

Chemical Processing: To ensure safe and efficient operation by preventing cross-contamination.

HVAC Systems: To maintain the proper flow of refrigerants and air in heating, ventilation, and air conditioning systems.

Pharmaceuticals: For maintaining sterile conditions and preventing contamination.

Installation and Maintenance Tips

Proper installation and maintenance are crucial for the optimal performance of check valves. Here are some tips:

Correct Orientation: Ensure that the valve is installed in the correct direction of flow, as indicated by the arrow on the valve body.

Regular Inspection: Periodically inspect the valve for any signs of wear or damage, especially in high-pressure or corrosive environments.

Cleanliness: Keep the valve and the surrounding piping clean to prevent debris from obstructing the valve operation.

Freture Techno Pvt. Ltd.: Leading Manufacturer of Check Valves in Mumbai, India

Freture Techno Pvt. Ltd. is a leading company that manufactures high-quality check valves in Mumbai, India. With a commitment to innovation and excellence, Freture Techno Pvt. Ltd. offers a wide range of check valves designed to meet the diverse needs of various industries. Their products are known for their durability, reliability, and superior performance, making them a trusted choice for fluid control solutions. Whether you need check valves for industrial, commercial, or residential applications, Freture Techno Pvt. Ltd. provides the expertise and quality you can rely on.

#check valves#types of check valves#check valve applications#check valve manufacturers#freture techno

1 note

·

View note

Text

Instrumentation valves: Advantages, Applications, Selection

Instrumentation valves are essential in the piping system for restricting or controlling fluid flow. They perform multiple functions in a piping system, like water cooling rate control in cooling lines by regulating temperature.

These valves in instrumentation also help manage the flow of fluids like concentrated acids and bases. These valves also redirect, restrict, and automatically stop fluid flow, preventing the failure of the piping system.

Advantages of different types of instrumentation valves

Gate valves offer lower fluid resistance.

Ball valves have a bubble-tight sealing effect and low pressure.

Globe valves offer low-pressure losses and laminar flow.

Plug valves can tolerate abrasive, poisonous, and corrosive fluid.

Pinch valves have low friction and turbulence.

Butterfly valves have a great sealing effect at low pressure.

Needle control valves have excellent control of the flow rate.

Check valves to help maintain pressure and prevent fluid backflow.

Diaphragm valves trap solid waste.

Applications of instrumentation valves

Instrumentation valves are essential to carry out different functions as follows:

They are essential in the food and beverage industry, pharmaceuticals sector, and chemical processing.

Instrumentation valves like ball valves carry corrosive fluids, liquids, slurries, gases, etc., and control pressure and flow.

Different types of valves in instrumentation find applications in the oil and gas sector, chemical storage, residential applications, petrochemical sector, and manufacturing sector.

The valves are essential for maintaining high pressure and low temperature in the system.

Selecting instrumentation valves in a piping system

There are multiple types of valves in instrumentation, and selecting these valves depends on the system’s performance and application. Following are the ways to choose instrumentation valves in the piping system:

Selection based on end connection

One must consider the pipe’s end connection for selecting the valves. Some common end connections of valves involve:

Flanged

Butt-welded

Socked welded

Screwed

Wafer

Selection based on valve material

Depending on the valve construction material one can select valves made of metals and non-metals like alloy steel, carbon steel, iron, aluminum, stainless steel, PVC, monel, etc.

Selection based on the actuator’s operation

Instrumentation valves have different ways of operating the actuators. These involve:

Hand lever

Chain

Hand Wheel

Gear operator

Electric Geared Motor

Pneumatic and hydraulic operators

Selection based on the mechanical movement

Instrumentation valves involve two prime mechanical motions as follows:

Linear Motion: These valves control, regulate, throttle, or stop the fluid flow as the component responsible for shutting off the valve has a straight line motion. Valves having liner motion involves gate valves, diaphragm valve, glove valve, lift check valves, and more.

Rotary Motion: These valves have a closing member moving in a circular or angular direction like in a ball valve, butterfly valve, plug valve, swing check valve, and eccentric valve. Since these valves depend on rotational motion.

Selection based on the port size

One can also select the valves depending on their port size. Since ports are responsible for the bigger internal opening of the valve. Different types of instrumentation valves are available per the port size.

Selection based on pressure and temperature rating

One can also select valves based on different temperature and pressure ratings. Depending on the pressure and temperature ratings valves are available in classes like:

Class 150 with a pressure range of up to 16 bars.

Class 300 with a pressure range of up to 40 bars.

Class 400 suitable for piping.

Class 600 with a pressure range of up to 100 bars.

Class 900 with a pressure range of up to 160 bars.

Class 1500 with a pressure range of up to 250 bars.

Class 250 with a pressure range of up to 400 bars.

Class 400 is the most common in piping applications.

Final thoughts

Piping systems require instrumentation valves for their efficient function. These valves offer extensive applications and advantages. If you are looking for high-quality instrumentation valves, visit Arcellor Controls (India), a leading instrumentation valve supplier in India.

The company features instrumentation valves like check valves, needle control valves, manifold valves, etc. Explore their website today!

0 notes

Text

Getting My Diaphragm gas meters To Work

Gas Train for Burners The Itron meters are the simplest and safest to set up due to the Straightforward Switch (ET) top choice, which permits two-three times much more wrench swing when compared to the Opposition.

We have been delighted to carry on our partnership with Neptune Chemical Pumps this year. Neptune supplies a wide number of chemical feed gear, which include personalized skids and comprehensive deals.

The drive with the increasing gases brings about the piston to move within the cylinder which motion delivers mechanical electrical power that may be transformed into heat, that may then be utilized to do operate.

on the hose in a container of drinking water, enabling stress to come back in the valve and counting the number

Strain switches made for automatic burner controls, for use in furnace, ventilation and air con applications.

Remote studying has become common for gas meters. It is commonly accomplished by means of an Digital pulse output mounted over the meter. There are various styles accessible but most popular is really a Get in touch with closure swap. Move measurement calculations[edit]

explosion. Boiler operators can check to discover if their fuel train is functioning adequately by administering a Leak Check or maybe a

A gasoline meter can be a specialised stream meter, used to evaluate the amount of gasoline gases which include pure fuel and liquefied petroleum fuel. Gas meters are applied at residential, commercial, and industrial properties that take in gasoline gasoline provided by a gas utility. Gases are more challenging to evaluate than liquids, mainly because measured volumes are really influenced by temperature and strain.

Norgas Controls Inc utilizes cookies to improve your knowledge and have an understanding of the website traffic on our web site. By continuing to use our internet site, you settle for our usage of cookies.

Find a nearby distributor or reseller

Generally known as a sediment lure or a dust leg. This area of piping is designed to prevent any sediment Which may be in the fuel from moving into the program. This is essential for the reason that as Vitality enterprise mend buried lines, dirt or sand frequently receives in to the piping.

