#InjectionMouldingMachines

Text

The Super Plus Plastic Injection Moulding Machine is one of our premium products known for its high speed and accuracy. Designed using the finest raw materials, this machine is both robust and has a long life.

link:https://www.injectionmouldingmachine.co.in/super-plus.html

#Injectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinery#Injectionmouldingmachinerymanufacturer

2 notes

·

View notes

Text

प्लास्टफोकस 2024 में डायनेमेकः कंपन नियंत्रण समाधान

प्लास्ट फोकस 2024 में प्लास्टिक मशीनरी के लिए अत्याधुनिक एंटी-विब्रेशन समाधान की खोज करें।

उन्नत उत्पादों का पता लगाने और कंपन नियंत्रण प्रौद्योगिकी के लाभों के बारे में जानने के लिए डायनेमेक के बूथ पर हमसे मिलें ।

हमें यह घोषणा करते हुए खुशी हो रही है कि डायनेमेक एंटी वाइब्रेशन टेक्नोलॉजी आगामी अंतर्राष्ट्रीय प्लास्टिक एक्सपो, प्लास्टफोकस 2024 में भाग लेगी। यह बहुप्रतीक्षित कार्यक्रम 1 फरवरी से 5 फरवरी, 2024 तक नई दिल्ली, भारत में में आयोजित किया जाएगा।

प्लास्टफोकस 2024 प्लास्टिक प्रसंस्करण मशीनरी और उपकरणों में नवीनतम नवाचारों और रुझानों को प्रदर्शित करने के लिए एक उल्लेखनीय मंच होगा।

कंपन नियंत्रण में हमारी विशेषज्ञता के साथ, डायनेमेक को सभी प्रकार की प्लास्टिक मशीनरी के लिए अत्याधुनिक समाधान प्रदान करने पर गर्व है, जिसमें ब्लो मोल्डिंग मशीन, बाहरी और बाह्य रेखाएं और इंजेक्शन मोल्डिंग मशीनें शामिल हैं।

वंशक्रम में, हम प्लास्टिक मशीनरी के लिए एक स्थिर और कुशल कार्य वातावरण बनाए रखने के महत्व को समझते हैं। कंपन महत्वपूर्ण व्यवधान पैदा कर सकते हैं और यहां तक कि मशीनरी खराब भी हो सकती है। यही कारण है कि हमारे विशेषज्ञों की टीम ने उन्नत कंपन कम करने वाले समाधान विकसित किए हैं जो प्रभावी रूप से कंपन को कम करते हैं, सुचारू संचालन सुनिश्चित करते हैं और उपकरणों के जीवनकाल को बढ़ाते हैं।

प्लास्टफोकस 2024 में भाग लेकर, हमारा लक्ष्य हमारे एंटी-वाइब्रेशन उत्पादों की अपनी व्यापक श्रृंखला का प्रदर्शन करना और हमारे समाधानों को लागू करने के लाभों के बारे में उद्योग के पेशेवरों के साथ चर्चा करना है। हमारे उत्पादों को विशेष रूप से प्लास्टिक मशीनरी के सामने आने वाली अनूठी चुनौतियों का समाधान करने के लिए डिज़ाइन किए गए हैं, जो असाधारण प्रदर्शन और विश्वसनीयता प्रदान करते हैं।

चाहे आप ब्लो मोल्डिंग, एक्सट्रूज़न, या इंजेक्शन मोल्डिंग या किसी अन्य औद्योगिक मशीनरी के व्यवसाय में हों, डायनेमेक के पास आपके लिए एकदम सही कंपन नियंत्रण समाधान है।

हमारे अभिनव उत्पादों को अनुसंधान और विकास के वर्षों द्वारा समर्थित किया जाता है, जो शीर्ष स्तर की गुणवत्ता और प्रभावशीलता की गारंटी देता है। हमारे नवोन्वेषी उत्पाद वर्षों के अनुसंधान और विकास द्वारा समर्थित हैं, जो उच्चतम गुणवत्ता और प्रभावशीलता की गारंटी देते हैं।

