#a182

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Duplex F61 Steel – High-Strength, Corrosion-Resistant Alloy for Industrial Applications

Discover the superior strength and corrosion resistance of Duplex F61 steel. It is ideal for harsh environments and offers excellent performance in oil, gas, and marine industries. You can learn more about its benefits and uses.

0 notes

Text

Super Duplex f61 Round Bars Supplier & Exporter in Mumbai, India

Reliable Overseas offers top-quality Super Duplex f61 Round Bars. Explore our wide selection of high-performance steel products, ideal for demanding industrial applications.

#super duplex f61#duplex f61#a182 f61#hardox 400 suppliers#hardox plate supplies#hardox 500 plates supplier

0 notes

Text

Stainless Steel Flanges Manufacturer & Exporter in UAE: The Role of Metalloy International

The UAE has solidified its position as a global hub for industrial and economic activities, with a robust infrastructure that supports a myriad of industries. Among these, the manufacturing and export of stainless steel flanges play a pivotal role. As a cornerstone of this essential industry, Metalloy International stands out as a premier manufacturer and exporter of stainless steel flanges in the UAE.

Understanding Stainless Steel Flanges

Stainless steel flanges are integral components used to connect pipes, valves, pumps, and other equipment, ensuring the smooth operation and integrity of fluid flow systems. These flanges come in various types, including:

Weld Neck Flanges: Ideal for high-pressure applications, providing a secure connection.

Slip-On Flanges: Easy to install, suitable for lower pressure settings.

Socket Weld Flanges: Used in smaller sizes and high-pressure systems.

Lap Joint Flanges: Accommodate quick assembly and disassembly of pipelines.

Blind Flanges: Used to seal off pipelines, valves, and pressure vessel openings.

Advantages of Stainless Steel in Flange Manufacturing

Stainless steel is the preferred material for flange manufacturing due to its numerous advantages:

Corrosion Resistance: Stainless steel's inherent resistance to corrosion makes it ideal for use in harsh environments, including those with high humidity, salinity, and chemical exposure.

Durability: The strength and durability of stainless steel ensure that flanges can withstand high pressure and temperature, making them suitable for various industrial applications.

Hygiene: Stainless steel is easy to clean and maintain, making it suitable for industries like food and beverage, pharmaceuticals, and healthcare.

Aesthetic Appeal: The sleek, modern look of stainless steel adds a visual appeal, which is an added advantage in industries where appearance matters.

Metalloy International: Leading the Way in Stainless Steel Flanges

Metalloy International has established itself as a trusted name in the stainless steel flange industry. Here’s why:

State-of-the-Art Manufacturing Facility

Our advanced manufacturing plant is equipped with the latest machinery and technology, ensuring precision and consistency in every flange we produce.

Strict Quality Control

Quality is our top priority. Our products undergo rigorous testing and inspection at every stage of production to ensure they meet international standards.

Wide Range of Products

We offer a comprehensive range of stainless steel flanges, catering to the diverse needs of our clients across various industries.

Skilled Workforce

Our team of highly skilled engineers and technicians bring their expertise and innovation to every project, ensuring the highest levels of craftsmanship.

Global Reach

As a leading exporter, we serve clients across the globe, delivering products that meet stringent international quality standards.

Customer-Centric Approach

Our commitment to customer satisfaction drives us to offer personalized solutions, timely delivery, and exceptional after-sales support.

Applications of Our Stainless Steel Flanges

Metalloy International's stainless steel flanges find applications in a wide range of industries, including:

Oil and Gas

Petrochemical

Power Generation

Water Treatment

Food and Beverage

Pharmaceuticals

Shipbuilding

Commitment to Sustainability and Innovation

At Metalloy International, we are dedicated to sustainable manufacturing practices. We continuously invest in research and development to innovate and improve our products and processes, minimizing our environmental impact while maximizing efficiency and quality.

.

#SS 304 FLANGES MANUFACTURER#STAINLESS STEEL 304 SLIP-ON FLANGES#SS 304 BLIND FLANGES#STAINLESS STEEL 304 FORGED FLANGES#SS 304 FLANGES#ASTM A182 SS 304 FLANGES#STAINLESS STEEL 304 RAISED FACE FLANGES

0 notes

Text

Alloy Steel ASTM A182 F22 forged fittings are essential components in industrial piping systems known for their robustness, high-temperature resistance, and superior mechanical properties. These fittings are forged from chromium-molybdenum alloy steel, specifically designed to withstand corrosive environments and high-pressure conditions. This blog explores the properties, applications, and advantages of Alloy Steel ASTM A182 F22 forged fittings, highlighting their critical role in various industrial sectors.

