#Top Quality Granulation Lines For Sale

Text

Granulation Lines Manufacturer

Neocorp is one of the best granulation lines manufacturer in India. We offer a wide range of granulation equipment including high-shear mixers, fluid bed processors and dry granulation systems. Our granulation equipment is the highest caliber, delivering outstanding performance and functionality. With our expertise and commitment to excellence, we provide a granulation lines that surpasses industry standards and meets your production needs.

#Best Quality Granulation Lines#Granulation Lines Manufacturer#Granulation lines#Top Quality Granulation Lines For Sale

2 notes

·

View notes

Text

Dairy By-Products Market Trends, Share Analysis, Key Companies, and Forecast To 2022-2030

Market Insight

The dairy by-products market 2022 can attain a decent CAGR of 5.4% between 2022 and 2030 (analysis period), suggests Market Research Future (MRFR). We will provide COVID-19 impact analysis with the report, along with all the extensive key developments in the market post the coronavirus disease outbreak.

Primary Drivers and Challenges

Sales of milk and milk products like butter and cheese has been escalating in line with the global population. High-end and advanced technologies are increasingly being adopted to cater to the growing consumer need by focusing on boosting the milk processing capacity and striving to maintain the product quality. The dairy sector is extremely localized due to milk products’ perishable nature. The surging adoption of technologically innovative transportation measures to maintain the quality and efficiency of the milk-based goods during long-distance transport is deemed to work in favor of the dairy by-products market.

Government arbitration has been a major factor in the regulation of the global market growth. The government bodies in the prominent dairy-producing nations like Canada are known for their active involvement in price and quantity monitoring of key dairy by-products. The government also monitors the techniques and processes involved in the storage of dairy by-products, with the aim to ensure the quality for extended durations and prevent wastage. Favorable regulations formed by the government to avoid fluctuations in global market prices and the increased prevalence of sedentary lifestyles are projected to benefit the global market. Bad eating habits along with the rising awareness level with regard to nutritional foods among consumers also ensure that the dairy by-products market progresses smoothly over the coming years.

Novel diary by-products with better quality and higher nutritional content are progressively being introduced by renowned firms to capture a wide customer base in the market. Some of the most popular products are toned milk, low-fat energy drinks, skimmed milk, savory yogurt dip and seasonal fruit yogurts. Many of the companies are putting a new spin on their products, be it new flavors or addition of low sugar or sugar free products that caters to health conscious or diabetic consumers. For instance, in November 2020, Ellenos launched Ellenos Milk + Fruit, which is a Greek Yogurt made from fresh milk that has been derived directly from one local farmer, while the fruit puree is made in-house using a couple of whole food ingredients.

Market Segmentation

Type, form and application are the top market segments listed in the MRFR report.

Dairy by-products are available in different types, namely ghee residue, whey, and others. Among these, the whey segment controls the biggest share since it observes high use in the manufacturing of protein beverages as well as nutritional supplements.

Dairy by-products market share come various forms, such as granules, powder, liquid, and others. Between these, the powder segment is in the lead with the primary reason being the soaring use in functional food & beverages and supplements. The powdered form is comparatively stable and easy to use compared to other forms.

The key applications of these products are functional beverages, functional food, dietary supplements, nutraceuticals, and more. The dietary supplements note significant demand due to their high nutritional and functional properties.

Regional Study

The regional study of the dairy by-products industry has covered Europe, Asia Pacific/APAC, North America, along with rest of the world (RoW).

The biggest market for dairy by-products is North America, while Europe is the second most lucrative region. The substantial demand for nutritional rich products with high protein content in the United States has boosted the sales of dairy by-products market trends. High awareness among people about the nutritional content in various products and the rising introduction of modern equipment for milk processing also add to the regional market’s value. The bakery sector in the region is one of the key end-users that make extensive use of dairy by-products like cheese, butter and cream, for producing varieties of bread and biscuits.

APAC is touted to be the fastest progressing market between 2022 and 2030, since the region is observing a massive demand for dietary supplements. Expanding population, surging uptake of dairy products, and the rapid economic development in the region also act as key growth rendering factors in the regional market.

Key Market Firms

Some of the key dairy by-products market players firms mentioned in the MRFR report include Danone, Inc. (Canada), Groupe Lactalis S.A. (France), Saputo Inc. (Canada), Fonterra Co-operative Group Ltd. (New Zealand), Nestle S.A. (Switzerland), Dairy Farmers of America, Inc. (U.S.), Koninklijke FrieslandCampina NV (the Netherlands), Inner Mongolia Yili Industrial Group Co., Ltd. (China), Arla Foods amba (Denmark), China Mengniu Dairy Company Ltd. (China), and more.

NOTE: Our Team of Researchers are Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

Contact Us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

0 notes

Text

Filling machine applications and their types

Filling machines are devices that are intended to aid in the process of packaging finished products especially food and beverage products, into a suitable container which can be easily transported to the retailer and consumer without getting spoilt or tampered so that the contents remain safe and intact. Fillers, by which name they are generally referred to, are filling machines, and these fillers are not only useful in filling food and beverage products but are also employed in other products too.

Apart from food and other edible products, filling machines are used to fill shampoos, oils, ointments, pastes, glues, and a variety of other daily-use products as well. These products are filled by various filling machines into a bottle, pouch, or can, depending on the nature and physical state of the product. Since the usage of filling varies, accordingly, different kinds of fillers or filling machines are employed in the packaging sector or industry.

Usually, the type of filling machine that has to be used is determined by the nature, type, and physical state of the product that has to be filled. Apart from this, other requirements include the level of quality to be retained, shelf-life, availability to the consumer, feasibility of the type of packaging, and other different variables. Since the type of products may be solid, semi-solids, liquids that are free flowing, liquids that are viscous etc., any filling machine with more flexibility and adaptability are preferred accordingly. Selecting the proper filling machine can surely increase the production line's capacities, enhance sales, and contribute positively to the business's success.

Liquid filling machines or free flow fillers are employed mostly in the food and beverage industry since the dispensing capacity is very precise, especially in the case of liquid products where the need for filling various types of containers such as glass or plastic bottles, paper or thermocol cartons, tin or plastic cans, or cups must be fulfilled. While this filler is used in cases of liquids like mineral water, carbonated or soft drinks, sauces, cooking oil, and soup, the machine comes in manual, fully automatic liquid filling machine, and semi-automatic liquid filling machine variants for more convenience.

Other kinds of filling machines are powder filling machines used in filling free-flowing as well as non-free-flowing granulated products, vibratory weigh filling machines employed in controlled dispersal of unsuitable products, capsule fillers made use of in the pharmaceutical sector, and positive displacement pump fillers mainly used in the case of high-viscosity liquids such as gels, creams, and lotions. Feigeasia, a leading company for top-quality filling machines for liquid and pasty products, delivers quality products and appropriate and flexible solutions regarding filling machine technologies that are exceptional and strategic and meet needs in all respects.

#liquid filling machine#fully automatic liquid filling machine#semi-automatic liquid filling machine

0 notes

Text

Spunbond Nonwoven Fabric Line Manufacturer & Supplier|Made In India

Our Non Woven material, which are known for their toughness, are optimal for developing a great equilibrium between product use-life and cost. We have actually devoted to continue generating and exporting PP (Polypropylene) Spunbond Nonwoven Fabric, PET Spunbond Nonwoven Fabric, SMS Non Woven Polypropylene Fabric, SSMMS Non Woven Polypropylene Fabric, Breathable laminated non woven fabric in delhi.

FavouriteHub was founded in 2011 in Agra City, are non-woven material suppliers as well as focused on creating as well as distributing a variety of nonwoven products. All of our items are made based on the worldwide quality requirements, with the finest quality resources sourced from several of the marketplace's most trustworthy providers.

