#rapidprototyping

Explore tagged Tumblr posts

Text

Sheet metal fabrication custom laser cut metal sheets aluminum housing for sheet metal cutting bending service

#gdprototyping#sheetmetal#metalsheet#lasercut metal sheets#Rapidprototyping#Manufacturingservice#fabricationservices#rapid prototyping#prototype machining

3 notes

·

View notes

Text

Maadhu Creatives offers expert industrial model services to turn your ideas into reality. Our dedicated team focuses on delivering high-quality, precise models that meet your needs. Whether you have an ongoing project or need support, we're here to help! Visit our website for more information or contact us directly for clear communication. Let us bring your vision to life with top-tier industrial model solutions.

#industrialmodelmaking#3dprinting#cadsoftware#rapidprototyping#advancedmaterials#sustainablemanufacturing#automation#industrialdesign#prototype#modelmakingservices

2 notes

·

View notes

Text

The AU project leverages the benefits of additive manufacturing , (AM), computational design and the use of composite materials to drive innovation in the medical and healthcare sector. By integrating these advanced technologies, AU aims to:

Optimize pressure distribution and comfort using personalized pressure mapping data.

Reduce weight, product size, and part count, enhancing ergonomics and usability.

Ensure more effective cooling and breathability.

Extend product longevity, performance, and customizability.

Introduce cutting-edge aesthetics to help combat stigma.

Improve sustainability by prioritizing additive over traditional subtractive manufacturing processes.

For more information, get in touch or check out our submission: 🔗 Link

#industrialdesign#product#composites#design#designer#rapidprototyping#3dprinting#additive manufacturing#cushion#computationaldesign

2 notes

·

View notes

Text

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

From Brainstorm to Breakthrough, In Just Days!

Got a brilliant product idea? Don’t let it collect dust on the drawing board. With CreateProto’s Rapid Prototyping & Tooling, you can bring your vision to life faster than ever.

Whether you're fine-tuning a product, pitching to investors, or validating a bold concept, speed is your secret weapon, and CreateProto delivers it with precision.

Turn ideas into impact. https://createproto.com/services/rapid-prototyping-and-tooling/

#RapidPrototyping#InnovationInMotion#CreateProto#ProductDevelopment#HardwareStartups#DesignSprint#FromIdeaToReality#EngineeringExcellence#SpeedToMarket

0 notes

Text

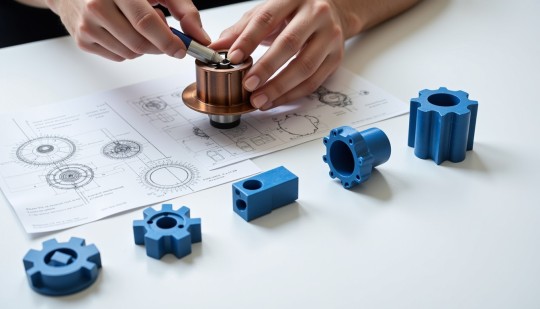

Auckam Technologies specializes in custom mechanical part design, 3D prototyping, and precision manufacturing. Using advanced CAD software and expert engineering, we turn complex technical drawings into functional components for industries like automotive, aerospace, robotics, and industrial automation. Ideal for businesses seeking rapid product development, custom gear prototyping, or CNC-ready designs. 🌐 Learn more at www.auckam.com

#CustomMechanicalParts#3DPrototyping#CADDesign#MechanicalEngineering#PrecisionManufacturing#ProductDevelopment#EngineeringServices#CNCPrototyping#RapidPrototyping#AuckamTechnologies#wwwauckamcom

0 notes

Text

Experience Design Flexibility with 3D Printing Services in India

3D printing services in India help in eliminating the setup costs and time associated with creating specialized molds or tooling. It generates less waste by adding material layer by layer, unlike subtractive manufacturing methods.Are you ready to know about our service?Know More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing/mechanical-testing-prototyping/3d-printing.htm

0 notes

Text

Try SLA 3D Printing for Free — Limited Time Offer

ver wanted to test SLA 3D printing before buying?

