#amr robot

Explore tagged Tumblr posts

Text

Meet the AMR Robot: The Smart Teammate Revolutionizing Warehouses

In today’s hyperconnected, fast-paced world of e-commerce and just-in-time manufacturing, warehouses have evolved into strategic nerve centers. No longer just spaces to stash goods, they’re critical hubs that can make or break a business’s ability to deliver quickly, efficiently, and profitably. At the heart of this warehouse revolution stands a sleek, smart, and tireless teammate: the AMR robot, or Autonomous Mobile Robot.

The Rise of the AMR

Gone are the days of bulky machines tied to rails or conveyor belts. Today’s AMRs are nimble, autonomous, and surprisingly intelligent. Using a mix of advanced sensors, real-time mapping, and onboard AI, these robots can independently navigate complex warehouse layouts. They can identify and avoid obstacles, reroute in case of congestion, and reach their destinations without needing fixed paths or constant human intervention.

Think of them as the self-driving cars of the warehouse world—only quieter, more efficient, and trained to never break the speed limit.

A New Age of Warehouse Handling Equipment

When it comes to warehouse handling equipment, the AMR robot is a category-defining marvel. Traditionally, equipment like forklifts, conveyor systems, and pallet jacks required skilled operators and constant supervision. That meant higher labor costs, increased chances of human error, and limitations in scaling during peak demand seasons.

Enter the Autonomous Mobile Robot—a compact, battery-powered solution that works 24/7 without fatigue. Whether it’s moving raw materials to production lines, picking customer orders from shelves, or transporting finished goods to loading docks, AMRs handle it all with unshakable precision.

The result? Fewer mistakes, faster cycle times, and more efficient warehouse operations.

A Teammate, Not a Replacement

A big concern with automation has always been the fear of replacing human workers. But the beauty of AMRs lies in their collaborative nature. These robots are designed to work alongside people, not in place of them. While the AMR robot tackles repetitive, physically taxing, and time-consuming tasks, human workers can focus on strategic responsibilities—like quality control, equipment maintenance, or optimizing processes.

This collaboration between humans and machines boosts morale at work in addition to productivity. No more exhausting journeys via enormous warehouses or back-breaking lifting. Workers instead take on the role of overseers of efficiency and operators of intelligent systems.

The reasons everyone is discussing AMRs

AMRs are receiving a lot of attention in the industrial and logistics industries for a reason. They are enticing to contemporary businesses because of the following main advantages:

Adaptability: AMRs are easily reconfigurable, in contrast to typical automation systems that need established infrastructure. With minimal downtime, you may scale operations, modify workflows, and adjust to new layouts.

Rapid Deployment: Since AMRs are not reliant on predetermined routes or tracks, they may be deployed rapidly. This is very helpful for businesses that are seasonal or growing rapidly.

Smart Navigation: AMRs navigate through dynamic environments, including those shared with people and forklifts, with confidence by utilising technology such as LiDAR, SLAM (Simultaneous Localisation and Mapping), and obstacle recognition.

Data-Driven Operations: AMRs produce a lot of data, including route efficiency and journey times. This knowledge can enhance overall operational effectiveness and optimize warehouse layouts.

Safety First: With sensors and integrated safety procedures, AMRs lower the possibility of mishaps, making them a reliable component of contemporary warehouse handling machinery.

Not only for storage facilities

Autonomous Mobile Robots are becoming more and more popular in a wide range of other settings, even though they excel in warehouses. They deliver lab samples and medications to hospitals. They manage security and baggage at airports. They oversee the replenishment of goods in shop backrooms. Because of their versatility, they can be used in any facility that has to move items precisely and repeatedly.

Bottom-Line Enhancers

Although the technology is impressive, what about the ROI?

AMRs save money over time in a number of ways. They minimise downtime from fatigue or absence and reduce workforce expenses by minimising reliance on human labour. Their accuracy reduces order errors and product damage. Additionally, businesses benefit from improved service levels and quicker turnaround times due to their ability to work continuously.

Determine the difference between AMR and AGV

AMRs and AGVs (Automated Guided Vehicles) are frequently confused in the automation field. Although they are both utilised for material transportation, their navigational strategies differ significantly.

AGVs are dependent on fixed pathways, such as implanted wires, magnetic strips, or QR codes. They halt and wait for anything to move out of their way. AMRs, however, are more intelligent. They avoid obstacles, adjust to shifting conditions, and plot routes dynamically using onboard intelligence.

Because they offer flexibility and scalability that conventional automated guided vehicles just cannot, AMRs are sometimes regarded as the next generation of AGVs.

What will happen to AMRs next?

The capabilities of the AMR robot will advance in tandem with advancements in robotics, artificial intelligence, and warehouse management systems. Better object detection, collaborative arms for choosing, and even machine learning-based route optimisation are possible features of future versions.