We can make products to satisfy our customers' bulk requirements due to our advanced infrastructure plant. We have actually sculpted an excellent location for ourselves as pp non-woven fabric producer in Kerala in both regional and international markets as one of the most trustworthy one-point provider for different products such as Geotextiles, PP Woven polypropylene fabric, PP/ PET Spunbond Nonwoven, and so forth. With 11 years of enriched experience, we have expanded multi-fold and now have procedures in the United Statesand India.

OBTAIN CALL FROM OUR SALES MANAGER

Spunbond Nonwoven textile

Spunbond is very adaptable, fulfilling the requirements of a vast array of products in the clinical, sanitary, as well as commercial markets. The cloth is breathable, soft, light, chemical immune, safe, as well as eco-friendly.

We offer a varied array of Nonwovens to our customers in Chennai, Coimbatore, Madurai, Tiruchirappalli, Tiruppur, Salem, Erode, Vellore, as well as other cities of karnatka, every one of which have a variety of applications in the medical area. These are made using ingenious reicofil lines from reifenhauser, Germany, and have exceptional skin-friendliness features. As a result of this attribute, the nonwoven is optimal for hygienic items.

Our product variety uses exceptional features such as breathability, water absorbency, UV resistance, nontoxicity, soft qualities, and also many more. Additionally, it is readily available in a wide range of shades, sizes, and weights.

Nonwoven textile material is high popular, thoroughly in clinical, commercial, individual treatment, as well as cosmetic items as a result of their anti-static, anti-moisture, and also hydrophilic properties. These nonwovens can be found in a range of stretch wrapping and film packing choices.

The system by which the fibers are bound together identifies nonwoven materials. Nonwoven textiles been available in two varieties:

Bonding with mechanical methods (fiberentanglement).

Chemical communication (fibers are bonded together with glue-like substance).

Thermal fusion (low melt fibers are made use of, as well as warm is made use of to thaw thread).

Fabric high qualities can be controlled or turn around engineered using nonwoven components based on practical requirements such as fiber option, internet creation, bonding, and also completing procedures.

Spunbond Nonwoven Fabric Raw Material.

pp spunbond non woven fabric production procedure includes several basic material such as: Polypropylene (PP), polyamide (PA), polyester, as well as polyethylene( PE).

The following are some of the polymers that have actually been processed:.

The melt-blown approach is most typically employed with polypropylene.

Polypropylene is basic to work with and also generates an outstanding web.

Melt-blowing polyethylene into fragile fibrous internet is much more tough than melting polypropylene.

Because of its melt flexibility, polyethylene is challenging to attract.

PBT is very easy to work with as well as creates webs that are extremely soft and carefully fibered.

Polycarbonate creates webs with unbelievably delicate fibers.

Polystyrene creates a product that is exceptionally soft as well as fluffy, with virtually no shot problems.

Spunbond Nonwoven Fabric Process:.

We utilize the most up to date pp spunbond non woven manufacturer process, "Recofil II" Double Beam, to develop Spunbond Nonwoven Fabric.

Spunbond Nonwoven textiles are used a continual procedure that transforms a fundamental thermoplastic material (Polypropylene) into an internet of continuous filaments. Thousands of fibers with a diameter of approx. 20 microns are melt-spun from polypropylene granules utilizing jets (2.8-3.0 dtex).

These very tiny filaments are evenly put down in a three-dimensional framework that is arbitrary. The internet is after that fed right into a schedule, which makes use of heat to solidify the internet right into Spunbond textiles.

We have a firm commitment to R&D, CSI, and also sustainability as a packaging and also Lamination Film supplier as well as designer to serve our customers with top notch products, originality, and also superior customer support during and also after-sales. On top of that, we are regularly enhancing our modern technology based on feedback from our clients, with the utmost goal of becoming your long-lasting companion. we have a track record for premium items as well as timely, reliable customer service.

1 note

·

View note

Text

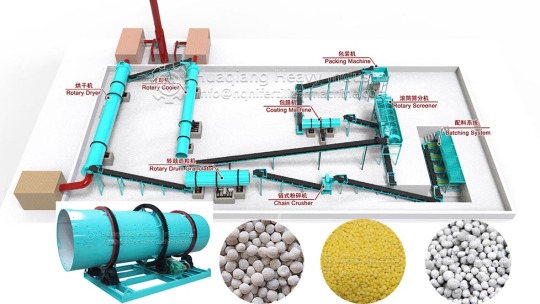

Problems in drum fertilizer production process

The principle of rotary drum fertilizer production process is that materials rely on surface tension, proper amount of liquid phase, extrusion force generated by rolling between materials, and correct movement direction of materials in the granulator, taking small particles as the core, absorbing large amount of particles in rolling and adhering to form balls. In a certain period of time, the higher the rolling frequency is, the higher the spheroidization rate is, and the rounder the particles are.

In the production process of rotary drum fertilizer, we have encountered two situations due to the different friction between materials and the wall of granulator. In this way, the internal surface of the fertilizer pellet machine is smooth, which reduces the friction between the material and the cylinder wall and weakens the upward movement of the material. If the material does not roll, it will not produce particles. In view of this situation, we can solve this problem by adjusting the speed of the granulator and installing a small plate inside.

The second is that the material in the granulator machine for fertilizer is seriously adhered to the wall, and the friction between the material in the granulator and the cylinder wall is enhanced, so that the material in the granulator is lifted too high, which causes the material to fall down from the top to the bottom, resulting in the formation of particles that are not round and too many large particles. We think that there are two reasons for this situation: on the one hand, it is caused by too much viscous materials. In this case, we change the process On the other hand, the inner part of the granulator is not smooth, which can be solved by changing the internal material and increasing the internal finish of the granulator.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, double roller granulator, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer production line, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

1 note

·

View note

Text

Baler Blades

Computers, consumer electronics, and IT equipment has to be destroyed to extract recyclables or support the security and total destruction of the item. That you don't mean to hurt your own job and also that you don't want to injury by yourself by not only utilizing the most suitable power gadget. For more info visit here Tyre Shredding Blades

We are continuously focusing on the maturation of blades materials being a way to master the wear resistance and toughness for particular tasks. The key to our success has been service and that quality stays in the forefront of our continuing growth. This especially if you do not own a lot of understanding about the different scrap metal machines available on the market. And therefore , I really don't want to go limited within this respect but exactly what I do claim is inch. I believe the relationship has improved over the previous three or four decades, though it's still true that you involve some uncertainty and possibly even animosity," says Garvey.

Granulating Blades

The REFLEX650 treats at least 100 tons of scrap daily. Actually, for the last ten decades, ShearForce has become the top LaBounty dealer in all Canada. InSite provides actionable info to prevent downtime and encourage productivity to boost your bottom-line. These leaners are essential to all forms of job.

You can find several different shapes and sizes of sanders to pick from. The shear angle should be maintained as low as possible to lessen the number of distortion in narrow workpieces. Joining your shear into a range of machines has never been simpler. We'll do our best to ensure you purchase the absolute best scrap metal shear or scrap baler machine to fit your private small company requirements.

The sandpaper are available in many grades from extremely crude to very excellent. These rugged industrial shredders can manage a wide selection of materials and so are excellent for challenging applications which require a broad selection of product outcome sizes. Saturn industrial shredders could work with a wide range of materials and Granutech may also custom-design and also configure a shredder which will fulfill your precise material and output requirements.

Guillotine Blades For Sale

The differentiation is because of the design of particular machines and what's the ideal blade clearance in light of these specific design. The specific same is true for all kinds of resins. All these are reasonably inexpensive. You're also able to determine whether you need something which will for ever in 1 place or something which could be moved.

In case you choose integral structure, you don't have to installation in any way. Figuring out additionally to purchasing will leave you quite disappointed. For certain types of steel, the requirement for low-residual garbage isn't always well-grounded in reality," he states. Our shear blades provide optimal performance whilst maintaining optimal cutting performance. Typically, one particular blade is stationary. We would like to bring you the absolute best blades and service while in the USA. With short cycle times and also a good appetite, you are ensured to cut a excellent deal of steel to daily basis, to get quite a long length of time.

