#VibrationDamping

Text

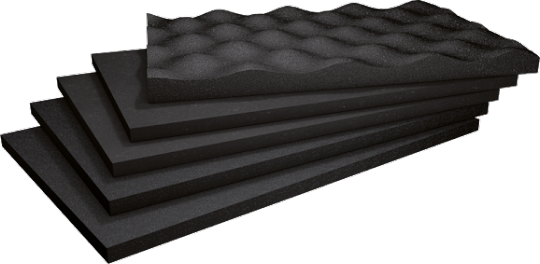

Dynemech Vibration isolation tables, also known as vibration damping tables or Dynemech Vibration Isolation Tables are used in industrial and scientific settings to control the effects of vibrations. These tables are designed to reduce vibrations caused by processes such as machining or grinding, which can lead to inaccurate results when measuring delicate items. Vibration isolation tables provide an effective way to minimize unwanted vibrations, ensuring accuracy and consistency in measurements.

The construction of vibration isolation tables typically consists of a rigid frame and a layer of vibration damping material. This layer helps to absorb and control the energy from vibrations, allowing for a higher level of accuracy in measurements. The design of the table will depend on its application and the environment it is being used in; for example, if it is to be used outdoors, then the table may need to be designed with more robust materials to withstand environmental elements.

Our Anti Vibration Tables find use in

Biomedical research

Precision Measurement applications such as metrology, dimensional inspection, and quality control.

Materials research

Environmental Testing

Medical Imaging

Medical and Pharmaceutical

Manufacturing Industry

Automotive Industry

Electronics Industry

Energy Industry - testing and assembly of parts and components and equipments

Food Testing Labs

Contact on +91 9911145131, +91-9911145131, +91-9212258131; e-mail - [email protected] to get more insights into the best anti-vibration solutions suiting your needs or to share any feedback

#VibrationIsolationTables

# vibrationdampingtable

# antivibrationtable

# Laser-opticalexperiments

# MedicalImaging

#VibrationIsolation

#antivibrationtable

#vibrationdamping

#antivibration

#vibrationcontrol

#novibration

#machineryvibration #vibrationmountsindia.com #vibrationdampingpads.com @dynemech #dynemech

#VibrationIsolationTables#vibrationdampingtable#antivibrationtable#Laser-opticalexperiments#MedicalImaging#VibrationIsolation#vibrationdamping#antivibration#vibrationcontrol#novibration#machineryvibration#vibrationmountsindia.com#vibrationdampingpads.com @dynemech#dynemech

2 notes

·

View notes

Text

#AerospaceIndustry#PrecisionEngineering#MisalignmentCompensation#EngineeringComponents#VibrationDamping#StructuralIntegrity#spherical washer

0 notes

Text

Why Vibration-Dampening Techniques Are Important To Kill Vibrations?

If you are used to working with machines, you know how damaging can vibrations be. Vibrations of high magnitudes can also damage any movable or fixed part of the machines. As compared to inertial force and elastic force, vibrations are smaller in magnitude.

In general, vibrations are more damaging. This is why engineers always ensure that they make use of advanced techniques to kill vibrations. In specialized circumstances, vibrations can cause a lot of damage. This is why there is always a huge demand for vibration damping material at present.

• Specialized thermoplastic fibres can be used as pads to kill vibrations

• Thermoplastic material tends to cancel vibration before machine parts can be damaged

• The movable parts of the machine can easily get damaged if vibrations are not controlled

Why is vibration dampening?

Vibration cannot be beneficial in most cases. Thus it is important to reduce and lower the vibration generated. One of the most common techniques used to reduce vibration is by placing vibration-dampening material like a pad in between two layers.

The material that is used to manufacture the pad is made up of quality thermoplastic. The material acts like a layer that can absorb the vibrations. Thus the damaging effects of vibrations can be reduced or lowered. The material that is placed in between two layers can change the frequency of the vibration.

Why use thermoplastic material?

