#Thermal Testing Lab Thermal Testing Of Composites

Text

Understanding the Importance of a Material Testing Lab

In today's competitive market, ensuring the quality and reliability of materials is crucial for the success of any product. This is where a material testing lab becomes indispensable. These specialized facilities play a critical role in assessing the properties and performance of materials, ensuring they meet the required standards and specifications.

Material testing labs are equipped with advanced technologies and instruments designed to conduct a wide range of tests. These tests can include mechanical, thermal, chemical, and environmental assessments, among others. By examining materials under various conditions, these labs help in understanding their behavior, durability, and suitability for specific applications.

One of the primary functions of a material testing lab is to evaluate the mechanical properties of materials. This includes tests for tensile strength, hardness, impact resistance, and fatigue. Such evaluations are essential for determining how materials will perform under different stresses and loads, which is crucial for applications in construction, automotive, aerospace, and manufacturing industries.

In addition to mechanical testing, material testing labs also conduct thermal analysis to assess how materials respond to temperature changes. This includes tests for thermal conductivity, expansion, and thermal stability. Understanding these properties is vital for materials used in environments with extreme temperatures or thermal cycling.

Chemical analysis is another key area of focus. Material testing labs analyze the chemical composition and purity of materials to ensure they meet industry standards and regulatory requirements. This is especially important in industries such as pharmaceuticals, food and beverage, and electronics, where material contamination can have significant consequences.

Moreover, environmental testing evaluates how materials perform in various environmental conditions such as humidity, corrosion, and UV exposure. This helps in predicting the lifespan and reliability of materials when exposed to real-world conditions.

By providing accurate and reliable data, material testing labs help manufacturers and researchers make informed decisions, enhance product quality, and ensure compliance with safety standards. Investing in material testing not only improves product performance but also reduces the risk of failures and recalls.

In conclusion, material testing labs are an essential component of modern industry. Their expertise and advanced testing capabilities ensure that materials meet the necessary standards and perform reliably in their intended applications. Whether you're developing new products or evaluating existing ones, partnering with a reputable material testing lab is key to achieving success and maintaining quality.

1 note

·

View note

Text

Top 5 Plastic Testing Labs in Abu Dhabi: An In-Depth Review of Services and Expertise

Abu Dhabi is emerging as a significant player in the manufacturing and technology sectors, with plastic testing labs playing a pivotal role in ensuring product quality, safety, and compliance. These labs are equipped with advanced technology and staffed by experts dedicated to providing rigorous testing services. In this comprehensive review, we highlight the top 5 plastic testing lab in Abu Dhabi, including METS Laboratories, detailing their services, expertise, and contributions to the plastic industry.

1. Apex Plastic Testing Laboratory

Overview: Apex Plastic Testing Laboratory is a premier facility in Abu Dhabi, recognized for its state-of-the-art technology and broad range of testing services. The lab serves multiple industries, including construction, automotive, and consumer goods.

Services:

Mechanical Testing: Apex offers mechanical testing services such as tensile strength, impact resistance, and hardness testing to evaluate the durability and performance of plastic materials under various conditions.

Chemical Analysis: The lab conducts chemical analysis to determine the composition and properties of plastics, ensuring they meet required industry specifications and standards.

Environmental Testing: Apex performs environmental testing to assess how plastics hold up under different environmental conditions, including temperature extremes and UV exposure.

Expertise: Apex boasts a skilled team with extensive experience in material science and engineering, providing crucial support for product development, quality assurance, and regulatory compliance.

2. Gulf Testing Services

Overview: Gulf Testing Services is a well-established plastic testing lab in Abu Dhabi, known for its comprehensive testing solutions and dedication to industry standards. The lab caters to various sectors, including automotive, packaging, and construction.

Services:

Physical Property Testing: Gulf Testing Services specializes in assessing physical properties such as density, melt flow index, and specific gravity to ensure plastic material quality and performance.

Thermal Analysis: The lab provides thermal analysis services, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), to evaluate the thermal behavior and stability of plastic materials.

Regulatory Compliance Testing: Gulf Testing Services helps manufacturers ensure their plastic products meet local and international regulations, offering necessary certifications and documentation for compliance.

Expertise: Known for its focus on regulatory compliance and physical property testing, Gulf Testing Services is a trusted partner for manufacturers seeking to adhere to industry standards and ensure product safety.

3. Abu Dhabi Material Testing Center (AD-MTC)

Overview: The Abu Dhabi Material Testing Center (AD-MTC) is a leading plastic testing lab with a broad range of testing services and advanced technology. The lab supports industries including construction, automotive, and consumer goods.

Services:

Mechanical and Physical Testing: AD-MTC offers comprehensive mechanical and physical testing services, including tensile, compression, and impact tests to assess the strength and durability of plastic materials.

Chemical and Environmental Testing: The lab conducts chemical and environmental tests to evaluate the stability and performance of plastics under varying conditions.

Custom Testing Solutions: AD-MTC provides customized testing solutions to address specific client needs, including tailored methodologies and specialized equipment.

Expertise: AD-MTC is renowned for its flexibility and capability to provide customized testing services. Its expertise in both mechanical and chemical testing makes it an invaluable resource for detailed material analysis.

4. Advanced Plastic Testing Laboratory

Overview: Advanced Plastic Testing Laboratory is recognized for its focus on innovative testing methods and cutting-edge technology. The lab serves diverse industries such as packaging, automotive, and construction.

Services:

Innovative Testing Techniques: The lab employs advanced techniques like high-speed impact testing and sophisticated thermal analysis to assess plastic materials’ performance.

Product Development Support: Advanced Plastic Testing Laboratory aids product development by helping manufacturers optimize plastic formulations and improve product performance.

Quality Assurance: The lab provides quality assurance testing to ensure that plastic products meet industry standards and specifications, offering valuable insights for quality control.

Expertise: With a focus on innovation and product development, Advanced Plastic Testing Laboratory is a key player in supporting manufacturers with advanced testing techniques and quality assurance services.

5. METS Laboratories

Overview: METS Laboratories is a prominent plastic testing lab in Abu Dhabi, known for its comprehensive range of testing services and commitment to high standards. The lab serves various sectors including automotive, construction, and consumer goods.

Services:

Standard and Specialized Testing: METS Laboratories offers both standard and specialized testing services, including mechanical, chemical, and environmental tests to evaluate various aspects of plastic materials.

Consulting Services: The lab provides consulting services to help manufacturers interpret testing results and make informed decisions about product development and quality enhancement.

Certifications and Compliance: METS Laboratories assists manufacturers in obtaining necessary certifications and ensuring compliance with international standards and regulations, supporting market access and product safety.