This assures superb linearity Despite having using little valves. As a result of optimized slides, Qmin these meters is stable as well as the fuel meter isn't vulnerable to contamination. The measuring device is altered by a patented needle-and-scale method. Even though the style with the these Gas Meters is rather sturdy, the gasoline meters remain measuring devices and as such ought to be dealt with with treatment.

Call our staff of gurus now To find out more on gasoline meters. We’ll be content to suggest the top fuel meters, gasoline regulators, and fuel valves to your software. Moreover, we have a significant inventory of items prepared to ship, no matter how huge or smaller your get.

We're Sage Metering. We manufacture thermal mass flow meters, which evaluate and observe fuel mass stream. If you have an interest in a special meter model, may well I propose Finding out more about some great benefits of thermal mass move measurement? Or else, here are other one-way links to articles sharing the advantages and limitations of each engineering: diaphragm gas meters

0 notes

Text

Do You Have These Products?

The industry type we are talking about will never do anything with our requirement.

Thus, it becomes a deal that we learn through and expect the things to go the way expected.

Thus, have you ever needed Lined Pipes, Fittings, Valves and other such customized products?

Do share your thoughts, and now – We are going to share the product types you should have in place for the operations to get going.

Below are the products you can directly get out from AblazeLining!

Ball Valve

Ball Check Valve

Butterfly Valve

Lined Globe Valve

Diaphragm Valve

Flush Bottom Valve

Lined Swing Check Valve

Plug Valve

Full View Sight Glass

Double Window Type Sight Glass

Dip Pipe

PTFE Stirrer & Agitators

Feed Pipe

Lined Pipe

Lined Elbow 45

Lined Elbow 90

Lined EQUAL TEE

Lined Concentric Reducer

Lined Equal Cross

Lined Unequal Cross

Lined Blind Flanges

Solid Spacer

Lined Spacer

If you are the person and need these products to conducting business operations at an ease, just make sure that you are switching to Ablaze Lining! They have been a leading and trustworthy Lined Pipes, Fittings, Valves and Customized Products’ manufacturer and supplier. They will also manage to serve you as per your requirement and needs. Make sure that you are filling in their contact form, and get to the every detail they have mentioned on their website. It will ensure you are having everything you need to have reasonable decision in place. On top of everything – They have served countless customers and always ensure the requirements clients use their products for taking on everything in the best possible manner. So, visit the recommendation for sure!

Final Thoughts

Thus, in case you are still looking for the Lined Swing Check Valve Manufacturer, the recommendation we talked about will do the best.

Just ensure to stick with the guide and take it as a reference.

These are the products we shared are what Ablaze Lining offers!

On a sweeter note – Thanks for the read, though!

0 notes

Text

Lloyd AC Technologies in India + the Best Models & Tips

India is a nation that's ultimately hot. Thus, humidity and heat are common in India. Now, to overcome the heat at houses, air conditioners are considered to be the ideal solution. With everything becoming net-linked, millennials and generation-z desire their appliances to be clever.

Among those brands that cater to the cooling needs with intelligent technologies is Lloyd. And in addition, it appears to be among the earliest AC manufacturers in India that Havells obtained in 2017.

Lloyd is your number two manufacturer by earnings after Voltas. Lloyd provides both windows and splits air conditioners. Lloyd AC Review contains all the specification of the best Lloyd AC Brand.

Thus, what's making people run following Lloyd ACs? Why you need to (or perhaps not) purchase a Lloyd AC, let us see in this report.

Key Lloyd AC Technology

Rapid Cooling with 4-Way Swing

Is not it frustrating on a sunny day that you come directly to your house after a day outside in the sunlight, and your AC requires some time to cool down if it had been turned off sooner?

Well, this issue is using the AC for ages. But luckily, brands such as Lloyd are creating positive changes in this way to lessen the cooling time.

New Lloyd ACs include Quick Cooling technology that's designed using a 4-way cooling system that the firm believes can cool the room down in under two minutes.

It accomplishes Rapid Cooling utilizing a 4-way blade swing that thrusts the cool air into 4 distinct sides and hence done the Cooling considerably quicker than normal ACs.

Wireless AC Control

Among the main USP of Lloyd AC is its own wireless AC control utilizing a Wi-Fi system. This feature liberates you from the trouble of looking to your remote to control the huge cooling appliance.

Now all you must get a smartphone download the Lloyd AC distance program, and control your AC from any place on your palms. Just consider it: you're into the bedroom, but your AC is operating in the hallway, and nobody is around.

You may just turn off the AC in your hallway by lying on the mattress of your area without having to get up from the bed! Not turning off and on, other configurations such as fever, style, swing, etc., may also be controlled via this mobile application.

BLDC Motor and EEV For Energy Conservation and Optical Climate Control

Premium split ACs by Lloyd include a BLDC motor rather than a conventional induction engine. BLDC motor stands for brushless DC motor, and the principal differentiating factor is that the BLDC engine has permanent magnets when compared with electromagnets within an induction engine.

BLDC motor is famous for reliability, efficiency, and very low sound emission. ACs coming using BLDC motor are readily attached to the house inverter.

This is quite advantages for individuals who have regular power cuts in their house and rely on inverters during load shedding. BLDC motors at Lloyd ACs are complimented with a digital expansion valve (EEV) which regulates the flow of refrigerant.

EEV contributes to efficient and better cooling, notwithstanding erratic fever or varying climatic state out. Premium Lloyd ACs can operate even at a temperature as large as 60oC.

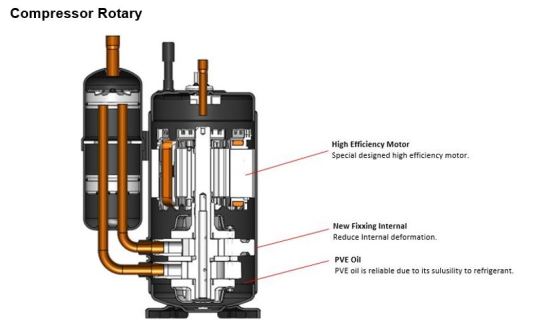

10-step Inverter with Twin Rotary Compressor

New split ACs introduced by Lloyd include a 10-step inverter controller. Do not confuse this futon compressor technology using all the inverters you use for powering your homes through the power cut.

Inverters used within the AC are for the velocity controller so that AC runs in line with the load. A 10-step inverter means that there are 10 unique frequencies where the compressor can operate.

Inverter technology could be considered an automobile accelerator. Just like as soon as the compressor requires more electricity, the inverter gives it more electricity by running at higher frequencies. If it requires less power, it provides less electricity by conducting at reduced frequencies.

With this technology, the AC’s compressor is always on but brings less power or much more electricity based upon the warmth of the incoming air and the amount set from the thermostat. The speed and strength of the compressor are corrected appropriately.

