#TechShot

Explore tagged Tumblr posts

Photo

DREAM & POWER WHEELS ▫️ Look High resolution short on May Behance profilo mariobarbieri #auto #dreamcar #wheels #automotive #motorvalleyfest #motor #ferrari #lamborghini #maserati #abarth #pagani #techshot #ruote #cerchinlega #hotwheels (presso Modena, Italy) https://www.instagram.com/p/CRB4BPdtgoo/?utm_medium=tumblr

#auto#dreamcar#wheels#automotive#motorvalleyfest#motor#ferrari#lamborghini#maserati#abarth#pagani#techshot#ruote#cerchinlega#hotwheels

0 notes

Text

NTT DATA Business Solutions और Moneycontrol की पेशकश - 'The Future TechShot': विकास के पथ पर डिजिटल बदलाव का सफर

NTT DATA Business Solutions और Moneycontrol की पेशकश – ‘The Future TechShot’: विकास के पथ पर डिजिटल बदलाव का सफर

आजकल, ‘डिजिटल’ शब्द हर बिज़नेस में चर्चा का विषय बन गया है. चाहे वह डिजिटल टेक्नोलॉली हो, डिजिटल डेटा हो, डिजिटल मीडिया हो, डिजिटल ट्रांसफॉर्मेशन हो या फिर डिजिटल मार्केटिंग हो, हर सेक्टर में कंपनियां तेजी से अपने डिजिटल प्लेटफ़ॉर्म को विकसित करने पर ध्यान दे रही हैं. COVID-19 महामारी ने डिजिटल साधनों को अपनाने की गति को बढ़ा दिया है, जिससे कंपनियां नए ग्राहक बनाने से लेकर ग्राहक सेवा देने तक के…

View On WordPress

0 notes

Text

Tomorrow’s Technology on the Space Station Today

Tablets, smart appliances, and other technologies that are an indispensable part of daily life are no longer state-of-the-art compared to the research and technology development going on over our heads. As we celebrate 20 years of humans continuously living and working in space aboard the International Space Station, we’re recapping some of the out-of-this-world tech development and research being done on the orbiting lab too.

Our Space Technology Mission Directorate (STMD) helps redefine state-of-the-art tech for living and working in space. Here are 10 technologies tried and tested on the space station with helping hands from its astronaut occupants over the years.

1. Astronaut Wanna-Bees

Astronauts on the space station are responsible for everything from conducting science experiments and deploying satellites to tracking inventory and cleaning. While all are necessary, the crew can delegate some jobs to the newest robotic inhabitants – Astrobees.

youtube

These cube-shaped robots can work independently or in tandem, carrying out research activities. Once they prove themselves, the bots will take on some of the more time-consuming tasks, such as monitoring the status of dozens of experiments. The three robots – named Bumble, Honey, and Queen – can operate autonomously following a programmed set of instructions or controlled remotely. Each uses cameras for navigation, fans for propulsion, and a rechargeable battery for power. The robots also have a perching arm that lets them grip handrails or hold items. These free-flying helpers take advantage of another STMD technology called Gecko Grippers that “stick” to any surface.

2. Getting a Grip in Microgravity

We wanted to develop tools for grabbing space junk, and something strong and super-sticky is necessary to collect the diverse material orbiting Earth. So, engineers studied the gecko lizard, perhaps the most efficient “grabber” on this planet. Millions of extremely fine hairs on the bottom of their feet make an incredible amount of contact with surfaces so the gecko can hold onto anything. That inspired our engineers to create a similar material.

Now the Gecko Gripper made by OnRobot is sold on the commercial market, supporting industrial activities such as materials handling and assembly. The NASA gecko adhesive gripper that’s being tested in microgravity on the Astrobee robots was fabricated on Earth. But other small plastic parts can now be manufactured in space.

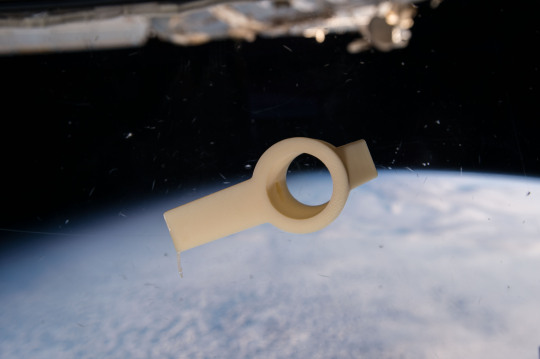

3. Make It, or Don’t Take It

Frequent resupply trips from Earth to the Moon, Mars, and other solar system bodies are simply not realistic. In order to become truly Earth-independent and increase sustainability, we had to come up with ways to manufacture supplies on demand.

A demonstration of the first 3D printer in space was tested on the space station in 2014, proving it worked in microgravity. This paved the way for the first commercial 3D printer in space, which is operated by Made In Space. It has successfully produced more than 150 parts since its activation in 2016. Designs for tools, parts, and many other objects are transmitted to the station by the company, which also oversees the print jobs. Different kinds of plastic filaments use heat and pressure in a process that’s similar to the way a hot glue gun works. The molten material is precisely deposited using a back-and-forth motion until the part forms. The next logical step for efficient 3D printing was using recycled plastics to create needed objects.

