#Types of Plummer Block

Explore tagged Tumblr posts

Text

Advantages and Disadvantages of Using Plummer Blocks

Plummer blocks are essential components in industrial machinery, providing reliable support for rotating shafts. From heavy-duty equipment to light conveyor systems, Plummer blocks are used across a wide range of applications. In this blog, we’ll explore what is Plummer block, the different types of Plummer block, and the key advantages and disadvantages of using them in your operations.

What is Plummer Block?

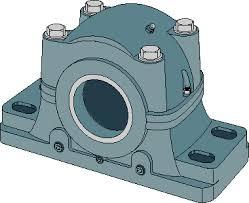

A plummer block, also known as a bearing housing or pillow block, is a mounting unit that houses rolling bearings. It is designed to support a rotating shaft and maintain alignment, allowing for smooth rotation with minimal friction.

These blocks are generally made from cast iron, cast steel, or sometimes thermoplastic, depending on the application. Plummer blocks simplify machinery maintenance, provide excellent support under load, and protect bearings from contaminants such as dust and moisture.

They are widely used in industries like:

Cement and mining

Power plants

Food processing

Conveyors and material handling systems

Types of Plummer Block

There are several types of Plummer block available, designed to accommodate different shaft sizes, loads, and installation requirements. Choosing the right one depends on the nature of your application.

1. Split Plummer Block Housing

These are the most common types, featuring a two-piece design that allows easy assembly, disassembly, and maintenance.

2. Solid Plummer Block Housing

Made in a single piece, these housings provide extra strength and rigidity, suitable for high-load applications.

3. Heavy-Duty Plummer Block

Built for extreme industrial conditions, they can handle high-speed and high-load environments effectively.

4. Light-Duty Plummer Block

Ideal for applications involving low speeds and light loads, such as small conveyors or agricultural machinery.

5. Adjustable Plummer Block

These offer flexibility in alignment and positioning, making them suitable for applications that require frequent adjustments.

Advantages of Using Plummer Blocks

Now that we’ve covered what is Plummer block and the various types of Plummer block, let’s look at the key benefits of using them.

1. Easy Installation and Maintenance

Plummer blocks, especially the split-type, allow for easy bearing inspection and replacement without dismantling the shaft. This reduces machine downtime and labor costs.

2. High Durability

Made from robust materials like cast iron or steel, Plummer blocks are designed to endure harsh environments and heavy mechanical loads.

3. Effective Shaft Support

They offer excellent shaft support and alignment, reducing the risk of vibration, misalignment, and wear in machinery.

4. Versatile Applications

With a wide range of sizes and configurations, Plummer blocks can be adapted to suit various applications—from lightweight machinery to high-load industrial systems.

5. Enhanced Bearing Protection

Plummer blocks often come with sealing mechanisms to protect the internal bearing from contaminants, extending the life of the bearing and the equipment.

6. Cost-Effective

Though they require initial investment, Plummer blocks prove economical in the long term by reducing bearing failure, machine downtime, and maintenance frequency.

7. Alignment Flexibility

Some Plummer blocks include self-aligning bearings that compensate for shaft deflections and misalignments, improving performance and reducing wear.

Disadvantages of Using Plummer Blocks

While Plummer blocks offer many benefits, they also have a few limitations to consider:

1. Size and Weight

Some Plummer blocks, particularly heavy-duty models, can be bulky and add extra weight to the machinery.

2. Initial Setup Complexity

Proper alignment and installation require technical expertise. Errors during setup can lead to premature bearing failure.

3. Limited Speed and Load Range

Not all types are suitable for extremely high speeds or heavy loads. Using the wrong Plummer block can result in system inefficiency.

4. Ongoing Maintenance Required

Although Plummer blocks simplify maintenance, they still require routine lubrication and inspection to function effectively.

5. Cost Variability

Advanced Plummer blocks with high-grade materials and specialized seals may have higher upfront costs, which can affect budgeting for large-scale installations.

Conclusion

Understanding the advantages and disadvantages of using Plummer blocks is essential for engineers, maintenance professionals, and equipment managers. These bearing housings provide a reliable, versatile, and cost-effective solution for supporting rotating shafts in industrial environments.

By knowing what is Plummer block and the various types of Plummer block available, you can select the right configuration to enhance your system’s performance and longevity. Despite a few limitations, Plummer blocks remain a smart investment for reducing downtime, improving equipment reliability, and ensuring smoother operation in demanding conditions.

Whether you're selecting bearing housings or sourcing from a trusted shaft mounted gearbox manufacturer in India, trust Nisuka Industries for performance, durability, and service.