To kill vibration the material needs to have properties very much similar to rubber material. This property is very much common in thermoplastic materials. Such materials are also termed anti-vibration materials.

The vibrations that are generated on account of friction can easily be absorbed by thermoplastic material that is placed in between two layers as a pad. This technique is widely used in manufacturing industries and commercial places where vibrations can cause severe damage.

How Thermoplastic is more applicable?

Earlier it has been told that thermoplastic may have properties very much similar to rubber material. There is yet another reason why thermoplastic is better. If you are using engineered thermoplastics then it is obvious that you are aware of its durability as well.

Compared to normal rubber material, the thermoplastic material is more durable and tough. The material does not get damaged and so it can withstand heavy vibration. Due to this property, the material is also used to manufacture machine parts.

Ability to withstand heat

The vibration of any level will always produce heat. The heat that is produced on account of vibration, may be more damaging. The heat can burn moving parts of the machine because of friction force. It is important to kill vibration if excess heat is produced.

The thermoplastic material can easily absorb heat. The main property of this material is that it does not get burned. The thermoplastic material can withstand high heat and is thus useful. The material reflects vibration-dampening coefficient properties even at high temperatures.

If you are looking forward to kill vibrations, then you need to check out the unique properties of thermoplastic materials. You can check out the properties of Ecomass material. It can be used to replace rubber and offer durability as well.

0 notes

Photo

XCMG Vibration Damper #XCMG #xcmgparts #Vibrationdamper #damper https://www.instagram.com/p/CKdbuPFFIll/?igshid=1glpuo1bskx60

0 notes

Photo

Il Maglio - Dettaglio by Noothera https://flic.kr/p/c1UqEu

0 notes

Text

Dynemech Quick Selling Vibration Mounts Catalogue - Complete Range of Industrial Vibration Control Solutions

Dynemech Systems Pvt. Ltd. showcases their comprehensive range of vibration control solutions designed for various industrial applications. The company specializes in manufacturing precision vibration mounts, isolators, and anti-vibration platforms to mitigate the harmful effects of vibrations on machinery and equipment.

The catalog features an extensive selection of products, including:

Wedge Mounts (Series DF, DB, DBO, etc.): Designed for precision leveling and vibration isolation of machine tools, CNC machines, presses, and other heavy industrial equipment. These mounts offer adjustable leveling and can incorporate insulation plates for enhanced vibration damping.

Screw Support Mounts (Series DLC, DLM, DLK, etc.): Simple and effective vibration dampers for machines with threaded holes in the base. These mounts provide low-frequency attenuation and stable machine leveling, suitable for various applications like presses, textile machines, and CNC equipment.

Leveling Mounts and Machinery Raiser Damping Blocks (Series DML, DR, DRS): Designed for economical and easy installation of lightweight machines, with options for leveling and raising the machine height while providing vibration damping.

Sandwich Mounts (Series DMS, DSM): Constructed with layers of elastomer bonded to steel plates, these mounts can withstand high compressive loads and are suitable for supporting motors, pumps, and other equipment mounted on machines.

Flexifoot Mounts (Series DGF): Offering quick and easy installation, these mounts are well-suited for generators, blowers, pumps, and other applications requiring vibration damping in compression and shear.

Stud Mounts (Series DS): Compact and highly effective vibration dampers for compressors, pumps, fans, motors, and various other applications involving compressive loads.

Anti-Vibration Platforms and Tables (Series VIP, DIT): Designed for vibration-sensitive equipment like precision lab balances, microscopes, testing instruments, and measuring machines. These platforms incorporate elastomeric isolation, auto-leveling pneumatic mounts, or membrane air springs for effective vibration isolation.

Spring Isolators (Series MAI, MBI, RBD, etc.): Offering a range of natural frequencies, these spring isolators are suitable for various applications, including textile machines, chillers, generators, presses, and heavy industrial machines. Options include enclosed, open, and restrained types with viscous damping.

