#Vertical Turret Milling Machine Manufacturer

Text

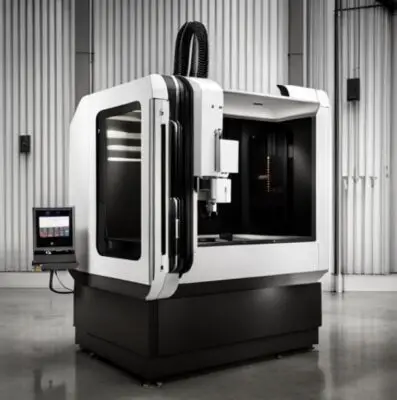

Vertical Turret Milling Machine| Vertical Turret Milling Machine supplier| Vertical Turret Milling Machine manufacturer in pune

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Text

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Link

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in ...

0 notes

Text

Maximizing Efficiency with Advanced Machining Technologies

In today's competitive manufacturing landscape, the efficiency and precision of machining processes are critical for success. Advanced technologies such as Vertical Turret Lathes, Hydraulic Fixtures for Machining Centers and Deep Hole Drilling Machines have revolutionized the industry, offering unparalleled capabilities and reliability.

Exploring Precision And Versatility With Vertical Turret Lathe

A Vertical Turret Lathe (VTL) is a staple in the machining world, known for its precision and versatility. These machines are designed to handle large, heavy workpieces with ease. The vertical orientation allows gravity to assist in stabilizing the workpiece, reducing the likelihood of deflection and improving accuracy. VTLs are particularly effective for machining large diameter components, such as wheels, flanges and various circular parts.

One of the key advantages of a VTL is its ability to perform multiple operations in a single setup, including turning, drilling and milling. This multi-functionality reduces the setup time, minimizes the risk of errors and enhances overall productivity.

Enhancing Stability With Hydraulic Fixtures

Hydraulic Fixtures for Machining Centers are essential for maintaining stability and precision during the machining process. These fixtures use hydraulic pressure to securely clamp the workpiece, ensuring it remains in the exact position required for accurate machining. This method is far superior to manual clamping, providing consistent and repeatable results.

The benefits of hydraulic fixtures include improved cycle times, reduced operator fatigue and enhanced safety. By automating the clamping process, hydraulic fixtures also allow for quicker changeovers, making them ideal for high-mix, low-volume production environments. This increased efficiency can significantly reduce production costs and improve the overall quality of the final product.

Achieve Ultimate Accuracy With Deep Hole Drilling Machine

Deep Hole Drilling Machines are specialized tools designed to drill holes with high depth-to-diameter ratios. These machines are crucial for industries such as aerospace, automotive and oil & gas, where precise deep hole drilling is required. The technology behind these machines allows for the creation of holes that are not only deep but also straight and accurate, with minimal deviation.

Advanced features of deep hole drilling machines include high-pressure coolant systems, which help to remove chips and cool the drill bit, thereby extending its life and maintaining accuracy. The ability to drill deep holes efficiently and accurately opens up new possibilities in component design and manufacturing.

Why WIDMA Is The Best For Superior Machining Solutions

When it comes to advanced machining technologies, WIDMA stands out as a leader in the field. With a strong commitment to innovation and quality, WIDMA provides a comprehensive range of solutions that cater to the diverse needs of the manufacturing industry. From Vertical Turret Lathes to Hydraulic Fixtures for Machining Centers and Deep Hole Drilling Machines, WIDMA's products are designed to deliver exceptional performance and reliability.

WIDMA's expertise and dedication to customer satisfaction ensure that their machines not only meet but exceed industry standards. By choosing WIDMA, manufacturers can trust that they are investing in technology that will enhance their operational efficiency, improve product quality and drive business success. For those looking to stay ahead in the competitive world of machining, WIDMA is the partner of choice.

#widma#vertical turret lathe#hydraulic fixtures in machining centers#deep hole drilling machine price#deep hole boring

0 notes

Text

Are the CNC and Lath machine same Explain ??

Lathes and CNC machines are both popular tools used in the manufacturing industry for cutting and shaping materials. Although they may seem similar in some aspects, they differ in several ways. In this article, we will explore the differences between the two machines.

A lathe machine is a tool that rotates a workpiece about an axis of rotation to perform various cutting, drilling, and threading operations. The workpiece is held in place by a chuck or collet, and the cutting tool moves along the workpiece to shape it. Lathes come in different types, such as engine lathes, turret lathes, and CNC lathes.

On the other hand, a CNC (Computer Numerical Control) machine is a type of machine tool that uses pre-programmed computer software to control the movements of the machine. The machine can perform a variety of operations, including drilling, milling, and cutting. CNC machines can be used to manufacture complex parts and components with high precision and accuracy.

One of the main differences between a lathe machine and a CNC machine is their level of automation. A lathe machine is operated manually, with the operator controlling the movement of the cutting tool and the workpiece. In contrast, a CNC machine is fully automated and operates based on pre-programmed instructions. Once the program is loaded, the machine can run continuously without any human intervention, except for maintenance and occasional monitoring.

Another difference is the level of precision and accuracy. Lathes are generally used for basic operations such as turning, facing, drilling, and threading. While they can achieve a reasonable level of accuracy, they are not suitable for high-precision tasks. CNC machines, on the other hand, can produce parts with extremely high accuracy and precision due to the use of computer software to control the machine's movements.

CNC machines are also capable of producing complex geometries and shapes that are difficult or impossible to achieve using a lathe machine. This is because the CNC machine can move the cutting tool in multiple directions simultaneously, allowing for more intricate designs and shapes.

In terms of speed, 5 Achsen CNC machines are generally faster than vertical lathe machines. This is because the CNC machine can operate continuously without stopping, while a lathe machine requires the operator to manually stop and start the machine for each operation.

Lastly, cost is a significant difference between the two machines. CNC machines are typically more expensive than lathe machines due to their complexity and automation. However, the increased efficiency, precision, and versatility of CNC machines can justify the higher initial cost in the long run.

