#amardeep complex

Explore tagged Tumblr posts

Text

Amardeep Luxuria is a modern residential development that sets a new standard for luxury living. Located in a prime area, this architectural masterpiece combines elegance, comfort, and modernity, catering to individuals and families seeking an upscale lifestyle. With its state-of-the-art amenities, thoughtfully designed living spaces, and premium location, Amardeep Luxuria is a perfect blend of sophistication and practicality.

Prime Location

One of the standout features of Amardeep Luxuria is its strategic location. Nestled in a thriving neighborhood, it provides seamless connectivity to major landmarks, business hubs, educational institutions, and healthcare facilities.

Residents enjoy the convenience of having shopping malls, fine dining restaurants, and recreational spots just a stone’s throw away. The location ensures that every aspect of urban life is easily accessible, saving time and enhancing the quality of life.

Exquisite Design and Architecture

Amardeep Luxuria is a testament to modern design and innovation. The architecture seamlessly blends contemporary aesthetics with functional spaces, ensuring that every square foot is utilized effectively. The exteriors exude grandeur with a sleek, sophisticated finish, while the interiors are meticulously crafted to provide a warm and inviting ambiance. High ceilings, large windows, and open layouts create an airy and spacious environment, perfect for modern living.

The apartments are designed with the utmost attention to detail, featuring premium fittings, elegant flooring, and high-quality materials. Every corner reflects luxury and comfort, making it a haven for residents.

World-Class Amenities

Amardeep Luxuria offers an impressive array of amenities designed to cater to every need. For fitness enthusiasts, there is a fully equipped gymnasium and a jogging track. Those seeking relaxation can unwind in the spa, swimming pool, or landscaped gardens. Children can enjoy dedicated play areas, while elders have serene spaces for leisure and social interaction.

The project also boasts a multi-purpose clubhouse, perfect for hosting events and gatherings. Security is a top priority, with 24/7 surveillance, advanced access control systems, and trained personnel ensuring a safe environment for all residents.

Sustainability and Green Living

In addition to luxury, Amardeep Luxuria emphasizes sustainability. The project incorporates eco-friendly features such as rainwater harvesting, energy-efficient lighting, and waste management systems. The lush green surroundings and landscaped gardens not only add to the aesthetic appeal but also promote a healthier lifestyle.

A Community That Feels Like Home

Amardeep Luxuria is more than just a residential complex; it’s a community where like-minded individuals come together to create meaningful connections. The vibrant social atmosphere, combined with the luxurious living spaces, fosters a sense of belonging among residents.

Conclusion

Amardeep Luxuria is a visionary project that redefines luxury living in today’s urban landscape. With its exceptional location, world-class amenities, and focus on sustainability, it offers an unparalleled lifestyle for those who demand the best. Whether you’re looking for a dream home or an investment opportunity, Amardeep Luxuria stands out as an ideal choice for modern living.

0 notes

Text

High-Temperature Hero: Discover Alloy Steel P91 Pipes

By Amardeep Steel Centre LLP

In industries where extreme heat and pressure are the norm, only the strongest materials can withstand the challenge. Alloy Steel P91 Pipes are one such innovation — a true high-temperature hero trusted across power plants, refineries, and petrochemical industries. At Amardeep Steel Centre LLP, we bring you the finest quality ASTM A335 P91 Pipe products, designed to deliver unmatched strength, longevity, and performance under severe service conditions.

What Are Alloy Steel P91 Pipes?

Alloy Steel P91 Pipes are chromium-molybdenum-based alloy steel pipes that offer high mechanical strength and excellent resistance to oxidation and corrosion at elevated temperatures. The "P" in P91 refers to pressure, while "91" is the grade within the ASTM A335 standard. These pipes are engineered to meet the needs of high-temperature and high-pressure systems — especially in boiler components, heat exchangers, and superheaters.

Standards & Grades We Offer

At Amardeep Steel Centre LLP, we stock and supply a wide range of P91 products compliant with international specifications:

ASTM A335 P91 Type 2

ASTM A335 P91 Pipe

ASME SA335 P91 Pipe

ASTM A335 P91 Seamless Pipe

Chrome Moly Alloy A335/SA335 Grade P91 Pipe

ASTM A335 Gr P91 Welded Pipe

Each type is tailored for specific applications and project needs.

Key Features of ASTM A335 P91 Pipes

High Creep Strength – Ideal for long-term use under high temperatures.

Excellent Corrosion Resistance – Performs well in aggressive environments.

Good Weldability – Suitable for fabrication in complex systems.

Thermal Stability – Maintains structural integrity under thermal cycling.

Enhanced Durability – Longer service life reduces maintenance and replacement costs.

Applications of Chrome Moly Alloy A335/SA335 Grade P91 Pipe

Thanks to its high performance under stress, P91 alloy steel pipe is widely used in:

Power plants (especially superheaters and reheaters)

Petrochemical and refineries

High-pressure steam lines

Industrial boilers

Heat exchangers

Furnace components

Why Choose Amardeep Steel Centre LLP?

With 40+ years of expertise in manufacturing and supplying steel pipes and tubes, Amardeep Steel Centre LLP is a trusted name in the global steel market. Here's why clients prefer us:

Quality Assurance: We supply pipes that meet ASTM and ASME standards with complete material traceability.

Wide Inventory: Seamless and welded P91 pipes in various sizes and wall thicknesses.

Global Reach: Exporting to 60+ countries with prompt and reliable delivery.

Custom Solutions: Pipes tailored as per your project specs and schedules.

When it comes to handling heat, pressure, and corrosion, Alloy Steel P91 Pipes stand strong as a reliable performer. Whether you’re upgrading your existing pipeline system or building a new high-temperature application, trust the strength of ASTM A335 P91 Seamless Pipe and ASTM A335 Gr P91 Welded Pipe from Amardeep Steel Centre LLP.

Get in touch today to discover how our Chrome Moly Alloy A335/SA335 Grade P91 Pipes can enhance the efficiency and durability of your industrial projects.

0 notes

Text

Choose The Top Customized Buddhist Pilgrimage Tours

A Buddhist pilgrimage tour allows spiritual travelers to discover the places where the Buddha lived while walking along paths he took during his life. The year 2025 brings personalized Buddhist pilgrimage tours between India and Nepal which allow visitors to experience the historic depth of Buddhist sites together with their spiritual tranquility.

You can actually book for Customized Buddhist Pilgrimage Tours 2025 as then you can plan it as per your travel needs. Beginning in Bodh Gaya in your India Nepal Buddhist Circuit Tours 2025 allows pilgrims to visit the site where Siddhartha Gautama reached enlightenment under the Bodhi tree. Visiting the spiritual space of Mahabodhi Temple complex as a UNESCO World Heritage site brings an eternal memory to all religious visitors.

The religious pilgrimage in the India Nepal Buddhist Circuit Tours 2025 then makes its way to Sarnath near Varanasi where the Buddha delivered his first discourse allowing him to establish the Wheel of Dharma. Both the Dhamek Stupa and ancient ruins of monasteries provide travelers access to history so they can meditate on Buddha's wisdom.