The catalog also highlights the company's expertise in foundation isolation, air spring isolators, precision leveling mounts, and customized solutions for specific industry requirements.

Dynemech's vibration control products are engineered to provide effective vibration isolation, stable machine leveling, and reliable performance across a wide range of industrial sectors, including metalworking, packaging, textiles, pharmaceuticals, and precision manufacturing.

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salе[email protected]

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#VibrationControl#PrecisionMounts#Isolators#AntiVibrationPlatforms#MachineryLeveling#VibrationDamping#IndustrialEquipment#WedgeMounts#ScrewSupportMounts#LevelingMounts#MachineryRaiserDampingBlocks#SandwichMounts#FlexifootMounts#StudMounts#AntiVibrationTables

1 note

·

View note

Text

Improved Machinery Performance with High-Precision Leveling and Alignment Mounts

Today’s demand for precision manufacturing and high production rates, necessitates the importance of a strong foundation and accurate alignment in precision machinery. Precise levelling and alignment mounts play a vital role in maintaining the stability and accuracy of machinery in many industries, such as industrial, automotive, metal processing, and medical equipment, hence assuring optimal performance and longevity. These specialized anti vibration high precision levelling and alignment mounts play a crucial role in reducing vibrations, offering higher levelling range , maintaining precise alignments, and ensuring optimal performance.

The Need for Precision in Manufacturing:

Precision machines, such as CNC equipment, lathes, grinders, other tool room machinery and measuring instruments, require a stable and level foundation to operate at their best. Misalignments or vibration can lead to product inaccuracies, reduced productivity, and premature wear and tear of machinery. Over time, shop foundations may deform due to factors like rapid load changes and machine movements, necessitating machinery readjustment to maintain precise alignment. High-precision leveling and alignment mounts provide a reliable solution for reinforcing machine beds and minimizing vibrations.

High-Precision Leveling and Alignment Mounts, Series DFL & Series VHS

Precision levelling mounts are engineered to transmit machine loads to the ground , even in the presence of an angle difference between the machine base and foundation. The unique levelling mechanism enables high-precision leveling with minimal torque, making them suitable for long bed machine tools, roll grinders, large-scale precision measuring instruments, and other heavy duty equipments like boilers, turbines, long bedded lathes etc.

Benefits of High-Precision Leveling and Alignment Mounts:

By minimizing vibrations, these mounts protect sensitive components from vibration transmission and ensure optimal machinery and allied equipment performance besides enhancing operator comfort and safety.

High-precision levelling and alignment mounts provide unparalleled stability, preventing machinery from shifting during operation. The ability to achieve precise leveling ensures that machines are perfectly aligned, maintaining critical tolerances and improving overall accuracy.

Vibrations can significantly accelerate the wear and tear of moving parts, leading to premature failure and increased maintenance costs. High-precision leveling and alignment mounts absorb shocks and vibrations, mitigating their impact on machinery components.

when coupled with Dynemech Vibration Isolation Pads, High-precision leveling and alignment mounts act as a barrier, isolating the equipment from external disturbances like construction activity or traffic movement , HVAC equipments air flow /pressure etc. to ensure precision in manufacturing/testing processes.

By providing a stable and precisely aligned foundation, high-precision leveling and alignment mounts directly contribute to enhanced machinery performance, thereby resulting in higher product quality, increased throughput, and minimized rejections.

#HighPrecisionMounts #LevelingAndAlignment #MachineryPerformance #VibrationDamping #IndustryInnovation

Event Details:

PMTX 2024

Date: 25-28 May 2024

Stall Number: B-104

Hall Number: 1

Venue: Pune International Exhibition and Convention Center, Moshi, Pune.

