#Visit Resin Flooring Company

Text

Unleash Your Creativity: Bespoke Resin Flooring Designs

Are you tired of cookie-cutter flooring options that lack personality and flair? It's time to elevate your space with Bespoke Resin Flooring Designs. These custom flooring solutions offer limitless possibilities for creativity, allowing you to express your unique style and personality like never before. But what exactly are bespoke resin flooring designs, and why are they the perfect choice for homeowners and businesses looking to make a statement with their floors? Let's dive into the world of bespoke resin flooring designs and discover the endless possibilities they hold.

What Are Bespoke Resin Flooring Designs?

Bespoke resin flooring designs are custom-created flooring solutions that are tailored to meet the specific needs and preferences of each individual client. Unlike traditional flooring options that come in standard sizes, colors, and patterns, bespoke resin flooring designs are completely customizable, allowing you to choose everything from the color and texture to the shape and layout of your floors. Whether you're looking to create a bold and dramatic statement or a subtle and sophisticated look, bespoke resin flooring designs offer unparalleled flexibility and creativity.

The Beauty of Customization

Endless Color Options: With bespoke resin flooring designs, the color options are virtually endless. Whether you prefer vibrant hues that make a bold statement or soft, muted tones that create a serene atmosphere, you can choose the perfect color palette to suit your style and taste.

Unique Patterns and Textures: From sleek and seamless finishes to intricate patterns and textures, bespoke resin flooring designs offer endless possibilities for customization. Whether you want to replicate the look of natural stone, wood, or even abstract art, you can create a one-of-a-kind flooring design that reflects your personality and complements your space.

Tailored to Your Space: Bespoke resin flooring designs are not just about aesthetics – they're also about functionality. Whether you're designing a residential living room, a commercial showroom, or an industrial warehouse, bespoke resin flooring designs can be tailored to meet the specific needs and requirements of your space, ensuring a perfect fit every time.

Why Choose Bespoke Resin Flooring Designs?

Choosing bespoke resin flooring designs offers a multitude of benefits that go beyond just aesthetics. From durability and versatility to sustainability and ease of maintenance, bespoke resin flooring designs are the perfect choice for anyone looking to create a truly unique and unforgettable space.

The Benefits of Bespoke Resin Flooring Designs

Durability: Resin flooring is known for its exceptional durability and resistance to wear and tear. With bespoke resin flooring designs, you can enjoy all the benefits of resin flooring while adding a touch of personalization and style to your space.

Versatility: Whether you're looking to create a sleek and modern look or a rustic and natural aesthetic, bespoke resin flooring designs offer unmatched versatility. With endless options for customization, you can create a flooring design that perfectly complements your space and reflects your personality.

Sustainability: Many bespoke resin flooring designs are made from eco-friendly materials that are both sustainable and environmentally friendly. By choosing a bespoke resin flooring design, you can create a beautiful and functional space while also reducing your carbon footprint and supporting sustainable practices.

Conclusion: Express Yourself with Bespoke Resin Flooring Designs

In conclusion, bespoke resin flooring designs offer a unique and creative way to express yourself and enhance the beauty and functionality of your space. Whether you're designing a residential home, a commercial showroom, or an industrial facility, bespoke resin flooring designs offer endless possibilities for customization and creativity. So why settle for ordinary flooring when you can create something truly extraordinary? Contact a resin flooring specialist today and unleash your creativity with bespoke resin flooring designs. Your floors will thank you for it!

#Commercial Resin Flooring Services#Durable Resin Floors for Businesses#Visit Resin Flooring Company#Seamless Resin Flooring Systems#High-Quality Resin Floor Coatings#Anti Static Resin Flooring Options

1 note

·

View note

Note

what made you choose a deer for your fursona?

It's a long story that I am all too happy to tell!

I first attended Midwest Furfest in 2018, after years of being curious about it. My boyfriend at the time was a member of the Neo-Futurists Theater, and the Neo's had a longstanding relationship with the MFF community. They perform their flagship show (Too Much Light Makes the Baby Go Blind, later rebranded as The Infinite Whale) there every year, and when the theater company's former founder attempted to steal their show name/copyright following his ousting due to sexual assault allegations, MFF really came through to offer considerable moral support.

There was lots of goodhearted joking about the furry community within that theater space, and I'd always been curious about furries and a supporter of them in heart if not in fact, and so I finally decided one year to tag along, see my boyfriend performing there, and walk around the convention floor and visit the dealer's den during my down time.

I absolutely LOVED IT. I was completely blown away by the artistry of the suits and the playful spirit of the suiters. I ran into a few friends there, outing them as furries to me, and we grew closer. I also took notice of some teal, sparkly resin antlers while I was in the Dealer's Den:

I snapped those things up and put them on immediately. Some stranger started to pet me right away (which is technically a convention consent violation, and should *not* be done, but I personally was the opposite of troubled by being treated in this way) and I was hooked.

I had always had a "thing" for antlers and horns since playing the PS2 game Ico back in the early 2000's. The young male protagonists horns representing an unwanted appendage and a visible "curse" was very appealing to me... as a boy who had been saddled with two very unwanted appendages of my own. (trangsender). I also have had many very magical encounters with deer in Ohio and Pennsylvania where I grew up. As a skiddish bottomy freak whose caused a lot of car accidents, a prey animal that also has the power to kill people in vehicles seemed plenty apt. So when I found some antlers to wear, it seemed like a natural enough fit for a potential fursona.

Then my friend @jettvector designed my fursona, using the teal antlers as a jumping off point. (this art has his old watermark on it, but he goes by jettvector now. commission him!):

Now that I had a friend-assigned fursona and was officially a furry, I ran with it, and began commissioning some art that further refined my image of the character:

this is from 9inko on Instagram

this one is from @heresvix, who specializes in deer

and this one is from @murgzt . I am currently having a partial fursuit of this iteration of the character made by Daring Duck Designs!! :0

A few things that I love about my sona's design: I love that his ears are big and really stick out, as my ears do the same, I love that he has a spot reflecting my monroe piercing, I love that deers are spotted in general, which can allow me to recast my own bacne scars in a more positive light, and i love that his greenish teal skin reflects my own olive complection (which I used to get a lot of weird comments about as a kid and felt self conscious about).

I also accumulated some gear in the meantime that allowed me to better embody my deersona, who I now call DD (which stands for Deer Devon, Docile Deer, Devon Dawn, my former DD tits, or any numer of potential things haha)

Hood by Miss Kinky Latex UK, photo by @photopotamus.

I have become a little bit more of a furry with each passing year, and it wouldn't have been possible without the hard work and creativity of so many people within the fandom, many of whom are beloved friends. <3 That's part of what makes it so special. Thanks for asking!

69 notes

·

View notes

Text

Exploring the Booming Waterborne Polyurethane Market

Overview and Scope

Waterborne polyurethane refers to a polyurethane polymer resin that can be dispersed in water. It has good adherence to numerous surfaces, including glass and polymeric fibres, and can be formed into coatings and adhesives.

Sizing and Forecast

The waterborne polyurethane market size has grown strongly in recent years. It will grow from $5.07 billion in 2023 to $5.41 billion in 2024 at a compound annual growth rate (CAGR) of 6.6%. The growth in the historic period can be attributed to government investments in research and development, environmental regulations, market demand shift, advancements in formulation, industry adoption..