Expertise: METS Laboratories is renowned for its detailed testing services and consulting expertise. The lab’s comprehensive approach to analysis and regulatory compliance makes it a valuable partner for manufacturers looking to enhance product quality and adhere to industry standards.

Conclusion

Plastic testing labs in Abu Dhabi are instrumental in ensuring the quality, safety, and compliance of plastic products. Apex Plastic Testing Laboratory, Gulf Testing Services, Abu Dhabi Material Testing Center (AD-MTC), Advanced Plastic Testing Laboratory, and METS Laboratories are leading the way in providing thorough testing solutions and specialized expertise. Their commitment to advanced technology, regulatory compliance, and quality assurance supports manufacturers in developing high-performance plastic products and maintaining industry standards. As Abu Dhabi continues to evolve as a global manufacturing hub, these labs will remain crucial in driving excellence and fostering innovation in the plastic industry.

0 notes

Text

Top Electrical Conductors and Conducting Materials Testing Services | Delhi Test House

In the world of electrical engineering, the reliability and efficiency of conducting materials are paramount. Whether it’s for power transmission, electronics, or industrial applications, the quality of these materials directly impacts performance and safety. Top Conductors and Conducting Materials Testing Services at Delhi Test House ensures reliability and safety of material.

Why Electrical Conductivity Testing is Crucial

Electrical Conductivity Testing is vital for assessing the ability of a material to conduct electric current. This property is essential in various industries, including electronics, power generation, and telecommunications. Conductors Testing Services ensure that materials such as copper, aluminum, and other metals meet the required standards for performance and safety.

Comprehensive Testing at Delhi Test House

Delhi Test House offers a broad range of testing services for Electrical Conductors and Conducting materials. These services are designed to meet the needs of manufacturers, suppliers, and regulatory bodies. Here are some of the key services provided:

1. Electrical Conductors Materials Testing

Delhi Test House specializes in testing various electrical conductors materials to determine their suitability for different applications. This includes testing for:

- Conductivity: Ensuring the material has the required electrical conductivity.

- Resistance: Measuring the resistance to ensure minimal energy loss.

- Durability: Assessing the material’s ability to withstand environmental and mechanical stresses.

2. Conducting Materials Testing Lab

The Conducting Materials Testing Lab at Delhi Test House is equipped with state-of-the-art equipment and staffed by experienced professionals. The lab performs rigorous testing to provide accurate and reliable results. Services include:

- Chemical Analysis: Determining the composition of the material to ensure it meets the required specifications.

- Mechanical Testing: Evaluating the strength and flexibility of the material.

- Thermal Testing: Assessing the material’s performance under various temperature conditions.

3. Delhi Electrical Testing Laboratory

The Delhi Electrical Testing Laboratory at Delhi Test House is a leading facility for testing electrical conductors and materials. The lab offers a range of specialized tests, including:

- High-Voltage Testing: Ensuring materials can withstand high voltage without degrading.

- Insulation Testing: Assessing the effectiveness of insulation materials in preventing electrical leakage.

- Aging Tests: Simulating long-term use to evaluate how materials will perform over time.

Why Choose Delhi Test House?

Delhi Test House is renowned for its commitment to quality and precision. Here are some reasons to choose their services:

- Authorization: Delhi Test House is authorized by leading industry bodies, ensuring that their testing methods meet international standards.

- Expertise: The team at Delhi Test House comprises highly qualified professionals with extensive experience in electrical conductivity testing and materials analysis.

- State-of-the-Art Facilities: The laboratory is equipped with the latest technology to provide accurate and reliable testing results.

For businesses and industries in need of reliable Electrical Conductivity Testing and Conductors Testing Services, Delhi Test House offers unparalleled expertise and state-of-the-art facilities. Whether you are looking to test Electrical Conductors Materials or require a comprehensive Conducting Materials Testing Lab, Delhi Test House is your go-to destination for all your testing needs. Trust in their services to ensure the safety, efficiency, and longevity of your electrical materials.

Contact US

Phone: 011–47075555

Email: [email protected]

0 notes

Text

Applications of Microwave Lab Ovens in Modern Research

Kerone is a leading provider of thermal processing solutions, offering a wide range of industrial heating equipment such as MW lab ovens. Specializing in custom-designed heating systems, Kerone caters to diverse industries including pharmaceuticals, food processing, and automotive. With a focus on innovation and efficiency, Kerone's microwave lab ovens are particularly notable for their ability to quickly and uniformly heat samples, making them essential tools in modern research. These ovens play a crucial role in advancing scientific knowledge and have become key instruments for researchers looking to achieve precise control over the heating process in various industrial applications.

Microwave lab ovens have revolutionized industrial research by providing a fast and efficient method for heating samples. These ovens use microwave radiation to heat materials uniformly and quickly, making them essential tools in a wide range of industrial applications. Microwave lab ovens are revolutionizing research techniques in several industries, from food processing to pharmaceuticals. Modern microwave lab ovens' small size and accurate temperature control have made them indispensable in industrial settings, increasing output and improving the precision of research. These ovens have become vital for improving innovation and promoting industrial research advancement in the constantly shifting field of research today.

Application

Material Synthesis: MW-Lab ovens facilitate rapid and uniform heating, crucial for synthesizing new materials like nanomaterials, polymers, and composites, ensuring consistent quality and properties throughout the batch.

Sample Drying: They offer precise control over temperature and environment, making them ideal for drying samples quickly without degradation, preserving the integrity of sensitive biological or chemical samples.

Chemical Reactions: Accelerate chemical reactions with consistent, controlled heating, enhancing reaction rates and yields, and enabling experiments that require specific thermal conditions for optimal results.

Sterilization: Efficiently sterilize lab equipment, glassware, and instruments by maintaining high temperatures, ensuring the elimination of contaminants, bacteria, and viruses, crucial for maintaining a sterile lab environment.

Thermal Testing: Conduct thermal testing on materials to assess their stability, decomposition temperatures, and thermal conductivity, providing valuable data for material development and quality control.

Benefits

Enhanced Precision: MW-Lab ovens provide highly controlled heating environments, ensuring precise temperature regulation crucial for sensitive experimental procedures and reproducible results.

Rapid Heating: These ovens use microwave technology to achieve fast heating rates, significantly reducing the time needed to reach target temperatures compared to conventional ovens.

Energy Efficiency: MW-Lab ovens consume less energy by directly heating materials at the molecular level, leading to lower operational costs and a smaller environmental footprint.

Uniform Heating: They ensure even distribution of heat throughout the sample, minimizing temperature gradients and preventing hotspots that could compromise the integrity of experiments.

