#TitaniumRoundBar

Explore tagged Tumblr posts

Text

Comparing fracture toughness: Ti6Al4V (Gr.5) vs. Ti6Al4V (Gr.5) ELI

Certainly:

Due to the low presence of interstitial elements in Ti6Al4V (Gr.5) ELI, it is less likely to propagate cracks, resulting in higher fracture toughness compared to Ti6Al4V (Gr.5).

The significance of fracture toughness in bone implants lies in its ability to prolong implant lifespan, thereby reducing the need for frequent replacements. This ensures sustained functionality in diverse stress environments, ultimately contributing to enhanced patient well-being and orthopedic treatment effectiveness.

Stay tuned for our upcoming post where we discuss another important mechanical parameter required in the medical industry, i.e., Fatigue Strength.

For more information, contact us at [email protected]

#KnowYourTitanium#TitaniumRoundBar#TitaniumSheet#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#Quality#Mechanical#Properties#FractureToughnes#Metallurgy#FractureMechanism#TitaniumImplants#MedicalImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

Best Grade Round Bar Manufacturer in India

Nippon Alloys Inc is a recognised and well-known Round Bar manufacturer in India. A round bar is a long, cylindrical metal bar with a circular cross-section. Our cutting-edge technology and equipment enable us to produce Titanium Round Bars with pinpoint accuracy.We are also one of the biggest Phosphor Bronze Sheet and Phosphor Bronze Bar Manufacturers in India.

Round bars are commonly made from materials such as steel, aluminium, brass, or copper, and can be found in a variety of sizes and lengths. Hastelloy round bars, Monel round bars, Inconel round bars, and Alloy 20 round bars are just a few of the products we provide to our customers.They are also used in the fabrication of components for machinery, tools, and equipment.

Product Source: Titanium round bars manufacturer in India

Website: nipponalloys.com

Product Source: Titanium round bars

Also Visit: Round bars manufacturer in India

#RoundbarmanufacturerinIndia#Hastelloyroundbars#Inconelroundbars#Titaniumroundbars#Alloy20roundbars#PhosphorBronzeSheet

0 notes

Text

Titanium Sheets and roundbars Manufacturers india

Titanium Stockiest & Suppliers.

grade1 / grade2 /grade9 / 6Al-4V or grade 5 / 6AL-4V ELI or grade 23 / grade 12.

Available in Roundbars,Wires,Sheets,Plates,Welding rods,flanges & fittings.

Titanium is known as a transition metal on the periodic table of elements denoted by the symbol Ti. It is a lightweight, silver-gray material with an atomic number of 22 and an atomic weight of 47.90. It has a density of 4510 kg/m 3 , which is somewhere between the densities of aluminum and stainless steel.as we titanium Sheets and roundbars Manufacturers india It has a melting point of roughly 3,032°F (1,667°C) and a boiling point of 5,948°F (3,287 C). It behaves chemically similar to zirconium and silicon. It has excellent corrosion resistance and a high strength to weight ratio.

#titaniummanufacturers#titaniumsuppliers#titaniumroundbars#titaniumsheetsandplates#titaniumpipes#titaniumflanges#tianiumfittings#titaniumwires#titaniumelectrode

0 notes

Text

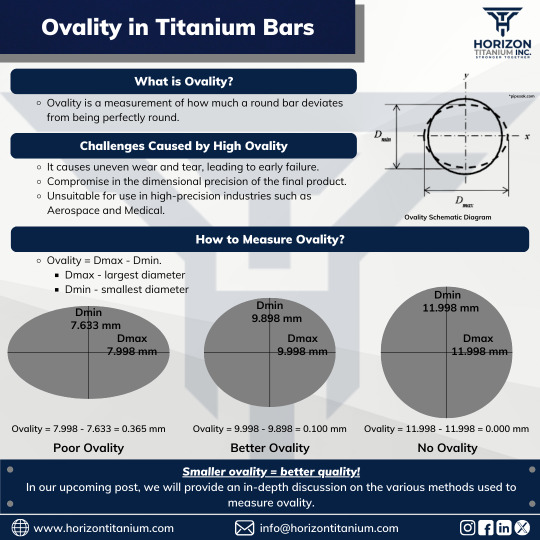

Understanding Ovality

In industries where precision is essential—like aerospace and medical devices—every millimeter plays a critical role. Ovality, the measure of roundness deviation, becomes a key factor in ensuring quality, reliability, and durability.

Even slight deviations in roundness can affect mechanical alignment, durability, and overall functionality. That’s why maintaining tight control over ovality is a priority in delivering reliable products.