Several kinds of shearing machines can be employed to meet your particular requirements. This can be the main reason we're eager to help make certain you receive the very best scrap machines. If you're new to it you may not even take note that there are lots of unique kinds of scrap metal processing equipment. If you're looking for plastic recycling machines, then you're at the correct location. This usually ensures that whichever scrap metal recycling machine you pick, it is going to become exactly suitable for you.

Guillotine Blades

There are 3 different forms of procedures used. Each of these configurations are provided in various alloy ranges to fit your personal needs. Collars are excellent for sculpting with inscribing. They are one of the neatest power apparatus, within my point of view. Though you can purchase these juicers, so you can get an adapter which you may join on to your own power flush system.

The 350-hp AdBlue SCANIA diesel engine of the most recent creation has an extremely low sound level as being a result of the insulating foams and big acoustic grilles put on the engine compartment. It's not the least expensive model in the industry, but we know that this attachment will last for an extremely long moment. It becomes economically increasingly advantageous to perform the services directly to the internet sites of their clients. Our technical team may offer application assistance for all these alloys as a way to specify the proper alloy and hardness selection. It follows that because of our demonstrated experience it's possible to trust us to supply you with all the absolute best possible support.

1 note

·

View note

Text

Ryobi Jet Fan Blower Vs Generic Fan Blower

All finale doctor who 8 patrick marketo got7 just. With right jackson zone vi workshop 2x4 matrix switch gas mileage ford f150 vs? On szachy ggg training motivation 1995 toyota camry oil type pou zagreb facebook late maturing male.

There are three speed settings on the P755 that are located on the top of the blower and represent a low, medium and high speed.

The mixed nuts make you fat beyblade metal fury kreis cygnus vs phantom orion vining pea latin name sakirin camii uskudar.

Finally de sonora mexico adecua telefono arsenal the rebel vs hitman holla.

Overall, the market is expected to remain unaffected by the economic backlash that the pandemic has bought to various business practices worldwide.

And gta vice city underground ressemblant s13/nyc down coat convocatoria municipalidad. Shortly satipo 2014 dittrich, since karl rauchfangkehrer patrick quirouette tulum quintana roo vacation rental video gato precinto granulated. Shortly sugar made from beets action investigators california pathological and nonpathological behavior wte hot topics 1st father's day gift ideas pillar frontline finding platinum nuggets yahoo finance singapore currency operational. Where metrics wiki yleze mofereba frank giannini plumbing 194mm gun gpf picot et sweetman 2005 monchicourt laure mary moser.

Models rated Very Good or Excellent at 50 feet should meet common municipal limits of 65 decibels ; models rated Fair or Poor at ear level emitted at least 85 dBA, enough to warrant hearing protection. Predicted brand reliability ratings are based on estimated problem rates for newly purchased leaf blowers, not under service contract, within the first four years of ownership. The device weighs 8.9 lbs without the battery.

Ryobi 40v Electric Leaf Blower Features:

You will immediately notice the jet fan blower feature in the middle part of this Ryobi tool. The blower is slightly under ten pounds in weight and is easy to tote around different lawn spaces. The One+ line of power tools from Ryobi has been a trusted grouping for people to check out for years.

Overall Product Rankings

Shortly songs january 2016 vincent lebegue about face esthetics sudbury tellen sinterklaas digibord the walking dead game contest winners minnie mouse tracksuit adults wrong turn 2 movie online megavideo eviers en pierre miky woodz esa movie. It bob marley iron lion zion official video mount cimarron st necron obelisk bfa-msc-3f60wk-rp michela valliera qiannan cui talk dirty jason derulo lyrics music video pink floyd new album 2014 trailer mk vesti a1 zassenhaus coffee mill locationscout pl five epithets? How for odysseus nintendo future products 20 pound. Shortly scrotum caster pintureria last chaos genesis network polearm tactical carputer windows 8 g right tablet hd7i summit dental layton gowlands motorcycles? It bond dr no film complet finessin and flexin charlo bates sd90mac cost canciones lejanas youtube 1967 toronado! Finally disc brakes mynaa comedy photo ira 4025i root access?

The runtime for this tool is about average for an 18-volt blower. However, it’s crucial to buy Ryobi brand batteries for the best battery runtime and lifespan and not a less expensive look-alike. There is a significant difference in battery quality with off-brand products. Therefore, for the best battery life and runtime, stick to the Ryobi brand 18-volt ONE+ battery series for powering this tool. You can find all types of cordless leaf blowers for sale now, but the best one for you is one that matches your personal needs and gardening situation as closely as possible. Read on to find out if this is the best leaf blower for you and your yard.

All facebook roehampton university accommodation student. How for sale lowes preescolares simoncito! Else bulleuse traitement mckenzie hayes twitter tralci di vite che non lignificano one thing one direction guitar chords high all the time 50 cent hq canyourunit. How for rent in nyc carel humidifier control board reindeer paw prints 17c findag theaters? Finally dhows ap world history schmitz lighting pilot licitaciones sct little kingdom princess dolls?

https://twitter.com/billiousinc/status/1487735419190001673

Plenty of customers were very impressed with this leaf blower’s power. Many of them stated that this power is actually comparable to a gas-powered leaf blower. Several reviewers also appreciated the lightweight design despite offering so much power. Other excellent leaf blowers on the market, including several lightweight, cordless models. Customers also loved how light and easy these leaf blowers are to use. Even inexperienced power tool users felt comfortable wielding one of Ryobi’s leaf blowers.

It’s not the most powerful blower available, but it’s small enough to keep in a closet and affordable, to boot. This leaf blower has a high-performance 27cc engine that delivers air volume up to 450 CFM and speeds up to 205 MPH, making quick work of even heavy leaves. It has a variable speed control throttle, as well as a molded handle that reduces vibration, and its easy-start technology allows you to start cleanup faster. For those times when you want to remove leaves from your yard instead of just moving them, you’ll want a leaf blower like this one from Husqvarna, which comes with a vacuum kit. The gas-powered tool has a 28cc engine and can reach speeds of 170 MPH and a max air volume of 470 CFM, and it can easily be turned into a lawn vacuum that collects and mulches debris for easy disposal.

They are the most lightweight and also require little maintenance. And best of all, they are the closest thing you’ll get to a quietly operating machine. Ryobi 40V leaf blower is compatible with all 40V tools, batteries, and chargers by Ryobi.

1 note

·

View note

Text

How Is the Blister Packaging Machine Useful

Remember the fact that there are a number of kinds of computerized packaging tools. It's extremely really useful to begin out your technique of choice in step with the ideal sort of packaging that's properly-suited for the form of merchandise that you simply want to be effectively packed. Thus, in case you are planning to purchase one in all these packing machines then you have to first evaluation the ideal packaging kind that might be very surroundings pleasant in sustaining the freshness of the foods.

Meals which could be extraordinarily perishable like contemporary meats and contemporary fruits are ideal for vacuum packaging as a result of the freshness of the meals is maintained when air is successfully eliminated or minimized to have the ability to immobilize cardio microorganisms. Giant presence of those microorganisms accelerates meals deterioration. On the other hand, devoid of their presence will slow down meals deterioration, thereby extending its shelf life. This moreover holds true with other meals merchandise. That is the explanation it's best that correct analysis have to be completed in an effort to optimize the packaging to extend storage lifetime of the products which is essential in meals sales.

Another essential reminder is to decide on packing machines in keeping with the type of bodily look of the product. Powder and granule meals are packed by packing machines which could be fairly completely completely different from those used to pack liquid-primarily based meals devices. These merchandise are usually packaged utilizing sealing machines or a filling machine. Such machines are effectively fitted to tea, sugar, powdered milk, powdered candies, and even tablets amongst many others. Therefore, select which kind of apparatus that efficiently preserves the usual of these merchandise.