Compact Design: MW-Lab ovens are typically compact, saving valuable lab space and allowing for easy integration into various laboratory setups without requiring extensive modifications.

Futures

Rapid Heating: MW-Lab ovens offer quick and uniform heating, significantly reducing the time required for experiments and increasing overall lab efficiency by quickly reaching desired temperatures.

Energy Efficiency: These ovens use microwave technology to directly heat samples, minimizing energy loss and reducing overall power consumption compared to conventional heating methods, making them cost-effective and eco-friendly.

Precise Temperature Control: MW-Lab ovens provide accurate temperature regulation, allowing for precise experimental conditions and repeatability, which is crucial for reliable and reproducible scientific results.

Versatile Applications: They are suitable for a wide range of applications, including chemical synthesis, drying, and sterilization, making them a versatile tool in various scientific and industrial fields.

Reduced Thermal Damage: The localized heating minimizes the risk of thermal damage to sensitive materials, preserving sample integrity and ensuring high-quality outcomes, especially in biological and chemical research.

Conclusion

Microwave lab ovens have transformed industrial research by offering a fast, efficient, and uniform heating method. Utilizing microwave radiation, these ovens are crucial in various industries, including food processing and pharmaceuticals, due to their ability to rapidly and uniformly heat samples. Their compact design and precise temperature control make them indispensable in industrial settings, enhancing productivity and research precision. By increasing output and ensuring accurate experimental results, microwave lab ovens are essential tools driving innovation and advancement in industrial research. In today's dynamic research landscape, their role in fostering progress and efficiency highlights their significance in promoting ongoing scientific and industrial development.

0 notes

Text

Custom Scientific Glassware Solutions for Unique Industrial Challenges

Scientific glassware performs a critical role in the ever-changing world of industrial research and industry. It's not enough to have the correct equipment for the task; you also need tools that are precisely suited to the specific needs and problems of your sector. This is where unique scientific glassware solutions come into play, providing personalized assistance for the complexities of varied industrial applications.

The Importance Of Customization

Standard scientific glassware, such as beakers, flasks, and tubes, is used in most laboratory situations. However, when dealing with specific jobs or unique industrial constraints, off-the-shelf solutions frequently fall short. Custom scientific glassware solutions are intended to solve this gap by offering equipment that meets the exact criteria necessary for specialty experiments, manufacturing operations, or quality control methods.

Optimized to Business Specific Needs

Individual sectors face distinct obstacles. For example, the pharmaceutical industry requires glassware that can endure harsh sterilizing treatments without jeopardizing the chemical composition of delicate chemicals. Meanwhile, environmental science labs may require bespoke glassware to accurately analyze trace quantities of contaminants in different matrices. Custom solutions allow enterprises to ensure that their scientific glassware is not only suitable for purpose, but also improves the efficiency and accuracy of their processes.

Reducing Reliability and Efficiency

Custom scientific glassware is precisely created to improve accuracy and efficiency in industrial laboratories. For example, a custom-designed reactor vessel could allow for more effective mixing and reaction control, resulting in increased output and cheaper costs. Similarly, specialized volumetric flasks with precise calibration marks can prevent measurement mistakes, ensuring that tests and operations are carried out with maximum precision.

Longevity and Safety

Safety and durability are critical in industrial settings, where equipment failure may be extremely costly, not only financially but also in terms of human safety and environmental effect. Custom glassware can be created from materials such as borosilicate glass, which is noted for its remarkable resistance to thermal stress and chemical corrosion, guaranteeing that the glassware can withstand harsh industrial conditions. Custom designs can also include safety features designed to address specific industrial concerns, such as pressure resistance for high-temperature applications or shatterproof coatings to protect laboratory personnel.

The Role Of Professional Glassware Designers

Developing successful custom scientific glassware solutions is not a chore for the unskilled. To understand the unique requirements of each project, competent glassblowers and designers must collaborate with scientists and industrial experts. The best custom glassware providers take a collaborative approach, taking the time to understand the nuances of each client's industrial processes and challenges, ensuring that the end result is more than just a piece of glassware, but also a solution that improves scientific inquiry and industrial efficiency.

Source URL: https://medium.com/@gohiljadav95/custom-scientific-glassware-solutions-for-unique-industrial-challenges-5265264a7830

Investing in Specific Solutions

While the initial investment in handmade scientific glassware may be costlier than that of off-the-shelf goods, the long-term benefits frequently surpass the costs. Custom solutions can enhance outcomes, increase productivity, and minimize waste, eventually saving money and time. Furthermore, by tackling unique industrial difficulties face on, custom glassware can promote innovation and growth, accelerating scientific discovery and industrial advancement.

Conclusion

In the face of Goel Equipments specific industrial difficulties, specialized scientific glassware solutions provide a road to increased precision, efficiency, and safety in research and manufacturing operations. By customizing glassware to meet unique demands, industries can overcome constraints, push the limits of what is possible, and pave the path for future improvements. Investing in custom scientific glassware is more than just purchasing tools; it is an investment in the future of science and industry.

0 notes

Text

IQS: Your One-Stop Shop for High-Quality Non-Ferrous Forgings and Castings

In the ever-evolving landscape of metalworking, precision and quality reign supreme. IQS Engineering Solutions Pvt. Ltd. stands out as a leading non-ferrous forging and casting manufacturer, dedicated to exceeding expectations and providing unparalleled service.

A Diverse Portfolio: Crafting Exceptional Components

Our expertise encompasses a comprehensive range of non-ferrous metals, meticulously transformed into intricate and robust components. We specialize in:

Brass Forgings: Renowned for their strength, corrosion resistance, and machinability, brass forgings are ideal for a multitude of applications.

Aluminum Forgings: Lightweight yet robust, aluminum forgings cater to industries demanding a perfect balance between performance and weight reduction.

Copper Forgings: Offering exceptional thermal and electrical conductivity, copper forgings are vital in various sectors, including electrical and heat transfer applications.

Bronze Forgings: Combining durability with low friction properties, bronze forgings excel in wear-resistant components.

Aluminum Castings: Delivering intricate shapes and complex designs, aluminum castings cater to diverse applications requiring both form and functionality.

Brass Castings: Recognized for their excellent machinability and pressure-tight properties, brass castings are perfect for intricate parts and demanding environments.

Innovation at the Forefront: Partnering for Success

At IQS, we firmly believe in fostering strong relationships with our clients. Our collaborative approach involves:

In-depth Need Analysis: We take the time to understand your specific requirements and challenges.

Engineered Solutions: Leveraging our expertise, we develop innovative solutions tailored to your project's unique demands.