हमारी टीम आपको विस्तृत जानकारी प्रदान करने, आपके किसी भी सवाल का जवाब देने, और यह प्रदर्शित करने में खुशी महसूस करेगी कि हमारे उत्पाद आपकी प्लास्टिक मशीनरी की दक्षता और उत्पादकता को कैसे बढ़ा सकते हैं।

कंपन नियंत्रण प्रौद्योगिकी में नवीनतम प्रगति की खोज करने और डायनेमेक आपके उद्योग में जो अंतर ला सकता है, उसका प्रत्यक्ष अनुभव करने का यह अवसर न चूकें।

कार्यक्रम की जानकारी:

प्लास्टफोकस 2024

दिनांक: 1-5 फरवरी 2024

स्टॉल संख्या: L66

हॉल नंबर: 2

स्थान: यशोभूमि, द्वारका, सेक्टर-25 नई दिल्ली, भारत

Contact:

Dynеmеch Systеms Pvt Ltd.

Mob: +91-9810760131 ; +91-9911145131

Email: Salеs@dynеmеch.com

www.vibrationmountsindia.com | www.vibrationdampingpads.com

#PlastFocus2024#DynemechAntiVibrationTechnology#Dynemech#AntiVibration#VibrationControl#PlasticMachinery#VibrationDamping#BlowMouldingMachines#InjectionMouldingMachines#PrecisionLevellingWedges#LevelGripMounts

1 note

·

View note

Text

Are you interested in molds? We can design a variety of injection molds for plastic thin wall products.We offer you thin wall container mould,high speed mould, IML thin wall mould.The minimum wall thickness we can make to 0.35mm. Contact us.

our wbsite:www.aeromoulds.com

#injectionmouldingmachine#injectionmoldingmachine

#injectionmoldingmachines#moldingmachine

#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

#injectionmouldingmachine#injectionmoldingmachine#injectionmoldingmachines#moldingmachine#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

0 notes

Photo

Our company Ningbo Leadway Machinery Technology Co.,ltd is professional injection molding machines manufacturer. We were involved in ITALY OEM machines project since 2006. So we are professional in design and make European style injection machines. And we are the first supplier (maybe the only one) involved in making Eurostyle injection machines. Our quality is the most close to European machines quality. Our quality is leading in China. We can compete with Haitian in quality. Our machines are strong clamping, fast injection, energy saving, high precision, user-friendly which is mainly for mid-high end use. Now we have deleoped Italy, Spain, Czech, Poland, Tunis, Iran, India, Philipine, Malaysia, Russia, Mexico, Brazil, Argentina, Peru, etc. @fuhrungplasticinjectionmachine www.fuhrung.com [email protected] whatsapp:008618969867076 injection,injection molding,machine,plastic injection machine,injection molding machine,injection machine,plastic injection molding machine,plastic,eva injection moulding machine,injection moulding,pet preform injection molding machine,machines,injection machines,pu injection machine,pvc injection machine,lsr injection machine,mold injection machine,sound injection machine,top 50 injection machine,badge injection machine #injectionmoldingmachine #plasticinjectionmachine #injectionmachines #injectionmoldingmachines #injectionmouldingmachine #plasticinjectionmoldingmachine #injectionmouldingmachines #injectionmachinesize #specialistusedinjectionmachine #injectionmachinescrewdesign #injectionmachineforsale #injectionmachinesecondhand #injectionmachinetechnician #injectionmachinesetting #injectionmachineryturkey #verticalinjectionmouldingmachine #injectionmachinetraining #injectionmachinesumitomo #injectionmachinenozzle #injectionmachinebrands #injectionmachinetiebar #injectionmachinetoggle #injectionmachinecost #injectionmachinecalculation #injectionmachineinpoland #injectionmachineendcapangle (at China) https://www.instagram.com/p/BzPKMx0gPPK/?igshid=8to0gxba1p45

