#advancedmaterial

Explore tagged Tumblr posts

Text

Maadhu Creatives offers expert industrial model services to turn your ideas into reality. Our dedicated team focuses on delivering high-quality, precise models that meet your needs. Whether you have an ongoing project or need support, we're here to help! Visit our website for more information or contact us directly for clear communication. Let us bring your vision to life with top-tier industrial model solutions.

#industrialmodelmaking#3dprinting#cadsoftware#rapidprototyping#advancedmaterials#sustainablemanufacturing#automation#industrialdesign#prototype#modelmakingservices

2 notes

·

View notes

Text

When comparing alumina tubes, quartz tubes, and silicon carbide tubes, each material offers distinct advantages and drawbacks based on factors like temperature resistance, mechanical strength, chemical resistance, and cost. Here’s a detailed comparison to help you choose the best option for your specific application:

Temperature Resistance

Alumina Tubes:

Withstand temperatures up to 1800°C or more, particularly when made from high-purity alumina (99.7% or higher).

Suitable for extreme high-temperature environments, such as furnaces and kilns.

Quartz Tubes:

Can withstand temperatures up to 1100°C.

Suitable for moderate temperature applications but not ideal for extremely high temperatures.

Silicon Carbide Tubes:

Have the highest temperature resistance of the three, handling temperatures up to 1600–2400°C depending on the grade.

Ideal for applications involving extremely high heat and harsh environments, such as high-temperature furnaces or combustion chambers.

Mechanical Strength

Alumina Tubes:

Excellent mechanical strength and durability, making them resistant to wear and stress at high temperatures.

Can withstand heavy mechanical and thermal loads.

Quartz Tubes:

Fragile compared to alumina and silicon carbide. Quartz is more prone to breaking under mechanical stress or impact, making it less durable.

Silicon Carbide Tubes:

Superior mechanical strength and hardness, making them highly resistant to wear, abrasion, and thermal stress.

Often preferred in environments with high mechanical loads.

Thermal Shock Resistance

Alumina Tubes:

Good thermal shock resistance, but not as high as quartz. Rapid heating and cooling can cause cracking if not managed carefully.

Quartz Tubes:

Excellent thermal shock resistance. Quartz can withstand sudden changes in temperature without cracking, making it useful in applications where rapid heating or cooling occurs.

Silicon Carbide Tubes:

Moderate thermal shock resistance, better than alumina but not as good as quartz. Silicon carbide is tough, but extreme temperature fluctuations can still pose a challenge.

Chemical Resistance

Alumina Tubes:

Highly resistant to chemical attack, especially from most acids and bases. Ideal for processes involving reactive chemicals at high temperatures.

Quartz Tubes:

High resistance to chemical corrosion, particularly in oxidizing environments. However, it can be attacked by strong alkaline substances at high temperatures.

Silicon Carbide Tubes:

Extremely resistant to chemical corrosion from a wide range of chemicals, including strong acids and alkalis. This makes it suitable for highly corrosive environments.

Electrical Insulation

Alumina Tubes:

Excellent electrical insulator at high temperatures, making it ideal for applications where electrical insulation is crucial (e.g., thermocouple protection).

Quartz Tubes:

Also a good electrical insulator, although alumina is generally preferred when higher thermal stability and electrical insulation are needed.

Silicon Carbide Tubes:

Not a good insulator, as silicon carbide has some electrical conductivity, especially at high temperatures. It’s more suitable for applications where electrical conductivity is not a concern.

Cost

Alumina Tubes:

Typically, mid-range in terms of cost. They offer a balance between performance and price, particularly for high-temperature applications requiring strength and durability.

Quartz Tubes:

Generally more affordable than alumina or silicon carbide, especially for moderate temperature applications. However, the fragility may lead to more frequent replacements.

Silicon Carbide Tubes:

More expensive than both alumina and quartz due to their superior properties. However, their durability and high-temperature resistance can justify the cost in demanding applications.

Applications

Alumina Tubes:

Used in furnaces, thermocouple protection, kiln furniture, high-temperature processing, powder processing, and scientific research.

Preferred when both high-temperature resistance and mechanical strength are required.

Quartz Tubes:

Used in optics, semiconductor processing, light sources, and moderate temperature applications where thermal shock resistance is critical.