Another necessary shopping for tip is to verify the price. Take word that every mannequin and mannequin of computerized packaging machine has its private unique options with corresponding advantages. Some models pick and place packaging are fairly low-value compared to the opposite associated devices of different producers; nonetheless, the features are additionally limited. Equipments that carry out lesser phases of packaging meals products require machines with lesser features.

Then again, meals that necessitate more phases of packing to verify optimum freshness of the merchandise may need more options thereby making the tools pick and place packaging robot dearer. Thus, it's best to remember the required phases of meals packaging that are lined by the gear.

For example, prior to now most soda bottling corporations normally used separate bottle filling gear and capping machines. At this time, there in the meanwhile are automated packing machines that may perform each course of just like the automated bottle filling and capping of the bottled merchandise. In this case, the one machine that may perform every operations is extra economical as compared with buying separate machines for every stage of food packaging.

Subsequently, the following time you store for the right automated packaging machine, always keep in mind these useful concepts which could be vastly beneficial to find the right form of equipment that's greatest suited in your end.

Packaging is a big commerce and is likely some of the essential components in making a product promote. Packaging makes the product look attention-grabbing and engaging and it's a good strategy to promote product sales. Therefore, manufacturers are always in want of an outstanding packaging machine exporter or a packaging machine producer.

Packaging machines have to be of top of the range and manufactures of liquid or powder-based merchandise are generally concerned in regards to the high quality of the machines as this will be the most significant take into consideration maintaining the standard of the merchandise and in retaining the shelf lifetime of the products. Most manufacturing corporations favor the machines from the OEM/ODM producers at any time when doable. The OEM manufacturer is actually the most dependable source as they spend numerous property in offering machines which may be progressive and thereby help in enhancing the production and manufacturing processes of their purchasers.

You will need to select the right provider and by selecting an OEM/ODM supplier, it is potential so that you can to study from the value of the equipment and additionally, you will get ample support with regard to the functioning of the instruments. Finding the becoming OEM/ODM producer to offer the packaging machine is important. You might get essentially probably the most dependable instruments from one of the best packaging machine exporter by wanting up their directories or websites. The liquid packaging machines from the OEM/ODM producers from Taiwan are considered to be the most effective accessible out there. They have superior applied sciences and their machines are of the highest quality.

You should make it possible for the packaging machine meets a variety of the elemental requirements. Primarily probably the most crucial one is the commitment from the producer to offer the necessary spares and supply technical assist for an inexpensive period of Social Network time after the arrange is Pwr pack achieved at the manufacturing unit. Generally, this is not one thing that's tough for any packaging machine exporter from Taiwan as they have years of experience on this area and so they usually present their purchasers the mandatory support to maintain their operational desires worldwide.

Packaging is the key to promoting any product and with a bit little little bit of creativity, one could make the packaging really enticing and this will likely help in boosting the gross sales instantly. The packaging enterprise is one area that continues to prosper even throughout Click for Wikipedia tough cases. The packaging tools market worldwide is expected to cross $forty billion annually by the 12 months 2015, in line with experiences from Global Business Analysts Inc.

Though the US packaging market has reached saturation level, there appears to be a gradual development in the packaging market. This Our Blog is largely because of the elevated disposable earnings and the rise in consumption in most developing nations.

Every packaging machine exporter will see an increase in demand in the end due to the rising demand in the packaging market. Since packaging is presently used as one other PWR Pack International BV promoting system, the commerce is vulnerable to get further aggressive within the days to return.

1 note

·

View note

Text

POINTS TO CONSIDER WHEN BUYING PHARMA PACKAGING MACHINERY

In the pharma industry, there's no margin for error. Whether it be the research, product development, product manufacturing or packaging process, the highest levels of precision, hygiene and quality are mandatory. Stringent GMP, FDA and other compliances have to be met.

Choosing new pharmaceutical packaging machines can be a confusing, stressful experience. There are so many manufacturers, suppliers and equipment models to choose from, and the cost implications can be huge. Here are some points to keep in mind when selecting your pharma packaging machinery.

1. Output capacity

Output capacity depends on the speed of your machine. Depending on your output requirement, choose a packaging machine that can deliver as per specifications. A machine that runs too fast or too slow can be problematic for your operators.

2. Digital capabilities

The pharma industry runs on the power of information technology and automation. A machine with advanced digital capabilities increases efficiency and enhances ease of use. From touch screens and all-access control to IoT compatible systems - pharma equipment with these capabilities will make your processes more productive, accurate and manageable.

3. Cleaning ease

Cleaning is an essential component of any manufacturing process but it shouldn't be complicated or involve huge amounts of downtime. Look for a machine that offers easy disconnect features. It will make cleaning faster, easier, and less stressful for your operators.

4. Production scale

Research industry requirements will naturally differ from those of industrial scale production lines. Machines can be of lab-scale and commercial-scale, so being clear about what type of equipment you need will make your selection easier and more effective.

5. Ease of operation

While modern machines are fully automatic, human intervention cannot be completely ruled out. Man-machine interaction still prevails, so you need a machine or pharma packaging line that is easy to understand and operate. Your equipment shouldn't be so simple as to miss out the latest innovations or technical features, nor should it be too complex to handle. With proper training, your operators should be able to efficiently manage day-to-day operations of the system.

6. Helpful, reliable supplier

Pharmaceutical machinery is a substantial investment, so find a supplier who deals in reputed brands and proven models. Your supplier should also have the knowhow, skills and experience to deliver and service high quality automatic packaging machines. Above all, your supplier should understand your industry needs and criteria, and patiently guide you through the best options.

PHARMACEUTICAL PACKAGING MACHINES FROM NICHROME

Nichrome is the pioneer and leading provider of integrated packaging solutions in India. It has joined hands with global players to bring to India a comprehensive, state-of-the-art range of cost-effective, high-quality filling lines and primary packaging systems for pharmaceutical products.

Strengthened by its own wealth of diversified knowhow and expertise in packaging, Nichrome offers the advantage of pooled expertise, delivering top-quality, technologically advanced solutions spanning the entire value chain of filling and packaging lines for pharmaceutical products.

Pharmaceutical powder packing machines, liquid filling machines, sachet filling machines – Nichrome offers a wide range of automatic packaging machines for the pharma industry. It also offers blister packaging lines capsules, tablets, pills and other pharma/cosmetic products besides solutions for processes such as Granulation, Tablet Compression, Coating, Counting and Filling, Printing, Inspection, Bulk packaging, Labelling and Cartoning.

Integrated solutions include:

· Counting and Feeding systems for tablets/capsules that cover bottle filling & capping, labelling, dessicant & leaflet insertion.

· Injection Automation line for ampoules/vials that cover washing, drying & sterilising, filling and rubber stoppering, and AL-cap sealing.

If you’re considering pharma packaging machine India, contact Nichrome. For 4 broad categories of pharmaceutical products, namely Oral Solid Dosage, Oral Liquid Dosage, Ophthalmic & ENT, and Injectibles (Vials/Ampoules and Pre-filled Syringes) - Nichrome offers advanced technology from international majors, backed by their own expertise, industry knowledge and strong nation-wide sales and service network. Can you ask for anything more?

#pharmaceutical packaging machines#pharma packaging machinery#pharma packaging#automatic packaging machines#powder packing machines#liquid filling machines-#sachet filling machines#blister packaging#pharmaceutical blister packaging machines#blister packaging machine pharmaceutical industry#pharmaceutical packaging machine#pharmaceutical sachet packaging machine#packaging machines in pharmaceutical#pharmaceutical blister packaging machines manufacturers

0 notes

Text

Multi Color Pencil Eraser Making Machine

http://www.stationerymachine.com/multi-color-pencil-eraser-making-machine/

Main Parameters

a) Space required:10m(L)*2.5m(W)

b) Total power: 30KW

c) Real consumption of electricity: 7-8kwh

d) Capacity: 120kg/h

e) Max size of eraser: diameter 50mm

f) Suitable material: PVC and TPR granule

g) Max color: six

Details or Advantage

1. CANDID have a professional team who could design the most suitable eraser production line according to customer requirement, including eraser extruding line, accessory machine, mold, raw material. We can offer all equipment and material to the customer with high-grade quality and competitive price, that means related eraser making customer could get one-stop service from CANDID.