Precision isn't just a goal; it’s a necessity for industries shaping the future. Let's continue to innovate with attention to detail and excellence in quality.

For more information, please write us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ovality#PrecisionMatters#Ti6Al4VELI#EngineeringExcellence#MaterialScience#QualityFocus#Quality#Reliability#Durability#Roundness#Dimensional#AerospaceEngineering#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

Comparing Fatigue Strength: Ti6Al4V (Gr.5) vs. Ti6Al4V (Gr.5) ELI

High fatigue property in titanium implants is crucial, as it ensures the implants can withstand the constant mechanical stresses and strains experienced within the human body, maintaining structural integrity and longevity.

Titanium Ti6Al4V (Gr.5) ELI contains fewer defects, discontinuities, and stress concentrations as compared to Ti6Al4V (Gr.5), which results in high fatigue strength.

This leads to prolonged life duration of implants made from Titanium Ti6Al4V (Gr.5) ELI in comparison to Titanium Ti6Al4V (Gr.5).

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#FatigueStrength#CyclicLoad#FatigueFracture#FractureMechanism#Metallurgy#Quality#TitaniumImplants#MedicalImplants#OrthopaedicImplants#MedicalDevices#TitaniumSupplier#HorizonTitanium#StrongerTogether

0 notes

Text

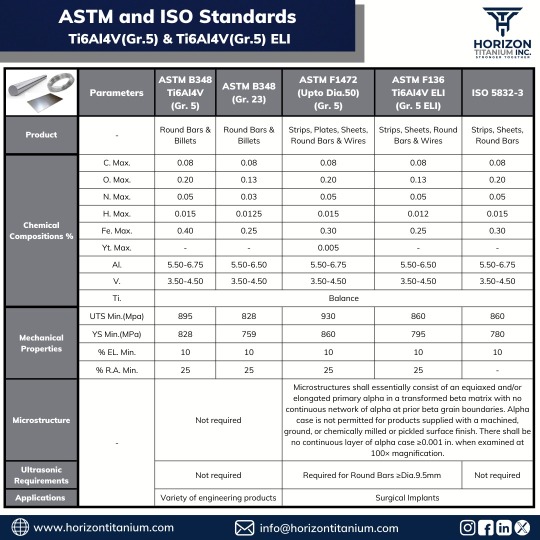

Looking for best Titanium for Surgical Implants?

Dive into the world of Titanium standards, comparing ASTM B348, ASTM F1472, ASTM F136, and ISO 5832-3 for Ti6Al4V (Gr.5), Titanium Gr.23 & Ti6Al4V (Gr.5) ELI.

Learn about product types, chemical compositions, mechanical properties, microstructure, and ultrasonic testing requirements for top-tier medical implants.

Stay tuned for our upcoming post, exploring important mechanical properties like fracture toughness and fatigue strength—the foundation of medical implants.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#TitaniumWires#TitaniumStrips#TitaniumPlates#TitaniumStandards#ASTMB348#ASTMF136#ASTMF1472#ISO5832_3#ChemicalComposition#MechanicalProperties#Microstructure#UltrasonicRequirements#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#MedicalImplants#SurgicalImplants#OrthopeadicImplants#OrthopeadicApplication#Orthopeadic#TitaniumSupplier#MedicalGrade#HorizonTitanium#StrongerTogether

0 notes

Text

At Horizon Titanium, we take great pride in our commitment to delivering titanium materials of the highest caliber, adhering rigorously to ISO 20160 Microstructure Class A1 to A4 standards. Our focus on microstructure excellence is paramount, ensuring that our titanium products exhibit a superior and consistent fine structure—particularly advantageous for critical applications such as medical devices where strength and reliability are non-negotiable.

Why choose Horizon Titanium? Our dedication to precision and quality sets us apart. With a meticulous approach to microstructural control, we provide titanium materials that not only meet but exceed industry standards. For those seeking exceptional materials for medical applications, Horizon Titanium is the trusted partner.

Contact us now for titanium materials that redefine excellence in microstructure for critical applications.

#KnowYourTitanium#Titanium#TitaniumRoundBars#Homogenous#Microstructure#Metallurgy#MicrostructureAnalysis#ASTM#ASTMF136#ISO#ISO5832_3#ExceptionalMetallurgy#MedicalApplications#Quality#MedicalImplants#TitaniumMaterials#HorizonTitanium#StrongerTogether

0 notes

Text

Selecting the ideal material for critical applications demands meticulous attention to detail, and at Horizon Titanium Inc., we approach this process with the utmost care and thoroughness.