Contact:

Dynemech Systems Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: [email protected]

Websites: www.vibrationmountsindia.com | www.vibrationdampingpads.com

1 note

·

View note

Text

प्लास्टफोकस 2024 में डायनेमेकः कंपन नियंत्रण समाधान

प्लास्ट फोकस 2024 में प्लास्टिक मशीनरी के लिए अत्याधुनिक एंटी-विब्रेशन समाधान की खोज करें।

उन्नत उत्पादों का पता लगाने और कंपन नियंत्रण प्रौद्योगिकी के लाभों के बारे में जानने के लिए डायनेमेक के बूथ पर हमसे मिलें ।

हमें यह घोषणा करते हुए खुशी हो रही है कि डायनेमेक एंटी वाइब्रेशन टेक्नोलॉजी आगामी अंतर्राष्ट्रीय प्लास्टिक एक्सपो, प्लास्टफोकस 2024 में भाग लेगी। यह बहुप्रतीक्षित कार्यक्रम 1 फरवरी से 5 फरवरी, 2024 तक नई दिल्ली, भारत में में आयोजित किया जाएगा।

प्लास्टफोकस 2024 प्लास्टिक प्रसंस्करण मशीनरी और उपकरणों में नवीनतम नवाचारों और रुझानों को प्रदर्शित करने के लिए एक उल्लेखनीय मंच होगा।

कंपन नियंत्रण में हमारी विशेषज्ञता के साथ, डायनेमेक को सभी प्रकार की प्लास्टिक मशीनरी के लिए अत्याधुनिक समाधान प्रदान करने पर गर्व है, जिसमें ब्लो मोल्डिंग मशीन, बाहरी और बाह्य रेखाएं और इंजेक्शन मोल्डिंग मशीनें शामिल हैं।

वंशक्रम में, हम प्लास्टिक मशीनरी के लिए एक स्थिर और कुशल कार्य वातावरण बनाए रखने के महत्व को समझते हैं। कंपन महत्वपूर्ण व्यवधान पैदा कर सकते हैं और यहां तक कि मशीनरी खराब भी हो सकती है। यही कारण है कि हमारे विशेषज्ञों की टीम ने उन्नत कंपन कम करने वाले समाधान विकसित किए हैं जो प्रभावी रूप से कंपन को कम करते हैं, सुचारू संचालन सुनिश्चित करते हैं और उपकरणों के जीवनकाल को बढ़ाते हैं।

प्लास्टफोकस 2024 में भाग लेकर, हमारा लक्ष्य हमारे एंटी-वाइब्रेशन उत्पादों की अपनी व्यापक श्रृंखला का प्रदर्शन करना और हमारे समाधानों को लागू करने के लाभों के बारे में उद्योग के पेशेवरों के साथ चर्चा करना है। हमारे उत्पादों को विशेष रूप से प्लास्टिक मशीनरी के सामने आने वाली अनूठी चुनौतियों का समाधान करने के लिए डिज़ाइन किए गए हैं, जो असाधारण प्रदर्शन और विश्वसनीयता प्रदान करते हैं।

चाहे आप ब्लो मोल्डिंग, एक्सट्रूज़न, या इंजेक्श�� मोल्डिंग या किसी अन्य औद्योगिक मशीनरी के व्यवसाय में हों, डायनेमेक के पास आपके लिए एकदम सही कंपन नियंत्रण समाधान है।

हमारे अभिनव उत्पादों को अनुसंधान और विकास के वर्षों द्वारा समर्थित किया जाता है, जो शीर्ष स्तर की गुणवत्ता और प्रभावशीलता की गारंटी देता है। हमारे नवोन्वेषी उत्पाद वर्षों के अनुसंधान और विकास द्वारा समर्थित हैं, जो उच्चतम गुणवत्ता और प्रभावशीलता की गारंटी देते हैं।

हमारी टीम आपको विस्तृत जानकारी प्रदान करने, आपके किसी भी सवाल का जवाब देने, और यह प्रदर्शित करने में खुशी महसूस करेगी कि हमारे उत्पाद आपकी प्लास्टिक मशीनरी की दक्षता और उत्पादकता को कैसे बढ़ा सकते हैं।