Unwavering Commitment to Quality: Every step of the process adheres to the latest ISO 9001:2015 standards, ensuring exceptional results.

Delivering on the Promise: Quality Ensured

IQS prioritizes delivering only the best to our valued customers. This unwavering commitment manifests in:

Stringent Quality Assurance: Our robust QA systems, built upon the latest ISO 9001:2015 guidelines, guarantee meticulous quality control throughout the manufacturing process.

Advanced Testing Facilities: In-house test labs equipped with cutting-edge technology enable us to measure:

Hardness

Temperature

Chemical composition

Metrology of the metals

Objective Analysis: The acquired data provides a comprehensive picture of the product's quality, ensuring complete transparency and adherence to the highest standards.

IQS: Committed to Excellence

At IQS, we are not merely a non-ferrous forging and casting manufacturer. We are a team of passionate professionals driven by a relentless pursuit of excellence. Our core values encompass:

Unwavering Quality: We are committed to providing our clients with products that consistently meet and surpass their expectations.

Unmatched Expertise: Our team possesses in-depth knowledge and experience in non-ferrous metalworking, ensuring exceptional solutions.

Collaborative Approach: We believe in building strong partnerships with our clients, fostering open communication and a commitment to shared success.

By partnering with IQS, you gain access to a reliable source of premium-quality non-ferrous forgings and castings, meticulously crafted to meet your specific needs. We are your trusted partner in delivering exceptional performance and propelling your projects to new heights.

Contact IQS today to discuss your requirements and experience the difference that unwavering quality and innovative solutions can make.

0 notes

Text

IQS: Your One-Stop Shop for High-Quality Non-Ferrous Forgings and Castings

In the ever-evolving landscape of metalworking, precision and quality reign supreme. IQS Engineering Solutions Pvt. Ltd. stands out as a leading non-ferrous forging and casting manufacturer, dedicated to exceeding expectations and providing unparalleled service.

A Diverse Portfolio: Crafting Exceptional Components

Our expertise encompasses a comprehensive range of non-ferrous metals, meticulously transformed into intricate and robust components. We specialize in:

Brass Forgings: Renowned for their strength, corrosion resistance, and machinability, brass forgings are ideal for a multitude of applications.

Aluminum Forgings: Lightweight yet robust, aluminum forgings cater to industries demanding a perfect balance between performance and weight reduction.

Copper Forgings: Offering exceptional thermal and electrical conductivity, copper forgings are vital in various sectors, including electrical and heat transfer applications.

Bronze Forgings: Combining durability with low friction properties, bronze forgings excel in wear-resistant components.

Aluminum Castings: Delivering intricate shapes and complex designs, aluminum castings cater to diverse applications requiring both form and functionality.

Brass Castings: Recognized for their excellent machinability and pressure-tight properties, brass castings are perfect for intricate parts and demanding environments.

Innovation at the Forefront: Partnering for Success

At IQS, we firmly believe in fostering strong relationships with our clients. Our collaborative approach involves:

In-depth Need Analysis: We take the time to understand your specific requirements and challenges.

Engineered Solutions: Leveraging our expertise, we develop innovative solutions tailored to your project's unique demands.

Unwavering Commitment to Quality: Every step of the process adheres to the latest ISO 9001:2015 standards, ensuring exceptional results.

Delivering on the Promise: Quality Ensured

IQS prioritizes delivering only the best to our valued customers. This unwavering commitment manifests in:

Stringent Quality Assurance: Our robust QA systems, built upon the latest ISO 9001:2015 guidelines, guarantee meticulous quality control throughout the manufacturing process.

Advanced Testing Facilities: In-house test labs equipped with cutting-edge technology enable us to measure:

Hardness

Temperature

Chemical composition

Metrology of the metals

Objective Analysis: The acquired data provides a comprehensive picture of the product's quality, ensuring complete transparency and adherence to the highest standards.

IQS: Committed to Excellence

At IQS, we are not merely a non-ferrous forging and casting manufacturer. We are a team of passionate professionals driven by a relentless pursuit of excellence. Our core values encompass:

Unwavering Quality: We are committed to providing our clients with products that consistently meet and surpass their expectations.

Unmatched Expertise: Our team possesses in-depth knowledge and experience in non-ferrous metalworking, ensuring exceptional solutions.

Collaborative Approach: We believe in building strong partnerships with our clients, fostering open communication and a commitment to shared success.

By partnering with IQS, you gain access to a reliable source of premium-quality non-ferrous forgings and castings, meticulously crafted to meet your specific needs. We are your trusted partner in delivering exceptional performance and propelling your projects to new heights.

Contact IQS today to discuss your requirements and experience the difference that unwavering quality and innovative solutions can make.

0 notes

Text

What is Inconel 690 Sheet & Plate ?

Chhajed Steel & Alloy Pvt Ltd. is a stockiest and trader of high-temperature Inconel 690 Sheet & Plate. We stock an unrivaled range of sheets and plates in different thickness, standards, designation, specifications, and custom lengths. One can enquire for too large and small quantities. We will gladly discuss any specific requirement of the clients that may fall outside from our inventory. We offer sheets and plates in multitude size and thickness supported by laser cutting, profiling, shearing and punching that cuts strips as exact specifications.

The Inconel 690 Sheet & Plate is a high chromium-nickel alloy having excellent resistance to many oxidizing media and elevated temperatures. These sheet and plates have the capacity to function in hoists or moderate temperatures. It also works where high surface stability is required. In addition to resistance property, these have high strength, favorable fabrication properties, and metallurgical stability. It is known for its high chromium nickel base composition with superior pitting and stress cracking resistance.

Inconel grade plates are extensively used because of its high-temperature strength, magnetic feature, and thermal expansion feature. These sheets are the versatile element and will be welded to other metals. Moreover, it has good hardenability and also toughness. These sheets have also the good tendency of formability and machinability that is ideal for constructing any complex design. Moreover, these come with tolerance limit and machining allowance for different types of applications. It is available in tempered and quenched states.

Inconel 690 Sheet & Plate is rolled with the hot and cold working process. Extra hardening is provided by heat treatment process and annealing process. The surface is refined by grinding or brushing process so the dimensions become more precise and finished. However, the bright black polish and SATIN coat prevents atmospheric eruption mostly at reducing environments.

Testing performed by us-

Following are the tests- flaring test, flattening test, Mechanical test, hardness test, tensile test, positive material test, micro and macro test, chemical test/ spectral analysis. Also, intergranular corrosion test, ultrasonic test, radiographic test, pitting corrosion test and visual inspection are also performed.