The Customized Buddhist Pilgrimage Tours continues when people visit Kushinagar because this location marks the spot where the Buddha attained Mahaparinirvana. The Amardeep Buddhist Society along with the Ramabhar Stupa create a hallowed atmosphere for deep reflection. Transit from Lumbini guides visitors through this holy place situated in Nepal where Siddhartha Gautama was born. Visitors who explore the Maya Devi Temple while walking the sacred gardens at the place find themselves approaching the beginnings of Buddhism.

Private Buddhist explorations enable visitors to discover holy locations while following individual schedules that extend with religious activities including monk encounters and quiet retreats and unseen temple tours or Customized Buddhist Pilgrimage Tours for planning it according to your suitability. The India Nepal Buddhist Circuit Tours 2025 offers a transcendental historical and spiritual experience which grants seekers enlightenment and peace because of its deep Buddhist heritage.

#Customized Buddhist Pilgrimage Tours#Buddhist Pilgrimage Tours India Nepal 2025#Buddha Heritage Tours India Nepal

0 notes

Text

What is Low Carbon Steel?

Steel is a highly versatile material, used in everything from wires to automobile parts, due to its wide range of types with varied compositions and properties. One popular type, low-carbon steel (also known as mild steel), has become essential across many industries. Its unique properties provide numerous benefits that make it suitable for diverse applications. But what exactly is low-carbon steel? Let’s explore this topic in our blog.

What is Low Carbon Steel?

Low-carbon steel, also known as mild steel, has a comparatively low ratio of carbon to iron compared to other steel types. Typically, its carbon content is within the range of 0.05% and 0.32% by weight. This gives low-carbon steel low strength while making it more malleable and ductile compared to high-carbon steel.

One of the major benefits of low-carbon steel is its cost-effectiveness. As it requires less carbon and other alloying elements, it's normally less expensive than other types of steel. Moreover, low-carbon steels are more readily available and simpler to work with than higher-carbon steels, which makes them a popular choice for a wide range of applications.

Low Carbon Steel Grades

Some of the most common low-carbon steel grades, all stocked by Amardeep Steel, include ASTM A36, A572 Grades 42 & 50, and A830-1020. Each of the low-carbon steel grades has moderate strength, high ductility, and lighter weight due to the low carbon content and addition of other alloys.

Some commonly used grades of low-carbon steel include:

ASTM International: Formerly known as American Society for Testing and Materials. An international standards organization that develops and publishes voluntary consensus technical standards.

AISI: The American Iron and Steel Institute, who play a lead role in the development and application of new steels and steelmaking technology.

SAE: Formerly the Society of Automotive Engineers, now known as SAE International.

Low Carbon Steel Melting Point

Steel with 0.05 to 0.15% of carbon content by weight is called mild or low carbon steel. It is also known as plain carbon steel. Apart from carbon, it also contains traces of copper (0.6%), manganese (1.65%), and silicon (0.6%). The melting point of low carbon steel is 1410°C (2570°F). This type is further classified into medium carbon steel, high carbon steel, and ultra-high carbon steel with melting temperatures ranging from 1425-1540°C (2600-2800°F). Steel with a 0.3 to 1.7% carbon content is called high-carbon steel.

How is Low-Carbon Steel Made?

The manufacturing process of low-carbon steel involves several complex steps, beginning with the melting of raw materials like iron ore and recycled material in a furnace. During the process, carbon monoxide gas is often introduced to reduce the iron ore to liquid steel. The carbon content in this molten steel is carefully controlled to ensure low-carbon levels. This liquid steel is then processed through a continuous casting machine.

These intermediate forms are further processed using methods like rolling and forging to produce the final low-carbon steel products. During these stages, precise temperature control is critical to achieve the desired mechanical properties. The steel may undergo various heat treatments, such as normalizing or controlled cooling, to refine its grain structure and improve properties like ductility and strength. This manufacturing process allows low-carbon steel to retain sufficient strength while also being malleable, setting it apart from higher-carbon steels.

Check Out Our Related Blog on - Low, Medium, and High-Carbon Steel: Everything You Need to Know

Read More - What are the uses of low-carbon steel?

0 notes

Text

Why Your Recycled Plastic May End Up in the Ocean

[By Monique Retamal, Elsa Dominish, Nick Florin and Rachael Wakefield-Rann]

We all know it’s wrong to toss your rubbish into the ocean or another natural place. But it might surprise you to learn some plastic waste ends up in the environment, even when we thought it was being recycled.

Our study, published today, investigated how the global plastic waste trade contributes to marine pollution.

We found plastic waste most commonly leaks into the environment at the country to which it’s shipped. Plastics which are of low value to recyclers, such as lids and polystyrene foam containers, are most likely to end up polluting the environment.

The export of unsorted plastic waste from Australia is being phased out – and this will help address the problem. But there’s a long way to go before our plastic is recycled in a way that does not harm nature.

Know your plastics

Plastic waste collected for recycling is often sold for reprocessing in Asia. There, the plastics are sorted, washed, chopped, melted and turned into flakes or pellets. These can be sold to manufacturers to create new products.

The global recycled plastics market is dominated by two major plastic types:

polyethylene terephthalate (PET), which in 2017 comprised 55 percent of the recyclable plastics market. It’s used in beverage bottles and takeaway food containers and features a “1” on the packaging

high-density polyethylene (HDPE), which comprises about 33 percent of the recyclable plastics market. HDPE is used to create pipes and packaging such as milk and shampoo bottles, and is identified by a “2."

The next two most commonly traded types of plastics, each with four percent of the market, are:

polypropylene or “5,” used in containers for yoghurt and spreads

low-density polyethylene known as “4,” used in clear plastic films on packaging.

The remaining plastic types comprise polyvinyl chloride (3), polystyrene (6), other mixed plastics (7), unmarked plastics and “composites”. Composite plastic packaging is made from several materials not easily separated, such as long-life milk containers with layers of foil, plastic and paper.

This final group of plastics is not generally sought after as a raw material in manufacturing, so has little value to recyclers.

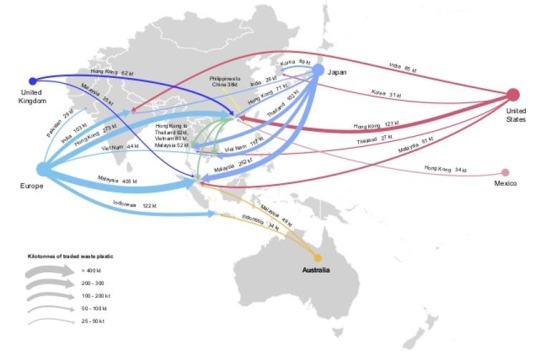

Shifting plastic tides

China banned the import of plastic waste in January 2018 to prevent the receipt of low-value plastics and to stimulate the domestic recycling industry.

