#VFD Market

Text

Variable Frequency Drive Market Will Reach USD 35.34 Billion By 2030

The variable frequency drive market is witnessing growth and is projected to reach USD 35.34 billion by 2030. This can be credited to the growing need for energy-effective electrical equipment like fans, motors, and pumps, and rising government guidelines in this field.

Fast industrial development is also one of the major reasons propelling the need for these drives.

With more and more sectors…

View On WordPress

#energy efficiency#HVAC#industrial applications#Key players#Manufacturing#market trends#Motor Control#Oil & Gas#Variable Frequency Drive#VFD Market

0 notes

Text

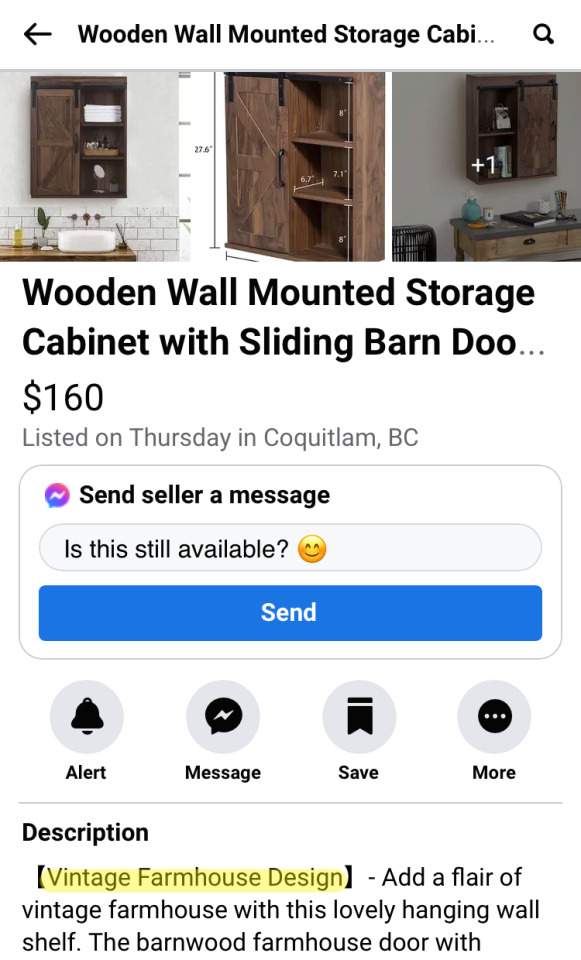

"Vintage Farmhouse Design"

-via a Facebook Marketplace listing

#vfd#lemony snicket#asoue#a series of unfortunate events#atwq#vintage farmhouse design#facebook marketplace#i have been looking for an unmirrored wood medicine cabinet for literally a year#there is a distinct gap in the market#probably going to handbuild one myself#vintage#farmhouse#design

17 notes

·

View notes

Text

We offer courses on PLC , SCADA, Industrial Automation, Embedded Systems, BMS ,CCTV, V FD in Trichy. Best training institute in Trichy, Tamil Nadu

1 note

·

View note

Text

Sony Mavica FD-7 (1997)

This is the Sony Digital Mavica FD-7, released in 1997!

Sony is probably more well known now for their line of professional mirrorless cameras, but back in the heyday of digital photography, Sony was doing some strange, strange things.

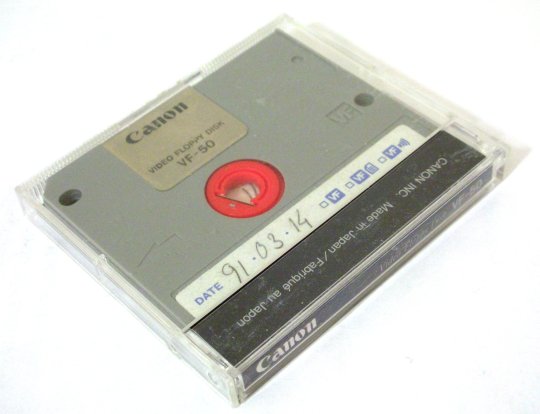

The history of Sony's ventures into digital photography has been covered extensively on the internet, so I won't go into it much, other than the quick facts. In 1981, the first product of theirs to bear the Mavica name was a prototype Still Video Camera from 1981. Still Video Cameras are a whole other can of worms as well (and one I really really want to get into when I inevitably come into possession of one). Mavica stood for MAgnetic VIdeo CAmera. The photos, which were just still frames taken from video were stored on these:

VFDs, or Video Floppy Disks. Again, this is a whole other beast when it comes to the history of digital photography. Sony manufactured a few of these Still Video Cameras under the Mavica line in the 1980s. Eventually this product line was discontinued, but Sony resurrected the Mavica name for a long-running series of floppy disk (and later CD) based cameras in the mid 1990s and 2000s.

The FD-7 was part of the first run of Sony's Digital Mavicas, along with the FD-5, pictured below, which was the lower end model with a fixed focus lens.

The FD-7 was the higher end model with a much larger lens, a 4.2-42mm f1.8, and has a 10x optical zoom. Both stored their images, as shown above, onto floppy disks.

You could store about 40 or so images in the camera's Standard mode, and about 20 in Fine mode, which for the time and the storage medium was pretty respectable. Floppy disks were everywhere at the time, so there really wouldn't have been any issue in terms of running out of storage.

One other quirk of these cameras I'd like to address are the Field/Frame modes. The Mavicas are actually doing something sort of clever here. The image sensor inside is still one used for video.

If you look at this image I've taken, you can see there's an after-image left behind on it. This is a result of the camera's sensor. The Field/Frame option does...something...that I think reduces the effect (Honestly Clint from LGR's video on this is where you should go for the technical details https://www.youtube.com/watch?v=3Nu6C-Ci7_Q)

ANYWAY. With all of that out of the way, here are some of the shots I've taken! (As with a LOT of digital cameras from around this time, the FD-7 shoots in 640x480 resolution, with quality modes delineating the amount of compression the image is given. All of these shots were taken in Fine mode.)

(This camera has a very good macro mode, btw!)

And there you have it! Honestly, I may just forego the rating portion of these after the first one. I want my concluding thoughts to be more interesting than a bunch of numbers.

If you like the challenges shooting with a low resolution and on a non-standard memory format, pick one of these up! USB floppy drives can be found for really cheap, and you can just drag and drop them from the disks right on to your computer, no fiddling required. I will say though, as a warning, that this stuff is nearing 30 years old. I actually have two of the FD-7s because my first one failed and refuses to focus in any way. Floppy disks can also be a problem, as I've had certain ones fail to record images due to bad sectors.

Other than that, these cameras feel surprisingly good in the hands, despite their boxiness, and are generally just really fun cameras to use. I have some of the later Mavicas, and while their image quality is better, (with the caveat that you can store much less images per disk) the original has this charm to it. It was the first of a series of really odd cameras that feel alien compared to today's camera market. And just for that, I think it's so cool.

4 notes

·

View notes

Text

Low Harmonic Drives: Driving Towards a Greener Future How Clean Power is Empowering the Automotive Industry

Over the past few decades, variable frequency drives (VFDs) have become widespread in industrial and commercial applications for their ability to control motor speed and torque. Traditionally, VFDs utilize pulse width modulation (PWM) techniques to vary motor voltage and frequency. However, PWM generates high harmonic currents that can damage motors, heat up transformers and power cables, and potentially cause voltage distortions on the utility grid. To address these challenges, a new generation of low harmonic drives has emerged based on advanced switching algorithms.

What are Harmonics?

In electrical systems, harmonics refer to sinusoidal voltages or currents having frequencies that are integer multiples of the fundamental power supply frequency, usually 50 or 60 Hz. Harmonics are produced by non-linear loads like adjustable speed drives that draw non-sinusoidal currents from the power source. The extra frequencies generated interact with the system impedance and generate losses, heating, vibrations, torque pulsations and can even cause misoperation of protective devices if sufficiently high in magnitude. Harmonics cause additional power losses in distribution transformers and overvoltages that reduce insulation lifetime. They can also interfere with communication lines.

