#ASTM A182

Text

Precision Manufacturer of ASTM A182 F55/DIN 1.4501/UNS S32760/ZERON 100 Round Bars in India

Discover unparalleled quality and reliability with our range of different Round Bars, meticulously crafted in India. As a Efficient Manufacturer of ASTM A182 F55/DIN 1.4501/UNS S32760/ZERON 100 Round Bars in India, We adhere to rigorous international standards, ensuring each bar meets exact specifications for strength, corrosion resistance, and durability

Contact Us

0 notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

Stainless Steel Flanges Manufacturer & Exporter in UAE: The Role of Metalloy International

The UAE has solidified its position as a global hub for industrial and economic activities, with a robust infrastructure that supports a myriad of industries. Among these, the manufacturing and export of stainless steel flanges play a pivotal role. As a cornerstone of this essential industry, Metalloy International stands out as a premier manufacturer and exporter of stainless steel flanges in the UAE.

Understanding Stainless Steel Flanges

Stainless steel flanges are integral components used to connect pipes, valves, pumps, and other equipment, ensuring the smooth operation and integrity of fluid flow systems. These flanges come in various types, including:

Weld Neck Flanges: Ideal for high-pressure applications, providing a secure connection.

Slip-On Flanges: Easy to install, suitable for lower pressure settings.

Socket Weld Flanges: Used in smaller sizes and high-pressure systems.

Lap Joint Flanges: Accommodate quick assembly and disassembly of pipelines.

Blind Flanges: Used to seal off pipelines, valves, and pressure vessel openings.

Advantages of Stainless Steel in Flange Manufacturing

Stainless steel is the preferred material for flange manufacturing due to its numerous advantages:

Corrosion Resistance: Stainless steel's inherent resistance to corrosion makes it ideal for use in harsh environments, including those with high humidity, salinity, and chemical exposure.

Durability: The strength and durability of stainless steel ensure that flanges can withstand high pressure and temperature, making them suitable for various industrial applications.

Hygiene: Stainless steel is easy to clean and maintain, making it suitable for industries like food and beverage, pharmaceuticals, and healthcare.

Aesthetic Appeal: The sleek, modern look of stainless steel adds a visual appeal, which is an added advantage in industries where appearance matters.

Metalloy International: Leading the Way in Stainless Steel Flanges

Metalloy International has established itself as a trusted name in the stainless steel flange industry. Here’s why:

State-of-the-Art Manufacturing Facility

Our advanced manufacturing plant is equipped with the latest machinery and technology, ensuring precision and consistency in every flange we produce.

Strict Quality Control

Quality is our top priority. Our products undergo rigorous testing and inspection at every stage of production to ensure they meet international standards.

Wide Range of Products

We offer a comprehensive range of stainless steel flanges, catering to the diverse needs of our clients across various industries.

Skilled Workforce

Our team of highly skilled engineers and technicians bring their expertise and innovation to every project, ensuring the highest levels of craftsmanship.

Global Reach

As a leading exporter, we serve clients across the globe, delivering products that meet stringent international quality standards.

Customer-Centric Approach

Our commitment to customer satisfaction drives us to offer personalized solutions, timely delivery, and exceptional after-sales support.

Applications of Our Stainless Steel Flanges

Metalloy International's stainless steel flanges find applications in a wide range of industries, including:

Oil and Gas

Petrochemical

Power Generation

Water Treatment

Food and Beverage

Pharmaceuticals

Shipbuilding

Commitment to Sustainability and Innovation

At Metalloy International, we are dedicated to sustainable manufacturing practices. We continuously invest in research and development to innovate and improve our products and processes, minimizing our environmental impact while maximizing efficiency and quality.

.

#SS 304 FLANGES MANUFACTURER#STAINLESS STEEL 304 SLIP-ON FLANGES#SS 304 BLIND FLANGES#STAINLESS STEEL 304 FORGED FLANGES#SS 304 FLANGES#ASTM A182 SS 304 FLANGES#STAINLESS STEEL 304 RAISED FACE FLANGES

0 notes

Text

Alloy Steel ASTM A182 F22 forged fittings are essential components in industrial piping systems known for their robustness, high-temperature resistance, and superior mechanical properties. These fittings are forged from chromium-molybdenum alloy steel, specifically designed to withstand corrosive environments and high-pressure conditions. This blog explores the properties, applications, and advantages of Alloy Steel ASTM A182 F22 forged fittings, highlighting their critical role in various industrial sectors.