Suitable for applications with rapid heating/cooling cycles but moderate temperature limits.

Silicon Carbide Tubes:

Used in high-temperature furnaces, combustion systems, heat exchangers, and abrasive environments.

Ideal for extreme temperature applications and environments with high mechanical or chemical stress.

Durability and Longevity

Alumina Tubes:

High durability, especially in high-temperature or chemically aggressive environments, leading to longer life spans compared to quartz.

Quartz Tubes:

Less durable due to their fragility, leading to shorter lifespans in environments with mechanical or thermal stress.

Silicon Carbide Tubes:

Highly durable, with excellent resistance to wear and tear, especially in abrasive or chemically corrosive environments.

#AluminaTubes#QuartzTubes#SiliconCarbideTubes#MaterialScience#HighTemperatureMaterials#IndustrialMaterials#FurnaceTechnology#ThermalResistance#MechanicalStrength#ChemicalResistance#ThermalShockResistance#MaterialComparison#EngineeringMaterials#HighTempApplications#CeramicMaterials#MaterialSelectionGuide#KilnTechnology#IndustrialEngineering#HeatResistantMaterials#AdvancedMaterials#ScientificResearchMaterials#ThermalInsulation#IndustrialFurnaces#MaterialDurability#ElectricalInsulation

2 notes

·

View notes

Text

Introducing the 2040 Futuristic Racing Suit: crafted from advanced, breathable, superhydrophobic, and highly elastic fabric. This suit seamlessly integrates a cooling system with thin, discreet tubes stitched along anatomical lines, ensuring maximum performance and comfort. Designed for complete freedom of movement and extreme elasticity, it embodies the perfect blend of cutting-edge technology and natural, ergonomic design. #FuturisticFashion #RacingSuit #TechWear #2040Innovation #AdvancedMaterials #GradoZero #PGZ #PGrado Zero

2 notes

·

View notes

Text

#PolymerConcrete#ConcreteInnovation#AdvancedMaterials#ConstructionMaterials#DurableInfrastructure#ChemicalResistantConcrete#IndustrialConstruction#InfrastructureDevelopment#CivilEngineering#SmartConstruction#SustainableBuilding#PolymerTechnology#ConcreteSolutions

0 notes

Text

Why Industrial Businesses Struggle with Sourcing Exotic Metals in Connecticut

🔧 If you are an industrial business owner in the USA, particularly in Connecticut, you have likely faced the uphill battle of sourcing high-quality exotic metals. These specialized materials like titanium, Inconel, and Hastelloy are critical for aerospace, defense, marine, medical, and high-performance manufacturing sectors. However, access to reliable suppliers and competitive pricing often feels like navigating a maze. Understanding how to secure exotic metals efficiently can be a game-changer for your operations, profitability, and product reliability.

🏭 Why Exotic Metals Matter for Industrial Applications

Exotic metals possess unique properties like exceptional heat resistance, corrosion protection, and strength-to-weight ratio, making them ideal for high-stress environments. Industries in Connecticut increasingly rely on these materials to meet performance standards and compliance requirements, yet many struggle to find dependable sources. If you are searching for exotic metals in Connecticut, you are not alone—many manufacturers are competing for the same limited resources.

📊 The supply exotic metals are currently facing difficulties.

Several factors affect the exotic metal market: global supply chain disruptions, stringent regulatory standards, and escalating demand. For Connecticut-based industries, the pressure intensifies due to regional competition and logistical barriers. Add to that the risk of counterfeit metals, and the stakes become even higher for business owners who demand precision and quality.

📈 How to Secure Quality Exotic Metals Without the Hassle

To stay competitive, it is vital to partner with a trusted metal supplier that specializes in exotic metals. Look for suppliers with established reputations, ISO certifications, and a proven track record of working with industrial businesses in Connecticut. An ideal partner should offer consultation, testing certifications, and tailored procurement strategies to meet your specific needs.

🧠 EEAT Principles: Your Guide to Safe Sourcing

When it comes to sourcing exotic materials, experience, expertise, authoritativeness, and trustworthiness (E-E-A-T) should guide your decisions. A high-quality supplier will demonstrate deep knowledge of metallurgy, compliance with industry standards, and transparency throughout the procurement process. The best ones will not just sell you metal they will act as long-term partners who understand your technical and operational goals.