Following the bans, the global plastic waste trade shifted towards Southeast Asian nations such as Vietnam, Thailand, Malaysia, and Indonesia. The largest exporters of waste plastics in 2019 were Europe, Japan and the US. Australia exported plastics primarily to Malaysia and Indonesia.

Australia’s waste export ban recently became law. From July this year, only plastics sorted into single resin types can be exported; mixed plastic bales cannot. From July next year, plastics must be sorted, cleaned and turned into flakes or pellets to be exported.

This may help address the problem of recyclables becoming marine pollution. But it will require a significant expansion of Australian plastic reprocessing capacity.

Map showing the import and export map of plastic waste globally. Authors provided

What we found

Our study was funded by Australia's federal Department of Agriculture, Water and the Environment. It involved interviews with trade experts, consultants, academics, NGOs and recyclers (in Australia, India, Indonesia, Japan, Malaysia, Vietnam and Thailand) and an extensive review of existing research.

We found when it comes to the international plastic trade, plastics most often leak into the environment at the destination country, rather than at the country of origin or in transit. Low-value or “residual” plastics – those left over after more valuable plastic is recovered for recycling – are most likely to end up as pollution. So how does this happen?

In Southeast Asia, often only registered recyclers are allowed to import plastic waste. But due to high volumes, registered recyclers typically on-sell plastic bales to informal processors.

Interviewees said when plastic types were considered low value, informal processors frequently dumped them at uncontrolled landfills or into waterways. Sometimes the waste is burned.

Plastics stockpiled outdoors can be blown into the environment, including the ocean. Burning the plastic releases toxic smoke, causing harm to human health and the environment.

Interviewees also said when informal processing facilities wash plastics, small pieces end up in wastewater, which is discharged directly into waterways, and ultimately, the ocean.

However, interviewees from Southeast Asia said their own domestic waste management was a greater source of ocean pollution.

A market failure

The price of many recycled plastics has crashed in recent years due to oversupply, import restrictions and falling oil prices, (amplified by the COVID-19 pandemic). However clean bales of PET and HDPE are still in demand.

In Australia, material recovery facilities currently sort PET and HDPE into separate bales. But small contaminants of other materials (such as caps and plastic labels) remain, making it harder to recycle into high quality new products.

Before the price of many recycled plastics dropped, Australia baled and traded all other resin types together as “mixed plastics”. But the price for mixed plastics has fallen to zero and they’re now largely stockpiled or landfilled in Australia.

Several Australian facilities are, however, investing in technology to sort polypropylene so it can be recovered for recycling.

Doing plastics differently

Exporting countries can help reduce the flow of plastics to the ocean by better managing trade practices. This might include:

improving collection and sorting in export countries

checking destination processing and monitoring

checking plastic shipments at export and import

improving accountability for shipments.

But this won’t be enough. The complexities involved in the global recycling trade mean we must rethink packaging design. That means using fewer low-value plastic and composites, or better yet, replacing single-use plastic packaging with reusable options.

The authors would like to acknowledge research contributions from Asia Pacific Waste Consultants (APWC) - Dr Amardeep Wander, Jack Whelan and Anne Prince, as well as Phil Manners at CIE.

Monique Retamal is Research Principal, Institute for Sustainable Futures, University of Technology Sydney.

Elsa Dominish is a Senior Research Consultant, Institute for Sustainable Futures, University of Technology Sydney.

Nick Florin is Research Director, Institute for Sustainable Futures, University of Technology Sydney.

Rachael Wakefield-Rann is a Research Consultant, Institute for Sustainable Futures, University of Technology Sydney.

This article appears courtesy of The Conversation and may be found in its original form here.

from Storage Containers https://www.maritime-executive.com/article/why-your-recycled-plastic-may-end-up-in-the-ocean via http://www.rssmix.com/

0 notes

Text

MGM Healthcare – super-speciality hospital requiring specialised lighting

India’s glorious past in medical education and sciences is world-renowned with famous experts such as Jivaka Kumarabhacca and Charaka showing the world how to treat diseases and illnesses. At a time when surgeries worldwide were done primitively, well-trained surgeons in India such as Sushruta performed the most advanced and complex surgeries, including cataract, plastic and reconstructive surgeries. Sushruta was also a great teacher who enabled students gain practical hands-on experience in surgical skills by making incisions on the skin of fruits. Inspired by such a glorious past, the Mahatma Gandhi Medical (MGM) College and Research Institute has built itself a reputation for medical education in India. The next stage in its evolution of becoming an integrated healthcare player has been the launch of India’s first USGBC LEED Platinum-certified hospital in Chennai, Tamil Nadu – MGM Healthcare. Its genesis is a “health-caring movement”, which redefines the patient experience across all parameters, through design, expertise, technology and environmental sustainability.

Lighting was recognized as an imperative element in this health-caring movement to support doctors and therapists during treatments, and promote the healing process in patients with an increased sense of wellbeing. The right light at the right time in the right place was considered critical in this movement characterized by acute cost awareness and savings as a result of lower energy costs. With a built-up area of over 300,000 sq. ft., this 11-floor 400-bedded super-specialty hospital is optimally designed to provide the most comforting ambience for healthcare. Every aspect of the hospital reflects an ethos of healing and a sense of serenity, from the city’s tallest vertical garden to the use of music therapy in critical care areas, to thematic art galleries on each floor celebrating various facets of Tamil Nadu. These myriad tasks and the vastly differential spaces and users demanded a variety of lighting treatments without compromising energy efficiency. Although utility in terms of way finding was non-negotiable, there was a lot of latitude to experiment with in terms of brightness, colour temperature and colour rendering. However, one general principle followed throughout the hospital was to make the effect of the 100% solid-state lighting as natural as possible so as to provide a better sense of wellbeing among patients and staff.

Lobby and VIP Lounge

The preliminary brief was to provide the functionality and style of a hospitality environment so as to elicit a certain emotional response from the hospital users. Therefore, the lobby had to be inviting yet professional to complement the furnishings and decor for creating an overall appeal. While a well-lit lobby was essential, care was taken not to flood it with overabundant illumination that might create environments akin to an emergency room. The lobby was divided into entrance, reception and waiting areas, with each area receiving its own lighting treatment to provide a different ‘feel’ for every area. The reception desk is well-lit and prominently highlighted with a decorative pendant in 3000K so that patients and visitors know exactly where to go first, and have adequate illumination for reading and signing necessary paperwork. The VIP Lounge is a waiting area specially allocated for important guests and visitors. The lighting solution was to create a relaxed and soothing atmosphere. Ceiling-mounted cylindrical 3000K downlights with adjustable heads provide accentuated illumination, which can also be used to highlight the paintings on the walls. Decorative floor lamps and wall-mounted up-downlights in 3000K are added next to seating areas to enable guests lounge with a book or socialize. Gold-finish luminaires are specified to match the beige and gold colour scheme used in the entire lobby and lounge areas.