The waterborne polyurethane market size is expected to see strong growth in the next few years. It will grow to $6.98 billion in 2028 at a compound annual growth rate (CAGR) of 6.6%. The growth in the forecast period can be attributed to consumer preferences for eco-friendly products, collaboration with industries, customization, impact of covid-19 pandemic, supply chain restrictions, manpower & equipment shortage.. Major trends in the forecast period include brand reputation and consumer awareness, energy efficiency, market penetration strategies, global economic trends, focus on health & safety..

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/waterborne-polyurethane-global-market-report

Segmentation & Regional Insights

The waterborne polyurethane market covered in this report is segmented –

1) By Type: Polyurethane Emulsion, Polyurethane Dispersion, Polyurethane Aqueous Solution

2) By Application: Coating, Sealant, Adhesive, Elastomer

3) By End-use industry: Building and construction, Automotive and transportation, Bedding and furniture, Electronics, Other End Users

Asia-Pacific was the largest region in the waterborne polyurethane market share in 2023. The regions covered in the waterborne polyurethane market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8316&type=smp

Major Driver Impacting Market Growth

The growth of the construction industry is expected to propel the growth of the waterborne polyurethane market going forward. The construction sector is involved in building infrastructure such as houses, buildings, bridges, and so on. Waterborne polyurethane coatings are used for both floor and wall coatings in various newly constructed buildings as a protective layer for abrasion resistance, weathering resistance, and chemical resistance, thereby increasing the demand for the waterborne polyurethane market. For instance, according to data by The Construction Index, a UK-based publisher of construction sector information, construction output increased by 1.7% in volume terms in March 2022 in comparison with February data in the UK. The rise in repair and maintenance (3.0%) and new work (1.0%) activity drove the increase in monthly construction production in March 2022. Therefore, the growth of the construction industry is driving demand for the waterborne polyurethane market.

Key Industry Players

Major companies operating in the waterborne polyurethane market report are Covestro AG, Koninklijke DSM NV, BASF SE, Allnex Belgium SA, Dow Inc., H.B. Fuller Company, Wanhua Chemical Group Co. Ltd., SNP Inc., Kamsons Chemicals Pvt. Ltd., Axalta Coating Systems Ltd., The Sherwin-Williams Company, Perstorp AB, C.L Hauthaway & Son Corporation, Lamberti S.p.A., Sun Polymers International Inc., R. STAHL GmbH, Chemtura Corporation, Lanxess AG, Lubrizol Corporation, Bayer MaterialScience AG, PPG Industries Inc., Capital Resin Corporation, Walter Wurdack Inc., Palmer Holland Inc., SIWO US Inc., Brilliant Group Inc., Aditya Birla Chemicals Ltd., Hauthaway Corporation, Henkel AG & Co. KGaA, Huntsman Corporation, Nippon Polyurethane Industry Co. Ltd.

The waterborne polyurethane market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Illustration By Antoine Maillard

AN EMPIRE DIVIDED! The Inside Story of How GE CEO Larry Culp Dismantled a 131-Year-Old American Giant.

— By Brooke Sutherland and Ryan Beene | March 20, 2024 | Businessweek | The Big Take

Big sheets of white paper line the perimeter of a meeting room at the General Electric Co. factory in Beavercreek, Ohio. Each sheet is scribbled on with markers and covered with neon Post-it notes outlining the steps needed to produce the tubes and ducts that will eventually be assembled into a jet engine.

The vibe is more elementary school science fair than American industrial icon. But the simplicity is the point. Determining the layout for the Beavercreek facility was tricky: The revamped plant opened last year, combining components of production that had previously been spread out across eight different sites. To figure out the best setup, plant leaders built a replica of furnaces, tube benders and welding booths out of cardboard boxes. That visual, along with the Post-it notes describing production steps such as “brazing,” “bending” and “trimming,” makes it easier to identify and root out manufacturing inefficiencies. The exercise also helps show visiting GE executives how the whole thing works.

Featured in Bloomberg Businessweek, March 25, 2024. Photo illustration: Todd St. John for Bloomberg Businessweek

About 250 managers from around the world have gathered here in the Cincinnati area, which will be the headquarters of GE Aerospace once the conglomerate completes its slow-moving breakup in early April. One stated goal of the executive retreat is to set a culture for the soon-to-be-standalone company. “Culture can’t be declared,” says Farah Borges, who oversees GE Aerospace’s assembly, test and maintenance operations. “You have to build it.” Some declaring is still apparently necessary, because the team spent the previous day at an event space a few miles away doing just that.

But under Chief Executive Officer Larry Culp, no leadership confab is complete without a gemba walk. Gemba in Japanese means “actual place,” as in the actual place where a product is made. It’s essentially a tour of operations with a heavy emphasis on Q&A with the factory staff. The practice is central to lean manufacturing, an influential operations philosophy developed by Toyota Motor Corp. that Culp has championed at GE.

Culp at the Beavercreek factory in February. Courtesy: General Electric

Factory floor visits aren’t a radical idea for an industrial company, but GE didn’t always do them this way. The company used to place more emphasis on polishing a PowerPoint presentation than on drilling into the details of manufacturing workflows, says Russell Stokes, the head of commercial jet engines and services, who’s been at GE for more than 25 years. Somewhere between the wrong-way financial bets that blew up in the 2008 economic crisis and a huge, disastrous acquisition of energy assets from Alstom SA in 2015, GE, with its persistent mindset that anyone with an MBA could run any business, forgot that it’s a manufacturer at heart.

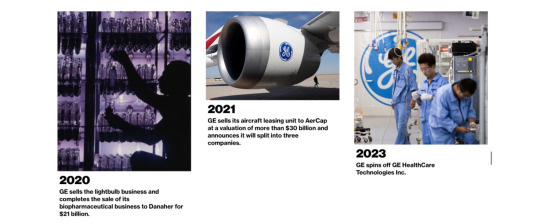

When Culp became CEO in 2018, GE was far too big and complicated for its own good, and the company’s businesses weren’t bringing in enough money to support its sky-high debts. “We were at risk of not making payroll, in a manner of speaking,” he says. He managed to pay down more than $100 billion of the debt through a series of well-timed divestitures. He dismantled GE Capital, its investment arm, largely untangling the company from a financial albatross. And then, in 2021, he announced that GE—the quintessential American conglomerate, which at one point or another sold washing machines, credit cards, plastic resins and TV advertising slots for NBC’s Super Bowl broadcasts—was breaking up. None of those efforts would’ve been as successful, and perhaps wouldn’t have even been possible, if Culp hadn’t tightened up GE’s operations and turned key businesses into stable, cash-generating entities that could stand on their own.

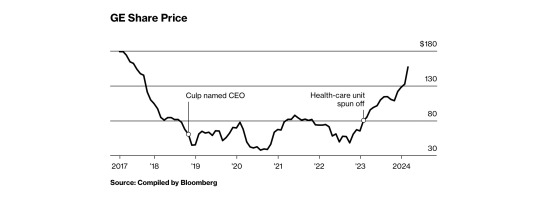

Today, GE’s stock is near a seven-year high. GE HealthCare Technologies Inc., which split off in 2023, is up about 50% from its debut. The final piece is the electric-grid, gas-power and wind-turbine business, which will become its own standalone company called GE Vernova on April 2.