📌 Key Tips for Industrial Buyers in Connecticut

Choose suppliers with a local presence or strong logistics networks in the Northeast.

Request samples or trial orders to evaluate quality firsthand.

Ask about volume discounts or recurring supply agreements for long-term savings.

Look for value-added services like CNC machining.

🚀 Act: Future-Proof Your Supply Chain Today

Do not let unreliable sourcing derail your production timelines or compromise your product integrity. Whether you are upgrading machinery, entering a new market, or fulfilling government contracts, sourcing the right exotic metals in Connecticut is critical to your success. Act now consult with a certified metal supplier who understands your industry and delivers quality you can trust.

🔚 Conclusion: Sourcing Exotic Metals Should Not Be a Struggle

Industrial business owners across the USA, especially in Connecticut, need reliable access to exotic metals to maintain operational efficiency and product excellence. With demand rising and supply chains under pressure, now is the time to prioritize quality sourcing. Make informed decisions, build strong supplier relationships, and align your business with the best in the industry. Secure your competitive edge—because in today's market, every component counts.

👉 Ready to streamline your exotic metal sourcing? Connect with industry-trusted suppliers in Connecticut now. Let your next project begin with confidence and quality.

❓Frequently Asked Questions

Q: What qualifies as an exotic metal?

A: Exotic metals include titanium, zirconium, tungsten, tantalum, and superalloys like Inconel. These materials outperform standard metals in extreme conditions and are often used in industries like aerospace, energy, and defense.

Q: Why is it difficult to find exotic metals in Connecticut?

A: While Connecticut has a strong industrial base, the specialized nature of exotic metals makes them harder to source locally. Few suppliers carry these materials in bulk, and even fewer offer custom solutions for niche industrial applications.

Q: How can I verify the quality of exotic metals before purchase? A: Reputable suppliers provide material traceability, mill certifications, and third-party testing data.

#ExoticMetals#IndustrialManufacturing#ConnecticutIndustry#AdvancedMaterials#ManufacturingUSA#SupplyChainSolutions#ConnecticutBusiness#HighPerformanceMetals#IndustrialGrowth

0 notes

Text

Ceramic Coating Market Expands in Asia-Pacific With Increasing Manufacturing and Industrial Output

The ceramic coating market has witnessed significant growth over the last decade, driven by increasing demand across various industries, including automotive, aerospace, energy, healthcare, and industrial manufacturing. Ceramic coatings are advanced materials applied to surfaces to enhance properties such as thermal resistance, corrosion resistance, wear resistance, and overall durability. These coatings offer long-lasting protection and performance enhancement, making them a vital component in modern engineering and manufacturing.

Market Dynamics

The growth of the ceramic coating market is fueled by a combination of factors. The automotive sector is a key driver, particularly with the growing trend of vehicle customization and paint protection. Consumers are increasingly turning to ceramic coatings to protect their vehicles from scratches, UV damage, oxidation, and chemical stains. This trend is particularly notable in North America, Europe, and rapidly developing economies in Asia-Pacific.

In the aerospace and defense sector, ceramic coatings are used for their high-temperature stability and ability to withstand extreme environments. Components such as turbine blades and engine parts benefit significantly from the heat-resistant properties of ceramic coatings, enhancing safety and operational efficiency.

Furthermore, the energy sector, particularly in power generation and oil and gas, employs ceramic coatings to reduce wear and corrosion in high-temperature and high-pressure environments. With a global focus on energy efficiency and operational longevity, these applications are gaining importance.

Key Market Segments

The ceramic coating market can be segmented based on product type, technology, and end-use industry. By product type, oxide coatings hold the largest share due to their excellent resistance properties and versatility. Other common types include carbide and nitride coatings, which are often used in specialized industrial applications.

In terms of technology, the market is broadly categorized into thermal spray, physical vapor deposition (PVD), chemical vapor deposition (CVD), and others. Thermal spray coating dominates due to its cost-effectiveness and widespread industrial use. However, PVD and CVD technologies are growing steadily, especially in electronics and semiconductor manufacturing where precision and quality are paramount.