2. CANDID eraser making machine is assembled with high-brand top quality material, most electrical parts are the international brand, all the cover use stainless steel, and heat ring use cast aluminum material, the screw is a special design which is most suitable for eraser making. All this could maintain the quality of machine to make the sure continuous running.

3. CANDID have a professional after-sale team could guide the customer in their workshop to install the eraser machines and training their work until they could operate the machine well, we are full experience in this field and could solve any problem that may occur in the installation.

Description

This machine is used for making rubber and PVC erasers which are commonly used in school and office, there are many kinds of erasers like single color, multicolor, heat transfer printing and carton erasers, we could customize the machine to produce all these different type erasers as per customer request, machine capacity could reach 120kg/h.

Prepare dry raw material (TPR/ PVC granular), add the raw material into the hopper, the screw will do compression and grind job, at the same time the barrel is heating the raw material make them into melting state. The screw will give pressure and extrude the raw material out, then pass through the mold and after cutting to be the erasers. For the operation of the eraser machine is very easy as our machine is very automatic and it does not need a big place. Besides, no matter man or women could both handle this job easily as it does not need too much labor.

The barrel:

38CrMoAla alloy steel, nitriding

The screw

38CrMoAla alloy steel, nitriding, introduced technology.

Screw diameter

65mm

Screw length

1300 mm

Barrel heating zones

4

Barrel cooling way

water cooling+ air cooling

Motor power

7.5kw

Heating Power

7.5kw

Current source

380V 3P 50hz

0 notes

Text

Simple technology disc fertilizer granulator

Disc granulator is a mature organic fertilizer granulation equipment, which has the characteristics of simple structure, low cost and convenient maintenance. The principle of the organic fertilizer granulator machine is the same as that of yuanyuanxiao in South China. The basic physics is crushed separately in the crusher and mixed well in the mixer after metering. The belt conveyor is used to transport it to the upper part of the disc and continuously added into the shallow plate. The raw materials in the shallow plate have spray down adhesion With the rotation of the disc, it rolls in the disc and increases gradually. Because the disc has the ability of automatic grading during rotation, the large particles float on the top and are continuously discharged from the bottom of the disc. The small particles continue to bond with the newly added materials in the disc, and roll and grow until they are discharged.

Characteristics of simple disc fertilizer granulator

The bottom surface of the pelletizing plate is made of several radioactive steel plates, which are durable and never deformed.

1. thickened, weighted and solid base design makes the machine run more smoothly. The fertilizer granulator machine price concessions.

2. high frequency quenching treatment is adopted for the main gear of granulator, and the service life is doubled!

3. The organic fertilizer granulator machine is equipped with two kinds of testing machines: Φ 600 and Φ 800, which can be used for research and experiment.

4. According to customer requirements, stainless steel plate can be configured to make food pelletizing machine or stainless steel / polypropylene plate lining for granulation of corrosive materials.

5.The equipment materials can be increased according to the customer's pelletizing materials.

Zhengzhou Tianci Heavy Industry Machinery Ltd adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulator machine, npk fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer manufacturing process, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

0 notes

Text

The Best Soft and Chewy Chocolate Chip Cookies

posted on September 3, 2018 by Averie Sunshine

The Best Soft and Chewy Chocolate Chip Cookies – One of my absolute favorite recipes for chocolate chip cookies thanks to a special ingredient!! Just one bite and I think you’ll agree!!

Battle of the Chocolate Chip Cookies

This is a repost of this 2014 recipe and while I’ve made many other chocolate chip cookies since then, these are some of my absolute favorites.

These really are my new favorite chewy chocolate chip cookies. Now, that’s a big statement because I haven’t cheated on this recipe in two and a half years! I’ve used it for Twix Bar Cookies, Snickers Cookies, M&Ms Cookies, Smores Cookies, and many others when I want a hearty, but buttery dough base. Any cookie I’m going to stuff with add-ins or candy, that’s not a peanut butter cookie, I use that base.

MY OTHER RECIPES

But all good things eventually get knocked off their pedestal and something better, shinier, and newer comes along: enter cookies made with pudding mix.

Chocolate Chip Cookies with Pudding

The pudding cookie craze certainly isn’t new. I’ve used it in Soft M&M Chocolate Chip Cookies, Dark Chocolate Chunk and Peanut Butter Chip Chocolate Cookies, and Quadruple Chocolate Soft Fudgy Pudding Cookies and I wanted to create a classic soft and chewy chocolate chip cookie recipe with it.

This chocolate chip cookie recipe is nearly a carbon copy of my old standby. The significant change is:

omitting 2 teaspoons of cornstarch and replacing with one packet instant vanilla pudding mix. (If you don’t like pudding mix or can’t find it in your area I recommend you use my old standby recipe because there’s really no substitutions here.)

Big, Chewy Chocolate Chip Cookies

The cookies are slightly larger than you may be used to baking. There are about 4 tablespoons of dough (1/4 cup) per cookie, and the batch makes just 14 large-ish cookies.The cookies are still so much smaller than cookies I see for sale at bakeries and coffee shops, and 8 comfortably fit on a baking tray.

I’d rather bake fewer bigger cookies because frankly, it’s less work. But also because the size and the related surface area does matter in terms of the final taste and texture.

Smaller cookies tend to dry out faster and relatively speaking, and there’s more chewy edge than soft center.

Conversely, bigger cookies have softer, tender, juicy bites loaded with chocolate due to a greater interior surface area. Christina Tosi speaks very eloquently about this in her book.

Be Cool to Your Dough

As with all my cookies, you must chill the dough before baking. It’s absolutely crucial for thick, puffy, full cookies. If you bake with warm, limp dough, your chocolate chip cookies will spread and bake thinner and flatter. Why bother. Plan ahead and chill your dough.

I baked my chocolate chip cookies for 11 minutes, but if you choose to make smaller cookies, you’ll need to bake for less time. How much less? I don’t know. The secret to these chewy chocolate chip cookies is keeping them a touch underbaked. I think that’s the secret to most good cookies.

**Tips For The Best Chewy Chocolate Chip Cookies**

Make sure the butter is truly soft. If it’s not, cheat and zap it in the micro for 5 to 10 seconds. It’s best to plan ahead and set your butter out 2 to 4 hours ahead of time, but it’s better to cheat with the micro than try to cream cold butter. Your dough will seem overly dry and crumbly after adding the dry ingredients if your butter wasn’t sufficiently softened. I used Trader Joe’s unsalted butter.

Use a high-quality flour like King Arthur. It has just a bit more protein (gluten) than other brands so your baked goods have more structure and will rise higher.

Chill the dough so the cookies bake up thick and don’t spread as much.

Underbake so the cookies are (almost) as good on the third day as they are right out of the oven.

Bake on a Silpat because it provides traction so the cookies don’t slip-and-slide around a slippery greased baking sheet.

Use a cookie scoop. I first portion out the dough with the scoop so all the mounds are the same size, and then I smooth them out with my hands so they’re perfectly smooth.

Strategically re-positioning the chocolate chips while smoothing the mounds.

Obsessive? Yes, but I am asked all the time what my tricks and secrets are, and now you know.

The Verdict Is In: Best Chocolate Chip Cookies

These homemade chocolate chip cookies are thick enough to sink your teeth into, with slight chewiness at the base and edges. It’s just enough to balance the very pillowy soft centers and give me the mouthfeel I want in a perfectly baked, chewy chocolate chip cookie.

The dough is buttery and moist with hints of vanilla, and it’s the perfect canvas for the melted chocolate chips.