The entire test performed in our LAB is certified by national and international norms under the supervision of experts. Additionally, last stage inspection is performed by third parties for top-notch quality.

Certificate that assures our quality-

We provide MTC report as per EN 10204 3.1 or 3.2, marketable invoice, specification guide, fumigation certificates, packing list like the net and gross weight, quantity and marks and number, NABL test report, and guarantee letter. Apart from this, Certificate origin by legalized manufacturers/ embassy, attested certificate by suppliers, raw material test report, mill test report, quality assurance plan, and heat treatment charts are also provided to our clients.

Delivery options-

Our Concise logistic service delivers your product within time also in a safe mode. We use standard packing so as to remove damages while exporting to global clients. In addition to providing extra protection from oxidation these are coated with the plastic film.

Purchase Inconel 690 Sheet & Plate at low rates from here for long-term engineering applications.

Standard Specification

SpecificationASTM B168 / ASME SB168Length2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm.Width1000mm / 1219mm /1250mm / 1500mm / 2000mmThicknessRanging from 0.3mm to 20mmHardnessAs per ASME A & NACE MR 175FinishHot rolled plate (HR), Cold rolled sheet (CR)

Inconel 690 Sheet & Plate Manufacturers in Mumbai, Inconel 690 Sheet & Plate Suppliers in Mumbai, Inconel 690 Sheet & Plate Stockists in Mumbai, Inconel 690 Sheet & Plate Exporters in Mumbai

0 notes

Text

Common Challenges in Foam Production: How Maeon Laboratory’s Testing Services Can Help

Foam production is a complex process that involves intricate chemistry and engineering, with the final product finding applications in a myriad of industries, from mattresses and upholstery to packaging and insulation. However, this versatility comes with its own set of challenges, necessitating stringent quality control measures. In this article, we delve into the common challenges faced in foam production and explore how Maeon Laboratory's state-of-the-art Foam Testing Lab can be a crucial ally in ensuring the quality and performance of foam products.

Balancing Act: Tradeoffs in Foam Production

One of the primary challenges in foam production lies in the delicate balance between various factors that influence the physical and chemical properties of the foam. Manufacturers need to carefully navigate tradeoffs between factors such as density, hardness, and compressibility. Adjusting one parameter often has a cascading effect on others, making it imperative to strike the right balance to meet the specific requirements of the end product.

For instance, increasing foam density may enhance durability but could compromise flexibility. Similarly, tweaking the chemical composition for improved flame resistance might inadvertently affect the foam's overall performance. These tradeoffs highlight the need for precise testing methods to validate and fine-tune the production process.

Challenges in Different Approaches to Foam Production

Foam production processes vary, and each approach comes with its unique set of challenges. Traditional methods, like open-cell and closed-cell production, each have their advantages and drawbacks. Open-cell foams offer breathability but may sacrifice insulation properties. Closed-cell foams, on the other hand, excel in insulation but may be less flexible.

Maeon Laboratory understands the nuances associated with different foam production methods and offers comprehensive testing services to address the specific challenges inherent in each approach. Our Foam Testing Lab is equipped with cutting-edge technology to evaluate foam samples for crucial parameters, ensuring that the end product aligns with industry standards and client specifications.

Addressing Common Issues in Foam Production

Foam production faces common issues such as uneven cell structure, inadequate curing, and variations in chemical composition. These issues can lead to inconsistent product quality, affecting the foam's performance and longevity.

Maeon Laboratory's Foam Testing Lab employs advanced analytical techniques to identify and rectify these issues. Our team of experts conducts thorough analyses of foam samples, detecting irregularities in cell structure, assessing curing efficiency, and verifying chemical composition. By addressing these common issues, we help manufacturers achieve a more uniform and reliable foam product.

Importance of Foam Testing in Product Quality and Performance

The significance of foam testing cannot be overstated. It serves as a critical quality control measure, ensuring that foam products meet industry standards, regulatory requirements, and customer expectations. Testing provides valuable insights into a foam's mechanical properties, thermal conductivity, and flame resistance, among other key characteristics.

Maeon Laboratory's Foam Testing Lab plays a pivotal role in this process by offering a comprehensive suite of tests tailored to the specific needs of foam manufacturers. From compression and tensile strength tests to thermal conductivity measurements, our testing services provide a holistic evaluation of foam performance, empowering manufacturers to deliver high-quality products consistently.

Enhancing Foam Production with Maeon Laboratory's Expertise

In the dynamic landscape of foam production, challenges are inevitable, but so are solutions. Maeon Laboratory's Foam Testing Lab stands as a beacon of reliability, offering manufacturers the tools and expertise needed to overcome common challenges and achieve excellence in foam production. By addressing tradeoffs, understanding diverse production methods, and mitigating common issues, our testing services contribute to the creation of superior foam products that meet the stringent demands of today's markets. Partner with Maeon Laboratory and elevate your foam production to new heights of quality and performance.

0 notes

Text

Lithium Battery Electrolyte Composition Testing Service Market Skyrocketing as Demand for Safer Batteries Increases!

Lithium Battery Electrolyte Composition Testing Service Market Grows

The lithium battery electrolyte composition testing service market is growing rapidly, as the demand for lithium ion batteries increases. According to a recent report from Reedley Exponent, testing services are being offered to assess and analyze the composition and quality of electrolytes used in lithium ion batteries. This is due to the fact that the safety of these batteries is of utmost importance, and the composition of the electrolytes must be tested to ensure that they meet industry standards.

The report states that the key players in the market are offering testing services for lithium ion batteries, including:

Thermal Analysis

Electrochemical Analysis

Chemical Analysis

Physical Analysis

These services are being offered to assess the performance of lithium ion batteries, and to ensure that they are safe for use. Additionally, the report states that the testing services are also being used to analyze the composition of the electrolytes used in lithium ion batteries, and to ensure that they are of the highest quality.

The report also states that the testing services are being used to assess the performance of lithium ion batteries in various applications, such as automotive, consumer electronics, and medical devices. Additionally, the report states that the testing services are also being used to analyze the composition of the electrolytes used in lithium ion batteries, and to ensure that they are of the highest quality.

The report concludes by highlighting the advantages of hiring ACS Lab, an industry trusted testing and compliance partner for hemp and cannabis. ACS Lab provides comprehensive testing services for all types of hemp and cannabis products, ensuring that they meet all safety and quality standards. With their expertise and experience, they can help ensure that your products are safe and compliant with all applicable regulations.

For more information about the lithium battery electrolyte composition testing service market, please visit Lithium Battery Electrolyte Composition Testing Service Market ... Reedley Exponent.