Traditional PWM Drives and their Harmonic Impact

Traditional PWM VFDs employ insulated-gate bipolar transistors (IGBTs) or thyristors to rapidly switch the motor voltages on and off, generating quasi-square wave voltages to control motor speed. However, when these non-sinusoidal voltages are applied to the motor windings, they produce harmonic currents in the supply lines that are integer multiples of the fundamental supply frequency. Specifically, PWM drive techniques generate dominant 5th and 7th order harmonics that can propagate back into the utility system if not properly filtered.

The harmonic currents not only stress motor windings but also increase I2R losses in the supply feeders and distribution transformers. Low Harmonic Drives can cause overheating in older transformers not designed for harmonics. Harmonic distortions also increase circulating currents within delta-wye grounded transformers. To mitigate these issues, dedicated harmonic filters need to be installed, increasing overall system costs. Excessive harmonics if left unchecked can even cause protective relays to malfunction.

Advancements in Low Harmonic Drive Technology

To address harmonic pollution from VFDs, innovative drive manufacturers have developed new low harmonic drive technologies based on advanced switching algorithms that naturally minimize the generation of lower order harmonics.

Pulse-Density Modulation

One such technique is pulse density modulation (PDM) where the IGBTs are switched at high frequencies using narrower pulses compared to traditional square waves. By spacing the pulses closer together over time, PDM produces quasi-sinusoidal drive output voltages that inherently contain lower harmonics. PDM drives generate less than 5% total harmonic distortion (THD) without additional filters.

Active Front End Drives

Another option is active front end (AFE) drives with a front-end rectifier consisting of IGBTs or MOSFETs instead of diode bridges. The AFE rectifier actively shapes the supply current waveform to follow the voltage waveform and provide near unity power factor without harmonics. AFE drives come with integrated DC chokes to absorb any remaining higher order harmonics internally, keeping them well below 5% THD.

Get more insights on Low Harmonic Drives

Also read related article on Ransomware Protection Market

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Low Harmonic Drives#Harmonic Mitigation#Low Harmonic VFD#Variable Frequency Drives#Harmonic Distortion Reduction#Energy-Efficient Drives#Harmonic Filters

0 notes

Text

The Future of Heavy Duty Slurry Pumps in India's Growing Infrastructure Projects

India's rapid urbanization and industrial expansion have positioned it as one of the fastest-growing economies in the world. Central to this growth is the nation's robust infrastructure development, which includes large-scale projects in sectors such as mining, construction, and power generation. These industries demand reliable and efficient equipment to handle the challenging conditions of material transportation, particularly in handling abrasive and corrosive slurries. Heavy duty slurry pumps in India have emerged as indispensable tools, driving efficiency and reliability in these sectors.

This article delves into the future of heavy duty slurry pumps in India’s growing infrastructure projects, focusing on the evolving market dynamics, technological advancements, and the role of slurry pumps dealers in India, with a special emphasis on slurry pump manufacturers in Coimbatore.

The Infrastructure Boom in India

India's infrastructure sector is set to receive significant investments over the next decade, with government initiatives like the National Infrastructure Pipeline (NIP) projecting an investment of over $1.5 trillion by 2025. The focus areas include transportation (highways, railways, ports), energy (renewable and conventional), water resources, and urban development. Each of these areas requires advanced machinery and equipment capable of operating in harsh environments, making heavy duty slurry pumps critical to the success of these projects.

In mining, for instance, the demand for efficient slurry transportation systems is paramount due to the nature of the extracted materials, which often include heavy metals, ores, and other abrasive substances. Similarly, in construction, slurry pumps are essential for dewatering, concrete mixing, and the removal of waste materials. Power plants, particularly thermal and hydroelectric facilities, also rely on slurry pumps for ash handling, coal slurry transportation, and water treatment processes.

Technological Advancements Shaping the Future

The future of heavy duty slurry pumps in India is being shaped by significant technological advancements. Manufacturers are focusing on enhancing the efficiency, durability, and environmental compatibility of their products to meet the evolving needs of infrastructure projects.

Material Innovations: One of the most critical areas of development is the use of advanced materials to improve the wear resistance and longevity of slurry pumps. Materials such as high-chrome alloys, elastomers, and ceramics are increasingly being used in pump components to withstand the abrasive nature of slurries. These materials not only extend the service life of the pumps but also reduce the frequency of maintenance, thereby lowering operational costs.