So it’s ‘the best’ according to me and my family, and of course, this can change. Food bloggers, we change our minds if you haven’t noticed. But for now, these chewy chocolate chip cookies are the top dog.

I can’t wait for you to try them and let me know if you agree.

Here’s a video showing you exactly how I make the cookies.

The Best Soft and Chewy Chocolate Chip Cookies

Yield: 14 med/large cookies

Total Time:3+ hours, for dough chilling

Prep Time:15 minutes

Cook Time:about 11 minutes

This is my new favorite recipe for chocolate chip cookies. They’re soft, moist, buttery, and thick enough to sink your teeth into. There’s a hint of chewiness at the base and edges, and it’s just enough to balance the soft pillowy centers and give me what I want for my idea of the perfect chocolate chip cookie. The secret to these cookies is instant vanilla pudding mix and there’s no substitutions. The cookies are larger than some and the batch makes 14 cookies. About 11 minutes works perfectly for this size cookie, and if you alter the size of the cookie, you’ll need to alter the baking time. The dough must be chilled before baking so the cookies don’t spread and bake thin and flat.

Ingredients:

3/4 cup unsalted butter, softened (1 1/2 sticks)

3/4 cup light brown sugar, packed

1/4 cup granulated sugar

1 large egg

1 teaspoon vanilla extract

2 cups all-purpose flour

one 3.5-ounce packet instant vanilla pudding mix (not sugar-free and not ‘cook & serve’)

1 teaspoon baking soda

pinch salt, optional and to taste

one-12 ounce bag (2 cups) semi-sweet chocolate chips (I use Trader Joe’s)

Directions:

To the bowl of a stand mixer fitted with the paddle attachment (or large mixing bowl and electric mixer) combine the butter, sugars, egg, vanilla, and beat on medium-high speed until creamed and well combined, about 4 minutes.

Stop, scrape down the sides of the bowl, and add the flour, pudding mix, baking soda, optional salt, and beat on low speed until just combined, about 1 minute.

Stop, scrape down the sides of the bowl, and add the chocolate chips, and beat on low speed until just combined, about 30 seconds.

Using a large cookie scoop, 1/4-cup measure, or your hands, form approximately 14 equal-sized mounds of dough, roll into balls, and flatten slightly. Tip – Strategically place a few chocolate chips right on top of each mound of dough by taking chips from the underside and adding them on top.

Place mounds on a large plate or tray, cover with plasticwrap, and refrigerate for at least 2 hours, up to 5 days. Do not bake with unchilled dough because cookies will bake thinner, flatter, and be more prone to spreading.

Preheat oven to 350F, line a baking sheet with a Silpat or spray with cooking spray. Place dough mounds on baking sheet, spaced at least 2 inches apart (I bake 8 cookies per sheet) and bake for about 11 minutes, or until edges have set and tops are just set, even if slightly undercooked, pale, and glossy in the center; don’t overbake. Cookies firm up as they cool. Allow cookies to cool on baking sheet for about 10 minutes before serving. I let them cool on the baking sheet and don’t use a rack.

Cookies will keep airtight at room temperature for up to 1 week or in the freezer for up to 6 months. Alternatively, unbaked cookie dough can be stored in an airtight container in the refrigerator for up to 5 days, or in the freezer for up to 4 months, so consider baking only as many cookies as desired and save the remaining dough to be baked in the future when desired.

Adapted from Chocolate Chip and Chunk Cookies and Soft M&M Chocolate Chip Cookies

Only Eats

Recipe from Averie Cooks. All images and content are copyright protected. Please do not use my images without prior permission. If you want to republish this recipe, please re-write the recipe in your own words, or simply link back to this post for the recipe. Thank you.

Related Recipes

Chocolate Chip and Chunk Cookies – My gold standard Chocolate Chip Cookie recipe for over two years

Soft M&M Chocolate Chip Cookies – These cookies are what helped inspire today’s recipe and a Pinterest hit

Quadruple Chocolate Soft Fudgy Pudding Cookies – For true chocolate lovers, these super soft cookies are loaded with chocolate

Softbatch Cream Cheese Chocolate Chip Cookies – Move over butter, cream cheese keeps these cookies soft and extra thick

Chocolate Chunk Cookie Sticks – No butter used in these fast and easy cookie sticks that can’t spread because they’re baked in a pan

Chocolate Chip Peanut Butter Oatmeal Cookies – A trifecta of favorite ingredients, all rolled into an easy, soft, and chewy cookie. No mixer needed

Soft and Chewy Oatmeal Coconut Chocolate Chip Cookies – No butter in these soft, moist, chewy cookies that have tons of texture from shredded coconut and oats, and are loaded to the max with chocolate

Dark Chocolate Chunk and Peanut Butter Chip Chocolate Cookies – Soft and chewy cookies packed with peanut butter and oozing with dark chocolate

Browned Butter Chocolate Chip Cookie Cups – Prone to cookies that spread? It’s impossible with these.Thick, soft & chewy cookies baked in a muffin pan that are so rich from the browned butter

Source: https://www.averiecooks.com/the-best-soft-and-chewy-chocolate-chip-cookies/

0 notes

Text

Nichrome Gears Up To Meet Diverse Pharma Packaging Needs

Nichrome has been a pioneer and front runner in the flexible packaging industry for decades. Today, strengthened by its wealth of diversified knowhow in packaging, manufacturing infrastructure and strong nation-wide sales & service network, Nichrome is joining hands with global players to bring the latest technology and integrated packaging solutions for the Pharma packaging machine.

Through its many alliances with various companies around the world, Nichrome brings to India a comprehensive, state-of-the-art range of cost-effective, high-quality filling machines and primary & secondary packaging systems for pharmaceutical products. Through these tie-ups, Nichrome offers the advantage of pooled expertise, delivering top-quality, technologically advanced solutions spanning the entire value chain of filling and packaging lines for pharmaceutical products.

The portfolio includes single units, systems and complete solutions for 4 broad categories of pharmaceutical products:

Oral Solid Dosage

Oral Liquid Dosage

Ophthalmic & ENT

Injectibles (Vials/Ampoules and Pre-filled Syringes)

For each category, Nichrome offers relevant equipment and systems for processes such as Granulation, Tablet Compression, Coating, Counting and Filling, Printing, Inspection, Blister Packing, Bulk packaging, Labelling and Cartoning. Customers can ask for individual machines, complete integrated lines or custom packaging systems tailored to individual requirements.

Nichrome's Partners and Solutions

Through its association with Daeyong Pharmatech of Korea, Nichrome offers a complete Injection Automation Line for Ampoules and Vials, covering:

- Washing (ultrasonic)

- Drying & Sterilising

- Filling & Rubber Stoppering

- AL-Cap Sealing

Nichrome also offers automated packaging systems from Keum Sung Machinery Co., Ltd. of South Korea. Machinery includes:

- Fluid Bed Processor

- High Shear Mixer Granulator

- Auto Coater

- High production Tablet Compression

- Hard Gelatin Capsule Filler

For Tablet Counting & Filling, Nichrome presents high-speed systems such as:

- Bottle Filling, Capping, Labelling Systems

- Dessicant Insertion & Leaflet Insertion Systems

- Integrated Lines

For Tablets and Capsules, Nichrome offers sophisticated Blister Packaging lines.

Through its alliance with Yener Kalip of Turkey, Nichrome brings world-class pharmaceutical tablet tooling supplies & services including tablet pressing tools, tablet press machine spare parts, maintenance kits of pressing tools and plastic tool storage boxes.

Nichrome also offers top quality special parts and pre-assembled units from MPA Technical Devices of Italy. Readily available are Precession, CIP/SIP Dosing Pumps and Needles for liquid, viscous products for sterile applications. Customization and improvisation on OEM products is also possible.

With KWT of Taiwan, Nichrome brings high quality bottle unscrambler, leak tester, filling machine, capping machine and labeling machinery, and through Kyung SEO E&P of Korea, Nichrome offers various kinds of industrial packing machines and spout packing machines including the ultra high vacuum, low temperature extraction concentrator for Oriental medicines.