For more information about the advantages of hiring ACS Lab, an industry trusted testing and compliance partner for hemp and cannabis, please visit ACS Lab.

0 notes

Link

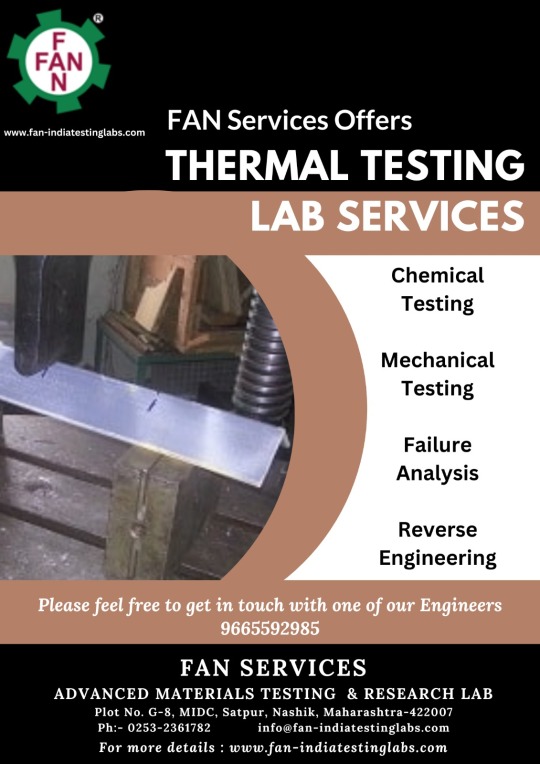

Fan Services can provide you Thermal testing services For Plastic,Rubber, Composite Products in Mumbai, Pune, Nashik, Chennai, Ahmedabad, Aurangabad,Hyderabad,Bangalore, Baroda, Nagpur,India

0 notes

Text

How to Test Purity of Silver in Silver Jewellery?

Silver is a widely utilized metal, much like gold or platinum, and it is often considered a valuable investment in India. It is a lustrous metal commonly employed in the creation of jewellery, cutlery, and durable goods. With proper care, silver jewellery and cutlery can last a lifetime due to their delicate nature. Whether you acquire sterling silver earrings or a silver ring, ensuring their authenticity is crucial. Therefore, it is important to verify the genuineness of any silver jewellery or flatware you purchase.

How Can I Check If Silver is Pure or Not?

Determining the authenticity of silver can be a crucial step in ensuring the quality of your silver items. There are several methods you can employ to ascertain if the silver you have is genuine. Here are some reliable ways to test the legitimacy of silver jewellery, coins, or cutlery:

Test in Lab

Acid Test: The acid test involves using nitric acid to assess the purity of silver. A small scratch is made on the item, and a drop of acid is applied to the scratch. Genuine silver will exhibit little to no reaction, while silver-plated or fake silver will show a noticeable discoloration or fizzing. It's important to handle acids with care and conduct this test in a well-ventilated area.

Hallmark Verification: Many countries have a hallmarking system that indicates the purity of silver. Look for official hallmarks or stamps on the item, such as the "925" mark, which signifies that it is made of 92.5% pure silver. Research the hallmarking standards of your region to identify the relevant marks.

XRF Testing: X-ray fluorescence (XRF) testing is a non-destructive method used by professionals to determine the composition of silver and other metals. A specialized instrument emits X-rays onto the item, and the resulting energy emissions provide precise information about its elemental composition.

Density Measurement: Silver has a specific density, and comparing the measured density of an item to the known density of silver can help identify its authenticity. Professional jewelers and experts often use density meters or hydrostatic weighing methods to determine if an item is made of genuine silver.

Microscopic Examination: A close examination of the item under a microscope can reveal intricate details that may indicate its authenticity. Look for signs of craftsmanship, such as intricate engravings or fine details, which are typically found in genuine silver items.

Remember, these methods require specialized knowledge, equipment, or professional expertise. If you have valuable or antique silver items that require thorough assessment, it is advisable to consult reputable jewelers, appraisers, or experts who can provide accurate evaluations.

By combining multiple testing methods, including those mentioned earlier, with these additional techniques, you can gain a comprehensive understanding of the authenticity of your silver items and make informed decisions about their value and quality.

If you want to test silver metal’s purity at home, try these methods:

Test at Home

Check the Label First: Examining the label or markings on your silver items is one of the simplest and most effective ways to determine their authenticity. Look for phrases such as "sterling" or "ster" which indicate that the silver content is 92.5%, meaning it is essentially pure silver. Older items may feature labels like "STERLING" or "STER." International markings may also indicate the silver content, such as 800, 900, or 925. Items containing between 80% and 90% silver are often referred to as "coin silver." If you remain unsure about an item's authenticity even after purchasing it, you can perform additional tests.

Ice Cube Test: The ice cube test is a straightforward method that works well for evaluating silver items with flat surfaces. Place an ice cube on your silverware or coin and observe its behavior. Silver, being highly thermally conductive, will cause the ice cube to melt more quickly compared to other metals. The high heat conductivity of silver expedites the melting process when it comes into contact with silverware or coins.

Test for Bleach: Bleach can be used to determine if a silver item is genuine. Apply a small amount of bleach to the silver object and observe its reaction. Genuine silver will tarnish and turn black when exposed to oxidizing substances like bleach.

Weigh-In: Silver is denser than most other materials, so its weight can provide a clue about its authenticity. If the silver weighs less, it may not be sterling silver but rather a lighter silver alloy or silver-plated item. On the other hand, pure silver tends to be heavier and exhibits a brighter appearance compared to silver-plated objects.

Magnet Test: The magnet test is another useful method for testing the authenticity of silver. You can use a magnet you already have at home to check the purity of the silver. Silver, being only slightly magnetic due to its paramagnetic nature, will have minimal or no attraction to a strong magnet like a neodymium magnet. If the silver item shows significant magnetic attraction, it is likely not genuine silver.

Smell Test: Hold the silver item close to your nose and observe if there is any odor. Authentic silver should not have any discernible smell or may have a very faint metallic scent. If the item smells like rust or has an unusual odor, it is likely made of other metallic materials or has a low silver content, such as silver-plated jewellery.

By employing these testing methods, you can gain a better understanding of the authenticity of your silver items and make informed decisions when purchasing new or used silver jewellery or flatware. However, it is important to remember that these tests provide indications rather than definitive results. For valuable or sentimental items, it is recommended to seek professional assessment from experts in evaluating antique silver items.

Conclusion

In conclusion, it is essential to ensure the authenticity of silver items that you own or plan to purchase. The methods discussed above offer practical ways to test the legitimacy of silver jewellery, coins, or cutlery. By checking labels, conducting tests such as the ice cube test, bleach test, weighing the item, using magnets, performing the ring test, and considering any unusual smells, you can gather valuable insights into the authenticity of silver.