Understanding Alloy Steel ASTM A182 F22 Forged Fittings

ASTM A182 F22 is a specification covering forged or rolled alloy steel pipe fittings intended for high-temperature service. The alloy composition includes chromium, molybdenum, and small amounts of other elements, enhancing the fittings' resistance to oxidation and corrosion. F22 forged fittings are available in a range of types such as elbows, tees, couplings, unions, and caps, providing versatility in piping system design.

Key Properties of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings exhibit several key properties crucial for industrial applications:

High Temperature Resistance: F22 fittings maintain mechanical strength and integrity at elevated temperatures, making them suitable for high-temperature service.

Corrosion Resistance: The alloy composition offers excellent resistance to oxidation, sulfide stress cracking, and chloride environments, ensuring longevity in corrosive conditions.

Mechanical Strength: These fittings provide high tensile strength and toughness, capable of withstanding high-pressure applications without deformation.

Weldability: F22 alloy steel is readily weldable using standard welding techniques, allowing for secure and reliable joint connections.

Durability: Forged fittings are known for their durability and resistance to mechanical wear, ensuring reliable performance in harsh industrial environments.

Versatility: Available in various sizes, pressure ratings, and configurations, F22 forged fittings accommodate diverse piping requirements.

Applications of Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings find widespread use across industries requiring robust performance under challenging conditions:

Power Generation: They are essential in steam turbine systems, boiler assemblies, and heat exchangers in power plants.

Oil and Gas Industry: F22 fittings are used in refineries, pipelines, and offshore platforms for their resistance to corrosive fluids and gases.

Chemical Processing: They find application in chemical plants for processing acids, alkalis, and corrosive solvents.

Petrochemical Industry: These fittings are utilized in petrochemical plants for handling hydrocarbons and aggressive chemicals.

Shipbuilding: They are employed in marine applications for seawater systems, shipbuilding, and naval vessels.

Industrial Manufacturing: F22 forged fittings support fluid conveyance in manufacturing equipment, machinery, and industrial systems.

Benefits of Using Alloy Steel ASTM A182 F22 Forged Fittings

Alloy Steel ASTM A182 F22 forged fittings offer several advantages, making them a preferred choice in industrial applications:

Reliability: High mechanical strength and corrosion resistance ensure reliable performance under extreme conditions.

Safety: They meet stringent industry standards for safety and durability, reducing the risk of leaks or failures.

Cost-Effectiveness: Despite initial investment, F22 forged fittings provide long-term savings due to their durability and minimal maintenance requirements.

Flexibility: Available in various types and configurations, they offer flexibility in system design and adaptation to specific application needs.

Compliance: F22 fittings conform to ASTM A182 standards, ensuring quality and performance consistency.

Conclusion

Alloy Steel ASTM A182 F22 forged fittings play a crucial role in industrial piping systems where strength, durability, and resistance to corrosion are essential. Their ability to withstand high temperatures and corrosive environments makes them indispensable in power generation, oil and gas, chemical processing, and other critical industries. Understanding the properties and applications of F22 forged fittings highlights their critical importance in ensuring efficient, safe, and reliable operations in modern industrial settings.

#Alloy Steel ASTM A182 F22 Forged Fittings#High Temperature Service#Corrosion Resistance#Power Generation#Oil and Gas Industry

0 notes

Text

0 notes

Text

https://www.siliconsteelalloys.com/duplex-steel-zeron-100-32760-sheet-plate-supplier-stockist.html

0 notes

Text

316 Stainless Steel Flanges - Nissan Steel offers a comprehensive range of Stainless Steel 316/316L/316Ti Flanges that are made using high-quality raw materials. Our products are known for their superior quality, precise dimensions, and long service life.

0 notes

Text

JF Engineering Products LLP is One of the leading Manufacturer, Supplier and Stockist of Duplex Steel UNS S32205 Fasteners, Duplex 2205 Fasteners, which provide best quality Fasteners at best price. We also provide Stainless Steel Nuts, Bolts and Fasteners. Buy Now.