Corridors

Great care had to be taken while moving patients in stretchers or wheelchairs so as to avoid direct glare from the corridors lighting. Bespoke ceiling-recessed double-asymmetric linear profiles in 4000K ‘wash’ the two walls of the corridors to provide glare-free vertical illumination as well as enable way finding. For nighttime use, these linear profiles can be dimmed using an analogue rotary-dimmer mounted on the entry walls of each corridor. Decorative pendants in 3000K highlight the nurse stations in all these corridors. In the executive floor corridors catering to the high-end suite rooms, circular coves with 3000K LED tape are used to provide soft warm illumination akin to a hotel corridor. Bespoke wall-mounted decorative up-downlights in 3000K provide supplemental illumination in all corridors.

Doctors’ office

The doctors’ offices combine the dual tasks of a regular office and an examination room. Office lighting has to be ergonomically correct and individually adaptable. Examination room lighting requires high levels of general illumination and good colour rendering to show the true tone of the skin for visual examination and deciding the right treatment. However, since majority of the consultancy in a doctor’s office consists of simply talking with the patient, soft general illumination was the best lighting solution. Modular panel luminaires in the modular grid ceiling were the best way of reaching the 500lux average requirement with a colour temperature of 4000K and high Ra 90 value.

Administration office

Direct indirect combined with task lighting provided the optimum-working environment for all paper and screen work in the hospital administration office. Decorative circular pendant luminaires of different sizes and configurations were used to create more intimacy and less of a clinical look. These luminaires were also selected to match with the exposed ductwork in the ceiling.

Cafeteria

When deciding how to light the cafeteria, it was important to determine the type of mood to be created based on itshours of operation. As this is a high-energy establishment with staff and visitors using the place 24×7, it required bright lighting to keep them awake and alert.

The ambient and punctual lighting elements define the design and feel of this cafeteria. Large windows let in ample amount of natural light during the day, while the rhythmic composition of ‘floating’ 3000K linear profiles integrated between the wooden rafters provide illumination at night.

Training rooms

The training rooms for conducting special training sessions for doctors also doubles up as an auditorium for hosting major conferences. Therefore these rooms were much more than spaces where doctors come to sit and learn – they’re dynamic environments where people meet, learn, share ideas and collaborate. In order to provide such flexibility, lighting has been designed for easy preprogramming and dimming. Ceiling coves with LED tapes in 4000K provide ambient illumination to eliminate glare and fill in the shadows on faces so that people look well. Additional spotlights in 4000K provide accentuated illumination.

Green wall

The pre-function area outside the training rooms features the city’s tallest vertical garden in the form of a living green wall. Although the large skylight allows ample natural light required for photosynthesis, supplemental illumination was required for those sections of the wall not receiving the required illumination. Additionally, the living wall becomes a nighttime feature especially during conferences, hence required special highlighting. Linear grazers in 4000K were used from the top-downwards and below-upwards to evenly wash the green wall. Rest of the lighting in the pre-function area was kept to be bare minimum to maintain focus on the green wall.

Façade and Landscape

With the aim of becoming India’s first USGBC LEED Platinum-certified hospital, the criteria were fairly clear with respect to minimising light trespass from the building and site, reducing sky-glow to increase night sky access, improving night-time visibility through glare reduction and reducing development impact from lighting on nocturnal environments. Minimal lighting is provided to highlight the façade patterns & low-level bollards are used to provide glare-free exterior lighting.

Few hospitals have a perfect lighting system, as the lighting demands are complex, and the need is for unique solutions that benefit both staff and patients. MGM Healthcare has strived to realise its motto of providing better health with lighting as one of the key elements.

Author Dr. Amardeep M. Dugar

Photographs Gowtham Raj

Project details

Location: Chennai – Tamil Nadu, India Client: Mahatma Gandhi Medical College & Research Institute Architecture: KGD Architecture Green Consultants: Conserve Consultants Lighting design: Lighting Research & Design Luminaire supply: Gojis Lifestyle + StudioPlus

http://lighting-rnd.in/

0 notes

Text

Missiles and Meal Service: The Hidden Toll of Flying in War-zones

Common occupational hazards in aviation; the not so new flight deck stressors would encompass turbulence, delayed pushbacks, and that one passanger having an issue with someone reclining their seat (this is so very common, believe me). Let’s not forget another one who thinks the seatbelt sign doesn’t apply to them while on active runway (because they are just itching for a snack they left inside their carry-on luggage in the overhead bin. Opens bin, then bag falls off on them and everyone around. SMH)

Back to business. Pilots and cabin crew flying over the Middle East lately, especially in and out of Qatar, well, there’s a new, less subtle source of anxiety: missile attacks. Who doesn’t know the news by now?

Yes, flying into Doha these days might involve dodging airspace closures, U.S. airbase targets, and the occasional Iranian and Israeli news. Glamorous, right?

Very.

While passengers worry about delayed in-flight meals and Wi-Fi speeds being too slow or disconnecting , the crew up front and in the aisles are dealing with something much much heavier: the psychological toll of flying through a region where geopolitics are very unpredictable, stormy, and always just over the horizon.

What Happened in Qatar Exactly, you ask?

In resent years, we’ve witnessed sensitive airspaces and in response, airlines have shut down their airspaces. Flights being rerouted faster than a teenager dodging chores have become commonplace, and airline dispatchers around the world had one collective panic attack.

Now just imagine this. Inflight, flight crew are prepping beverage carts while air defence systems light up the radar. Boom-Chaka-Boom! Just another day in the skies.

Cabin Pressure: Flying with a Side of Adrenaline

Yes, crew (deck crew and cabin crew) are trained to handle demarcates, but war is not an average Emmergency! It’s one thing to worry about fuel efficiency. It’s another to fly over a region where missiles are a real-time hazard.

There is a huge difference between trusting an aircraft, the team, and trusting geopolitics.

Constant anticipatory anxiety.

Hypervigilance, even on layovers.

The unsettling knowledge that their aircraft might share airspace with defense drones, military jets, and… well, more missiles.

Hospitality Meets Hostility

Cabin crew, as you know, are the face of calm, smile and all. Even so, smiling while you serve fish, beef and a gluten free meal on a flight skimming a conflict zone? That’s dark art right there.

Results:

Crew becoming emotionally disconnected from their jobs.

Guilt when evacuating people while others are left behind. 2020 clears throat!

Luxury inflight service inside a pressure cooker floating mid air at 40,000 feet while those on ground are ducking. Definately dystopian!

More Fuel, More Detours, More Fatigue

Yep! Practical stress:

Flights being rerouted to avoid hot zones, adding hours to duty time.

Longer flight hours mean more fatigue, which affects both performance and emotional bandwidth.

There’s no glamour-AT ALL in a 15 hour turnaround because there is no clearance to land.

What Airlines Are Maybe doing

Critical Incident Stress Management teams.

Therapy appointments.

Pre and post dispatch briefings.

Even so, lots of crews feel out of the loop. Why you ask?Because, you get the news that you’re flying a risky zone when you’re already on it.