4. The Nine Lives of Plastic

To help fragile technology survive launch and keep food safe for consumption, NASA employs a lot of single-use plastics. That material is a valuable resource, so we are developing a number of ways to repurpose it. The Refabricator, delivered to the station in 2018, is designed to reuse everything from plastic bags to packing foam. The waste plastic is super-heated and transformed into the feedstock for its built-in 3D printer. The filament can be used repeatedly: a 3D-printed wrench that’s no longer needed can be dropped into the machine and used to make any one of the pre-programmed objects, such as a spoon. The dorm-fridge-sized machine created by Tethers Unlimited Inc. successfully manufactured its first object, but the technology experienced some issues in the bonding process likely due to microgravity’s effect on the materials. Thus, the Refabricator continues to undergo additional testing to perfect its performance.

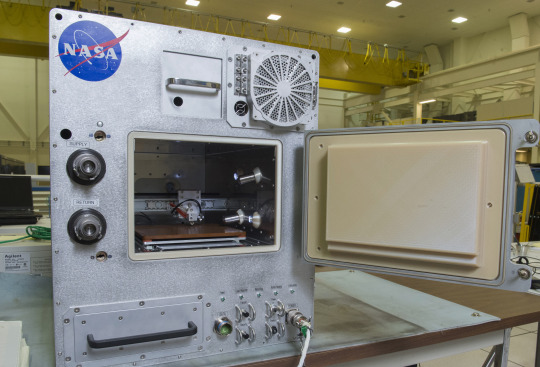

5. Speed Metal

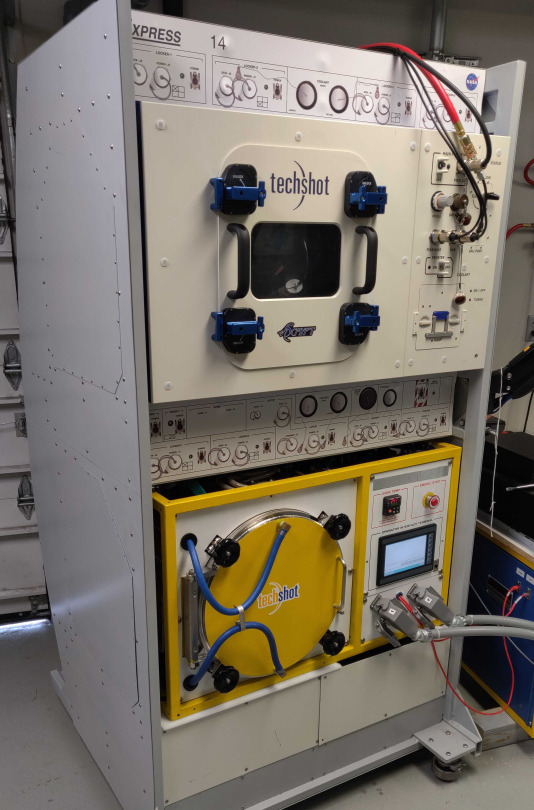

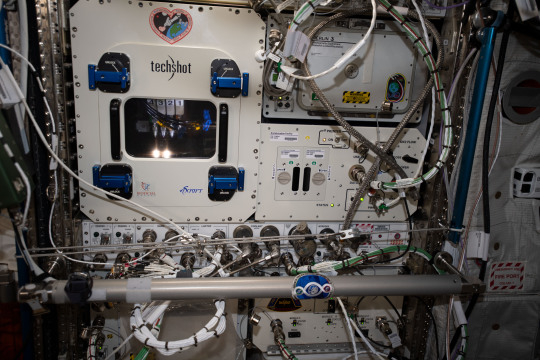

An upcoming hardware test on the station will try out a new kind of 3D printer. The on-demand digital manufacturing technology is capable of using different kinds of materials, including plastic and metals, to create new parts. We commissioned TechShot Inc. to build the hardware to fabricate objects made from aerospace-grade metals and electronics. On Earth, FabLab has already demonstrated its ability to manufacture strong, complex metal tools and other items. The unit includes a metal additive manufacturing process, furnace, and endmill for post-processing. It also has built-in monitoring for in-process inspection. When the FabLab is installed on the space station, it will be remotely operated by controllers on Earth. Right now, another printer created by the same company is doing a different kind of 3D printing on station.

6. A Doctor’s BFF

Today scientists are also learning to 3D print living tissues. However, the force of gravity on this planet makes it hard to print cells that maintain their shape. So on Earth, scientists use scaffolding to help keep the printed structures from collapsing.

The 3D BioFabrication Facility (BFF) created by TechShot Inc. could provide researchers a gamechanger that sidesteps the need to use scaffolds by bioprinting in microgravity. This first American bioprinter in space uses bio-inks that contain adult human cells along with a cell-culturing system to strengthen the tissue over time. Eventually, that means that these manufactured tissues will keep their shape once returned to Earth’s gravity! While the road to bioprinting human organs is likely still many years away, these efforts on the space station may move us closer to that much-needed capability for the more than 100,000 people on the wait list for organ transplant.

7. Growing Vitamins

Conditions in space are hard on the human body, and they also can be punishing on food. Regular deliveries of food to the space station refresh the supply of nutritious meals for astronauts. But prepackaged food stored on the Moon or sent to Mars in advance of astronauts could lose some nutritional value over time.