#Duplex Steel UNS S32205 Fasteners#Duplex Steel S32205 Bolts#UNS S32205 Fasteners#Duplex Steel S32205 Nuts#Werkstoff Nr.1.4462 Fasteners#ASTM A182 Duplex Steel S32205 Fasteners. UNS S32205 Bolts Supplier.

0 notes

Text

The Properties of ASTM A182 F51 Flanges

What are ASTM A182 F51 Flanges?

ASTM A182 F51 is a duplex stainless steel that belongs to the family of super duplex steels. In simple terms, duplex stainless steel refers to a combination of ferritic and austenitic stainless steel. This combination gives the steel enhanced strength, durability, and corrosion resistance compared to conventional stainless steels. ASTM A182 F51 is essentially a blend of chromium, molybdenum, and nitrogen, all of which offer excellent resistance to pitting, crevice corrosion, and stress corrosion cracking. These properties make ASTM A182 F51 Flanges highly suitable for use in harsh and corrosive environments.

Properties of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges have incredible mechanical properties, offering high tensile strength, ductility, and impact strength. They are perfect for use in applications that require high-pressure resistance, including subsea systems and flowlines. The flanges can withstand pressure up to 15000 psi, making them one of the most robust flanges available in the market.

Another advantage of these flanges is their resistance to abrasion, erosion, and corrosion. They can withstand temperatures as low as -50°C and up to 300°C without losing their mechanical or chemical properties. The flanges also have an excellent resistance to acids, alkalis, and saltwater, making them ideal for use in offshore and marine applications.

Manufacturing of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges are manufactured through a hot forging process that involves heating the metal to a specific temperature and shaping it into the desired shape. The forging process ensures that the material is dense and has a fine grain structure, which enhances its mechanical performance. After forging, the flanges undergo a heat treatment process, where they are heated to a specific temperature and cooled to increase their strength and durability.

Applications of ASTM A182 F51 Flanges

ASTM A182 F51 Flanges find applications in many industries, including offshore and marine, chemical processing, oil and gas, and power generation. In the offshore and marine sector, they are used in subsea systems, seawater treatment plants, and flowlines. In chemical processing, they are used in pipelines, valves, and pumps that handle corrosive acids and alkalis. In the oil and gas industry, they find extensive use in refineries, gas processing plants, and pipelines that transport crude oil and gas.

#ASTM A182 F51 Flanges#Applications of ASTM A182 F51 Flanges#Manufacturing of ASTM A182 F51 Flanges#Properties of ASTM A182 F51 Flanges#What are ASTM A182 F51 Flanges

0 notes

Text

Superior Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars

We are committed to providing products that comply with international standards. Piyush Steel super duplex round bars is certified and come with detailed documentation, including material test reports (MTRs), third-party inspection reports, and compliance with industry-specific regulations, which make us Trusted Manufacturer of Super Duplex ASTM A182/DIN 1.4410/UNS S32750/SAF 2507 Round Bars.

Contact Us

0 notes

Text

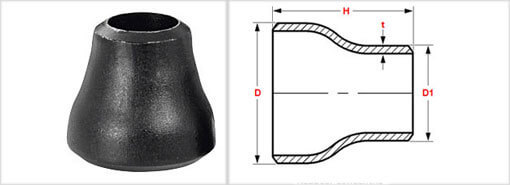

Concentric Reducers Exporters in India

CONCENTRIC REDUCERS

The Concentric Reducers are accessible in assortment of shapes and measurements to suit real pipeline establishment necessities in commercial ventures. This is a standout amongst the most generally utilized modern funnel fitting for adjusting distinctive channel sizes in a pipeline framework. It is fundamentally used to associate two funnels with various widths.