#injectionmoldingmachine#plasticinjectionmachine#injectionmachines#injectionmoldingmachines#injectionmouldingmachine#plasticinjectionmoldingmachine#injectionmouldingmachines#injectionmachinesize#specialistusedinjectionmachine#injectionmachinescrewdesign#injectionmachineforsale#injectionmachinesecondhand#injectionmachinetechnician#injectionmachinesetting#injectionmachineryturkey#verticalinjectionmouldingmachine#injectionmachinetraining#injectionmachinesumitomo#injectionmachinenozzle#injectionmachinebrands#injectionmachinetiebar#injectionmachinetoggle#injectionmachinecost#injectionmachinecalculation#injectionmachineinpoland#injectionmachineendcapangle

0 notes

Photo

Milacron Q Series 2k is the best home appliances manufacturer machine. Our Q Series 2k injection moulding machine is specially designed for making home appliances and two-component products.

1 note

·

View note

Text

Technology | Surelock Plastics| Technical Machineries

#PickandPlaceRobots#MoistureConditioningSystem#RawMaterialCentralConveyingSystem#AutoDozingEquipment#AutomatedPowderCoatingMachine#InjectionMouldingMachine#CNCMachine

0 notes

Text

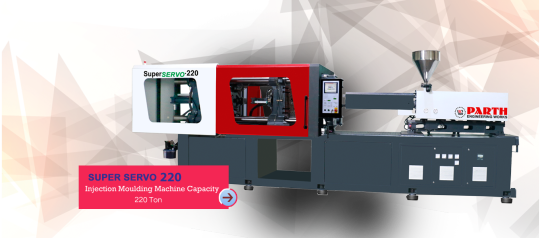

The Super Servo machine is powered by the robust Servo motor and powerful VDP pump. This Hydraulic Injection Moulding Machine comes with 5 stage opening and closing control for better safety.

link:https://www.injectionmouldingmachine.co.in/super-servo.html

#HydraulicInjectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinerymanufacturer#PlasticInjectionmouldingmachineManufacturers

0 notes

Text

Injection Transfer Moulding Machine:FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

http://www.shaktiind.net/ Shakti Industries - Manufacturer and Exporter of Injection Transfer Moulding Machine,FEP Lined Valve Machine,PFA impeller Machine,PVDF Lined Pump Machine,PFA Lined Pump Machine,Transfer Molding Machine,FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

#injectionmouldingmachine#manufacturer#exporter#supplier#ahmedabad#PFAimpellermachine#FEPLinedValveMouldingMachineAhmedabad#PFALinedPumpMachine#TransferMoldingMachineAhmedabad