In conclusion, lathe machines and CNC machines are both valuable tools used in the manufacturing industry. While they may seem similar, they differ significantly in terms of automation, precision, versatility, speed, and cost. Choosing the right machine for a particular task depends on the nature and complexity of the work, as well as the available budget and resources.

0 notes

Text

What You Should Know Before Buying a CNC Mill

Are you considering the purchase of a CNC (Computer Numerical Control) mill? With increasing options in precision machining and manufacturing, these specialized tools can provide powerful capabilities for detail-oriented work. Before taking the plunge into investing in a CNC mill, there are important points to consider such as cost and performance; understanding what is available on the market will help you make an informed decision. In this blog post, we'll explore some of the key features to look out for when buying a CNC mill so that you can find one that meets your needs while staying within budget.

What is a CNC Mill and how does it work?

A CNC mill is a machine used in manufacturing that employs computer-controlled engineering to produce highly precise parts and products. CNC mills utilize instructions in the form of numerical software to control the cutting process of a workpiece. The machine typically consists of a bed, spindle, motor, cutting tools, and worktable. The cutting tools, which range in shape and size, rotate at high speeds, shaving away material from the workpiece to create the desired shape.

The CNC mill allows for incredibly accurate and reliable production, making it ideal for creating complex and intricate parts for various industrial applications. The machine can be programmed to cut and shape a variety of materials, including metals, plastics, and composites, to create three-dimensional objects of nearly any shape.

The CNC mill works by utilizing a combination of computer software and hardware to control the process. A CAD (computer-aided design) program creates a digital model of the part or product, which is then translated into a series of instructions in G-code. The G-code provides the instructions for the CNC mill to precisely move the cutting tools and worktable, ultimately creating the desired shape.

Once the G-code is loaded into the CNC mill's computer, the machine begins cutting, precisely following the programmed instructions. The operator monitors the process, making adjustments as necessary to ensure the workpiece is produced to specifications.

The CNC mill provides a highly automated and precise way of manufacturing complex parts and products. By using a combination of computer software and hardware, the machine produces accurate and reliable results, meeting the demands of modern manufacturing processes.

What are the Different Types of CNC Mills and Their Uses?

Computer Numerical Control (CNC) mills are essential tools in modern-day manufacturing. CNC mills operate with the use of software and computer programs, which allow them to execute precise cutting and shaping of materials. Different types of CNC mills are available, and they come with varying capabilities to perform diverse functions.

Here are the different types of CNC mills and their uses:

1. Vertical Milling Machine:

Vertical milling machines are designed to work with flat or rectangular metal surfaces. The spindle is positioned vertically, enabling a wide range of cutting possibilities such as drilling, tapping, and milling. This type of mill is perfect for manufacturing large quantities of flat or rectangular parts.

2. Horizontal Milling Machine:

This mill is suitable for cutting and shaping materials from different angles. The spindle is positioned parallel to the worktable, allowing for precision cutting, drilling, and boring. Horizontal milling machines are excellent for producing parts in bulk quantities.

3. Bed Milling Machine:

Bed milling machines have a vertically adjustable spindle that moves along the Z-axis. The bed can move along the X and Y-axis, allowing the machine to cut along different paths. Bed milling machines are ideal for creating parts with various shapes and sizes.

4. Turret Mill:

A turret mill has a rotating spindle with a cutting tool at the end. This machine has a table that can be moved vertically and horizontally, giving it the capacity to cut and shape intricate forms. Turret mills are perfect for delicate jobs that need fewer cuts and a more precise finish.

5. CNC Router:

CNC routers are designed to remove material from a workpiece, allowing it to be formed into a particular shape or pattern. It uses a rotating cylindrical tool that moves along multiple axes, providing precision cutting for objects like wooden decorative pieces, furniture parts, signboards, and architectural moldings.

Different CNC mills are available for specific purposes, and the choice of the type depends on the materials, shapes, and productivity needs. While operating CNC mills may require skillful expertise, success hinges on selecting the right type of CNC machine for the particular task at hand.

Benefits of Using a CNC Mill for Manufacturing

Standard benefits:

- Increased accuracy and precision of parts compared to manual methods.

- Reduced production time with automated processes.

- Ability to produce complex shapes with ease.

Emotional benefits:

- Feel confident in the quality of your products due to increased accuracy and precision.

- Enjoy the satisfaction of creating high-quality parts quickly and efficiently using CNC Mill for Manufacturing technology.

Advantages and Disadvantages of CNC Milling

Computer Numerical Control (CNC) milling is a type of precision engineering process that utilizes computer-controlled cutting tools to remove material from the workpiece. CNC milling has become a popular manufacturing method due to its accuracy, efficiency, and versatility. However, just like any other manufacturing process, CNC milling has its own advantages and disadvantages that must be considered.

Advantages:

1. Precision and Accuracy: CNC milling machines are capable of producing complex and intricate shapes with high precision and accuracy. This is because the cutting tools are guided by the computer, which ensures that the dimensions are consistent throughout the production process.

2. Flexibility: CNC milling machines are extremely versatile and can produce a wide range of products. It is possible to create different shapes, sizes, and forms without the need for different setups.

3. Consistency: CNC milling machines can produce identical parts with high consistency. This means that once the program for a particular part has been created, it can be easily replicated with the same level of accuracy every time.

4. Efficiency: CNC milling machines are highly efficient and can produce a high volume of parts within a short time. This helps to reduce production time and costs.

5. Automation: The use of CNC milling machines reduces the need for manual labor, which can lead to a reduction in costs and an increase in productivity.

Disadvantages:

1. High Cost: CNC milling machines are expensive to purchase, install, and maintain. This makes it difficult for small businesses and startups to invest in this technology.

2. Complex Programming: CNC milling machines require complex programming to operate. This means that operators need to have specialized skills and knowledge to use them effectively.