Produced using best grades of stainless steel, these reducers are accessible in an extensive variety of sizes, divider thicknesses and weight evaluations to look over as indicated by the pipeline. Guaranteeing an in-line funnel shaped move between various widths of pressurized channels, these concentric reducers join the pipelines on the same axis.The development of these reducers is finished by joining the little breadths and expansive distances across on inverse closures of cone formed move area. Discover application in petrochemicals, sugar factories and refineries, steel plants and bond and development commercial ventures, the reducer has separate gulf and outlet closes.TECHNICAL SPECIFICATIONSSTANDARD MATERIAL GRADES OF BUTTWELD SS REDUCER

Stainless steel grades:

ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H, WP321, ASTM A815 S31803, S32750, S32760, S32205

Standard material grades in stainless steel:

ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L

Application Areas:

Oil and gas industry

Petrochemical industry

Power stations

Shipbuilding industry

10 notes

·

View notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539)

Duplex Steel:Grade: 2205 (1.4507)

Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750)

Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668)

Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225)

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html

Contact Us -9819523999

Email Id - [email protected]

4 notes

·

View notes

Text

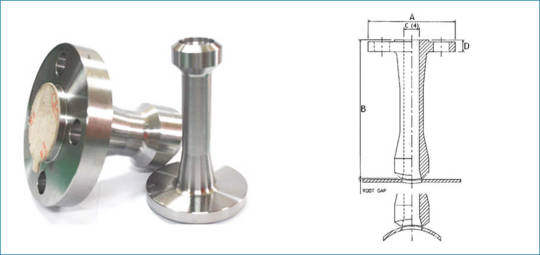

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Pipe End Caps: A Comprehensive Guide to Standards and Specifications

Pipe end caps are essential components in piping systems, used to seal or terminate the ends of pipes. Adhering to industry standards and specifications is crucial to ensure the quality, safety, and compatibility of pipe end caps.

Key Standards and Specifications for Pipe End Caps

ASME B16.9: The American Society of Mechanical Engineers (ASME) B16.9 standard covers forged steel pipe fittings, including end caps. It specifies dimensions, tolerances, and materials for various types of pipe end caps.

ANSI/ASME B16.11: This standard covers cast iron pipe fittings, including end caps. It provides guidelines for materials, dimensions, and testing requirements.

ASTM A105: This ASTM specification covers carbon steel forgings for low-temperature service, which includes pipe end caps. It outlines chemical composition, mechanical properties, and testing requirements.

ASTM A182: This specification covers forged steel pipe fittings, including end caps, for high-temperature service. It provides guidelines for materials, dimensions, and testing requirements.

ISO 2501: This international standard covers forged steel pipe fittings, including end caps. It specifies dimensions, tolerances, and materials for various types of pipe end caps.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including pipe end caps. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex pipe end caps are known for their:

Superior quality: Platinex pipe end caps are manufactured using advanced techniques and adhere to strict quality standards.

Adherence to standards: Platinex products comply with relevant industry standards, ensuring compatibility and reliability.

Customizable solutions: Platinex can provide customized pipe end caps to meet specific requirements.

Additional Considerations

When selecting pipe end caps, it's essential to consider the following factors:

Material: Choose the appropriate material based on the application's requirements for corrosion resistance, temperature tolerance, and pressure handling.

Size and dimensions: Ensure the pipe end caps are compatible with the pipe size and the specific application.

Pressure rating: Select pipe end caps with a pressure rating that meets or exceeds the operating pressure of the piping system.

End type: Determine whether you need flat end caps, beveled end caps, or other types based on the connection method.

By adhering to industry standards and specifications, and selecting high-quality products like those offered by Platinex, you can ensure the reliability and performance of your piping system.

0 notes

Text

Stainless Steel 304 Flanges

We are instrumental in offering high quality range of Stainless Steel 304 Flange to our clients. We execute the manufacturing process of these stainless-steel products at the most sophisticated production premise under proper supervision of industrial experts.

Flanges made of stainless steel are referred to as "stainless steel 304 flanges," also abbreviated as "SS 304 flange." Common material standards and grades include ASTM A182 Grade F304/L and F316/L, with pressure ratings ranging from Class 150 to 2500 and 300 to 600, respectively.

The flange sometimes need to be welded with an extra security. The UNS S30400 Weld Neck Flanges are made with a welded neck to them so that the joining and welding of the flange to the pies becomes easier and secure. The SS 304 RTJ Flange use rings that are attached to both sides of the connection so that the connection could be made stronger with bolting or welding.

#Stainless Steel 304 Flanges Manufacturers#Stainless Steel 304 Flanges Suppliers#Stainless Steel 304 Flanges Stockists

0 notes