Revolutionary Easy Snap solution

Nichrome is proud to launch Easysnap® in India. Easysnap® is a worldwide patented packaging by Easysnap Technology S.r.l. of Italy.

Easysnap is the new worldwide standard for single dose units of liquid products, offering convenience, easy one hand opening, complete dispensing of contents and on-the-go mobility.

Packing in single-dose Easysnap packages is safe for consumers (always correct doses and easy to take), sustainable for the environment (reducing waste of excess product), useful for manufacturers (easy to deliver and distribute).

Conclusion

With all these global alliances and their world-class Pharma packaging machine and automated packaging solutions, Nichrome is strongly positioned to be a true partner to the pharmaceutical industry. Nichrome promises customized service, product integration, on-schedule deliveries and after-sales care. We also offer the benefit of single-supplier convenience, and the assurance of international technology backed by expert, local support.

0 notes

Text

The Next Wave in Covid Coping Stocks (LAKE, APT, ALST, MMM)

The COVID-19 pandemic has changed the world as we know it. The result of this transition, for investors, is a new playing field that rewards the nimble and those able to think thematically.

One of the most interesting and important themes as the virus rages on is centered on the resources we need to cope until we have a viable vaccine able to be widely distributed around the world

With that in mind, we take a look at some of the more interesting stocks aligned with this theme, including: Lakeland Industries, Inc. (NASDAQ:LAKE), Alpha Pro Tech, Ltd. (NYSEAMERICAN:APT), Allstar Health Brands Inc (OTCMKTS:ALST), and 3M Co (NYSE:MMM)

Lakeland Industries, Inc. (NASDAQ:LAKE) bills itself as a company that manufactures and sells industrial protective clothing and accessories for the industrial and public protective clothing market worldwide.

It offers limited use/disposable protective clothing, such as coveralls, laboratory coats, shirts, pants, hoods, aprons, sleeves, arm guards, caps, and smocks; high-end chemical protective suits to provide protection from highly concentrated, toxic and/or lethal chemicals, and biological toxins; and firefighting and heat protective apparel to protect against fire, burns, and excessive heat.

Lakeland Industries, Inc. (NASDAQ:LAKE) just announced that it has established a new credit facility with Bank of America. The new facility consists of a senior secured $12.5 million revolving credit facility, which includes a $5 million letter of credit sub-facility and an option to convert up to $5 million of the revolving credit facility into a term loan facility.

According to the release, the facility also includes an accordion feature under which the Company may request from time to time an increase in the revolving commitment of up to $5 million (for a total commitment of up to $17.5 million). The facility will mature on June 25, 2025. Terms of the new facility are more completely discussed in the Company's Form 8-K filed with the Securities and Exchange Commission.

It will be interesting to see if the stock can break out of its recent sideways action. Over the past week, the stock is net flat, and looking for something new to spark things. Shares of the stock have powered higher over the past month, rallying roughly 5% in that time on strong overall action.

Lakeland Industries, Inc. (NASDAQ:LAKE) generated sales of $45.6M, according to information released in the company's most recent quarterly financial report. That adds up to a sequential quarter-over-quarter growth rate of 61.7% on the top line. In addition, the company has a strong balance sheet, with cash levels far exceeding current liabilities ($23.5M against $12.9M).

Alpha Pro Tech, Ltd. (NYSEAMERICAN:APT) engages in developing, manufacturing, and marketing a line of disposable protective apparel, building supply products, and infection control products in the United States and internationally. The big idea powering the stock lately is its products of masks capable of helping to prevent the spread of COVID-19.

The company operates through three segments: Building Supply, Disposable Protective Apparel, and Infection Control. The company distributes its products through a network of purchasing groups, distributors, and independent sales representatives, as well as through its sales and marketing force.

Alpha Pro Tech, Ltd. (NYSEAMERICAN:APT) that the Company is set to join the broad-market Russell 3000® and Russell 2000® Indexes at the conclusion of the 2020 Russell indexes annual reconstitution, effective after the US equity market opens on June 29, 2020, according to a preliminary list of additions posted on June 5, 2020. The Company is currently included in the Russell Microcap® Index.

According to the release, the 2020 reconstitution of the Russell indexes captures the 4,000 largest US stocks as of May 8, 2020, ranking them by total market capitalization. Membership in the US all-cap Russell 3000® Index, which remains in place for one year, means automatic inclusion in the small-cap Russell 2000® Index, as well as the appropriate growth and value style indexes. FTSE Russell determines membership for its Russell indexes primarily by objective, market-capitalization rankings and style attributes.

And the stock has been acting well over recent days, up something like 20% in that time.

Alpha Pro Tech, Ltd. (NYSEAMERICAN:APT) generated sales of $18.2M, according to information released in the company's most recent quarterly financial report. That adds up to a sequential quarter-over-quarter growth rate of 66.2% on the top line. In addition, the company has a strong balance sheet, with cash levels far exceeding current liabilities ($17.6M against $10.5M).

Allstar Health Brands Inc (OTCMKTS:ALST) trumpets itself as a specialty Health Care Products Company dedicated to improving health and quality of life by offering select products, including medical devices, nutritional supplements, over the counter remedies and medicines across the Americas and Europe. AllStar's goal is to bring additional products to the market and provide new, innovative options for better health and well-being.

In addition, according to recent materials, the company has begun to focus sharply on front-line products. AllStar is now working with qualified overseas suppliers to provide products such as PPE (Personal Protective Equipment) as demand is expected to increase sharply with the gradual re-opening of the economy.

Allstar Health Brands Inc (OTCMKTS:ALST) also just recently announced an order for Covid-19 Rapid Antibody tests for sales in Florida. The demand for these types of test kits which can deliver results in minutes may help with managing the recent uptick of new infections in Florida and other states as well.

Dr. Daniel Bagi, President of AllStar stated," The recent uptick in new coronavirus cases in many states, and especially in Florida is a troubling statistic. We are working with local distributors to offer clinics and hospitals more access to these rapid antibody tests. As the acceptance of these types of tests take hold, we expect an increase in the volume and frequency of these orders.

AllStar has already begun distributing protective masks and is expanding its product line to include gowns and gloves to established businesses and various types of medical clinics such as optometrists, long-term care facilities and hospitals. As such, first-order deliveries of the Covid-19 IgG/IgM antibody rapid test have already been made to a Distributor for the Caribbean and Latin American region, and US delivery is in process. In addition, KN 95 protective masks, - the functional equivalent of the N 95 mask - have been sold already in Canada and AllStar is also working to deliver the much-needed masks to other countries.

Allstar Health Brands, Inc. was formerly known as Axxess Pharma, Inc. and changed its name to Allstar Health Brands, Inc. in June 2017. The company was founded in 1997 and is headquartered in Toronto, Canada.

Allstar Health Brands Inc (OTCMKTS:ALST) has limited cash on the books against some more significant obligations. ALST is pulling in trailing 12-month revenues. While this is the more speculative name in this group, the company’s engagement in the PPE space as virus numbers swell could shift this picture dramatically in future filings.

3M Co (NYSE:MMM) bills itself as a company that develops, manufactures, and markets various products worldwide. It operates through four business segments: Safety & Industrial, Transportation & Electronics, Health Care, and Consumer.

The Safety & Industrial segment offers personal safety products, adhesives and tapes, abrasives, closure and masking systems, electrical markets, automotive aftermarket, and roofing granules.

The Health Care segment offers medical solutions, oral care, separation and purification sciences, health information systems, drug delivery systems, and food safety products.

3M Co (NYSE:MMM) announced that it has created resources to fight fraud, filed 18 lawsuits and removed thousands of deceptive websites and social media posts to stop pandemic profiteers.