Twin Rotary Compressor for Lower Noise Generation

Lloyd is among those silent AC manufacturers around. That is mainly because they utilize a twin rotary compressor which leads to significant sound reduction.

What's more, in addition, it trims down the energy consumption resulting in saving on energy bills. Furthermore, the low-noise fan blade, fantastic air-duct layout, and utilization of noise-isolating fabric modern Lloyd AC keep peacefully cool surroundings in your house.

There's also a mute style that brings the sound level to its underside to approximately 20 dB.

Copper Condenser

To save costs and deliver down the AC costs, many AC manufacturers favor utilizing aluminum condensers in their own versions as it's more economical.

But modern Lloyd AC includes a copper condenser using 100% inner grooved aluminum, which eases in a quicker and smoother flow of refrigerant.

Additionally, aluminum has better heat transport performance compared to aluminum. Copper is also a lot more lasting as it could withstand a greater volume of atmospheric pressure.

Thus, your AC with an aluminum condenser with continue long and lead to lower maintenance cost in the time of fixes.

PM 2.5 Filter with Self-Clean Technology

Together with the increasing air pollution, the filter has grown into one of the vital qualities to check from the ACs besides energy efficiency.

In accordance with WHO (World Health Organization) quotes, amounts of air pollution are on a significant increase in growing economies like India.

A lot of studies have indicated that air pollution may be the reason for increasing instances of respiratory ailments.

Thus, air filtration becomes one of the very significant facets of the AC, and the Lloyd is the air purifier manufacturer that's offering powerful and powerful PM 2.5 filters inside their own premium split ACs to handle this matter.

For the uninitiated particulate matter, PM 2.5 describes extremely fine particles within the air that are of the dimensions 2.5 microns in diameter (or less). Micron is a component of dimension on a microscopic scale with one inch equating to 25,000 microns.

Emission from vehicles along with the burning of timber and petroleum are the principal sources of PM 2.5 particulates. But thankfully, superior Lloyd split AC coming using PM 2.5 filter may filter these impurities within the air.

Aside from the impeccable air filtration technologies, superior Lloyd versions arrive with the Self Clean characteristic, where the filter cleans itself.

Through this automatic cleaning procedure, the indoor system is controlled at a cooling mode at a lower fan speed to ease the removal of dust out of evaporator fins.

Then it switches into a fan-only mode to dismiss the moist air disinfecting unit. This phase removes bacteria and fungus.

Pros and Cons of Lloyd AC

The operation of all Lloyd ACs, generally speaking, is remarkable. You'd see a lot of positive things from the Lloyd AC. Wi-Fi management comes among the very first notable things you'll notice in Lloyd divide ACs.

Assessing your AC working with a smartphone is surely a pleasant encounter. Another benefit is in its Quick Cooling that warms the space in a couple of minutes.

Yet another interesting thing we enjoyed about versions like LS24B22FI is the fact that it allows to switch off the index on the AC, which shows temperature. Because of its 4-way blade swings, the cooling system accomplished by the AC is uniform.

There isn't much to whine about the Lloyd air conditioners, but there are particular areas that require improvement. Energy efficiency is just one of these.

The ISEER evaluation of Lloyd ACs falls supporting the Japanese manufacturers such as Daikin and Mitsubishi. Yet another drawback of Lloyd AC is they do not arrive with an integrated voltage stabilizer.

Consequently, if the energy source in your house is inconsistent, you need to avert Lloyd ACs or need to purchase a stabilizer together with the AC.

Lloyd is a budget manufacturer, and if you're interested in finding an adequate excellent AC at a nice cost, then Lloyd is a superb selection. Their build quality might not be like that of high-quality brands such as Hitachi, Mitsubishi, Daikin, and so on, but they are great value for money.

Conclusion

Lloyd is an inexpensive luxury AC manufacturer, and that is why individuals who search for the equilibrium of great excellent AC, trendy technology, and fair price select for Lloyd AC.

Lloyd is among a few brands that have its own production plant in India. In reality, it used to provide parts for ACs to other manufacturers such as Voltas, Godrej, and Whirlpool.

Thus, Lloyd is unquestionably an ac specialist. Overall, Lloyd is a fantastic alternative if you're trying to purchase an AC. It includes a few cool features and provides great value for money.

Go for Lloyd AC in case that you use technologically innovative AC at a fantastic price point and have a steady power source in your home.

Which are the best AC models from LLOYD?

Lloyd is one such brand that's excelling in manufacturing high-quality Air Conditioners. The air conditioners in Lloyd are packaged with contemporary features.

They offer a variety of air conditioners, including Window ACs, Split air heaters, Tower ACs, Portable ACs in Addition to Cassette ACs. We'll be reviewing three of their ideal Lloyd ACs within this report.

Lloyd 1.5 Ton 3 Star Window AC

The first AC Inside this record is really a Window AC out of Lloyd. This Air Conditioner includes a 3-star evaluation from BEE. The capacity of the AC is 1.5 tons.

Another top quality characteristic of this AC is that the Air Filters, which can be useful in maintaining the standard of the air pure and fresh.

This AC also has a Dehumidification quality which enables the unit to function in Fan style or Cooling manner, thereby ensuring effective dehumidification without reducing the temperature of your room.

The AC also includes a"self-Diagnosis" role, which assists in discovering errors and then shows them on the LED of the AC's interior unit.

The condenser of this AC consists of 100 percent aluminum, making the Air purifier corrosion resistant. When there's a power failure abruptly, then the AC will automatically restart when the electricity is restored, and also, it is going to function from the prior setting.

Pros:

Air Filters assist keep the air dust-free and pristine.

The AC includes remote control.

The AC requires very low maintenance.

5 decades of warranty on the compressor.

Cons:

The compressor guarantee period is less when compared to other ACs.

2) Lloyd 1.5 Ton 5

This really is a Split Air Conditioner using an Inverter out of Lloyd. It has a 5-star rating along with a "PM-25 Air Filter", which assists in trapping all kinds of airborne contaminants, such as spores, pollen, dust, pollen, bacteria, etc.

It keeps the air clean and wholesome. With the support of this"Quick Cooling" attribute, this AC is likely to make your room more comfortable in only 45 minutes.

The AC also employs the"Air Cooled Electric Control Box" technologies, which assists in efficiently cooling the outside unit of the Air Conditioner even when the temperature outside is as large as 52 levels.

The Air Conditioner also includes"Golden Eva Coils," which protects the device from rainwater, polluted air, or dust. The LED screen also remains concealed, and the AC also doesn't require an outside stabilizer.

Pros:

Numerous air filters keep the air clean.

The AC is very energy efficient.

The LED display is hidden.

The AC takes only 45 secs to cool the room completely.

Cons:

After-sales service from the company isn’t commendable.