End-use industries range from automotive and aerospace to energy, medical, and electronics. The automotive industry remains the largest consumer, but the healthcare sector is showing increasing interest, particularly in coating medical implants and devices for better biocompatibility and durability.

Regional Insights

Geographically, the Asia-Pacific region dominates the ceramic coating market, led by China, Japan, India, and South Korea. The region benefits from a strong manufacturing base, rising industrialization, and increasing investments in automotive and aerospace sectors. Moreover, government initiatives aimed at boosting domestic production and technology adoption have further fueled market growth.

North America follows closely, driven by high demand for automotive customization, advanced aerospace applications, and innovations in energy infrastructure. Europe also holds a significant share, thanks to stringent environmental regulations that encourage the use of high-performance coatings for energy efficiency and sustainability.

Competitive Landscape

The ceramic coating market is moderately fragmented with the presence of global players and regional manufacturers. Major players include PPG Industries, AkzoNobel, A&A Coatings, Bodycote, Oerlikon Group, and Zircotec. These companies are actively investing in R&D to develop environmentally friendly and application-specific coating solutions.

Strategic collaborations, mergers, and acquisitions are common as companies seek to expand their global footprint and diversify product offerings. Innovation in application techniques and coating formulations is also key to gaining a competitive edge in this rapidly evolving market.

Challenges and Future Outlook

Despite its growth, the ceramic coating market faces challenges such as high application costs, the need for specialized equipment, and skilled labor for coating processes. Additionally, environmental and health regulations can impact the use and disposal of certain ceramic materials.

#CeramicCoatingMarket#CoatingIndustry#AdvancedMaterials#SurfaceTechnology#IndustrialCoatings#ProtectiveCoatings

0 notes

Text

Graphene Market Overview: Extensive Evaluation of Market Size, Share, Growth Opportunities

The global graphene market is anticipated to reach USD 1.60 billion by 2030 and is anticipated to expand at a CAGR of 35.1% during the forecast period, according to a new report by Grand View Research, Inc. The increasing penetration of graphene in various end-use industries such as automotive, electronics, aerospace, construction, and medical is expected to boost the market’s demand. In addition, rising demand from various multi-national companies and research institutions for research and development purposes is further expected to escalate market growth.

The ongoing research and development in graphene production is also expected to boost product utilization in various applications. For instance, the flash joule heating technique identified in 2020 showed promising results. Studies have demonstrated that the carbon-carbon bonds are reorganized into a graphene structure when significant amounts of electricity is passed through any carbon source. By using this method, any carbon-containing material, such as coal or even trash, can be converted into numerous pounds of high-quality graphene at a comparatively low cost.

Current manufacturing methods are capital-intensive as well as require high energy and resource costs. While current amounts of graphene available in market can meet demands of researchers, full commercialization market is still in early phases. The process of developing a novel material, its manufacturing, and application for a company involves many pounds of graphene powder and hundreds of graphene sheets, as well as a significant amount of time and work. This could pose a challenge for the manufacturers of graphene.

The market is governed by a complex regulation that encompasses safety, health, and environmental concerns. The manufacturing, handling, and application of graphene materials are heavily regulated by national and international regulatory authorities. These strict guidelines include potential health risks and environmental impact while ensuring the proper production and usage. Market participants are anticipated to benefit from compliance with these regulations by gaining a competitive edge over their competitors.

The market is highly dynamic and exhibits intense competition, owing to the presence of various small and medium-scale manufacturers. Key industry participants emphasize investments in research & development and product innovations in order to gain a competitive edge.

For More Details or Sample Copy please visit link @: Graphene Market Report

Graphene Market Report Highlights

Graphene oxide dominated the technology segment with more than 47.0% share in 2023 owing to its superior characteristics, including excellent thermal and electrical conductivity, transparency, permeability, and strength.

Reduced graphene oxide segment is expected to grow at the fastest CAGR over the forecast period.

Electronic component segment held the largest market share in 2023. Composite application is anticipated to witness fastest growth over the forecast period.

The automotive end-use segment dominated the market in 2023. The growth of this industry can be attributed to the rising disposable income and increasing purchasing power of the middle-income population in emerging economies.