And we may anticipate seeing these robots in mid-sized and even small businesses, not just the major players, as they become more widely available and reasonably priced.

It could be time to consider when, rather than if, you will implement AMRs if you work in manufacturing, logistics, or any other industry that requires moving materials. Because neither your customers nor the future are waiting.

0 notes

Text

Robouter Cerebro Robot

Robouter Cerebro Robot : El Cerebro de Alto Rendimiento para la Revolución de la Robótica Industrial En la era de la Industria 4.0, la automatización industrial y la eficiencia operativa son fundamentales para la competitividad. Exellios® presenta Robouter, una innovadora solución de alto rendimiento diseñada para potenciar Vehículos Guiados Automatizados (AGV) y Robots Móviles Autónomos (AMR).…

#Almacén automatizado#automatización industrial#Cómo mejorar la eficiencia con robots móviles autónomos#Codificación de video de alta resolución#Comprar computadora integrada AGV#Computadora de placa única AGV#Computadora de placa única AMR con procesamiento de video 8K#Computadora de placa única para robots móviles autónomos#Computadora integrada AGV#Conectividad industrial#Exellios Robouter#Fábrica inteligente#Gateway LoRaWAN 5G#Gateway LoRaWAN 5G para aplicaciones industriales#Gateway LoRaWAN 5G para entornos industriales#Industria 4.0#Inteligencia artificial (IA) robótica#IoT Industrial#Logística automatizada#Mejor computadora de placa única para AMR#Navegación autónoma#Placa de computadora integrada AGV con IA#Procesador octa-core para robótica industrial#Procesamiento de video 8K#Robótica industrial#Robots móviles autónomos (AMR)#Robouter#Sistema de control de alto rendimiento para AGV#Sistemas de navegación autónoma para AGV de almacén#Sistemas integrados industriales

0 notes

Text

Small but Mighty: The Gear Motor Changing the Robotics Game

Robots are becoming smarter, more compact, and more powerful than ever—and at the heart of this evolution is the compact gear motor. Just because it’s small doesn’t mean it lacks strength.

From collaborative robots to autonomous delivery bots and warehouse automation systems, compact drive technology is reshaping how robots move, work, and interact with the world. But what makes these small components such a big deal?

In our latest blog post, we break down the rising demand for compact gear motors in robotics and how BonSystems’ BSR reducers and BCSA smart actuators are pushing the boundaries of what's possible in tight spaces.

Curious how compact can still mean powerful? 🤖[Why the Robotics Industry Is Turning Its Eyes to Compact Gear Motors]

#Robotics#GearMotors#Automation#SmartActuators#CycloidalReducer#RobotDesign#AMR#AGV#CollaborativeRobots#BonSystems#FutureOfMotion

0 notes

Text

#Industry40#SmartManufacturing#AI#Automation#Robotics#SupplyChain#DigitalTransformation#FutureOfWork#Innovation#TechRevolution#IoT#Sustainability#Logistics#Cobots#AMRs

0 notes

Text

ABB to Spin Off Robotics Division as Separate Listed Company in Q2 2026

A strong performer in its industry at the core of secular and future automation trends ABB announced plans to spin off its Robotics division into an independent, separately listed company, with the intention of commencing trading in the second quarter of 2026. Strategic Rationale Behind the Spin-off The Swiss technology giant revealed on April 17 that it will propose the full separation of its…

View On WordPress

0 notes

Text

AMR with Industrial Automation Station and COBOT | Manufacturer in Pune

Hytech Didactic in Pune offers AMR and AGV training cells, COBOT automation stations, and robotics systems for education and industry. Explore innovation!

#AMR Training Cell Manufacturer Pune#AGV Training Cell Supplier Pune#Industrial Automation Station with COBOT Pune#Didactic Robocell Pune#Educational Robots Pune#Robotics Training Systems Pune#AMR and AGV Training Pune#Collaborative Robots Training Pune#SMR AGV Manufacturer Pune#Educational AMR Solutions Pune

0 notes

Text

Such a sad sad life. Wake up, work, eat, sleep and repeat

1 note

·

View note

Text

Unleashing Potential: The Rising Autonomous Mobile Robot Market

Introduction:

According to the study by Next Move Strategy Consulting, the global Autonomous Mobile Robot Market size is predicted to reach USD 3.13 billion by 2030, with a CAGR of 13.4% by 2030.

Request a FREE sample, here: https://www.nextmsc.com/autonomous-mobile-robot-amr-market/request-sample

In recent years, the world has witnessed a remarkable surge in the adoption of autonomous mobile robots (AMRs) across various industries. From warehouses to manufacturing facilities, hospitals to retail stores, AMRs are revolutionizing traditional workflows and redefining the concept of automation. As we delve deeper into the dynamics of this burgeoning market, it becomes evident that we are at the cusp of a transformative era, where the potential of AMRs is being unleashed at an unprecedented pace.