3) Lloyd 1.5 Ton 3

This is Just Another High-Quality Split Air Conditioner from Lloyd. The capacity of the AC is 1.5 a lot, and also the very attractive characteristic of this AC is its own "Ayurvedic Tulsi" air filter.

Tulsi is an excellent antioxidant and helps in providing powerful protection against germs, germs addition to fungi. The air filter also has activated carbon, which assists in absorbing damaging properties and discharge fresh and clean air.

The coil of this Air Conditioner consists of "Hydrophilic Aluminium Fins" to protects the AC's condenser against rust and thus increasing the life span of this Condenser coil.

Another fascinating aspect of this AC is the fact that it's the"smart Multi Fold Evaporator'', which economically pushes out the indoor warmth. When there's a power failure all of a sudden, then the AC will begin automatically from its previous setting once the electricity comes back.

Pros:

The LED display is hidden.

Compact in size.

The air filters ensure blowing out cool and fresh air.

It has a “Tulsi air filter” as well.

Cons:

Customer service is not commendable.

Conclusion

These are just three of the very best Air Conditioning made from the reputed Llyod business. Consequently, if you're wondering as to that Lloyd AC you ought to prefer purchasing, then this guide would be of fantastic support to you.

There are many brands in the marketplace selling a variety of kinds of air conditioners and, it's easy to become confused. We've clarified all of the characteristics of the three Lloyd air conditioners, so you have the entire value of the cash you invested and find the item of your own choice.

Lloyd AC is from which country?

The year 2020 watched a vast majority of Indians becoming aware of the brands they buy products from. Consumers showed much interest in purchasing from local brands in India to encourage Indian brands and especially boycott goods sold by Chinese manufacturers.

This further saw numerous internet users fad looking for the source of any organization's country. Likewise, since the summer season is already here, a range of individuals are thinking about purchasing a new air conditioner for themselves.

That is the reason why numerous individuals have been tendency hunting about AC brands along with the organization's origin. Interestingly, the firm Lloyd watched many individuals asking about"Lloyd AC nation," "Lloyd new from which nation," and related questions. This is more info regarding the business brand Lloyd and that nation it belongs to.

A word for LLOYD itself

According to the info stated on the official site of the newest Lloyd, it's been stated that Lloyd AC source is India. The official site claims the headquarters of the business is at Noida, Uttar Pradesh. Here's What the About Us' section on the official site of Lloyd reads:

Lloyd has carved a market across India with its impeccable quality criteria together with the unmatched item, service, and guarantee. We, Lloyd, have consistently thought that all of our merchandise is a package of pleasure delivering happiness to houses.

It has helped us get the confidence and smiles of more than 3 million clients. Due to this love and trust, we've been continuously evolving with a bevy of new-age inventions and smarter alternatives.

Lloyd is among the pioneers from the AC category. As we're poised to meet our promise of earning homes more happiness, we bring forth our selection of technologically innovative and visually styled outfits of new-age Air Conditioners, LED TV and Washing machines.

So, the bottom line is:

It's well worth noting that Lloyd is possessed by Havells India. Lloyd's started their travel in India as a joint venture beneath Fedders Lloyd from 1956.

The newest became a sacred brand from the year 2007 if Fedders went bankrupt in America. It was subsequently possessed by the BR Punj Group before it was acquired by HAvells India in Feb 2017.

Tips for making best use of LLOYD ACs

Below are a few of the advice for making use of space air-conditioners. Proper use of Modes and Settings readily available in your Space A.C. can guarantee decent health and relaxation to you and lower your energy bill also.

Below are a few hints!

Your area air-conditioner (A.C.) may or may not possess the Settings and Modes supplied below. Each Setting and Mode is clarified prior to notification when or how to utilize it.

1 – Cool Mode

What can it be? In Cool Mode, the fan operates constantly, and the compressor turns off and on just as needed to keep the set temperature.

When to use it? Utilize the Cool Mode if you desire Room A.C. to cool the space and take care of the room temperature as you set.

2 – Fan Mode

What can it be? In Fan Mode, the fan operates continuously along with the compressor off.

When to use it? Utilize the Fan Mode if you don't want cooling but need the fan in the A.C. to give ventilation (airflow ) from the area.

Rather than conducting the A.C. in Fan Mode (that will provide only restricted ventilation), then you might prefer to conduct the ceiling fan (if it's there in the area ) to get a comprehensive airflow.

3 – Dry Mode

What can it be? In Dry Mode, the fan along with the sealing machine of the A.C. operates; however, the A.C. doesn't blow out chilly air.

As the air moves through the A.C., the humidity (water vapors from the air) condenses on the evaporator, so the air comes out of the dryer.

Thus it's a function that reduces the humidity in the room, which makes it comfier when humidity beyond the area is high. But it’s clearly understood that the A.C.

in Dry Mode isn't meant to substitute a dehumidifier or function for a dehumidifier. The capability to dehumidify an A.C. is a lot lower than that of a dehumidifier.

When to use it? Utilize the Dry Mode through rainy and spring seasons once the temperature isn't hot enough to operate the Cool Mode. However, the humidity is somewhat high.

4 – Smart Fan Mode or Energy Saver Mode

What can it be? Energy Saver or Smart Fan Mode is Meant to decrease the energy intake of this AC.

If this style is set, the AC cools the space normally along with the compressor turn off and on as needed to keep the set temperature. When the temperature drops below the set temperature, the compressor turns off, and the fan will also be switched off to conserve energy absorbed by it.

However, the fan is going to be switched off and on every 2-3 minutes to look at the temperature within the room. When the temperature increases above the set temperature, the compressor will turn on together with the fan.

When to use it? It's always fantastic to use Energy Saver Mode since it reduces the energy intake of this AC. However, some users don't enjoy this manner due to turning their fan on/off repeatedly.

5 – Sleep Mode

What can it be? The Sleep Mode works just together with Cool Mode. The goal is that the AC will slowly increase the level of temperature preserved by it throughout your sleep.

This helps to boost your comfort level since, throughout sleep, the metabolism in the human body decreases, and thus the need for cooling additionally reduces. Another advantage of this model is the decrease in energy intake of this AC because of cooling.

When to use it? In case you've put your AC in Cool Mode along with the Timer isn't turned on before you go to sleep, then you need to use Sleep Mode.

6 – Temperature Setting

What can it be? From the newer-type ACs, the temperature maintained by the AC is shown in digital form, and also, this temperature could be put by the consumer in the desired value.

From the old-type ACs, the temperature isn't shown, while the temperature setting is permitted on a potentiometer using a round knob. It's been observed that lots of AC users place the temperature in the bottom value (16oC or even 18oC or"Really Cool"), believing this will give quicker cooling.

In fact, this doesn't occur because the AC, no matter the temperature air, injects cool air at 16oC into 18oC to space. The compressor turns off when the AC attains set temperature from the room, and then the temperature is kept at this setting by turning the breaker off and on.

