Text

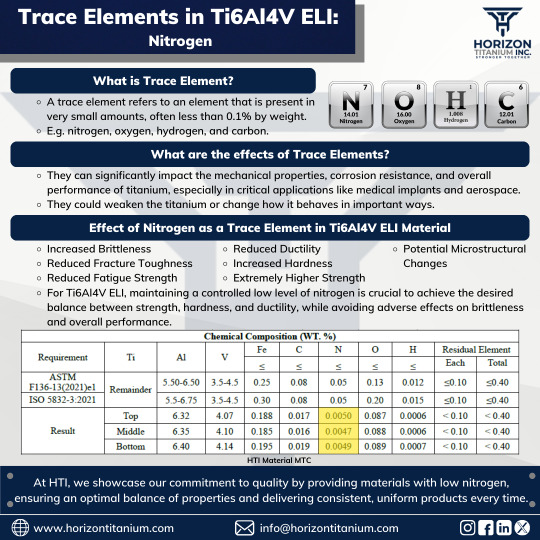

Trace Elements in Ti6Al4V ELI: The Impact of Nitrogen

When it comes to titanium alloys like Ti6Al4V ELI, trace elements such as nitrogen can have a significant impact on the material's mechanical properties. In this post, we dive deep into how trace amounts of nitrogen affect brittleness, fracture toughness, and strength.

Why does this matter?

1. Nitrogen can make your titanium alloy stronger, but there’s a balance! Too much can make it brittle. Too little, and you might lose strength. The key is finding that perfect balance.

2. In medical-grade titanium like Ti6Al4V ELI, precision is everything, and keeping nitrogen levels controlled ensures your material performs under the most demanding conditions.

Did you know? If the nitrogen content is low but your material still boasts high strength, you’re working with premium titanium! This means the strength is purely from the titanium and not from unwanted nitride phases like titanium nitride, which could weaken the material's long-term performance.

At HTI, we deliver consistent quality, ensuring that the material you get is optimized for strength, ductility, and durability—making it perfect for critical applications like medical implants.

For more technical insights, check out the composition chart in the post!

Let’s talk titanium! Have questions about material quality or trace elements? Drop a comment or reach out at [email protected]

#KnowYourTitanium#Titanium#Ti6Al4VELI#MaterialScience#TraceElements#NitrogenImpact#ChemicalComposition#MedicalGradeTitanium#Metallurgy#EngineeringExcellence#AdvancedMaterials#QualityControl#TitaniumStrength#TitaniumAlloys#PrecisionEngineering#HorizonTitanium#StrongerTogether

0 notes

Text

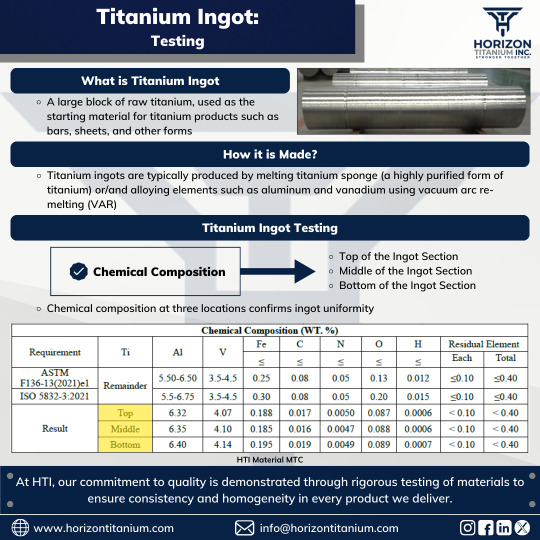

Titanium ingots play a crucial role as the starting material for producing bars, sheets, and other forms of titanium products used in medical devices and orthopedic implants.

What makes HTI titanium bars perfect for medical applications?

Quality and consistency are non-negotiable. That's why we ensure that every ingot undergoes rigorous testing, with special attention to key quality parameters such as:

1. Chemical Composition: Ensured uniformity through testing at the top, middle, and bottom sections.

2. Alloying Elements: Optimal levels of aluminum and vanadium for strength and durability.

3. Purity: Low levels of residual elements to meet medical standards, adhering to ASTM F136-13 and ISO 5832-3 guidelines.