That’s why the BioNutrients experiment is underway. Two different strains of baker’s yeast which are engineered to produce essential nutrients on demand are being checked for shelf life in orbit. Samples of the yeast are being stored at room temperature aboard the space station and then are activated at different intervals, frozen, and returned to Earth for evaluation. These tests will allow scientists to check how long their specially-engineered microbes can be stored on the shelf, while still supplying fresh nutrients that humans need to stay healthy in space. Such microbes must be able to be stored for months, even years, to support the longer durations of exploration missions. If successful, these space-adapted organisms could also be engineered for the potential production of medicines. Similar organisms used in this system could provide fresh foods like yogurt or kefir on demand. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet.

8. Rough and Ready

Everything from paints and container seals to switches and thermal protection systems must withstand the punishing environment of space. Atomic oxygen, charged-particle radiation, collisions with meteoroids and space debris, and temperature extremes (all combined with the vacuum) are just some conditions that are only found in space. Not all of these can be replicated on Earth. In 2001, we addressed this testing problem with the Materials International Space Station Experiment (MISSE). Technologists can send small samples of just about any technology or material into low-Earth orbit for six months or more. Mounted to the exterior of the space station, MISSE has tested more than 4,000 materials. More sophisticated hardware developed over time now supports automatic monitoring that sends photos and data back to researchers on Earth. Renamed the MISSE Flight Facility, this permanent external platform is now owned and operated by the small business, Alpha Space Test & Research Alliance LLC. The woman-owned company is developing two similar platforms for testing materials and technologies on the lunar surface.

9. Parachuting to Earth

Small satellites could provide a cheaper, faster way to deliver small payloads to Earth from the space station. To do just that, the Technology Education Satellite, or TechEdSat, develops the essential technologies with a series of CubeSats built by college students in partnership with NASA. In 2017, TechEdSat-6 deployed from the station, equipped with a custom-built parachute called exo-brake to see if a controlled de-orbit was possible. After popping out of the back of the CubeSat, struts and flexible cords warped the parachute like a wing to control the direction in which it travelled. The exo-brake uses atmospheric drag to steer a small satellite toward a designated landing site. The most recent mission in the series, TechEdSat-10, was deployed from the station in July with an improved version of an exo-brake. The CubeSat is actively being navigated to the target entry point in the vicinity of the NASA’s Wallops Flight Facility on Wallops Island, Virginia.

10. X-ray Vision for a Galactic Position System

Independent navigation for spacecraft in deep space is challenging because objects move rapidly and the distances between are measured in millions of miles, not the mere thousands of miles we’re used to on Earth. From a mission perched on the outside of the station, we were able to prove that X-rays from pulsars could be helpful. A number of spinning neutron stars consistently emit pulsating beams of X-rays, like the rotating beacon of a lighthouse. Because the rapid pulsations of light are extremely regular, they can provide the precise timing required to measure distances.

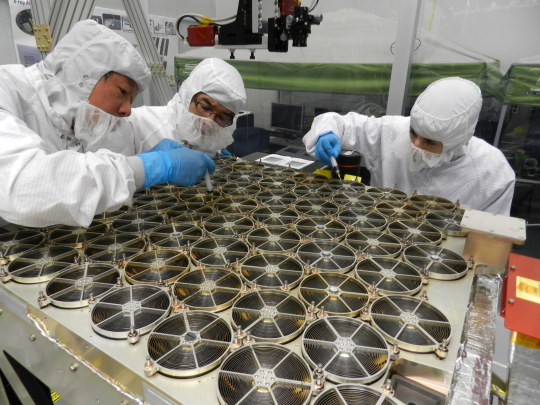

The Station Explorer for X-Ray Timing and Navigation (SEXTANT) demonstration conducted on the space station in 2017 successfully measured pulsar data and used navigation algorithms to locate the station as it moved in its orbit. The washing machine-sized hardware, which also produced new neutron star science via the Neutron star Interior Composition Explorer (NICER), can now be miniaturized to develop detectors and other hardware to make pulsar-based navigation available for use on future spacecraft.

As NASA continues to identify challenges and problems for upcoming deep space missions such as Artemis, human on Mars, and exploring distant moons such as Titan, STMD will continue to further technology development on the space station and Earth.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

1K notes

·

View notes

Photo

Tupperware shoots for the stars with a device meant to grow vegetables in space

Tupperware Brands is looking beyond the kitchen by going to space.

The Osceola County, Fla.-based company known for its plastic containers has been awarded a patent for a device intended to grow vegetables in low Earth orbit.

A partnership with NASA and research and manufacturing company Techshot, the device is called the Passive Orbital Nutrient Delivery System, or PONDS.

NASA needs its astronauts to grow food as the length of space missions increase to reach the moon and Mars. The project could also help Tupperware make money on Earth.

5 notes

·

View notes

Text

The Shape of Watering Plants in Space

ISS - International Space Station logo. March 4, 2020 The challenge: getting water to behave the way it does on Earth while in a microgravity environment. A collaboration between NASA, Techshot, Inc., and the Tupperware Brands Corporation is working to get the solution just right.