3. Dependence on Electricity: CNC milling machines rely on electricity to operate. This means that power outages or fluctuations can result in downtime and production delays.

4. Limited Material Handling: CNC milling machines are limited in their ability to handle certain types of materials. This means that operators will need to use different machines for different materials, leading to increased costs and longer production times.

5. Lack of Flexibility: While CNC milling machines are highly flexible, they can be limited in their ability to produce certain types of shapes and materials. This means that some parts may need to be produced through other methods, leading to longer production times and increased costs.

CNC milling has revolutionized the manufacturing industry by providing accurate and efficient production of various parts and products. However, it is important to consider the advantages and disadvantages of this technology before investing in it. By weighing these factors carefully, businesses can make informed decisions about whether CNC milling is the right choice for their production needs.

Factors to Consider When Purchasing a CNC Mill

If you're looking to purchase a CNC mill, there are several factors that you should consider before making your final decision. A CNC mill is a computer-controlled machine that uses rotating tools to remove material from a workpiece. It offers many benefits, such as increased accuracy, repeatability, and automation, which improves efficiency and saves time. Here are the factors that you should take into account when purchasing a CNC mill.

1. Machine Size:

The size of the CNC mill that you choose will depend on the size of the workpieces that you're planning to mill. If you're working with large pieces of material, you'll need a larger machine that can handle the size and weight of the workpiece. Conversely, if you're working with small pieces, you'll need a smaller machine to ensure accurate and precise cuts.

2. Machine Capability:

Different CNC mills have varying capabilities. You should choose a machine that has the capabilities that you need for your specific application. Factors to consider include the number of axes, spindle speed, and cutting capacity. If you're working with complex parts that require multiple cutting operations, you'll need a machine that has a high number of axes to achieve the required cuts accurately.

3. Machine Accuracy:

Precision and accuracy are critical in CNC milling. When purchasing a CNC mill, ensure that it has the required tolerances and accuracy level for your application. The accuracy of a CNC mill is usually measured in microns, so choose a machine with an accuracy level that meets your needs.

4. Machine Price:

The price of a CNC mill can vary significantly depending on its capabilities, size, and accuracy. Ensure that you have a budget in mind before purchasing a machine, and choose a machine that offers the best value for your needs. Avoid choosing a machine based on price alone, as lower-priced machines may not have the required capabilities or accuracy levels.

5. Machine Support:

When purchasing a CNC mill, ensure that the manufacturer offers excellent after-sales support, including installation, training, and maintenance. Ensure that the manufacturer has a good reputation in the market and is known for providing high-quality and reliable machines.

Purchasing a CNC mill is a significant investment, and it's essential to consider several factors before making your final decision. Ensure that you choose a machine that has the required capabilities, accuracy, and support to meet your specific needs.

How to Operate a CNC Mill Safely

CNC mills are powerful machines that operate on computer-aided designs (CAD) to produce precise cuts and shapes in a variety of materials, including wood, metal, and plastics. However, the safety of the operator and those around the machine should always be a top priority. Here are some guidelines for operating a CNC mill safely:

1. Familiarize yourself with the machine: Before operating the mill, it is important to read and understand the owner's manual. Make sure you know the location of all the emergency buttons, switches, and other safety features. Additionally, make sure you are knowledgeable about the materials and tools that will be used during the milling process.

2. Wear appropriate safety gear: Before operating the CNC mill, it is essential to wear appropriate safety gear. This includes safety glasses, earplugs, gloves, and a dust mask to protect yourself from flying debris, loud noise, and harmful dust particles.

3. Secure the workpiece: Ensure that the workpiece is securely fastened to the mill bed before starting the milling process. Use clamps or other securing devices to prevent the workpiece from moving during the operation.

4. Program the CNC mill: A program must be written and loaded into the CNC machine before it can operate. Always double-check the program for errors before running the machine. Pay careful attention that the program does not exceed the limits of the machine’s settings.

5. Stand clear of the machine: Once the milling process begins, stand clear of the machine and never hold the material by hand. Never lean or get too close to the machine while it is operating, and always remove any loose clothing or jewelry.

6. Monitor the milling process closely: Always be vigilant while the machine is operating to ensure everything is running smoothly. Watch for unusual noises or vibrations, which may indicate something is wrong with the machine or tooling.

7. Clean the work area: Once the milling process is complete, ensure that the work area is clean, and the machine is properly turned off. Remove any remaining debris and relabel the program for future use.

Taking the necessary safety precautions before and during milling is vital to reduce the risk of accidents and injury. By following these guidelines, you can ensure the safe and efficient operation of your CNC mill.

Conclusion:

When shopping for a CNC mill, aspiring machinists and hobbyists should put careful consideration into the budget, performance, brand, and model quality that best suits their specific needs. While this process may seem daunting at first, it ultimately ensures that buyers receive a machine that meets their desires in terms of speed, accuracy, available features and more.

Furthermore, some manufacturers offer free trials on certain models to give interested customers an opportunity to test before they buy. Before making any actual purchase decisions or commitments with the seller, prospective buyers should always read reviews or contact other satisfied users for guidance.

Ultimately, all those seeking a CNC mill should be dedicated to researching their options thoroughly in order to find the perfect model for their project needs!