In one sense, Culp is restoring GE to its original identity as a maker of stuff. But he’s also the guy dismantling a monument to American capitalism. From its inception as an outlet for Thomas Edison to commercialize the lightbulb through the era of rapid globalization embodied by Jack Welch, GE practically swallowed entire industries. It loaned planes to companies and money to real estate developers; for a time it even owned a large chunk of Dreyer’s Grand Ice Cream. Most of that is gone now. Culp divested the aircraft leasing arm, biopharmaceutical assets and the remnants of GE’s oil and gas operations and saw through sales of its locomotive and lightbulb units. Even the GE name is on loan. GE appliances are made and sold by China’s Haier Smart Home Co. The new GE will just be a manufacturer of jet engines, essentially, with a few random money pits left over from the old conglomerate, like insurance for elder care and a Polish mortgage business. “We constantly debated what the right structure was,” says Ed Garden, a GE board member since 2017. “But the first order of business was fixing the underlying businesses.”

On the gemba walk, Culp and his aerospace deputies stop to meet with the plant’s lean manufacturing leader, Cem Salahifar, who launches into an overview of the factory’s operations. He describes the facility’s transition from a single, giant furnace—known in manufacturing parlance as a monument—to a bunch of smaller ones spread out around the factory floor. This eliminates the need for employees to shuttle components back and forth and stand around waiting for the heating process to complete. Turnaround times for this part of the production process dropped to 30 minutes from four hours. Culp interjects: The team should appreciate how meaningful this change was, he says, for improving efficiency. He then asks them to find ways to rethink the monuments in their own factories. “We like to tear down monuments,” Culp says.

General Electric Through the Years

The historic American company amassed a sprawling portfolio that at one time or another included locomotives, washing machines, insurance, lightbulbs, MRI machines, credit cards, real estate and the television network NBC.

To be CEO of GE is to be compared with the late Jack Welch. For most of his two-decade reign, Welch made the company bigger, more valuable and more profitable. But the sun began to set on the age of the conglomerate by the time he retired in 2001, and soon other industrial giants were breaking up. Post-Welch CEOs at GE found themselves trying to explain why it made sense to be big for the sake of being big. Jeff Immelt, Welch’s handpicked successor, talked up the benefits of the “GE Store,” a shared repository of technological tools that the whole company could pull off the shelf. In reality, there was no good reason why one company needed to sell MRI machines, jet engines and wind turbines. Even worse, GE’s voluminous sprawl left too many places for problems to hide.

Left: A Leap engine at the Lafayette Engine Facility in Indiana. Photographer: Christopher Payne/Esto/Redux Right: A jet engine test operation. Photographer: Christopher Payne/Esto/Redux

One of the biggest problems was GE Capital, which helped fuel stock growth during the Welch years but proved to be a time bomb. GE had loaded up on debt to support its ventures in corporate lending, real estate, credit cards, mortgages and insurance. When the economic crisis arrived in 2008, GE Capital had more than $500 billion in assets and almost as much debt, which made it the largest financial company in the US that wasn’t technically a bank. As customers worldwide defaulted on loan payments and investors lost their appetite for risk, GE turned to Warren Buffett and the federal government for financial support. Immelt cut GE’s dividend for the first time since the Great Depression. He later sold off huge chunks of GE Capital, but it continued to haunt his successor, John Flannery, who in 2018 disclosed a $15 billion hole in a long-term-care insurance business Immelt had been unable to fully get rid of. The timing couldn’t have been worse: Flannery had cut the dividend two months earlier, to some shareholders’ dismay, and with the gas-power business in a slump and fewer GE Capital assets, there just wasn’t enough money from its operations to keep handing out such generous payments to investors.

GE’s stock was in free fall in 2018, and Flannery overhauled the board. One of the new directors was Culp. A graduate of and former senior lecturer at Harvard Business School, he’d previously been the CEO of Danaher Corp., a onetime industrial conglomerate in its own right that’s idolized by investors for its operational rigor. (Danaher eventually broke up, starting in 2016 with the spinoff of the industrial products company Fortive Corp., shortly after Culp left.)

Culp’s Message: “Everybody Around The Boardroom, Don’t Panic”

Flannery announced a plan to spin off GE’s health-care business in June 2018, but such a wholesale breakup quickly became untenable. The company couldn’t afford it: The remaining operations wouldn’t have generated enough cash to allow GE to pay off its mountain of debt. “We could not spin health care without putting everything fundamentally at risk,” Culp says.

GE’s directors asked Culp if he wanted to run the company. He turned them down—twice, he says—but an August 2018 visit to GE’s gas-power operations in Atlanta began to change his mind. The place was a mess, he tells Bloomberg Businessweek. “We were managing the business in a way that was probably 180 degrees from the way we ran things at Danaher,” he says. But Culp saw a path to fix GE’s operations. His message: “Everybody around the boardroom, don’t panic.”

GE directors offer a bingo card’s worth of MBA-speak to describe how rough the situation was. Tom Horton, former CEO of American Airlines, says he and Culp were both “eyes wide open” when they joined the board together in 2018: “Once we got under the hood, the challenges were more substantial than maybe we anticipated.”

Two months after his visit to Atlanta, Culp was named CEO. In short order, he slashed the dividend to $0.01 a share and killed the plan to spin off health care. Instead, Culp brokered a deal to sell GE’s biopharmaceutical unit to his former employer Danaher. GE received $21 billion in cash for the business, which makes equipment and materials used to manufacture drugs, and offloaded $400 million in pension obligations to Danaher. The transaction was completed in March 2020, about three weeks after the onset of the Covid-19 pandemic brought air travel to a halt, creating an existential challenge for the company’s jet engine business. “I don’t know what would have happened if we hadn’t closed that deal,” Culp says.

GE directors thought the pandemic had made Culp’s job harder, and they wanted to give their CEO another reason to stick with it. In August 2020, the board altered the terms of Culp’s compensation package to give him more time to reach performance targets for a one-time stock bonus and make it meaningfully easier for him to have access to the top payout of about $230 million. Shareholders representing a majority of voting stock opposed the pay deal, but their vote was nonbinding, and the board had already approved the changes anyway. Culp accessed the top tier of the equity grant in July 2023, and the shares will vest next year unless he retires before then. (GE later curbed other aspects of Culp’s compensation.) “We were securing Larry’s leadership for a longer period of time, and that’s proven to be certainly in shareholders’ interest,” Horton says.

There are parallels between Culp and Welch, a company legend who was also legendarily well-compensated. The underlying principles of the lean manufacturing philosophy Culp preaches aren’t all that different from Welch’s cult of Six Sigma, another corporate dogma focused on measuring the rate of operational defects and eliminating inefficiencies. But the two are otherwise very different. Welch’s habit of ranking employees by performance and summarily firing the bottom 10% created a culture of mistrust. Employees who survived layoffs started to think they were the smartest people in the industry, a mentality that persisted after Welch retired and GE began to fade.

Culp has been programming a new mantra into his subordinates, adapted from his time at Danaher: We’re not perfect. “You’ll have some home runs, but you don’t need them every day,” says Jim Lico, who worked for Culp at Danaher and is now president and CEO of Fortive. “No one is perfect.” That kind of talk might’ve gotten a Welch-era executive fired, but it’s part of Culp’s belief in continuous improvement that his team routinely parrots.

This often manifests with seemingly small changes that can make a big impact on productivity over time. In one instance, GE reduced the distance a part must travel around its plant in Greenville, South Carolina, by about 3 miles, says Scott Strazik, the CEO of the soon-to-be-spun-out energy business GE Vernova. Even something as small as reorganizing the toolboxes used by turbine repair technicians can make a big difference. “There’s a long way to go,” Strazik says. GE Aerospace is trying to get its many factories to coordinate more with one another and with the teams that handle contract reviews and other back-office tasks. That process isn’t “perfect,” even if it has improved, says Kayla Ciotti, materials and planning leader at GE Aerospace. “Ten years ago, we had brick walls. Five years ago, we had screen doors,” she says. “The door is open now. There’s no door.”