Image above: Canadian Space Agency astronaut David Saint-Jacques is photographed performing a reservoir fill on the Veggie Ponds facility in the Columbus module of the International Space Station in 2019. The primary goal of the hardware validation test was to demonstrate plant growth in a newly developed plant growing system, Passive Orbital Nutrient Delivery System (PONDS). Image Credit: NASA. For nearly 20 years, people have lived and worked continuously aboard the International Space Station, performing science to enable deep space exploration for NASA’s Artemis lunar exploration program and future human missions to Mars and to benefit people on Earth. The space station is about the size of a six-bedroom house, and it is a busy laboratory studying everything from fundamental science to practical applications, such as growing food in space. In the current method of growing plants in space in the station’s Veggie growth chamber, astronauts water plants with a syringe, pushing it into containers called plant pillows, which hold a limited amount of water. This works well for leafy greens like lettuce, but for larger plants that require more water, NASA needed an alternate system.

Image above: An assembled version of the PONDS-03 unit is photographed inside the Space Life Sciences Laboratory at NASA’s Kennedy Space Center in Florida. Twelve PONDS units are launching to the International Space Station on SpaceX’s 20th Commercial Resupply Services mission for their third technology demonstration in an effort to study the growth of lettuce in an entirely passive growth system. Photo credit: Techshot, Inc. Image Credit: Techshot, Inc. A collaboration between NASA, Techshot, Inc., and the Tupperware Brands Corporation introduced a plant growth unit called PONDS, short for Passive Orbital Nutrient Delivery System. The PONDS units are an entirely passive system – meaning no electricity, no pumps and no moving parts – and the basic concept involves using a free-standing reservoir of water that plants can draw from when needed, cutting down on time astronauts would spend watering plants during the growth interval. The reservoir holds 400 ml – or about 13.5 ounces – of water, allowing astronauts to go a week or more before needing to water smaller plants again, or every couple of days for full-size plants. “PONDS has kind of become the story of Goldilocks,” said Dave Reed, Florida operations director for Techshot. “The first time we tested in microgravity, too much water was delivered to the seeds. The second time, too little water. And the third time we hope is going to be just right. We’re in the fine-tuning phase now, and we’re excited to see this all come to fruition.” Initially sent to the space station in 2018 and then again in 2019 after undergoing some design and operational modifications, PONDS is returning to the orbiting laboratory for further testing. Twelve PONDS units are being sent to the station for their third technology demonstration, titled VEG-PONDS-03, on SpaceX’s 20th Commercial Resupply Services mission. In addition to carrying this experiment, the cargo Dragon will deliver additional science investigations, including research of particle foam manufacturing, water droplet formation and the human intestine.

Image above: Jeff Richards, an employee with the Laboratory Support Services and Operations (LASSO) contract at NASA’s Kennedy Space Center in Florida, assembles PONDS hardware components inside the Space Life Sciences Laboratory. Twelve PONDS units are launching to the International Space Station on SpaceX’s 20th Commercial Resupply Services mission for their third technology demonstration in an effort to study the growth of lettuce in an entirely passive growth system. Image Credit: Techshot, Inc. “You have to have this give and take, and a bit of trial and error; and I think part of that was seen in the first two PONDS experiments, with some things working and others not working,” said Howard Levine, creator of the initial PONDS concept and chief scientist of NASA’s Utilization and Life Sciences Office at the agency’s Kennedy Space Center in Florida. When astronauts travel to the space station, all their food, clothes, and anything else they may need is delivered to them through regular cargo resupply missions. Once the design of PONDS is perfected, astronauts will be able to use this method to grow fresh vegetables and perhaps even fruits in space, something that crew members will rely on to supplement their diet as they venture deeper into space. “The longer the duration of the mission, [resupply] becomes less and less viable, and you want to be able to actually grow your food,” said Levine. All 12 of the PONDS units being delivered will contain red romaine lettuce seeds and grow for 28 days inside the space station’s two Veggie growth chambers, and at harvest, crew members will have the opportunity to eat the lettuce they grew. At the end of the experiment, half of the PONDS units will be returned to Kennedy for engineers to evaluate. Six of the units have undergone design changes under the leadership of Levine, while the other six were given to Techshot and Tupperware to evolve. “We’re used to designing and perfecting products to help prevent food from going to waste. When we were approached for this experiment a few years ago, we knew it was a great opportunity to take our long history of food conservation and apply it to the conditions in space,” said David Kusuma, Tupperware’s vice president of research and design. “Adapting and engineering design to fit the unique conditions in orbit has been an exciting and educational journey for us. Helping NASA and Techshot open doors for astronauts of the future to germinate, grow and harvest fresh fruits and vegetables in space is something we’re quite proud of.”