These parameters ensure the material's strength, reliability, and compatibility for medical implants and devices.

At Horizon Titanium Inc., we source top-grade titanium bars to meet the stringent demands of the medical field.

For more information, contact us at [email protected]

#KnowYourTitanium#TitaniumIngot#Homogenous#Uniform#ChemicalComposition#MedicalGradeTitanium#OrthopedicImplants#MaterialQuality#MedicalIndustry#SupplierExcellence#HorizonTitanium#StrongerTogether

0 notes

Text

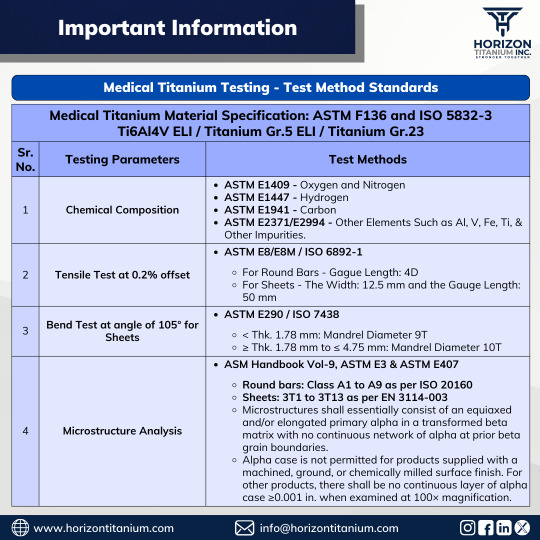

At Horizon Titanium, we believe in the importance of accurate testing for medical-grade titanium. We're sharing essential insights on the correct testing methods and standards to ensure the highest quality.

Need more information? We're here to help—just reach out to us at [email protected]

#KnowYourTitanium#TitaniumTesting#MedicalGradeTitanium#Ti6Al4VELI#Grade5ELI#Grade23#ASTMF136#ISO5832_3#QualityAssurance#Specification#TestMethod#ChemicalComposition#ASTME1409#ASTME1447#ASTME1941#Aluminium#Vanadium#ASTME2371#Mechanical#TensileTest#ASTME8#BendTest#ASTME290#MicrostructureAnalysis#ASMHandbookVol_9#MicrostructureClass#ISO20160#EN3114_003#HorizonTitanium#StrongerTogether

0 notes

Text

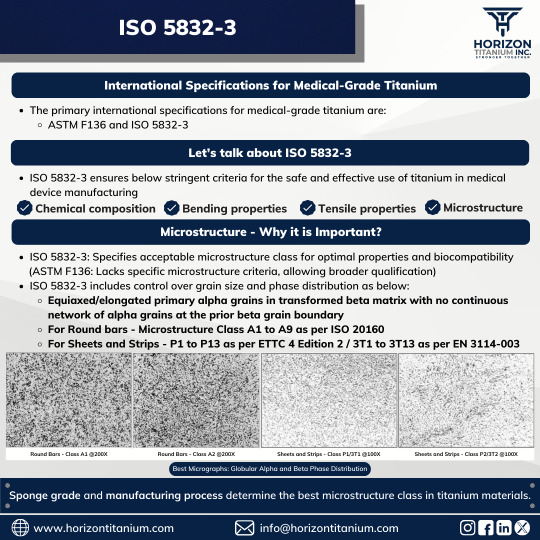

The properties of metals are determined by their metallurgy, and for applications such as medical use, these properties must be optimized. To achieve this, international standards specify the required microstructure. Two key standards for medical titanium materials are ASTM F136 and ISO 5832-3.

ISO 5832-3 defines microstructure classes with specific alpha and beta morphologies and phase distributions, detailed through micrographs. In contrast, ASTM F136 outlines microstructure requirements without specifying exact classes or providing micrographs, thus omitting precise details on alpha and beta phase distributions.