The rapid growth of the autonomous mobile robot market can be attributed to several factors. Firstly, advancements in technology, particularly in areas such as artificial intelligence, machine learning, and sensor technology, have significantly enhanced the capabilities of AMRs. These robots are now capable of navigating complex environments, avoiding obstacles, and performing a wide range of tasks with precision and efficiency.

Furthermore, the increasing demand for automation and operational efficiency across industries has fueled the adoption of AMRs. Businesses are constantly seeking ways to streamline their operations, reduce costs, and improve productivity, and AMRs offer a compelling solution to these challenges. By automating repetitive and labor-intensive tasks, AMRs enable organizations to optimize their workflows and reallocate human resources to more strategic and value-added activities.

Moreover, the pandemic has acted as a catalyst for the adoption of AMRs, particularly in sectors such as e-commerce, healthcare, and logistics. The need for contactless and socially distant operations has prompted many businesses to explore robotic solutions for tasks such as inventory management, order fulfillment, and sanitation. AMRs not only help minimize human contact and reduce the risk of transmission but also ensure continuity of operations in the face of disruptions.

The rising demand for AMRs is reflected in the diverse range of industries that are embracing this technology. From e-commerce giants such as Amazon to automotive manufacturers, from healthcare providers to food and beverage companies, AMRs are being deployed across a wide spectrum of applications. Whether it's automating material handling in warehouses, delivering medications in hospitals, or assisting with inventory management in retail stores, AMRs are proving to be versatile and adaptable solutions that can drive significant value for businesses.

Technological Advancements Driving Growth

Technological advancements have played a pivotal role in driving the growth of the autonomous mobile robot market. Over the years, there has been significant progress in key areas such as artificial intelligence (AI), machine learning, sensor technology, and navigation systems, enabling AMRs to perform a wide range of tasks with precision and efficiency.

One of the key breakthroughs in AMR technology is the development of advanced navigation systems. Traditionally, AMRs relied on predefined routes or magnetic tape guidance for navigation. However, recent advancements in simultaneous localization and mapping (SLAM) technology have enabled AMRs to navigate autonomously in dynamic and unpredictable environments. SLAM algorithms allow AMRs to create a map of their surroundings in real-time and localize themselves within that map, enabling them to navigate efficiently and avoid obstacles.

Another area of advancement is in the field of artificial intelligence and machine learning. AMRs are equipped with sophisticated AI algorithms that enable them to perceive and interpret their environment, make intelligent decisions, and adapt to changing conditions. Machine learning algorithms allow AMRs to learn from experience and improve their performance over time, making them more efficient and effective in their tasks.

Sensor technology is also playing a crucial role in enhancing the capabilities of AMRs. AMRs are equipped with a variety of sensors such as cameras, lidar, ultrasonic sensors, and infrared sensors, which allow them to perceive their environment and detect obstacles, people, and other objects in their path. These sensors provide AMRs with valuable information about their surroundings, enabling them to navigate safely and autonomously.

Applications Across Industries

The versatility and adaptability of AMRs have made them suitable for a wide range of applications across various industries. One of the key applications of AMRs is in the field of logistics and warehousing. With the growing demand for e-commerce and omnichannel retailing, there is a need for efficient and flexible warehousing solutions. AMRs are being used in warehouses and distribution centers to automate material handling tasks such as picking, packing, and palletizing, enabling faster order fulfillment and improved inventory management.

In the healthcare industry, AMRs are being deployed to automate tasks such as medication delivery, linen and waste management, and logistics. Hospitals are using AMRs to transport medications, medical supplies, and equipment between different departments, reducing the need for manual labor and improving efficiency. AMRs can also be used to deliver meals to patients, transport linen and waste, and assist with inventory management, allowing healthcare facilities to focus on providing quality patient care.

Inquire before buying, here: https://www.nextmsc.com/autonomous-mobile-robot-amr-market/inquire-before-buying

In manufacturing facilities, AMRs are being used to automate material handling tasks such as parts delivery, palletizing, and machine tending. AMRs can navigate autonomously in dynamic and crowded environments, allowing them to transport parts and materials between different workstations and production lines. By automating these tasks, manufacturers can reduce cycle times, improve productivity, and optimize resource utilization.

Retailers are also leveraging AMRs to improve the efficiency of their operations. AMRs can be used to automate tasks such as inventory management, shelf stocking, and order fulfillment, enabling retailers to streamline their operations and enhance the customer experience. AMRs can navigate aisles and shelves autonomously, scan barcodes, and identify out-of-stock items, allowing retailers to keep track of inventory levels in real-time and replenish shelves more efficiently.

Challenges and Opportunities

While the autonomous mobile robot market presents immense opportunities for growth and innovation, it also poses several challenges that need to be addressed. One of the key challenges is the high upfront cost of implementing AMR solutions. AMRs require significant investment in terms of hardware, software, and infrastructure, which can be a barrier for small and medium-sized businesses.