#Advantages of Using Plummer Blocks#Disadvantages of Using Plummer Blocks#what is plummer block#types of plummer block

0 notes

Text

Bearing housings - Functionality and designs Insights | Jayco Engineering

Bearing housings play a critical role in the performance and reliability of rotating machinery. These components provide secure and supportive enclosures for bearings, ensuring proper alignment, load distribution, and protection from external contaminants. Whether it's an industrial fan, conveyor belt system, or heavy-duty pump, the right Bearing Housing can significantly impact equipment efficiency and longevity.

In this comprehensive blog, we explore the functionality, design types, essential parts, and other insights into Bearing Housing systems. As a trusted Bearing Housing Manufacturer and Bearing Housing Supplier, Jayco Engineering is proud to offer high-quality solutions tailored to meet diverse industrial requirements.

What is Bearing Housing?

A Bearing Housing is a mechanical component used to house and support a bearing, enabling smooth and efficient shaft rotation. These housings are designed to accommodate radial and axial loads while protecting the bearing from dust, moisture, and misalignment. By maintaining the proper position of the bearing, a housing also simplifies installation, lubrication, and maintenance tasks.

Functionality of Bearing Housings

The main functionalities of a Bearing Housing include:

Support and Alignment: A bearing housing keeps the shaft and bearing properly aligned, reducing wear and improving machine performance. Proper alignment ensures a longer bearing life and smoother operation.

Protection: By enclosing the bearing, the housing shields it from external contaminants like dust, dirt, and moisture, reducing the chances of premature failure.

Load Distribution: Bearing housings distribute the load evenly to the bearing and shaft, ensuring optimal performance even under heavy or fluctuating loads.

Lubrication Management: Modern housings often include lubrication features such as grease fittings and seals to maintain adequate lubrication and prevent over-lubrication or leakage.

Ease of Maintenance: With accessible design and integrated seals, bearing housing assemblies are easier to inspect, maintain, and replace without disassembling the entire equipment.

Bearing Housing Types

Different applications require different types of bearing housings. Some of the most common bearing housing types include:

Plummer Block Housings (Pillow Block): Ideal for horizontal shafts, these are widely used in general industrial applications. They provide excellent support and are easy to install.

Flanged Bearing Housings: These come with flanges for mounting to a surface. Common in vertical applications or where space is limited.

Take-Up Housings: Designed for adjustable positions, mainly used in conveyor systems where belt tension needs to be maintained.

Split Housings: These are divided into two parts, which makes bearing inspection and replacement easier. They are used in heavy-duty or high-load applications.

Cartridge Type Housings: Compact and integrated units suitable for high-speed applications. Often used in pumps, compressors, and electric motors.

At Jayco Engineering, we manufacture and supply a wide variety of bearing housing types, ensuring optimal solutions for every industrial need.

Bearing Housing Parts

A standard bearing housing assembly includes multiple parts, each serving a specific role in bearing performance:

Housing body: The main frame that supports the bearing.

Seals and covers: Prevent entry of contaminants and retain lubrication.

Locking mechanisms: Secure the bearing in position.

Mounting holes: Allow for secure attachment to the machine base.

Lubrication ports: Enable easy greasing or oiling of the bearing.

Understanding these bearing housing parts helps maintenance teams make informed decisions during installation and service.

Choosing the Right Bearing Housing

When selecting a bearing housing, several factors must be considered:

Load Capacity: Choose a housing designed to handle the radial and axial loads of your application.

Operating Conditions: Evaluate exposure to dust, water, temperature, and chemical environments.

Material: Cast iron is common, but stainless steel and thermoplastics are available for specific needs.

Mounting Options: Depending on the available space and mounting surface, different housing types offer flexibility.

Speed and Vibration: High-speed applications may require precision housing and advanced sealing.

Consulting with a reliable Bearing Housing Supplier like Jayco Engineering ensures that you select the correct product tailored to your industry standards.

Industries Using Bearing Housings

Bearing housings are used in a wide range of industries, including:

Mining and Quarrying

Cement and Construction

Textile Machinery

Steel Manufacturing

Food and Beverage Processing

Chemical and Pharmaceutical Plants

Agricultural Equipment

Jayco Engineering proudly serves all these industries with precision-engineered solutions that guarantee durability and cost-efficiency.

Bearing Housing Price – What to Expect?

The bearing housing price depends on various factors such as:

Type and size of housing

Material (cast iron, stainless steel, etc.)

Customization and features (seals, grease fittings, etc.)

Quantity ordered

As a leading Bearing Housing Manufacturer, Jayco Engineering ensures competitive pricing without compromising on quality. Whether you need standard or customized bearing housing, we offer affordable solutions with long-term value.