Read the full article

0 notes

Text

Sltl vector 2d laser cutting machine

Laser Marking compared to Laser Engraving With Laser Engraving the material keeps its original shape. When a material (in most cases, metal) is etched, it expands and creates a raised cavity. However, it functions as a tool that melts the material rather than vaporizes it. Laser Etching may be used as a synonym for Laser Engraving. Is Laser Etching the same as Laser Engraving? There are laser machines that can laser cut and engrave but would still need a 2D file to function. Many different fields such as aerospace, automotive, medicine, or electronics rely on this technology as it cuts other materials and delivers a smooth finish. Laser cutting, as the name implies, creates clean cuts into the material. The model contained in the file will be converted into dots and the distance between them determines how deep the engraving will be. So you have to use formats like jpg, pdf, png, or ai that are 2D files. What type of file do you need for Laser Engraving? Laser Engraving systems can not read any 3D files like. While the first one uses vector images to follow paths or lines, the second vaporizes the material to create an image into the material or give the design a 3D-like impression. Two different forms should be distinguished: line engraving and surface engraving. When the Laser Engraving process starts, the beam creates a high heat that burns or evaporates the surface according to the image from the file. However, before the actual engraving process can begin, the machine needs a file sent from a computer to the machine’s controller, which then positions the laser. It is a subtractive manufacturing method. Saws for metal - others (hacksaws, slitting saws, circular.The aim of Laser Engraving is to engrave a specific picture or logo onto a selected material.Exapro recommends to check the details with the seller before a purchase The information of this classified ad are only indicative. Please note that this description may have been translated automatically. The machine also comes with innovative auto nozzle cleaning and changing feature. Thus this machine provides a valuable function for sign makers and those working with digital graphics because it allows designs to be cut out of a wide range of substrates with the high accuracy and quality that is provided by vector cutting. The laser starts at a predetermined point and continues along the course of the line until the shape has been cut out. Therefore the designing and cutting process relies on lines to create the desired output. The word vector itself essentially means “line”. SLTL – The World First manufacturer of Fiber Laser Cutting system has introduced ‘Vector’ fiber laser cutting machine, considering specific needs of metal cutting industry. Spring machines - multislide / formers / coilers 26.Shaping - vertical / horizontal shaping / slotting machines 34.Saws for metal - others (hacksaws, slitting saws, circular.) 94.Milling - portal / gantry milling machines 125.Milling - cnc universal milling machines 249.Milling - cnc bed type milling machines 319.Milling - universal milling machines 253.Milling - travelling column milling machines 67.Machining centers - high-speed (18000+ rpm) 28.Lathes - vertical turret lathes with cnc 162.Lathes - Multispindle automatic lathes 579.Lathes - > 3001 mm - heavy duty lathes 224.Grinding machines - surface grinders 303.Grinding machines - miscellaneous (crankshaft, sharpening, tool grinders.Grinding machines - cylindrical external / internal grinders 267.Grinding machines - cylindrical centerless grinders 134.Gear machines - others (milling, testing, inspection.) 33.Finishing - others (washing / tumbling / vibratory.) 28.Finishing - lapping / honing / deburring machines 74.Drilling - others (multispindle, column, pillar.) 29.Drilling - floor type drilling machines (column, pillar) 15.Drilling - automatic/ CNC turret drilling machines 29.Borers - table type boring machines CNC 150.Borers - table type boring machines 140.Borers - floor type boring machines CNC 78.Borers - deep hole boring / drilling machines 41.

0 notes

Text

ADVANTAGES OF VERTICAL TURNING LATHE

CNC Vertical lathes have long been recognized for their advantages in the machining of heavy or short workpieces. The latest vertical turning lathes also offer additional benefits in terms of diminished cycle times, due to the rapid workpiece transfer and short traverses that can be achieved by working in this plane. Our top-of-the-range vertical lathes have counter-spindles, allowing for even higher productivity. As with all lathes from our leading manufacturer, Index, the vertical lathes we offer are available with a wide range of configuration options that allow them to adapt absolutely to your demands, establishing that your cost-per-part is minimized.

Vertical lathes adapt the spindle in a fixed position in the vertical plane. The workpiece moves up or down to place it in line with the appropriate tool necessary for the desired operation.

Vertical lathes are less complex than horizontal machines. They provide the surpass option for projects that focus on a single side, like large metal plates and sinking dies. They hold an advantage over horizontal lathes in circumstances where workpiece sagging might be a factor.

Vertical turning lathes are large machines, also called vertical boring mills. These lathes are not high-production machines, but they are excellent for heavy-duty and high-power cutting of medium and large parts.

An essential influence of the VTL machine is the ease in which large heavy workpieces can be set and held in place for machining.

Vertical turning lathes that use the main spindle to load and unload themselves are finding consent as multitasking capabilities make them competent transforming centers for producing chucked parts.

Vertical turning lathes give foundries with machine shops as well as those that outsource machining the competence to cut bigger and abundant castings.

An indexable tool turret head distinguishes traditional VTLs from VBMs

Aside from the turret head or ram head, the VTL machine design uses a revolving table to support the workpiece and uses a bridge-type construction that carries the X-axis.

In terms of productivity, vertical turning centers typically progress cycle times because shops can be more aggressive with their cuts.

Jaewoo machines manufacture VMC that is a high-powered device that is perfect for cutting hard metals and metal alloys. Its faster chip removal rate and superior coolant delivery systems make it ideal for difficult jobs that require immense levels of accuracy. Its Servo increases the productivity of the machine making it optimal for cutting steel, cast iron and Aluminum. These machines are perfect for the automobile industry and the aerospace industry. These CNC milling machines will lend technical superiority to your workshop through their highly accurate milling, boring and drilling actions.

#Cnc turning programming#Cnc turning program#Cnc machine price in india#Vertical turning lathes#Indian machines#Price of cnc machine in india#Cnc machines price#Manufacturers of cnc machines in india#Cnc manufacturer#Cost of cnc machine in india#Machine manufacturing companies in india#Buy a cnc machine#Vmc machine tools#Best cnc machine in india

1 note

·

View note

Text

Best Milling Machine For Home Use Reviews

Guidelines HOW TO USE A MILLING MACHINE

This website page is best imprinted in Landscape design.

This data was initially ordered by the US Army.

Introduced to you free by American Machine Tools Company.

Processing is the way toward machining level, bended, or sporadic surfaces by taking care of the workpiece against a turning shaper containing various forefronts. The typical Mill comprises fundamentally of an engine driven axle, which mounts and rotates the processing shaper, and a responding movable worktable, which mounts and feeds the workpiece.

youtube

Processing machines are fundamentally delegated vertical or level. These machines are additionally delegated knee-type, slam type, assembling or bed type, and planer-type. Most processing machines have independent electric drive engines, coolant frameworks, variable shaft speeds, and force worked table feeds

Graph of average variable speed processing machine head

Graph of average "Bridgeport style" processing machine head

Kinds OF MILLING MACHINES

KNEE-TYPE

Knee-type plants are portrayed by a vertically flexible worktable laying on a seat which is upheld by a knee. The knee is a huge projecting that rides vertically on the processing machine segment and can be braced inflexibly to the segment in a position where the processing head and processing machine shaft are appropriately balanced vertically for activity.

The plain vertical machines are described by a shaft found vertically, corresponding to the section face, and mounted in a sliding head that can be exhausted and somewhere around hand or force. Current vertical processing machines are planned so the whole head can likewise turn to allow chipping away at rakish surfaces.

The turret and turn head get together is intended for making accuracy cuts and can be swung 360� on its base. Rakish slices to the even plane might be made with exactness by setting the head at any necessary edge inside a 180� bend.

The plain even processing machine's section contains the drive engine and equipping and a fixed position level processing machine axle. A customizable overhead arm containing at least one arbor underpins extends forward from the head of the section. The arm and arbor underpins are utilized to balance out long arbors. Supports can be moved along the overhead arm to help the arbor where backing is wanted relying upon the situation of the processing shaper or cutters.

The processing machine's knee rides up or down the section on an inflexible track. A substantial, vertical situating screw underneath past the processing shaper. The processing machine is fantastic for framing level surfaces, cutting dovetails and keyways, shaping and fluting processing cutters and reamers, cutting riggings, etc. Numerous exceptional tasks can be performed with the connections accessible for processing machine use. the knee is utilized for raising and bringing down. The seat settles upon the knee and supports the worktable. The seat moves in and out on a dovetail to control cross feed of the worktable. The worktable navigates to one side or left upon the seat for taking care of the workpiece past the processing shaper. The table might be physically controlled or power took care of.

All inclusive HORIZONTAL MILLING MACHINE

The essential distinction between an all inclusive level processing machine and a plain even processing machine is the expansion of a table turn lodging between the table and the seat of the widespread machine. This allows the table to swing up to 45� in either bearing for precise and helical processing activities. The general machine can be fitted with different connections, for example, the ordering installation, revolving table, opening and rack cutting connections, and different uncommon apparatuses.

Slam TYPE MILLING MACHINE

The slam type processing machine is described by a shaft mounted to a mobile lodging on the section to allow situating the processing shaper forward or aft in a level plane. Two famous slam type processing machines are the all inclusive processing machine and the turn shaper head smash type processing machine.

All inclusive RAM-TYPE MILLING MACHINE

The all inclusive slam type processing machine is like the general level processing machine, the distinction being, as its name suggests, the shaft is mounted on a smash or versatile lodging.

Turn CUTTER HEAD RAM-TYPE MILLING MACHINE

The shaper head containing the processing machine axle is joined to the smash. The shaper head can be turned from a vertical axle position to an even axle position or can be fixed at any ideal rakish situation among vertical and level. The seat and knee are hand driven for vertical and cross feed alteration while the worktable can be either hand or force driven at the administrator's decision.

Essential processing machine designs are appeared in Figure 8-1.

Wellbeing RULES FOR MILLING MACHINES

Processing machines require unique wellbeing precautionary measures while being utilized. These are notwithstanding those wellbeing safety measures depicted in Chapter 1.

Try not to reach the rotating shaper.

Spot a wooden cushion or appropriate spread over the table surface to shield it from conceivable harm.

Utilize the mate framework while moving overwhelming connections.

Try not to endeavor to fix arbor nuts utilizing machine power.

When introducing or eliminating processing cutters, consistently hold them with a cloth to forestall cutting your hands.

While setting up work, introduce the shaper last to abstain from being cut.

Never change the workpiece or work mounting gadgets when the machine is working.

Chips ought to be eliminated from the workpiece with a suitable rake and a brush.

NOTE Chip rake ought to be manufactured to the size of the T-openings (Figure 8-2).

Stop the machine before making any alterations or estimations.

When utilizing cutting oil, forestall sprinkling by utilizing proper sprinkle watches. Cutting oil on the floor can cause a tricky condition that could bring about administrator injury

Instruments AND EQUIPMENT

Processing CUTTERS

Arrangement of Milling Cutters

Processing cutters are typically made of fast steel and are accessible in an extraordinary assortment of shapes and sizes for different purposes. You should know the names of the most well-known characterizations of cutters, their utilizations, and, in an overall way, the sizes most appropriate to the current work.

Processing Cutter Nomenclature

Figure 8-3 shows two perspectives on a typical processing shaper with its parts and edges distinguished. These parts and points in some structure are normal to every single shaper type.

The pitch alludes to the precise separation between like or neighboring teeth.

The pitch is controlled by the quantity of teeth. The tooth face is the front oriented surface of the tooth that frames the forefront.

The bleeding edge is the edge on every tooth that plays out the cutting.

The land is the tight surface behind the front line on every tooth.

The rake point is the edge framed between the substance of the tooth and the centerline of the shaper. The rake edge characterizes the bleeding edge and gives a way to chips that are cut from the workpiece.

The essential leeway edge is the edge of the place where there is every tooth estimated from a line digression to the centerline of the shaper at the bleeding edge. This edge keeps every tooth from scouring against the workpiece after it makes its cut.

This edge characterizes the place where there is every tooth and gives extra freedom to section of cutting oil and chips.

The gap measurement decides the size of the arbor important to mount the processing shaper.

Plain processing cutters that are more than 3/4 inch in width are typically made with winding or helical teeth. A plain winding tooth processing shaper creates a superior and smoother finish and requires less capacity to work. A plain helical-tooth processing shaper is particularly alluring when processing a lopsided surface or one with openings in it.

Sorts of Teeth

The teeth of processing cutters might be made for right-hand or left-hand pivot, and with either right-hand or left-hand helix. Decide the hand of the shaper by taking a gander at the essence of the shaper when mounted on the axle. A right-hand shaper must pivot counterclockwise; a left-hand shaper must turn clockwise. The right-hand helix is appeared by the flutes prompting the right; a left-hand helix is appeared by the flutes prompting the left. The heading of the helix doesn't influence the cutting capacity of the shaper, however take care to see that the course of revolution is right for the hand of the shaper (Figure 8-4).

Saw Teeth

Saw teeth like those appeared in Figure 8-3 (above) are either straight or helical in the littler sizes of plain processing cutters, metal cutting saw processing cutters, and end processing cutters. The front line is generally given around 5 degrees essential leeway. Now and then the teeth are furnished with off-set scratches which separate chips and make coarser feeds conceivable.

Helical Milling Cutters

The helical processing shaper is comparative, to the plain processing shaper, however the teeth have a helix point of 45� to 60�. The precarious helix delivers a shearing activity that outcomes in smooth, sans vibration cuts. They are accessible for arbor mounting, or with a vital shank with or without a pilot. This sort of helical shaper is especially valuable for processing lengthened openings and for light cuts on delicate metal. See Figure 8-5.

Metal Slitting Saw Milling Cutter

The metal cutting saw processing shaper is basically an extremely slender plain processing shaper. It is ground marginally more slender toward the inside to give side freedom. These cutters are utilized for cutoff activities and for processing profound, slender spaces, and are made in widths from 1/32 to 3/16 inch.

Side Milling Cutters

Side processing cutters are basically plain processing cutters with the expansion of teeth on one or the two sides. A plain side processing shaper has teeth on the two sides and on the fringe. At the point when teeth are added aside just, the shaper is known as a half-side processing shaper and is recognized as being either a right-hand or left-hand shaper.

source

https://reviewkits.com/

1 note

·

View note

Text

What are the classifications of CNC machining centers?

What is a CNC machining center, what are the types of machining centers, what are the types of machining centers, and what are the similarities and differences between horizontal and vertical machining centers? The above questions you are concerned about, this article has a detailed introduction, please see the following.

Classification of CNC machining centers

Machining center, also known as multi-process automatic tool change CNC machine tool, is a kind of metal cutting processing equipment with the largest output and the most widely used in modern machinery manufacturing industry in the world today.

The control system of the machining center has many functions, and the machine tool uses at least three motion coordinate axes, and as many as a dozen axes. Its control function requires at least two-axis linkage control to realize linear interpolation and circular interpolation of tool movement, and most can perform five-axis linkage and six-axis linkage to complete the processing of more complex surfaces.

The machining center also has various auxiliary functions, such as machining canned cycle, automatic tool radius compensation, automatic tool length compensation, tool breakage alarm, tool life management, automatic overload overtravel protection, lead screw pitch error compensation, lead screw clearance compensation, fault compensation Automatic diagnosis, graphic display of workpiece and processing process, man-machine dialogue, online detection of workpiece, offline programming, etc., all play a positive role in improving the processing efficiency of equipment and ensuring the processing accuracy and quality of products.

The outstanding feature of the machining center is that it is equipped with a tool magazine, which stores various tools or inspection tools, which are automatically selected and replaced by the program during the processing process. This is the main difference between it and CNC milling machines and CNC boring machines.

Machining centers can be divided into four categories according to their functional characteristics:

1. Boring and milling machining center

The boring and milling machining center is mainly used for boring and milling, and is suitable for multi-process machining of special curves and surface contours of boxes, shells and various complex parts. The term "machining center" generally refers to boring and milling machining centers, while other functional machining centers should be preceded by attributives, such as turning machining centers, drilling machining centers, etc.

2. Drilling center

The drilling machining center is mainly based on drilling, and the tool magazine is mainly in the form of a turret head. It is suitable for multi-process processing such as drilling, reaming, reaming and tapping of small and medium parts.

3. Turning center

The turning machining center is mainly based on turning, and the main body is a CNC lathe. The machine tool is equipped with a turret-type tool magazine or a tool magazine composed of a tool-changing manipulator and a chain-type tool magazine. The CNC system of the machine tool is mostly equipped with two or three axis servo axes, that is, X, Z, and C axes. Some high-performance turning centers are equipped with milling power heads.

4. Compound machining center

A machining center that can complete multi-process machining such as turning, milling, boring, and drilling on one device is called a composite machining center, which can replace multiple machine tools to achieve multi-process machining. This method can not only reduce loading and unloading time, improve production efficiency, but also ensure and improve shape and position accuracy. The compound machining center refers to the five-sided compound machining center, and its spindle head can be automatically rotated for vertical and horizontal machining.

According to the number of motion coordinates and the number of coordinates controlled at the same time, the machining center can be divided into three-axis two-linkage, three-axis three-linkage, four-axis three-linkage, five-axis four-linkage, six-axis five-linkage, multi-axis linkage linear + rotary + Spindle swing, etc. Three-axis and four-axis refer to the number of motion coordinates that the machining center has, and linkage refers to the number of coordinates that the control system can control the motion at the same time, so as to realize the position and speed control of the tool relative to the workpiece.

Since we have had a preliminary understanding of CNC machining classification. One company we have to mention is Malante. Suzhou Malante Precision Machinery Co., Ltd. established in 2011, is a production-oriented enterprise specializing in the processing and assembly of mechanical parts. The company's production base is located in the well-equipped Suzhou Wuzhong Economic Development Zone-Hainde High-tech Industrial Park, has passed ISO9001: 2015 quality management system certification, weapons and equipment quality management system certification.

0 notes

Text

Things to Know About CNC Machining Before Finding a Machine Shop in Mississauga

Do you want top-quality CNC Machining services in Mississauga? You should trust a reliable CNC Machine shop in Mississauga to get the best solution. CNC machine shops rely on innovations and the latest trends to provide the highest standard machining solutions.

What are CNC Machines?

