#WarehouseRackingSystem

Explore tagged Tumblr posts

Text

Top Mistakes to Avoid When Choosing Warehouse Racking Systems

It's important to select the right warehouse racking system to store inventory, make sure it's safe and increase efficiency. Organizing inventory, ensuring safety and improving operational efficiency are all benefits of these systems. However, many businesses make bad choices, install or plan these systems, which leads to productivity and safety problems in the future.

In this blog, we’ll explore the top mistakes to avoid when choosing Warehouse Racking Systems, so you can build a storage setup that’s both scalable and secure.

1. Not Considering Load Requirements

A common error is failing to estimate the weight and type of products being stored. The choice of Warehouse Racking Systems without a proper load analysis can result in structural failure or overengineering that can result in high costs. In addition to calculating the average and peak loads per level and per bay, as well as dynamic loading factors for moving items, every Storage Rack Safety standard should be considered as well.

2. Ignoring Floor Space and Ceiling Height

Installing racks without understanding your warehouse dimensions leads to wasted vertical or horizontal space. Modern Racking Systems should be tailored to your exact layout. Skipping this step often results in racks that either block pathways or fail to utilize the available height. A poorly designed racking layout may even increase operational delays.

3. Overlooking Future Scalability

Often businesses plan by considering their current inventory. However, good Racking Systems should be capable of adjusting as the company grows. Whenever possible, choose modular racks that can be expanded, added levels or converted into different types of racks such as mezzanines or cantilevers racks. In order to plan properly, warehouse rack installation must be scalable and forward-looking.

4. Choosing the Wrong Rack Type

From selective pallet racks to drive-in or push-back systems, each type serves a different need. Selecting the wrong one could slow down your picking process or reduce density. Make sure the Warehouse Racking Systems you choose match your inventory rotation, item size, and picking speed. Understanding Industrial Racks Selection is key to efficiency.

5. Ignoring Safety Features

Neglecting safety features is a dangerous oversight. Rack end protectors, column guards, beam locks, and anti-collapse mesh should be considered essential — not optional. A safe Warehouse Storage System reduces accident risk and increases employee confidence. Implementing Safety Standards should be a top priority.

6. Poor Installation Practices

If the racks are poorly installed, they will not perform as well as well-designed racks will, Uneven floors, improper anchoring, and misaligned beams can pose safety hazards; Always utilize experienced professionals to install your Warehouse Racking Systems and ensure compliance with local codes and load specifications; Prioritize the installation of certified storage racks.

7. Skipping Regular Inspections and Maintenance

Once installed, Warehouse Racks need periodic checks. Over time, bolts loosen, uprights can get hit, and loads might shift. A regular inspection schedule keeps your system safe and compliant. Following a storage rack maintenance checklist helps prevent long-term failures.

8. Not Integrating with Warehouse Flow

Your racking should support — not disrupt — your warehouse's workflow. Poor layout planning can lead to bottlenecks, excess travel time, or difficulty accessing fast-moving stock. Align Warehouse Racking Systems with receiving, staging, and dispatch zones. A well-planned warehouse storage solution supports operational flow.

Final Thoughts

You will ensure that your Industrial Racks continue to serve your business for many years to come by avoiding these mistakes. A dynamic asset can be created with the right planning, professional guidance, and proactive maintenance. Investing wisely in your warehouse will maximize space, improve safety, and optimize every square foot.

By taking the time to assess your needs and investing wisely, you will maximize your warehouse's potential.

Need help planning your racking setup? Speak with expert consultants and explore scalable warehouse racking systems that match your exact operational needs.