Another challenge is the complexity of integrating AMRs into existing workflows and systems. AMRs need to be seamlessly integrated with other automation technologies, such as warehouse management systems (WMS), enterprise resource planning (ERP) systems, and robotic process automation (RPA) platforms, to ensure smooth and efficient operations. This requires careful planning, coordination, and collaboration between different stakeholders, including IT teams, operations teams, and robotics vendors.

Moreover, there are concerns about the impact of automation on jobs and the workforce. While AMRs can automate repetitive and labor-intensive tasks, there is a risk that they may replace human workers in some industries. It is important for businesses to adopt a responsible approach to automation and ensure that the benefits of AMRs are shared equitably among employees. This may involve reskilling and upskilling workers to take on more complex and value-added roles, as well as implementing measures to mitigate the social and economic impact of automation.

Despite these challenges, the autonomous mobile robot market presents immense opportunities for growth and innovation. With ongoing advancements in technology, increasing demand for automation, and evolving customer needs, the market is poised for continued expansion in the coming years. Businesses that embrace AMRs and harness their full potential will be well-positioned to gain a competitive edge and drive long-term success in an increasingly digital and automated world.

Conclusion

In conclusion, the rising autonomous mobile robot market represents a paradigm shift in how we perceive and leverage automation. With their ability to improve efficiency, enhance safety, and unlock new opportunities, AMRs are poised to become indispensable assets for businesses across industries.

As we harness the full potential of this transformative technology, we stand on the brink of a new era of innovation and progress. By embracing AMRs and leveraging their capabilities, businesses can streamline their operations, optimize their workflows, and drive sustainable growth in the years to come.

0 notes

Text

Reinventing Operations: Autonomous Mobile Robot Market in E-commerce

Introduction

The landscape of e-commerce has been witnessing a seismic shift in recent years, with the advent of innovative technologies reshaping the way businesses operate and serve their customers. Among these transformative technologies, Autonomous Mobile Robots (AMRs) stand out as a key enabler for enhancing efficiency, agility, and customer satisfaction in the e-commerce supply chain. According to a study by Next Move Strategy Consulting, the global Autonomous Mobile Robot Market size is predicted to reach USD 3.13 billion with a CAGR of 13.4% by 2030. This article delves into the role of AMRs in revolutionizing e-commerce operations, exploring their impact on warehouse management, order fulfillment, customer experience, and sustainability efforts.

The Rise of E-commerce and Operational Challenges

The exponential growth of e-commerce in recent years has been fueled by shifting consumer preferences, technological advancements, and the proliferation of digital platforms. Today, consumers expect seamless shopping experiences, fast deliveries, and a wide range of product choices at their fingertips. While e-commerce offers unparalleled convenience and accessibility, it also poses significant challenges for businesses, particularly in the landscape of fulfillment and logistics.

Request for a sample, here: https://www.nextmsc.com/autonomous-mobile-robot-amr-market/request-sample

Traditional warehouse operations often struggle to keep pace with the dynamic nature of e-commerce, leading to inefficiencies, bottlenecks, and increased operational costs. Manual processes, outdated systems, and limited scalability hinder the ability of e-commerce companies to meet the evolving demands of customers and compete effectively in the market. As order volumes continue to surge and delivery expectations rise, there is a pressing need for innovative solutions that can revolutionize e-commerce operations and drive sustainable growth.

Enter Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) have emerged as a disruptive force in the e-commerce industry, offering a paradigm shift in warehouse automation and logistics management. Unlike traditional automation solutions that rely on fixed conveyor systems or robotic arms, AMRs are agile, flexible, and intelligent robotic systems capable of autonomously navigating through warehouse environments, picking and packing items, and transporting them to designated locations.

Equipped with advanced sensors, cameras, lidars, and artificial intelligence algorithms, AMRs possess the ability to perceive their surroundings, avoid obstacles, and adapt to changes in real-time. This inherent agility and adaptability make AMRs well-suited for the dynamic and unpredictable nature of e-commerce operations, where rapid order fulfillment and seamless logistics are paramount.

Transforming Warehouse Management

At the heart of e-commerce operations lies the warehouse, where inventory management, order processing, and fulfillment activities take place. Traditional warehouses often rely on manual labor and static infrastructure to manage inventory and fulfill orders, leading to inefficiencies and operational bottlenecks. AMRs offer a transformative solution to these challenges by automating repetitive tasks, optimizing workflows, and maximizing operational efficiency.

By deploying AMRs in warehouses, e-commerce companies can significantly reduce reliance on manual labor, minimize errors, and accelerate order fulfillment processes. AMRs can autonomously navigate through warehouse aisles, locate items, and transport them to packing stations with precision and efficiency. This not only improves the speed and accuracy of order processing but also enables warehouses to handle higher order volumes and peak demand periods without compromising on performance.