Energy Efficiency: With the growing emphasis on sustainability, energy-efficient slurry pumps are gaining traction in the market. Modern pumps are being designed with optimized hydraulics, reducing energy consumption while maintaining high performance. Variable frequency drives (VFDs) and advanced control systems are also being integrated to adjust pump speed and flow rates according to the specific requirements of the application, further enhancing energy efficiency.

Smart Pumping Solutions: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in slurry pumps is revolutionizing the industry. Smart pumps equipped with sensors and monitoring systems can provide real-time data on pump performance, predict maintenance needs, and even automatically adjust operating parameters to optimize efficiency. These advancements are particularly beneficial in large infrastructure projects, where downtime can lead to significant delays and cost overruns.

Environmental Considerations: Environmental regulations are becoming more stringent, prompting manufacturers to develop slurry pumps that minimize environmental impact. Innovations such as leak-proof designs, reduced noise levels, and the ability to handle environmentally hazardous materials safely are becoming standard features in new-generation slurry pumps. These advancements not only ensure compliance with regulations but also contribute to the sustainability of infrastructure projects.

The Role of Slurry Pumps Dealers in India

As the demand for heavy duty slurry pumps in India continues to grow, the role of slurry pumps dealers in India becomes increasingly important. These dealers serve as the critical link between manufacturers and end-users, ensuring that the right products are available for various applications. They provide essential services such as technical support, maintenance, and after-sales services, which are vital for the smooth operation of infrastructure projects.

Dealers also play a key role in educating customers about the latest technological advancements and helping them choose the most suitable products for their specific needs. By maintaining close relationships with both manufacturers and end-users, slurry pumps dealers in India are well-positioned to anticipate market trends and provide products that meet the evolving demands of the industry.

Coimbatore: A Hub for Slurry Pump Manufacturing

Coimbatore, often referred to as the "Manchester of South India," is a major industrial hub with a strong presence in the manufacturing of pumps and other engineering products. The city is home to several leading slurry pump manufacturers in Coimbatore, who have established a reputation for producing high-quality, durable pumps that cater to the needs of India's growing infrastructure sector.

Manufacturers in Coimbatore are known for their focus on innovation and quality. They are continuously investing in research and development to introduce new technologies and improve existing products. The presence of a skilled workforce, advanced manufacturing facilities, and a supportive business environment has further strengthened Coimbatore's position as a key player in the slurry pump industry.

These manufacturers are not only catering to the domestic market but are also expanding their reach to international markets, showcasing the capabilities of Indian engineering on a global stage. As infrastructure projects in India continue to expand, the demand for high-quality slurry pumps from Coimbatore is expected to rise, driving further growth and innovation in the sector.

Conclusion

The future of heavy duty slurry pumps in India’s growing infrastructure projects looks promising, driven by technological advancements, a strong manufacturing base, and the crucial role played by slurry pumps dealers in India. As the country continues to invest in infrastructure development, the demand for efficient, durable, and environmentally-friendly slurry pumps will only increase.

Manufacturers, particularly those based in Coimbatore, are well-positioned to meet this demand with their focus on innovation and quality. By embracing new technologies and materials, and by continuing to prioritize energy efficiency and environmental sustainability, these manufacturers will play a vital role in shaping the future of India’s infrastructure landscape.

In conclusion, heavy duty slurry pumps in India are set to play an increasingly important role in the nation’s infrastructure development, ensuring that projects are completed efficiently, sustainably, and cost-effectively. As the industry continues to evolve, the collaboration between manufacturers, dealers, and end-users will be key to driving growth and innovation in this critical sector.

0 notes

Text

Elevator parts suppliers in dubai

18 Elevator repair companies

19 Elevator repair service

20 Electronics components uae

21 Medical equipment repair near me 22 Marine electronic repair

Horizon expands its expertise beyond standard electronic repairs, offering specialized services in HMI and display repair, Mitsubishi elevator board maintenance, and inverter repairs across the UAE. As a leading PCB repair service provider, they excel in VFD repairs and comprehensive elevator repair services, positioning themselves as a top choice for elevator maintenance in Dubai and nearby areas. Horizon not only repairs but also supplies elevator parts, serving as a one-stop solution for elevator companies. Their diverse portfolio extends to medical equipment repair and marine electronic systems, showcasing their versatility in handling complex electronic components. With a strong presence in the UAE's electronics market, Horizon continues to be a trusted partner for businesses seeking reliable and efficient electronic repair solutions across various industries.