Why Choose Jayco Engineering for Bearing Housings?

At Jayco Engineering, we blend engineering excellence with customer-centric service. Here’s why we stand out:

Wide Product Range: From plummer blocks to cartridge housings, we cater to diverse requirements.

Custom Manufacturing: We design and fabricate custom bearing housings to meet specific operational demands.

Quality Assurance: Every unit undergoes stringent quality checks for durability and performance.

Timely Delivery: With a streamlined manufacturing process, we ensure prompt order fulfillment.

Expert Support: Our technical team helps you choose the right bearing housing assembly for your application.

Bearing housings are more than just mechanical support components—they are key to equipment longevity, safety, and performance. From selecting the right Bearing Housing Type to understanding the assembly and parts involved, this knowledge empowers industries to make the right investment.

If you're looking for a reliable Bearing Housing Manufacturer or Bearing Housing Supplier, Jayco Engineering is your go-to source. With high-quality manufacturing, competitive bearing housing prices, and customized solutions, we support industries across the globe.

Jayco Engineering – Precision that Powers Progress.

For more info: https://www.jaycohousing.com/

Email ID: [email protected]

Call us: 9512244473 Location: Plot No. 18,19,20, Dharti Industrial Park, P.O. Mirjapur, Ahmedabad-Indore Highway, Ahmedabad, Gujarat, INDIA.

#Bearing Housing#Bearing Housing Manufacturer#Bearing Housing Supplier#Bearing housing assembly#Bearing housing types#Bearing housing parts#Bearing housing price

0 notes

Text

Mounted Bearing Market Projected to Reach $2,122.1 Million by 2030

The global mounted bearing market is experiencing significant growth, with its size estimated at $1,451.0 million in 2023. Projections indicate a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030, leading to an anticipated market value of $2,122.1 million by 2030.

This upward trajectory is primarily driven by the increasing demand for specialized bearings across various industries, aiming to optimize costs through enhanced efficiency, extended lifespan, and reduced maintenance requirements.

Key Market Drivers:

Industrial Diversification: Mounted bearings are witnessing heightened adoption in sectors such as mining, food and beverages, aerospace, automotive, agriculture, chemicals, and pharmaceuticals. In the food and beverage industry, for instance, the U.S. Department of Agriculture reported that in 2021, this sector accounted for 16.8% of the nation's manufacturing sales and 15.4% of its employment. The meat processing segment alone held a 26.2% share of these sales, underscoring the critical role of efficient machinery components like mounted bearings in maintaining production efficacy.

Technological Advancements: The integration of Internet of Things (IoT) sensor-based bearing units is propelling industries toward smarter operations. Manufacturers are focusing on improving bearing designs to enhance energy efficiency and performance. Innovations in materials for cages, raceways, and rolling elements, along with advancements in sealing and lubrication technologies, are contributing to the growing demand for these components.

Regulatory Compliance and Hygiene Standards: In industries such as food processing, adherence to hygiene and sanitation regulations is paramount. Investments in processing and packaging equipment are increasing to boost output, reduce costs, and minimize waste, all while complying with standards set by agencies like the FDA. Selecting appropriate mounted bearings, particularly those made from food-grade stainless steel, ensures safety and efficiency in operations where contact with consumable products may occur.

Market Segmentation:

By Product Type:

Ball Bearings: Widely used across various industrial machinery, especially in the food and beverage sector, due to their ability to handle both radial and axial loads.

Roller Bearings: Preferred in heavy-duty applications such as mining and construction, owing to their capacity to support large radial loads.

By Housing Type:

Plummer Block: Offers high load-carrying capacity and is commonly used in conveyors and crushers.

Flanged Block: Ideal for applications where the mounting surface is perpendicular to the shaft.

Take-Up Block: Utilized in applications requiring adjustable shaft centers, such as belt-driven systems.

By End-User Industry:

Food & Beverages: Demands bearings that meet stringent hygiene standards.

Agriculture: Requires durable bearings capable of withstanding harsh environmental conditions.

Automotive & Transportation: Needs high-precision bearings for various vehicle components.

Future Outlook:

The mounted bearing market is poised for sustained growth, driven by continuous industrialization and the pursuit of operational efficiency across sectors. As industries evolve, the demand for advanced bearing solutions that offer durability, efficiency, and compliance with regulatory standards is expected to rise, presenting lucrative opportunities for manufacturers and stakeholders in the market.