In contrast with the cutthroat culture at Welch’s GE, Culp’s employees will get some leeway if they do walk into walls. “That doesn’t mean that if you screw something up and you do it repeatedly, there isn’t responsibility to bear,” Culp says. “But a problem-solving culture is far more effective operationally than a finger-pointing culture.”

Brian Carlson remembers his first gemba walk with Culp. Carlson, who runs the 1.2-million-square-foot GE factory in Schenectady, New York, that makes power plant generators, watched Culp stop at one production line in 2019 to inspect a reel of copper wire, which workers fashion into long, braided slabs bent like hockey sticks at both ends. Known as stator bars, these parts are installed inside the guts of enormous generators, which can weigh more than 400 tons. Culp was checking the manufacturing date on a reel of wire. Dozens of reels were stacked on shelves and pallets at the station, burning cash as long as they sat unused. “Others had visited Schenectady before, but it wasn’t into that level of detail,” Carlson says. “When Larry Culp shows up and wants to see how long your material’s been sitting on the factory floor, that simple gesture really sets a tone.”

The foam model at the Schenectady factory. Courtesy: General Electric

After that visit, workers cleared out a large room that once housed office space near the factory’s entrance and spent months building a scale model of the entire factory from hand-cut pieces of white and green foam, which they carefully laid out on rows of folding tables. Placards hang overhead marking each section of the factory, the largest of which declares the purpose of this enormous diorama: “Take it to the model before you take it to the floor.”

The foam factory is now a hub of Schenectady’s operations. Factory staff simulate projects first in the room before testing them on the factory floor. This is part of what’s known inside GE as a kaizen event. Culp loves a good kaizen. The Japanese term means continuous improvement and is another tenet of lean manufacturing. It’s a method for problem-solving that Culp has pushed throughout the company, in which executives and hourly workers dedicate a week to improve a production process, such as the stator bars that caught his attention during his visit in 2019. The goal is to come up with a solution by Friday and have the new process in motion on Monday.

The old way of making stator bars involved moving parts by crane through a 26-step process that took about three months to complete. Each bar now moves on rollers through an eight-step process in as little as three weeks. And now there’s only enough copper wire on hand to sustain a single shift.

On an unusually warm day in late February, Carlson motions to an area on the stator bar line where more improvement is needed. They still use a crane to hoist bars over an active walkway that crosses through the assembly line. A fix is in the works. “See,” he says, “we’re not perfect yet.”

“We Do Not Intend, Let Me Be Clear, To Be All Things To All People”

By early 2021, Culp’s turnaround of GE was starting to take hold, but the company was still sitting on too much debt. A solution arrived that March, when AerCap Holdings NV agreed to acquire GE’s aircraft leasing unit. The deal would allow GE to pay off $30 billion it had borrowed, reducing its debt to the point where the company could realistically think about establishing three separate businesses—in aerospace, health care and energy—that investors would actually want to own.

Culp started mapping out a breakup plan and gave it a code name: Project Revere, inspired by a monument to American patriot Paul Revere near Culp’s home in Boston. He liked the history motif. As GE’s board deliberated a split-up, a defining moment came in a PowerPoint presentation. A slide illustrated the degree to which investors were avoiding the stock simply because it was a conglomerate. “When you just looked at the companies that folks who really wanted to bet on the energy transition or on commercial aerospace were invested in, it was not with us,” Culp says.

In November, a week after the AerCap deal closed, GE announced the spinoff plan. “Everyone felt the weight of that decision,” Culp says at GE Aerospace’s Learning Center in Evendale, Ohio, where visitors can tour a museum of the company’s aerospace achievements, starting with the first American jet engine.

A breakup was never the only option, but it was the best one. Although modern conglomerates do exist (Alphabet, Amazon, Microsoft), GE’s ye olde smokestack model wasn’t working anymore. Investors were getting burned by its bigness more often than they were getting rewarded. The conglomerate structure is especially limiting when it comes to spending money, says David Giroux, a portfolio manager and chief investment officer of T. Rowe Price Investment Management. Massive companies tend to make the wrong acquisitions and overpay for them.

One deal Culp didn’t do was to pay an acquirer to make GE’s insurance problem go away. “There were checks back in the dark days that we could have written that would have been akin to having people tear our eyeballs out,” Culp says. “But you never want to be on the other side of that sort of trade.” Although GE hasn’t done any new business in long-term-care insurance in almost two decades, it’s still paying off claims it agreed to back for other providers. It’s now closed the $15 billion insurance funding shortfall, and investors treat the appendage as more of a quirk than the crisis it was in 2018. Culp says he might get rid of the business someday. But he’s not in any rush.

After the breakup, GE Aerospace will have $25 billion of cash to spend on dividends, share buybacks and acquisitions—with the first two taking priority. Culp won’t say what kinds of deals GE Aerospace might do, only that he’ll look for complementary and easily digestible assets. “We do not intend, let me be clear, to be all things to all people,” he told investors in early March.

All of GE’s gemba walks and kaizens and the intense scrutiny of its manufacturing operations look especially prudent after a series of high-profile quality-control failures among its peers. RTX Corp. is recalling thousands of jet engines because of a manufacturing glitch; Siemens Energy AG sought help from the German government after defects in its wind turbines resulted in massive losses; and Boeing Co. can’t even deliver its 737 Max with all the bolts properly installed.

When there are three GEs, Culp hopes the old name still means something to investors. He says that’s one reason he took the job in the first place: “It’s GE.”

At the company’s off-site in Ohio, executives gathered at Carillon Historical Park in Dayton. It’s home to the Wright Brothers’ Wright Flyer III, the first practical airplane. This piece of aviation history sits next to Culp’s Cafe, which serves an All-American egg sandwich and coffee for $13. The cafe has nothing to do with GE’s CEO. It’s named after Charlotte Gilbert Culp, who founded a baked-goods business in 1902 as a young widow in Dayton. At that time, GE was still just an electrical company.

#Bloomberg#Businessweek#The Big Take#General Electric#GE | CEO | Larry Culp#Dismantling of GE#An Empire Divided

0 notes

Text

Advantages of Applying Structural Concrete Repair!

In Melbourne, some reliable structural concrete repair businesses use high-quality materials and labour to restore concrete walls and floors and extend their life and lifespan.

Their concrete resurfacing services are highly effective in repairing wall cracks and restoring floor surfaces, preserving the beauty and usefulness of walls and floors.

Some recognised concrete repairing and resurfacing companies in Melbourne provide low-viscosity epoxy crack repair services for concrete structural crack repair.

These companies use the best specifically designed concrete crack filler equipment and epoxy resin, which can eradicate cracks due to their improved crack-filling capabilities and surpass all other types of crack injection systems on the market.

Advantages of Applying Concrete Repairing and Resurfacing:

Repairing concrete floor joints for warehouses, commercial properties, and deck repair is important for the safety of warehouse staff, products, and equipment as soon as they are found.

These companies hire experts who thoroughly inspect the floor or wall and choose the best solution for structural concrete repair from the source of the fractures.

They recognise the significance of fundamental repairs and make certain that the major root causes of the cracking are addressed before beginning masonry crack repair services.

Their experts have the knowledge and experience to tackle any concrete-related concerns at work, offering speedy and inexpensive repair and restorative solutions.

Their concrete cleaning services are vast, and they can repair a wide range of concrete floor concerns, such as paint, epoxy, grime, and other faults.