Furthermore, AMRs enable e-commerce companies to optimize warehouse layouts, maximize storage capacity, and minimize travel distances, thereby reducing operational costs and improving overall productivity. With their ability to adapt to changing demand patterns and dynamically reconfigure workflows, AMRs empower warehouses to operate more efficiently and effectively in the fast-paced world of e-commerce.

Enhancing Order Fulfillment

Efficient order fulfillment is critical to the success of any e-commerce business, as it directly impacts customer satisfaction, retention, and brand reputation. Delays, errors, and inaccuracies in order processing can lead to dissatisfied customers, increased returns, and lost revenue opportunities. AMRs play a crucial role in enhancing order fulfillment processes by streamlining picking, packing, and shipping operations with speed, accuracy, and reliability.

Traditionally, order picking – the process of retrieving items from warehouse shelves – has been a labor-intensive and time-consuming task in e-commerce fulfillment centers. Manual pickers navigate through aisles, locate products, and collect them for packing and shipping. However, this manual approach is inherently inefficient and prone to errors, particularly in large warehouses with extensive product inventories.

AMRs revolutionize order picking by automating this process with precision and efficiency. Equipped with advanced navigation systems and intelligent algorithms, AMRs can autonomously traverse warehouse aisles, identify pick locations, and retrieve items with speed and accuracy. This not only reduces the time and labor required for order picking but also minimizes errors and improves order accuracy, resulting in higher customer satisfaction and fewer returns.

Moreover, AMRs enable e-commerce companies to implement dynamic order fulfillment strategies such as batch picking and zone picking, which further optimize efficiency and reduce cycle times. By orchestrating the movement of multiple AMRs simultaneously and coordinating picking activities in real-time, warehouses can achieve higher throughput rates and handle a greater volume of orders with ease.

Elevating Customer Experience

In the era of e-commerce, customer experience has become a key differentiator for businesses seeking to stand out in a crowded marketplace. Today's consumers expect fast, reliable, and convenient shopping experiences, with seamless order fulfillment and timely deliveries being top priorities. AMRs play a pivotal role in elevating the customer experience by enabling e-commerce companies to meet and exceed these expectations with efficiency and precision.

By accelerating order processing and reducing delivery times, AMRs enable e-commerce companies to offer same-day or next-day delivery options, thereby enhancing convenience and satisfaction for customers. The speed and agility of AMRs in navigating warehouse environments and fulfilling orders enable e-commerce companies to fulfill orders faster and more accurately, resulting in shorter lead times and improved on-time delivery performance.

Moreover, the accuracy and reliability of AMRs in picking and packing tasks ensure that customers receive the right products in perfect condition, leading to higher satisfaction and fewer returns. By minimizing order errors, discrepancies, and damages, AMRs help e-commerce companies build trust and loyalty with their customers, driving repeat purchases and positive word-of-mouth recommendations.

Furthermore, AMRs enable e-commerce companies to offer innovative delivery options such as autonomous last-mile delivery, where robots autonomously deliver packages directly to customers' doorsteps. This not only enhances convenience and flexibility for customers but also reduces delivery costs and environmental impact, making it a win-win solution for businesses and consumers alike.

Driving Sustainability Efforts

In addition to improving operational efficiency and enhancing the customer experience, AMRs also play a vital role in driving sustainability efforts in the e-commerce industry. As concerns about environmental impact and carbon emissions continue to grow, businesses are under increasing pressure to adopt sustainable practices and reduce their ecological footprint. AMRs offer a sustainable solution to e-commerce logistics by optimizing warehouse operations, minimizing energy consumption, and reducing carbon emissions associated with order fulfillment and transportation.

By optimizing warehouse layouts and route planning, AMRs help e-commerce companies minimize the distance traveled by workers and vehicles within the warehouse, thereby reducing fuel consumption and greenhouse gas emissions. The efficiency and precision of AMRs in picking and packing tasks also contribute to reducing waste and minimizing the need for excess packaging materials, further reducing the environmental impact of e-commerce operations.

Moreover, AMRs enable e-commerce companies to implement more efficient and sustainable transportation strategies, such as route optimization and load consolidation, which help minimize fuel consumption and emissions associated with order deliveries. By leveraging AMRs for autonomous last-mile delivery, businesses can further reduce reliance on fossil fuels and mitigate the environmental impact of traditional delivery methods, while also enhancing efficiency and reducing costs.

Overall, the adoption of AMRs in e-commerce operations represents a significant step towards achieving sustainability goals and mitigating the environmental impact of e-commerce logistics. By optimizing efficiency, reducing waste, and minimizing carbon emissions, AMRs help e-commerce companies operate in a more environmentally responsible and socially conscious manner, aligning with growing consumer demand for sustainable and ethical business practices.