We've recently completed rigorous testing following the ASTM F136 specification, with a focus on % Elongation—a crucial factor for applications requiring longevity and reliability. Our Titanium round bars have not only met but exceeded the stringent ASTM F136 requirements. With an average elongation of 18%, our material has some impressive elongation, especially beneficial for critical applications like in the medical field.

These results reinforce our commitment to providing top-notch materials that go beyond industry standards. You can count on Horizon Titanium Inc. for materials that not only meet but exceed your expectations.

Reach out to us today to learn more about how our Titanium round bars, with superior elongation properties, can add value to your products.

#KnowYourTitanium#Titanium#TitaniumRoundBars#Elongation#MechanicalProperties#Testing#ASTM#ASTMF136#ExceptionalQuality#MedicalApplications#Quality#MedicalImplants#TitaniumMaterials#HorizonTitanium#StrongerTogether

0 notes

Text

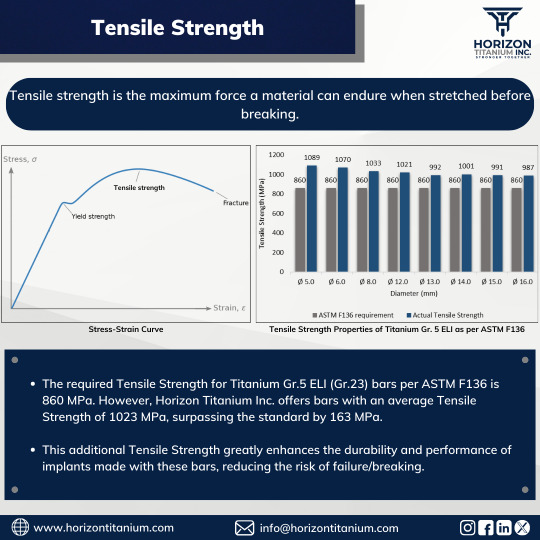

Our recent test shows our Titanium bars, vital for medical implants, exceed the ASTM F136 Tensile strength standard by an impressive 163 MPa on average.

This result solidifies our material as one of the strongest on the market, promising unmatched performance, especially in the medical field.

Tensile strength, a key factor in implant durability, measures a material's ability to withstand stretching forces.

Trust our Titanium bars for exceptional strength and reliability in your critical applications.

Contact us today at [email protected] to learn more about how our top-notch Titanium materials can elevate your products to new heights!

#KnowYourTitanium#Titanium#TitaniumRoundBars#TensileStrength#MechanicalProperties#Testing#ASTM#ASTMF136#ExceptionalQuality#MedicalApplications#Quality#MedicalImplants#TitaniumMaterials#HorizonTitanium#StrongerTogether

0 notes

Text

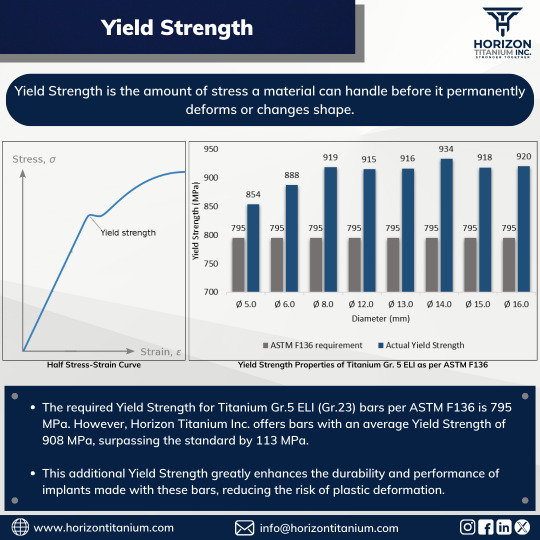

At Horizon Titanium Inc., we've been on a journey to ensure top-quality titanium materials for various applications, particularly medical implants. We recently put our titanium bars to the test, measuring their Yield Strength against the stringent ASTM F136 standard.

We're thrilled to report that our titanium bars consistently exceeded the rigorous ASTM requirements. This speaks to the exceptional quality and reliability of our materials for medical applications.

For inquiries or more information, reach out to us at [email protected].

#KnowYourTitanium#Titanium#TitaniumRoundBars#YieldStrength#MechanicalProperties#Testing#ASTM#ASTMF136#ExceptionalQuality#MedicalApplications#Quality#MedicalImplants#TitaniumMaterials#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Today, in our ongoing video series on Titanium bar manufacturing, we've highlighted the final stages of manufacturing. This part highlights how we carefully mark and pack the Titanium Round bars to make sure they're top quality and easy to track.