The full form of CNC Machines is Computer Numerical Control Machines! CNC machines are electro-mechanical devices that use computer programming inputs to manipulate machine shop tools and manufacture products with precision and perfection. CNC machines were first developed in the 1940s and 1950s that relied on telecommunication data storage technology like perforated paper tape and punched tape.

In the 1950s and 1960s, CNC machines transitioned from analog to digital computer processing. CNC machines are continuously improving their efficiency with the evolution of new technologies.

What is the Motive of CNC Machines?

The motive of CNC machines is to produce products in mass quantity by assuring high precision work and safe operation. CHC machines do not require to pay attention once it is set up right for the task. No doubt, CNC machines save labor costs!

What are the various types of CNC Machines?

CNC Milling:

CNC Milling machines come in different sizes and shapes. It uses a rotating cylindrical cutter to move along multiple axes.

Most advanced CNC milling machines are assembled with horizontal and vertical machining centers.

CNC Turning:

CNC turning machines are different varieties, like multi-spindle, screw turning machines and multi-turret lathes. The turning machines come in various lengths and attachments.

CNC Router:

A CNC router is used for cutting various materials, like wood, aluminum, plastics, steel, glass, and foams. It is a computer-controlled cutting device. These machines are best for light materials production.

What Materials Used in CNC Machines?

A wide variety of materials like copper, aluminum, steel, wood, titanium, and more, can be used in a CNC machine. It depends on the application and project requirement to use the best material. CNC machines ensure versatile production to benefit a variety of projects.

What to Expect from a Reliable Machine Shop for CNC Machining Requirements?

When working with a trustworthy CNC machine shop for your project in Mississauga, you best the highest standard of service and best quality products with precision work at the most reasonable price.

Contact Today!

If you are looking for a reputable CNC Machine Shop in Mississauga, contact GTA Machining Solutions!

We have an efficient team of CNC programmers, Engineering, Machinists, and Quality control specialists to take care of your complex project. Our expert team can deal with tight deadlines that ensure the work is done on time every time. At GTA Machining Solutions, our CNC machines are equipped with Renishaw Probes and custom programming to make precision and efficient parts.

Give us a call today at 905-678-6226 to know more about our CNC machining technology and solutions in Mississauga!

For more details, stay social with us on: Facebook …

0 notes

Text

Buy Vertical Turret Milling Machine at best cost. Best Vertical Turret Milling Machine Supplier, Vertical Turret Milling Machine manufacturer Company in Pune, Mumbai, Delhi, India.

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

0 notes

Text

#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer

0 notes

Text

The Impact of Vertical Turret Lathes, Hydraulic Fixtures, and Deep Hole Drilling Machines

In today's engineering landscape, vertical hydraulic fixtures are key to diversifying and perfecting the realm of machine centers and deep-hole drilling operations. They are transforming manufacturing possibilities, elevating precision and efficiency to new heights. This blog delves into how these technological advancements have revolutionized manufacturing, heralding a new era of engineering excellence.

The Role of Vertical Turret Lathes in Modern Manufacturing

Vertical turret lathes (VTLs) are some of the most advanced marvels in engineering technology designed for modern manufacturing and ideally meet the multifaceted needs of processing units. With these capabilities to perform hard turning and milling operations to very high levels of precision, VTLs become an engineering necessity in creating most large, heavy, and complex components.

The recent trends in VTL design are the critical innovations of improved tooling versatility, higher levels of automation, and new control systems to adapt them for efficiency and usability in industries as diverse as aerospace, energy, and others. VTLs are basic machine tools in the manufacturing arsenal since they allow manufacturers to make complex precision parts quickly.

Hydraulic Fixtures Save Machining Time on Machining Centers

Hydraulic fixtures are enhancing traditional machining centers with their powerful clamping capabilities and versatility. They utilize hydraulic pressure to secure parts during machining, offering more consistent clamping forces and achieving greater precision at a faster pace compared to manual setups. Their adaptability in holding systems allows for the efficient machining of complex parts in a single setup, significantly reducing production time and boosting throughput. Through the use of hydraulic fixtures in machining centers, manufacturers can realize a level of efficiency and precision that has been far beyond their reach.

Precision of Deep Hole Drilling Machines

Deep hole drilling machines have revolutionized the creation of deep, precise holes with diameters difficult to achieve through traditional drilling methods. These machines are vital for industries like oil and gas, automotive, and aerospace, where precision is crucial. Equipped with modern features like high-pressure coolant systems and specially designed cutting tools, these advanced machines provide drilling solutions with unparalleled depth and accuracy. They can generate the most accurate operations that make deep-hole drilling machines an indispensable part of precision engineering.

Synergy Among Technologies

Integrating Vertical Turret Lathes, Hydraulic Fixtures, and Deep Hole Drilling Machines into a unified manufacturing setup creates a synergistic effect that enhances the entire production process. This combination allows for the production of parts with tight tolerances and complex geometries in a single setup, leveraging an automated centralized system to boost productivity further. The interoperability of these technologies streamlines the workflow from initial machining to final finishing, ensuring each part is crafted with utmost precision.

WIDMA's Influence on Advancing Manufacturing Technologies

In the evolving world of manufacturing, WIDMA stands out as a pivotal force, contributing significantly to the revolution that is reshaping the industry. Renowned for its innovative solutions in cutting tools and machining centers, WIDMA has become synonymous with precision, efficiency, and adaptability. This section explores how WIDMA's cutting-edge technologies and systems are enhancing the capabilities of Vertical Turret Lathes, Hydraulic Fixtures, and Deep Hole Drilling Machines, further propelling the manufacturing sector into the future.

Future Trends in Manufacturing Technologies

The constant development of these technologies holds the promise of further revolutionizing the manufacturing sector for years ahead. Integrating AI and automation, in particular, portends bringing faster gestation periods without losing accuracy.