We’re offering free rental of high-resolution, industrial-grade SLA 3D printers — ideal for: ✅ Engineers ✅ Product designers ✅ Hardware startups

No cost. No commitment. Just performance.

👉 Apply here: https://www.3dprotomat.com/sla-3d-printer-free-rental/

1 note

·

View note

Link

#AIdiagnostics#cross-bordervalidation#interoperabilitysolutions#patient-centricinterfaces#PreventiveHealthcare#rapidprototyping#RegulatorySandboxes#telehealthintegration

0 notes

Text

#PanasonicIndustry#IoTPrototyping#EmbeddedDevelopment#RapidPrototyping#WirelessConnectivity#powermanaement#powersemiconductor#powerelectronics

0 notes

Text

Turnkey Manufacturing: You’re End-to-End Solution for Seamless Production

Discover how Tesla Mechanical Designs simplifies your product journey with turnkey manufacturing. From initial concept and design to prototyping and delivery, we manage every step so you don’t have to. Our skilled team ensures high quality, fast timelines, and cost-effective solutions for industries like automotive, consumer products, and custom machinery. Trust us to bring your ideas to life—efficiently and reliably.

Start Your Project: Turnkey Manufacturing: You’re End-to-End Solution for Seamless Production

1 note

·

View note

Text

#engineeringdesign#3Dmodelmaking#prototyping#CADmodeling#productprototype#architecturalmodel#rapidprototyping#modelmaking#prototypebuilding#industrialdesign

3 notes

·

View notes

Text

Tesla’s ability to manage complex projects is a testament to the company’s innovative approach to project management. By integrating agile methodologies, lean principles, and cutting-edge technology, Tesla has been able to overcome substantial challenges and achieve rapid growth. The company’s success with high-stakes projects like the Model 3 production ramp-up and the construction of its Gigafactories provides valuable lessons in risk management, speed, and collaboration.

Tesla’s ability to balance ambition with execution shows that, with the right strategy, even the most complex projects can be successfully managed and scaled. For other companies looking to replicate Tesla’s success, the key lies in fostering an innovative mindset, focusing on continuous improvement, and staying agile in the face of uncertainty.

#Tesla#ProjectManagement#AgileManagement#Innovation#LeanManufacturing#Gigafactory#ElectricVehicles#ProjectExecution#SupplyChainManagement#RiskManagement#CrossFunctionalTeams#RapidPrototyping#BusinessStrategy#SustainableManufacturing#ProjectLeadership

0 notes

Text

Crystal-Clear Concepts: The Magic of Transparent Prototyping

What if your prototype didn’t just function right, but looked exactly like the final product? That’s where CreateProto’s Clear Prototyping shines.

With cutting-edge materials and precision finishing, CreateProto produces transparent prototypes that offer both visual clarity and mechanical performance.

Ready to bring clarity to your concepts? https://createproto.com/services/clear-prototyping/

#ClearPrototyping#ProductDevelopment#InnovationInDesign#CreateProto#IndustrialDesign#ProductVisualization#RapidPrototyping#DesignValidation#EngineeringDesign#SeeTheDifference

1 note

·

View note

Text

Emerging Trends and Technologies in Rapid Prototyping Services in the UK

Introduction

The demand for rapid prototyping services in the UK is growing rapidly as businesses seek faster and more efficient ways to develop innovative products. Companies across industries, from manufacturing to software development, rely on prototyping to bring ideas to life, test functionalities, and make improvements before mass production. With emerging technologies and innovative approaches, rapid prototyping is becoming more precise, cost-effective, and accessible.

In this blog post, we will explore the latest trends and technologies shaping rapid prototyping services in the UK. We’ll also discuss their practical applications, benefits, and how a custom website development company can integrate these advancements into their processes for better results.

Key Trends in Rapid Prototyping Services

1. 3D Printing Advancements

3D printing has transformed rapid prototyping services, allowing businesses to create complex designs with precision. Recent advancements include:

Multi-material printing: Enables the creation of prototypes with different textures and functionalities.