The way to use it? The ideal temperature setting in the factors of your health in addition to relaxation is 24oC to 27oC (24 to 27-degree Celcius).

At precisely the exact same time, this setting (rather than the typical setting of 18oC or so) will prevent substantial wastage of money and safeguard the environment also. In the case of old-style ACs, the temperature knob ought to be placed around mid-way.

7 – Fan Speed Setting

What can it be? As a Frequent practice, the Majority of the space ACs have three configurations of Fan Speed, which are Low, Medium, and High, Together with an Off position.

The fan is intended for venting or flow of the chilled air created by the AC. The fan speed doesn't alter the cooling created by the AC, but greater ventilation has a superior cooling effect on the residents of the room.

The way to use it? The Fan Speed ought to be chosen in accordance with the venting (airflow ) desired. It's usually much better to choose Low or moderate-rate AC fan and utilize a ceiling fan to get a comprehensive airflow in the room.

8 – Timer-Off Setting

What can it be? The Timer-Off air is supposed to set time delay or the shifting time (in minutes or hours ) to turn off the AC mechanically when air conditioning isn't required, and so prevent wastage of money and electricity.

The way to use it? Ordinarily, the Timer-Off is placed appropriately in the time of going to break or to bed with the space AC running, so the AC will be automatically switched off after the wait or in the specified period.

9 – Timer-On Setting

What can it be? The Timer-On Setting is supposed to set time delay or the shifting time (in minutes or hours ) to switch on the AC automatically. As a normal situation, the consumer might prefer the space to be chilled a bit before he returns from the workplace in the day.

He could use this timer setting to change on the AC mechanically at the proper time, rather than maintaining the AC running through the day. The usage of Timer-On can consequently offer a great deal of energy conservation.

The way to use it? The Timer-On could be placed appropriately (as soon as the AC is off), so the AC will be automatically charged following the specified delay or in the specified period.

#air conditioning#AC#Review#Blog#tumblrpost#tumblraesthetic#tumblrtextpost#tumblrposts#tumblrquotes#tumblrphoto#tumblrtextposts#tumblrstuff

1 note

·

View note

Text

Functions as well as benefits of industrial ball valves

Industrial ball valves are primarily a kind of device that has a round closure system which supplies on/off circulation control. The sphere may contain a port called as bore in the center. The round valve could make use of perforated, hollow, as well as pivoting sphere. It is normally open when the circulation remains in positioning with round opening and also closed when pivoted at 90 levels by a valve. The valve is not just carrying out well yet additionally are long lasting that provide a reliable closure cycle.

Let me inform you a lot more concerning industrial ball valves

Exactly how does industrial ball valves function?

When the ball valve obtained positioned in such a way that the bore obtained straightened towards the pipeline, it is called open. When turned to 90 levels, the bore will certainly be perpendicular to the course that plainly means the Trunnion ball valve manufacturer got shut and the flow can not be seen.

The industrial ball valves with plug shutoffs as well as butterfly valve becomes part of a valve family. They are bubble-tight securing as well as reliable. Therefore they function as one of the excellent selections for numerous applications where Shut On/Off is necessary. The body of the ball obtained made using steel and also is durable in addition to nickel plating. In general, there are 4 basic industrial ball valves namely-.

Trunnion mounted-It has extra anchoring at top and also bottom on the sphere. Suitable for greater stress valve and bigger pressure shutoffs.

Floating stem- it includes turn as well as tilt operation that eliminates seal rubbing.

Full-port- it is known as full-bore that has an inner diameter equal to pipeline ID. It is used in refining, chemical, and also petrochemical industries.

Reduced port- it is called as reduced-bore in which there is two or one small sizes.

Features of industrial ball valves:.

The leading round valve maker made the product in such a way that it has different attributes that fit in application such as:.

Swing check- the check will certainly provide valve function of inspecting the valve. It therefore avoids media from entering into the system.

Valve stops- this is a stopper that will certainly permit you to revolve the valve to 90 levels.

Placement signs- a piston indication will certainly be positioned over the top of the round valve to make sure that direction of circulation can be shown. It can be made use of in multi-port valves too.

Requirement one-on-one dimensions- the measurement of the valve will comply with criteria of ASMS and hence makes it very easy to retrofit as well as replaced in-line.

Anti-static- this anti-static design function allows the prevention of static power that got build because of valve massaging.Here is my page:https://perfect-valve.com/ It can be positioned much like a fire-hazard if any system has liquids that are combustible.

Fire-safe- fire-safe feature is very important as the metal seat is secured when the round obtain rests over the seal.

The advantage of sphere valve:.

The round valve can be set up easily and avoid burn out. It is used combined with packaging gland so regarding offer triple sealing. The two-piece body can be used as a dual link for adding protection and also can be related to metal-to-metal between the bodies. Compatible installations, along with accessories like pin extension as well as aluminum bars can be used. This is all about Industrial ball valves.

1 note

·

View note

Text

Let me tell you extra about industrial ball valves

Industrial ball valves are basically a sort of gadget that has a spherical closure device which provides on/off flow control. The sphere might include a port called as bore in the facility. The ball valve might make use of perforated, hollow, as well as pivoting round. It is normally open when the circulation remains in positioning with ball opening and also closed when pivoted at 90 degrees by a valve. The valve is not only performing well however additionally are long lasting that supply a dependable closure cycle.

What is the industrial ball valves as well as how it functions?

Exactly how does industrial ball valves work?

When the sphere valve got placed as though the bore got straightened towards the pipe, it is called open. When rotated to 90 degrees, the birthed will be perpendicular to the course that plainly suggests the Top entry ball valve manufacturer got closed and the flow can not be seen.

The industrial ball valves with plug valves as well as butterfly valve belongs to a valve household. They are bubble-tight sealing and also dependable. Hence they act as one of the great choices for numerous applications where Shut On/Off is needed. The body of the ball got made using steel and also is long lasting along with nickel plating. As a whole, there are 4 basic industrial ball valves namely-.

Trunnion mounted-It has additional anchoring at leading as well as bottom on the ball. Suitable for higher stress valve as well as larger stress shutoffs.

Drifting stem- it incorporates turn and also tilt procedure that gets rid of seal massaging.

Full-port- it is referred to as full-bore that has an internal diameter equal to pipe ID. It is used in refining, petrochemical, and also chemical industries.

Decreased port- it is called as reduced-bore in which there is two or one nominal dimensions.

Attributes of industrial ball valves:.

The top ball valve manufacturer made the product in such a way that it has various features that fit in application such as:.

Swing check- the check will provide valve feature of examining the valve. It hence stops media from going into the system.

Valve quits- this is a stopper that will certainly allow you to rotate the valve to 90 levels.

Placement signs- a piston sign will certainly be put over the top of the ball valve so that instructions of circulation can be shown. It can be utilized in multi-port valves as well.