They have a team of experienced concrete grinding equipment and knowledge, in addition to repair, to give smooth and levelled surfaces in residential and business settings such as manufacturing.

They have a team of experienced concrete grinding equipment and knowledge to produce smooth and levelled surfaces in corporate and industrial buildings such as manufacturing plants, warehouses, and domestic garages, along with repair.

These well-known services have worked on a wide range of projects, including commercial concrete projects, specialised concrete infrastructure projects, building alterations, upgrades and refurbishments, and greenfield projects.

They provide the greatest outcomes for commercial and industrial concrete resurfacing and repair needs in Melbourne by utilising a qualified team and cutting-edge equipment.

Overall, examine whether they employ high-quality materials, epoxy, advanced tools and processes, as well as their knowledge and understanding, to detect and repair problems from the ground up.

Visit their websites to contact them, request a quote to compare, and speak with them to learn about their customer service.

Finally, carefully examine and select the proper service to ensure the quality and endurance of concrete walls and floors.

Source

0 notes

Text

Alfatherm Insulation: Your Premier Provider of High-Performance Fiber glass Wool Products

We are engaged in to offering a comprehensive range of Fiber Glass Wool Insulation that are thermal and acoustic insulated. This Fiber Glass Wool Products finds its application in building, industrial and air-conditioning industries. We made these products spun and compacted in several ways and then bond them with a thermos-setting resin, in order to achieve the various densities required. We provide these products to our clients at a competitive price range

The Significance of Fiber Glass Wool Insulation

Fiber Glass Wool Insulation has become synonymous with efficient energy management. Alfatherm recognizes its significance not only in temperature control but also in reducing environmental impact. The benefits span from energy efficiency to sustainability, making it a preferred choice for conscientious consumers.

Alfatherm Insulation: A Pioneer in the Industry

Established as a pioneer in the insulation industry, Alfatherm boasts a rich history and a commitment to setting industry standards. The company’s journey is marked by innovation, reliability, and a relentless pursuit of excellence.

Comprehensive Range of Products

What sets Alfatherm apart is its comprehensive range of insulation products. From thermal insulation solutions to soundproofing materials, each product is designed with precision to meet the diverse needs of residential and commercial spaces.

Quality Assurance and Standards

Alfatherm places a premium on quality assurance. All products undergo rigorous testing to ensure they not only meet but exceed industry standards. This commitment is further reinforced by certifications attesting to the company’s dedication to excellence.

Advantages of Choosing Alfatherm

Choosing Alfatherm as your fiber glass wool insulation service provider comes with undeniable advantages. The cost-effectiveness and durability of their products make them a smart investment, providing long-term benefits for your property.

Wide Range of Fiberglass Wool Products:

Alfatherm Insulation offers a comprehensive range of Fiber Glass Wool Products to meet the diverse needs of our customers:

Batt Insulation: Available in various thicknesses and densities, ideal for insulating walls, roofs, and floors.

Roll Insulation: Provides continuous insulation for large areas, such as attics and crawl spaces.

Loose-Fill Insulation: Suitable for filling hard-to-reach areas and providing excellent soundproofing.

Pipe Insulation: Protects pipes and ducts from heat loss and sound transmission.

Fire Blankets: Provide fire protection for openings in walls and floors.

Acoustic Panels: Absorb sound waves and reduce noise levels in various environments

Alfatherm Insulation is committed to providing our customers with the highest quality fiberglass wool insulation products. Our products are rigorously tested to meet the most stringent industry standards. We also offer a comprehensive range of insulation products and services to cater to your specific needs.

Visit-https://www.alfatherminsulation.com/fiber-glass-wool-products/

1 note

·

View note

Text

Envirosmart Limited

Envirosmart Limited only use the best environmentally friendly materials with any of the installations we conduct. Serving Scotland with sustainable insulation and home conversions. Our team of approved installers have a wealth of experience using all aspects of energy efficiency best practise advised by the Energy savings trust. We are an authorised agent for Icynene spray foam insulation, however, the company specialises in installing sustainable sheep wool insulation as well as all other types of home insulation including earth-wool and insulation boarding for walls and roofs. Advice will be provided to homeowners on the markets best renewable energy systems helping to create monthly heating and energy bill savings to any property.

Services we offer include:

Home Insulation - Knauf mineral wool insulation for lofts, roofs, room in roof spaces, internal walls and underfloor spaces including suspended flooring. Icynene spray foam insulation available for small commercial work and other suitable domestic projects.

Resin Driveways - we are "VUBA " The Resin Mill" approved contractors for installing resin bound driveways, paths and patios which we supply and fit throughout Scotland, mainly in the Central Belt.

Garden Landscaping - full garden makeovers including fencing, decking, artificial grass, real grass turf and more.

Home Conversions - garage and loft conversion projects undertaken locally in the West of Scotland.

Windows and Doors - new double and triple glazing, patio doors, composite doors and more.

Insulate or transform your home today! To arrange a free, no obligation quote please call 0800 8611394 or visit www.envirosmartlimited.co.uk

Website:

https://envirosmartlimited.co.uk

Address :

Unit 55, Magbiehill Park, Dunlop Road, Stewarton, East Ayrshire, KA3 3DX

Phone Number:

07745 597355

Business Hours:

9:00 am - 5:00 pm

1 note

·

View note

Text

Envirosmart Limited

Our team of approved installers have a wealth of experience using all aspects of energy efficiency best practise advised by the Energy savings trust. We are an authorised agent for Icynene spray foam insulation, however, the company specialises in installing sustainable sheep wool insulation as well as all other types of home insulation including earth-wool and insulation boarding for walls and roofs. Advice will be provided to homeowners on the markets best renewable energy systems helping to create monthly heating and energy bill savings to any property.

Services we offer include:

Home Insulation – Knauf mineral wool insulation for lofts, roofs, room in roof spaces, internal walls and underfloor spaces including suspended flooring. Icynene spray foam insulation available for small commercial work and other suitable domestic projects.

Resin Driveways – we are “VUBA ” The Resin Mill” approved contractors for installing resin bound driveways, paths and patios which we supply and fit throughout Scotland, mainly in the Central Belt.

Garden Landscaping – full garden makeovers including fencing, decking, artificial grass, real grass turf and more.

Home Conversions – garage and loft conversion projects undertaken locally in the West of Scotland.

Windows and Doors – new double and triple glazing, patio doors, composite doors and more.

Insulate or transform your home today!

To arrange a free, no obligation quote please call 0800 8611394 or visit

fencing Ayrshire

1 note

·

View note

Text

High Resistance Epoxy Flooring

Companies manufacturing medicinal drugs need floor coating resisting oils, acids, and solvents. That’s where Epoxy has an important role. Epoxy flooring is highly resistant to all kinds of Chemicals, and acids. Epoxy flooring’s coating is resistant to abrasion. Epoxy flooring coatings can really offer durable and hard-wearing solutions for heavy traffic and machinery. Epoxy is so thick and durable that it finds industrial applications, especially in pharmaceuticals, warehouses, and commercial kitchens. Epoxy flooring offers a wide range of benefits from installations to maintenance. Floor areas with epoxy coatings can easily be cleaned or moped free of dust, and dirt. Epoxy is a thermos-setting resin that forms tightly linked cross-polymer structures. That makes it upholds its toughness and adhesion. When used as floor coatings, any floor surface can stand the test of time. When the commercial epoxy flooring coating dries, it gives a high-gloss surface.