Image above: All 12 PONDS units are photographed inside the Space Life Sciences Laboratory at NASA’s Kennedy Space Center in Florida following assembly. The PONDS units are launching to the International Space Station on SpaceX’s 20th Commercial Resupply Services mission for their third technology demonstration in an effort to study the growth of lettuce in an entirely passive growth system. Image Credit: Techshot, Inc. Some modifications to Techshot and Tupperware’s units include using narrower, skinnier wicks made of a different material to hold the plant seeds in place; adding a structure to the top of the units to keep sponges treated to repel water flat against the top surface to provide oxygen to the plants’ roots; and taking a piece of that same sponge and running it down the length of the flower pot-like root zone, providing a column of air going all the way to the bottom to ensure the plant roots are getting enough air. Levine’s units have larger and wider wicks for the plant seeds, and they will contain blocks of oasis foam – a material that has been used many times before in space to grow plants – near the wicks at the top to draw excess water away from the sprouting seeds. By exploring these design changes, NASA, Techshot and Tupperware hope to find the perfect balance for controlling how water behaves in space. “Even people who are fluids experts – and we’ve worked with some of the best that NASA knows – tell us they’re constantly surprised by what fluids do in low gravity,” said Reed. “So, a lot of thought has gone into this design. Things that would seem arbitrary when you look at them are absolutely not. We have engineered the heck out of this system to get it to where it is today.” The Space Life and Physical Sciences Research and Applications Division (SLPSRA) of NASA’s Human Exploration and Operations Mission Directorate at NASA Headquarters in Washington is sponsoring the Veg-PONDS-03 investigation as part of its mission to conduct research that enables human spaceflight exploration. Related links: PONDS: https://images.nasa.gov/details-KSC-20200304-PH-NAS01_0001 Growing plants in space: https://www.nasa.gov/content/growing-plants-in-space SLPSRA: https://www.nasa.gov/directorates/heo/slpsra Humans in Space: https://www.nasa.gov/topics/humans-in-space International Space Station (ISS): https://www.nasa.gov/mission_pages/station/main/index.html Images (mentioned), Text, Credits: NASA/KSC/Danielle Sempsrott. Greetings, Orbiter.ch Full article

21 notes

·

View notes

Photo

nScrypt has 3D bioprinted a human knee meniscus in space Microdispensing specialist nScrypt and aerospace company TechShot have successfully completed the first functional 3D bioprinting experiment in space. Using the BioFabrication Facility (BFF) on board the ISS, with the help of the non-profit Geneva Foundation and the Uniformed Services University of the Health Sciences (USU), they 3D bioprinted a human knee meniscus as part of […] https://buff.ly/2T4AOee

1 note

·

View note

Text

Tupperware Develops With NASA a Product For Growing Vegetables in Space

Do you know those plastic jars you use at home to store food? Well, now Tupperware Brands has developed, in partnership with NASA and TechShot, a space engineering company, a product exclusively dedicated to growing vegetables in space. The product is called POND, an acronym for Passive Orbital Nutrient Delivery System and was developed with technology created on the International Space Station (ISS). The astronauts, in 2014, developed the "Veggie", a system for planting consumable leaves and vegetables in space. From there, Tupperware began collaborating to create a product that used fewer resources for production, even in a hostile environment such as the space station. Read the full article

0 notes

Text

Orbital tool Raptor

orbital tool– latitude longitude altitude Modes of operation: pitch, roll,———– trajectory, velocity Rodent Research-19 utilizes existing Rodent Research (RR) hardware, including four Transporters (two for flight, two for ground), , the Techshot Bone Densitometer, and various kits including those used for rodent food bar change, water refill, anesthetization, and treatment injections. A Rágcsáló…

View On WordPress

0 notes

Text

Space…. Not just for rocket scientists! This is an exciting announcement that highlights how multi-disciplinary the Space industry is with regards to the sciences. Scientific exploration in biology is an important aspect of space-based research that can impact us here on earth. #spaceeconomy #spaceindustry #space

0 notes

Text

NASA is approaching the printing of artificial organs in space

NASA is approaching the printing of artificial organs in space

https://theministerofcapitalism.com/blog/nasa-is-approaching-the-printing-of-artificial-organs-in-space/

In America, at least 17 people a day die waiting for an organ transplant. But instead of waiting for a donor to die, what if one day we could grow our own organs?

Last week, six years later NASA announced its vascular tissue challenge, a competition designed to accelerate research that could one day lead to artificial organs, the agency named two winning teams. The challenge required the teams to create thick, vascularized human organ tissue that could survive for 30 days.

The two teams, named Winston and WFIRM, both of the Wake Forest Institute of Regenerative Medicine, used different 3D printing techniques to create laboratory-grown liver tissue that met all of NASA’s requirements and maintained its function.

“We took two different approaches because when you look at tissues and vascularity, you look at the body doing two main things,” he says. Anthony Atala, WFIRM team leader and director of the institute.

The two approaches differ in how vascularization is achieved, how blood vessels form inside the body. One used tubular structures and the other spongy tissue structures to help provide cellular nutrients and remove waste. According to Atala, the challenge represented a hallmark for bioengineering because the liver, the body’s largest internal organ, is one of the most complex tissues to replicate due to the high number of functions it performs.

Liver tissue created by the Winston team for the NASA Vascular Tissue Challenge.

WAKE FOREST INSTITUTE FOR REGENERATIVE MEDICINE

“When the competition came out six years ago, we knew we had tried to solve this problem on our own,” Atala says.

In addition to advancing in the field of regenerative medicine and facilitating the creation of artificial organs for humans in need of transplants, someday the project could help astronauts on future missions into deep space.