To illustrate this, consider the example of the color blue. ASTM F136 broadly accepts any shade of blue for medical applications. However, ISO 5832-3 specifies exact color codes, categorizing shades from Class Sr. No. A1 to A9, and thus sets rigorous microstructure requirements for medical grades. ASTM F136 lacks this level of detail and does not categorize shades of blue, merely stating that any blue is acceptable for medical use.

Therefore, adhering to the ISO 5832-3 standard is crucial for ensuring the precise microstructure requirements in Titanium materials needed for medical device manufacturing.

To know more about the importance of microstructure in titanium materials for medical applications, write us at [email protected]

#KnowYourTitanium#Titanium#Metallurgy#ISO5832_3#ASTMF136#Microstructure#MicrostructureClass#ISO20160#EN3114_003#SpongeGrade#TitaniumPurity#ManufacturingProcess#Biocompatibility#MaterialsScience#Standards#MedicalGradeTitanium#TitaniumImplants#PrecisionMicrostructure#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

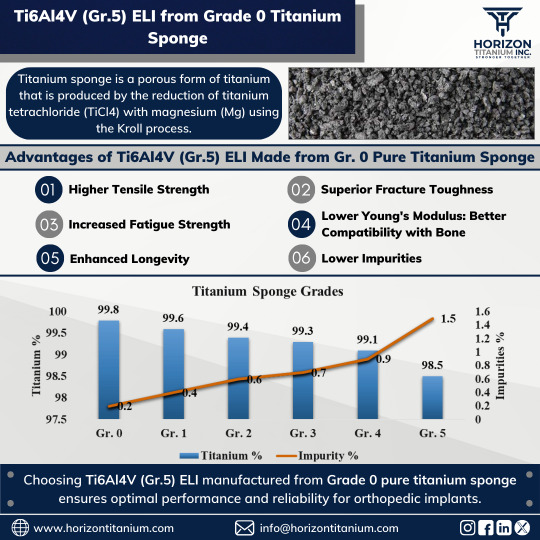

Titanium is vital in the medical field due to its biocompatibility, strength, and corrosion resistance. However, the quality of medical-grade titanium depends on the grade of titanium sponge used in production. Let's explore how titanium sponge impact the quality of titanium for medical devices and implants.

What is Titanium Sponge?

Titanium sponge, made through the Kroll process, is a porous, brittle form of titanium. It needs further processing and alloying with elements like aluminum and vanadium (Ti6Al4V (Gr.5) ELI) to be used in manufacturing medical devices. Its quality and purity are critical for the final titanium properties.

Importance of Choosing the Right Grade

The grade of titanium sponge used to manufacture titanium material for medical applications has a profound impact on the quality and performance of the final product. By selecting the right grade, manufacturers can ensure that medical devices made from high-purity Sponge Gr. 0 material will meet the stringent standards required for medical use, providing safe and effective solutions for patients.

If you need any further information, reach out at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumSpongeGrade0#TitaniumManufacturing#KrollProcess#Ti6Al4VELI#Grade5ELI#HigherTensileStrength#SuperiorFractureToughness#IncreasedFatigueStrength#LowerYoungModulus#EnhancedLongevity#LowerImpurities#MaterialScience#TitaniumQuality#MedicalGradeTitanium#TitaniumImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

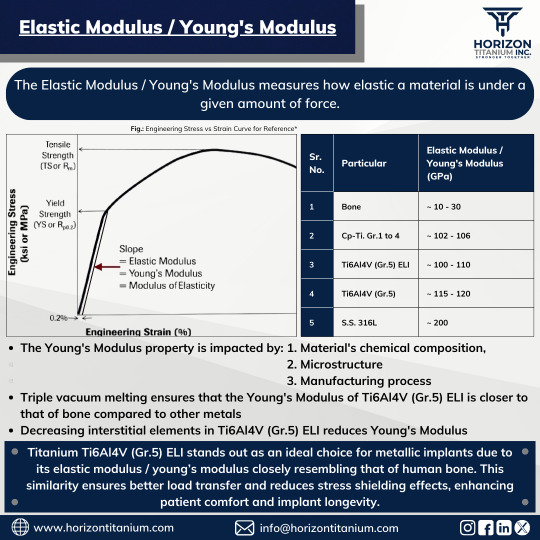

Stress shielding is a phenomenon observed when metal implants, such as bone plates and screws, are employed in the treatment of fractures or during joint replacement surgery.