Asia Pacific dominated the market owing to the presence of a large number of manufacturers and consumers. Increasing production volumes in various sectors including automobile, marine, defense, and aerospace are expected to drive the market in this region over the forecast period.

Market players operating in market include Nanoxplore Inc.; Telga Group, Directa Plus S.p.A, Graphene Laboratories, Inc., GRAPHENE SQUARE INC, and ACS Material, Applied Graphene Materials, 2D Carbon Graphene Material Co., Ltd., Thomas Swan & Co. Ltd.

In March 2023, Directa Plus S.p.A. announced the partnership with Colombo Industrie Tessili. Both companies produced a new innovative fabric, obtained using a graphene-based dyeing treatment. The key characteristic of this new fabric is its thermal capability, which allows for consistent temperatures and heat dispersion. The dyeing technique of Graphene Plus on the fabric imparts antistatic properties required by the military and workplace, as well as antimicrobial, antibacterial, and antiviral properties to the cloth.

0 notes

Text

"High Temperature Insulation Materials: Powering Efficiency and Safety in Extreme Environments – 2025 Spotlight"

High temperature insulation materials are critical components in industries that operate under extreme heat—such as aerospace, metallurgy, power generation, and petrochemicals. These advanced materials, including ceramic fibers, aerogels, and insulating firebricks, are engineered to withstand temperatures exceeding 1000°C while minimizing heat loss, boosting energy efficiency, and enhancing operational safety. In 2025, with a strong push for energy conservation and sustainability, demand for lightweight, eco-friendly, and high-performance insulation solutions is at an all-time high. Innovations are also focusing on recyclable and low-carbon insulation alternatives that align with global green mandates. These materials not only protect equipment and personnel but also play a key role in reducing emissions across high-heat industries.

#HighTempInsulation#ThermalProtection#EnergyEfficiency2025#IndustrialInnovation#HeatResistance#SustainableEngineering#AdvancedMaterials#GreenIndustry#AerospaceTech#SmartManufacturing

0 notes

Text

Ink Receptive Coatings Market Witnesses Increased Application in Sustainable Paper and Film Alternatives

The ink receptive coatings market has seen substantial growth over the past decade, largely due to advancements in digital printing technologies, the rise of customization in consumer goods, and the increasing demand for sustainable printing solutions. However, like many markets, it has not been immune to volatility. Market volatility refers to the unpredictable and sometimes rapid changes in demand, pricing, supply chain stability, and input costs. In the case of ink receptive coatings, several factors ranging from raw material fluctuations to shifting industry demands contribute to this volatility. Understanding these factors is essential for manufacturers, suppliers, and end-users aiming to navigate and adapt to market uncertainties.

Supply Chain Disruptions and Raw Material Price Fluctuations

One of the key sources of volatility in the ink receptive coatings market is the fluctuation in raw material prices. Most ink receptive coatings are composed of complex chemical formulations that rely on polymers, resins, solvents, and other additives. Many of these inputs are derived from petrochemical sources, making them highly sensitive to changes in global oil prices and geopolitical tensions.

For instance, when oil prices surge due to conflict or regulatory constraints, the cost of production for solvent-based and even some water-based coatings rises. These increased production costs are often passed down the supply chain, affecting pricing and margins at multiple levels. Additionally, supply chain disruptions, such as those experienced during the COVID-19 pandemic or due to geopolitical unrest, can lead to delays in raw material procurement. This not only slows down manufacturing but also causes price spikes, adding to market unpredictability.

Shifting Regulatory Landscape

Environmental regulations are another major driver of market volatility. Around the world, governments are tightening regulations on the use of volatile organic compounds (VOCs) and other environmentally harmful substances found in certain types of coatings. While this has led to a positive shift toward eco-friendly formulations, it has also introduced instability for manufacturers that must rapidly adapt their formulations to stay compliant.

For example, new environmental rules may render a commonly used ingredient non-compliant, requiring reformulation or the search for alternative materials both of which take time and investment. This can temporarily disrupt production and affect market supply. Moreover, compliance costs can rise unpredictably as regions impose differing environmental standards, making it challenging for global manufacturers to maintain a consistent product line across markets.