Explore comprehensive insights and detailed analyses in the full Mounted Bearing Market Report: https://bityl.co/NtUM

0 notes

Text

0 notes

Text

Double Cone Blender

Double Cone Blender, sometimes known as a double cone mixer, is ideal for blending various types of powders. It also includes a medicinal powder mixer. By turning the vessel continually, the products are tumble distributed. Stainless steel 304, 316, or mild steel can be used to make blenders, depending on the specifications. Two conical frustums on either side of the shell of the vessel, a manual butterfly valve for discharge on one side, and a lid for charging with clamps that close and open quickly on the other. Both inside the vessel and on the cylindrical shell wall is a central baffle. The vessel is designed with zero retention. Operating mechanisms of the machine include a motor with a reduction gearbox, a vessel set on a Plummer block, and a specifically made chain sprocket. A limit switch that is linked with the motor on the safety guard guarantees safe operations.

0 notes

Text

Love, Theoretically ⁕ Book Review

This review contains spoilers. You have been warned!

Overall Thoughts ⁕ This book was so refreshing! It has single-handedly pulled me out of a years long reading slump. It’s the first story in a long time that I genuinely say I had fun reading! No stressing out about traumatic character demises, no overwhelming or dense worldbuilding, no putting it down for months before finally picking it up again. Just straight up, good, I-Want-A-Man-Like-Jack vibes.

Synopsis ⁕ Elsie Hannaway is an adjunct professor and trying her best to make her monthly rent, which leads her to taking gigs as a fake girlfriend. But when she puts her best foot forward for her dream career at MIT, Jack Smith-Turner stands in the way at every turn, in more ways than she can count.

Warnings ⁕ Chronic illness (Type 1 Diabetes), discussions of a parental death, explicit sexual content, medical situations, mentions of alcohol (a few side characters get drunk at a party), misogyny and sexism, power dynamics, sexual harassment.

Rating ⁕ ★ ★ ★ ★ ★

Plot

Going back to my reading roots with some sweet, sweet contemporary romance. There’s just something about a girl being so overwhelmed by her life, only to be reinvigorated by the thought of sticking it to her worst enemy... who has been in love with her the entire time. The plot progression at no point felt too fast or slow. It was a steady ride of genuine growth between Elsie and Jack. From one-sided loathing to “I want to eat you out for the rest of my life”, their relationship with one another is nothing short of sincere and considerate.

Characters

Elsie Hannaway ⁕ I love her! She is a great representation of what it’s like to be in your late twenties with seemingly no relief in sight. Her arc of breaking away from those who stifle her is very well done. She feels real. She has real concerns, real problems, real insecurities. After finishing this book, Elsie has skyrocketed to being one of my favorite protagonists. Jack Smith-Turner ⁕ This man. This man. One might say I need this man so fucking bad. And if one did say that, they would be so fucking correct. He’s so casually domineering and unapologetically interested in everything about Elsie. Sure, I was constantly saying how much of a dick he is out loud to myself, but I was doing it with a smile on my face.

Things I Liked

I listened to the audio book for this one, and the narrator, Thérèse Plummer, was great! If this story ever receives an adaptation, I’m going to need her to play every role in various costumes. If you looked up Ali Hazelwood in the dictionary, you’d find the word ‘hilarious’ next to her name. I can’t emphasize how much I smiled during this book! I couldn’t stop smiling — literally kicking my feet and giggling the entire time! Elsie is actually me in disguise, excluding the science stuff. All the way down to eating a cheese block in her room while reading Twilight fanfiction. Carbon copy.

Things I Disliked

The ending felt a little abrupt. Just Elsie handing him a letter was a little anti-climatic for me. I was confused when there wasn’t more after that. Also, the fact that we didn’t meet the infamous Kirk! I need a short story about Cece and her new beau as soon as possible! Just a little spin-off, please and thank you, Ali!

Other Notes

Once again, I want to acknowledge that this book was genuinely fun. I had a great time with it! I think it will be the one that can look back on and say that it successfully pulled me out of a years long reading slump.

1 note

·

View note

Text

0 notes

Link

Nishi Enterprise is pioneer plummer blocks and pillow block bearings manufacturers and supplier based in Ahmedabad, India. Our high-performance plummer block housings are made from cast irons that display excellent rigidity and are easy to handle.