0 notes

Text

0 notes

Text

JUST-IN; Power Tussle Brews at NASD As Shareholders Call Changes

A growing power tussle is unfolding at NASD PLC as VFD Group PLC, a key stakeholder, calls for a strategic overhaul of the alternative market platform ahead of its 11th Annual General Meeting (AGM).

The proprietary investment firm has expressed dissatisfaction with NASD’s financial performance, governance structure, and its failure to meet shareholder expectations.

VFD Group, a significant player…

0 notes

Text

Energy Efficiency in Lowara End Suction Pumps: Reducing Operational Costs

In today’s energy-conscious world, businesses and industries are increasingly focusing on reducing operational costs and minimizing their environmental impact. Pumps, which are integral to many systems, can account for a significant portion of energy consumption in industrial and commercial operations. Lowara end suction pumps, known for their efficiency and reliability, offer a range of features designed to enhance energy efficiency, thereby reducing operational costs. In this blog, we’ll explore how Lowara end suction pumps contribute to energy savings and how investing in these pumps can benefit your operation in the long run.

1. The Importance of Energy Efficiency in Pump Systems

Why Energy Efficiency Matters: Pumps account for a significant portion of energy consumption in industrial and commercial applications. By choosing energy-efficient pumps, businesses can reduce their energy bills, decrease their carbon footprint, and comply with increasingly stringent environmental regulations.

Operational Cost Savings: Energy-efficient pumps reduce power consumption, leading to lower operational costs. Over time, these savings can be substantial, especially in systems where pumps operate continuously.

2. Lowara’s Commitment to Energy Efficiency

Innovative Design: Lowara end suction pumps are designed with advanced hydraulic components that minimize energy loss and maximize performance. The streamlined design reduces friction and turbulence, allowing the pump to operate more efficiently.

High-Efficiency Motors: Many Lowara end suction pumps are equipped with IE3 or IE4 motors, which are among the most energy-efficient in the market. These motors reduce energy consumption without compromising the pump’s performance, leading to significant cost savings.

3. Key Energy-Efficient Features of Lowara End Suction Pumps

Optimized Hydraulics: The hydraulic design of Lowara end suction pumps is optimized to reduce energy consumption. By minimizing internal losses and ensuring smooth fluid flow, these pumps achieve high efficiency even under varying operating conditions.

Variable Frequency Drives (VFDs): Lowara pumps can be paired with VFDs to adjust the pump’s speed according to the system’s demand. This not only reduces energy consumption during low-demand periods but also extends the lifespan of the pump by reducing wear and tear.

Lowara Smart Pump Technology: Some Lowara models are equipped with integrated control systems that monitor and optimize pump performance in real-time. These smart features ensure that the pump operates at peak efficiency, automatically adjusting to changing conditions to minimize energy use.

4. Real-World Energy Savings with Lowara Pumps

Case Study: Industrial Water Circulation System

Scenario: A manufacturing plant was experiencing high energy costs due to outdated and inefficient pumps in its water circulation system. The pumps were running continuously at full speed, even during periods of low demand.

Solution: The plant upgraded to Lowara e-NSC end suction pumps with integrated VFDs. The new pumps adjusted their speed based on real-time system requirements, reducing energy consumption during off-peak hours.

Outcome: The plant saw a 25% reduction in energy costs within the first year of operation, with a payback period of less than two years. The pumps also required less maintenance, further reducing operational expenses.

5. Environmental Benefits of Lowara End Suction Pumps

Reducing Carbon Footprint: By consuming less energy, Lowara end suction pumps contribute to a reduction in greenhouse gas emissions. This not only helps businesses meet environmental regulations but also supports global efforts to combat climate change.

Sustainable Operations: The combination of energy efficiency and durable construction ensures that Lowara pumps have a longer operational life, reducing the need for frequent replacements and minimizing waste.