These technologies will be key in creating a smart factory that fuels Industry 4.0, producing hardware of diverse geometries in a manner that the machine wants, working together with machines and systems while simultaneously optimizing and autonomously reviewing the process of manufacture. The upgrading in continuous innovation in manufacturing puts pressure on integrating disruptive smart technologies associated with productive methods.

Conclusion

The integration of Vertical Turret Lathes, Deep Hole Drilling Machines, and Hydraulic Fixtures into Machining Centers is at the heart of today's manufacturing revolution, pushing the boundaries of precision and efficiency to new heights. These technological powerhouses are poised for further evolution, set to transform manufacturing into a smarter, quicker, and more accurate domain. We are witnessing the dawn of an era of precision engineering, opening up a new horizon of manufacturing possibilities.

0 notes

Text

Just What Is Actually Computer Numerical Control Machining? Everything You Required To Know

Computer numerical control machining is actually a term commonly used in production as well as industrial uses. But exactly what is actually Computer numerical control? And what is a CNC device?

The condition Computer numerical control means 'computer numerical control', as well as the CNC machining meaning is actually that it is actually a subtractive manufacturing method which typically hires computerized controls and also device tools to take out coatings of product coming from a stock item known as the blank or even workpiece and also creates a custom-made component. This procedure agrees with for a wide range of materials, including metals, plastics, hardwood, glass, foam, and also composites, and also discovers use in a selection of markets, such as huge Computer numerical control machining, machining of parts and models for telecommunications, as well as CNC machining aerospace components, which require tighter resistances than various other industries. Note there is actually a difference between the CNC machining meaning and the Computer numerical control device interpretation- one is actually a process and the other is actually a machine. A Computer numerical control device is actually a programmable machine that is capable of autonomously executing the operations of CNC machining.

Subtractive manufacturing processes, like Computer numerical control machining, are actually often offered compare to additive manufacturing methods, like 3D printing, or even formative manufacturing processes, like liquefied injection molding. While subtractive processes eliminate levels of material from the workpiece to produce custom-made designs as well as styles, additive procedures construct levels of material to create the wanted kind as well as developmental processes displace as well as impair inventory material in to the desired design. The automated attributes of custom fabrication makes it possible for the manufacturing of high precision and also high accuracy, straightforward parts and also cost-effectiveness when satisfying medium-volume and one-off manufacturing operates. Nonetheless, while CNC machining illustrates certain advantages over various other creating processes, the degree of complexity as well as details possible for part concept and the cost-effectiveness of making complicated parts is actually limited.

Outline of cnc machining Procedure

Developing from the numerical control (NC) machining process which used punched tape memory cards, numerical control machining is a manufacturing process which uses computerized controls to manage and run machine and also reducing resources to form inventory component-- e.g., metallic, plastic, timber, foam, complex, and so on-- right into personalized parts and also layouts. While the CNC machining method delivers various abilities and also functions, the fundamental concepts of the process continue to be greatly the exact same throughout every one of them. The general CNC machining method consists of the adhering to phases:

youtube

Creating the CAD model,

Changing the COMPUTER-AIDED-DESIGN data to a CNC program,

Preparing the Computer numerical control device,

Executing the machining procedure.

Kinds Of CNC Machining Procedures

CNC machining is actually a production method suitable for a variety of fields, featuring motor vehicle, aerospace, development, and agriculture, and able to make a stable of items, including car structures, operative tools, aircraft motors, gears, and palm and also garden resources. The method encompasses several different computer-controlled machining operations-- consisting of mechanical, chemical, electrical, as well as thermal procedures-- which take out the essential component coming from the work surface to make a custom-designed part or item. While chemical, electric, as well as thermic machining procedures are actually covered in a later segment, this segment looks into some of one of the most common mechanical CNC machining procedures featuring:.

Boring,

milling,

turning.

CNC Drilling

Drilling is actually a machining process which utilizes multi-point rotary tool bits to produce cylindrical gaps in the work surface. In CNC drilling, generally the Computer numerical control device supplies the revolving rotary tool bit perpendicularly to the position of the workpiece's area, which produces vertically-aligned openings along with dimensions equal to the size of the rotary tool little utilized for the drilling procedure. Slanted drilling functions may additionally be actually done through the usage of concentrated device setups as well as workholding tools. Functional capacities of the drilling procedure feature counterboring, countersinking, reaming, and touching.

Computer numerical control Milling

Milling is a machining procedure which works with turning multi-point cutting resources to eliminate product from the work surface. In Computer numerical control milling, the Computer numerical control device usually feeds the work surface to the reducing device parallel as the reducing tool's turning, whereas in hands-on crushing the machine feeds the work surface in the opposite path to the reducing tool's turning. Working functionalities of the milling procedure consist of face milling-- reducing shallow, standard areas and flat-bottomed tooth cavities in to the work surface-- as well as peripheral milling-- cutting deeper cavities, including strings and also ports, in to the workpiece. If you searcn about welder near me, you should check out DieSand web site.

Computer numerical control Turning

Turning is a machining method which employs single-point cutting tools to clear away product coming from the switching workpiece. In CNC turning, the machine-- commonly a Computer numerical control turret device-- supplies the cutting device in a straight movement along the surface of the switching work surface, clearing away component around the circumference till the wanted size is accomplished, to make round parts with outside and internal features, such as ports, tapers, and also strings. Operational functionalities of the turning process include boring, facing, grooving, and also thread cutting. When it boils down to a CNC factory vs. turret, milling, along with its own spinning cutting tools, works better for even more facility parts. Turrets, along with turning work surfaces as well as fixed cutting devices, job most effectively for faster, a lot more correct production of round components.

CNC Metal Spinning

Near relatives to turrets, CNC turning turret devices involve a lathe prepared with a blank (a steel slab or even tube) that rotates at broadband while a metallic turning curler shapes the work surface into a wanted form. As a "cool" procedure, Computer numerical control metallic spinning forms pre-formed metal-- the abrasion of the spinning lathe calling the roller makes the force essential to form the component.

0 notes