Technological Shifts and Evolving End-Use Demands

The ink receptive coatings market is closely tied to the printing industry, which is itself undergoing rapid change. The rise of digital printing technologies such as inkjet and UV printing is reshaping the landscape, pushing demand for more specialized coatings that can handle a broader range of substrates and ink types.

However, this evolution also brings volatility. As new technologies emerge, older formulations may become obsolete, and demand can shift rapidly. Coating manufacturers must be agile, investing in R&D to stay relevant. At the same time, end-user industries from packaging to textiles to electronics are constantly updating their preferences and performance expectations. This can lead to fluctuations in demand, with sudden increases for some formulations and declines for others.

The growing trend toward personalization and short-run printing also introduces instability. While digital printing and ink receptive coatings are perfectly suited to meet these demands, they often require smaller batches and rapid formulation adjustments, making production and inventory management more complex.

Global Economic Uncertainty

Macroeconomic factors also play a significant role in market volatility. Economic slowdowns, inflation, currency fluctuations, and interest rate changes can affect both the demand for printed products and the investment capacity of manufacturers. For example, in times of economic uncertainty, businesses may cut back on marketing and packaging expenditures, leading to a temporary reduction in demand for ink receptive coatings.

Likewise, interest rate hikes and inflation can impact borrowing costs and operational expenses, making it harder for smaller coating manufacturers to invest in innovation or expand capacity. These macroeconomic pressures contribute to an uneven market landscape where sudden booms may be followed by equally sudden contractions.

Navigating Volatility: Strategies for Stakeholders

To address and adapt to market volatility, stakeholders in the ink receptive coatings sector are adopting several strategies:

Diversification of raw material sources to minimize the impact of supply chain disruptions.

Investment in research and development to stay ahead of technological changes and evolving customer needs.

Agile manufacturing practices that allow for quick formulation changes and batch flexibility.

Geographical diversification to spread risk across multiple markets and regulatory environments.

By embracing these strategies, companies can not only cushion themselves against volatility but also find new avenues for growth and innovation.

Conclusion

The ink receptive coatings market, while full of promise, is subject to a range of volatile forces. From supply chain instability and raw material price swings to regulatory shifts and technological disruption, stakeholders must remain vigilant and adaptable. Volatility, while challenging, can also drive innovation pushing companies to become more resilient, responsive, and forward-thinking in their approach. For those willing to invest in agility and innovation, the ink receptive coatings market continues to offer significant opportunities despite its inherent unpredictability.

0 notes

Text

Leading the Charge in Metal Excellence with a Trusted Ferroalloy Manufacturer in India

As a leading ferroalloy manufacturer in India, Sarojini Group is fully geared to meet future challenges. They continuously invest in R&D to develop advanced ferroalloys and explore new applications across industries such as automotive, aerospace, energy, and infrastructure.

0 notes

Text

Ballistic Composites: Providing Protection through Advanced Material Engineering

Ballistic composite materials are engineered materials designed to withstand high-velocity impact from projectiles such as bullets or fragments from an explosion. These specialized materials are constructed through a process called laminating, where layers of different materials are bonded together to achieve properties greater than the individual components. Ballistic Composites - https://www.patreon.com/posts/evolution-of-127795756

0 notes

Text

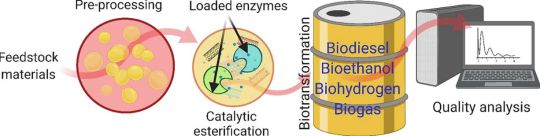

⚗️ Powering the Green Revolution: Nanomaterials Accelerate Biofuel Production from Lignocellulosic Biomass

By Hafiz Muhammad Husnain Azam Researcher, Brandenburg University of Technology Cottbus-Senftenberg 📘 Published 🔗 Read Full Study on Elsevier

The Biofuel Bottleneck—and the Nanotech Breakthrough

With fossil fuel dependency driving climate change, geopolitical instability, and economic volatility, the world is racing to scale up renewable energy solutions. Among these, biofuels—biodiesel, bioethanol, biogas, bio-oil, and biohydrogen—are gaining momentum as scalable, low-carbon alternatives.