For more Visit https://www.epoxyguy.com/

0 notes

Text

Why must you move for decorative laminates in your spaces?

Ornamental laminates are a kind of fabric this is typically used in a huge sort of applications, which includes furniture, floors, walls, and ceilings. Numerous layers of paper, fabric, or other substances are layered together to create those laminates, which are then pressed into thin, flat sheets after being joined via a resin. In addition to having a good sized range of colors, patterns, and finishes, decorative laminates additionally have many benefits over different sorts of substances. Sturdiness is one of the principal elements contributing to decorative laminates’ recognition. They may be a terrific alternative for excessive-traffic areas like kitchens, lavatories, and entryways because of their splendid resistance to scratches, abrasions, and impact damage. Ornamental laminates can endure spills and stains with out getting damaged due to the fact they're moisture and chemical resistant. The versatility of ornamental laminates is another crucial benefit. They can be used for a huge range of factors, including countertops, partitions, and flooring. This shows that they can be used to present a place a unified look at some point of, which may be vital in expert environments like motels, restaurants, and retail shops. Additionally, an expansion of styles, from the modern and sleek to the traditional and baroque, may be created with ornamental laminates. Ornamental laminates are sturdy and versatile, and they’re also easy to put in and maintain smooth. They may be used to cowl almost any floor due to the fact they may be simple to cut to size and shape. Decorative laminates are a top notch option for households with youngsters and pets as well as busy business settings for the reason that they require very little protection after they are located. The pricing of ornamental laminates is one among its most vital benefits. Decorative laminates cost lots less than different materials like real stone, hardwood, or ceramic tile. This makes them a first-rate choice for households and companies on a good price range who need to achieve a high-cease appearance. Furthermore, ornamental laminates are available a variety of finishes, including matte, smooth, and textured. At the same time as smooth finishes offer a excessive-shine, reflecting floor that is outstanding for conveying a sense of luxury and sophistication, matte finishes are greater subdued and create a swish, current look. On the other side, textured finishes can imitate the arrival and texture of natural substances like stone, timber, or brick, giving a area a greater natural, rustic sense. As a result, ornamental laminates are flexible and lower priced substances that have numerous advantages over other substances. They are a first rate choice for excessive-visitors regions due to the fact they are fantastically fairly proof against wear and pressure. Formica’s ornamental laminates are made from the best satisfactory substances, supplying you with the most strong and aesthetic finish. Our laminate series is available in diverse colours and styles to in shape your home. You can discover luxury and premium laminates on our internet site. Https://formica-india. Com/, you could research everything you want to realize about laminates from the information supplied on the internet site and then make a clever choice.

Formica India is a leading provider of branded, High Pressure Laminates solutions for commercial and residential customers worldwide. For More info visit our website. https://formica-india.com/

Formica India do laminates, fenix , kitchen laminates, laminates for kitchen cabinets, kitchen laminate design, decorative laminates, best laminates in india, top laminate brands in india, best laminate brand in india, laminate sheets, laminate designs, high pressure laminates, designer laminates, formica, DecoMetal , Homapal Laminates, Homapal, DecoMetal Laminates, Luxury Laminates, Cleaning fenix, fenix cleaning ,etc.

#laminates#fenix#kitchen laminates#laminates for kitchen cabinets#kitchen laminate design#decorative laminates#best laminates in india#top laminate brands in india#best laminate brand in india#laminate sheets#laminate designs#high pressure laminates#designer laminates#formica#DecoMetal#Homapal Laminates#Homapal#DecoMetal Laminates#Luxury Laminates#Cleaning fenix#fenix cleaning

0 notes

Text

Why should you go for Formica for your spaces?

Go no further than formica if you're searching for a high-end, premium laminate choice. Formica is a leading supplier of laminates and lamination services.

The decorative surface material known as Formica laminates is used in both residential and business settings. Formica laminates are layers of paper that have been impregnated with resin, bound together under great pressure, and then heated to a high temperature to create a tough, adaptable material. They are utilised in a multitude of applications, including countertops, cabinets, furniture, and flooring, and are renowned for their accessibility, toughness, and adaptability.

We shall go into great detail about the advantages of Formica laminates in this article. We'll examine the qualities of Formica laminates that make them a preferred option for homeowners, architects, and interior designers. We will also go through the many Formica laminate types that are offered and how well suited they are for various uses.

Formica laminates are available in a vast array of hues and designs, and they can imitate the appearance of elements found in nature including metal, stone, and wood. They are a popular option for signs, advertising, and branding because they may also be custom printed with pictures or graphics.

Moreover, Formica laminates are simple to work with and may be drilled, moulded, and cut using common woodworking equipment. They are appropriate for a variety of applications since they may be placed using a variety of techniques, such as adhesive, screws, or clips.

The environmental effects of Formica's manufacturing techniques and product line have been addressed in a number of ways. The business has put in place an Environmental Management System (EMS) that is intended to ensure adherence to environmental laws, cut down on waste, and lessen the company's impact on the environment. A number of policies and practices are part of the EMS, including the use of sustainable materials, the use of energy-efficient technologies, and the reduction of waste and emissions.

To find areas for improvement and confirm compliance with environmental requirements, Formica also regularly evaluates its facilities.

The business has collaborated with suppliers and other stakeholders to advance sustainability along its supply chain, and it has put several waste management and recycling programmes into place.

In order to lessen the negative effects of its operations and goods on the environment, Formica has started a variety of sustainability initiatives. One of these programmes aims to guarantee the safe and ethical disposal of Formica goods when their useful lives are up. As part of the initiative, discarded products are gathered and recycled, while new products are created with easy recycling or repurposing in mind.

Although Formica laminates are frequently utilised in building and interior design, there have long been questions about their effects on the environment. Even while Formica's manufacturing methods and materials do present some environmental concerns, the business has made a number of measures to address these problems through its sustainability efforts and environmental policies. Formica's dedication to sustainability is commendable, and the company's initiatives to lessen its environmental effect and promote sustainability throughout its supply chain are a step in the right direction.

Formica India is a leading provider of branded, High Pressure Laminates solutions for commercial and residential customers worldwide. For More info visit our website. https://formica-india.com/

Formica India do laminates, fenix , kitchen laminates, laminates for kitchen cabinets, kitchen laminate design, decorative laminates, best laminates in india, top laminate brands in india, best laminate brand in india, laminate sheets, laminate designs, high pressure laminates, designer laminates, formica, DecoMetal , Homapal Laminates, Homapal, DecoMetal Laminates, Luxury Laminates, Cleaning fenix, fenix cleaning ,etc.

#laminates#fenix#kitchen laminates#laminates for kitchen cabinets#kitchen laminate design#decorative laminates#best laminates in india#top laminate brands in india#best laminate brand in india#laminate sheets#laminate designs#high pressure laminates#designer laminates#formica#DecoMetal#Homapal Laminates#Homapal#DecoMetal Laminates#Luxury Laminates#Cleaning fenix#fenix cleaning

1 note

·

View note

Text

Particle Board Manufacturer Kerala

Pre-laminated particle board is a highly popular & cost-effective building material in Kerala, India. It is a versatile product that can be used for a wide range of applications, such as furniture, wall panels & flooring. The board is made by compressing wood particles with a resin binder under high pressure and temperature and then laminating it with a decorative paper layer. This process produces a durable and scratch-resistant surface that is easy to clean and maintain. With its affordability and versatility, pre-laminated particle board is a popular choice for both residential and commercial projects in Kerala. If you are looking for a particle board and pre-laminated particle board in Kerala, India, then look nowhere above Positive Chip Boards India Pvt Ltd. We are one of the #1 chipboard suppliers & producers of particle board and pre-laminated particle board in Southern India – Positive Chipboards India[P] Limited. For more information, give us a call at 092077 89995 or send an email to [email protected] For more information visit our blog:

0 notes

Text

Philadelphia PA - The Crucible of the Nation

Located in Pennsylvania, Philadelphia is one of the most popular tourist destinations in the United States. The city is known for its history and rich culture, as well as its diverse attractions. It is also famous for its restaurants, museums and parks.