Requirement individually dimensions- the measurement of the valve will comply with standards of ASMS and thus makes it easy to retrofit in addition to replaced in-line.

Anti-static- this anti-static style function enables the avoidance of fixed electrical power that got construct because of valve massaging.Also visit my weblog:perfect-valve.com If any type of system has liquids that are flammable, it can be presented simply like a fire-hazard.

Fire-safe- fire-safe attribute is important as the steel seat is sealed when the sphere get rests over the seal.

The advantage of sphere valve:.

The sphere valve can be set up quickly and stop burn out. It is utilized combined with packaging gland so regarding provide three-way securing. The two-piece body can be used as a double link for adding protection as well as can be put on metal-to-metal in between the bodies. Interchangeable installations, as well as accessories like pin extension and aluminum levers can be utilized. This is all about Industrial ball valves.

1 note

·

View note

Text

Let me inform you extra concerning industrial ball valves

Industrial ball valves are essentially a type of tool that has a spherical closure system which provides on/off flow control. The ball might have a port called as birthed in the facility. The round valve could use perforated, hollow, and pivoting sphere. When the circulation is in alignment with round hole and also closed when pivoted at 90 levels by a valve, it is generally open. The valve is not only executing well however additionally are long lasting that supply a reliable closure cycle.

What is the industrial ball valves and exactly how it works?

Exactly how does industrial ball valves work?

When the ball valve got positioned as though the birthed obtained straightened towards the pipe, it is called open. When rotated to 90 levels, the bore will certainly be perpendicular to the course that plainly indicates the Swing check valve supplier obtained shut and the flow can not be seen.

The industrial ball valves with plug valves and butterfly valve becomes part of a valve household. They are bubble-tight securing as well as dependable. Therefore they act as one of the fantastic choices for different applications where Shut On/Off is necessary. The body of the ball obtained made using steel and is durable together with nickel plating. In general, there are four fundamental industrial ball valves namely-.

Trunnion mounted-It has additional anchoring at bottom and also top on the ball. Appropriate for greater stress valve and also larger pressure shutoffs.

Floating stem- it includes turn as well as tilt operation that removes seal rubbing.

Full-port- it is referred to as full-bore that has an inner size equal to pipeline ID. It is made use of in petrochemical, refining, as well as chemical industries.

Minimized port- it is called as reduced-bore in which there is two or one small dimensions.

Functions of industrial ball valves:.

The leading ball valve manufacturer made the product as if it has various attributes that fit in application such as:.

Swing check- the check will certainly give valve feature of inspecting the valve. It thus avoids media from going into the system.

Valve stops- this is a stopper that will certainly allow you to rotate the valve to 90 degrees.

Position signs- a piston indication will be positioned over the top of the sphere valve so that instructions of circulation can be suggested. It can be used in multi-port shutoffs also.

Standard one-on-one dimensions- the measurement of the valve will abide by requirements of ASMS as well as hence makes it easy to retrofit as well as replaced in-line.

Anti-static- this anti-static layout attribute permits the avoidance of fixed electrical energy that obtained develop because of valve massaging.Also visit my weblog:perfect-valve.com It can be presented just like a fire-hazard if any type of system has liquids that are flammable.

Fire-safe- fire-safe function is essential as the steel seat is sealed when the round obtain relaxes over the seal.

The benefit of round valve:.

The ball valve can be set up quickly as well as stop blow out. It is made use of combined with packaging gland so as to provide three-way securing. The two-piece body can be utilized as a dual link for including safety and security and also can be related to metal-to-metal between the bodies. Interchangeable installations, as well as accessories like pin expansion and aluminum bars can be used. This is all about Industrial ball valves.

1 note

·

View note

Text

Attributes as well as benefits of industrial ball valves

Industrial ball valves are generally a sort of gadget that has a round closure system which supplies on/off flow control. The ball could consist of a port called as birthed in the center. The round valve might utilize perforated, hollow, and also pivoting round. When the circulation is in alignment with ball opening and closed when rotated at 90 levels by a valve, it is typically open. The valve is not just executing well yet likewise are sturdy that offer a reliable closure cycle.

Allow me inform you much more concerning industrial ball valves

Exactly how does industrial ball valves work?

When the round valve got placed in such a way that the birthed obtained aligned in the direction of the pipeline, it is referred to as open. When revolved to 90 degrees, the bore will be perpendicular to the course that plainly indicates the Bellow-sealed globe valve got shut and the flow can not be seen.

The industrial ball valves with plug shutoffs and butterfly valve belongs to a valve family. They are bubble-tight sealing and trustworthy. Thus they function as one of the terrific choices for numerous applications where Shut On/Off is needed. The body of the round got made using steel and is sturdy in addition to nickel plating. In general, there are 4 standard industrial ball valves specifically-.

Trunnion mounted-It has added anchoring at bottom and top on the round. Suitable for greater pressure valve as well as bigger pressure valves.

Drifting stem- it incorporates turn and also tilt operation that gets rid of seal massaging.

Full-port- it is called full-bore that has an inner size equivalent to pipe ID. It is made use of in chemical, petrochemical, and refining sectors.

Reduced port- it is called as reduced-bore in which there is 2 or one nominal sizes.

Attributes of industrial ball valves:.

The leading round valve manufacturer made the product as though it has various attributes that suit application such as:.

Swing check- the check will give valve function of checking the valve. It therefore protects against media from going into the system.

Valve quits- this is a stopper that will allow you to revolve the valve to 90 levels.

Setting signs- a piston indicator will certainly be put over the top of the ball valve to ensure that direction of flow can be indicated. It can be made use of in multi-port valves too.

Criterion individually measurements- the dimension of the valve will comply with criteria of ASMS as well as therefore makes it easy to retrofit in addition to changed in-line.

Anti-static- this anti-static style feature allows the prevention of static electricity that got build as a result of valve massaging.Here is my web site:Perfect-Valve If any type of system has fluids that are flammable, it can be postured just like a fire-hazard.

Fire-safe- fire-safe function is essential as the steel seat is secured when the round get relaxes over the seal.

The benefit of sphere valve:.

The sphere valve can be set up conveniently and stop burn out. It is used combined with packaging gland so as to offer triple sealing. The two-piece body can be utilized as a dual connection for adding security and can be put on metal-to-metal between the bodies. Interchangeable installations, in addition to accessories like pin extension as well as light weight aluminum levers can be made use of. This is all about Industrial ball valves.

1 note

·

View note

Text

Functions and also benefits of industrial ball valves

Industrial ball valves are primarily a type of device that has a spherical closure system which offers on/off circulation control. The round could consist of a port called as birthed in the center. The ball valve may utilize perforated, hollow, and rotating round. When the circulation is in placement with sphere hole and also closed when pivoted at 90 degrees by a valve, it is normally open. The valve is not only carrying out well yet additionally are sturdy that provide a trusted closure cycle.