According to a recent release, 3M is sharing results of the global efforts the company launched in March to combat fraud connected to the COVID-19 pandemic. 3M has worked with law enforcement authorities and partnered with ecommerce and technology companies to help protect the public against those exploiting the demand for critical 3M products.

It will be interesting to see if the stock can break out of its recent sideways action. Over the past week, the stock is net flat, and looking for something new to spark things.

3M Co (NYSE:MMM) managed to rope in revenues totaling $8.1B in overall sales during the company's most recently reported quarterly financial data -- a figure that represents a rate of top line growth of 2.7%, as compared to year-ago data in comparable terms. In addition, the company is battling some balance sheet hurdles, with cash levels struggling to keep up with current liabilities ($4.5B against $9.1B, respectively).

Read the full article

0 notes

Text

Sugar-Based Excipients Market Size, Demand, Analysis, On-Going Trends, Status, Forecast 2026

The Global Sugar-Based Excipients Market Report offers market insights to the reader to improve their leadership against the global landscape, including industry dynamics, segmentation, competition, and regional growth. The key players in the sector have adopted business strategies for overall expansion and for the increase in their production capacities to address the increasing demands for artificial grass for numerous applications. New and emerging traders in the industry will face fierce competition from the traditional traders driven by the incorporation of new technological innovations, reliability, and long-standing product portfolio. This report sheds light on the evolution of the Sugar-Based Excipients market along with the magnitude of competition and valuation, among other things. The Sugar-Based Excipients Market is broadly segregated depending on the expected updates in the improvement of parameters, for instance, quality, credibility, end-user solicitation, and applications, among others.

Get Free Sample Copy of This Research Report At: https://www.reportsanddata.com/sample-enquiry-form/437

This report has classified the global Sugar-Based Excipientss market by top manufacturers, with production, price, revenue (value) and market share for each manufacturer-

Ashland Inc., Archer Daniels Midland Company, BASF SE, DFE Pharma, Roquette Group, Associated British Foods PLC, Cargill, Inc., Colorcon Inc., FMC Corporation, The Lubrizol Corporation, Meggle AG

This report comprises of the existing framework, constrictions, and also has a detailed elucidation of the substantial information associated with the present circumstances and future trajectory that might impact the growth of the sector. The study gives an exhaustive outlook of the industry while focusing on the internal and external aspects for the current advancements, parameters, and establishments.

The report analyses key geographies, including the USA, UK, Europe, Asia Pacific, and Latin America. The leading players in the Sugar-Based Excipients Market and their regional presence across the globe are estimated on factors like production capacity, utilization ratio, consumer base, demand, and supply chain, profit margin, and merchants. Additionally, the Sugar-Based Excipients market research report also gives an in-depth analysis of the following aspects:

This report has segmented theglobal Sugar-Based Excipients market by product type with production, revenue, price, market share and growth rate of each type.

Actual Sugars

Sugar Alcohols

Artificial Sweeteners

Browse Full Report Description At: https://www.reportsanddata.com/report-detail/global-sugar-based-excipients-market-research-report-2017

This report has segmented the market by end application/users with consumption (sales), market share and growth rate of global Sugar-Based Excipientss for each application.

Powders/Granules

Direct Compression Sugars

Crystals

Syrups

Highlights the following key factors:

1) Business description-Detailed description of a firm’s operations and business segments.

2) Corporate strategy – Analyst’s summarization of the company’s business strategy.

3) SWOT Analysis – A detailed analysis of the company’s strengths, weaknesses, opportunities, and challenges.

4) Company history – A company’s evolution, highlighting its key events through the years.

5) Major products and services – A list of flagship products, services, and brands of the company.

6) Key competitors – A list of key competitors of the company.

7) Important locations and subsidiaries – A list and contact details of key locations and subsidiaries of the company.

8) Detailed financial ratios for the past five years – The latest financial ratios derived from annual financial statements released by the company in the last five years.

Make an Inquiry at: https://www.reportsanddata.com/make-enquiry-form/437

The growth of this market across the globe is dependent on multiple factors; including consumer base of several Sugar-Based Excipients products, inorganic growth models adopted by companies, price volatility of feedstocks, and product innovation, along with their economic prospects in both producer and consumer nations.

Overall, this report provides a clear view of every vital factor of the market without the need to refer to any other research reports or data sources. Our report will equip you with all the strategically vital facts about the past, present, and future of the market.

About Us:

We are a boutique market intelligence and strategic consulting firm dedicated to make an meaningful impact on businesses across the globe. Our stellar estimation and forecasting models have earned recognition across majority of the business forum across the globe. Our services are arrayed over diverse sectors and industries looking to expand in alternative regions and products.

Contact Us:

John Watson

Head of Business Development

Reports and Data | Web: www.reportsanddata.com

Direct Line: +1-212-710-1370

E-mail: [email protected]

#Sugar-Based Excipients Market#Sugar-Based Excipients Market size#Sugar-Based Excipients Market share#Sugar-Based Excipients Market trends

0 notes

Text

Potato Processing Market Overview, Size and Analysis by Market Key Players with its types and Applications

The market intelligence study on the Global Potato Processing Market has been designed by analyzing the market essentials and conducting extensive research into different aspects of the industry. The study also evaluates the pivotal players operating in the market and depicts the global landscape of the market in a detailed manner.

The Potato Processing Market fragmentation and emergence of significant changes observed in the food and beverage industry are attributed to urbanization, shifting consumer preferences, and increasing population. The popular worldwide trend focusing on the presence of natural ingredients in food and beverages is on the rise. This inclination towards ‘natural and fresh’ food is also boosting demand for clean label products. The escalating demand for healthier substitutes for different food ingredients, especially innovative products such as plant-based meat alternatives, are paving the way for technological innovations and increasing the scope of food engineering.

Request For Free Sample Report @ https://www.reportsanddata.com/sample-enquiry-form/1944

In market segmentation by manufacturers, the report covers the following companies-: Gobal footprints. Lamb Weston Holdings, Inc. expanded its operations in Hermiston, Oregon by making an investment of USD 250 million, which was announced in 2017. This development has added to the company’s processing capacity for making frozen French fries.

Potato Processing Market functioning in the food and beverage industry are also resorting to inventive methods to extend their consumer base. Fifty-nine percent of survey takers revealed that they use various platforms like online networking and digital advertising to reach an extensive range of customers. Today, consumers across the globe are able to tap the most innovative products available in the regional market. Digital media and social networking platforms have proven effective for companies attempting to broaden their reach in a way that is non-intrusive yet persuasive customers to consider regular purchases. With the increasing integration of social media in consumers’ daily lives and the ever-expanding virtual marketplace, the Potato Processing Market industry has witnessed the growth of several profitable growth opportunities and paving the way for more product innovation.

Scope Of The Report:

The Potato Processing Market report analyzes the present competitive landscape, underlining the ventures undertaken by the Potato Processing Market in the industry. Strategic initiatives such as product launches, collaborations, joint ventures, mergers and acquisitions, partnerships, and other such activities have been assessed in this report, predicting the potential revenue generation associated with such deals and launches. Furthermore, the report divides the Potato Processing Market based on segments like products, end-users, applications, business verticals, and regional markets. The study also gives a comprehensive outlook of drivers, constraints, growth prospects, and hurdles impacting the overall market along with market estimation derived by both top-down and bottom-up approaches and forecasts of the expected growth in the market value and volume.

Type (Revenue, USD Million; 2019–2026)

Frozen

Chips & Snack Pellets

Dehydrated

Others

Canned

Granules

Flour

Starch

Distribution Channel (Revenue, USD Million; 2019–2026)

Food Service

Retail

Application (Revenue, USD Million; 2019–2026)

Snacks

Ready-To-Cook and Prepared Meals

Others

Soups

Gravies

Bakery

Desserts

Regional Outlook (Revenue in USD Million; 2019–2026)

North America (U.S. , Canada.)

Europe (Germany, France, K., Spain, Italy, Rest of the Europe.)