These metal implants exhibit greater stiffness compared to the surrounding bone, thus reducing the stress experienced by the bone.

Consequently, this alteration in stress distribution can trigger bone resorption, a process wherein bone is broken down and absorbed by the body, resulting in a loss of bone mass around the implant.

To prevent stress shielding, it's best if the implant material's elasticity is as close as that of the bone.

Among the metallic materials used in implants, Ti6Al4V ELI (Grade 5 ELI) possesses the closest elasticity to that of bone.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#StressShielding#YoungsModulus#Elasticity#MedicalImplants#BonePlate#Screw#JointReplacementSurgery#Stiffness#StressDistribution#BoneResorption#BoneDensity#BoneHealth#BoneDegradation#Grade5ELI#Ti6Al4VELI#TitaniumSupplier#OrthopedicImplants#TitaniumImplants#HorizonTitanium#StrongerTogether

0 notes

Text

Metal implants play a crucial role in biomedical engineering, offering durability and reliability for bone reconstruction.

With superior mechanical properties compared to ceramics and polymers, metals like Titanium Ti-6Al-4V (Gr.5) ELI are preferred for handling heavy loads. In fact, 80% of implants are made from metal, with Titanium Ti-6Al-4V (Gr.5) ELI being the major choice, especially due to its higher fatigue strength and fracture toughness.

The value of the Elastic Modulus / Young's Modulus, should closely match that of the bone to minimize the stress-shielding effect between the bone and the implant. We will delve into more details about the stress-shielding effect in our next post.

Ti-6Al-4V ELI closely matches bone's Young's modulus as compared to other metallic implantable materials, making it a top choice for bone replacements.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#ElasticModulus#YoungsModulus#ModulusofElasticity#Elasticity#StressStrainCurve#EngineeringStressStrainCurve#BoneYoungsModulus#TitaniumYoungsModulus#StainlessSteelYoungsModulus#StressShieldingEffects#CPTitanium#Ti6Al4V#Ti6Al4VELI#SS316L#ChemicalComposition#Microstructure#3VAR#ELI#TitaniumImplant#OrthopeadicImplant#PatientComfort#ImplantLongevity#HorizonTitanium#StrongerTogether

1 note

·

View note

Text

Comparing Fatigue Strength: Ti6Al4V (Gr.5) vs. Ti6Al4V (Gr.5) ELI

High fatigue property in titanium implants is crucial, as it ensures the implants can withstand the constant mechanical stresses and strains experienced within the human body, maintaining structural integrity and longevity.

Titanium Ti6Al4V (Gr.5) ELI contains fewer defects, discontinuities, and stress concentrations as compared to Ti6Al4V (Gr.5), which results in high fatigue strength.

This leads to prolonged life duration of implants made from Titanium Ti6Al4V (Gr.5) ELI in comparison to Titanium Ti6Al4V (Gr.5).

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#FatigueStrength#CyclicLoad#FatigueFracture#FractureMechanism#Metallurgy#Quality#TitaniumImplants#MedicalImplants#OrthopaedicImplants#MedicalDevices#TitaniumSupplier#HorizonTitanium#StrongerTogether

0 notes

Text

Comparing fracture toughness: Ti6Al4V (Gr.5) vs. Ti6Al4V (Gr.5) ELI

Certainly:

Due to the low presence of interstitial elements in Ti6Al4V (Gr.5) ELI, it is less likely to propagate cracks, resulting in higher fracture toughness compared to Ti6Al4V (Gr.5).

The significance of fracture toughness in bone implants lies in its ability to prolong implant lifespan, thereby reducing the need for frequent replacements. This ensures sustained functionality in diverse stress environments, ultimately contributing to enhanced patient well-being and orthopedic treatment effectiveness.

Stay tuned for our upcoming post where we discuss another important mechanical parameter required in the medical industry, i.e., Fatigue Strength.