Metal 3D printing: Ideal for producing durable and high-quality industrial prototypes.

Faster printing speeds: Reduces turnaround time, making prototyping more efficient.

2. AI and Automation in Prototyping

Artificial intelligence (AI) is streamlining the prototyping process by:

Optimizing design parameters to reduce material waste.

Predicting design flaws and suggesting improvements.

Automating repetitive tasks to accelerate prototype development.

3. CNC Machining for High-Precision Prototyping

While 3D printing is widely used, CNC machining remains a preferred choice for high-precision parts. It provides:

High accuracy and durability.

Compatibility with various materials, including metals and plastics.

Smooth surface finishes for final product-like prototypes.

4. Integration with Digital Twins

A digital twin is a virtual replica of a physical prototype, allowing businesses to test and modify designs before creating physical versions. This technology:

Enhances product simulations.

Reduces errors and unnecessary costs.

Improves efficiency in prototype iterations.

5. On-Demand Prototyping Services

Many businesses are opting for on-demand rapid prototyping services in the UK to:

Reduce production costs by only creating prototypes when needed.

Avoid unnecessary inventory storage.

Ensure quick modifications and updates based on customer feedback.

Practical Applications of Rapid Prototyping Services

Product Development

Companies use prototyping to visualize product concepts before mass production. This includes consumer goods, automotive components, and medical devices.

Custom Website Development

A custom website development company in the UK can utilize rapid prototyping to:

Test UX/UI designs before launching a website.

Create interactive wireframes and mockups.

Ensure seamless user experiences through iterative design improvements.

Medical Industry Innovations

From prosthetics to medical implants, rapid prototyping enables healthcare professionals to create custom-fit solutions for patients, improving treatment effectiveness.

Aerospace and Automotive Advancements

The aerospace and automotive industries rely on high-precision prototyping for designing lightweight, durable components that enhance vehicle performance and safety.

FAQs

1. How fast can I get a prototype made?

The turnaround time depends on the complexity of the design and the chosen prototyping technology. Some prototypes can be produced within hours, while others may take a few days.

2. What materials can be used in rapid prototyping?

Materials include plastics, metals, resins, and composites. The choice depends on the intended application and durability requirements.

3. Can a custom website development company benefit from prototyping?

Yes! Custom website development companies in the UK use prototyping for web design mockups, user testing, and interface refinements.

4. Is rapid prototyping cost-effective for small businesses?

Absolutely! On-demand prototyping eliminates the need for bulk production, reducing costs and ensuring that businesses only create what they need.

Conclusion

The evolution of rapid prototyping services in the UK is transforming industries by making product development faster, more efficient, and cost-effective. Emerging technologies like AI, digital twins, and advanced 3D printing are enhancing precision and innovation. Whether you are an entrepreneur, a manufacturer, or a custom website development company in the UK, adopting modern prototyping techniques can give you a competitive edge in the market.

By staying ahead of these trends, businesses can optimize their processes, reduce costs, and deliver high-quality products or services to their customers. Investing in rapid prototyping services today can pave the way for a more innovative future!

0 notes

Text

The Future of the Fiberglass Mold Market: Strength, Precision, and Innovation

The Fiberglass Mold Market is shaping industries worldwide, from automotive and aerospace to wind energy and marine manufacturing. With its high strength-to-weight ratio, corrosion resistance, and design flexibility, fiberglass is the go-to choice for manufacturers aiming for durability and efficiency.

🔹 Why is the Fiberglass Mold Market Growing?

Boom in Renewable Energy: The demand for wind turbine blades is skyrocketing.

Lightweight Automotive Components: Fuel efficiency and sustainability are driving innovations.

Advancements in Composite Materials: New resin technologies enhance performance and longevity.

🌍 As industries shift towards sustainable and high-performance materials, fiberglass molds continue to be a critical player in global manufacturing. The future is strong, lightweight, and full of potential.

#FiberglassMold#CompositeMolding#ManufacturingInnovation#MoldTechnology#AdvancedManufacturing#RapidPrototyping

0 notes