Hidden Costs: Forget Fuel and Insurance

Mental Health RiskWhat It Looks LikePTSD or traumaFlashbacks, fawning, sleep interruptions, avoidanceBurnoutEmotional numbness, lack of purposeAnxietyReccuring worry, overanalysing proceduresIsolationFeeling detached and lack of support on layovers or at home

These risks don’t show up on a flight log, but hey, they impact safety, morale, and retention. We talk about maintaining aircraft fatigue limits. What about crew fatigue limits?

Where Do We Go From Here?

How about a Flight Plan for Mental Health in Conflict Zones:

Transparent Security Briefings.

Weight & balance before takeoff is paramount, so is mental health balance.

Flight Debriefs After High-Stress Flights.

Better Global Oversight, meaning ICAO, IATA and other relevant bodies must update protocols for mental wellness involving high-risk routes.

Bottom line, pilots and cabin crew are indeed professionals for they train, adapt, and make sure to get the job done. But, they are people too and not robots. People who fly into the world’s most dangerous zones with nothing more than a safety manual and nerves of steel.

We owe them patience, understanding, protection and genuine support as they navigate war zones with grit and grace.

Fly safe. Check on your crew friends, and just maybe skip the missile jokes during boarding.

Source: Missiles and Meal Service: The Hidden Toll of Flying in War-zones

3 notes

·

View notes

Text

Monochrome Digital photography In The Digital Age By Low Jeremy.

Trainees couldn't wait for July, when the brand-new name comes to be official, so they improved the university's indications themselves. White possums, also referred to as lemuroid ringtails, are discovered simply above 3000 feets in the plants in Daintree forests and are actually quite sensitive to temp improvements. We have actually found some great white pies in our opportunity, and also those ones definitely deserve our interest. Because of his Muslim article source name Khan, Khan's other half began to criticize him of what happened. Another label that has caused a fair volume from complication through this calling structure is the 'top light brown'. After that, perform your due diligence to take a look at testimonials, find out your cleaning professional's name as well as what types of repayment they take prior to they turn up at your door, March suggests. As is actually signified in the reputation, there are actually seven towers over in Disney's Powder snow White motion picture. Much from the blame can be placed straight at the feet of President Trump, which has actually steadfastly chosen not to name nominees to over 200 government placements. That may also suggest a white colored panther, which is actually a cougar, cat, or even leopard , but along with all white colored fur, or even incredibly pale hair. Select C travel in which the previous OS is put up (Take care) and also delete it. (If you want to conduct well-maintained install remove all dividers). A really pleasant means to start profaning is to merely utilize sounds to convey exactly what you locate pleasurable. People was actually preserved by Peabody Power to provide review from EPA's Clean Electrical power Planning. If you wish to add a little light to your shade yard, choose 'Gilt Side,' which includes white blossoms along with purple areas and also glossy fallen leaves with golden edges. Likewise see to it to cleanse the rug lengthwise, do not leave behind a single area untreated. Lately, Amardeep Singh, a Sikh committed and co-founder and course director of the Sikh Union, the biggest Sikh company Human Rights in the United States were actually needed to the Advisory Committee of the White Home. The main reason for the title may be an early job of shades to the path from the compass-- dark pertaining to the north, and also reddish describing the south. The decisive guideline is actually readied to the dirty guideline very first (as this macro has actually been contacted this is taken over that the dirty tip suggest a now-complete set from records). That truly bothers me, I thought it has to must do one thing with my obsessive uncontrollable disorder as well as my cope this, my key repulsion with unclean restrooms. Often along with beautiful views from White Moss if you stray off the road you are going to discover numerous delightful spots. After participating in the Guy without Title in Sergio Leone's 'spaghetti Westerns' in the 1960s, Eastwood ended up being Dirty" Harry Callahan, the police officer that broke all the rules. Also located in Luzerne Region, Pennsylvania, Natural honey Container acquired its label coming from the swarms from untamed honey bees at that location. Insects need natural dust that arises from losing skin, household pet dander, animal food, pee and cocktail spills, hair, and also sweat, simply to name a few sources. It is actually supposedly a simple and quick means to clean regions (or clothing) in your residence. They simply lug an incredibly unusual genetics that creates their hair white instead of orange (as well as gives them blue eyes), while still maintaining the red stripes. As opposed to minimizing the name to something less complex, search for methods which the total business label may be exemplified through equally as a picture.

0 notes

Text

ST52 Seamless Tubes – The Industrial Standard for Reliability

By Amardeep Steel Centre LLP – Trusted ST52 Carbon Steel Pipe Distributor in India

In the world of industrial engineering and structural applications, ST52 Seamless Tubes have earned a reputation for unmatched strength, precision, and dependability. Made from high-quality carbon steel, these tubes are built to withstand extreme loads and harsh environments, making them an essential component in various industries.

At Amardeep Steel Centre LLP, we take pride in being a leading ST 52 Tubes Supplier and EN 1.0570 Precision Steel Tube supplier in Mumbai, delivering quality that performs under pressure.

🔍 What Sets ST52 Seamless Tubes Apart?

✅ High Tensile Strength – Perfect for heavy-duty applications and high-stress conditions.

✅ Excellent Toughness – Withstand impacts and dynamic loading without deformation.

✅ Flawless Surface Finish – Suitable for precise machining and hydraulic applications.

✅ Superior Weldability – Easy to fabricate and customize in complex systems.

✅ Corrosion Resistance – Long-lasting performance even in demanding environments.

Whether you’re sourcing DIN 1.0570 Seamless Steel Tubes, ST52.3 Steel Cold Finished Tube, or ST52 Hot Finished Seamless Tubes, Amardeep Steel Centre LLP has you covered.

🏭 Applications of ST52 Seamless Tubes:

🏗 Structural Engineering – Used in columns, beams, and load-bearing frameworks

🚜 Automotive and Heavy Machinery – Ideal for axles, frames, and components

🔩 Hydraulic Systems – Perfect fit for precision cylinders and actuators

🏭 Oil & Gas Industry – Trusted for pipeline construction and fluid transport

🛠 General Fabrication – Used in tools, equipment, and mechanical systems

🌍 Why Choose Amardeep Steel Centre LLP?

🌟 Trusted Supplier of ST 52.3 Steel Welded Tube

📍 Based in Mumbai, supplying across India & globally

🧪 Full Quality Certifications and Material Traceability

🔧 Customization Available in Size, Shape & Finish

📦 Quick Delivery & Competitive ST52 Tube Pricing

We are proud to be recognized as a top ST52 Carbon Steel Pipe distributor in India, delivering only the best in reliability and service.

📐 Know the Material – ST52 (DIN 1.0570 / EN 1.0570)

Grade: ST 52.3 / EN 1.0570

Type: Carbon Steel

Form: Seamless & Welded Tubes

Properties: High strength, ductility, and excellent formability

🔗 Strength. Precision. Trust.

Choose ST52 Seamless Tubes from Amardeep Steel Centre LLP – Where quality meets industrial excellence.