Philadelphia is the second most populous city in the state and the fourth most populous urban area in the U.S. It has a population of about 1.3 million people.

The city is home to various cultural and artistic events throughout the year. The Reading Terminal Market, for example, is America's oldest continuously operated farmer's market and it features a huge selection of produce, meats, cheeses, seafood and confectionery.

Many people visit Philadelphia for its museums, which are filled with art from all over the world. The Philadelphia Museum of Art is particularly impressive and it houses an extensive collection of impressionist and post-impressionist works. Other museums include the Barnes Museum, Rodin Museum and Penn Museum to name but a few.

If you're looking for something a little different to do on your trip, you can always check out the Mummers' Parade that takes place every New Year. The parade sees performers strut down Broad Street dressed in elaborate costumes and fancy floats.

The city is an important hub of industry in Pennsylvania and it is home to a number of large industrial companies. These companies make up a significant portion of the local economy. They are in the fields of information technology, oil refining, food processing, healthcare, biotechnology and tourism.

During the 1800s, the city became an international industrial leader thanks to its manufacturing sector. It is home to the headquarters of various Fortune 500 companies, including Comcast Corporation, Aramark, Crown Holdings and FMC Corp.

Philly is also known for its vibrant music scene. The city is home to a wide variety of musical genres, from pop and rock to classical music. The city is a major concert venue with live jazz bars, orchestral concerts and ballets.

Its history is rooted in its religious beliefs and values, as well as its ethnic traditions. It is a major center of Quaker religion, but it also has many other religious groups.

The city has been called "the crucible of the nation," because of its rich history and strong social traditions. It is a city where tolerance is the rule rather than the exception. The city has a long tradition of racial and ethnic tolerance, as well as anti-hate legislation.

While the city is still a major center for racial and ethnic diversity, it has been experiencing a significant decline in its population. The city lost a fifth of its population in the past four decades and those who moved away found employment outside of Philadelphia.

In the early 20th century, Philadelphia was a major destination for African-Americans. Its Black population increased rapidly during the first half of the twentieth century, as a result of the migration of Southern-born Blacks to the area. However, the influx of African-Americans into the city was not without problems.

How to Prepare Concrete For Epoxy Flooring

Epoxy flooring is one of the most popular types of flooring. It is aesthetically appealing, durable, and easy to customize. This material is also incredibly affordable, making it a great choice for homes and businesses.

It is a two-part coating consisting of a resin and hardener/activator. It can be easily found at many home improvement, paint, and hardware stores.

This coating is used to protect concrete floors from damage. It is a good option for areas with high traffic, such as garages and basements, because it resists stains and damage. It is also resistant to chemical exposure, such as brake fluids or oils.

If you are putting epoxy on your floor, it is important to prepare the concrete surface properly. This is crucial because it will ensure proper adhesion between the epoxy and the floor.

The process of preparing the surface begins by using a shot blaster, which removes any flaky or rough concrete. It is also recommended to use a self-leveling concrete primer. This will give your floor a smoother surface to bond to and help prevent bubbles in the final coating.

After the primer has dried, it is time to mix the epoxy. Be sure to clean the floor thoroughly and apply a coat of painters tape or duct tape before mixing the floor coating.

Once the mix is ready, pour it out in a 1′′-2′′ ribbon along the back border of the section you are working on. Continue to roll it out in this manner until it is all poured out.

Epoxy floor coating is a durable and high-quality product. It can withstand heavy traffic and remains beautiful for years to come.

Flake epoxy floors are a great option for those looking to add a little color and style to their garage, basement or other space.

Philadelphia Epoxy Flooring

1625 W Oregon Ave, Philadelphia, PA 19145

(215) 500-2612

https://epoxyflooringphiladelphia.com/

0 notes

Photo

The sky’s the limit for Sherwin-Williams at Teesside International airport

Sherwin-Williams, the leading global manufacturer of paints and coatings, has announced that its pioneering Resuflor™ high build epoxy floor coating system has been successfully applied at a hangar in Teesside International Airport, the location for the Royal Air Force’s (RAF) Interim Red Air Aggressor Training Service (IRAATS). A Resuflor™ Topcoat system has been used to ensure a reliable and robust floor surface for the L-159E aircraft that are being used to conduct combat training.

Ensuring that the 2,000m2 hangar used by IRAATS has a floor coating that can withstand the rigours of activities that take place there was the responsibility of Darlington based specialist flooring contractor, MJF Group. The company’s managing director, Martin Ferguson, said, ‘As you would expect from a project that involves the RAF, only the very best in class products could be used in order to offer the required levels of health and safety. We assessed a number of products from various floor coatings manufacturers and felt that Sherwin-Williams’ Resuflor™ coating system offered the required protection and resistance to Skydrol.’

Skydrol is a phosphate ester hydraulic fluid that is widely used in aircraft. It is fire resistant and retains a low viscosity at very low temperatures at altitudes of 10,000m or more, which are important considerations within aviation and aerospace. While highly effective, Skydrol is also incredibly corrosive and can easily damage a concrete floor if it is not adequately protected.

‘Industrial epoxy resin flooring is impact resistant, fast curing and holds up well against fluctuating temperature changes,’ explained Jay Livingstone, Business Development Manager at Sherwin-Williams. ‘Within the aerospace industry floors also need to be able to resist the corrosive capabilities of Skydrol. Although there are various Skydrol resistant products on the market, Resuflor™ is the only one that is available straight off the shelf. While other manufacturers have to modify their existing products using expensive additives – with a price tag to match – Sherwin-Williams offers a readily available, cost effective and hardworking solution that also looks good.’

MJF Group shotblasted the existing concrete floor and then used a diamond grinding process to correct irregularities such as minor pits and divots. A coat of Resuprime NVT was used and then two coats of grey Resuflor™ HB were applied – one 300 micron and one 250 micron – with quartz used in specific parts of the floor. In terms of maintenance, Sherwin-Williams has provided specialist tyre mark and oil removers, as well as general cleaning solutions, to achieve the breakdown and removal of deposits, maintain the aesthetic qualities of the floor and maximise its operational lifespan.

Jay Livingstone of Sherwin-Williams concluded, ‘We are delighted that MJF Group used Resuflor™ for this project. The work that the RAF is undertaking at Teesside International Airport is of vital importance to us all at this time of geopolitical turbulence and we are proud to be able to play a role by providing a hardwearing and chemically resistant floor coating that is required in this environment. The RAF now benefits from a cost-effective solution that offers unrivalled protection against Skydrol and other contaminants.’

For further information please visit https://industrial.sherwin-williams.com/emeai/gb/en/resin-flooring.html

0 notes

Text

The Creative Uses of Acrylic Laminates for your Projects in Interior Designs -

Acrylic laminates are sheets made from a polymer called polymethyl methacrylate (PMMA), commonly known as acrylic or plexiglass.

These laminates have a high resistance to weather, chemical and UV exposure, making them a popular material for a wide range of applications, such as signboards, point of purchase displays, furniture, and window glazing. They offer excellent transparency, clarity, and durability, and can be easily cut, drilled, bent and formed into various shapes.

