#Variable Frequencies Drives Market size

Text

Middle East Variable Frequency Drives Market - Forecast(2024 - 2030)

Middle East Variable Frequency Drive Market Overview:

Variable frequency drive is a type of motor controller that is opted for driving the motor by varying its frequency. The necessity for adjusting speed to enhance system efficiency, match the speed of the drive to the process requirements are driving the VFD market. Further, rising demand for energy efficient systems across every end-user industry is propelling the growth of VFD across the region. Manufacturer in these ecosystems is continuously evolving their products, including a multitude of features and innovations to provide energy efficient products to sustain in the market. Building automation is also one among the key industry utilizing variable frequency drive market. Moreover, the rise in population, an expanding economy along with changing climatic conditions will lead in demand for electricity consumption which in turn will increase the demand for variable frequency drives as they are extensively used in electric motors. Also, the government emphasis on power generation from clean energy will further fuel the growth of VFD market in the region. Middle East Variable Frequency Drive market is projected to grow with CAGR of 5.05% from $103.38M in 2017 to $138.94M in 2023 during the forecast period of 2018-2023.

Request Sample

Middle East Variable Frequency Drive Market Outlook:

The population of the world is anticipated to increase by 1.9 billion by 2040 according to the International Energy Forum, hereafter, the expansion in energy consumption will be increased by roughly 5000 million tons of oil equivalent. The energy consumption by increasing demand for an electric device that can conserve energy, enhance the process control and optimize the operation of various applications will increase the demand for energy. Furthermore, Government initiatives for energy efficiency and smart cities are boosting the growth of the smart homes market and concurrently the adoption of variable frequency drive market. According to the International Trade Administration, the urban construction sector in Dubai region has more than 3,200 active projects resulting in the estimated value of $425 billion in the year 2018. Building automation in the Middle East for VFD market will grow at a CAGR of 6.99% during the forecast period of 2018-2023.

Wastewater treatment industry in the Middle East has a tremendous importance due to the water scarcity, variable frequency drives enable pumps to accommodate the fluctuating demand by running these pumps at a lower speed and thereby consuming less amount of energy. The wastewater treatment of VFD market is estimated to reach the value of $13.79M by 2023 with the CAGR of 7.27% during the forecast period of 2018-2023. Moreover, In Industrial and automation process a significant number of electrical devices are deployed in the system for motion control applications and assembled with several types of motors and control systems for controlling the rotation of the motor shaft, which has huge scope for driving the growth of VFD market.

Inquiry Before Buying

Middle East Variable Frequency Drive Market Growth Drivers: Consumption of electricity in the Middle East region for building automation in commercial, as well as the residential purpose, depicts very high. Adoption of VFD in this region will improve the efficiency of motor-driven equipment and simultaneously require low maintenance costs. On the other hand, investment in machinery and equipment for manufacturing sectors in food & beverages products, basic materials and, manufacture fabricated materials is increasing. It amounts to 76% of the total investments made in the industrial sector, which will increase the demand of VFD because of extensive use in various applications such as conveyor belts, fans, pumps, and compressors.

Middle East Variable Frequency Drive Market Challenges: Electrical interference is limiting the growth of variable frequency drive. Variable frequency drives need special cables to avoid interference that increases the cost of the complete VFD. Few special motors are also employed with this to prevent damage from high voltage spikes which is adding the cost of variable frequency drives. Moreover, installation of frequency drives requires a significant space thus add cost and complexity in the environment.

Schedule a Call

Middle East Variable Frequency Drive Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the Middle East Variable Frequency Drive Market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of voltage and power range in Middle East Variable Frequency Drive Market, and their specific applications and end users.

Middle East Variable Frequency Drive Market Report: Industry Coverage

Voltage Range: Single Phase, Three-Phase

Power Range: Single Phase, Three-Phase

Application for Middle East Variable Frequency Drive: Actuators, Fans, Pumps, Extruders, Compressors, Conveyors, Cranes, and others

End-User of Middle East Variable Frequency Drive: Building Automation, Food & Beverage, Chemical & Petrochemicals, Mining and Metals, Pulp and Paper, Oil & Gas, Automotive, Water/waste water treatment, and others

The Middle East Variable Frequency Drive Market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The countries covered in the study include:

Middle East: UAE, KSA, Kuwait, Oman, Qatar, Lebanon, Jordan, and Others

Buy Now

Middle East Variable Frequency Drive Market Trends:

In order to upgrade the infrastructure and meet the requirements of increasing population in Saudi Arabia, the government is working on few major projects such as King Abdullah Economic City in the construction sector, Jeddah Public Transportation Program and Riyadh Metro to increase the infrastructure. The ongoing major projects in the country is a huge potential for the implementation of variable frequency drives.

Airport expansion in Middle East region of Abha regional airport, King Abdullah bin Abdulaziz airport and King Khalid international airport will be resulting in an increase in the demand for HVAC systems which in turn increases the demand for variable frequency drives.

Ministry of Electricity & water of Kuwait has laid out an energy conservation program in 2014 according to this all the fan motors of cooling towers irrespective of their sizes and locations have to be equipped with variable frequency drives in order to minimize water consumption and optimize power utilization. This resulted in increased adoption of VFD in various industry and significantly boosted the growth of VFD market in the country.

#middle east variable frequency drives market#middle east variable frequency drives market size#middle east variable frequency drives market shape#middle east variable frequency drives market forecast#middle east variable frequency drives market analysis#middle east variable frequency drives market price#middle east variable frequency drives market research#middle east variable frequency drives market report

0 notes

Text

Variable Frequencies Drives Market Forecast 2024 to 2032

Variable Frequency Drives (VFDs), also known as Variable Speed Drives (VSDs) or Adjustable Speed Drives (ASDs), are devices used to control the speed and torque of electric motors by varying the frequency and voltage of the power supplied to the motor. They are commonly used in industrial and commercial applications to optimize energy consumption, improve process control, and enhance motor performance.

The Variable Frequencies Drives Market was valued at USD 18.54 Million in 2022 and is expected to register CAGR of 3.54% by 2032.

The Variable Frequencies Drives market is driven by key factors such as energy efficiency and cost savings, industrial automation and process control and technological advancements.

Get PDF Sample Report: https://www.xcellentinsights.com/enquiry/sample/931

By Market Vendors:

Company A

Company B

…

By Types:

Low Voltage Drives

Medium Voltage Drives

High Voltage Drives

By Applications:

Pumps

Fans

Compressors

Conveyors

Extruders

Get Full report + Tables + Graphs: https://www.xcellentinsights.com/reports/variable-frequencies-drives-market-931

About Us:

Xcellent Insights is a market intelligence provider and consulting firm. We offer data-driven research services based on multiple analysis frameworks which helps businesses across the globe to understand current market scenario and align their strategic initiatives.

We offer syndicated research reports, customized research reports, consulting services and datasets which are mapped across multiple datapoints.

We provide research reports for all the industry sectors like Consumer Goods, Packaging, Chemicals and Materials, Healthcare, Pharmaceuticals, Medical Devices, Agriculture, Food and Beverages, Automobile and transportation, Electronics and Semiconductors, IT and Communication, Energy and Power, Machinery and Equipment.

Contact Us:

Name: Willie J

Phone: US: +1 4086277717

UK: +44 2086386439

Email: [email protected]

#Variable Frequencies Drives Market#Variable Frequencies Drives Market size#Variable Frequencies Drives Market share#Variable Frequencies Drives Market trend

0 notes

Text

0 notes

Text

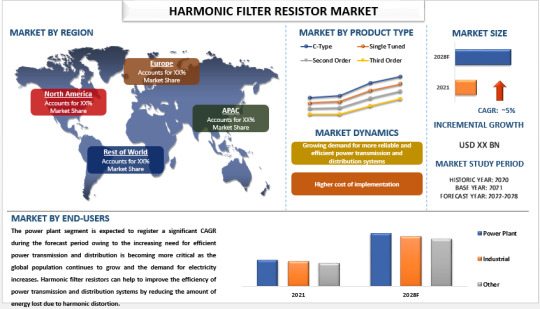

Harmonic Filter Resistor Market Size, Share, Growth & Forecast

The Asia-Pacific harmonic filter resistor market is expected to grow at a significant rate in the coming years, driven by a number of factors. One of the key drivers of the market is the increasing use of power electronics in industrial and commercial applications across the region. Power electronics, such as variable frequency drives and motor control centers, generate harmonic distortion in the power system, which can cause equipment damage and reduce system efficiency. Harmonic filter resistors are used to reduce the level of harmonic distortion in these systems, improving their performance and reliability. Another driver of the market is the growing demand for renewable energy sources in the region. Renewable energy systems such as wind and solar power can generate significant levels of harmonic distortion in the power system, which can cause equipment damage and reduce system efficiency. Harmonic filter resistors are used to reduce the level of harmonic distortion in these systems, improving their performance and reliability. In addition, the increasing use of smart grid technologies in the region is also driving the demand for harmonic filter resistors. Smart grids rely on power electronics and other advanced technologies to manage the flow of electricity, and these systems can generate harmonic distortion in the power system. Harmonic filter resistors are used to reduce the level of harmonic distortion in these systems, improving their performance and reliability.

Further, the APAC Harmonic Filter Resistor Market is expected to grow at a strong CAGR of 5.0% during the forecast period (2022-2028). APAC is anticipated to emerge as the fastest-growing Harmonic Filter Resistor market primarily driven by the increasing use of power electronics in industrial and commercial applications, the growing demand for renewable energy sources, and the increasing use of smart grid technologies in the region. The market is expected to present significant opportunities for players in the industry.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=38486

Based on product type, the market is segmented into C-type, single tuned, second order and third order. The third order segment is expected to hold a significant market share during the forecast period. Third order harmonic filters are the most advanced type of harmonic filter and consist of multiple capacitors, inductors, and resistors that are connected in a specific way to form a third-order filter. These filters are capable of reducing harmonic distortion to very low levels. In addition, the design of third order harmonic filters is complex and requires careful consideration of the specific requirements of the power system. The filter components must be carefully selected and optimized to ensure that the filter is effective at reducing harmonic distortion while minimizing the impact on system stability and power quality.

Based on end-users, the market is segmented into power plants, industrial, and others. The power plant segment is expected to register a significant CAGR during the forecast period owing to the increasing need for efficient power transmission and distribution is becoming more critical as the global population continues to grow and the demand for electricity increases. Harmonic filter resistors can help to improve the efficiency of power transmission and distribution systems by reducing the amount of energy lost due to harmonic distortion. Also, power quality issues, such as harmonic distortion, can have a negative impact on the performance and longevity of electrical equipment, including motors, transformers, and generators. Harmonic filter resistors can help to improve power quality by reducing the amount of harmonic distortion in the power system.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Effective A/B Testing Strategies for Email Campaigns

Introduction

A/B testing, also known as split testing, is a powerful method for optimizing email marketing campaigns. By comparing two versions of an email to see which performs better, marketers can make data-driven decisions that enhance engagement and conversion rates. Here are some effective A/B testing strategies to help you maximize the impact of your email campaigns.

1. Identify Clear Objectives

Before launching an A/B test, it’s crucial to define what you want to achieve. Are you aiming to increase open rates, click-through rates, or conversions? Having a clear objective will guide your testing process and help you choose the right elements to test. For instance, if your goal is to boost open rates, focus on testing subject lines or sender names.

2. Choose One Variable to Test

To accurately assess the impact of your changes, test only one variable at a time. This could be the subject line, email layout, call-to-action (CTA) button color, or even the time of day you send the email. By isolating a single element, you can clearly see how it affects your campaign’s performance. For example, if you’re testing subject lines, keep the email content and design consistent across both versions.

3. Segment Your Audience

When conducting A/B tests, it’s essential to segment your audience randomly. This ensures that each version of your email is sent to a similar demographic, reducing bias in your results. Most email marketing platforms allow you to split your list easily, ensuring that each segment receives one version of the email. This randomization helps in obtaining reliable data on which version performs better.

4. Use a Sufficient Sample Size

To achieve statistically significant results, ensure that your sample size is large enough. A small sample may lead to inconclusive results, making it difficult to determine which version is truly better. Use your email marketing platform’s analytics to calculate the minimum sample size needed based on your average open and click rates. This will help you avoid premature conclusions from your tests.

5. Analyze Timing and Frequency

Timing can significantly impact the success of your email campaigns. Experiment with different sending times and frequencies to see what resonates best with your audience. For instance, you might test sending emails on weekdays versus weekends or at different times of the day. Analyzing the results can help you identify the optimal times to reach your subscribers.

6. Monitor Key Metrics

After sending your A/B test emails, closely monitor key performance metrics such as open rates, click-through rates, and conversion rates. These metrics will provide insights into how well each version performed. Use this data to determine which version was more effective and why. For example, if one subject line led to significantly higher open rates, analyze what made it more appealing.

7. Iterate and Optimize

A/B testing is an ongoing process. Once you identify a winning version, use it as your new control and continue testing other elements. This iterative approach allows you to refine your email marketing strategy continually. For instance, if you find that a particular CTA button color drives more clicks, you can then test different wording or placement for that button in future campaigns.

8. Document Your Findings

Keep a record of your A/B testing results and insights. Documenting what you tested, the outcomes, and any patterns you observe will help inform future campaigns. This knowledge base can be invaluable for understanding your audience’s preferences and improving your overall email marketing strategy.

Conclusion

A/B testing is an essential tool for optimizing email marketing campaigns. By identifying clear objectives, testing one variable at a time, segmenting your audience, and analyzing key metrics, you can make informed decisions that enhance engagement and drive conversions. Embrace A/B testing as a continuous process, and you’ll be well on your way to creating more effective email campaigns that resonate with your audience.

#emailmarketing#digitalmarketing#marketing#socialmediamarketing#seo#onlinemarketing#socialmedia#contentmarketing

0 notes

Text

The Forced Draft Fan market is projected to grow from USD 3,031.09 million in 2024 to USD 4,353.6 million by 2032, reflecting a compound annual growth rate (CAGR) of 4.63%.The Forced Draft Fan (FDF) market is witnessing significant growth, driven by the rising demand for energy-efficient industrial processes and the increasing adoption of advanced technologies in various sectors. Forced Draft Fans, also known as FD Fans, play a crucial role in enhancing the efficiency of combustion processes by supplying a continuous stream of air to boilers, furnaces, and other industrial applications. This article delves into the key factors fueling the growth of the Forced Draft Fan market, the challenges faced by industry players, and the future outlook of this essential market.

Browse the full report at https://www.credenceresearch.com/report/forced-draft-fan-market

Market Overview

Forced Draft Fans are integral components in industries such as power generation, cement, steel, chemical, and oil & gas. These fans are designed to push air through the combustion chamber, ensuring complete combustion of fuel and thereby increasing the efficiency of the process. The market for Forced Draft Fans has expanded steadily due to the growing need for optimizing industrial processes and reducing energy consumption.

Key Market Drivers

1. Increasing Industrialization and Urbanization:

The rapid pace of industrialization and urbanization, particularly in developing economies, has led to a surge in demand for power and other industrial goods. As industries expand, the need for efficient and reliable Forced Draft Fans has become more pronounced, driving the market forward.

2. Stringent Environmental Regulations:

Governments worldwide are implementing stringent regulations to reduce emissions and promote energy efficiency. Forced Draft Fans help industries meet these regulations by improving the efficiency of combustion processes, leading to lower emissions and reduced fuel consumption.

3. Technological Advancements:

The integration of advanced technologies, such as variable frequency drives (VFDs) and automation, has significantly enhanced the performance of Forced Draft Fans. These innovations have resulted in better control over airflow, reduced energy consumption, and lower operational costs, making these fans more attractive to end-users.

4. Rising Demand for Energy-Efficient Solutions:

Energy efficiency has become a top priority for industries across the globe. Forced Draft Fans are designed to optimize combustion processes, leading to significant energy savings. As a result, there is a growing demand for these fans in various sectors, including power generation, cement, and steel industries.

Challenges in the Market

1. High Initial Investment:

One of the primary challenges facing the Forced Draft Fan market is the high initial investment required for installation. While the long-term benefits in terms of energy savings and operational efficiency are significant, the upfront cost can be a barrier for small and medium-sized enterprises (SMEs).

2. Maintenance and Operational Costs:

Forced Draft Fans require regular maintenance to ensure optimal performance. The cost of maintenance and potential downtime can be a concern for industries, especially those operating on tight budgets.

3. Market Competition:

The Forced Draft Fan market is highly competitive, with several established players vying for market share. The presence of numerous local and international manufacturers has led to intense price competition, which can impact profit margins.

Future Outlook

The Forced Draft Fan market is poised for robust growth in the coming years, driven by increasing industrial activities, technological advancements, and the growing emphasis on energy efficiency. The market is expected to benefit from ongoing innovations, such as the development of more energy-efficient fan designs and the integration of smart technologies for better monitoring and control.

Moreover, as industries continue to prioritize sustainability and reduce their carbon footprint, the demand for Forced Draft Fans is likely to increase. The market is also expected to witness significant opportunities in emerging economies, where industrialization and urbanization are rapidly advancing.

Key Player Analysis

Buffalo Blower (New York Blower Company)

Zibo Fan Limited Company

Siemens AG

Mitsubishi Heavy Industries

ABB Group

Howden Group

Twin City Fan & Blower

Dongfang Electric Corporation

TLT-Turbo GmbH

BHEL (Bharat Heavy Electricals Limited)

GE Power

Yutong Blower

Kawasaki Heavy Industries

FläktGroup

Alstom Power

Segments:

Based on Fan Type:

Axial fans

Centrifugal fans

Based on Design Configuration:

Single inlet

Double inlet

Based on Drive Type:

Direct drive

Belt drive

Based on Industry:

Agricultural

Automotive

Building materials

Chemical

Food and Beverages

Metal and Mining

Oil and Gas

Others

Based on the Geography:

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/forced-draft-fan-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Soft Starters Market Are Driving Growth in Power Efficiency Trends

The soft starter market offers effective solutions for motor starting across industries by facilitating smooth acceleration and reducing voltage spikes. Soft starters are employed to start induction motors in a gradual, controlled manner without high start-up currents occurring. They prevent mechanical and electrical stresses on equipment, reduce power consumption, and enhance motor lifespan. The devices simplify motor operation, offer low maintenance requirements and high reliability.

The global soft starter market size was valued at US$ 2,386.5 million in 2022 and is anticipated to witness a compound annual growth rate (CAGR) of 8.23% from 2023 to 2030.

Key Takeaways

Key players

Key players operating in the soft starter market are Siemens AG, Aucom Electronics Ltd (Benshaw Inc.), Schneider Electric SE, IGEL Electric GmbH, Eaton Corporation PLC, Crompton Greaves Ltd., ABB Ltd., Toshiba Corporation, Rockwell Automation Inc., Fairford Electronics Inc. (Motortronics UK Ltd), and Danfoss Group. Each of these players has strengthened its position in the market through product launches and expansions.

Growing demand

Growing industrialization and infrastructure development has increased Soft Starter Market demand for industrial equipment and commercial buildings which require heavy duty applications like compressors, pumps, fans and conveyors that utilize AC induction motors. Growing electricity cost concerns have also fueled adoption of soft starters for enhanced energy efficiency.

Global expansion

Key soft starter manufacturers are focusing on expanding their geographic footprint through partnerships and joint ventures in developing regions including Asia Pacific, Middle East and Latin America. Rapid industrialization and initiatives towards smart infrastructure and green buildings in these regions will drive future demand.

Market key trends

The Soft Starter Market Size and Trends rising popularity of variable frequency drives (VFDs) and their declining costs are prompting end-users to replace traditional starters with VFDs. VFDs provide enhanced control functionality, energy savings and control speed in addition to starting and stopping electric motors, replacing conventional soft starters. However, soft starters still remain competitive for small to medium capacity motors and are preferred for simplicity and lower cost.

Porter's Analysis

Threat of new entrants: Low start-up costs and weak intellectual property rights in some countries pose a moderate threat of new entrants in the soft starter market.

Bargaining power of buyers: Large industrial buyers have significant bargaining power due to the significant volume of their purchases. However, the availability of substitutes provides a balance in buyers power.

Bargaining power of suppliers: The high dependence of original equipment manufacturers (OEMs) on a few component suppliers results in moderate bargaining power of suppliers in the soft starter market.

Threat of new substitutes: Technological advancements have increased the demand for variable speed drives and frequency converters, posing a moderate threat of substitution to soft starters.

Competitive rivalry: The presence of numerous global and regional players results in high competitive rivalry in the soft starter market. Key differentiation factors include product innovation, reliability, and customer support.

Geographical Regions

North America accounted for the largest share of the soft starter market in 2024, with the United States being the major revenue generator. Growth in end-use industries such as oil & gas, mining, food & beverage, and others is fueling market demand.

The Asia Pacific region is projected to register the fastest CAGR through 2031. Rapid industrialization and urbanization in China, Japan, and India are key growth drivers. Increasing focus on energy efficiency and growing adoption of VFDs and soft starters are supporting regional market expansion.

Europe is a major soft starter market, with Germany, France, and the UK generating sizeable revenues. Strict emission norms and the need to optimize process performance are stimulating adoption. The soft starter market is diversifying with new technologies and customized offerings for renewable energy applications as well.

Get more insights on Soft Starter Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Coherent Market Insights#Soft Starter Market#Soft Starter#Motor Control#Electrical Equipment#Motor Starter#Industrial Automation#Energy Savings#Reduced Voltage Starter#Motor Protection

0 notes

Text

#VFD#VariableFrequencyDrive#IndustrialCables#VFDTechnology#Automation#EnergyEfficiency#IndustrialAutomation#PowerTransmission#CableTechnology#VFDMarket#ElectricalEngineering#IndustrialEquipment#CableManagement#EnergySolutions#MarketResearch

0 notes

Text

How to Choose the Right Vertical Centrifugal Pump for Your Needs?

What is a Vertical Centrifugal Pump?

A vertical centrifugal pump is simply a device that moves fluid or fuel by converting the rotational power of electric motor into kinetic energy. A case is had by these circular pumps an impeller that turns within it. The gas or liquid gets in at the biggest market related to the pump and it is forced external by centrifugal pressure ended up being discharged in the direction of the top of this housing or up and down upwards.

The vertical centrifugal pumps are commonly located in industries such as gas and oil, chemical, dishes and drink, and water therapy. Their layout allows them to deal with different fluids successfully, from destructive chemicals to thick substances. These pumps are valued for their durability, power efficiency, and ability to operate popular settings, ensuring constant and reputable efficiency throughout different industrial applications.

Advantages of Vertical Centrifugal Pump

There are a number of benefits of making application of a vertical centrifugal pump. Definitely, one of primary advantages it could be used to manage huge quantities of liquid or gas. The vertical centrifugal pump have actually been additionally extremely functional and consequently can be made use of in a number of various applications.

One more advantage is their compact dimension. Given that the impeller and electric motor are set up and down, these pumps occupy less room on the flooring than their straight equivalents. What this implies is a lot more pumps could be set up in a smaller sized location, causing boosted productivity.

Innovation in Vertical Centrifugal Pump

Development in upright centrifugal pumps has resulted in the advancement of a number of new features. As an example, some pumps will have an inbuilt variable frequency drive (VFD) that adjusts the motor rate to fit the system's demands. This particular feature conserves yourself power by making certain the engine runs just when essential.

An additional cutting-edge function the usage ceramic bearings, which often tend to be a lot more durable and longer-lasting than typical metal bearings. These bearings can endure extreme operating and require much less maintenance. A trusted thermic fluid pumps manufacturer typically incorporates such sophisticated products to improve the toughness and performance of their pumps, making certain trusted efficiency popular settings.

Safety in Use of Vertical Centrifugal Pump

Security is simply a top priority utilizing a Vertical Centrifugal Pump. The centrifugal pump upright must be properly endured all the correct piping electrical wiring. Normal assessment and maintenance concerning the pump are extremely essential to guarantee it is really operating correctly.

It can be very vital to use correct individual safety equipment collaborating with these pumps. This contains safety glasses, gloves, and hearing protection. A respectable centrifugal multi stage pump manufacturer highlights the significance of safety and security and guarantees that their products are created to minimize threats, however appropriate PPE remains vital for secure operation

How to Utilize Vertical Centrifugal Pump?

To take advantage of an upright pump, it is very important initially to go through the directions and stay with the producer's recommendations. This is made up of correct instalment positioning, and maintenance connected with pump.

Before starting the pump, make sure that it is topped with fluid to avoid issues for the impeller. When the pump is running, check it for virtually any kind of indicators of breakdown or vibration. Executing a routine tracking schedule can help find possible troubles early, permitting prompt intervention and minimizing downtime in crucial industrial processes.

Service and Quality

Service and quality are important variables when picking a vertical centrifugal pump. A credible pump should offer exceptional customer and assistance, consisting of technological help, upkeep, and repair work solutions.

The caliber of the pump need to be described as also a leading factor to consider. High-quality materials and handiwork are necessary to ensure the pump's integrity and longevity. Investing in a pump from a credible supplier not just makes certain optimum performance however additionally reduces downtime and upkeep costs, offering lasting worth for industries that depend on constant and reputable procedure.

Applications of Vertical Centrifugal Pump

Upright centrifugal pumps are made use of in a broad array of. They are widely utilized in wastewater treatment plants, desalination plants, and chemical processing centers. Additionally, they exist in power plants, beverage and meals handling, and coal and oil markets.

Other applications amongst these pumps include irrigation, mining, and marine procedures. Normally, in many these firms, Vertical centrifugal pumps are important elements of the systems, and their trustworthy operation would certainly be to ensure the smooth and reliable procedure of facility. A leading centrifugal chemical pump manufacturer plays a crucial function in supplying these necessary pumps, providing items that meet the strenuous needs of different commercial applications.

#Vertical Centrifugal Pump#Vertical Centrifugal Pump Manufacturer#Thermic Fluid Pumps Manufacturer#Centrifugal Multi Stage Pump Manufacturer#Centrifugal Process Pump#Centrifugal Chemical Pump Manufacturer#Ahmedabad#India

1 note

·

View note

Text

High-Quality Fly Ash Brick Making Machines Available in India

The construction industry in India is experiencing rapid growth, and with it comes an increasing demand for sustainable and cost-effective building materials. Fly ash bricks have emerged as a popular alternative to traditional clay bricks, offering superior strength, durability, and environmental benefits. To meet this growing demand, manufacturers are turning to advanced fly ash brick making machine in India. In this comprehensive guide, we'll explore the world of high-quality fly ash brick making machines available in India, their benefits, and how they're revolutionizing the construction industry.

The Rise of Fly Ash Bricks

Before delving into the machines that produce them, it's essential to understand why fly ash bricks have gained such popularity in recent years:

1. Environmental Sustainability: Fly ash bricks utilize waste materials from thermal power plants, reducing the environmental impact of brick production.

2. Cost-Effectiveness: These bricks are often more economical to produce than traditional clay bricks.

3. Strength and Durability: Fly ash bricks exhibit excellent compressive strength and resistance to weathering.

4. Consistency: Machine-made fly ash bricks offer uniform size and quality, ensuring better construction outcomes.

Advanced Fly Ash Brick Making Machines

BTM Product, a leading manufacturer in India, offers state-of-the-art fly ash brick making machines that cater to various production needs. These machines are designed to produce high-quality bricks efficiently and consistently. Let's explore the key features and benefits of these advanced machines:

1. Automated Production Process

Modern fly ash brick making machines employ sophisticated automation technologies to streamline the production process. This automation ensures:

- Consistent mix ratios

- Uniform compression

- Precise cutting and shaping

- Reduced manual labor and human error

2. High Production Capacity

Fly ash brick making machines available in India come in various capacities to suit different production requirements. Some high-end models can produce up to 20,000 bricks per day, making them ideal for large-scale construction projects.

3. Versatility in Brick Types

Advanced machines offer the flexibility to produce different types of bricks, including:

- Standard fly ash bricks

- Hollow blocks

- Solid blocks

- Interlocking bricks

This versatility allows manufacturers to cater to diverse market demands using a single machine.

4. Energy Efficiency

Modern fly ash brick making machines are designed with energy efficiency in mind. They incorporate features such as:

- Variable frequency drives

- Energy-efficient motors

- Optimized hydraulic systems

These features not only reduce energy consumption but also lower production costs.

5. Quality Control Mechanisms

To ensure consistently high-quality output, advanced machines are equipped with various quality control mechanisms, including:

- Pressure sensors for uniform compression

- Moisture control systems

- Automatic brick rejection systems for defective units

6. User-Friendly Interface

Many modern fly ash brick making machines feature intuitive control panels and touchscreen interfaces, making operation and monitoring easy for workers of various skill levels.

Complementary Machines: Expanding Your Production Line

While fly ash brick making machines are the cornerstone of brick production, manufacturers often expand their product lines to include other construction materials. Two popular additions are interlocking tiles making machine in India and paver block making machine in India.

Interlocking Tiles Making Machines

Interlocking tiles have gained popularity for their ease of installation and aesthetic appeal. BTM Product offers advanced interlocking tiles making machine in India that complement their fly ash brick making machine in India. These machines produce high-quality interlocking tiles suitable for various applications, including:

- Walkways

- Driveways

- Patios

- Indoor flooring

The interlocking tiles making machine in India offered by BTM Product feature:

- Multiple mold options for various designs

- High production capacity

- Precision cutting and shaping

- Durable construction for long-term use

Paver Block Making Machines

Paver blocks are another essential product in the construction industry, widely used for outdoor flooring and landscaping. BTM Product's range of paver block making machine in India are designed to produce high-quality, durable paver blocks efficiently. These machines offer:

- Versatility in block shapes and sizes

- High compressive strength for the finished products

- Efficient production process

- Easy maintenance and operation

By incorporating both interlocking tiles making machine in India and paver block making machine in India alongside fly ash brick making machines, manufacturers can diversify their product offerings and cater to a broader market.

Choosing the Right Fly Ash Brick Making Machine

When selecting a fly ash brick making machine in India, consider the following factors:

1. Production Capacity: Determine your required daily output and choose a machine that meets or exceeds this capacity.

2. Brick Specifications: Ensure the machine can produce bricks that meet the required size, shape, and strength specifications for your target market.

3. Automation Level: Consider the level of automation that best suits your production needs and workforce skills.

4. Energy Efficiency: Look for machines with energy-saving features to reduce long-term operational costs.

5. Maintenance Requirements: Choose machines that are easy to maintain and have readily available spare parts.

6. Manufacturer Reputation: Opt for reputable manufacturers like BTM Product, known for their quality and after-sales support.

7. Cost and ROI: Evaluate the initial investment against the expected return on investment based on your production goals and market demand.

The Future of Brick Making in India

As the construction industry in India continues to evolve, the demand for high-quality, sustainable building materials is expected to grow. Fly ash brick making machine in India, along with complementary products like interlocking tiles making machine in India and paver block making machine in India, are poised to play a crucial role in meeting this demand.

Manufacturers like BTM Product are at the forefront of this revolution, continually innovating and improving their machines to meet the changing needs of the industry. As technology advances, we can expect to see even more efficient, versatile, and environmentally friendly brick making machines in the future.

Conclusion

High-quality fly ash brick making machines available in India are transforming the construction industry by providing a sustainable, cost-effective alternative to traditional brick production methods. These advanced machines, offered by reputable manufacturers like BTM Product, combine automation, efficiency, and quality control to produce superior bricks that meet the demanding standards of modern construction.

By investing in a fly ash brick making machine in India, manufacturers can position themselves at the forefront of the sustainable construction movement. Moreover, by expanding their product lines to include interlocking tiles making machines in India and paver block making machine in India, they can offer a comprehensive range of construction materials to meet diverse market needs.

As the industry continues to evolve, the importance of choosing the right equipment cannot be overstated. By carefully considering factors such as production capacity, energy efficiency, and manufacturer reputation, businesses can make informed decisions that will drive their success in the competitive construction materials market.

With the right fly ash brick making machine and a commitment to quality and innovation, manufacturers in India can contribute to a more sustainable, efficient, and prosperous construction industry for years to come.

#fly ash brick making machine in India#paver block making machine in India#interlocking tiles making machine in India

0 notes

Text

Smart Plug Market Report, Consumer Insights, Growth Prospects, Industry Outlook 2024-2032

The Smart Plug Market is Experiencing Rapid Growth, Driven by Increasing Demand for Home Automation and Energy Management Solutions. The smart plug market research report provides a comprehensive analysis of the key factors influencing the industry, including market trends, growth opportunities, challenges, and technological advancements.

Smart plugs are becoming essential components of smart home systems, allowing users to control their appliances remotely and monitor energy consumption. The rising awareness of energy efficiency, coupled with the growing trend of home automation, is propelling the demand for smart plugs. Additionally, advancements in technologies such as the Internet of Things (IoT) and voice-activated systems are further driving the adoption of smart plugs across various applications.

Request a Free Sample Report of the Smart Plug Market: https://www.snsinsider.com/sample-request/1382

Competitive Landscape

A detailed analysis of the competitive landscape reveals key players dominating the smart plug market. These companies are at the forefront of innovation and are continually developing advanced products to meet the evolving demands of consumers. The report includes insights into their market share, product portfolios, financial performance, and strategic initiatives.

Key companies in the smart plug industry include:

D-Link Corporation

Panasonic Corporation

SDI Technologies Inc.

TP-Link Corporation Limited.

EDIMAX Technology

Belkin International, Inc.

Insteon

Leviton Manufacturing Co., Inc.

Hangzhou BroadLink Technology Co.,Ltd

Etekcity Corporation

Market Segmentation

The smart plug market can be segmented based on various criteria, providing a clearer picture of market dynamics and growth potential. This segmentation includes:

By Product Type

WiFi

Bluetooth

By Application:

Industrial

Household

Commercial

Regional Insights

The report offers an in-depth analysis of the smart plug market across key regions. North America is expected to lead the market, driven by high adoption rates of smart home devices and increasing awareness of energy-saving technologies. The Asia-Pacific region is anticipated to experience significant growth, fueled by rapid urbanization and the rising disposable income of consumers.

Enquire Before Buying: https://www.snsinsider.com/enquiry/1382

Key Questions Addressed

What are the primary factors driving growth in the smart plug market?

How are consumer preferences shifting towards smart home technologies?

What challenges are manufacturers facing in the development of smart plugs?

How do regional differences impact the adoption of smart plugs globally?

窗体顶端

窗体底端

Related Report:

Bluetooth IC Market Size

Marine Variable Frequency Drive Market Size

Time of Flight Sensor Market Share

Automotive Rain Sensor Market Size

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company’s aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Akash Anand - Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

#Smart Plug Market#Smart Plug Market Size#Smart Plug Market Share#Smart Plug Market Growth#Smart Plug Market Trends

0 notes

Text

North And Latin America Water Pumps Market is Estimated to Witness High Growth owing to Rising Construction Activities

The North and Latin America water pumps market consists of various product segments including centrifugal pumps, rotary pumps and reciprocating pumps. Centrifugal pumps function on the principle of centrifugal force to transport water from a low-pressure system to a high-pressure system. They are ideal for large flow rate applications like commercial HVAC systems, agriculture and wastewater treatment. Rotary pumps use a roller or sliding vane to push water from the inlet to the outlet. They are energy efficient and commonly used for hydraulic applications. Reciprocating pumps utilize a plunger or piston to transport water in a linear back-and-forth motion. They are suitable for high-pressure applications like boiler feed water and desalination. The water pumps find extensive usage in industrial, municipal, agriculture and residential sectors for applications like irrigation, drainage, filtration, dosing and liquid transfer.

North and Latin America water pumps market is estimated to be valued at US$ 12.72 Bn in 2024 and is expected to exhibit a CAGR of 4.7% over the forecast period from 2024 to 2031.

Key Takeaways

Key players operating in the North and Latin America water pumps are KSB AG, Ruhrpumpen Group, Flowserve Corporation, Kirloskar Brothers Limited, Sulzer AG, Xylem Inc., Ebara Corporation, Wilo SE, GRUNDFOS, and The Weir Group PLC.

The market provides significant opportunities in sectors like construction, agriculture, irrigation, wastewater treatment and power generation. Rising investments in infrastructure projects are fueling the demand for water pumps.

North And Latin America Water Pumps Market Demand are expanding to Latin American countries like Brazil, Mexico and Argentina through acquisitions, partnerships and distribution agreements to take advantage of opportunities in the growing regional market.

Market drivers

The main driver for the growth of North and Latin America water pumps market is the rising construction activities in the residential, commercial and industrial sectors. There is rising expenditure on construction of buildings, roads, bridges and other infrastructure which involves extensive usage of water pumps. The development of water supply and wastewater treatment infrastructure is another key factor driving the market growth.

PEST Analysis

Political: The regulations for water pumps vary in different countries across North America and Latin America. There are regulations regarding the efficiency and safety of pumps.

Economic: The economic growth and investment in industries like agriculture, mining will drive the demand for water pumps in the region. Repair and replacement of aging infrastructure also boosts market growth.

Social: Access to clean water is increasing in the region. Population growth and urbanization requires efficient water distribution which supports market growth.

Technological: Advances in material, design and variable frequency drives has improved pump efficiency. Integration of IoT enables remote monitoring of pumps.

Geographical regions with high market concentration

The United States accounts for the largest North And Latin America Water Pumps Market Size And Trends backed by investments in irrigation and water supply projects. Mexico, Canada and major countries in Central and South America also contribute significantly to the regional market.

Fastest growing region

Central and South America are projected to experience strong growth during the forecast period due to ongoing infrastructure projects, economic development and improving access to water and sanitation facilities across the region. Countries like Brazil, Colombia and Peru are expected to drive the future demand.

Get More Insights On, North and Latin America Water Pumps

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#North and Latin America Water Pumps Market Demand#North and Latin America Water Pumps Market Size#North and Latin America Water Pumps Market Trends#North and Latin America Water Pumps#North and Latin America Water Pumps Market

0 notes

Text

Industry Giants Invest in Advanced VFD Technologies to Capture Growing Market Share"

Overview :

Variable Frequency Drives market size is expected to be worth around USD 37.6 billion by 2033, from USD 23.3 billion in 2023, growing at a CAGR of 4.9% during the forecast period from 2023 to 2033.

Get a Sample Copy with Graphs & List of Figures @ https://market.us/report/variable-frequency-drives-market/#requestSample

The Variable Frequency Drives (VFD) Market refers to the sector that deals with devices used to control the speed and torque of electric motors by varying the frequency and voltage of the electrical power supplied to them. VFDs are critical components in many applications, from HVAC systems in commercial and residential buildings to automation in industrial processes. By adjusting motor speed, VFDs enhance energy efficiency, reduce wear and tear on equipment, and improve operational control, making them an integral part of modern energy management systems.

The market for VFDs is experiencing growth due to increased adoption across various sectors. The rise of connected devices and smart technologies in commercial, residential, and automotive applications is driving demand for more efficient and flexible motor control solutions. Additionally, significant investments in infrastructure development are boosting the need for advanced HVAC systems, which rely heavily on VFDs for optimal performance. As these systems become more prevalent and technology advances, the VFD market is set to expand, reflecting broader trends toward automation and energy efficiency in modern industry and infrastructure.

Market Segments :

By Product Type

AC Drives

DC Drives

Servo Drives

By Power Range

Micro (0-5 kW)

Low (6-40 kW)

Medium (41-200 kW)

High (>200 kW)

By Application

Pumps

Electric Fans

Conveyors

HVAC

Extruders

Other Applications

By End-Use

Oil & Gas

Power Generation

Infrastructure

Other End-Uses

Product Type Analysis:In 2023, AC Drives dominated the Variable Frequency Drives (VFD) market, capturing about 68.6% of the share. Their widespread use across industries like food and beverage, power generation, and automotive highlights their importance in controlling motor speed and enhancing operational efficiency. Meanwhile, DC Drives are expected to grow at a 6.1% CAGR through 2032.

Power Ranges Analysis :Low Power drives led the market in 2023, accounting for over 42.3% of the share. They are commonly used in applications such as pumps and fans where moderate power is required. The medium power range drives are also seeing growth, expected to increase by 6.8% from 2023 to 2032, due to their versatility in industries like mining and petrochemicals.

Application Analysis:Pumps were the leading application in 2023, holding over 30.2% of the market share. They are crucial for moving fluids in various industries and benefit significantly from the energy-saving capabilities of VFDs. The HVAC segment is projected to grow by 5.9% between 2023 and 2032, driven by the rising demand for energy-efficient climate control systems.

End-Use Analysis:Oil and gas applications led the VFD market in 2023, with over 20.3% of the share. VFDs are essential in processes like pumping, drilling, and refining, enhancing efficiency and reducing power consumption. The infrastructure sector is expected to grow at a 6.8% CAGR through 2032, driven by increased industrial activities and the shift from mechanical to electric motors.

Маrkеt Кеу Рlауеrѕ

ABB Ltd

Siemens AG

Danfoss A/S

Rockwell Automation

GE Power

Toshiba International Corporation

Schneider Electric

Mitsubishi Electric Corporation

Honeywell International Inc.

Emerson Industrial Automation

Fuji Electric Co. Ltd

Johnson Controls Inc.

Eaton PLC

Hitachi Ltd.

Nord Drive Systems

Eaton

Drivers:Variable Frequency Drives (VFDs) are increasingly essential across industries due to their energy-saving capabilities and precise motor control. Major projects in countries like China and India, which involve substantial cement and paper production, drive demand for these drives. VFDs help optimize energy use in millions of motors worldwide, leading to cost savings and enhanced efficiency.

Restraints:The oil and gas sector, a significant user of VFDs, has faced stagnation due to reduced exploration and production activities. Volatile oil prices create uncertainty, causing companies to hesitate on new investments in VFD technology. Additionally, stringent regulations aimed at reducing greenhouse gas emissions impose further challenges, potentially leading to decreased VFD usage as companies navigate the complexities of compliance and pollution control.

Opportunities:Upgrades to aging power infrastructure present a significant opportunity for VFD manufacturers. In regions like the US and Canada, improving outdated power networks and reducing power outages are critical needs. New regulations and investments in power systems create a growing demand for VFDs, offering a chance for companies to capitalize on the expanding market for these essential components in power management.

Challenges:The COVID-19 pandemic disrupted the production of electric motors and VFDs due to factory closures and supply chain interruptions. Key manufacturing hubs in China and the US experienced slowdowns, impacting the availability and cost of components. This has led to financial strain for companies reliant on these parts, complicating production and distribution efforts in the VFD market.

0 notes

Text

Asynchronous Motors Market Forecast and Analysis Report (2023-2032)

The global Asynchronous Motors Market reached a valuation of USD 12584.2 Million in 2023 and is anticipated to surge to USD 25155.9 Million by 2032, exhibiting a robust CAGR of 8.00% from 2024 to 2032.

The asynchronous motors market, also known as the induction motors market, is a significant segment within the electric motor industry. These motors operate on the principle of electromagnetic induction, where the electric current required to produce torque is obtained through electromagnetic induction from the magnetic field of the stator winding. They are widely used due to their robustness, reliability, and efficiency. The market for asynchronous motors is driven by their extensive application across various industries, including industrial machinery, HVAC systems, household appliances, and automotive. The increasing demand for energy-efficient motors is also a significant factor propelling market growth, as asynchronous motors are known for their high efficiency and lower energy consumption compared to traditional motors.

Technological advancements, such as the development of variable frequency drives (VFDs) and the integration of Internet of Things (IoT) technologies, are enhancing the performance and functionality of these motors, further boosting their adoption. Additionally, the shift towards renewable energy sources and the growth of the electric vehicle market are creating new opportunities for asynchronous motors. However, the market faces challenges such as high initial costs and the availability of alternative motor types, which may hinder growth to some extent. Overall, the asynchronous motors market is poised for steady growth, supported by ongoing industrialization, urbanization, and the global emphasis on energy conservation and sustainability.

The asynchronous motors market faces several challenges that could impact its growth and adoption across various industries. These challenges include:

High Initial Costs: Asynchronous motors, particularly those with advanced features and higher efficiency, often come with a higher initial cost compared to other types of motors. This can be a deterrent for small and medium-sized enterprises that may have budget constraints.

Competition from Alternative Motors: The market for electric motors includes various alternatives such as synchronous motors, servo motors, and permanent magnet motors. These alternatives sometimes offer better performance characteristics for specific applications, creating competitive pressure on asynchronous motors.

Energy Efficiency Regulations: While asynchronous motors are generally efficient, meeting the increasingly stringent energy efficiency regulations and standards set by governments and regulatory bodies can be challenging. Compliance with these standards may require additional costs for redesigning and upgrading existing motor models.

Technological Advancements in Competing Technologies: Continuous advancements in motor technology, especially in areas like permanent magnet synchronous motors (PMSMs) and brushless DC motors (BLDCs), can outpace the improvements in asynchronous motors, making them more attractive for certain applications.

Maintenance Requirements: Asynchronous motors, particularly older models, may require more frequent maintenance compared to newer motor types. This can increase the total cost of ownership over the motor's lifespan, affecting their desirability for some users.

Supply Chain Disruptions: The global supply chain for motor components can be vulnerable to disruptions due to geopolitical tensions, natural disasters, and pandemics. Such disruptions can affect the availability and cost of critical components needed for manufacturing asynchronous motors.

Market Saturation in Developed Regions: In mature markets such as North America and Europe, the adoption rate of asynchronous motors is already high, leading to market saturation. Growth opportunities in these regions may be limited compared to emerging markets.

Environmental Concerns: The production and disposal of asynchronous motors involve the use of materials and processes that can have environmental impacts. Increasing awareness and regulations related to environmental sustainability may pressure manufacturers to adopt greener practices, which could increase costs.

Technological Integration Challenges: Integrating asynchronous motors with modern control systems, IoT platforms, and Industry 4.0 frameworks can be complex and costly. Ensuring seamless compatibility and functionality with these advanced systems can be a barrier to adoption.

Economic Factors: Economic downturns and fluctuations in industrial activity can affect the demand for asynchronous motors, as capital investments in new machinery and equipment tend to decrease during such periods.

Key Players:

ABB

Emerson

GE

TECO

Regal-Beloit

Nidec

Siemens

Tatung

Hitachi

WEG

Bosch Rexroth

SEW-Eurodrive

Cummins

YASKAWA

Toshiba

VEM

NORD

Landert

ABM Greiffenberger

SPG

Brook Crompton

More About Report- https://www.credenceresearch.com/report/asynchronous-motors-market

The key findings of a study on the asynchronous motors market highlight several critical insights and trends that shape the market's landscape. These findings include:

Market Growth and Size: The asynchronous motors market is experiencing steady growth, driven by increased demand across various industries, including manufacturing, automotive, HVAC, and household appliances. The market size is projected to expand significantly over the next few years due to rising industrial automation and energy efficiency initiatives.

Energy Efficiency: One of the primary drivers for the market is the emphasis on energy efficiency. Asynchronous motors are increasingly preferred for their ability to reduce energy consumption and operational costs. The implementation of stringent energy efficiency regulations globally has further accelerated the adoption of high-efficiency asynchronous motors.

Technological Advancements: Innovations in motor design, materials, and control systems have enhanced the performance, reliability, and efficiency of asynchronous motors. The development of variable frequency drives (VFDs) and integration with smart technologies and IoT platforms are notable advancements that are positively impacting the market.

Applications and End-Use Industries: Asynchronous motors find extensive application in diverse industries. The industrial machinery sector remains the largest end-user, followed by the HVAC and automotive industries. The growing popularity of electric vehicles (EVs) is also creating new opportunities for asynchronous motor adoption.

Geographical Trends: The market shows varied growth patterns across different regions. Asia-Pacific is the largest and fastest-growing market, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, supported by technological advancements and established industrial bases.

Competitive Landscape: The market is highly competitive, with several key players investing in research and development to innovate and improve their product offerings. Leading companies are focusing on mergers, acquisitions, and collaborations to expand their market presence and enhance their technological capabilities.

Challenges and Constraints: Despite the positive growth outlook, the market faces challenges such as high initial costs, competition from alternative motor types, and compliance with evolving energy efficiency standards. Addressing these challenges is crucial for sustained market growth.

Regulatory Impact: Government regulations and policies aimed at reducing carbon emissions and promoting energy conservation are significantly influencing the market. Compliance with these regulations is driving the adoption of energy-efficient asynchronous motors, thereby boosting market growth.

Future Outlook: The future of the asynchronous motors market looks promising, with continued advancements in technology and increasing demand for energy-efficient solutions. The shift towards renewable energy sources and the growth of the electric vehicle market are expected to provide new growth avenues.

Sustainability Initiatives: There is a growing emphasis on sustainability within the industry. Manufacturers are focusing on developing eco-friendly motors and adopting green manufacturing practices to minimize environmental impact, aligning with global sustainability goals.

Segmentation:

By Type of Asynchronous Motors:

Single-Phase Induction Motors

Three-Phase Induction Motors

Squirrel Cage Induction Motors

Wound Rotor Induction Motors

Single-Speed Induction Motors

Variable-Speed Induction Motors

By Enclosure Type:

Open Drip-Proof (ODP) Motors

Totally Enclosed Fan-Cooled (TEFC) Motors

Totally Enclosed Non-Ventilated (TENV) Motors

Explosion-Proof (XP) Motors

Water-Cooled Motors

By Power Rating and Application:

Fractional Horsepower (FHP) Motors

Medium-Horsepower Motors

High-Horsepower Motors

Browse the full report – https://www.credenceresearch.com/report/asynchronous-motors-market

Browse Our Blog: https://www.linkedin.com/pulse/asynchronous-motors-market-projections-global-tjdlc

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Sustainable Agriculture: Exploring the Benefits of No-Till and Minimum-Till Equipment Market | BIS Research

The agricultural industry is increasingly adopting sustainable practices to enhance soil health, improve crop yields, and reduce environmental impact. One of the pivotal shifts in modern farming is the adoption of no-till and minimum-till practices, which are supported by specialized equipment designed to reduce soil disturbance.

According to BIS Research, the Global No-Till and Minimum-Till Equipment Market was estimated to be worth $6.58 billion in 2023 and is projected to grow at a CAGR of 6.15% to reach $8.87 billion by 2028.

Understanding No-Till and Minimum-Till Practices

No-Till Farming involves planting crops directly into the residue of previous crops without tilling the soil, thereby minimizing soil disturbance.

Minimum-Till Farming, while involving some soil disturbance, significantly reduces the intensity and frequency of tillage compared to conventional practices. Both methods aim to preserve soil structure, enhance water retention, and reduce erosion.

Key Market Dynamics

Several factors are driving the growth of the global no-till and minimum-till equipment market:

Environmental and Soil Health Benefits:

- Improve soil health by preserving organic matter

- Reduce erosion and enhance water infiltration

- Drive adoption due to long-term soil sustainability and productivity advantages

Increasing Awareness of Climate Change:

- Growing concerns about climate change and greenhouse gas emissions

- Gain traction due to carbon sequestration in soil and reduced fuel consumption

Technological Advancements:

- Advances in agricultural equipment technology, such as precision planting and seed drill systems

- Enhance efficiency and effectiveness of no-till and minimum-till farming

- Improve accuracy of seed placement and ensure optimal crop emergence

Economic Considerations:

- Reduce labor and fuel costs, providing economic benefits to farmers

- Improved soil health can lead to higher crop yields

- Reduced need for fertilizers and pesticides

Government Support and Incentives:

- Promotion of conservation tillage practices through subsidies, grants, and educational programs

- Encourage adoption of no-till and minimum-till equipment by farmers

Want to excel in the market? Download FREE Sample PDF Report on No-Till and Minimum-Till Equipment Market Research.

No-Till and Minimum-Till Equipment Market Segmentation

Segmentation by Application:

- Farms and Agricultural Fields

- Orchards and Vineyards

- Pastures and Grazing Lands

- Nurseries and Urban Agriculture

Segmentation by Product:

- Seed Drills and Planters

- Cover Crop Seeders

- Cultivators and Tillage Equipment

- Precision Agriculture Technologies

Segmentation by Region:

- North America

- South America

- Europe

- Asia-Pacific

- China

- U.K.

- Middle East and Africa

Key Challenges and Market Opportunities

While the no-till and minimum-till equipment market presents substantial opportunities, it also faces several challenges:

Initial Investment Costs: The high cost of no-till and minimum-till equipment can be a barrier for small and medium-sized farms, limiting widespread adoption.

Technical Knowledge and Training: Successful implementation of no-till and minimum-till practices requires technical expertise and training, which may be lacking in some regions in the agriculture industry.

Variable Soil and Climate Conditions: The effectiveness of no-till and minimum-till practices can vary based on soil types and climatic conditions, requiring tailored approaches for different regions.

Conversely, the market presents numerous opportunities:

Expansion in Emerging Markets: Improving agricultural infrastructure and rising awareness in emerging markets present significant growth opportunities for no-till and minimum-till equipment manufacturers.

Development of Affordable Solutions: Innovations aimed at reducing the cost of no-till and minimum-till equipment can make these practices accessible to a broader range of farmers.

Focus on Education and Training: Increasing education and training programs for farmers on the benefits and use of no-till and minimum-till equipment can boost adoption rates.

Collaborations and Partnerships: Partnerships between equipment manufacturers, agricultural organizations, and governments can drive product development and market penetration.

Conclusion

The Global No-Till and Minimum-Till Equipment Industry is poised for significant growth, driven by the environmental and soil health benefits, increasing awareness of climate change, technological advancements, economic considerations, and government support. By addressing challenges related to initial investment costs, technical knowledge, and variable soil conditions, and leveraging opportunities in emerging markets, affordable solutions, education, and collaborations, the potential of no-till and minimum-till equipment in transforming agriculture can be fully realized.

#No-Till and Minimum-Till Equipment Market#No-Till and Minimum-Till Equipment Report#No-Till and Minimum-Till Equipment Industry#No-Till and Minimum-Till Equipment Market Size#No-Till and Minimum-Till Equipment Market CAGR#No-Till and Minimum-Till Equipment Market Research#Agriculture#BIS Research

1 note

·

View note