0 notes

Text

Why ST52 Welded Pipes & Tubes Are Preferred for Structural Applications

By Amardeep Steel Centre LLP – Trusted ST 52.3 Carbon Steel Welded Pipe Supplier

When it comes to modern structural engineering, the materials chosen play a significant role in determining the safety, durability, and long-term performance of any project. One such material that has gained wide acceptance in the industry is the ST52 welded pipe. Its strength, weldability, and cost-effectiveness make it an ideal choice for structural applications.

At Amardeep Steel Centre LLP, we take pride in offering high-quality ST52 Carbon Steel Welded Pipe and DIN 2391 ST52 Welded Pipe solutions to meet the evolving demands of construction and engineering industries.

🔍 What is ST52 Welded Pipe?

ST52 welded pipes are made from low alloy carbon steel with enhanced strength and toughness. These pipes are manufactured under the DIN 2391 ST52 Pipe specification and are commonly used in structural, mechanical, and civil engineering applications. The welded construction allows for greater flexibility in large-scale production while maintaining high mechanical integrity.

We offer both DIN 2391 ST 52 ERW pipe and standard welded variants to suit a wide range of technical requirements.

🛠️ Key Advantages of ST52 Welded Pipes in Structural Applications

✅ High Yield & Tensile Strength

ST52 Carbon Steel Welded Pipe is engineered to handle high-stress environments. Its mechanical properties support heavy load-bearing and structural reliability.

✅ Superior Weldability

The material offers excellent weldability, making it easier for fabricators to create complex frameworks without compromising strength.

✅ Cost-Effective & Efficient

Compared to seamless pipes, ST52 welded pipes are more economical and quicker to produce—without sacrificing performance for structural use.

✅ Dimensional Accuracy

DIN 2391 ST52 Welded Pipe ensures consistency in wall thickness and outer diameter, crucial for precision in structural assemblies.

✅ Corrosion Resistance

ST52 steel provides good resistance to atmospheric corrosion, particularly important in outdoor and exposed installations.

🏢 Common Applications of ST52 Welded Pipes

Structural frameworks for buildings and bridges

Machinery bases and equipment frames

General fabrication and civil structures

Automotive body frames and chassis components

Architectural supports and construction scaffolding

Industrial fabrication and plant construction

Whether you are working on a high-rise structure or building heavy industrial equipment, DIN 2391 ST 52 ERW Pipe offers the strength and flexibility you need.

🌐 Why Choose Amardeep Steel Centre LLP?

As a leading ST 52.3 Carbon Steel Welded Pipe Supplier, we offer:

✅ Certified products with mill test reports

✅ Timely delivery across domestic and international markets

✅ Custom sizes, wall thicknesses, and surface finishes

✅ Decades of experience in structural steel supply

✅ Competitive pricing and quality assurance

📞 Ready to Build with Strength?

Connect with Amardeep Steel Centre LLP for top-grade ST52 Welded Pipes and DIN 2391 ST52 Pipe tailored to meet your structural needs. Let us support your next project with reliable materials and expert service.

0 notes

Text

In today’s demanding industrial environments, the need for materials that can endure high pressure, extreme temperatures, and corrosive conditions is more critical than ever. Alloy Steel T11 Tubes have emerged as a reliable solution for high-pressure systems, particularly in industries such as power generation, oil & gas, petrochemicals, and boilers. These tubes offer superior strength, thermal resistance, and corrosion protection.

At Amardeep Steel Centre LLP, we are a leading ASTM A213 / ASME SA213 T11 Alloy Steel Seamless Tube Manufacturer, delivering top-quality tubing solutions for high-stress applications around the world.

What is Alloy Steel T11?

Alloy Steel T11 is a ferritic alloy used in seamless tubing applications, specifically designed for high-temperature service. Composed of chromium and molybdenum, T11 tubing offers excellent resistance to oxidation and corrosion while maintaining structural stability under thermal stress.

UNS K11597 T11 Boiler Tube is the unified numbering system designation for this grade.

It conforms to both ASTM A213 T11 tubing and ASME SA213 T11 tubing standards.

Key Specifications of ASTM A213 T11 Tubing

As per the ASTM A213 Standard, T11 tubing is defined for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes.

ASTM A213 T11 Tubing Specification Includes:

Outside Diameter: 6mm to 101.6mm

Wall Thickness: 1mm to 12.7mm

Length: Single Random, Double Random & Custom Lengths

Forms: T11 Alloy seamless rectangular tube, round tubes, and U-bend configurations

Why Alloy Steel T11 Tubes Are Perfect for High-Pressure Systems

1. High Creep and Rupture Strength

ASME SA213 T11 Alloy Steel SMLS Tubes are engineered to withstand elevated pressure and temperature over long periods, offering exceptional creep resistance. This makes them perfect for boilers and steam piping systems.

2. Thermal and Oxidation Resistance

The chromium and molybdenum content in Alloy Steel A213 T11 Tube enhances oxidation resistance, allowing these tubes to perform efficiently in environments with continuous thermal cycling.

3. Excellent Weldability and Fabrication

T11 tubes have excellent weldability, which means they can be easily installed in complex piping networks without compromising their structural integrity.

4. Ideal for Boiler & Heat Exchanger Applications

UNS K11597 T11 Boiler Tube and EN 10216-2 10CrMo5-5 Boiler Fin Tube are commonly used in heat exchangers and boilers, where high-pressure steam and heat transfer are routine.

5. Seamless Construction

As a leading ASME SA213 T11 Alloy Steel Seamless Tubes supplier, we ensure that our tubes are free from welding joints, which minimizes the risk of failure under pressure.

Common Applications of T11 Alloy Steel Tubes

High-pressure boiler systems

Superheaters and reheaters in thermal power plants

Heat exchangers in petrochemical refineries

Pressure vessels in chemical industries

Steam piping systems in power generation

Why Choose Amardeep Steel Centre LLP?

As a reputed Alloy Steel A213 T11 Tube Manufacturer in India, Amardeep Steel Centre LLP provides superior tubing solutions with strict quality control and third-party inspection. We stock and supply a wide range of ASTM A213 T11 tubing and ASME SA213 T11 Alloy Steel Seamless Tubes in various sizes and shapes including round and T11 Alloy seamless rectangular tube.

With decades of industry experience and a global client base, we ensure timely delivery, competitive pricing, and adherence to international standards.

0 notes

Text

Why Inconel 718 Round Bars Are Preferred for High-Stress Applications

Amardeep Steel Centre LLP is a leading supplier and exporter of Inconel 718 Round Bars, renowned for their outstanding performance in high-stress and high-temperature applications. These round bars are manufactured using a nickel-chromium-based superalloy, which includes essential elements like molybdenum, niobium, iron, and titanium. This unique composition enhances the strength, durability, and corrosion resistance of Inconel 718 round bars, making them a preferred choice in critical industrial applications.