कंपन नियंत्रण प्रौद्योगिकी में नवीनतम प्रगति की खोज करने और डायनेमेक आपके उद्योग में जो अंतर ला सकता है, उसका प्रत्यक्ष अनुभव करने का यह अवसर न चूकें।

कार्यक्रम की जानकारी:

प्लास्टफोकस 2024

दिनांक: 1-5 फरवरी 2024

स्टॉल संख्या: L66

हॉल नंबर: 2

स्थान: यशोभूमि, द्वारका, सेक्टर-25 नई दिल्ली, भारत

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salеs@dynеmеch.com

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#PlastFocus2024#DynemechAntiVibrationTechnology#Dynemech#AntiVibration#VibrationControl#PlasticMachinery#VibrationDamping#BlowMouldingMachines#InjectionMouldingMachines#PrecisionLevellingWedges#LevelGripMounts

1 note

·

View note

Text

📣 Exciting News! Dynemech Anti Vibration Technology is thrilled to announce our participation in PlastFocus 2024, the leading international plastics expo in New Delhi, India. Join us from February 1 to February 5, 2024, as we showcase our cutting-edge vibration damping solutions for plastic machinery, including Blow Moulding Machines, Extruders & Extrusion lines, and Injection Moulding Machines.

We've got you covered through our exhaustive range of precision levelling wedges, Level Grip Mounts, Screw Support Circular Mounts, High Adjustment and Alignment Mounts, Viscous Damped Spring Isolators and many more.

Don't miss out on discovering the latest innovations and trends in plastics processing machinery! #PlastFocus2024 #DynemechAntiVibrationTechnology"

Event Details:

Plastfocus 2024

Date: 1-5 Feb 2024

Stall Number: L66

Hall Number: 2

Venue: Yashobhoomi, Dwarka, Sector-25 New Delhi, India

#PlastFocus2024, #DynemechAntiVibrationTechnology, #Dynemech, #PlastFocus2024, #AntiVibration, #VibrationControl, #PlasticMachinery, #VibrationDamping, #BlowMouldingMachines, #InjectionMouldingMachines, #PrecisionLevellingWedges, #LevelGripMounts,

# CircularVibrationControlMounts,

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salеs@dynеmеch.com

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#PlastFocus2024#DynemechAntiVibrationTechnology#Dynemech#AntiVibration#VibrationControl#PlasticMachinery#VibrationDamping#BlowMouldingMachines#InjectionMouldingMachines#PrecisionLevellingWedges#LevelGripMounts#CircularVibrationControlMounts

1 note

·

View note

Text

Feel like you missed out on the dynamic and immersive experiences at IMTEX Forming 2024? No worries! Take a journey through the event, where the artistry of machinery alignment and precision leveling mounts, coupled with cutting-edge vibration control technology, reshaped the manufacturing landscape.

Seeing the innovation in metal metal-forming scenario, sparked meaningful conversations, forged collaborations, and fostered insightful interactions. Professionals from diverse sectors engaged in enriching discussions explored the seamless convergence of anti-vibration technologies for metal forming excellence.

Thank you for attending Dynemech Stall @IMTEX2024 and for sharing your valuable insights and feedback. We appreciate your contributions and hope that you found the event to be a valuable learning experience. Your support means a lot to us!

Thank you for your enthusiastic participation! We couldn’t have had such a fantastic time without you!!

Dynemech Systems Pvt. Ltd.

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: ; 9810760131

Email: [email protected]

#IMTEX#IMTEX2024#metalforming#manufacturing#engineering#industrialengineering#mechanicalengineering#machineshop#metalworking#engineer#Imtexforming#@IMTMA#ManufacturingExhibition#InnovationInManufacturing#Dynemech#vibrationcontrol#antivibrationtech#vibrationdamping

0 notes

Text

Increase Machinery Life and Enhance Productivity with Dynemech Anti-Vibration Technology

In manufacturing, keeping machines running smoothly is critical for product efficiency and achieving production goals.