However, it is important to note that these tests provide helpful indications, but they may not guarantee absolute accuracy in all cases. If you have valuable or sentimental items that hold significant importance to you, it is advisable to seek the expertise of assessors who specialize in evaluating antique items.

Whether you are buying new silver jewellery or considering the purchase of used items, these testing methods can assist you in verifying the authenticity of silver and making informed decisions. Remember, ensuring the genuineness of silver items contributes to your overall satisfaction and helps you establish a collection of quality and valuable possessions.

Source: https://thefira.com/blogs/blog/how-to-test-purity-of-silver-in-silver-jewellery

0 notes

Text

Why Cement Testing Labs in Dubai are Crucial for Ensuring Structural Integrity

In the thriving construction landscape of Dubai, ensuring the structural integrity of buildings and infrastructure is of paramount importance. Cement, being a fundamental component of construction, plays a vital role in the strength and durability of structures. Cement testing lab in Dubai are essential for verifying the quality of cement, thereby ensuring that it meets the required standards for safety and performance. This blog explores why these labs are crucial for maintaining structural integrity in Dubai’s construction projects.

The Importance of Cement Quality in Construction

Cement quality directly impacts the overall strength, durability, and longevity of construction projects. High-quality cement ensures that buildings and infrastructure can withstand environmental stresses and loads over time. Poor quality cement, on the other hand, can lead to structural failures, increased maintenance costs, and safety hazards. Therefore, rigorous testing of cement is necessary to prevent these issues and guarantee the reliability of construction.

Key Functions of Cement Testing Labs

Cement testing labs in Dubai perform a variety of tests to assess the physical and chemical properties of cement. These tests provide valuable insights into the material’s quality and suitability for specific construction applications. Here are some of the key functions of cement testing labs:

Compressive Strength TestingCompressive strength is a critical property that determines the ability of cement to withstand axial loads. Testing labs measure the compressive strength of cement to ensure it meets the specified requirements. This test is crucial for assessing the load-bearing capacity of concrete structures.

Fineness TestingThe fineness of cement affects its hydration rate and strength development. Testing labs use techniques such as sieve analysis and laser diffraction to measure the particle size distribution of cement. Ensuring the correct fineness helps in achieving the desired workability and strength.

Setting Time TestingSetting time is the duration required for cement to start hardening and gaining strength. Labs perform initial and final setting time tests to determine the usability window of cement. This information is vital for planning construction activities and avoiding premature setting.

Soundness TestingSoundness tests assess the volume stability of cement to ensure it does not undergo significant expansion or contraction after setting. This test is essential to prevent cracking and structural failures caused by volume changes.

Chemical AnalysisChemical analysis identifies the composition of cement, ensuring it contains the necessary compounds in the right proportions. Techniques like X-Ray Fluorescence (XRF) provide detailed information about the elemental composition, helping to verify compliance with standards.

Heat of Hydration TestingThe heat of hydration test measures the heat generated during the hydration process of cement. This information is crucial for understanding the thermal behavior of cement, which impacts the curing process and long-term performance.

Advanced Testing Techniques

Cement testing labs in Dubai employ advanced testing techniques to ensure accurate and reliable results. Some of these techniques include:

X-Ray Fluorescence (XRF): Provides precise chemical composition analysis.

Laser Diffraction: Measures particle size distribution with high precision.

Calorimetry: Assesses the heat of hydration and predicts setting behavior.

Scanning Electron Microscopy (SEM): Examines the microstructure of cement, revealing details about particle morphology and pore structure.

These advanced techniques enhance the accuracy of testing and provide comprehensive data for evaluating cement quality.

Ensuring Compliance with Standards

Cement testing labs in Dubai ensure that the cement used in construction projects complies with local and international standards. Compliance with standards set by organizations such as the Emirates Authority for Standardization and Metrology (ESMA), ASTM, BS EN, and ISO is crucial for:

Legal Approval: Meeting regulatory requirements for construction projects.

Safety Assurance: Ensuring the safety and reliability of structures.

Performance Optimization: Achieving the desired performance characteristics for specific applications.

Compliance with these standards helps in maintaining the structural integrity of buildings and infrastructure, preventing potential legal and safety issues.

Benefits of Using Cement Testing Labs in Dubai

Quality AssuranceBy rigorously testing cement, labs provide assurance that the material meets the required quality standards. This assurance is essential for maintaining the structural integrity of construction projects.

Risk MitigationIdentifying and addressing potential quality issues early helps in mitigating risks associated with structural failures. Testing labs play a crucial role in detecting defects and ensuring corrective measures are taken.

Cost SavingsUsing high-quality cement reduces the likelihood of structural issues and the associated repair and maintenance costs. Investing in testing services can lead to significant long-term savings.

Enhanced DurabilityEnsuring the quality of cement enhances the durability of structures, prolonging their lifespan and reducing the need for frequent repairs. This durability is especially important in Dubai’s harsh environmental conditions.

Optimized PerformanceComprehensive testing provides valuable data that helps in optimizing the performance of cement for specific applications. This optimization leads to better construction outcomes and improved structural integrity.

The Role of Cement Testing Labs in Dubai’s Construction Industry

Cement testing labs in Dubai are integral to the city’s construction industry. Their role extends beyond quality assurance to include:

Supporting Innovation: Labs contribute to the development of new cement formulations and innovative construction techniques by providing precise data and analysis.

Enhancing Sustainability: By ensuring the optimal use of resources and reducing waste, testing labs support sustainable construction practices.

Educating Stakeholders: Labs provide valuable insights and education to construction professionals, helping them make informed decisions about material selection and usage.

Conclusion

Cement testing labs in Dubai are crucial for ensuring the structural integrity of construction projects. Through comprehensive testing services, advanced techniques, and strict compliance with standards, these labs provide the necessary assurance that the cement used in building and infrastructure projects meets the highest quality standards. This not only enhances the safety and durability of structures but also contributes to the overall success and sustainability of Dubai’s construction industry. By partnering with reputable cement testing labs, construction professionals can ensure that their projects are built on a solid foundation, capable of withstanding the test of time and environmental challenges.

0 notes

Text

Major Types of Industrial Testing in the UK

Industrial testing is a fundamental practice in the United Kingdom, upholding the safety and quality of products across diverse sectors. This crucial process plays a pivotal role in industries such as construction, manufacturing, and healthcare.