🔹 Why Inconel 718 Round Bars Excel in High-Stress Applications:

✅ High Tensile and Yield Strength: Inconel 718 round bars exhibit remarkable tensile and yield strength, even under extreme load and pressure conditions. This high-strength property makes them ideal for applications where mechanical stress is a major concern.

✅ Superior Fatigue and Creep Resistance: These bars are specifically designed to withstand fatigue and creep deformation over prolonged exposure to high temperatures. They maintain their structural integrity, preventing cracks and deformation, even after long-term service in elevated temperature environments.

✅ Corrosion and Oxidation Resistance: Inconel 718 round bars provide excellent resistance to oxidation and corrosion in various aggressive environments, including acidic, alkaline, and seawater conditions. This property makes them suitable for offshore, chemical, and marine applications.

✅ Thermal Stability at High Temperatures: These round bars retain their mechanical properties at temperatures ranging from cryogenic conditions up to 700°C, making them perfect for applications that demand high thermal stability.

✅ Excellent Weldability and Machinability: Inconel 718 bars can be welded and fabricated with ease, offering greater flexibility in complex engineering designs and structures. Their excellent machinability enhances productivity while ensuring precision in various applications.

📌 Key Applications of Inconel 718 Round Bars:

🔸 Aerospace and Aviation: Used extensively in turbine blades, jet engines, afterburners, and exhaust systems due to their high heat and stress resistance.

🔸 Gas Turbines and Power Generation Plants: Ideal for high-temperature components, including turbine disks, heat exchangers, and combustion chambers, ensuring reliability in power plants.

🔸 Oil and Gas Industry: Inconel 718 round bars are utilized in downhole tools, wellhead equipment, and pipeline systems that encounter extreme pressure and corrosive environments.

🔸 Marine and Subsea Applications: Highly resistant to seawater and chloride-induced corrosion, making them suitable for offshore platforms, marine hardware, and subsea components.

🔸 Chemical and Petrochemical Processing: Widely used in heat exchangers, reactors, and pressure vessels that handle corrosive chemicals and operate at high temperatures.

🎯 Why Choose Amardeep Steel Centre LLP for Inconel 718 Round Bars?

✅ ISO-Certified Manufacturer with Over 40 Years of Industry Expertise ✅ Precision Engineering and Strict Quality Control Standards ✅ Wide Range of Sizes and Specifications Available ✅ Quick Turnaround and Global Supply Capability ✅ Trusted Vendor for Industry Giants like KNPC, Alfa Laval, L&T, and Qatar EnergyWith a commitment to quality and precision, Amardeep Steel Centre LLP ensures that Inconel 718 round bars meet international standards and provide unmatched performance in critical applications.

0 notes

Text

Inconel 625 Round Bar: A Game-Changer for Aerospace Heat Shields and Exhaust Systems

Introduction

Inconel 625 is a high-performance nickel-based superalloy known for its excellent strength, corrosion resistance, and high-temperature stability. These properties make Inconel 625 round bars an ideal choice for aerospace applications, particularly in heat shields and exhaust systems. This alloy can withstand extreme thermal conditions, making it a crucial material in industries requiring high durability and resistance to oxidation.

Inconel 625 Applications in Aerospace

Due to its outstanding mechanical properties, Inconel 625 is widely used in various aerospace components, including:

Heat Shields: Provides thermal protection in high-temperature environments.

Exhaust Systems: Withstands extreme heat and oxidation.

Jet Engine Components: Ensures durability under extreme stress.

Turbine Blades & Ducting Systems: Offers excellent resistance to creep and fatigue.

Rocket Motor Casings: Provides high strength-to-weight ratio and oxidation resistance.

Key Properties of Inconel 625 Round Bars

High-Temperature Resistance: Performs well in extreme heat and oxidizing conditions.

Superior Corrosion Resistance: Resists pitting, crevice corrosion, and oxidation.

Excellent Weldability & Fabrication: Can be easily machined and welded for complex aerospace structures.

Fatigue & Creep Resistance: Ensures long-term performance under mechanical stress.

Non-Magnetic: Suitable for critical aerospace applications.

Inconel 625 Round Bar Price & Availability

The price of Inconel 625 round bars depends on various factors such as size, supplier, and market conditions. Due to its superior properties, it is considered a premium alloy, but its durability and longevity provide excellent value for aerospace applications.

For the most competitive Inconel 625 round bar price, connect with reliable Inconel 625 suppliers in the UK, such as Amardeep Steel Centre LLP, offering high-quality materials at competitive rates.

Leading Inconel 625 Suppliers in the UK

Finding a trusted supplier is crucial for ensuring material quality and performance. Amardeep Steel Centre LLP is a renowned supplier of Inconel 625 round bars, catering to aerospace, marine, and industrial applications in the UK and globally.

Why Choose Us?

Premium Quality Material

Competitive Pricing

Reliable & Timely Delivery

Expert Technical Support

Conclusion

Inconel 625 round bars are a game-changer in the aerospace industry, particularly for heat shields and exhaust systems. Their exceptional corrosion resistance, high-temperature strength, and mechanical durability make them a preferred choice for demanding applications. For top-quality Inconel 625 round bars, competitive pricing, and reliable supply in the UK, trust Amardeep Steel Centre LLP—your global metal solutions provider.

For inquiries, pricing details, or technical specifications, contact us today!

0 notes

Text

Inconel 718 Round Bar : The Backbone of Jet Engine Components

In the aerospace industry, where extreme temperatures and high-pressure conditions are the norm, materials must offer superior strength, corrosion resistance, and thermal stability. Inconel 718 round bar has emerged as a top choice for manufacturing critical jet engine components. This nickel-based superalloy is renowned for its excellent mechanical properties, making it indispensable in the aviation sector.

Why Inconel 718 Round Bar is Ideal for Jet Engine Components

Jet engines operate under extreme conditions, requiring materials that can withstand high heat, pressure, and corrosive environments. Inconel 718 bar stock is known for its exceptional properties, including:

High-Temperature Resistance: Inconel 718 maintains its strength and toughness even at temperatures up to 1300°F (704°C).

Corrosion and Oxidation Resistance: It resists oxidation, pitting, and crevice corrosion, ensuring durability in aerospace applications.

Excellent Creep and Stress Rupture Strength: The alloy prevents deformation under prolonged exposure to high-stress conditions.

Good Weldability: Unlike many other superalloys, 718 Inconel round bar can be welded without cracking, making it easier to fabricate complex components.

Superior Fatigue Resistance: It ensures longevity and reliability in dynamic applications like aircraft engines.

Applications of Inconel 718 Bar in Aerospace

Due to its outstanding properties, Inconel 718 bar is widely used in various jet engine components, including:

Turbine Blades: Withstanding high rotational speeds and extreme temperatures.

Compressor Discs: Ensuring the efficient compression of air before combustion.

Combustion Chambers: Handling intense heat and pressure conditions.

Fasteners and Bolts: Providing secure fittings in engine assemblies.