Dynemech is transforming the industry with its most innovative and a variety of anti-vibration technology for all industries and machinery, delivering unparalleled benefits in operational efficiency and product quality. Vibrations can damage equipment, leading to premature wear, reduced life expectancy and higher costs. Vibration is effectively controlled with Dynemech’s advanced vibration control solutions, providing longer machine life and improved operational reliability.

By using Dynemech’s anti-vibration technology, companies can significantly reduce the risks associated with vibration damage and downtime. Dynamec's innovative, precisely designed products eliminate vibration and effectively absorb vibration, protecting critical machine parts from undue stresses, thereby reducing downtime due to machine maintenance therefore decreased This reduced maintenance costs, extended machine life, ultimately Increased productivity and cost savings were achieved.

One of the key benefits of Dynamec's anti-vibration solutions is the dramatic improvement in product quality, worker comfort, and reliable manufacturing accuracy. By reducing vibration, manufacturers can have achieved high levels of accuracy, precision and efficiency in their operations and production processes. This improves product quality, reduces defects and increases productivity. With Dynemech’s technology, companies can streamline manufacturing processes, increase productivity and meet growing market demand.

#wedgemounts

#antivibrationtable

#vibrationdamping

#antivibration

#VibrationControl

#novibration

#machineryvibration

#vibrationmountsindia.com

#vibrationdampingpads.com

@dynemech

#dynemech

Contact:

Dynemech Systems Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: [email protected]

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#dynemech#vibrationmountsindia.com#anti vibration mounts#machinery#manufacturing#antivibration#vibrationdamping

1 note

·

View note

Text

"Ready to get hands-on- Our stall at DMTX 2023 is a product extravaganza!

Product Extravaganza:

"Ready to get hands-on? Our stall at DMTX 2023 is a product extravaganza! From anti-vibration tables to spring isolators, we're ready to impress. Stall D102, Hall 11 is where the action happens

#vibrationtech

#antivibrationtables

#metrology tables

#dynemech

#DMTX2023

#ManufacturingExpo

#AntiVibration

#PrecisionMetrology

#DynemechSystems

#DelhiEvents

#MachineTools

#VibrationControl

#DMTX

#MTX

#IMTEX

@DMTX

#DELHIEXPO

#DELHIMTX2023

#metalcutting

#metalprocessing

#wedgemounts

#antivibrationtable

#vibrationdamping

#antivibration

@dynemech

Hall 11 StallD102 Pragati Maidan, Delhi

[email protected] | +91-9911145131 | vibrationmountsindia.com

#vibrationless#vibrationmountsindia.com#dynemech#anti vibration mounts#vibrationdamping#antivibrationtables#metrology tables

0 notes

Text

VISIT US #IMTEX2024 Hall 3A Stall C123

BIEC, Bangalore , Karmnataka , India

Are you looking for ways to optimize your industrial processes and increase

productivity? Look no further than Dynemech Anti Vibration Technology!

We are excited to announce our participation in the upcoming IMTEX FORMING 2024 , where

we will be showcasing our latest anti-vibration solutions.

Optimize machinery performance with our expertise in Vibration Reduction, Precision Levelling, and Machinery Alignment. Elevate precision and efficiency for seamless operations.

EngineeringExcellence #MachineryOptimization

IMTEX #IMTMA @IMTEX @IMTMA #metalforming #metalprocessing #wedgemounts

antivibrationtable #vibrationdamping #antivibration #vibrationcontrol #novibration

machineryvibration #vibrationmountsindia.com #vibrationdampingpads.com @dynemech

dynemech

Contact:

E: [email protected]

M:+91-9810760131

Website: www.vibrationmountsindia.com

1 note

·

View note

Text

Dynemech-anti-vibration-imtex2024

Discover the full range of premium and comprehensive machinery installation and vibration reduction solutions for your business! At Dynemech #AntiVibration Technology, we specialize in providing complete vibration damping solutions for a wide array of machinery, including CNC machines, Power Presses, Lathe Machines, Textile Machines, Generators, Compressors, Tool Room Machines, Forging Hammers, and all other types of heavy industrial machinery.

