#Vibrating Rod Point Level Switch For Solids

Explore tagged Tumblr posts

Text

Trumen Technologies Pvt. Ltd.” is an ISO 9001:2015 certified ,Indian based Manufacturer and Exporters of Level and Pressure sensing instruments. We at Trumen is a team of professionals having years of experience in Level and Pressure Instruments manufacturing who understands what customer needs, and try to fulfill those requirements in appropriate time with best Quality.

We have wide range of CE certified product like Radar Level Transmitters, Ultrasonic Level ,Vibrating fork solid level switch, Vibrating fork liquid level switch, Admittance point level switch, Capacitance point level switch, Vibrating rod point level switch, Conductivity point level switch, Capacitive continuous level transmitter, Hydrostatic continuous level transmitter, etc.

Our products used in different industrial applications in various industries like Power and Water, Oil and Gas, Petrochemical, Mining and Metal, Food and Beverages, Cement ,Pharmaceutical and many more. We are regularly supplying our products to NTPC, IOCL,BPCL, BORL, Cipla, Lupin, Cadila healthcare, Praj High Purity Systems , Ultratech Cement, Shree Cement ,Jindal Group ,TATA, Asian Paints, Procter & Gamble, Hindustan Unilever Ltd, Kirloskar, Vedanta, Nestle, Pepsi, BASF, Novartis and many more.

We are regularly exporting our products to USA, UK, South Korea, Italy ,Thailand, Taiwan, UAE, Tanzania, Turkey ,Sri Lanka ,Saudi Arabia , Kuwait ,Malaysia, Sweden, Canada, Egypt , Brazil ,Singapore etc.

Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001

Web: https://trumen.in/

Contact: 0731 497 2065

#VibratingForkLevelSensor

#VibratingForkLevelSwitch

#VibratingRodPointLevelSwitch

#Vibratingrodpointlevelswitchmanufacturersinindia

#Vibratingrodpointlevelswitchsupplierinindia

#TuningForkPointLevelSwitch

#AdmittancePointLevelSwitch

#RotatingPaddleLevelSwitch

#RadarLeveltransmitter

#LevelSensor

#solidlevelswitch

#powderlevelswitch

#limestone

#coalbunker

#PVCpowder

#levelinstruments

#Levelswitch

#levelindicator

#leveltransmitter

#vibratingforklevelswitch#radarleveltransmitter#levelsensor#solidlevelswitch#capacitanceleveltransmitter#levelswitchinindia#levelindicator#rotatingpaddlelevelswitch#cementlevelsensor#vibratingforklevelsensor

2 notes

·

View notes

Link

Jayceetech is best Vibrating Rod Point Level Switch for Solids supplier, Vibrating Rod Point Level Switch for Solids Manufacturer Company in pune, Maharashtra, India

0 notes

Link

Jayceetech is best Vibrating Rod Point Level Switch for Solids supplier, Vibrating Rod Point Level Switch for Solids Manufacturer Company in pune, Maharashtra, India

0 notes

Photo

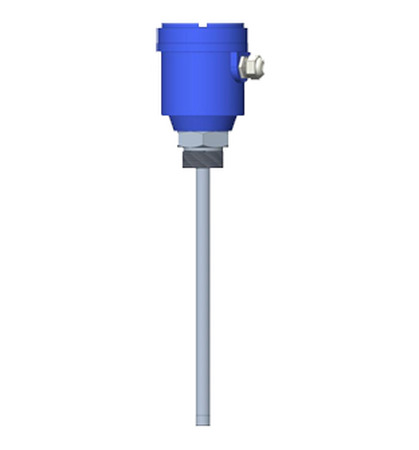

Vibrating Rod Point Level Switch For Solids

Vibrating Rod Point Level Switch For Solids utilizes a piezoelectric crystal that vibrates the rod at a natural frequency for level detection of powders and bulk solids.

0 notes

Text

Solid, Liquid, and High Level Switch in India at Affordable Price.

Trumen at a Glance

We are an ISO 9001:2015 certified manufacturer & exporter of level sensing, measurement, indication and control instruments. Trumen came into existence in 2009 and initially started with the manufacturing of Tuning Fork Level Switch for liquid and solid applications. With time, the manufacturing range increased with the addition of Capacitance Level Transmitter & Capacitance Level Switch, RF Admittance Level Switches, Rotating Paddle Level Switches, Conductivity Type Solid Level Switch, Vibrating Rod Level Switches, Hydrostatic Level Transmitter, and Radar Level Transmitter & Ultrasonic Liquid Level Switch Transmitter

“To be among the leading solution provider for process sensing, control & automation by working for continuous excellence and innovation in process sensing, measurement, indication and control instruments contributing to dependable process control.”

Solid Level Switch

a) Rotating Paddle Level Switch for Solids

Rotating paddle type Level Switch are basically a spring-loaded, eccentrically driven rotating vanes or blades which rotate at a very slow rotation of one revolution per minute, using an ace synchronous motor.

b) Vibrating Fork Point Level Switch for Solids

Electronics of LSV excites the piezo-electric-crystals inside the tuning fork, which makes the fork tines vibrate at their natural resonance frequency in free air.

c) Vibrating Rod Point Level Switch for Solids

Vibrating rod is a single element tunned mechanical element-type Solid Level Switch sensing device. Electronics of LSV-R excites the piezo-electric-crystals inside the tuning rod, which makes the rod vibrate at its natural resonance frequency in free air.

d) Compact Vibrating Fork Point Level Switch for Liquids & Solids

Electronics of LFV11 excites the piezo-electric-crystals inside the tuning fork, which makes the fork tines vibrate at their natural resonance frequency in free air.

Level Switch

a) Admittance Point Level Switch

RF Admittance is a static level sensor with no moving parts. Its sensing parts are:- 1) Earth Extension (body) 2) Compensation Shield 3) Sensing Rod

b) Capacitance Point(s) Level Switch

LMC Capacitance type limit Level Switch is a static level sensor, Sensing parts of LMC capacitance level limit switch is: 1) Earth Extension (metallic process connection may be used as earth in-place of earth extension tubes). 2) Sensing Rod (or Rope as per application).

c) Compact Capacitance Level Switch

LMC30 is a compact capacitance Solid Level Switch limit switch for solids specially intended for see-through plastic window material sensing in packing hoppers. LMC30 can be mounted on any M30 compatible mounting hole and it is supported by two supplied mounting nuts. LMC30 deploys touch sense on its rear, so as to set its switching point and no potentiometer or touch button is presently enhancing the operational life of the device.

d) Top Mounted Magnetic Level Switch MLS20

It operates on the basic buoyancy principle. It uses a float that glides on the surface of liquids. This Level Switch consists of – Terminal Enclosure, Float Stem with Hermetically sealed Reed Switches and Float with magnets assembled inside. As the float rises or falls with a liquid level, the internal magnet moves in or out of the field of the switch resulting in its opening or closing. A non-magnetic barrier tube containing the reed switch isolates it from the process. These type level controls are available for controlling level at up to four different preset locations and can virtually be made of any length. This switch is highly effective and costs shedding and also finds use in a wide range of industries.

Liquid Level Switch

a) Rotating Paddle Level Switch for Solids

Rotating paddle type Level Switch are basically a spring-loaded, eccentrically driven rotating vanes or blades which rotate at a very slow rotation of one revolution per minute, using an ac synchronous motor. The Level Switch LMFS is capable of faithfully detecting industrial fluids and powders using Frequency Sweep technology. Utilizing the resonance of electrical capacitance created by media di-electric and conductivity, LMFS learns the signature of the media to be sensed and thus performs better than other level detection methods for fluids and powders.

b) Conductivity Point(s) Level Switch for conductive liquids

LWS Conductivity Liquid Level Switch is static rendered furnished devices with no moving parts. A low voltage sine-wave is provided into the liquid using a reference rod (or electrode). The electronics continuously scans the sensing rod (or electrode) for the presence of a sine-wave signal on it.

c) Compact Tuning Fork Point Level Switch for Liquids

Electronics of LFV12 excites the piezo-electric-crystals inside the tuning fork, which makes the fork tines vibrate at their natural resonance frequency in free air. When the fork tines are immersed in liquid, the frequency of fork vibration falls due to the density of the liquid.

1 note

·

View note

Text

Vibration Level Switch Market Size, Share, Growth and Regional Analysis by Segmentation and Country Forecast to 2028

The Vibration Level Switch Market study formulated by Data Bridge Market Research, presents a detailed analysis of the influential trends prevailing in this business sphere. The Vibration Level Switch research report highly intends to analyse historic, current and future trends of the market. Major historic and current occurrence in the market has been analysed in the report to provide through assessments of market trends, segments, competition, share, size and growth of the market.

Vibration level switch market is expected to grow at a compound annual growth rate of 7.2% in the forecast period of 2021 to 2028. Data Bridge Market Research report on vibration level switch provides analysis and insights regarding the various factors expected to be prevalent throughout the forecasted period while providing their impacts on the market’s growth.

Vibrating level switches are broadly used as low-level indicators or overfill security devices in liquids and also in powdery and granular bulk solids. These switches identify the dampening that happens when a vibrating probe is flooded in a process medium. Vibration level switch comprises a wide range of applications such as overfill or dry run protection, pump controls, dry and wet indication in pipes and high and low fail-safe limit switch.

Avail Exclusive Sample Report + Graphs & Charts@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-vibration-level-switch-market

Vibration level switch market is segmented on the basis of technology, application and end user. The growth among segments helps you analyze niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

Based on technology, the vibration level switch market is segmented into vibrating fork and vibrating rod.

The application segment of the vibration level switch market is segmented into liquids and solids.

On the basis of end user, the vibration level switch market is segmented into oil and gas, chemicals, water and wastewater, food and beverages, pharmaceuticals, power generation, metals and mining and others.

Key Pointers Covered in the Vibration Level Switch Market Industry Trends

Market Size

Market New Sales Volumes

Market Replacement Sales Volumes

Market Installed Base

Market By Brands

Market Procedure Volumes

Market Product Price Analysis

Market Shares in Different Regions

Recent Developments for Market Competitors

Market Upcoming Applications

Market Innovators Study

Access Full Report @ https://www.databridgemarketresearch.com/reports/global-vibration-level-switch-market

Strategic Points Covered in Table of Content of Vibration Level Switch Market:

Introduction

Market segmentation

Executive summary

Premium insights

Impact analysis of covid-19

Market overview

Global Vibration Level Switch Market, by battery type

Global Vibration Level Switch market, by hub motor location

Global Vibration Level Switch market, by mode

Global Vibration Level Switch market, by battery power

Global Vibration Level Switch market, by class

Global Vibration Level Switch market, by usage

Global Vibration Level Switch market, by geography

Global Vibration Level Switch market, company landscape

Swot analysis

Company profile

Questionnaire

Related reports

Get Detailed TOC@ https://www.databridgemarketresearch.com/toc/?dbmr=global-vibration-level-switch-market

The major players covered in the vibration level switch market report are Endress+Hauser Group Services AG, VEGA Grieshaber KG, Emerson Electric Co., KROHNE Messtechnik GmbH, Siemens AG, ABB, AMETEK Inc., Magnetrol, Pepperl+Fuchs, Nivelco zRt, Matsushima Measure Tech Co. Ltd., Dwyer Instruments, Inc., Flowline, WIKA Alexander Wiegand SE & Co. KG, Schneider Electric, OMRON Corporation, Honeywell International Inc., Baumer, Zimmer Automation GmbH and Gems Sensors, Inc. among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Browse Related Reports@

Solid-State Cooling Market

Surface Mount Technology Market

Swarm Intelligence Market

Telecom Electronic Manufacturing SErvices Market

Testing Inspection and Certification Market

Thermal Imaging Market

Thermoelectric AsSEmblies Market

0 notes

Text

Vibration Level Switch Market Revenue, Price, Trend Analysis and Growth Rate to 2023

The global Vibration Level Switch Market is estimated to reach USD 605.5 million by 2018 and USD 833.8 million by 2023, growing at a CAGR of 6.6% during that period. Benefits over other point level measurement technologies, growing demand in pharmaceuticals and food & beverages industries, and emphasis on safety of overfill protection systems are some of the key factors driving the market’s growth. However, impaired performance of vibration level switches in certain media will be a major restraining factor and the requirement of diversified certifications for end markets will be the key challenge for this market.

The market for vibrating fork level switches is likely to exhibit a significant growth during the forecast period. These switches offer better value over other point level measurement technologies as they require minimal maintenance and can accurately and reliably measure product levels even under conditions such as flow, turbulence, bubbles, foam, and vibrations. Owing to these advantages, vibrating fork switches are increasingly displacing mechanical and float level switches in plants. The market for vibrating rod level switches is expected to grow for solids applications. These switches are used as limit level switches in granular and coarse-grained bulk solids measurement applications, and are widely employed in industries such as food & beverages, pharmaceuticals, metals & mining, and cement.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=189804078

Vibration level switches are used for measuring levels of solid as well as liquid media. However, for liquids applications, vibrating fork level switches are the most preferred solution; solids level measurement market is dominated by other point level technologies such as capacitive and paddle switch; and the adoption of these switches is increasing in industries such as food & beverages, chemicals, and pharmaceuticals. Consequently, the market for liquids measurement applications is expected to grow at a higher CAGR than solids applications from 2018 to 2023.

The market for the pharmaceuticals industry is expected to grow at the highest CAGR amongst all industries during the forecast period. This industry operates in an environment of strict requirements for safety, sterility, and accuracy. In drugs manufacturing, hygienic design and accuracy of level measurement switches are important factors to comply with regulatory standards. Vibration level switches are usually used in reaction vessels, silos, mixers, bioreactors, fermenters, and storage tanks for overspill protection and high/low level alarm applications. The pharmaceuticals industry has experienced exceptional growth in recent years and is estimated to expand rapidly, which offers the vibration level switch market significant growth opportunities during the forecast period.

APAC is expected to become the fastest-growing market for vibration level switches during the forecast period. The region’s increasing population (China and India being the most populous) makes it a major market for pharmaceuticals, oil & gas, chemicals, food & beverages, and power generation industries. Apart from being a mere consumer, APAC has also witnessed significant growth in manufacturing due to low production costs and supportive local governments. The economic growth of heavily regulated industries, such as oil & gas and power generation, has increased the demand for safety-related process instruments in APAC. India and China are considered lucrative markets for vibration level switches owing to huge industrial manufacturing activities in these countries. A number of players are expanding their presence in APAC to cater to growing demand. For instance, in January 2018, Endress+Hauser expanded its production capacity by building a 16,500m2 facility in Suzhou, China, for manufacturing measurement solutions. Similarly, in November 2017, Emerson Electric opened a measurement technology center in Beijing to support its automation solutions business in China and across Asia.

About MarketsandMarkets

MarketsandMarkets provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 5000 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Contact: Mr. Shelly Singh MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA : 1-888-600-6441 Email: [email protected]

0 notes

Text

Fasteners Manufacturers in USA,UAE,UK

Materials Of Fasteners Manufacturers

Fasteners Manufacturers in USA,UAE,UK are normally made from alloy, however, in a few software, they truly are simply just made from vinyl. Many metal attachments are constructed out of stainless steel, bronze, bronze, or ceramic.

Steel

can be really a formable strong, powerful, and long-lasting iron metal. Steel attachments are very popular to be used with a broad range of software, based on their own renewable content.

Stainless steel

can be another durable steel. It's a well-known option for most businesses, like auto technology, as these stainless steel bags are powerful and resistant to rust.

Brass

can be really a light-duty metal of aluminum and calcium. It's solid, corrosion-resistant, also an attractive yellowish tone. Makers usually utilize metal screws to fasten cosmetic bits, practical goods they wish to appear fine, and also for what to be applied at or around seawater.

Bronze

is just another light-duty aluminum metal. This moment, it's alloyed with magnesium. Bronze metals are ductile, lightweight, excellent conductors of heat and power, as well as non-meat. Such as metal, they got a wonderful tone and sheen, even although it could detract overtime. Bronze fasteners might be properly used for software very much like metal.

Titanium

attachments would be the number 1 decision for your aerospace marketplace as they're long-lasting enough to function as air-plane construction attachments. Also, they are exceptionally light weight as well as potent.

Plastic fasteners

are utilized for really light-duty software, for example, youngsters' toys, even at which durability isn't just a big worry.

Considerations and Customization Of Fasteners

When assigning or designing attachments to their own clients, fastener producers believe a few essential factors. Included in these are the burden which the fastener is going to be likely to endure, the ecological requirements, and also the distance limits.

These factors support Fasteners Manufacturers to customize and choose details just like the mind sort, the span, the fastener substance, needed coatings, thread grade durability, and also cosmetic parts. Additionally, they will pick threads, or absence there of, thread feel (rough threads, eloquent threads, etc.), and also ribbon dimensions.

These specifics are important for several explanations. To begin with, the mind type creates a gap, because being a broader head features push to an increased area. Then, the right span guarantees the fastener is flush with the outer lining. Third, mainly because nearly all exterior apps require attachments that'll withstand ultraviolet and corrosion deterioration, manufacturers need to regularly employ coatings. Fourth machines, makers pick the power level which is going to continue to keep the fastener from undergoing failure or breakage throughout surgery. Subsequent, as soon as a fastener can be applied decoratively or re-writing an ornamental bit, makers ought to be certain that they select a fastener that isn't going to expose the mind. In the end, threads chiefly dictate the method by which a fastener will soon function.

Fasteners Manufacturers in USA,UAE,UKTypes Of Fasteners

To discover the optimal/optimally company we are able to split industrial attachments to two different categories: threaded fasteners and non-threaded attachments.

Threaded Fasteners

Threaded fasteners are such attachments that contain spiral ridges, named threads, so in your own physique. Threads aid them to keep stable.

Prominent samples of thread attachments included screws, nuts, screws, pliers, clinching fasteners, Hex Bols Manufacturers, self-tapping screws, cover screws, tap-end studs, double-end studs, along with continuous-thread figurines.

Nuts are alloy cubes made to utilize magnets as a way to generate a robust attachment in between your linking surfaces. To accomplish this, they utilize inner threads which in shape and grip on the top rotating shaft of bolts.

Bolts (bolt stud fasteners),

he counterpart of nuts, include an outside, partly stitched rotating shaft. End users drive them throughout the entire workpiece and fasten them across the flip hand together using nuts. Additionally, bolts and nuts are called bolt and nut assemblies.

Screws

are immensely extensive sounding threaded attachments. Generally, they comprise a spiral-shaped ribbon rotating shaft along with a mindset. As they comprise a mind, they don't need every additional component to keep in place.

Studs

are alloy bottoms or sticks with ribbons on either side.

Clinching fasteners,

some times called decorative attachments, self-clinching attachments, or captive fasteners, are attachments that if driven into the ductile alloy, deform the alloy around the workpiece mounting gap. In case they perform, therefore, the metal chilly escapes right into an annular recess found inside the fastener pilot or shank. Clinching attachments distinction with all those attachments that deform once they're put in.

Hex bolts

are routers that contain a hexagon-shaped headset. They truly are very common to usage in structure.

Self-tapping screws

may exploit their very own hole for being a user pushes them right into the spot.

Cap screws

are totally threaded attachments developed to secure components.

Tap-end studs

are claws that contain prolonged threads on 1 side and brief ends across the opposite. The lengthy run is known as a nut-end. Users may around or chamfer the lengthy run, plus so they are able to twist the brief end into holes that are exploited.

Double-end studs

are such claws that contain chamfered threads and points of equivalent spans on the endings. Fairly usually, clients get such a fastener to get flange bolting.

Continuous thread studs

are claws that do not have any fracture inside his or her own drool. Rather they are threaded continually in the end. Clients also regularly utilize constant ribbon claws to get flange bolting, nevertheless to accomplish this, they also have to utilize two nuts.

Non-Threaded Fasteners

Non-threaded fasteners are such attachments that don't contain threads. With stickers, they're simpler to set up and simpler to get rid of. Moreover, they don't require add-ons such as screwdrivers.

One of their absolute most often occurring non-threaded fastener forms include snare attachments, maintaining bands, rivet attachments, blind rivet attachments, along with dowel pins.

Pin fasteners

are steel hooks that are most frequently pliable. With all the assistance of the clip ultimately they secure device parts with each other and/or maintain them. All these arrive inconvenient at assemblies at which in fact the fastener has to be taken away usually, such as, for instance, a tractor wagon. It'd be overly awkward to twist and loosen off a spool every moment. By comparison, consumers may put in and eliminate a trap second.

Retaining ring fasteners

grip areas and assemblies from housings or on bottoms. They stop both the assemblies or 2 parts out of slipping falling or around. They're able to do so as, after installed they are secured to place at a groove. A few will also be self-locking mechanics. Clients purchase keeping rings to be used on pulleys, door hinges, and electronic equipment, in addition to on home furniture to sort links.

Rivet fasteners,

or rivets, are mechanical attachments composed of the mind attached with your smooth vertical rotating shaft. Users put in it by setting it in a punched hole. Once they perform so, the tail end of this shaft deforms, turning into roughly a half times broader. This also enables the rivet to remain set up indefinitely. Clients usually invest in rivets together side hooks to get longer durable and tamper-proof retains on pulleys and hinges.

Blind fastener rivets

grip two areas jointly in the mind of the rivet. Some times referred to as soda fastener rivets or Blind Rivet Nuts Manufacturers, then all these attachments contain the tubular rotating shaft and also a mandrel managing throughout the center. Users put in it by setting it at a hole that is drilled and pulling onto the mandrel having a rivet weapon. As end-users pull from the mandrel, then it is going to pop or split, inducing the rivet mind blind-ending, to enlarge and also grip both parts with each other. Manufacturers usually do not advise blind rivet attachments for significant structural uses since the mandrel may fall-out and as they truly are more prone to corrosion and vibration. If clients are doing invest in blind rivets, then it's often for utilizing with elements they are able to simply reach in 1 facet.

Dowel pins

grip parts collectively equally to guarantee appropriate orientation. These reliable directional rods are usually quite tiny and therefore are therefore helpful in software such as toy making and pubs affirms. To adapt the apps, they could possibly be wrapped, tapered, or even interrogate.

Snap Fasteners

Snap fasteners are specialization attachments created for the usage on stuff such as tops, trousers, along with a few totes. Some times called hinges, media claws, or poppers, they consist of 2 plastic or metal interlocking disks. To secure users only need to utilize pressure plus so they are going to snap closed. Frequently, snap attachments proceed at the place of switches.

0 notes

Link

Sapcon provides you with the Vibrating Rod Type Level Sensor/Switch for Solids. It consumes less power, requires no maintenance and has a long life. Click the link and choose a better option for your type level sensor requirement

0 notes

Text

Trumen Technologies Pvt. Ltd. is a renowned, ISO 9001:2015 certified Indian manufacturer and exporter specializing in advanced Level and Pressure sensing instruments. With years of expertise in the industry, Trumen’s dedicated team of professionals is committed to delivering high-quality products that meet the diverse needs of customers, ensuring timely delivery without compromising on quality.

We offer a broad range of CE-certified products, including:

Radar Level Transmitters

Ultrasonic Level Transmitters

Vibrating Fork Solid and Liquid Level Switches

Admittance Point Level Switches

Capacitance Point Level Switches

Vibrating Rod Point Level Switches

Conductivity Point Level Switches

Capacitive Continuous Level Transmitters

Hydrostatic Continuous Level Transmitters

Our instruments find application across various industries such as Power & Water, Oil & Gas, Petrochemical, Mining & Metals, Food & Beverages, Cement, Pharmaceuticals, and more. We are proud to serve major companies like NTPC, IOCL, BPCL, BORL, Cipla, Lupin, Cadila Healthcare, Praj High Purity Systems, Ultratech Cement, Shree Cement, Jindal Group, TATA, Asian Paints, Procter & Gamble, Hindustan Unilever, Kirloskar, Vedanta, Nestlé, Pepsi, BASF, Novartis, and many others.

Trumen Technologies is also a trusted supplier to international markets, exporting to countries including the USA, UK, South Korea, Italy, Thailand, Taiwan, UAE, Tanzania, Turkey, Sri Lanka, Saudi Arabia, Kuwait, Malaysia, Sweden, Canada, Egypt, Brazil, Singapore, and more.

Contact: 0731 497 2065

Contact Information: Address: 39, Mangal Nagar, Behind Sai Ram Plaza, Near Rajeev Gandhi Circle, AB Road, Indore, Madhya Pradesh 452001 Website: http://trumen.in/

1 note

·

View note

Photo

Jayceetech is best Vibrating Rod Point Level Switch for Solids supplier, Vibrating Rod Point Level Switch for Solids Manufacturer Company in pune, Maharashtra, India

0 notes

Text

Global Vibration Level Switch Market

Global Vibration Level Switch Market was valued US$ 0.56 Bn in 2017 and is estimated to reach US$ 0.95 Bn by 2026 at a CAGR of more than 6.83% during a forecast period.

Global Vibration Level Switch Market is segmented by Technology, by Application, by Industry and by Region.

Vibration Level Switch Market by Technology segment is classified into Vibrating Fork & Vibrating Rod. By Application segment classified into Liquids and Solids. By Industry segment into Oil & Gas, Chemicals, Food & Beverages and Pharmaceuticals. Geographically split into North America, Europe, Asia Pacific, Middle East & Africa and Latin America.

In terms of Technology Segment Vibrating Fork segment is major in Vibration level Switch Market. In difficult level monitoring and control application for measuring liquid and solid Vibration level switches are used. Vibrating fork level switches are the most preferred solution for liquids applications. These switches are used in safety-critical applications such as overfill prevention, retention dike level alarms, and seal pot low level indication. Vibrating fork switches are a suitable option. They can safely, reliably, and accurately perform under such hazardous conditions and they are easy to use.

In terms of Application Segment Liquid segment is major in Vibration level Switch Market. Which held the largest market share. whose expecting growth rate is higher than solid.

With growing adoption in industries such as chemicals, food & beverages, and pharmaceuticals, the demand for vibration level switches is likely to grow for liquids measurement applications during the forecast period.

In terms of Industry Segment Food & Beverages is major in Vibration level Switch Market. Food & beverages industry, which require exact and reliable level monitoring equipment. Point level measurement instruments operating in the food & beverages industry must fulfil with safety and hygiene regulations. Vibration level switches offer reliable point level measurement of liquids and bulk solids, under hygienic process conditions.

Demands of Vibrational Level Switch Market increases because its Strength on functional safety of overfill protection system is better. The execution of various functional safety directives and industrial process and machine safety guidelines in the region are driving the demand for vibration level switch. Growth in food & beverages and pharmaceuticals industries also offer significant opportunities for the growth of the vibration level switch market Cost-effectiveness, reliability, and ease of operation of vibrating fork level switches also boost their demand within the market.

Europe hold the major share in the Vibration Level switch Market. The increasing adoption of automation in process industries, Europe is making a greater need for their functional safety. Asia Pacific can be primarily attributed to growth of industries in the region and prepare to expand CAGR. All other regions are following to contribute the growth in Vibration Level Switch Market.

The report includes detailed profiles of the prominent market players that are trending in the market. Endress+Hauser, VEGA Grieshaber, Emerson Electric, KROHNE Messtechnik, Siemens ABB, AMETEK, Magnetrol International, Bürkert Fluid Control Systems, Pepperl+Fuchs, Nivelco Process Control, Finetek Group, Matsushima Measure Tech, Dwyer Instruments, Flowline among others.

For more information visit @https://www.maximizemarketresearch.com/market-report/global-vibration-level-switch-market/16810/

Global Vibration Level Switch Market By Technology:

• Vibrating Fork

• Vibrating Rod

Global Vibration Level Switch Market By Application:

• Liquids

• Solids

Global Vibration Level Switch Market By Industry:

• Oil & Gas

• Chemicals

• Food & Beverages

• Pharmaceuticals

Global Vibration Level Switch Market By Region:

• North America

• Europe

• Asia Pacific

• Latin America

• The Middle East and Africa

Key Player analysed in the Global Vibration Level Switch Market:

• Endress+Hauser

• VEGA Grieshaber

• Emerson Electric

• KROHNE Messtechnik

• Siemens ABB

• AMETEK

• Magnetrol International

• Bürkert Fluid Control Systems

• Pepperl+Fuchs

• Nivelco Process Control

• Finetek Group

• Matsushima Measure Tech

• Dwyer Instruments

• Flowline

This Report Is Submitted By @Maximize Market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

Address: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +919607195908

0 notes

Photo

The vibrating rod point level switch is the ideal answer for single point level exchanging in free flowing solids over a wide density range, from fine powders to grains. A single rod design provides the answer for tuning forks which may wind up blocked or crossed over. Vibrating rod level switch is intended to identify the nearness and nonappearance of powder and mass strong materials of moderate to heavy weight.

0 notes

Text

Transzilla—We Install The SuperMatic 4L85-E From Chevrolet Performance

If you’re old enough to remember when a street rodder wanting an automatic transmission had to choose between a slant pan Hydramatic or a Powerglide you probably recall how exciting it was when the Turbo 350 became readily available. And when four-speed overdrive automatics hit the scene they were a real game changer. Suddenly there was an automatic that had a low First gear to launch the car from a standing start and an overdrive top gear to keep the engine’s rpm in a reasonable range at highway speeds.

Another development that has changed street rodding is the ease with which horsepower can be obtained. Today we have crate motors making 500 hp and more with torque figures to match, fortunately there are overdrive automatics that can handle that kind of power and one of the best of the breed is SuperMatic GM 4L85-E from Chevrolet Performance.

The SuperMatic 4L85-E Basics

The 4L80-E series introduced in 1991 GM trucks could trace its lineage to the rugged Turbo-Hydramatic TH400. Many of the internal parts were the same, however the 4L80-E offered the advantages of an overdrive top gear, lock-up torque converter, and sophisticated electronic controls. But while the 4L80-E is rated at 440 lb-ft of torque, the monster of the series is the 4L85-E rated at 690 lb-ft of torque. The primary difference between the two is the 4L80-E planetary gear sets have four pinion gears as opposed to the 4L85-E gear sets that have five pinion gears.

As delivered by Chevrolet Performance the SuperMatic 4L85-E has an improved valve body for firmer shifts and is equipped with additional clutch plates for greater torque capacity. Gear ratios are: First: 2.482, Second: 1.482, Third: 1.000, Fourth: 0.750, Reverse: 2.077. In comparison, the gear ratios of the popular 700-R4 are: First: 3.060, Second: 1.620, Third: 1.000, Fourth: 0.700, Reverse: 2.077.

Wiring Harness

Like all computer-controlled transmissions without an electronic control unit to tell it what to do, a 4L85-E is just an aluminum box full that might as well be full of rocks. Fortunately there are a variety of easy-to-install control kits available from Chevrolet Performance, MSD, and others. Typically the wiring harness connections for a 4L85-E are: the transmission (20 pin) connector, output speed sensor (OSS), input speed sensor (ISS), transmission control unit (TCU), throttle position sensor (TPS), tach lead on the distributor cap (carbureted engines), ignition power (12V with key in run position), battery power (12V at all times), and ground (battery negative terminal or solid engine ground).

The Chevrolet Performance transmission controller includes a long list of functions, such as brake light switch activated torque converter unlock, A/B calibration switch that allows a second calibration to be activated, dyno mode, which allows the transmission to be “locked” in gear for chassis dyno testing. Also, part of the package will be a laptop connection for calibration and data acquisition and a connection for optional manual shift operation. In some cases the wiring harness will provide for optional connections, such as a tachometer, speedometer, and oil pressure gauge connections, however they are not required for transmission operation.

Chevrolet Performance points out that all transmission controller kits require the use of a throttle position sensor as all shift points and pressures are determined from driver throttle input. The Holley TPS kit must be installed on the Holley Carbureted crate engine and the Chevrolet Performance harness will plug into the sensor. Ramjet engines can use the single TPS signal wire from the engine harness, as can LS installations.

MSD

Bob Kliner is the proud owner of a 1954 Kaiser Manhattan powered by a 502-inch big-block Chevy backed by a 700-R4 transmission. When he decided to install a 4L85-E he elected to go with an MSD transmission controller because the engine was equipped with an MSD Atomic fuel injection system.

The Atomic injection is unique in that the ECU and sensors, including the TPS, are integrated into the throttle body. That means there is no way to tap into the TPS to give the transmission controller the throttle position indication that it needs. However, MSD offers a throttle position sensor module designed to be used with the MSD Atomic throttle body fuel injection system. It connects inline to the Atomic TBI communication network and provides a common 0- to 5V throttle position output signal that is required for the operation of an electronic overdrive transmission, such as the 4L85-E.

MSD’s Atomic Trans Control Module kit is available for most GM and Ford four-speed automatics, including the 4L85-E. MSD allows the operating parameters of the transmission, including shift points, torque converter clutch behavior, shift firmness, and more using the supplied handheld monitor—no PC is required. MSD points out the handheld monitor can be left in place to monitor the transmission in real time, or disconnected once the configuration is complete.

Once connected, only a few basic parameters have to be entered via the monitor such as: the number of engine cylinders, rearend gear ratio, and tire height. Once that information has been entered the vehicle can be driven and the Advanced Setup menu set to: Adjust shift points. Adjust torque converter clutch behavior. Select different levels of shift firmness. Select between auto-shift mode and manual-shift mode. Activate Dyno Mode to deliver repeatable chassis dyno results.

Cooler Lines

Automatic transmission cooler lines are ordinarily very simple, but when it comes to the 4L85-E, using an incorrect fitting can severely damage the transmission.

The 4L85-E cooler line fittings are unique in that they are not threaded and use a push-lock method of attachment. It’s common to swap fittings to allow the use of AN lines, but it takes a special fitting to accomplish that.

At the back of the transmission is the return connection from the cooler and the fitting in the transmission is unique—it has an extension that sprays fluid on internal components to keep them cool. Without that part of the cooling system functioning transmission failure will occur in short order.

A special adapter fitting that includes the extension tube and will allow the use of an AN fitting is available from Sweet Performance and others.

One Tough Transmission

When it comes to handling huge horsepower and torque numbers the Chevrolet Performance 4L85-E is rugged enough to take what’s thrown at it. At 32-1/16 inches long, the 4L85-E is longer than the 700-R4 that measures 30-3/4 inches. The 4L85-E tips the scales at 230 pounds dry versus 200 pounds dry for the 700. Big and strong, the 4L85-E truly is the Transzilla of automatics.

We caught Bob Kliner in the act of installing a Chevrolet Performance SuperMatic 4L85-E in his big-block Chevy-powered 1954 Kaiser Manhattan.

Here’s the 700-R4 on the left; on the right is the 4L85-E. Both will bolt to a Gen I small-block or any big-block.

Normally a 700-R4 transmission is often thought of as being large, however in this case it’s smaller than the 4L85-E that’s replacing it.

When swapping transmissions the shift lever from the 700-R4 can be removed and placed onto the 4L85-E; it fits perfectly.

This is the often-troublesome throttle valve cable that connects to the throttle linkage and controls hydraulic pressure inside the transmission. The more sophisticated 4L85-E uses a computer.

Depending on the year of the transmission, the input shaft in a 700-R4 is either 27- or 30-spline, depending on the year of manufacture.

By comparison the larger input shaft of the 4l85-E has 35 splines.

The output shaft of the 4L85-E has 35 splines. Note the position of the transmission mount.

This is the smaller-diameter output shaft of the 700-R4; it has 27 splines

On the left is the 700-R4 driveshaft yoke that takes a 1310 to 1350 U-joint; on the right is the 4L85-E yoke that takes the 1350 to 1480 series U-joint.

As the trans mount on the 4L85-E is 7-inched further back than the 700-R4, Bob had to modify the Kaiser’s transmission mount and shorten driveshaft 1-1/2 inches.

To help the torque converter slide in place easily and seat properly the O-ring on the input shaft was lubricated. Before installation 6-8 ounces of transmission should be added to the torque converter to prevent a dry start.

Chevrolet Performance SuperMatic torque converters require the use of a 164-tooth flexplate (the smaller 153-tooth will not work).

Fluid capacity of the 4L85-E is 13.2 quarts dry (pan holds 7.7 quarts) and uses Dexron VI fluid or equivalent, such as AMSOIL INC. Signature Series ATF.

To attach the torque converter to the flexplate Bob used ARP hardware. Made from chromoly steel, the correct bolts are 10 mm in diameter by 1-1/2 inches long.

To prevent any possible fluid seepage the GM transmission dipstick has a rubber seal and a positive lock mechanism.

The dipstick tube fits into a seal in the transmission and attaches to the block with one of the transmission attaching bolts.

Original equipment cooler lines have a shoulder that locks into the fittings in the transmission.

The cooler lines snap into the push-lock fittings in the transmission then rubber seals fit over the assembled connection.

Cooler lines on the 4L80E are widely separated, unlike those of the 700-4R that are next to both at the front of the case.

This is the tool used for dealing with the OEM cooler lines.

Look closely and the retainers that hold the cooler lines in place can be seen.

As we explained in the text the rear cooler line fitting is critical to the transmission’s longevity. The upper example has the proper extension, accepts an A/N fitting, and is available from Sweet Performance.

To keep the cooler lines from vibrating they were secured with clamps from Kugel Komponents.

This is a Chevrolet Performance SuperMatic transmission controller; it works with 4L60-E, 4L65-E, 4L70-E, 4L80-E, and 4L85-E automatic transmissions.

The Chevrolet Performance ECU connects to the transmission’s wiring harness with a screw-on plug.

The ECU harness includes a connection for optional manual shift operation.

Once all the setup information is entered the SuperMatic ECU allows full programming of shifting, as well as part throttle, wide-open throttle, and shift firmness.

MSD offers a complete system to control the 4L85-E (as well as other transmissions) transmission control module, PN 2760; MSD transmission controller harness, PN 2770 (not shown); and MSD TPS, PN 2939.

The TPS is MSD’s throttle position sensor (PN 2939) that plugs in line to the Atomic TBI EFI system.

Another option for a TPS is the cable-controlled style; note the black cable connected to the throttle arm.

The other end of the cable connects to the remote TPS mounted to a bracket.

This is the main connector the ECU harness connects to.

The transmission connector is capable of being installed incorrectly if forced into place. The arrow on the harness connector will face up the 4L85-E when installed correctly.

The 4L80E has two speed sensors, the forward monitors turbine input speed and compares that to engine speed and output shaft speed …

… and the second sensor monitors output shaft speed. By comparing the two sensors the stock PCM can command the engine to momentarily drop power during a shift if there’s a possibility of clutch damage.

As the 4L85-E lacks the 700-R4’s cable drive, Kliner converted the speedometer to a Classic Instruments Sky Drive that uses GPS satellites to monitor the vehicles speed.

The post Transzilla—We Install The SuperMatic 4L85-E From Chevrolet Performance appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/transzilla-install-supermatic-4l85-e-chevrolet-performance/ via IFTTT

0 notes