Understanding Alloy Steel ASTM A182 F22 Forged Fittings

ASTM A182 F22 is a specification covering forged or rolled alloy steel pipe fittings intended for high-temperature service. The alloy composition includes chromium, molybdenum, and small amounts of other elements, enhancing the fittings' resistance to oxidation and corrosion. F22 forged fittings are available in a range of types such as elbows, tees, couplings, unions, and caps, providing versatility in piping system design.

Key Properties of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings exhibit several key properties crucial for industrial applications:

High Temperature Resistance: F22 fittings maintain mechanical strength and integrity at elevated temperatures, making them suitable for high-temperature service.

Corrosion Resistance: The alloy composition offers excellent resistance to oxidation, sulfide stress cracking, and chloride environments, ensuring longevity in corrosive conditions.

Mechanical Strength: These fittings provide high tensile strength and toughness, capable of withstanding high-pressure applications without deformation.

Weldability: F22 alloy steel is readily weldable using standard welding techniques, allowing for secure and reliable joint connections.

Durability: Forged fittings are known for their durability and resistance to mechanical wear, ensuring reliable performance in harsh industrial environments.

Versatility: Available in various sizes, pressure ratings, and configurations, F22 forged fittings accommodate diverse piping requirements.

Applications of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings find widespread use across industries requiring robust performance under challenging conditions:

Power Generation: They are essential in steam turbine systems, boiler assemblies, and heat exchangers in power plants.

Oil and Gas Industry: F22 fittings are used in refineries, pipelines, and offshore platforms for their resistance to corrosive fluids and gases.

Chemical Processing: They find application in chemical plants for processing acids, alkalis, and corrosive solvents.

Petrochemical Industry: These fittings are utilized in petrochemical plants for handling hydrocarbons and aggressive chemicals.

Shipbuilding: They are employed in marine applications for seawater systems, shipbuilding, and naval vessels.

Industrial Manufacturing: F22 forged fittings support fluid conveyance in manufacturing equipment, machinery, and industrial systems.

Benefits of Using Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings offer several advantages, making them a preferred choice in industrial applications:

Reliability: High mechanical strength and corrosion resistance ensure reliable performance under extreme conditions.

Safety: They meet stringent industry standards for safety and durability, reducing the risk of leaks or failures.

Cost-Effectiveness: Despite initial investment, F22 forged fittings provide long-term savings due to their durability and minimal maintenance requirements.

Flexibility: Available in various types and configurations, they offer flexibility in system design and adaptation to specific application needs.

Compliance: F22 fittings conform to ASTM A182 standards, ensuring quality and performance consistency.

Conclusion

Alloy Steel ASTM A182 F22 forged fittings play a crucial role in industrial piping systems where strength, durability, and resistance to corrosion are essential. Their ability to withstand high temperatures and corrosive environments makes them indispensable in power generation, oil and gas, chemical processing, and other critical industries. Understanding the properties and applications of F22 forged fittings highlights their critical importance in ensuring efficient, safe, and reliable operations in modern industrial settings.

#Alloy Steel ASTM A182 F22 Forged Fittings#High Temperature Service#Corrosion Resistance#Power Generation#Oil and Gas Industry

0 notes

Text

Precision Manufacturer of ASTM A182 F55/DIN 1.4501/UNS S32760/ZERON 100 Round Bars in India

Discover unparalleled quality and reliability with our range of different Round Bars, meticulously crafted in India. As a Efficient Manufacturer of ASTM A182 F55/DIN 1.4501/UNS S32760/ZERON 100 Round Bars in India, We adhere to rigorous international standards, ensuring each bar meets exact specifications for strength, corrosion resistance, and durability

Contact Us

0 notes

Text

0 notes

Text

https://www.siliconsteelalloys.com/duplex-steel-zeron-100-32760-sheet-plate-supplier-stockist.html

0 notes

Text

316 Stainless Steel Flanges - Nissan Steel offers a comprehensive range of Stainless Steel 316/316L/316Ti Flanges that are made using high-quality raw materials. Our products are known for their superior quality, precise dimensions, and long service life.