Attributes and also advantages of industrial ball valves

Exactly how does industrial ball valves work?

When the round valve obtained positioned as if the birthed got aligned in the direction of the pipeline, it is referred to as open. When revolved to 90 degrees, the bore will be perpendicular to the path that clearly indicates the Side entry ball valve got closed as well as the circulation can not be seen.

The industrial ball valves with plug shutoffs and butterfly valve belongs to a valve family members. They are bubble-tight securing as well as reliable. Thus they work as among the fantastic selections for various applications where Shut On/Off is required. The body of the round got used steel as well as is durable in addition to nickel plating. As a whole, there are four fundamental industrial ball valves namely-.

Trunnion mounted-It has extra anchoring at top and also lower on the ball. Suitable for higher pressure valve as well as bigger pressure shutoffs.

Drifting stem- it includes turn and tilt operation that gets rid of seal massaging.

Full-port- it is known as full-bore that has an internal diameter equivalent to pipeline ID. It is made use of in refining, petrochemical, and chemical sectors.

Decreased port- it is called as reduced-bore in which there is 2 or one small dimensions.

Attributes of industrial ball valves:.

The top round valve manufacturer made the product as if it has different functions that suit application such as:.

Swing check- the check will provide valve attribute of inspecting the valve. It therefore avoids media from entering into the system.

Valve quits- this is a stopper that will certainly allow you to turn the valve to 90 levels.

Placement signs- a piston sign will certainly be placed over the top of the sphere valve so that instructions of circulation can be suggested. It can be used in multi-port valves also.

Requirement one-on-one measurements- the dimension of the valve will adhere to criteria of ASMS and therefore makes it simple to retrofit in addition to changed in-line.

Anti-static- this anti-static layout feature permits the avoidance of fixed power that got build due to valve rubbing.Here is my page: perfect-valve.com It can be posed just like a fire-hazard if any type of system has liquids that are flammable.

Fire-safe- fire-safe function is very important as the metal seat is sealed when the sphere obtain relaxes over the seal.

The benefit of sphere valve:.

The round valve can be put together quickly and also stop blow out. It is made use of along with packing gland so regarding provide three-way sealing. The two-piece body can be made use of as a dual connection for adding security and also can be applied to metal-to-metal between the bodies. Compatible installations, in addition to devices like pin expansion as well as aluminum bars can be utilized. This is everything about Industrial ball valves.

1 note

·

View note

Text

Nuclear Check Valve Market Value Projected to Expand by 2024

A nuclear check valve is a one-way valve that allows a fluid to flow in a single direction with minimum resistance. The fluid could contain either liquid or gas. A nuclear check valve consists of a body, bonnet, and disc. The body comprises two ports: one for the fluid to enter and the other for it to exit. Nuclear check valves are used in various nuclear power plant applications such as cooling water circuits, preheaters, vaporizers, and turbines. They are employed in the nuclear industry to control feed water systems, as well as in dump lines, miscellaneous process systems, and monitoring and sampling systems. Nuclear check valves also help avoid reverse flow with minimal leakage. They prevent excessive heat transfer between two fluids and play a pivotal role in providing safety against explosion and meltdowns in the nuclear power industry. Installing them not only aids the protection of sensitive components such as pumps, but also inhibits the inadvertent draining of tanks.

Request For Toc@ https://www.transparencymarketresearch.com/sample/sample.php?flag=T&rep_id=17399

Straight-way swing and angle are the two primary types of check valves used in nuclear power plants. The former is likely to dominate the nuclear check valve market during the forecast period primarily due to its simple design, low pressure drop, low cost, reliable sealing, and availability in a wide range of sizes. Swing check valves offer better leak tightness compared to angle check valves. Furthermore, they have advantages such as a good closing and throttling feature. These valves are employed widely in high-pressure service applications.

Check valve failures can result in increased costs, significant operating transients, and reduced system availability. The nuclear check valves market is primarily driven by stringent regulations on the spillage of dangerous chemicals and the maintenance of safety features of the plant and equipment. The growing capacities of nuclear power and the upgrading and renovation of existing plants are other features propelling this market. An increasing need to isolate pumps & equipment and to control feed flow is also projected to boost the requirement for nuclear check valves. The escalating incidence of non-safety systems such as check valves facing failure has been a concern for the nuclear power industry. Therefore, introducing improvements in the operational efficiency of nuclear check valves provides new opportunities for manufacturers to develop smarter valves that can be controlled by solenoid, digital, hydraulic, electric, or pneumatic energy.

The global market for nuclear check valves is distributed over North America, Latin America, Europe, Asia Pacific, and Middle East & Africa. Asia Pacific, Europe, and North America are predicted to be the dominant regions during the forecast period, principally due to the rapid industrialization in the developing economies of India and China. The overall rise in demand for energy as well as in foreign investments in developing countries is also motivating the nuclear valve market. The U.S. and Russia offer significant potential due to technological innovations in the field of check valves taking place in these regions. Thus, a surge in upgrading activities due to substantial investments in nuclear power plants is anticipated to add to the demand for nuclear check valves.

Key players operating in this market include Crane Nuclear, Inc, Velan Inc, BNL Industries.Inc, Daher, ValvTechnologies, Valcor Engineering Corporation, MSA, a.s., and Pentair Ltd.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

The study is a source of reliable data on:

Market segments and sub-segments

Market trends and dynamics

Supply and demand

Market size

Current trends/opportunities/challenges

Competitive landscape

Technological breakthroughs

Value chain and stakeholder analysis

The regional analysis covers:

North America (U.S. and Canada)

Latin America (Mexico, Brazil, Peru, Chile, and others)

Western Europe (Germany, U.K., France, Spain, Italy, Nordic countries, Belgium, Netherlands, and Luxembourg)

Eastern Europe (Poland and Russia)

Asia Pacific (China, India, Japan, ASEAN, Australia, and New Zealand)

Middle East and Africa (GCC, Southern Africa, and North Africa)

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Request For Broucher@ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=17399

Highlights of the report:

A complete backdrop analysis, which includes an assessment of the parent market

Important changes in market dynamics

Market segmentation up to the second or third level

Historical, current, and projected size of the market from the standpoint of both value and volume

Reporting and evaluation of recent industry developments

Market shares and strategies of key players

Emerging niche segments and regional markets

An objective assessment of the trajectory of the market

Recommendations to companies for strengthening their foothold in the market

1 note

·

View note

Text

Globe Valve Manufacturer in USA

SVR Global is a trust-worthy Globe Valve Manufacturer in USA that provides a vast selection of globe valves that are specifically built to meet industrial standards. Our designs are specifically made to provide the highest standards in the entire production process, a high degree of dependability, sustainability and durability.