The concept of tissue engineering has been around for more than 20 years, he says Laura Niklason, a professor of anesthesia and biomedical engineering at Yale, but the growing interest in space-based experimentation is beginning to transform the field. “Especially as the world is looking at private and commercial travel in space, the biological impacts of low gravity will be increasingly important, and this is a great tool to help understand this.”

But winning teams have to overcome one of the most important hurdles in tissue engineering: “Making things survive and maintain their function for an extended period of time is really a challenge,” he says. Andrea O’Connor, head of biomedical engineering at the University of Melbourne, who considers this project and others like him ambitious.

Equipped with a $ 300,000 cash prize, the first team, Winston, will soon have the opportunity to send his research to the International Space Station, where research has already been conducted. similar organs.

In 2019, astronaut Christina Koch activated the BioFabrication Facility (BFF), which was created by the aerospace research company based in Greenville, Indiana. Techshot to print organic fabrics in microgravity.

Source link

0 notes

Text

Small Businesses with Big Plans for the Moon and Mars

Today is Small Business Saturday, which the U.S. Small Business Administration (SBA) recognizes as a day to celebrate and support small businesses and all they do for their communities.

Source: Techshot

We are proud to partner with small businesses across the country through NASA’s Small Business Innovative Research (SBIR) and Small Business Technology Transfer (STTR) programs, which have funded the research, development and demonstration of innovative space technologies since 1982. This year, we’ve awarded 571 SBIR/STTR contracts totaling nearly $180 million to companies who will support our future exploration:

Techshot, Inc. was selected to bioprint micro-organs in a zero-gravity environment for research and testing of organs-on-chip devices, which simulate the physiological functions of body organs at a miniature scale for health research without the need for expensive tests or live subjects.

CertainTech, Inc., with the George Washington University, will demonstrate an improved water recovery system for restoring nontoxic water from wastewater using nanotechnology.

Electrochem, Inc. was contracted to create a compact and lightweight regenerative fuel cell system that can store energy from an electrolyzer during the lunar day to be used for operations during the lunar night.

Source: Electrochem

Small businesses are also developing technologies for the Artemis missions to the Moon and for human and robotic exploration of Mars. As we prepare to land the first woman and next man on the Moon by 2024, these are just a few of the small businesses working with us to make it happen.

Commercial Lunar Payload Delivery Services

Masten Space Systems, Astrobotic and Tyvak Nano-Satellite Systems are three NASA SBIR/STTR alumni now eligible to bid on NASA delivery services to the lunar surface through Commercial Lunar Payload Services (CLPS) contracts. Other small businesses selected as CLPS providers include Ceres Robotics, Deep Space Systems, Intuitive Machines, Moon Express, and Orbit Beyond. Under the Artemis program, these companies could land robotic missions on the Moon to perform science experiments, test technologies and demonstrate capabilities to help the human exploration that will follow. The first delivery could be as early as July 2021.

A Pathfinder CubeSat

One cornerstone of our return to the Moon is a small spaceship called Gateway that will orbit our nearest neighbor to provide more access to the lunar surface. SBIR/STTR alum Advanced Space Systems will develop a CubeSat that will test out the lunar orbit planned for Gateway, demonstrating how to enter into and operate in the unique orbit. The Cislunar Autonomous Positioning System Technology Operations and Navigation Experiment (CAPSTONE) could launch as early as December 2020.

Tipping Point for Moon to Mars

We selected 14 companies as part of our Tipping Point solicitation, which fosters the development of critical, industry-led space capabilities for our future missions. These small businesses all proposed unique technologies that could benefit the Artemis program.

Many of these small businesses are also NASA SBIR/STTR alumni whose Tipping Point awards are related to their SBIR or STTR awards. For example, Infinity Fuel Cell and Hydrogen, Inc. (Infinity Fuel) will develop a power and energy product that could be used for lunar rovers, surface equipment, and habitats. This technology stems from a new type of fuel cell that Infinity Fuel developed with the help of NASA SBIR/STTR awards.

CU Aerospace and Astrobotic are also small businesses whose Tipping Point award can be traced back to technology developed through the NASA SBIR/STTR program. CU Aerospace will build a CubeSat with two different propulsion systems, which will offer high performance at a low cost, and Astrobotic will develop small rover “scouts” that can host payloads and interface with landers on the lunar surface.

Small Businesses, Big Impact

This is just a handful of the small businesses supporting our journey back to the Moon and on to Mars, and just a taste of how they impact the economy and American innovation. We are grateful for the contributions that small businesses make—though they be but “small,” they are fierce.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

794 notes

·

View notes

Text

Techshot, Inc. - Innovate. Explore. Discover.

Techshot, Inc. – Innovate. Explore. Discover.

Techshot has developed new technologies for the aerospace, defense and medical industries that have flown aboard the International Space Station. — Read on techshot.com/

View On WordPress

0 notes

Text

3D Printing, Biology Research Make the Journey Back to Earth aboard SpaceX’s Dragon

ISS - International Space Station logo. April 3, 2020 On March 9, 2020, a Dragon cargo spacecraft arrived at the International Space Station carrying dozens of scientific experiments as a part of SpaceX’s 20th cargo resupply mission. Now, Dragon heads home. On April 7, it is scheduled to undock from station, bringing samples, hardware and data from completed investigations back to Earth on its return trip. Here are details on some of the investigations returning to the ground for further analysis and reporting of results. Generating a nutritional meal

Image above: These BioNutrients packets aboard the International Space Station demonstrate a technology that enables on-demand production of human nutrients during long-duration space missions. Image Credit: NASA. Planning ways to supply food for a multi-year mission on the Moon or Mars while keeping astronauts healthy on the long trip may require making fresh food and nutrients in space. BioNutrients demonstrates a technology that enables on-demand production of nutrients needed for during long-duration space missions.