#pillow block bearings manufacturers#plummer blocks#plummer block manufacturers in ahmedabad#plummer block bearing types#pedestal block bearing#pillow block bearing manufacturers in india#plummer block suppliers

0 notes

Photo

A pillow block bearing (or plummer block) is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing.use of plummer block?A pillow block usually refers to a housing with an included anti-friction bearing, wherein the mounted shaft is in a parallel plane to the mounting surface, and perpendicular to the center line of the mounting holes, as contrasted with various types of flange blocks or flange units. A pillow block may contain a bearing with one of several types of rolling elements, including ball, cylindrical roller, spherical roller, tapered roller, or metallic or synthetic bushing.[1] The type of rolling element defines the type of pillow block. These differ from "plummer blocks" which are bearing housings supplied without any bearings and are usually meant for higher load ratings and a separately installed bearing.[1] Plummer block bearings are designed for more corrosive environments.A pillow block bearing (or plummer block) is a pedestal used to provide support for a rotating shaft with the help of compatible bearings and various accessories. The assembly consists of a mounting block which houses a bearing.[1] The block is mounted to a foundation and a shaft is inserted allowingLikeCommentShare

0 notes

Text

Types of Plummer Block and Their Applications

Introduction

In any industrial setup where rotating shafts are involved, proper support and stability are crucial. One of the most important components used for this purpose is the Plummer block. A Plummer block houses and protects bearings while supporting shafts that are subjected to heavy loads and tough working conditions. At Nisuka Industries, a leading conveyor gearbox manufacturer in India, we recognize the critical role that Plummer blocks play in ensuring machinery efficiency, longevity, and safety.

There are several types of Plummer blocks, each designed to handle specific applications and environments. In this blog, we will explore the major types of Plummer blocks and their typical industrial uses.

Types of Plummer Block

1. Standard Plummer Blocks (SN Series)

The most common type of Plummer block is the Standard Series (SN Series). These blocks are designed for general-purpose applications. They are robust and can accommodate both spherical roller bearings and ball bearings, providing excellent load-handling capacity.

Applications:

Conveyor systems

Agricultural machinery

Fans and blowers

Light mining equipment

At Nisuka Industries, we often pair SN Series Plummer blocks with our products like conveyor belt tensioner manufacturer in India solutions to enhance performance and reduce maintenance needs.

2. Heavy-Duty Plummer Blocks (SD Series)

Heavy-duty Plummer blocks, also known as SD Series, are used in very demanding environments where extremely high loads and harsh conditions are present. These blocks are larger, made with stronger materials, and can handle both radial and axial loads efficiently.

Applications:

Mining operations

Cement plants

Crushers

Heavy conveyor systems

For industries that require strength and reliability, heavy-duty Plummer blocks are a perfect match, especially when installed alongside robust conveyor systems driven by solutions from a trusted SMSR gearbox manufacturer in India like Nisuka Industries.

3. Split Plummer Blocks

Split Plummer blocks are designed with a housing that can be separated into two parts, making installation and maintenance very convenient. This design allows easy replacement of bearings without removing the shaft, saving downtime and labor costs.

Applications:

Conveyor belts

Material handling systems

Marine industries

Paper and pulp industries

Split Plummer blocks are an ideal choice where frequent maintenance or bearing replacement is needed, helping industries maintain consistent productivity.

4. Flanged Plummer Blocks

Flanged Plummer blocks differ from the standard design by having a mounting flange. These blocks are used when the shaft must be supported perpendicular to the mounting surface.

Applications:

Vertical conveyors

Pump shafts

Vertical drive shafts

Gear drives

With products like conveyor belt tensioner in India and specialized gearboxes, Nisuka Industries ensures that flanged Plummer blocks are integrated into systems where space and alignment are critical factors.

5. Take-Up Plummer Blocks

Take-up Plummer blocks are specially designed to allow adjustment of the shaft position. They are used where the system needs to accommodate shaft expansion, tensioning, or contraction due to operational demands.

Applications:

Conveyor belt tensioning systems

Crushers and screening machines

Vibratory screens

Bucket elevators

As a recognized conveyor gearbox manufacturer in India, Nisuka Industries often supplies take-up Plummer blocks with adjustable systems that ensure smooth conveyor operations, minimizing wear and tear.

Importance of Choosing the Right Type of Plummer Block

Choosing the correct Plummer block is essential to maximize the performance of the entire system. Selecting the wrong type can lead to bearing failures, misalignment, increased downtime, and costly repairs.

Key factors to consider include:

Load capacity (both radial and axial)

Shaft size

Operating environment (dusty, wet, clean, etc.)

Installation space and accessibility

Maintenance requirements

Working with an expert like Nisuka Industries ensures you get the right advice, high-quality products, and excellent after-sales support to make the best choice.

Why Trust Nisuka Industries?

At Nisuka Industries, we pride ourselves on being more than just a Shaft mounted gearbox manufacturer in India. We offer complete solutions that enhance industrial efficiency and reliability. Whether you are looking for high-quality gearboxes, Plummer blocks, or conveyor belt tensioner in India, we provide end-to-end support — from consultation to installation and beyond.