Definition of a Globe Valve:

A globe valve gets its name from the shape of its body. An internal baffle divides the body of a globe valve's two parts. It consists of a stem that swings up and down to control fluid flow and a disc (ball or composition or plug) attached to it. The flow line is either parallel to or inclined in the direction of the seats. By sliding the disc against the flow stream, it ceases the flow of fluid.

Since a globe valve is bi-directional, fluid can flow through it in either direction. It can be utilized automatically or manually.

The most frequent application of a globe valve is to open, close, or throttle flow in systems.

Applications of a Globe Valve:

SVR Global is a trust-worthy Globe Valve Manufacturer in USA that has applications such as-

Applications for steam.

Extraction drains and condensing air extraction systems.

Feedwater, condenser air, chemical feed.

Fuel oil system.

Piping in small sizes.

Plumbing sector.

Provide flow control.

Provide leak tightness.

Pumps and compressors.

Used as an emergency shutdown valve.

Used in low-point drains and high-point vents.

Used in systems that require frequent stroking, vacuum or a wide variety of temperature extremes.

Used in systems where pressure drop is not an issue.

Water-cooling systems.

Advantages of a Globe Valve:

Bubble tight shut-off.

Can be utilized as a stop-check valve by altering the design.

Controlled precision.

Easy to maintain.

Excellent sealing ability.

Fast-acting.

Fast operation due to shorter stroke length.

No fear of wear of seat and disc; hence good for frequent operation.

Great and precise throttling ability.

Has excellent closure ability.

Repair work is easy to repair as the seat and disc can be accessed from the valve top.

Seats are easy to machine and resurface

Suitable for high-pressure systems.

Used for corrosive or highly viscous fluids.

Disadvantages of a Globe Valve:

Can be installed only in one direction.

Complex design.

Create noise during operation.

Expensive.

Heavier.

High head loss from two or more right-angle turns of flowing fluid. through the valve body.

High pressure drops due to numerous directional shifts.

High torque.

Huge power is required to open.

Internal trim parts can be damaged by pulsations and shocks.

Large disc assembly opening.

Longer operating time.

Low-flow coefficients.

Not recommended to use in pipes with big diameter.

Not suitable for sterile or clean applications.

Susceptible to Cavitation and flow-induced vibrations.

The disc is mounted on the stem in a cantilevered position.

More power is required to seat the valve.

Throttling flow under the seat and shutoff flow over the seat.

Industries where Globe Valves are operated:

Marine

Oil and Gas

Power generation

Pulp and Paper

Refinery

Types of a Globe Valve:

API Globe Valve

The two sides of a globe valve are unscrewed to open and close the valve. It is most commonly used in systems to open, close, or throttle flow. A globe valve has a stem that swings up and down to control flow, as well as a disc (ball, composition, or plug) and a seat that are both linked to the valve body. The flow line is either parallel to or inclined towards the seats. A globe valve is bi-directional, meaning the fluid can flow in either direction within the valve. It allows you to control the flow and pressure as well as full cut off the flow. It can be used both manually as well as automatically.

Bellow Seal Globe Valve

A Bellow Seal Globe Valve is a control valve with a compact structure that uses bellow to seal the valve stem components. The bellow valve has a bellow within, and the stainless-steel bellows' lower end is welded to the stem to keep the system fluid from eroding it. To produce a permanent seal, the other end is positioned between the body of the valve and the cover of the valve. This double seal construction prevents leakage, as the stem packaging will prevent additional leakage even if the bellows collapse. The bellows are welded to the valve stem to guarantee consistent working efficiency and to avoid valve stem vibration caused by valve insert movement.

Forged Steel Globe Valve

Forged steel is a material created by fusing iron and carbon under extreme pressure. Forged steel has lower surface porosity, a finer grain structure, stronger tensile and fatigue strength, and more ductility than other treated steels. Steel becomes ductile and malleable when heated to forging temperature, allowing it to be shaped into the required shape with force and pressure.

Forged valves are created using a process known as forging, which involves shaping metals & alloys while they are still solid. Forged valves are known for their strength, making them excellent for high-pressure and high-temperature applications.

According to body type-

Angle type

Y type or Wye Type

Z type or Tee Type

According to body bonnet type-

Bolted Bonnet

Pressure Sealed Bonnet

Screwed Bonnet

Welded Bonnet

Description of a Globe Valve:

SVR Global is a trust-worthy Globe Valve Manufacturer in USA providing an extensive range of valves, in numerous sizes, styles and designs.

Body Material: Cast Iron, Cast steel [LCB, LCC, WCB, WCC, WC6, WC9], Ductile Iron, Stainless Steel [CF8, CF8M, F3, F304, F316, F31L, F51, F55, F91, SS304, SS316, SS316L, SS904L]

Class: 150 to 2500; PN 10 to PN 450

Ends: Buttweld, Flanged, Socketweld, Threaded

Operations: Gear-operated globe valve, Hand-wheel operated globe valve, Pneumatic actuated globe valve, Electric actuated globe valve

Size: DN 10 to DN 1200

Know more about various globe valves provided by SVR Global - https://svrglobal.net/products/globe-valve/

0 notes

Photo

We are leading lined swing check valve manufacturers in India. We ensure that these lined swing check valves are made using quality assured raw materials. The ablaze lining also exporting the lined valves.

0 notes

Text

Wafer Dual Plate Check Valve

Here at CWT Valve we manufacture our own line of Check Valves in a variety of designs such as swing check, lift check, ball check, dual plate check, and single plate check. If you want to buy a Wafer Dual Plate Check Valve in bulk, you can easily order it at our store. Our designs ensure our valves are easy to maintain, economical, and fully functional in horizontal and upward flow applications. CWT Check Valves are automatic and do not require any external control. Other designs include cryogenic, silent check, and ball check valves.

0 notes

Text

syicasting.com

Ductile iron pip is pipe made of ductile cast iron commonly used for potable water transmission and distribution. This type of pipe is a direct development of earlier cast iron pipe, which it has superseded. The ductile iron used to manufacture the pipe is characterized by the spheroidal or nodular nature of the graphite within the iron. Typically, the pipe is manufactured using centrifugal casting in metal or resin lined moulds. Protective internal linings and external coatings are often applied to ductile iron pipes to inhibit corrosion: the standard internal lining is cement mortar and standard external coatings include bonded zinc asphalt or water-based paint. In highly corrosive environments loose polyethylene sleeving (LPS) to encase the pipe may also be used. Life expectancy of unprotected ductile iron pipes depends on the corrosiveness of soil present and tends to be shorter where soil is highly corrosive. However, a lifespan in excess of 100 years has been estimated for ductile iron pipelines installed using "evolved laying practices", including use of properly installed LPS (polyethylene encasement). Studies of ductile iron pipe's environmental impact have differing findings regarding emissions and energy consumed. Ductile iron pipe manufactured in the United States has been certified as a sustainable product by the Institute for Market Transformation to Sustainability.