As leaders in the manufacture and supply of anti-vibration mounts, vibration isolation, and shock absorption products, we cordially invite you to explore our cutting-edge solutions at IMTEX FORMING 2024. Our team will be at Stall C123 in Hall 3A, showcasing the latest innovations that can enhance the performance of your machinery.

Event Details:

IMTEX FORMING 2024

Date: 19-23 JAN 2024

Stall Number: C123

Hall Number: 3A

Venue: BIEC, Bangalore, Karnataka, India

Join us at IMTEX FORMING 2024 to witness how our expertise in anti-vibration technology can benefit your operations. Experience firsthand our commitment to delivering top-notch solutions for your machinery's vibration-related challenges.

We look forward to the opportunity to connect with you and discuss how our solutions can make a positive impact on your business.

@IMTEX @IMTMA #IMTEX #metalcutting #metalprocessing #wedgemounts

antivibrationtable #vibrationdamping #antivibration #vibrationcontrol #novibration

machineryvibration #vibrationmountsindia.com #vibrationdampingpads.com @dynemech

dynemech

Contact:

E: [email protected]

M:+91-9810760131

Website: www.vibrationmountsindia.com

1 note

·

View note

Text

We thrilled to announce that we’ll be exhibiting at IMTEX 2024 in Hall 3A, Stall C123, Dynemech Anti Vibration Technology

Come and visit our stall to discover our latest products and have a chat with our team. We can't wait to meet you there!

19th - 23rd January 2024

#IMTEX2024,#manufacturing, #engineering, #vibration control,

Event Details:

Date: 19th - 23rd January 2024

Stall: C123

Hall: 3A

Venue: BIEC Bangalore

Welcome to Dynemech Vibration Control technology, where innovation meets excellence. At Dynemech, we pride ourselves on pushing boundaries, driving progress, and delivering exceptional solutions to our clients.

Established with a vision to redefine vibration control solutions for all industrial setup, we've grown into a trusted leader, renowned for our commitment to quality, innovation, indigenous manufacturing and customer satisfaction.

Our success is built on the dedication and expertise of our talented team. United by a common goal, we strive to exceed expectations in every project we undertake.

Whether it's anti-vibration wedge mounts, Grip Level Mounts, Taper Shim Levelling Mounts, High Precision Levelling & Alignment Mounts or the recently developed Precision Metrology Instruments Anti Vibration Table, our solutions are designed to contain any vibrations affecting the manufacturing or industrial setups.

We take pride in being at the forefront of Vibration Control Solutions and contributing to indigenous innovation.

Over the years, we've achieved vibration control in more than one million + installations. These accomplishments reflect our unwavering commitment to excellence and continuous improvement.

But don't just take our word for it. Hear what our satisfied clients have to say about their experience partnering with Dynemech.

we remain dedicated to delivering cutting-edge solutions and forging lasting partnerships.

Subscribe to our channel to stay updated on our journey of innovation and success in the field of #vibrationdamping and #antivibrationtechnology.

Contact:

M:+91-9810760131

Website: www.vibrationmountsindia.com

1 note

·

View note

Text

"Unlock the Future of Machinery Performance with Dynemech's Cutting-Edge Anti-Vibration Technology! 🚀 Join us at #IMTEXFORMING2024, Stall C123, Hall 3A, BIEC, Bangalore (India) . Don't miss the pulse of innovation! #IMTEX2024, #AntiVibration, #Dynemech, #vibrationDamping, # VibrationControl, #WedgeMounts,#antivibratiobtable,

Contact:

Dynemech Systems Pvt Ltd.

Mob: +91-9810760131, +91-9911145131

Email: [email protected]

#dynemech#vibrationmountsindia.com#anti vibration mounts#machinery#manufacturing#antivibration#freedomfromvibrations#fulfillingdreams#inspirehopecelebrate#cherishbuildcelebrate

1 note

·

View note