0 notes

Text

JF Engineering Products LLP is One of the leading Manufacturer, Supplier and Stockist of Duplex Steel UNS S32205 Fasteners, Duplex 2205 Fasteners, which provide best quality Fasteners at best price. We also provide Stainless Steel Nuts, Bolts and Fasteners. Buy Now.

#Duplex Steel UNS S32205 Fasteners#Duplex Steel S32205 Bolts#UNS S32205 Fasteners#Duplex Steel S32205 Nuts#Werkstoff Nr.1.4462 Fasteners#ASTM A182 Duplex Steel S32205 Fasteners. UNS S32205 Bolts Supplier.

0 notes

Text

The Properties of ASTM A182 F51 Flanges

What are ASTM A182 F51 Flanges?

ASTM A182 F51 is a duplex stainless steel that belongs to the family of super duplex steels. In simple terms, duplex stainless steel refers to a combination of ferritic and austenitic stainless steel. This combination gives the steel enhanced strength, durability, and corrosion resistance compared to conventional stainless steels. ASTM A182 F51 is essentially a blend of chromium, molybdenum, and nitrogen, all of which offer excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. These properties make ASTM A182 F51 Flanges highly suitable for use in harsh and corrosive environments.

Properties of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges have incredible mechanical properties, offering high tensile strength, ductility, and impact strength. They are perfect for use in applications that require high-pressure resistance, including subsea systems and flowlines. The flanges can withstand pressure up to 15000 psi, making them one of the most robust flanges available in the market.

Another advantage of these flanges is their resistance to abrasion, erosion, and corrosion. They can withstand temperatures as low as -50°C and up to 300°C without losing their mechanical or chemical properties. The flanges also have an excellent resistance to acids, alkalis, and saltwater, making them ideal for use in offshore and marine applications.

Manufacturing of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges are manufactured through a hot forging process that involves heating the metal to a specific temperature and shaping it into the desired shape. The forging process ensures that the material is dense and has a fine grain structure, which enhances its mechanical performance. After forging, the flanges undergo a heat treatment process, where they are heated to a specific temperature and cooled to increase their strength and durability.

Applications of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges find applications in many industries, including offshore and marine, chemical processing, oil and gas, and power generation. In the offshore and marine sector, they are used in subsea systems, seawater treatment plants, and flowlines. In chemical processing, they are used in pipelines, valves, and pumps that handle corrosive acids and alkalis. In the oil and gas industry, they find extensive use in refineries, gas processing plants, and pipelines that transport crude oil and gas.

#ASTM A182 F51 Flanges#Applications of ASTM A182 F51 Flanges#Manufacturing of ASTM A182 F51 Flanges#Properties of ASTM A182 F51 Flanges#What are ASTM A182 F51 Flanges

0 notes

Text

High-Strength 422 Stainless Steel Bar – Built to Last

Discover the strength and durability of 422 stainless steel bars, ideal for high-temperature applications. Perfect for industrial use.

#422 stainless steel bar#422 stainless steel suppliers#ss 422 chemical composition#stainless steel 422#Stainless Steel 422 Bright Bars#super duplex f61#duplex f61#a182 f61#hardox 400 suppliers#hardox plate supplies#hardox 500 plates supplier#abrex 400 sheet plates stockists#abrex 400 sheet plates importers#hardox 450 suppliers#quard 400 vs hardox 400

0 notes

Text

Need to Know About A182 Gr F55 Lock Nuts

What Are A182 Gr F55 Lock Nuts?

A182 Gr F55 lock nuts are made from high-grade stainless steel designed to resist corrosion and wear. The nuts have an internal threading feature, allowing for quick and easy installation with minimal effort. The exterior design of the nut is also square shaped to ensure maximum grip when tightened onto a bolt or screw.

Additionally, these nuts contain a built-in locking feature that prevents them from loosening over time – making them ideal for applications where vibration or shocks may be present.

Applications of A182 Gr F55 Lock Nuts

A182 Gr F55 Lock Nuts can be used in various applications, including automotive parts, machine components, furniture assembly & repair, aircraft parts manufacturing, and more. They are extremely versatile due to their corrosion resistance and ability to withstand extreme temperatures - making them suitable for indoor and outdoor use. These nuts can also be used for permanent and removable assemblies depending on the application needs.

Benefits of A182 Gr F55 Lock Nuts

The primary benefit provided by A182 Gr F55 lock nuts is their durability and reliability – even under extreme conditions. This makes them ideal for high-stress environments such as off-road vehicles or industrial machinery where vibration or shocks are present.