However, biofuel production from lignocellulosic biomass—agricultural waste, forestry residues, and organic by-products—has historically been hampered by complex conversion processes and low yields. Our latest article addresses this challenge with a cutting-edge solution: nanomaterials.

How Nanomaterials Are Revolutionizing Biofuel Efficiency

Nanomaterials possess extraordinary physicochemical properties—high surface area, catalytic efficiency, and tunable morphology. These qualities make them ideal for enhancing biomass-to-biofuel conversion processes like:

Transesterification (for biodiesel)

Hydrolysis and fermentation (for bioethanol and biogas)

Pyrolysis and gasification (for bio-oil and biohydrogen)

They act as nano-catalysts, replacing harsh chemicals and enabling cleaner, faster, and more efficient transformations. This drastically improves both yield and cost-efficiency while reducing environmental impact.

Bridging the Gap Between Energy Demand and Sustainability

With global leaders striving to meet Net-Zero targets, biofuels play a critical role in the transition from fossil fuels to renewable energy. Yet, for biofuels to become a backbone of this transition, the production systems must be radically optimized. This is where nanotechnology emerges as a strategic enabler.

Our review reveals:

Enhanced metabolic and catalytic activity via nanomaterials

Improved thermal stability and recyclability of catalysts

Lower activation energy for biomass breakdown

Reduced process time and chemical waste

Future Outlook: Opportunities and Challenges

Despite their game-changing potential, the commercial deployment of nanomaterials faces hurdles:

High production costs

Limited scalability

Safety and environmental concerns

Regulatory gaps

Addressing these through targeted research, policy frameworks, and interdisciplinary collaboration will be key to unlocking the full potential of nanotech in renewable energy.

Let’s Drive the Conversation Forward

This research is a call to action for materials scientists, chemical engineers, policy leaders, and energy stakeholders. Nanomaterials are not just a lab innovation—they are a viable industrial solution in the making.

📖 Explore the full article: Elsevier – Nanomaterials in Biofuel Production

https://doi.org/10.1016/j.fuel.2021.122840

https://go.nature.com/4j0ywq

#Nanomaterials#Biofuels#Biodiesel#Bioethanol#Biogas#Biohydrogen#LignocellulosicBiomass#GreenEnergy#CleanTech#SustainableEnergy#Nanotechnology#Catalysis#RenewableEnergy#EnvironmentalEngineering#EnergyTransition#CircularEconomy#CarbonNeutral#WasteToEnergy#FutureFuels#AdvancedMaterials#ClimateTech#Decarbonization#GreenInnovation#FuelTheFuture#ScienceForSustainability#EnergyResearch#ZeroCarbonFuels#NetZero2050#NanoCatalysts#BiomassConversion

1 note

·

View note

Text

🧱 Why Carbon Black N990 is the Game-Changer for Refractory Applications | iSTAR Materials

Looking for superior performance in high-temperature and refractory environments? 🔥

Carbon Black N990 from iSTAR Materials is the high-purity, low-conductivity additive trusted in furnace linings, kilns, castables, crucibles, and more.

🌟 Key Advantages:

✔️ Easy mixing & dispersion ✔️ Thermal shock resistance ✔️ Low electrical conductivity ✔️ Long-lasting durability ✔️ Smooth processing

Whether you're in refractory manufacturing, rubber compounding, or industrial molding, N990 delivers the thermal stability and structural integrity you need.

👉 Learn more: https://www.istarmaterials.com 📩 Free samples + Technical support available!\

https://istarmaterials.com/product-details.php?slug=carbon-black-n990

#CarbonBlackN990#RefractoryMaterials#ThermalAdditives#RubberCompounds#FurnaceLining#IndustrialMaterials#iSTARMaterials#RefractoryTechnology#AdvancedMaterials#HighTemperatureAdditives#N990CarbonBlack#RefractoryIndustry#FoundrySupplies#KilnTech#MaterialScience

0 notes

Text

#ConstructionComposites#CompositeMaterials#SustainableConstruction#GreenBuilding#ConstructionInnovation#ModernConstruction#AdvancedMaterials#CompositeStructures#BuildingMaterials#ConstructionTechnology#PrefabConstruction#ConstructionIndustry#FutureOfBuilding

0 notes

Text

Dive into futuristic materials that make flight possible.