These laminates are lightweight, shatter-resistant, and have high optical clarity, making them a popular choice for a wide range of applications such as displays, signage, furniture, and architectural interiors.

They also offer good resistance to weathering and UV radiation, making them suitable for outdoor use.

Acrylic laminates are composite materials made from layers of acrylic resin and other materials such as paper, cloth, or aluminum. They are often used in the construction of countertops, cabinets, and other decorative surfaces because of their durability, resistance to water and stains, and ease of maintenance.

Acrylic laminates can also be molded into various shapes, making them suitable for use in a wide range of applications. Additionally, they are often chosen for their glossy appearance and are available in a variety of colors and patterns.

Visit Uro Veneer World Now and Buy your Favorite Acrylic Laminates for Kitchen and for your House Decor.

Creative uses of acrylic laminates in interior designs -

Acrylic laminates can be used in a variety of ways in interior design: -

Wall paneling: Acrylic laminates can be used to create high-gloss or matte finish wall panels to add visual interest to a room.

Kitchen countertops: Acrylic laminate countertops are durable and easy to clean, making them a popular choice for kitchen design. Acrylic laminates can be used to create high-quality and durable kitchen countertops.

Cabinet doors: Acrylic laminates can be used to create cabinet doors that are both functional and stylish.

Furniture: Acrylic laminates can be used to create furniture such as desks, tables, and chairs that are both modern and durable.

Backsplashes: Acrylic laminates can be used as a backsplash in kitchens and bathrooms to add a pop of color or texture.

Ceiling tiles: Acrylic laminate ceiling tiles can add a unique and modern touch to any room.

Decorative accents: Acrylic laminates can be used to create decorative accents such as wall art, lampshades, or picture frames.

Lighting fixtures: By combining acrylic laminates with lighting elements, designers can create stunning lighting fixtures for various rooms in a home or office.

Flooring: Acrylic laminates can be used as flooring in high-traffic areas, as they are durable and easy to clean.

Overall, acrylic laminates can add a modern and sophisticated touch to any interior design project, while also providing practical benefits like durability and easy maintenance.

Contact Us for more info!!!

Uro Veneer World is a Bangalore based company that specializes in providing an array of premium interior products and decor solutions to both the commercial and residential sector. We are a one stop shop that caters to the requirements of South India’s leading Architects, Interior Décor Firms, Design Consultants, Builders & Developers and Individual HomeOwners.

Process of installing acrylic laminates -

The process of installing acrylic laminates involves the following steps:-

Clean and prepare the surface: Clean the surface thoroughly and make sure it is free of any dust, grease, or other contaminants.

Clean and dry the surface where the laminate will be installed. Ensure it is smooth, flat, and free of any debris or contaminants.

Measure and cut the laminate: Measure the surface and cut the laminate to the right size and shape.

Measure the surface to determine the correct size of the laminate. Cut the laminate to size, if necessary.

Apply adhesive: Apply a suitable adhesive to the surface, making sure to spread it evenly.

Apply a suitable adhesive to the surface or to the back of the laminate. Be sure to follow the manufacturer's instructions regarding the amount and type of adhesive to use.

Place the laminate: Carefully place the laminate onto the surface and smooth out any air bubbles or wrinkles.

Carefully place the laminate onto the surface, aligning it with any markings or lines as necessary.

Trim the edges: Trim the edges of the laminate with a sharp blade, taking care not to damage the surface or laminate.

Allow the adhesive to cure completely, following the manufacturer's recommended time.

Finish and seal: Apply a sealant to the edges to prevent moisture from entering and to give a finished look to the installation.

Trim any excess laminate and clean the surface to remove any adhesive residue.

Note: The exact process may vary depending on the specific laminate and adhesive being used, so it is important to always follow the manufacturer's instructions.

It is important to follow the manufacturer's instructions carefully when installing acrylic laminates to ensure a successful and long-lasting installation.

Visit Us Now!

Get Quotes and View Prices.

#laminates sheets#laminates#living room#laminate flooring#decorative laminates#home decor#decor#interiors#interior design#interior decorating#wood veneer#uro veneer world#laminate sheets#digital laminates#premium laminates#luxury laminates#designer laminates#best laminates in india#best quality#laminates for kitchen cabinets#laminates price in bangalore#acrylic#acrylic laminates#rehau ace brilliant laminates#acrylic laminates price in bangalore#acrylic laminates sheets#acrylic laminates price#acrylic laminates sheet price in bangalore#acrylic laminates price in Bangalore#home improvement

0 notes

Text

Importance Of Laminam Porcelain Slabs

Laminam Porcelain Slabs constructed using advanced technology which combine lower thicknesses and big dimensions while exhibiting excellent resistance to chemical and mechanical stress wear, scratches, and large scratches. In its nature, the material is safe and resistant to frost mildew, and the UV radiation effects.

Laminam is the most innovative handmade, 100% Italian-made high-quality, minimal-thickness ceramic slab made using modern technology. It's a huge surface, 1620x3240mm of pure porcelain stoneware , compacted to a thickness of 6mm, 20mm or 12mm.

Laminam Porcelain Slabs come in various sizes and thicknesses. Each is recommended for a specific application, which guarantees the highest quality and performance for every use. Our experience and technical expertise allows us to provide the most efficient solutions. Slabs have a lightweight design but in addition to their striking aesthetic component can be used for exterior claddings and facades as well as their durability and compactness can be used to cover indoor areas and more substantial products are ideal for the furniture industry.

Importance Of Laminam Porcelain Slabs

Laminam creates ceramic slabs that challenge the traditional applications of this material. They create huge minimal thickness surfaces that can be used for exterior architecture as well as interior design and furniture.

Laminam has become one of the fresh lines of advanced engineered stone. The process of manufacturing at Laminam is based on an exclusive method to compress precisely selected and refined clays and feldspars. This is the industrial process that transforms your raw stone into quartz.

Disrupting the conventional notion of surfaces, Laminam is a complete body Italian Porcelain Slab that is large in dimension with very little thickness. Perfect for flooring or kitchen splashbacks as well as other decorative surfaces like wall pillars or feature walls, Laminam has an assortment of colors and styles that you can choose from.

By using engineered stones, "slabs" consist of small quartz pieces which are joined together with an exclusive resin and pigments. It gives a unique appearance that commercial and residential customers are enthralled by. Because different companies mix their resins, pigments and quartz in different proportions and proportions, no two pieces are identical from one manufacturer in the same way from another.

All You Need To Know About Engineered Stone Countertops

There are numerous types and brands of quartz that are available, meaning there are no two slabs that appear exactly the same between different brands. While it's not "made to be ordered," it is designed using the latest trends in design in mind. Quartz manufacturers can mix the colors they require to get the exact hue they wish to offer on the market. With the variety of styles and colors to choose from, homeowners are able to find the one that matches their style.

Engineered Stone Countertops are built to withstand the tests of time. It's a durable and tough stone, meaning it isn't likely to be damaged when a knife slips (though cutting boards are still suggested) the scorch mark is less likely in the event that a hot pan is placed on the countertop for a brief period of time. But it's necessary to use common sense precautions, like making use of pot holders, and avoid cutting food directly onto the surface of the countertop to ensure the longevity and appeal of stone countertops made from engineered stones.

In order to get access to the best services in terms of Porcelain slabs or the engineered stone countertops make sure to visit the official website of the Alrafahia.

0 notes