Animation above: NASA astronaut Andrew Morgan works with packets for the BioNutrients investigation aboard the space station. Animation Credit: NASA. The process uses microbes, such as baker’s yeast, expressly engineered to make fresh nutrients for human consumption starting from dry powdered media — food for the yeast — and water. The fresh nutrients can supplement potential vitamin losses from food that is stored for very long periods. Over the five-year period of the demonstration, astronauts intermittently activate specially designed packets containing the yeast — or other microorganisms, in the future — and their food. They warm the packets for two days to allow the yeast to do its job, growing and producing the desired nutrients, and then freeze them for return to Earth for analysis. These tests will allow scientists to check how long their specially engineered yeast can be stored on the shelf and still be able to churn out fresh nutrients that humans need to stay healthy in space. Some samples will be returning on this SpaceX Dragon capsule. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet. Toward printing human organs in space Biological printing of the tiny, complex structures found inside human organs, such as capillaries, has proven difficult in Earth’s gravity. Under Earth’s gravity, an initial scaffolding, or support structure, is necessary to form the desired shape of the tissue. The BioFabrication Facility (BFF) attempts to take the first steps toward printing human organs and tissues in microgravity using ultra-fine layers of bioink that may be several times smaller than the width of a human hair. This research is part of a long-term plan to manufacture entire human organs in space using refined biological 3D printing techniques.

Image above: NASA astronaut Christina Koch handles media bags for the BioFabrication Facility (BFF), a 3D biological printer that could become a part of a larger system capable of manufacturing fully functioning human organs in microgravity. Image Credit: NASA. Launched to station in July 2019 on the 18th SpaceX cargo resupply flight, the facility now comes back to Earth. According to Techshot President and CEO John Vellinger, the facility has proven basic functionality. The team is bringing the facility back to Earth to make upgrades that will enable high throughput use when it returns to the space station. Helping the heart The Engineered Heart Tissues study looks at how human heart tissue functions in space. It uses unique 3D tissues made from heart cells derived from human induced Pluripotent Stem Cells (hiPSCs), essentially adult stem cells. The engineered heart tissues, or EHTs, are complex 3D structures, each about the size of a few grains of rice. These structures are more similar to tissues in the body than flat cell cultures in a petri dish or those floating in a flask of liquid.

Image above: NASA astronaut Jessica Meir works on a media change for the Engineered Heart Tissues investigation inside the Life Sciences Glovebox. Image Credit: NASA. Researchers expect significant differences in function, structure and gene expression between EHTs in microgravity and those on the ground. Understanding these differences could help them find ways to prevent or mitigate problematic changes on future long-duration missions. The hardware developed for the experiment also has created advanced, more efficient and more cost-effective technology for use on Earth. Researchers are bringing some EHTs back to Earth to see whether they recover from changes thought to occur in microgravity. Biofilm festival

Animation above: NASA astronaut Christina Koch conducts operations for Space Biofilms. This investigation examines microbial species and their formation of biofilms, communities of microorganisms that attach to each other and to different surfaces. Animation Credit: NASA. Samples from the Space Biofilms investigation, which examines microbial species and their formation of biofilms, are returning on Dragon. Biofilms are collections of one or more types of microorganisms – including bacteria, fungi and protists – that grow on wet surfaces. In spacecraft, biofilm formation can cause equipment malfunction and human illness, and it could pose a serious problem on future long-term human space missions. Better control of biofilms may help maintain crewed spacecraft and protect the health and safety of crew members as well as help prevent the introduction of Earth-based microbes to planetary bodies on which humans land. Examining amyloid formation in microgravity

Image above: NASA astronauts Christina Koch and Nick Hague are pictured inside the U.S. Destiny laboratory module. Hague was setting up the Microgravity Sciences Glovebox to begin operations for the Ring-Sheared Drop experiment to understand how fluids flow in the human body and other materials. Image Credit: NASA. The Ring Sheared Drop investigation takes advantage of the fact that fluids float in microgravity, allowing researchers to examine formation of amyloid fibrils in liquids held together by surface tension rather than by a container. Amyloids are abnormal fibrous deposits found in organs and tissues and are associated with neurodegenerative conditions such as Alzheimer’s disease. These proteins can denature -- or lose characteristic properties -- and precipitate, or come out of solution. As they accumulate over time, they may disrupt the healthy function of tissues and organs. Results from this experiment could contribute to a better understanding of and treatments for these neurodegenerative diseases. Data on the flow of liquids without the complications associated with solid walls also could contribute to development of advanced materials. Samples from this experiment are returning on Dragon. Related links: BioNutrients: https://www.nasa.gov/ames/bionutrients BioFabrication Facility (BFF): https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Facility.html?#id=7599 Engineered Heart Tissues: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=8217 Space Biofilms: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7955 Ring Sheared Drop: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7383 ISS National Lab: https://www.issnationallab.org/ Space Station Research and Technology: https://www.nasa.gov/mission_pages/station/research/index.html International Space Station (ISS): https://www.nasa.gov/mission_pages/station/main/index.html Images (mentioned), Animations (mentioned), Text, Credits: NASA/Michael Johnson/JSC/International Space Station Program Research Office/Erin Winick. Greetings, Orbiter.ch Full article