0 notes

Photo

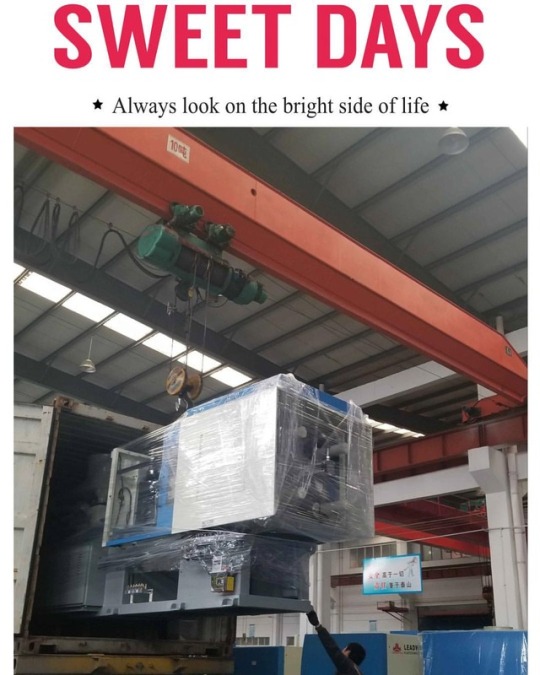

This 180 ton plastic injection molding machines are being loaded into container. This injection machines will go for Philippines Manila. Meanwhile. There is another container loading 220 ton injection machines for Tunis. #philippines #tunis #manila #manilaphilippines #envasesplasticos #plasticinjectionmolding #plasticinjection #plasticinjectionmold #plasticinjectionmolds #injectionmolding #injectionmoulding #injectionmoldingmachine #injectionmold #injectionmouldingmachine #injectionmould #injectionmoulds #injectionmouldingmachines #injectionmoulders #plasticindustry #arabplast2019 #chinaplas2019 #plasticware #plasticitems #plasticinjectionmoldingmachine #monday (在 Manila, Philippines) https://www.instagram.com/p/BsVAc3ijMvq/?utm_source=ig_tumblr_share&igshid=1n2xxaj8wa530

#philippines#tunis#manila#manilaphilippines#envasesplasticos#plasticinjectionmolding#plasticinjection#plasticinjectionmold#plasticinjectionmolds#injectionmolding#injectionmoulding#injectionmoldingmachine#injectionmold#injectionmouldingmachine#injectionmould#injectionmoulds#injectionmouldingmachines#injectionmoulders#plasticindustry#arabplast2019#chinaplas2019#plasticware#plasticitems#plasticinjectionmoldingmachine#monday

0 notes

Photo

Omega Servo is the best plastic food container making machine of Milacrone India. This injection moulding machine comes with a unique prefill cylinder design and a twin-cylinder injection unit. The Robust Performer OMEGA series of machines have a proven track record in the industry. They serve a wide variety of applications across industries.

0 notes

Text

Comparison of advantages and disadvantages of injection molding and 3D printing

Injection molding is a traditional industrial manufacturing technology. By injecting molten material into the mold, this manufacturing technique can quickly shape your product, and then the material will cool down and reach the final solid shape.3D printing is a process. You can use a 3D printer to produce parts without creating a mold. You only need a 3D printing model file, and there are many different 3D printing technologies and materials available on the market.What are the advantages of injection molding?Injection molding has great advantages, it can be produced in large quantities, and has high precision and perfect repeatability. When using plastic injection molding, you can choose from a variety of materials. There can be thousands of changes for each material through additives, each of which leads to different characteristics. Material weight, cost, flexibility, just for plasticity and possibilities, seem to be endless.What are the advantages of 3D printing?The use of 3D printing has many advantages, making it a true complement to traditional manufacturing techniques. First of all, 3D printing is very suitable for product iteration. For a long time, 3D printing has been considered a rapid prototyping technology. This is no longer the case, because it has also become a reliable manufacturing technology. However, quick and easy prototyping is still one of the best advantages provided by this manufacturing technology. When using 3D printing, you can print the project for testing, use the 3D printing modeling software to make all the modifications, and then print again to confirm the changes. The flexibility of this process will help you save time and money, but it can also help you improve your product design.

more: http://lisongmachine.com/news/industry-news/comparison-of-advantages-and-disadvantages-of-injection-molding-and-3d-printing.html

0 notes

Photo

Plastindia 2018

Feb 7-12, 2018, Gandhinagar

Visit Our Stall

#injectionmouldingmachine

For More Details Please Visit Us Online At: http://www.injectionmouldingmachine.co.in/news-events.html

or Call Us: +91-9879404967

0 notes

Text

K 2016: A Resounding Success For ENGEL

“K 2016 confirmed the very good mood in the plastics industry ,” says Dr. Christoph Steger, Chief Sales Officer at the ENGEL Group. “In Düsseldorf we found that the investment climate was extremely positive. On the basis of discussions with our clients, we are confident that the trend will continue in the months ahead. We are encouraged to see that a positive impetus is coming from every region – things are even looking up in Russia.”