Choosing the Right Inconel 718 Bar Suppliers

When sourcing Inconel 718 round bar, it is crucial to choose a reliable supplier that guarantees quality and compliance with industry standards. Amardeep Steel Centre LLP is a leading supplier of high-quality Inconel 718 bar stock, catering to the aerospace, automotive, and marine industries. We provide certified materials that meet stringent industry specifications.

Inconel 718 Round Bar Price Considerations

The Inconel 718 round bar price depends on factors such as size, grade, and order quantity. Market fluctuations, raw material availability, and custom processing also influence pricing. At Amardeep Steel Centre LLP, we offer competitive pricing and customized solutions to meet diverse industry requirements.

0 notes

Text

A286 / 660D: A High-Temperature Alloy for Aerospace Fasteners

Aerospace applications demand materials that can withstand extreme conditions, including high temperatures, pressure, and corrosion. One such material widely used in aerospace fasteners is A286 / 660D, a high-strength, corrosion-resistant superalloy. This alloy is designed to perform exceptionally well in elevated-temperature environments, making it a preferred choice in the aerospace and automotive industries.

What is A286 / 660D?

A286, also known as Alloy 660, is an iron-based superalloy that exhibits excellent mechanical strength, oxidation resistance, and high-temperature stability. This material is commonly used in fasteners, springs, and components that require superior strength and corrosion resistance under extreme heat conditions.

A286 / 660D is available in various specifications, including AMS 5737, AMS 5731, and AMS 5732, each offering specific properties suitable for different aerospace applications.

Key Properties of A286 / 660D

High-Temperature Strength: A286 / 660D retains its mechanical properties at temperatures up to 1300°F (700°C), making it ideal for aerospace fasteners.

Oxidation & Corrosion Resistance: The alloy resists oxidation and corrosion in harsh environments, ensuring durability in jet engines and gas turbines.

Excellent Creep Resistance: A286 / 660D can withstand prolonged exposure to high stress and temperature without deformation.

Good Fabricability & Weldability: The alloy can be readily machined and welded, making it a versatile option for manufacturing complex aerospace components.

Applications of A286 / 660D in Aerospace Fasteners

A286 / 660D is extensively used in the aerospace industry due to its high-performance characteristics. Some common applications include:

Turbine Engine Fasteners: High-temperature stability ensures the integrity of critical engine components.

Exhaust Manifold Bolts & Studs: High resistance to thermal expansion and oxidation.

Jet Engine Components: Ensures longevity and reliability in high-stress environments.

Structural Fasteners: Used in aircraft frames to provide strength and corrosion resistance.

ASTM A286 & AMS 5737 Material Specifications

A286 / 660D is manufactured in compliance with industry standards such as ASTM A286 and AMS 5737 material. These standards ensure the alloy meets the required mechanical and chemical properties for aerospace-grade fasteners.

AMS 5737: Covers solution-treated and age-hardened A286 bars and forgings for high-strength applications.

AMS 5731 & AMS 5732: Provide specifications for other variations of A286 tailored to specific aerospace and industrial requirements.

Why Choose Amardeep Steel Centre LLP for A286 / 660D Fasteners?

At Amardeep Steel Centre LLP, we are a leading supplier of high-performance alloys, including AMS 5732 material, AMS 5737, and ASTM A286 fasteners. We offer premium-quality products that adhere to global standards, ensuring reliability and durability in extreme environments. Our expertise in sourcing and supplying high-temperature alloys makes us a trusted partner for the aerospace, automotive, and industrial sectors.

Conclusion

A286 / 660D is an exceptional high-temperature alloy, making it the ideal choice for aerospace fasteners. With superior strength, oxidation resistance, and excellent performance at high temperatures, it meets the rigorous demands of the aerospace industry. Amardeep Steel Centre LLP is committed to providing top-quality AMS 5737 material, AMS 5732 material, and ASTM A286 fasteners to meet your industry requirements. Contact us today for the best solutions in high-temperature alloys!

0 notes

Text

35NCD16: A High-Toughness Alloy Round Bar for Aerospace Landing Gear Systems

The aerospace industry demands materials that offer exceptional strength, toughness, and durability. One such material that stands out in critical applications like landing gear systems is 35NCD16 steel. This high-toughness alloy round bar is known for its superior mechanical properties, making it an ideal choice for aircraft components that require high fatigue resistance and excellent impact strength.

What is 35NCD16 Material?

35NCD16 is a nickel-chromium-molybdenum alloy steel that provides high toughness, excellent hardenability, and good wear resistance. It is widely used in the aerospace sector for manufacturing landing gear, engine components, and structural parts. The combination of nickel, chromium, and molybdenum enhances its ability to withstand high stress and extreme conditions, making it a reliable choice for safety-critical applications.

35NCD16 Equivalent Material

35NCD16 has several equivalent materials that are used across different industries. Some of the commonly recognized equivalents include:

SAE 8620 Steel: A low-alloy steel that offers good toughness and wear resistance, commonly used in aerospace and automotive applications.

ASTM A322: A specification covering alloy steel bars used in mechanical and structural applications.

ASTM A331: A standard for cold-finished alloy steel bars, ensuring high-quality machining and performance.

Applications of 35NCD16 Alloy Round Bars

Due to its outstanding mechanical properties, 35NCD16 material is extensively used in several critical aerospace applications, including:

Landing Gear Systems: Provides exceptional strength and shock resistance to withstand repeated impacts.

Engine Components: Used in high-stress parts due to its high fatigue resistance.

Structural Aerospace Parts: Ideal for frames and supports that require high durability.

Automotive and Defense Applications: Utilized in performance-driven industries where reliability is crucial.

Advantages of 35NCD16 Steel

High Strength and Toughness – Ensures durability under extreme conditions.

Excellent Fatigue Resistance – Enhances lifespan in cyclic loading applications.

Good Machinability – Allows for precision manufacturing of complex aerospace components.

Superior Wear Resistance – Extends the operational life of parts in harsh environments.

Why Choose Amardeep Steel Centre LLP for 35NCD16 Alloy Round Bars?

As a leading supplier of aerospace-grade materials, Amardeep Steel Centre LLP provides high-quality 35NCD16 steel round bars that meet stringent industry standards. Our products adhere to international specifications such as ASTM A322, ASTM A331, and SAE 8620 steel equivalents, ensuring reliability and performance.

We supply 35NCD16 material with precise dimensional accuracy and superior surface finish, making it the preferred choice for aerospace manufacturers worldwide. Whether you require small or bulk quantities, our efficient supply chain ensures timely delivery.

Conclusion

35NCD16 steel is a premium aerospace alloy known for its high toughness, fatigue resistance, and durability, making it an essential material for landing gear systems and other critical applications. If you are looking for a trusted supplier of 35NCD16 alloy round bars, Amardeep Steel Centre LLP offers top-quality products that meet global industry standards.

For inquiries or to place an order, contact Amardeep Steel Centre LLP today and get the best-quality 35NCD16 material for your aerospace needs!

0 notes