Our strengths include:

Top-quality manufacturing with precision engineering

Expertise in handling heavy-duty industrial requirements

Custom solutions based on client needs

Prompt delivery and strong after-sales support

With decades of experience in the industry, Nisuka Industries has become a preferred partner for industries across India and internationally.

Conclusion

Plummer blocks play a vital role in supporting rotating shafts in various industries. From standard types for everyday applications to heavy-duty and flanged designs for specialized systems, the right Plummer block can drastically improve system efficiency and lifespan.

Understanding the different types of Plummer blocks and their applications is essential for maintaining machinery health and productivity. Whether you operate in mining, cement production, agriculture, or conveyor systems, choosing the right Plummer block is crucial.

Trust Nisuka Industries, the leading conveyor gearbox manufacturer in India, Plummer block manufacturer in India, and supplier of conveyor belt tensioner in India, to provide reliable, durable, and efficient solutions for all your industrial needs.

0 notes

Text

What does Pillow Block Bearing mean?

In mechanical power transmission systems, Pillow Block Bearing units are typically contained with a machined mounting surface supporting shafts and couplings. The shaft is normally perpendicular to the mounting screws and parallel to the mounting surface. An example of a housed-bearing unit is them. These might be equipped with several bearing types, including ball bearings, cylinder bearings, tapered roller bearings, or synthetic bushings.

Despite having a little difference in their structure, they are occasionally referred to as "Pummel blocks." The distinction between the pillow and pummelled block-bearing units must be understood. Although the design is fairly similar and the bearings are the same, the applications differ. Pillow blocks are utilized for lightweight applications, while Plummer blocks are used to transfer high power and support big industrial weights. Due to this distinction, their choice of construction material and bearing types may also differ.

Types of pillow block bearings

Regarding home construction, there are two types of pillow block bearings.

Solid Housed Bearings

Split Housed Bearings

Split-housed bearings have two-piece housings as opposed to single-piece housings for solid-housed bearings.

Steps to Choose Pillow Block Bearings

Choose a bearing type appropriate for your application, considering the load type, shaft size, running speed, misalignment, etc. The following bearing varieties may be present.

frank bearing

Ball-bearing

Tapered roller bearings, Cylindrical roller bearings, and spherical roller bearings are types of roller bearings.

Depending on your application and environment, choose the appropriate housing material.

Select the appropriate shaft attachment. Units may come with a set screw, tapered adapter, single or double set collar, eccentric lock, or set screw.

Give it some thought if a split type is required and might facilitate installation.

Select a pummel block-bearing unit with an appropriate bearing type for heavy load applications.

There are many kinds of seals as well, such as auxiliary type seals, light contact, heavy contact, and clearance seals.

Uses for pillow block bearings

These devices are extremely adaptable and have a wide range of uses. Shafts supported by a single or several bearing units are all possible. For instance:

Linking motors and pumps using belt drives

Rolling machines

Ventilation techniques

Paper shredders

Long shafts linking industrial gearboxes and motors

Roller for conveyor belt

All types of Pillow Block Bearings for sale in Rainbow Precision Products. You can rely on our skilled staff to provide you with unmatched, individualized customer care as you search for the ideal Worldwide Electric product for your particular application.

0 notes

Text

Automotive Bearing Market Revenue, Worth, Size, Segment by Type, Application, Key Companies | FMI

According to ESOMAR-certified Future Market Insights’ (FMI) - In 2022, the Automotive Bearing Market size is anticipated to increase at a y-o-y rate of 4.94%, reaching US$ 180 Bn.

Automotive bearings are accountable for smooth, economical and frictionless running of automobiles. They are present in almost every part of the automobile to ensure movement safety, load handling as well as balance. Several types of bearings are used in automobiles. To name a few, thrust bearings, ball bearings, roller bearings, housed units, needle roller bearings, Plummer blocks, plain bearings, spherical roller bearings, slim section bearings, ball thrust bearings, tapered roller bearings and specialized bearings are used. These bearings are made up of different material such as metal-polymers, engineered plastics, metals and bimetals and fibre reinforced composite.

The growth of the automotive bearing market is driven by various aspects such as rising technological developments, increasing production of vehicles across the globe, increasing demand for advanced bearings from emerging economies, increasing use of bearings in luxury cars etc. However, high pricing and counterfeiting are main challenges faced by the global market for automotive bearings.