#warehouseracking#warehouserackingsystem#racksforwarehouse#warehouserackinstallation#racking mistakes

1 note

·

View note

Text

Meeting customer expectations for speedy order delivery has become essential for businesses. With the rise of e-commerce and changing consumer habits, companies must adopt strategies that enhance efficiency and streamline operations within their supply chains. One critical component of achieving this is optimizing the warehouse racking system, which plays a pivotal role in improving order fulfillment. Learn more - https://sic-productions.com/leveraging-warehouse-racking-systems-for-faster-order-fulfillment/

0 notes

Text

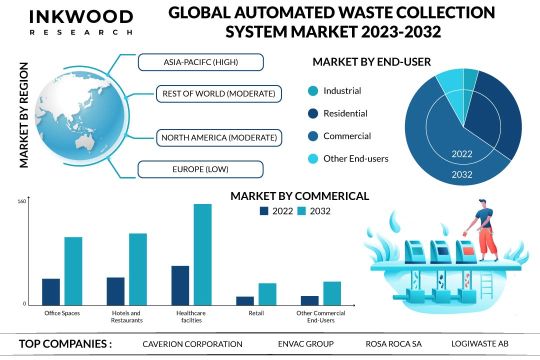

Government Initiatives for Waste Disposal Propel the Global Automated Waste Collection System Market

Inkwood Research anticipates the Global Automated Waste Collection System Market to propel with a 10.19% CAGR during the forecast period 2023-2032.

Browse 51 market data Tables and 48 Figures spread over 218+ Pages, along with an in-depth analysis of the Global Automated Waste Collection System Market by Type, Operation, End-User, & by Geography.

Refer to the Report Summary Here: https://inkwoodresearch.com/reports/automated-waste-collection-system-market/#report-summary

This insightful market research report by Inkwood Research focuses on market trends, leading players, supply chain trends, technological innovations, key developments, and future strategies. The report covers all the aspects of this comprehensive market by assessing major geographies and is a valuable asset for existing players, new entrants, and future investors. The study presents a detailed market analysis, with inputs derived from industry professionals across the value chain.

Global Automated Waste Collection System Market Scenario

Waste management efficiency varies globally, heavily influenced by the economic status of different countries. Almost all waste produced is collected in economically prosperous regions, whereas in low-income countries, waste collection rates drop significantly - only about 48% in urban areas and a meager 26% in rural areas, as per World Bank statistics. Furthermore, the type of waste generated varies with the economic class, reflecting diverse consumption patterns.

Conversely, in middle and lower-income countries, organic waste constitutes over half the waste collected, and recyclable materials are just 16%. This highlights the importance of waste segregation before processing, primarily recycling. Governments worldwide are enforcing regulations for waste collection and segregation, but the scale of operation poses challenges, prompting a shift towards automated solutions.

The Global Automated Waste Collection System Market report provides data tables and includes charts and graphs for visual analysis.

Request a Free Sample Report for Global Automated Waste Collection System Market by Type, Operation, End-User, & by Geography: https://inkwoodresearch.com/reports/automated-waste-collection-system-market/#request-free-sample

Market Segmentation

Market by Type

Full Vacuum System

Gravity Vacuum System

Market by Operation

Stationary

Mobile

Market by End-User

Industrial

Residential

Commercial

Other End-Users

Report Highlights

- The report provides a detailed analysis of the current and future market trends to identify the investment opportunities - Market forecasts till 2032, using estimated market values as the base numbers - Key market trends across the business segments, regions, and countries - Key developments and strategies observed in the market - Market dynamics such as drivers, restraints, opportunities, and other trends - In-depth company profiles of key players and upcoming prominent players - Growth prospects among the emerging nations through 2032

Companies Profiled

NORD ENGINEERING SPA

STREAM ENVIRONMENT

AWC BERHAD GROUP

ROSA ROCA SA

CAVERION CORPORATION

GREENWAVE SOLUTIONS

MABAT

ECOSIR GROUP

LOGIWASTE AB

AMCS GROUP

GULF TEAM

AERBIN APS

MARIMATIC OY

ENVAC GROUP

MEIKO GROUP

Related Reports

GLOBAL E-WASTE MANAGEMENT MARKET

The global e-waste management market is set to grow at a 12.37% CAGR during the forecast period 2021-2028.

GLOBAL HAZARDOUS WASTE MANAGEMENT MARKET

The global hazardous waste management market is estimated to propel a 6.04% CAGR during the forecast period, 2019-2027.