6. Tips for Maximizing Energy Efficiency with Lowara Pumps

Proper Sizing: Ensure that the pump is correctly sized for your application. An oversized pump can lead to inefficiencies and higher energy consumption, while an undersized pump may struggle to meet system demands, leading to increased wear and tear.

Regular Maintenance: Routine maintenance is essential to keep the pump operating at peak efficiency. Regularly check for signs of wear, leaks, or other issues that could impact performance.

Monitor Performance: Use smart monitoring systems to track the pump’s performance and energy consumption. This allows for early detection of inefficiencies and enables timely adjustments to optimize operation.

Consider Upgrading: If your system is running on older pumps, consider upgrading to more modern, energy-efficient models like those in the Lowara e-NSC or e-SH series. The initial investment can be offset by long-term energy savings and reduced maintenance costs.

7. The Economic Case for Energy-Efficient Pumps

Return on Investment (ROI): Although energy-efficient pumps may have a higher upfront cost, the long-term savings in energy and maintenance costs result in a positive ROI. Many businesses find that the savings achieved through energy efficiency pay for the pump within a few years.

Incentives and Rebates: In many regions, governments and utility companies offer incentives or rebates for installing energy-efficient equipment. These programs can further reduce the initial investment cost and improve the ROI of Lowara pumps.

Investing in energy-efficient Lowara end suction pumps is a smart decision for businesses looking to reduce operational costs and enhance sustainability. With advanced features like optimized hydraulics, high-efficiency motors, and smart control systems, Lowara pumps deliver exceptional performance while minimizing energy consumption. By choosing Lowara, you not only save money but also contribute to a greener future. For more info contact Lowara Pump Supplier in UAE or call us at +971 4 2522966.

#lowara pump suppliers#lowara pumps#lowara pump supplier#lowara pump distributors#lowara pump dealer in dubai#lowara pumps uae

0 notes

Text

The Forced Draft Fan market is projected to grow from USD 3,031.09 million in 2024 to USD 4,353.6 million by 2032, reflecting a compound annual growth rate (CAGR) of 4.63%.The Forced Draft Fan (FDF) market is witnessing significant growth, driven by the rising demand for energy-efficient industrial processes and the increasing adoption of advanced technologies in various sectors. Forced Draft Fans, also known as FD Fans, play a crucial role in enhancing the efficiency of combustion processes by supplying a continuous stream of air to boilers, furnaces, and other industrial applications. This article delves into the key factors fueling the growth of the Forced Draft Fan market, the challenges faced by industry players, and the future outlook of this essential market.

Browse the full report at https://www.credenceresearch.com/report/forced-draft-fan-market

Market Overview

Forced Draft Fans are integral components in industries such as power generation, cement, steel, chemical, and oil & gas. These fans are designed to push air through the combustion chamber, ensuring complete combustion of fuel and thereby increasing the efficiency of the process. The market for Forced Draft Fans has expanded steadily due to the growing need for optimizing industrial processes and reducing energy consumption.

Key Market Drivers

1. Increasing Industrialization and Urbanization:

The rapid pace of industrialization and urbanization, particularly in developing economies, has led to a surge in demand for power and other industrial goods. As industries expand, the need for efficient and reliable Forced Draft Fans has become more pronounced, driving the market forward.

2. Stringent Environmental Regulations:

Governments worldwide are implementing stringent regulations to reduce emissions and promote energy efficiency. Forced Draft Fans help industries meet these regulations by improving the efficiency of combustion processes, leading to lower emissions and reduced fuel consumption.

3. Technological Advancements:

The integration of advanced technologies, such as variable frequency drives (VFDs) and automation, has significantly enhanced the performance of Forced Draft Fans. These innovations have resulted in better control over airflow, reduced energy consumption, and lower operational costs, making these fans more attractive to end-users.

4. Rising Demand for Energy-Efficient Solutions:

Energy efficiency has become a top priority for industries across the globe. Forced Draft Fans are designed to optimize combustion processes, leading to significant energy savings. As a result, there is a growing demand for these fans in various sectors, including power generation, cement, and steel industries.

Challenges in the Market

1. High Initial Investment:

One of the primary challenges facing the Forced Draft Fan market is the high initial investment required for installation. While the long-term benefits in terms of energy savings and operational efficiency are significant, the upfront cost can be a barrier for small and medium-sized enterprises (SMEs).