ENGEL noticed the rise in visitors numbers compared to K 2013, which itself was very well attended: the company’s stand attracted a stream of visitors throughout the event. However, Steger emphasised that the quality of dialogue – which was generally excellent – was more important than the actual number of visitors. “During the fair we discussed numerous new projects and got them moving. The number of agreements we concluded was far in excess of our target, which was an ambitious one,” concludes Steger.

Comprehensive inject 4.0 solution

Industry 4.0 – the core theme of K 2016 – was strongly in evidence at the ENGEL stand, which was designed to resemble a smart factory. With concrete products and solutions for all three areas of the smart factory – smart machine, smart service and smart production – ENGEL is already offering customers a coherent concept known as inject 4.0. Many products and solutions are firmly established in practical situations, while other new solutions were premiered at K. With its modular structure, inject 4.0 promises plastics processors a very straightforward, step-by-step introduction to digitalisation. “Processing businesses used the trade event to find out how they can make the most of the opportunities presented to them by Industry 4.0,” says Dr. Stefan Engleder, Chief Technical Officer and designated CEO of ENGEL. “A lot of visitors to the fair were amazed to find that even individual, small-scale solutions can make a big difference in terms of optimising production processes.” Just like process technology and automation, Industry 4.0 calls for tailored solutions – another point underlined at the ENGEL stand.

All machines exhibited were equipped with the inject 4.0 products best suited to their particular application. At the same time, ENGEL demonstrated how to maximise the potential of smart machine in practical situations by manufacturing inject 4.0 logos on an ENGEL e‑motion 80 TL injection moulding machine. Fluctuating process conditions were simulated in the machine’s CC300 control unit, while visitors were able to monitor the automatic readjustment of the iQ weight control and iQ clamp control assistance systems live on the machine display.

Technological innovations for higher cost-effectiveness

be the first: the ENGEL motto is both an aspiration and a promise to customers. ENGEL demonstrated its technological pre-eminence yet again in Düsseldorf – not just with its inject 4.0 range, but also its machine exhibits. Through a wide array of demanding applications, ENGEL presented innovative process technologies for the target sectors of Automotive, Teletronics, Technical Moulding, Packaging and Medical.

The DecoJect process emerged as a magnet to visitors. ENGEL unveiled the film solution for high quality parts visible in car interiors (developed with system partners) using fully automated manufacturing cell. One special feature of the technology is the combination of injection moulding and in-mould graining in the roll-to-roll process on an ENGEL duo injection moulding machine. Surface structures, colour and haptical features are created through the film. By using different base materials, DecoJect simplifies the harmonisation of interior components. The application presented in Düsseldorf also incorporated MuCell technology to save raw materials as well as component weight. Trade fair visitors were impressed by the high degree of process integration and the extremely compact footprint of the manufacturing cell.

In-situ polymerisation also attracted a great deal of attention as ENGEL showcased an integrated manufacturing cell ready for industrial use for the first time. Over the eight days of the fair, thermoplastic-based, functional composite components were produced from dry reinforcing fabrics in a single work step. To achieve this, polymerisation and the injection moulding process take place in parallel in the ENGEL v-duo machine. The fibre fabrics are inserted into the first cavity of the mould and infiltrated with ε-Caprolactam. After polymerisation to polyamide 6, the preform is transferred to the second cavity in order to inject reinforcing ribs directly, for example. This kind of process integration guarantees cost effective composite processing, which is particularly important to the automobile industry. Visitors to the event were also impressed by the new reactive aggregate, which reduces thermal load by melting and processing monomers according to need.

More precise injection

ENGEL staged the world premiere of the new hydraulic injection units for its ENGEL duo and ENGEL victory injection moulding machines at K 2016. The units are based on years of development work that focused on precision, ergonomics and efficiency. “The new injection units enable even more precise injection and generally improve process stability,” says Engleder. “We have also enhanced energy efficiency and ergonomics. The new ENGEL duo and ENGEL victory machines are fitted with the ENGEL servohydraulic ecodrive as standard. Energy efficiency remains an important issue to our customers.”

0 notes