For more information, contact us at [email protected]

#KnowYourTitanium#TitaniumRoundBar#TitaniumSheet#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#Quality#Mechanical#Properties#FractureToughnes#Metallurgy#FractureMechanism#TitaniumImplants#MedicalImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

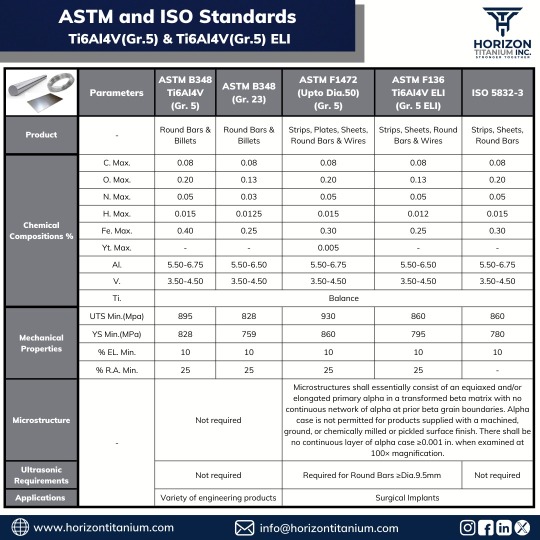

Looking for best Titanium for Surgical Implants?

Dive into the world of Titanium standards, comparing ASTM B348, ASTM F1472, ASTM F136, and ISO 5832-3 for Ti6Al4V (Gr.5), Titanium Gr.23 & Ti6Al4V (Gr.5) ELI.

Learn about product types, chemical compositions, mechanical properties, microstructure, and ultrasonic testing requirements for top-tier medical implants.

Stay tuned for our upcoming post, exploring important mechanical properties like fracture toughness and fatigue strength—the foundation of medical implants.

For more information, contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#TitaniumSheets#TitaniumWires#TitaniumStrips#TitaniumPlates#TitaniumStandards#ASTMB348#ASTMF136#ASTMF1472#ISO5832_3#ChemicalComposition#MechanicalProperties#Microstructure#UltrasonicRequirements#Ti6Al4V#Ti6Al4VELI#Grade5#Grade5ELI#MedicalImplants#SurgicalImplants#OrthopeadicImplants#OrthopeadicApplication#Orthopeadic#TitaniumSupplier#MedicalGrade#HorizonTitanium#StrongerTogether

0 notes

Text

The muffle heating technique empowers orthopaedic implant manufacturers, providing precise temperature control and ensuring uniform Titanium heating. By carefully controlling atmospheric conditions, oxide formation is prevented, safeguarding the integrity of Titanium.

Explore how this correct heating method enhances mechanical properties, elevating strength and fatigue resistance to unparalleled levels. Additionally, this technique minimises thermal gradients within the Titanium, mitigating the risk of thermal stress-induced deformations and also enhances the microstructural properties, resulting in superior mechanical performance. Experience the precision of tailored heating protocols, designed to meet the demands of orthopaedic implant manufacturing while ensuring consistent quality and reliability.

For more information on optimal titanium heating practices, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumHeating#MuffleFurnace#UniformHeating#HomogeneousStructure#AlphaCaseFree#ImprovedMechanicalProperties#HorizonTitanium#StrongerTogether

0 notes

Text

Heating Titanium is crucial for ensuring top-notch quality products. However, conventional methods can sometimes lead to undesirable outcomes. When Titanium is heated in open air or subjected to induction heating, it reacts with atmospheric gases, risking compromised quality. Moreover, with induction heating, only the outer surface receives adequate heat, leaving the inner layers insufficiently heated. This imbalance can lead to titanium failure, often resulting in cracking.

Stay tuned for our upcoming post, where we'll dive into the correct techniques for heating Titanium, ensuring optimal performance and durability.

#KnowYourTitanium#Titanium#TitaniumHeating#OpenAirHeating#InductionHeating#AlphaCaseFormation#UnevenHeating#SurfaceContamination#InhomogeneousMicrostructure#DiminishedMechanicalProperties#HorizonTitanium#StrongerTogether

0 notes

Text

0 notes