1 note

·

View note

Text

Ceramic Coating Market Trends Highlight Expansion in Automotive and Aerospace Thermal Barrier Applications

The ceramic coating market is experiencing significant growth, driven by its increasing application across multiple industries, such as automotive, aerospace, electronics, and industrial goods. Ceramic coatings are thin layers of ceramic material applied to metal or plastic surfaces to improve properties like corrosion resistance, thermal insulation, and wear resistance. As technology advances and environmental regulations tighten, demand for high-performance, eco-friendly coatings has surged, placing ceramic coatings in a pivotal position within the global coatings industry.

Market Drivers and Key Applications

One of the primary drivers of the ceramic coating market is its growing adoption in the automotive sector. With the rise in demand for durable, aesthetically appealing, and easy-to-maintain vehicles, automotive manufacturers are integrating ceramic coatings to protect exterior surfaces from UV rays, acid rain, and minor abrasions. Additionally, ceramic coatings improve the vehicle's gloss and provide a hydrophobic finish, enhancing consumer satisfaction.

In the aerospace industry, ceramic coatings are utilized for their thermal barrier properties. Jet engines and other high-heat components benefit from ceramic thermal barrier coatings that help them withstand extreme temperatures and reduce fuel consumption by maintaining optimal operating conditions. The aerospace segment’s focus on fuel efficiency and performance longevity has made ceramic coatings essential for engine components and turbine blades.

In the electronics sector, miniaturization and heat management are key concerns. Ceramic coatings help dissipate heat and offer electrical insulation, making them suitable for printed circuit boards, semiconductors, and other high-performance electronics. Moreover, in industrial equipment, ceramic coatings offer resistance to corrosion, wear, and chemical exposure—extending equipment life and reducing maintenance costs.

Emerging Trends and Innovations

Innovations in nanotechnology have led to the development of nano-ceramic coatings, which provide even stronger protective barriers with thinner layers. These coatings offer enhanced mechanical strength, superior hydrophobic and oleophobic properties, and better transparency compared to traditional coatings. The integration of AI and automation in the manufacturing process is also improving the consistency and quality of coating applications, while reducing labor costs.

Sustainability is becoming a major trend across all materials and processes. Ceramic coatings, due to their durability and non-toxic nature, are increasingly being seen as an eco-friendly alternative to traditional solvent-based coatings. As more industries push toward environmentally conscious manufacturing practices, ceramic coatings stand to benefit from their low environmental impact and extended service life.

Another growing trend is the aftermarket ceramic coating services for vehicles. With rising awareness among consumers regarding paint protection and aesthetic value, businesses specializing in ceramic coating services are expanding rapidly. This consumer-driven demand, particularly in developing economies, is a significant growth opportunity.

Regional Insights and Market Segmentation

Geographically, Asia-Pacific dominates the ceramic coating market, owing to rapid industrialization, rising automotive production, and robust infrastructure development, particularly in China and India. North America and Europe follow, with strong contributions from aerospace and defense sectors. The Middle East and Africa are emerging markets, particularly in energy and oil & gas applications, where ceramic coatings are used to enhance pipeline durability and performance.

In terms of material type, oxide coatings are most commonly used due to their cost-effectiveness and compatibility with various substrates. Carbide and nitride-based ceramic coatings are also gaining attention for applications requiring higher hardness and thermal stability.

Market Challenges and Opportunities

Despite the promising outlook, the ceramic coating market faces challenges such as high application costs and complex manufacturing processes. Specialized equipment and skilled labor are often required for effective application, which can increase overall project costs. Additionally, the need for precise temperature and environmental controls can hinder adoption in some regions.

However, the growing demand from emerging sectors such as renewable energy—particularly in solar panel and wind turbine applications—presents new opportunities. Coatings that enhance surface performance, reduce wear, and extend component life are essential in harsh operating environments typical of renewable energy systems.

Conclusion

The ceramic coating market is poised for robust growth, driven by increasing demand across diverse sectors and rapid advancements in coating technologies. With a strong push for sustainability, efficiency, and performance, ceramic coatings are expected to become even more integral to modern manufacturing and industrial processes. As companies continue to innovate and expand applications, the market will likely see sustained expansion in the coming decade.

0 notes