Furthermore, these nuts can withstand extreme temperatures without losing their strength or integrity, making them suitable for indoor and outdoor use. Additionally, they require minimal maintenance once installed – allowing engineers and technicians alike to focus on other tasks instead of constantly checking if the nut has come loose over time.

#Benefits of A182 Gr F55 Lock Nuts#Applications of A182 Gr F55 Lock Nuts#What Are A182 Gr F55 Lock Nuts

0 notes

Text

Weld Neck Flanges Exporters

ASME B16.5 Socket Weld Flange are normally utilized on more clear sizes of high-pressure pipes. These consider a smooth bore and better advancement of the liquid or gas inside the line. Tempered Steel Socket Weld Flange are added by embeddings the line into the connection end and applying filet weld around the top.

0 notes

Text

Superior Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars

We are committed to providing products that comply with international standards. Piyush Steel super duplex round bars is certified and come with detailed documentation, including material test reports (MTRs), third-party inspection reports, and compliance with industry-specific regulations, which make us Trusted Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars.

Contact Us

0 notes

Text

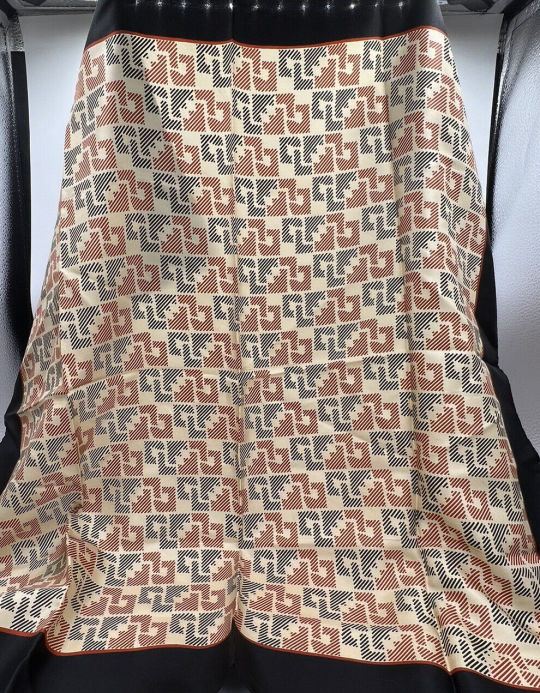

Pre-Owned Vintage Givenchy Silk Geometric Scarf ebay South Beach Antiques

LAUREN RALPH LAUREN Blue Geometric Silk Scarf 36.5 35.5” EC ebay Luxury Ties and Much More

Kimchi Blue Square Scarf Adult One Size Black Yellow Geometric Lightweight Silk ebay MikenSales

STRIPES ORANGE LARGE silk scarf 31 in #A182 ebay De luxe Designer

VINTAGE AUTHENTIC GEOMETRIC ART COLORFUL SILK SCARF WHITE YELLOW BLACK ORANGE ebay SCARVES PLANET

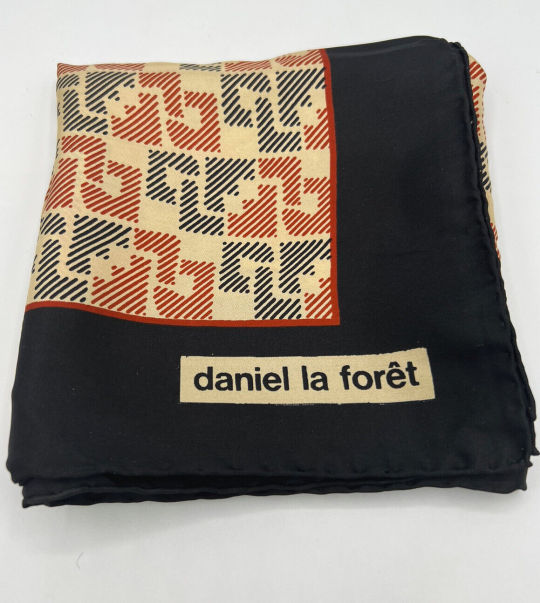

100% Silk Fall Scarf Paris Designer Daniel la Foret 26” Square Hand Rolled Hem ebay baring7892

Fabulous Large Silk Feel Scarf Brown Teal & White Geometric Print Square 35” VGC ebay orangevintagedewdrop

Jonathan Adler Red And Black Geometric Scarf Square All Silk D4 ebay Auntie M's

5 notes

·

View notes