For more Information: https://www.futuremarketinsights.com/reports/automotive-bearings-market

5 Key Highlights on Global Automotive Bearing Market

Ball thrust bearings segment by bearing type category to represent significant share in the coming years. This segment is also expected to gain a high BPS by the end of the assessment period and is poised to register a CAGR of 5.3% throughout the 2017-2022 period

Fibre reinforced composite segment by material type is expected to be the fastest growing segment during the assessment period. This segment is projected to reflect a high CAGR of 5.2% with a significant market share. It holds high potential in the coming years

Asia-Pacific excluding Japan (APEJ) region is the most lucrative region for the growth of the automotive bearing market. This region is ahead of other regions with respect to growth rate as well as market valuation during the period of assessment. This region is poised to register CAGR of 5.2% through 2017-2022

OEM segment by sales channel is expected to grow at a high pace during the assessment period. However, the aftermarket segment in this category, as of 2017, holds a high market share of 63.4%

Light commercial vehicles segment by vehicle type is a potential segment with respect to the use of automotive bearings and is expected to register the highest CAGR of 5.3% throughout the period of assessment

Key Player Profiles in the Global Automotive Bearing Market

The research report on global market for automotive bearings has included profiles of key players such as:

The Timken Company, Schaeffler AG, RKB Bearing Industries, NTN Corporation, NRB Bearings Ltd., Minebea Mitsumi Inc., JTEKT Corporation and ILJIN Bearing Co., Ltd.

Market segmentation

Bearing Type

Ball Bearing

Roller Bearings

Ball Thrust Bearings

Roller Thrust Bearings

Tapered Roller Bearings

Specialized Bearings

Others

Material Type

Metal-Polymer

Engineered Plastics

Fiber Reinforced Composite

Metal and Bimetal

Sales Channel

OEM

Aftermarket

Vehicle Type

Compact Passenger Cars

Mid-sized Passenger Cars

Premium Passenger Cars

Luxury Passenger Cars

Light Commercial Vehicles

Heavy Commercial Vehicles

Two-Wheeler

0 notes

Text

Double Cone Blender

youtube

Double Cone Blender (double cone mixer) including pharmaceutical powder mixer suitable for the mixing of different type of powders. The products are tumble diffused by continuously rotating the Vessel. Blender can be made in Stainless Steel 304, 316 or Mild Steel as per requirements. Vessel having two conical frustums either side of shell of the vessel having lid on one side for charging with quick closing and opening clamps and butterfly valve (Manual) on other side for discharge. Central baffle is provided inside the vessel and on the wall of cylindrical shell. The design of the vessel is zero retention design. The machine works on motor with reduction gearbox and the vessel mounted on Plummer block and specially designed chain sprocket. Safety guard is provided with limit switch interlocked with motor which ensures safe operations.

0 notes

Photo

What is the use of plummer block? The plummer block, which is an assembly comprising of a self-aligning ball bearing or spherical roller bearing placed in bearing boxes of various shapes, has a large load capacity and is easy to handle, therefore it is widely used in general industrial machinery such as conveyors. What are the types of plummer block? SKF manufacture three different types of plummer block housings namely, the 'SNA', 'SN' and 'SD' plummer blocks. SNA plummer blocks are designed for use with bearings mounted on adapter sleeves or with a cylindrical bore. What is the difference between plummer block and pillow block? Plummer blocks and pillow blocks have a similar design and both use the same types of bearing but they do differ in respect to their applications. Pillow blocks are used for more lightweight applications and plummer blocks are used to transfer high power and support heavy industrial loads.

0 notes

Text

Difference between Plummer Block vs. Pillow Block for industrial use

Introduction

In industrial machinery, supporting rotating shafts is critical for smooth operation and long service life. Two commonly used bearing housings for this purpose are plummer blocks and pillow blocks. While they might look similar, each has unique features suited for different industrial applications.

At Nisuka Industries, a trusted conveyor gearbox manufacturer in India, we understand the importance of using the right components to maintain reliable, efficient operations. In this blog, we explain the key differences between plummer blocks and pillow blocks for industrial use.

What is a Plummer Block?

A plummer block is a type of bearing housing designed to support a rotating shaft using a bearing inside it. It is usually made from heavy-duty materials like cast iron or cast steel, providing strong support for shafts operating under high loads and severe conditions. Plummer blocks are commonly used in heavy industries where durability, strength, and the ability to handle misalignment are essential.

These housings can accommodate spherical roller bearings or ball bearings and are often fitted with seals to protect against dust, dirt, and moisture.

Key features of Plummer Blocks:

High load-bearing capacity

Suitable for harsh environments

Can handle shaft misalignment

Designed for easy maintenance

What is a Pillow Block?

A pillow block is also a bearing housing that holds a rotating shaft but is usually designed for lighter-duty applications compared to plummer blocks. Pillow blocks are often made from lighter materials like pressed steel or cast iron and typically house ball bearings.