Contact Us:

Inkwood Research

169, Harrison Avenue

Boston, MA 02111

Tel: 1-(857)293-0150

Email: [email protected]

Website: www.inkwoodresearch.com

#WarehouseRackingSystemMarket#WarehouseRackingSystem#AutomationIndustry#IndustrialAutomation#Inkwoodmarketresearch#Marketresearchreports

0 notes

Link

Armstrong is India’s biggest Intralogistics automation company, with 20 years of experience, over 1000 projects, in 14 countries. We build intelligent intralogistics solutions. With innovative know-how, we automate your inbound, outbound, storage and sorting operations. Our uniquely crafted solutions double your productivity, with 100% visibility and eliminate pilferage. To enhance your profitability, we deploy Robotics, Artificial Intelligence, Machine Learning and Business Intelligence. All our customers including Fortune 500 companies engage us for years together. If you wish to make your operations Faster, Smarter and Cheaper, your search ends at Armstrong.

To provide operational excellence effortlessness, Armstrong leads the way towards innovative intralogistics and warehouse automation solutions. Our transformations are based on Industry 4.0 solutions.

301A, Gera 77. 3rd Floor, Besides Agakhan Palace, Nagar Road, Kalyani Nagar, Pune - 411014, Maharashtra, India.

https://www.armstrongltd.com/

+91 96 73 00 29 42

0 notes

Video

instagram

#mobilearchivesystem #mobileshelving #shelves #shelf #file #filecabinet #shelvesdesign #shelvingsystem #warehouseracking #warehouseracks #storageracks #warehousesolutions #manufacturing #storage #storageideas #storagesystems #warehouse #warehousestorage #warehouserackingsystem #storagesystem #warehousestorage #warehouseracking #metalwardrobe #metalcabinet #metalfurniture https://www.instagram.com/p/B8F9cMfBzJX/?igshid=1kx0ntzz8f0tn

#mobilearchivesystem#mobileshelving#shelves#shelf#file#filecabinet#shelvesdesign#shelvingsystem#warehouseracking#warehouseracks#storageracks#warehousesolutions#manufacturing#storage#storageideas#storagesystems#warehouse#warehousestorage#warehouserackingsystem#storagesystem#metalwardrobe#metalcabinet#metalfurniture

0 notes

Link

Armstrong is India’s biggest Intralogistics automation company, with 20 years of experience, over 1000 projects, in 14 countries. We build intelligent intralogistics solutions. With innovative know-how, we automate your inbound, outbound, storage and sorting operations. Our uniquely crafted solutions double your productivity, with 100% visibility and eliminate pilferage. To enhance your profitability, we deploy Robotics, Artificial Intelligence, Machine Learning and Business Intelligence. All our customers including Fortune 500 companies engage us for years together. If you wish to make your operations Faster, Smarter and Cheaper, your search ends at Armstrong.

https://www.armstrongltd.com/

Contact 301A, Gera 77. 3rd Floor, Besides Agakhan Palace, Nagar Road, Kalyani Nagar, Pune - 411014, Maharashtra, India.

+919673002942

0 notes

Link

Armstrong is India’s biggest Intralogistics automation company, with 20 years of experience, over 1000 projects, in 14 countries. We build intelligent intralogistics solutions. With innovative know-how, we automate your inbound, outbound, storage and sorting operations. Our uniquely crafted solutions double your productivity, with 100% visibility and eliminate pilferage. To enhance your profitability, we deploy Robotics, Artificial Intelligence, Machine Learning and Business Intelligence. All our customers including Fortune 500 companies engage us for years together. If you wish to make your operations Faster, Smarter and Cheaper, your search ends at Armstrong.

https://www.armstrongltd.com/

Contact 301A, Gera 77. 3rd Floor, Besides Agakhan Palace, Nagar Road, Kalyani Nagar, Pune - 411014, Maharashtra, India.

+91 96 73 00 29 42

0 notes