2. Maintenance and Operational Costs:

Forced Draft Fans require regular maintenance to ensure optimal performance. The cost of maintenance and potential downtime can be a concern for industries, especially those operating on tight budgets.

3. Market Competition:

The Forced Draft Fan market is highly competitive, with several established players vying for market share. The presence of numerous local and international manufacturers has led to intense price competition, which can impact profit margins.

Future Outlook

The Forced Draft Fan market is poised for robust growth in the coming years, driven by increasing industrial activities, technological advancements, and the growing emphasis on energy efficiency. The market is expected to benefit from ongoing innovations, such as the development of more energy-efficient fan designs and the integration of smart technologies for better monitoring and control.

Moreover, as industries continue to prioritize sustainability and reduce their carbon footprint, the demand for Forced Draft Fans is likely to increase. The market is also expected to witness significant opportunities in emerging economies, where industrialization and urbanization are rapidly advancing.

Key Player Analysis

Buffalo Blower (New York Blower Company)

Zibo Fan Limited Company

Siemens AG

Mitsubishi Heavy Industries

ABB Group

Howden Group

Twin City Fan & Blower

Dongfang Electric Corporation

TLT-Turbo GmbH

BHEL (Bharat Heavy Electricals Limited)

GE Power

Yutong Blower

Kawasaki Heavy Industries

FläktGroup

Alstom Power

Segments:

Based on Fan Type:

Axial fans

Centrifugal fans

Based on Design Configuration:

Single inlet

Double inlet

Based on Drive Type:

Direct drive

Belt drive

Based on Industry:

Agricultural

Automotive

Building materials

Chemical

Food and Beverages

Metal and Mining

Oil and Gas

Others

Based on the Geography:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/forced-draft-fan-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Marine VFD Market is expected to reach USD 1.6 billion by 2030 from USD 1.1 billion in 2023 at a CAGR of 5.0% during the 2023–2030 period according to a new report by MarketsandMarkets™. Marine VFDs are essential because they help reduce power consumption, prevent damage, and enhance safety. VFDs also allow remote tracking of ship VFDs, regulate speed and torque, and provide fuel savings. The majority of propeller applications use VFDs, which can boost energy efficiency.

0 notes

Text

Introduction

In the fast-paced world of industrial automation, the need for efficient, dependable, and scalable solutions has never been greater. Whether it's a manufacturing plant, a food processing facility, or a mining operation, enterprises from all industries rely on motor drives to keep things moving smoothly. Motor drives regulate the speed, torque, and position of electric motors, allowing for seamless control and improved overall performance. Motor Drives Australia, a reputable provider of high-quality motor drives and automation solutions, is at the forefront of this technology in Australia.

In this blog, we'll look at the importance of motor drives in various industrial applications, the different types of motor drives available, and why Motor Drives Australia should be your go-to resource for all things industrial automation.

The Importance of Motor Drives in Industrial Applications

Motor drives are a necessary component in almost every automated system. Their the primary role is to regulate the operation of electric motors by varying speed, torque, and current flow. This level of control is critical in applications where accuracy and efficiency directly affect productivity and safety. For example, proper speed control in conveyor systems promotes a smooth process, avoiding bottlenecks and decreasing waste. Motor drives in HVAC systems are critical for maximising energy consumption while maintaining desirable environmental conditions.

Industries such as mining, manufacturing, oil & gas, and utilities rely extensively on motor drives. Companies can reduce cost on energy, lengthen the life of their equipment, and increase operational reliability by fine-tuning motor performance. In a market where downtime can result in severe financial losses, having robust and reliable motor drives is non-negotiable.

Types of Motor Drives and Their Applications

When selecting a motor drive, it is critical to understand your application's specific requirements. There are two types of motor drives: AC drives (also known as variable frequency drives, or VFDs) and DC drives. Each has unique qualities and advantages.

1. AC Drives (VFDs) are often used in applications that require precise speed control. VFDs can control motor speed by adjusting the frequency and voltage supplied to it. They are suitable for HVAC systems, pumps, fans, and conveyor belts, providing significant energy savings while minimising wear and tear on mechanical parts.

2. DC Drives: While less popular than AC drives, they are ideal for applications that require precise torque control and high beginning torque. They are commonly found in rolling mills, cranes, and other heavy-duty equipment. DC drives perform well in situations where continuous torque is required regardless of speed.

Why Choose Motor Drives Australia?

Motor Drives Australia stands itself not just for its diverse product offering, but also for its persistent commitment to quality and customer satisfaction. The company provides a broad assortment of motor drives adapted to diverse industrial applications, guaranteeing that clients find the ideal solution for their requirements.

1. Motor Drives Australia offers a diverse product range, including AC and DC drives, soft starters, and automation accessories. Their goods are intended to fulfil both general-purpose and specialised needs.

2. Expert Technical Support: When it comes to industrial automation, choosing the proper drive for your application is crucial. The Motor Drives Australia team has years of industry knowledge and provides personalised advice to help clients make educated decisions.

3. Motor Drives Australia prioritises quality in all aspects of their operations. Their products are rigorously tested to meet international standards, ensuring durability and constant performance even in severe environments.

4. After-Sales Service: Motor Drives Australia offers maintenance, troubleshooting, and repair support to keep your operations running well even after the initial purchase.

Innovations in Motor Drive Technology

Motor drive technology is continually improving as a result of advances in electronics, software, and material research. Modern motor drives are becoming more intelligent, energy-efficient, and responsive to the demands of Industry 4.0. Features like as predictive maintenance, IoT connectivity, and improved diagnostics are changing the way enterprises approach automation.

Motor Drives Australia is determined to keep ahead of these trends. Their products include the latest innovations, such as intelligent VFDs that can automatically modify parameters based on real-time feedback, thereby increasing efficiency and minimising downtime. Motor Drives Australia invests in innovation to guarantee that its clients have access to innovative technologies, allowing them to remain competitive in a continually changing landscape.

Optimizing Energy Efficiency with Modern Motor Drives

Energy efficiency is a significant goal for enterprises that want to minimise operational expenses and reduce their environmental effect. Modern motor drives play an important role in this regard since they improve motor performance, reduce energy waste, and reduce carbon footprints.

For example, VFDs can adjust motor speed based on load needs, keeping the motor from running at maximum speed when it is not needed. This not only reduces energy consumption, but also extends the life of the motor and its components. Motor Drives Australia offers energy-efficient solutions to assist businesses reach their sustainability goals while maintaining high levels of productivity.

Case Studies: Success Stories with Motor Drives Australia

Real-world success stories are a great way to appreciate the value that Motor Drives Australia provides. Let's look at few examples:

• Upgraded Manufacturing Facility: Outdated motor control systems caused frequent malfunctions at a large manufacturing plant. Motor Drives Australia supplied a comprehensive upgrade solution, including innovative VFDs and improved automation controls. What was the result? A 20% boost in operating efficiency and substantial cost savings.

• Motor Drives Australia successfully reduced energy expenses by 30% by implementing smart VFDs in a water treatment plant. These drives optimise pump operations in response to variable demand, ensuring optimal energy utilisation without sacrificing performance.

• Heavy-Duty Machinery Revamp: A mining operation needed reliable DC drives to replace outdated equipment. Motor Drives Australia offers high-performance DC drives with improved torque control, increasing total productivity while reducing downtime.

Conclusion

Motor drives are the foundation of modern industrial automation, and selecting the appropriate partner is critical to success. Motor Drives Australia brings a wealth of experience, a diverse choice of excellent goods, and exceptional customer service to the table. Whether you're replacing current systems or starting a new automation project, their solutions assure peak performance, energy savings, and long-term reliability.

Motor Drives Australia is the brand to trust when it comes to high-quality motor drives and automation solutions for businesses. Consult their specialists today to learn more about customised solutions that meet the particular needs of your industry.

Contact number : +03-9312-4722, OTP Number : +61 438 060 997

Address : Unit 9, 94 Boundary Road, Sunshine West 3020

Website : https://www.motordrives.com.au/

Contact Email : [email protected]

LinkedIn : https://www.linkedin.com/company/motordrives-australia-pty-ltd/

Opening Hours : 7:30am to 3:30pm - Saturday & Sunday Closed

0 notes