They are ideal for systems that operate at moderate speeds and loads, such as conveyors, agricultural equipment, and light industrial machinery.

Key features of Pillow Blocks:

Easy installation

Lower load-bearing capacity

Generally used in cleaner environments

Cost-effective for lighter applications

When to Choose a Plummer Block?

If your application involves high loads, high speeds, or tough environmental conditions (such as mining, heavy conveyor systems, cement plants, or crushers), a Plummer block is the better choice. At Nisuka Industries, as a trusted SMSR gearbox manufacturer in India, we often recommend Plummer blocks for industries that need robust and heavy-duty solutions to keep their production lines running smoothly.

Plummer blocks also allow for easy bearing replacement without disturbing the shaft alignment, saving downtime during maintenance.

When to Choose a Pillow Block?

If you are working with lighter loads and relatively clean environments, such as food processing units, small conveyors, packaging lines, or agricultural machinery, a pillow block is a cost-effective and practical solution. Pillow blocks are quick to install, easy to replace, and ideal for machines that don't experience extreme working conditions.

Many of our customers who use our conveyor belt tensioner manufacturer in India products in smaller setups also prefer pillow blocks due to their easy integration with conveyor systems.

Importance of Choosing the Right Bearing Housing

Choosing the wrong type of bearing housing can result in increased wear and tear, frequent breakdowns, and costly downtime. By selecting the correct housing — whether a plummer block or a pillow block — industries can ensure:

Better load distribution

Reduced maintenance costs

Longer equipment life

Smoother machine operation

As a leading conveyor gearbox manufacturer in India, we always guide our customers to select components that match their specific operational needs.

Main Differences Between Plummer Block and Pillow Block

Plummer blocks and pillow blocks differ in several key features that make them suitable for different industrial applications. When it comes to load capacity, plummer blocks are designed for high-load conditions, whereas pillow blocks are built to handle moderate to low loads. In terms of material, plummer blocks are constructed from heavy-duty cast iron or cast steel, giving them the strength needed for tough environments, while pillow blocks are typically made from cast iron or pressed steel, making them lighter and more suitable for less demanding applications.

The application areas for each also vary significantly. Plummer blocks are commonly used in heavy industries such as mining, cement production, and crushers, where equipment is exposed to extreme stress and harsh working conditions. In contrast, pillow blocks are used in light to medium industries, including conveyor systems and agricultural machinery, where the operational environment is more controlled. Speaking of environments, plummer blocks are built to withstand harsh, dusty, and wet conditions, whereas pillow blocks perform best in cleaner, indoor, or semi-protected environments.

When it comes to the type of bearings used, plummer blocks are versatile and can house spherical roller bearings or ball bearings, making them ideal for handling misalignment and heavy stresses. Pillow blocks, on the other hand, mostly use ball bearings, which are sufficient for moderate operational loads. Maintenance needs also differ; plummer blocks require regular maintenance to ensure longevity and optimal performance, especially given the tough conditions they face. Pillow blocks, by comparison, require minimal maintenance and are easier to manage in routine operations.

Finally, the cost is an important distinguishing factor. Plummer blocks are generally more expensive because of their robustness, high load capacity, and durable construction. Pillow blocks are a more economical choice, offering an affordable solution for applications that do not demand heavy-duty performance.

Nisuka Industries – Your Trusted Partner

At Nisuka Industries, we don’t just manufacture high-quality gearboxes and conveyor accessories; we also guide our customers in choosing the right mechanical components for their applications. As a reputed Shaft mounted gearbox manufacturer in India and a supplier of conveyor belt tensioner in India, we know that even small choices like the correct bearing housing can make a big difference in system performance.

We offer:

Expert consultation for selecting plummer blocks or pillow blocks

High-quality gearboxes for conveyor systems

Durable tensioning solutions to extend belt and bearing life

Reliable after-sales service and support

Our mission is to deliver complete, reliable, and efficient solutions to industries across India and beyond.

Conclusion

Both plummer blocks and pillow blocks are essential components in industrial machinery, but their applications differ based on load, environment, and operational needs. Plummer blocks are the preferred choice for heavy-duty, harsh environments, while pillow blocks are ideal for lighter, cleaner operations.

If you are setting up or upgrading your industrial machinery, trust Nisuka Industries — the leading conveyor gearbox manufacturer in India, SMSR gearbox manufacturer in India, and supplier of conveyor belt tensioner in India — to provide the right advice, products, and support for your success.

#what is Plummer block#plummer block manufacturer in India#shaft mounted gearbox manufacturer in india

0 notes