Challenges and Considerations

While Autonomous Mobile Robots (AMRs) offer numerous benefits and opportunities for e-commerce businesses, their adoption and integration into existing operations also pose challenges and considerations. One of the key challenges is the initial investment required for deploying AMRs, including the cost of hardware, software, integration, and training. While the long-term benefits of AMRs in terms of efficiency, productivity, and cost savings are significant, businesses must carefully evaluate the return on investment and weigh the upfront costs against the potential long-term gains.

Another consideration is the complexity of integrating AMRs into existing warehouse management systems (WMS) and e-commerce platforms. Seamless integration with existing systems and workflows is essential for maximizing the benefits of AMRs and minimizing disruption to operations. Businesses must ensure compatibility, interoperability, and scalability when deploying AMRs, and may require support from experienced integrators or consultants to streamline the integration process.

Inquire before buying, here: https://www.nextmsc.com/autonomous-mobile-robot-amr-market/inquire-before-buying

Furthermore, the deployment of AMRs also raises considerations related to workforce management and human-robot collaboration. While AMRs automate repetitive tasks and optimize efficiency, they also require oversight, maintenance, and supervision by human operators. Businesses must ensure proper training and upskilling for employees to operate and interact with AMRs safely and effectively, and to address any concerns or resistance among workers regarding job displacement or automation.

Moreover, regulatory and safety considerations also play a critical role in the deployment of AMRs in e-commerce operations. Businesses must adhere to industry standards, safety regulations, and ethical guidelines when deploying and operating AMRs in warehouse environments to ensure the safety of workers, customers, and assets. This includes implementing robust safety protocols, emergency stop mechanisms, and fail-safe systems to prevent accidents and mitigate risks associated with autonomous robotic systems.

Future Outlook and Conclusion

The future of e-commerce operations is undoubtedly intertwined with the evolution and proliferation of Autonomous Mobile Robots (AMRs) as a key enabler for efficiency, agility, and sustainability. As technology continues to advance and costs decrease, the adoption of AMRs in e-commerce is expected to accelerate, with more businesses leveraging these intelligent robotic systems to streamline warehouse operations, enhance order fulfillment, and elevate the customer experience.

Looking ahead, the integration of AMRs into e-commerce operations holds immense promise for revolutionizing the way businesses operate and serve their customers in a rapidly evolving digital economy. From optimizing warehouse management and order fulfillment to driving sustainability efforts and enhancing the customer experience, AMRs offer a transformative solution to the complex challenges facing e-commerce businesses today.

In conclusion, the integration of Autonomous Mobile Robots (AMRs) into e-commerce operations represents a paradigm shift in the way businesses manage and optimize their supply chain processes. By harnessing the power of automation, intelligence, and agility, AMRs enable e-commerce companies to reinvent their operations, drive efficiency, and deliver unparalleled value to customers. As the global Autonomous Mobile Robot (AMR) Market continues to expand and evolve, e-commerce businesses stand to benefit greatly from embracing this transformative technology to navigate the challenges and opportunities of the digital age.

0 notes

Text

How Autonomous Mobile Robots Are Revolutionizing Logistics

The logistics industry is undergoing a rapid transformation, and one of the key drivers behind this change is the rise of autonomous mobile robots (AMRs). These smart machines are reshaping warehouse operations, offering businesses a new way to streamline material handling, boost efficiency, and reduce costs.

What are Autonomous Mobile Robots?

An AMR robot is an autonomous machine designed to navigate and transport goods without human intervention. Equipped with advanced sensors, cameras, and mapping technologies, these mobile robots can make real-time decisions, avoid obstacles, and adapt to dynamic environments. Whether it's moving pallets or sorting inventory, AMRs are built to handle repetitive tasks efficiently.

Benefits of Using AMRs in Warehouses

Increased Efficiency The primary advantage of using autonomous mobile robots is their ability to work around the clock without needing breaks. This maximizes productivity and helps warehouses meet the increasing demands for faster order fulfillment.

Cost Savings While there is an initial investment involved, AMRs provide long-term savings by reducing labor costs and minimizing errors. With these mobile robots handling routine tasks, human workers can focus on more complex and high-value activities, such as quality control or customer service.

Scalability and Flexibility As your business grows, so can your fleet of AMR robots. These systems are scalable and can be easily expanded or reconfigured to accommodate changing warehouse layouts or seasonal spikes in demand.

Improved Safety With autonomous mobile robots taking on the more physically demanding tasks, the risk of workplace accidents decreases. These robots are designed to follow safety protocols, ensuring a safer working environment for humans.

Incorporating mobile robots into your warehouse operations is no longer a futuristic idea, it’s a strategic move for businesses looking to stay competitive in the fast-evolving logistics industry.

0 notes

Text

AGV vs AMR: 5 Key Differences to Overcome the Confusions

The terms ‘automated’ and ‘autonomous’ are frequently mixed up and used interchangeably, yet they possess distinct and inherent differences in meaning.

Automated: This concept revolves around the utilization of computer-controlled machinery to execute predefined tasks, often operating with minimal or no human intervention read more here…

0 notes

Text

AGVs: The Unsung Heroes of Smart Logistics 🚀

Ever wondered how warehouses run with machine-like precision? How goods seem to flow effortlessly from one point to another without human intervention? The secret lies in AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots)—the silent powerhouses of modern logistics.

These robotic transporters don’t just move materials; they think, adapt, and optimize—navigating complex environments, rerouting in real time, and working tirelessly 24/7. But beneath the sleek automation lies something even more crucial: their motors and reducers.

Without a high-torque, energy-efficient motor, an AGV is just a shell. It needs: ⚙️ Power to carry heavy loads effortlessly 🔋 Efficiency to run continuously without excessive energy consumption 🛠️ Durability to withstand long-term operations

In the world of intelligent logistics, the right motor doesn’t just power a machine—it drives an entire industry forward.

0 notes

Text

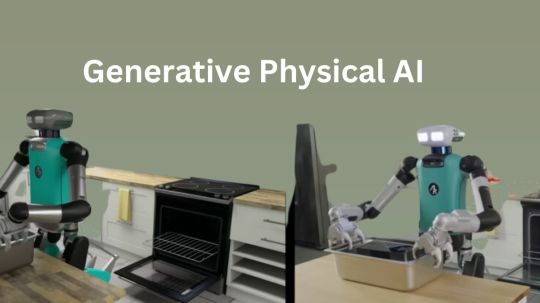

What Is Generative Physical AI? Why It Is Important?

What is Physical AI?

Autonomous robots can see, comprehend, and carry out intricate tasks in the actual (physical) environment with to physical artificial intelligence. Because of its capacity to produce ideas and actions to carry out, it is also sometimes referred to as “Generative physical AI.”

How Does Physical AI Work?

Models of generative AI Massive volumes of text and picture data, mostly from the Internet, are used to train huge language models like GPT and Llama. Although these AIs are very good at creating human language and abstract ideas, their understanding of the physical world and its laws is still somewhat restricted.

Current generative AI is expanded by Generative physical AI, which comprehends the spatial linkages and physical behavior of the three-dimensional environment in which the all inhabit. During the AI training process, this is accomplished by supplying extra data that includes details about the spatial connections and physical laws of the actual world.

Highly realistic computer simulations are used to create the 3D training data, which doubles as an AI training ground and data source.

A digital doppelganger of a location, such a factory, is the first step in physically-based data creation. Sensors and self-governing devices, such as robots, are introduced into this virtual environment. The sensors record different interactions, such as rigid body dynamics like movement and collisions or how light interacts in an environment, and simulations that replicate real-world situations are run.

What Function Does Reinforcement Learning Serve in Physical AI?

Reinforcement learning trains autonomous robots to perform in the real world by teaching them skills in a simulated environment. Through hundreds or even millions of trial-and-error, it enables self-governing robots to acquire abilities in a safe and efficient manner.

By rewarding a physical AI model for doing desirable activities in the simulation, this learning approach helps the model continually adapt and become better. Autonomous robots gradually learn to respond correctly to novel circumstances and unanticipated obstacles via repeated reinforcement learning, readying them for real-world operations.

An autonomous machine may eventually acquire complex fine motor abilities required for practical tasks like packing boxes neatly, assisting in the construction of automobiles, or independently navigating settings.

Why is Physical AI Important?

Autonomous robots used to be unable to detect and comprehend their surroundings. However, Generative physical AI enables the construction and training of robots that can naturally interact with and adapt to their real-world environment.

Teams require strong, physics-based simulations that provide a secure, regulated setting for training autonomous machines in order to develop physical AI. This improves accessibility and utility in real-world applications by facilitating more natural interactions between people and machines, in addition to increasing the efficiency and accuracy of robots in carrying out complicated tasks.

Every business will undergo a transformation as Generative physical AI opens up new possibilities. For instance:

Robots: With physical AI, robots show notable improvements in their operating skills in a range of environments.

Using direct input from onboard sensors, autonomous mobile robots (AMRs) in warehouses are able to traverse complicated settings and avoid impediments, including people.

Depending on how an item is positioned on a conveyor belt, manipulators may modify their grabbing position and strength, demonstrating both fine and gross motor abilities according to the object type.

This method helps surgical robots learn complex activities like stitching and threading needles, demonstrating the accuracy and versatility of Generative physical AI in teaching robots for particular tasks.

Autonomous Vehicles (AVs): AVs can make wise judgments in a variety of settings, from wide highways to metropolitan cityscapes, by using sensors to sense and comprehend their environment. By exposing AVs to physical AI, they may better identify people, react to traffic or weather, and change lanes on their own, efficiently adjusting to a variety of unforeseen situations.