10 notes

·

View notes

Photo

Techshot’s Bioprinter Successfully Fabricates Human Menisci in Space Current Bioprinting in space could become a pathway that guides future decisions for biofabrication on Earth as well as in orbit. Astronauts have already used two bioprinters on the... View the entire article via our website. https://buff.ly/2xXj5h9

1 note

·

View note

Text

SpaceX Falcon 9 Rocket Successfully Launched With 3D Bioprinter, Supplies for ISS

https://sciencespies.com/news/spacex-falcon-9-rocket-successfully-launched-with-3d-bioprinter-supplies-for-iss/

SpaceX Falcon 9 Rocket Successfully Launched With 3D Bioprinter, Supplies for ISS

A space capsule carrying a 3D printer to make human tissue and about 5,000 pounds (roughly 2270 kgs) of other experiments and supplies is on its way to the International Space Station (ISS) after a thunderous SpaceX launch.

The private company’s Falcon 9 rocket dodged threatening clouds in its Thursday evening lift-off sending a Dragon capsule on its third trip to the orbiting outpost. The ship will dock with the ISS early Saturday.

Dragon is carrying science experiments, several of which concentrate on cellular science, as well as normal supplies.

Officials at biotech companies nScrypt and Techshot say the mini-refrigerator-sized 3D printer will be controlled by scientists on the ground and print nerve cells, muscle cells and proteins. The experiment uses the near lack of gravity to help the cells hold their shape.

NASA in a press statement said, “After a picture-perfect launch and spacecraft separation, Dragon is now drawing power from its solar arrays as it begins its solo, two-day trip to the orbiting laboratory. This is the first time a Dragon spacecraft will journey to the space station for a third time. To mark this accomplishment, it is outfitted with three noteworthy stickers: two station badges representing the previous resupply missions it has flown (CRS-6 and CRS-13) and the Apollo 50th anniversary logo.”

As we mentioned, the Dragon capsule will rendezvous with the ISS on Saturday, and NASA will be holding a live stream on its website – starting from 8:30am EDT (6pm IST, Saturday). The spacecraft is scheduled to dock at 10am EDT (7:30pm IST) and will then be installed on the bottom of the Harmony module of the ISS. It will remain there until August 20, after which it is planned to return with research and return cargo.

Written with inputs from AP

For the latest tech news and reviews, follow Gadgets 360 on Twitter, Facebook, and subscribe to our YouTube channel.

YouTube Videos Featuring Kids Get More Views: Pew Research Centre

Spider-Man: Far From Home Swings Past $1 Billion at Worldwide Box Office, the First Spidey Film to Do So

#News

0 notes

Text

SpaceX launches ISS mission using twice-flown Dragon for the first time

SpaceX has launched CRS-18, the 18th commercial resupply mission its flown for NASA to deliver experiment, research and supply materials to the International Space Station. This mission’s cargo included IDA-3, the second automated docking ring set to be installed on the ISS, which will enable autonomous docking capabilities for future commercial spacecraft visiting the station with both crew and cargo on board. CRS-18 took off from Cape Canaveral in Florida at 6:01 PM ET (3:01 PM PT) on Thursday, after an attempt Wednesday was scrubbed due to weather.

There are around 5,000 lbs of cargo on board the Dragon launched for this mission. CRS-18 also carried an research mission into engineering organic tissue for use in 3D bioprinting from a company called Techshot, as well as experiments in tire material manufacturing from Goodyear. There’s even Nickelodeon’s signature green slime (yes, the slime you’re thinking of) which is being sent up care of the ISS U.S. National Laboratory to help astronauts educate students on how fluid operates in microgravity environments.

SpaceX previously flew the Falcon 9 first stage rocket booster used on this mission just two months ago for the last ISS resupply mission, CRS-17. That’s a quick turnaround for one of its refurbished rockets, and another sign that it’s making good progress in its goal of achieving fully reusable launch capabilities. The Dragon cargo capsule used for this mission also flew before – twice, including for CRS-6 in April, 2015 and once again in December 2017 for CRS-13.

The landing of the Falcon 9 from CRS-18, sped up 2X.

This launch included a recovery attempt for the Falcon 9, too, and it returned and landed as planned at the company’s LZ-1 landing zone at Cape Canaveral Air Force base. The first-stage booster separated from the second stage and Dragon craft as planned, and then returned to Earth, landing successfully after a controlled descent. This was SpaceX’s 44th successful recovery of a Falcon 9 first-stage after launch.

Next up for the Dragon capsule is for it to dock with the ISS, which is set to happen on Saturday. It’ll then have its cargo unloaded by the astronauts on board the station, and receive 3,300 lbs of return cargo which it’ll bring back to Earth with a return trip that’ll conclude with a splash down in the Pacific Ocean.

0 notes