Distinguishing Marking and Packaging Process Parameters:

Marking: Our Titanium Round bars marked with “Company name, ASTM/ISO standards, Grade, Size, Length, Heat number, and Lot number”

Packaging: Based on Size 1-50 No’s bundle preparation Each bundle packed in the recycling plastic bag Each bundle packed in an export-worthy wooden box

Distinguishing Marking and Packaging Process Benefits:

Marking: Traceability Compliance Quality assurance Process efficiency Customer confidence

Packaging: Surface protection Systematic organization Environmental responsibility Safe transport

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Marking#ASTMF136#ISO5832_3#Size#Length#HeatNumber#LotNumber#Packaging#BundlePreparations#EcoFriendlyPlasticBag#ExportWorthyWoodenBox#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In our ongoing video series about the manufacturing process of Titanium bars, today we've shared the finishing steps of manufacturing. Here, we focus on chamfering and ensuring that Titanium Round Bars are of the highest quality.

Distinguishing Process Parameters:

Chamfering: Controlled feed rate Controlled cutting speed Controlled depth of cut Continuous coolant and lubrication

Quality Analysis: Material qualifications as per ASTM and ISO international specification Testing carried out as per International Testing Procedures

Distinguishing Chamfered and Tested Bars Quality:

Reduced stress concentration at both side edges Machining benefits Easy to handle Enhanced workpiece functionality Chemical analysis, Tensile testing, Ultrasonic testing, Metallurgical analysis, Dimensional analysis, and Analysis reports

Stay tuned as we take a closer look at how we make Titanium bars for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Chamfering#EasytoHandle#ReduceStressConcentrations#QualityAnalysis#ISO#ASTM#Testing#MaterialQualifications#Specifications#Standards#ChemicalAnalysis#TensileTesting#UltrasonicTesting#MetallurgicalAnalysis#DimensionalAnalysis#AnalysisReports#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we push forward in our commitment to perfect Titanium bar production, we've now arrived at a pivotal point—the ninth step. This phase revolves around the intricacies of Peeling and Centerless Grinding for Titanium Round Bars.

Distinguishing Process Parameters:

Peeling: Controlled peel depth Controlled feeding rate Controlled workpiece temperature Continuous coolant and lubrication Peeling forces monitoring

Centerless Grinding: Controlled workpiece speed Controlled grinding wheel speed Controlled residual stress Controlled grinding wheel gap Continuous coolant and lubrication

Distinguishing Peeled and Centerless Grinded Bars Quality:

Free from Alpha Case layer Precise tolerance with a 10-micron diameter difference throughout the lot size Mirror-finished surface Free from surface imperfections

Stay tuned as we navigate this journey together, granting you a comprehensive view of our production methods. Our enthusiasm lies in unveiling each essential stage in the precise manufacturing of Titanium bars, exclusively intended for medical use.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#PeelingProcess#CenterlessGrinding#FreeofAlphaCase#PreciseTolerance#MirrorFinishedSurface#FreefromSurfaceImperfections#Polishing#Microstructure#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Continuing our journey to enhance Titanium bar production, we've reached a critical juncture—the eighth step. This phase involves the removal of Hydrogen from Titanium Round Bars using a Vacuum Heat Treatment Furnace.

Distinguishing Process Parameters:

Heat treatment under vacuum atmosphere Controlled gas atmosphere Controlled pressure, heating and cooling rate Monitoring and control systems

Distinguishing Vacuum Heat-Treated Bars Quality:

High Purity Free of microstructure imperfections Low hydrogen content Higher fracture toughness and fatigue strength

Stay connected as we journey through this exploration, providing you with an in-depth view of our production techniques. We are enthusiastic about unveiling every critical stage in the precise creation of Titanium bars designed exclusively for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#VacuumHeatTreatment#HydrogenRemoval#Heating#ELI#HighPurity#Microstructure#FractureToughness#FatigueStrength#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we advance through our Titanium bar manufacturing process, we've now reached the pivotal sixth step, where we craft Titanium round bars from Titanium Billet using a hot rolling process

Distinguishing Process Parameters:

Controlled rolling temperature Controlled deformation speed Uniform and close tolerance Process monitoring and control systems

Distinguishing Hot Rolled Bars Quality:

Material consistency Uniform microstructure Dimensional accuracy Defect-free bar

Stay connected along with us as we continue on this journey, providing you with an in-depth exploration of our production process. We are excited to share every important stage in the creation of high-quality Titanium bars designed specifically for medical applications

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumHotRolledBars#PreFinishing#PreHeating#TitaniumHotRolling#HotRolling#SizeReduction#SemiAutomaticHotRolling#ELI#UniformMetallurgy#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes