#VibrationAnalysis

Explore tagged Tumblr posts

Text

Enhance Machinery Efficiency with Vibration Analysis Service in Duba

For industries operating in high-demand environments, unexpected equipment failures can lead to costly downtimes. That’s why predictive maintenance tools like Vibration Analysis Service in Duba are becoming essential. At Bafco Reliability, we specialize in helping businesses in Duba improve their machinery health, efficiency, and reliability through expert vibration analysis.

What is Vibration Analysis?

Vibration analysis is a critical technique used to monitor the condition of rotating machinery such as motors, pumps, compressors, and turbines. By capturing vibration signals and analyzing them, we can detect mechanical issues like imbalance, misalignment, bearing faults, and looseness before they escalate into major breakdowns.

Regular vibration analysis allows maintenance teams to plan repairs in advance, thereby reducing downtime and extending the lifespan of machinery.

Why Bafco Reliability?

As a trusted name in the field of industrial maintenance, Bafco Reliability offers advanced Vibration Analysis Service in Duba using modern tools and expert insights. Our certified technicians provide accurate diagnostics, helping you make data-driven decisions to keep your operations smooth and safe.

We cater to a wide range of industries, including oil & gas, manufacturing, power plants, marine, and more. With customized service plans and quick response times, we’re committed to your equipment’s optimal performance.

Key Benefits

Early Fault Detection: Catch problems before they affect production.

Minimized Downtime: Schedule maintenance without disrupting operations.

Cost Efficiency: Reduce emergency repair and replacement costs.

Enhanced Safety: Ensure a safer workplace with healthier machines.

Extended Equipment Life: Maximize the return on your machinery investment.

Serving Industries Across Duba

Whether it’s a small-scale facility or a large industrial setup, we bring the same level of precision and professionalism to every project. Our deep understanding of local industry needs in Duba positions us as the go-to choice for reliable condition monitoring.

Invest in the health of your machinery today with Bafco Reliability and experience the difference that expert vibration analysis can make.

#BafcoReliability#VibrationAnalysis#DubaIndustry#ConditionMonitoring#PredictiveMaintenance#IndustrialServicesDuba#RotatingEquipmentCare#MachineryHealth#MaintenanceSolutions#PreventDowntime

0 notes

Text

Dynamic Balancing of Rotating Parts is essential for improving the performance and lifespan of industrial equipment like blowers, fans, pumps, motors, and shafts. At S.V. Engineers, we offer precise on-site and workshop dynamic balancing services using advanced balancing machines and tools. Our service helps reduce vibration, prevent premature bearing failure, and minimize downtime. We serve a wide range of industries across South India, ensuring smoother operation and energy efficiency in all rotating machinery. Call us today for expert dynamic balancing solutions that keep your equipment running at its best.

dynamic balancing, rotating equipment balancing, industrial fan balancing, motor balancing, vibration reduction, blower balancing, Chennai, South India, S.V. Engineers.

#DynamicBalancing#VibrationAnalysis#FieldBalancing#RotatingEquipment#IndustrialMaintenance#PredictiveMaintenance#ConditionMonitoring#MachineHealth#AlignmentServices#VibrationMonitoring

0 notes

Text

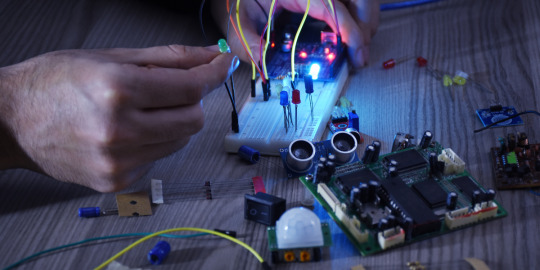

🛠️ Want to avoid sudden machine breakdowns? 🚨

If you're in charge of industrial equipment, you know that one failure can lead to huge losses. That’s why having preventive maintenance monitoring equipment is a game changer! Our vibration analysis tools track your machinery in real time, detecting potential issues before they cause major failures. 🏭⚙️

💡 Stay ahead with smart monitoring! Our system ensures longer equipment life, reduced downtime, and better efficiency. Stop guessing and start predicting with advanced diagnostics. Learn how to protect your machines today!

#MachineHealth#PreventiveMaintenance#SmartMonitoring#IndustrialTech#PredictiveMaintenance#VibrationAnalysis#IndustrialEfficiency#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign#ElectricPreventiveMaintenance

0 notes

Text

Vibration Meter R Tek RK63A

Measurement Range : Acceleration: 0.1~199.9m/s2 Velocity: 0.1~199.9m/s Displacement: 0.001-1.999mm P.P

Accuracy : +5%

LCD Display : 3.5 digits display

Operation Condition : 0~40°C

Unit Size : 183*67*30mm,

Standard Carton Size : 51.7*40.5*32CM

Power : 9V Battery

Buy : https://vegabazaar.com/product/Vibration-Meter-R-Tek-RK63A/

#VibrationMeter#vibrationanalysis#conditionmonitoring#predictivemaintenance#industrialtools#machineryhealth#EquipmentMonitoring#Manufacturing#factoryautomation

0 notes

Text

Optimizing Machinery Health with Vibration Analysis

Enhance equipment reliability and performance with our advanced vibration analysis. Detect issues early, reduce downtime, and ensure optimal operation through precise monitoring. Trust Semeq for expert vibration analysis solutions.

0 notes

Text

Optimizing Steel Performance through Advanced Heat Treatment Processes

At Jalpa Devi, our commitment to excellence is evident in our comprehensive range of heat treatment processes designed to enhance the quality and durability of steel components. Our state-of-the-art Heat Treatment processes are fully equipped to address a diverse spectrum of industry-specific needs and applications, making us the preferred choice for those seeking exceptional heat treatment services.Backed by our state-of-the-art facilities and skilled team. Jalpadevi is one of the trusted partners for heat treatment of steel. We are committed to delivering exceptional quality and precision in all our heat treatment processes, ensuring that your steel components meet the highest industry standards.

Contact us today to explore how our heat treatment services can benefit your projects and further your infrastructure development goals.

visit us- https://jalpadeviengg.com/HeatTreatment-Fettling.aspx

#MechanicalEngineering#EngineeringDesign#Mechanics#Thermodynamics#FluidMechanics#MaterialsScience#CADDesign#Manufacturing#Robotics#AutomotiveEngineering#AerospaceEngineering#StructuralEngineering#MachineDesign#HeatTransfer#ControlSystems#FiniteElementAnalysis#MechanicalSystems#VibrationAnalysis#EnergyConversion#EngineeringEthics

0 notes

Text

5 Best Predictive Maintenance Techniques

Predictive maintenance relies on real-time data and predictive analytics to identify equipment failures before they lead to unplanned downtime or costly repairs.

Read More: https://cmmssoftware.leantransitionsolutions.com/software-blogs-details/best-predictive-maintenance-techniques

#CMMS#predictivemaintenance#cmmssoftware#cmmssystem#reactivemaintenance#infraredthermography#ultrasonictesting#vibrationanalysis#oilanalysis#machinedowntime#ultrasoundmicrophone#equipmentdowntime#equipmentfailure#cmmsprogram#preventivemaintenance#predictivetools#maintenanceprogram#cmmsmaintenance#maintenanceactivities#pdmmaintenance#lts#Industry 4.0#Leantransitionsolutions

0 notes

Text

Vibration Analysis In Kalpakkam

https://www.arunstudy.com/vibration-analysis-in-kalpakkam/

Vibration Analysis in Kalpakkam

🚀 Unlocking the Secrets of Machinery Health with Vibration Analysis in Kalpakkam! 🌍

🔧 What is Vibration Analysis? It's a cutting-edge tool in mechanical engineering that studies the oscillatory motions of machinery and structures. Whether it’s rotating engines, natural resonances, or external forces, understanding these vibrations helps engineers maintain peak performance and safety.

💡 Why Does It Matter?

Predictive Maintenance: Detect early signs of wear, misalignments, or imbalances before they become costly failures.

Structural Integrity: Monitor bridges, buildings, and other structures to ensure safety and longevity.

Innovation: Aid in designing robust systems, from prototypes to production.

Aerospace Applications: Ensure the safety and efficiency of aircraft components under complex dynamic forces.

📊 How It Works Using advanced sensors like accelerometers, vibrations are measured and analyzed for frequency, amplitude, and phase. These insights allow industries to: ✅ Minimize downtime ✅ Reduce operational costs ✅ Extend equipment lifespan

🌟 Kalpakkam’s Edge In a hub like Kalpakkam, where innovation meets precision, vibration analysis ensures the smooth operation of critical systems across industries. From nuclear facilities to infrastructure, this tool is shaping a safer, more efficient future.

🔗 Join the Revolution! Explore how vibration analysis is transforming engineering and infrastructure in Kalpakkam and beyond.

#VibrationAnalysis #EngineeringInnovation #KalpakkamTech #PredictiveMaintenance #StructuralHealthMonitoring #AerospaceEngineering #SmartMaintenance

Would you like to add a local event, expert highlight, or technical infographic to enhance engagement? 😊

0 notes

Text

Harmonizing Performance: The Dynamics of the NVH Testing Market

The NVH Testing market is experiencing significant growth as industries prioritize superior product quality and user experience. Noise, Vibration, and Harshness (NVH) testing is essential for evaluating and improving the acoustic and mechanical performance of products, ranging from automobiles and consumer electronics to industrial machinery.

With the increasing demand for quieter and more refined products, NVH testing has become a critical tool in identifying and mitigating unwanted noise and vibration issues during design and development phases. As the automotive and electronics sectors continue to evolve, NVH testing technology is advancing to cater to more complex scenarios, leading to enhanced testing methodologies, accurate measurement techniques, and immersive simulation tools.

Request For Free Sample : https://www.globalinsightservices.com/request-sample/GIS10212

#NVHTesting #AcousticPerformance #VibrationAnalysis #ProductQuality #UserExperience

0 notes

Text

Vibration isolation has always been a core theme in the design of turntables, let's check out how we could solve it~ 😉 #audiophile #vibrationanalysis #vibrationcontrol #design #phono

0 notes

Text

Condition Monitoring Technicians in Yanbu: Expert Reliability Solutions with Bafco

Effective condition monitoring is essential for ensuring the smooth operation of industrial machinery and reducing unexpected breakdowns. Bafco Reliability provides highly skilled Condition Monitoring Technicians in Yanbu to help industries maintain peak performance through advanced diagnostic techniques and predictive maintenance strategies.

The Role of Condition Monitoring Technicians

Our experienced Condition Monitoring Technicians in Yanbu specialize in detecting early signs of equipment failure, allowing for timely maintenance and repairs. This proactive approach prevents costly downtime and enhances overall operational efficiency.

Key Condition Monitoring Services We Offer

1. Vibration Analysis

Identifies misalignment, imbalance, and mechanical looseness to prevent machine failures.

2. Thermal Imaging

Detects overheating components to prevent electrical and mechanical failures.

3. Oil Analysis

Monitors lubricant quality and identifies potential wear and contamination issues.

4. Ultrasonic Testing

Detects air and gas leaks, electrical discharges, and mechanical anomalies before they lead to failures.

5. Motor & Gearbox Inspection

Ensures optimal performance and longevity of critical rotating equipment.

Industries Benefiting from Our Condition Monitoring Services in Yanbu

- Oil & Gas Industry:

Enhances safety and reliability of drilling, refining, and processing equipment.

- Power Plants:

Prevents sudden failures and increases energy efficiency.

- Manufacturing & Heavy Industries:

Reduces operational costs and improves machinery lifespan.

- Marine & Offshore Operations:

Minimizes maintenance issues for marine engines and offshore structures.

Why Choose Bafco Reliability?

Bafco Reliability is a leader in predictive maintenance, with a team of expert Condition Monitoring Technicians in Yanbu who use cutting-edge technology to optimize industrial machinery performance. Our approach minimizes downtime, improves safety, and maximizes asset reliability.

Keep your industrial equipment in peak condition with Bafco Reliability’s expert monitoring solutions.

Contact Bafco Reliability Today! For more details on our condition monitoring services in Yanbu, get in touch with Bafco Reliability now!

#ConditionMonitoringYanbu#BafcoReliability#PredictiveMaintenance#IndustrialEfficiency#VibrationAnalysis#ThermalImaging#UltrasonicTesting#ReliabilityEngineering#EquipmentMaintenance#PreventiveMaintenance

0 notes

Link

Manovisions provides detailed vibratory solutions to structural vibrations, linear and non-linear vibrations, random vibrations and Rotordynamics. We have expertise to carry out Modal, Spectrum and Dynamic analyses. We can provide support to Condition Monitoring, Predictive and Preventive Maintenance and NVH control.

0 notes

Text

Advanced Noise Vibration & Harshness Solutions

Understanding of the Applications & Features of #NVH Products from OROS SA and Manner Sensortelemetrie, and provides you Advanced Noise Vibration & Harshness Solutions.

OROS SA: NVH Testing and Analysis Source / Transfer Path / Response:

1. Noise Analysis: Sound Power, Source Localization, Sound Quality, Transfer Path Analysis, Holography

2. Structural Dynamics

3. Rotating Analysis: Gears, Hybrid Transmissions / CVT, Engines, Torsion, Balancing

4.Single Unit 2-32 Channels

See their Products at https://www.aimil.com/partners/oros-s-a

Manner Sensortelemetrie: High Precision Telemetry Systems for Torque Measurements Application!

1. Torque, Rotation Speed and Power of the Gear, Rotor and Generator Shafts.

2. Bonding and Torsional Moment of the Rotor Blades

3. Vibration Analysis of the Rotors Blades

4. Pressure and Tractive Force Loads on individual drive train components

5. Temperature Profiling in Rotating Shafts.

See their Products at https://www.aimil.com/partners/manner-sensortelemetrie

#Advanced Noise Vibration & Harshness Solutions#nvh#NVH services#MannerSensortelemetrie#AimilLtd#NoiseAnalysis#VibrationAnalysis

0 notes

Text

Pump maintenance – ignore it at your peril

Regular pump system maintenance is essential to prevent significant cost and reputational issues. Thomas Marks, General Manager at the Association for Electrical and Mechanical Trades (AEMT) looks at several issues that poor pump maintenance can lead to and outlines some of the key steps that can be taken to minimise the chance of them emerging. Failing to adequately maintain industrial pumps can lead to various issues that can compromise the safety, efficiency, and longevity of the equipment and the wider systems the pumps are part of. One of the most immediate risks is the failure of the pump itself. Worn-out parts, clogged systems, or misalignments can cause a pump to break down, leading to potentially costly unplanned downtime. In addition, further unnecessary costs can be incurred when a poorly maintained pump consumes more energy to deliver the same output. Inadequate maintenance can also accelerate the wear and tear of pump components, leading to more frequent parts replacement and higher maintenance costs. And pumps that are not adequately maintained tend to have a shorter operational lifespan, leading to more frequent pump replacements. Frequent breakdowns, reduced efficiency, and the need for replacement parts can significantly increase operational costs. Leakages Worn-out seals or corroded parts can lead to leakages, resulting in the loss of valuable fluids, environmental contamination, and safety hazards. Without proper lubrication or cooling, pumps can overheat, damaging internal components and reducing their lifespan. Other issues, such as misalignment or imbalance, can cause excessive vibrations, damaging the pump and its supporting infrastructure. While cavitation, which can be a symptom of poor maintenance, can damage a pump's impeller and other components as vapour bubbles in the pumped liquid collapse, causing destructive shock waves. Of course, without regular cleaning, contaminants can enter the pump, affecting the quality of the fluid being pumped and potentially damaging the pump. Reputational damage Leakages, overheating, and equipment failures can pose safety risks to personnel working around the pumps. This can lead to accidents, injuries, or even fatalities. While leaks or spills due to poor maintenance can also lead to environmental contamination, which can result in regulatory penalties and damage to a company's reputation. And for companies that rely on pumps for critical operations, frequent breakdowns or safety incidents can also damage their reputation and customer trust. Indeed, in some industries, ensuring that equipment like pumps are adequately maintained is a regulatory requirement. Failure to comply can lead to financial penalties or legal actions. Good maintenance practices

Regularly inspecting pumps for signs of wear, damage, or corrosion is essential. This helps in identifying potential issues before they escalate. Proper lubrication is also vital for the smooth operation of pumps. It's essential to use the correct type of lubricant and to ensure it is applied at the correct intervals. Regularly checking and replacing worn-out seals is crucial, as is ensuring that cooling systems are working efficiently to prevent overheating. Vibration analysis Vibration can indicate misalignment, imbalance, or other mechanical issues. Regularly monitoring and analysing vibrations can help with the early detection of problems. Ensuring that the pump and its motor are properly aligned is also essential to prevent wear and tear and to ensure efficient operation. As part of condition monitoring solutions, vibration sensors can now continuously monitor a pumping system to identify vibration-related issues as they emerge, and other types of sensors can track a pump's performance and help to identify problems like reduced flow or increased energy consumption. Systems such as these can also monitor the state of bearings to enable them to be replaced as soon as any performance issues are indicated. Ensuring the maintenance team is well-trained and updated with the latest maintenance practices is crucial. This ensures that they can identify and address issues promptly and are fully up to date with and following necessary safety protocols during maintenance activities to prevent accidents and injuries. Keeping detailed records of maintenance activities, parts replacements, and performance metrics can help plan future maintenance and identify recurring issues. While having a well-stocked inventory of essential spare parts, which can be informed by historical requirements, can reduce downtime in case of failures. And understanding the expected lifecycle of a pump and planning for eventual replacement or upgrades can help in budgeting and ensuring continuous operations. Industrial pump maintenance is a comprehensive process that involves a combination of regular checks, timely interventions, and proactive measures to ensure the longevity and efficient operation of the pumps. But it is essential, if the risks that can lead to wide-ranging consequences, from increased operational costs to safety hazards and environmental damage, are to be avoided and the smooth operation of industrial pumping systems is to be ensured. For more information on the AEMT, please send an email to [email protected] www.theaemt.com Read the full article

0 notes

Text

ENERGY EFFICIENCY LUBE

The more there is friction on the rolling element of bearing; motor exerts more power thereby increase your energy consumption. Suitable and correct amount of lubricants feed into the bearing will lessen friction, reduces load (HP), and make the whole drive system more efficient.

Bearing failure is a major cause of equipment downtime in today‘s industrial environment, most often resulting from improper lubrication. Improper lubrication scenarios include the contamination of the lubricant by dust, dirt and moisture, inadequate amounts of lubricant applied to the bearing, and/or over-lubrication of the bearing.

Each bearing failure directly impacts the production cycle. While bearings can be expensive, replacement cost alone is often miniscule compared to lost production and the cost to repair the damage.

Fig 1 shown that 51% of motor failure is caused by bearings. This is our experience in the repair of motors.

According to a recent study as shown in Fig. 2, 15% is caused by insufficient lubrication; 5% liquid contamination; 20% solid contamination (grease container exposed to environment not properly covered or sealed).

Contamination is caused by foreign substances getting into bearing lubricants or cleaning solutions. These include dirt, abrasive grit, dust, steel chips from contaminated work areas and dirty hands or tools.

Why, in the age of technology, is this a problem? It is because many bearings are still lubricated manually. No matter how diligently a maintenance staff adheres to a lubrication schedule, it is a difficult task. Because employees are expected to manage multiple responsibilities in the lean environment of today‘s plants, it is common that proper lubrication is not considered a priority.

Solutions:

Use the appropriate type and correct amount of lubricant, avoid grease loss, and follow appropriate re-lubrication intervals.

Filter the lubricant using automatic lubricators and clean work areas, tools, fixtures and hands to reduce the risk of contamination.

Reference: http://www.slideshare.net/dmanney/why-electric-motors-fail

Automatic Lubrication for Manufacturing Applications

ATS Electro-Lube manufactures self contained single-point and multi-point automatic lubrication products that provide effective, dependable lubrication for manufacturing equipment of all types. Our self-contained mechanical lubricators can deliver up to two full years of continuous lubrication, and can be installed almost anywhere—including remotely, as much as 30‘ from the lubrication point. Our devices are a safe, efficient alternative to daily manual lubrication.

We also offer a variety of accessories, including mounting brackets, control options and power options. ATS‘ motor-driven units, the ULTIMATE, TITAN, OILER and JACK series can all lubricate multiple points with a single unit via distribution blocks. Our TITAN, OILER and JACK units are refillable, for added convenience.

ATS‘ innovative auto lubers are ideal for bearing lubrication, engine lubrication, and any other machine lubrication needs your manufacturing processes may have. Our automatic mechanical lubricators deliver a reliable, consistent solution for any machinery that requires regular lubrication.

#Alignment, #VibrationAnalysis, #MotorEnergySavings, #MotorRepairs, #MotorRewinding, #Coolingtower, #EnergyefficiencyHVAC, #pumps, #blowers, #gearbox

http://alpsmsi.com/alps/energy-efficiency-lube/

#Alignment laguna#vibration analysis laguna#Motor Energy Savings laguna#Motor repairs laguna#Motor rewinding laguna#Cooling tower laguna#Energy efficiency HVAC laguna#pumps laguna#blowers laguna#gearbox laguna#marine laguna#general construction laguna#electric motors laguna#Permanent Magnet Synchronous laguna#Motors Reluctance laguna#motors laguna#Industrial controls laguna#Conveyor drives laguna#Automation laguna#Circuit breakers laguna#Condition monitoring laguna#Geared motors laguna#Control engineering laguna#Converters laguna#Inverters laguna#Coupling laguna#Crane drives laguna#Industrial communications laguna#instruments laguna#Distribution systems Gears laguna

0 notes