In this article, we will explore various types of industrial testing in the UK, including Plastic Testing labs and cement testing labs. Mechanical Testing: Mechanical testing entails evaluating the physical properties of materials, including strength, toughness, and elasticity.

This type of testing ensures that materials can withstand the stresses and strains associated with their intended applications. Tensile testing, compression testing, and hardness testing are some examples of mechanical testing. Chemical Testing: Chemical Testing involves analyzing material composition and identifying impurities or contaminants. This testing is vital for ensuring the safety and quality of products, particularly in sectors such as food, pharmaceuticals, and cosmetics. Chromatography, spectroscopy, and mass spectrometry are common techniques employed in chemical testing. Environmental Testing: Environmental testing examines materials and products for their ability to withstand environmental factors like temperature, humidity, and UV exposure.

This testing ensures that products can endure their intended environments while remaining safe and functional. Thermal testing, humidity testing, and UV testing are among the methods used in environmental testing. Non-Destructive Testing: Non-destructive testing assesses materials and products without causing damage or alteration. This form of testing is critical to ensuring product integrity even after testing. Ultrasonic testing, X-ray testing, and magnetic particle testing are examples of non-destructive testing methods.

Plastics Testing: Plastics testing focuses on examining the physical and chemical properties of plastic materials. This testing guarantees the safety and functionality of plastic products. Tensile testing, impact testing, and flammability testing are common procedures in plastics testing. Accredited plastic testing labs in the UK perform testing on a wide range of plastic materials and products. Cement Testing: Cement testing involves evaluating the properties of cement and concrete materials. This testing ensures the safety and durability of concrete structures, such as buildings, bridges, and roads. Compressive strength testing, water absorption testing, and setting time testing are examples of cement testing procedures. Accredited cement testing labs in the UK conduct testing on various cement and concrete materials.

In conclusion, industrial testing is indispensable in maintaining the safety and quality of products across different sectors in the UK. Mechanical testing, chemical testing, environmental testing, non-destructive testing, plastics testing, and cement testing are some of the key testing types performed. Accredited plastic testing labs and cement testing labs in the UK contribute significantly to ensuring the safety and functionality of materials and products in their respective domains.

0 notes

Text

Synthetic Sapphire Market: Key Industrial Applications

As one of the first gems to be synthesized, synthetic sapphire, or lab-grown sapphire, comprises the exact chemical composition of organic sapphire. Moreover, it is also one of the hardest minerals, following diamond, and is highly durable, as well. According to Inkwood Research, the global synthetic sapphire market is estimated to rise with a CAGR of 6.50% over the forecasted years of 2022 to 2030. The market growth of the region is fuelled by key factors, such as the growing adoption of LED lighting, rising applications in the electronics industry, and technological advancements in the manufacturing process.

Synthetic Sapphire Market – A Detailed Look at Industrial Applications

On account of its excellent properties, sapphire is utilized in several industrial products and applications. For instance, owing to the material’s high scratch resistance, transparency, and hardness, synthetic sapphire is often utilized in ball bearings and wristwatches. Over recent years, the material has also found widespread usage in fingerprint authentication sensors and smartphone lens covers.

Aligning with this, some of the top applications of synthetic sapphire are as follows –

Sapphire Substrates –

Sapphire is characterized by exceptional electrical insulation, good thermal conductivity, transparency, as well as high rigidity properties. As a result, it is a preferred material for substrates and is thus utilized in LED as well as microelectronic circuits and ultra-high-speed integrated circuits.

Sapphire substrates also play a significant role in the production of several other electronic devices, owing to their remarkable electrical properties.

Consumer Electronics –

The expansion of the consumer electronics industry is expected to provide synthetic sapphire manufacturers with lucrative growth opportunities. This is primarily accredited to the material’s growing demand for the production of smartphones, camera lenses, and watches, among other devices.

Moreover, the use of synthetic sapphire as a scratch-resistant material further drives the growth of the consumer electronics segment as a key end-user.

Display –

Sapphire has been used as a covering for cellphone camera lenses, in addition to being tested by manufacturers of electronic tablets for shatter-proof display screens.

Furthermore, sapphire glass is also ideal for display devices subject to significant wear and tear, like smartwatches and fitness trackers.

Optical –

Since sapphire is radiolucent (transparent to X-rays), it is ideal for use in MRI, CT, and various other intraoperative imaging procedures. In addition to resulting in clear imagery, the use of synthetic sapphire in optical applications also enables enhanced diagnostic capability. Furthermore, the material’s thermal conductivity facilitates enhanced cooling, predominantly for laser procedures.

Synthetic sapphire windows are also utilized on a large scale as they are stronger compared to standard glass windows.

Accordingly, as per Inkwood Research’s analysis, the optical segment is projected to dominate the application category during the forecast years.

Synthetic sapphire is also largely used in the medical sector for a varied range of applications. These include endoscope lens covers, scalpels, hematology inspection filters, as well as medical plunger pump parts. Furthermore, the adoption of synthetic sapphire in emerging regions of the Asia-Pacific, such as Thailand, India, and China, is set to rise rapidly over the upcoming years, predominantly on account of the increase in new construction and infrastructure activities.

Top Trend | Government Guidelines Encourage Synthetic Gems Production

The manufacturing process of synthetic sapphire is less polluting and environmentally friendly compared to the production of various alternative materials. Moreover, the material comprises minimal contamination, with negligible defects and grain boundaries, thus providing synthetic sapphire with a wide range of desirable properties. Accordingly, governments of developing economies, such as India, are considering the propositions of the jewelry industry with a view to promoting manufacturing and exports. These predominantly include facilitating shipments through e-commerce and establishing common facility centers.

For instance, as per the Gem & Jewellery Export Promotion Council (GJEPC), India’s government separated the Indian Trade Clarification (ITC) code for rough synthetic gemstones into non-diamonds and diamonds. The initiative is expected to enable organizations to monitor the exact quantities of lab-grown diamonds brought into the jewelry industry, thereby encouraging their wide-scale manufacture. As a result, these factors are expected to contribute to the overall growth of the global synthetic sapphire market during the forecast years.

By Shruti Vanjare

FAQs:

What are some of the key companies operating in the global synthetic sapphire market?

Juropol Sp ZOO, Iljin Display Co Ltd, Namiki Precision Jewel Co Ltd, Crystalwise Technology Inc, and others are among the key companies operating in the global synthetic sapphire market.

What are the top factors driving the Asia-Pacific synthetic sapphire market’s dynamic growth? The growth of the region’s medical as well as consumer electronics industry, rapid construction activities and infrastructural development, as well as the rising demand for LED products, are set to drive the dynamic growth of the Asia-Pacific synthetic sapphire market.

0 notes