Smart Spaces: Large interior areas like factories and warehouses, where everyday operations include a constant flow of people, cars, and robots, are becoming safer and more functional with to physical artificial intelligence. By monitoring several things and actions inside these areas, teams may improve dynamic route planning and maximize operational efficiency with the use of fixed cameras and sophisticated computer vision models. Additionally, they effectively see and comprehend large-scale, complicated settings, putting human safety first.

How Can You Get Started With Physical AI?

Using Generative physical AI to create the next generation of autonomous devices requires a coordinated effort from many specialized computers:

Construct a virtual 3D environment: A high-fidelity, physically based virtual environment is needed to reflect the actual world and provide synthetic data essential for training physical AI. In order to create these 3D worlds, developers can simply include RTX rendering and Universal Scene Description (OpenUSD) into their current software tools and simulation processes using the NVIDIA Omniverse platform of APIs, SDKs, and services.

NVIDIA OVX systems support this environment: Large-scale sceneries or data that are required for simulation or model training are also captured in this stage. fVDB, an extension of PyTorch that enables deep learning operations on large-scale 3D data, is a significant technical advancement that has made it possible for effective AI model training and inference with rich 3D datasets. It effectively represents features.

Create synthetic data: Custom synthetic data generation (SDG) pipelines may be constructed using the Omniverse Replicator SDK. Domain randomization is one of Replicator’s built-in features that lets you change a lot of the physical aspects of a 3D simulation, including lighting, position, size, texture, materials, and much more. The resulting pictures may also be further enhanced by using diffusion models with ControlNet.

Train and validate: In addition to pretrained computer vision models available on NVIDIA NGC, the NVIDIA DGX platform, a fully integrated hardware and software AI platform, may be utilized with physically based data to train or fine-tune AI models using frameworks like TensorFlow, PyTorch, or NVIDIA TAO. After training, reference apps such as NVIDIA Isaac Sim may be used to test the model and its software stack in simulation. Additionally, developers may use open-source frameworks like Isaac Lab to use reinforcement learning to improve the robot’s abilities.

In order to power a physical autonomous machine, such a humanoid robot or industrial automation system, the optimized stack may now be installed on the NVIDIA Jetson Orin and, eventually, the next-generation Jetson Thor robotics supercomputer.

Read more on govindhtech.com

#GenerativePhysicalAI#generativeAI#languagemodels#PyTorch#NVIDIAOmniverse#AImodel#artificialintelligence#NVIDIADGX#TensorFlow#AI#technology#technews#news#govindhtech

3 notes

·

View notes

Text

AMR with Industrial Automation Station and COBOT | Manufacturer in Pune

Hytech Didactic in Pune offers AMR and AGV training cells, COBOT automation stations, and robotics systems for education and industry. Explore innovation!

#AMR Training Cell Manufacturer Pune#AGV Training Cell Supplier Pune#Industrial Automation Station with COBOT Pune#Didactic Robocell Pune#Educational Robots Pune#Robotics Training Systems Pune#AMR and AGV Training Pune#Collaborative Robots Training Pune#SMR AGV Manufacturer Pune#Educational AMR Solutions Pune

0 notes

Text

Some random HELLDIVERS 2 ideas floating around in my head

This is just gonna be a post thats gonna consist of things i've seen others mention or things i've thought about myself, anyways, here's the list i guess:

Scout Rifle (Unlocked at Level 5) - Modified Sniper Rifle equipped with a Thermal Scope & Silencer designed for more stealthier approaches in missions, its not as powerful as the Anti-Material Rifle but still packs a very mean punch (basically a singular point lower in the Armor Penetration Scale compared to AMR, additionally, it should be noted that it works best in positions where you are far away from the enemy, just because its silenced, it doesn't mean enemies nearby your position cant hear it).

2. Weapon & Armor Customization (+ A Bonus Thing)- I think almost about everyone underneath the sun has talked about this, while i do understand it'd probably be a bit difficult to add it in right now, i would potentially like to see in the future considering that most of the weapons look like they were meant to be detachable at one point (such as certain weapons sharing attachments, that one HD2 Trailer where each Helldiver had a different attachment on each of their Liberator, and other things im forgetting about), and also they did mention they were gonna introduce color variations for armor sometime in the near future, however what I'd honestly like to see it be added in the form of something you have to unlock (sorta similar to how in MGSV you can unlock variations of an existing gun but cannot customize them until you get the Legendary Gunsmith, which once you do, you are able to pull from the various attachments each gun you researched onto any weapon that accepts them):

2a. It could be a Ship Upgrade but as to the name of it... I'm honestly very unsure, I dont think it has a name so i'll call it "LIBERTY & DEMOCRACY QUARTERS" considering the words 'LIBERTY' & 'DEMOCRACY' are in front of the Armory & Unusable Terminal, anyways, upgrades are as followed:

2b. Data Acquisition Terminal (Common Samples Required) - The D.A.T allows for information to be gathered from the Battlefield via the power of Marking & Gathering (This basically gives you a beastiary/logbook for various items & enemies you face off against, which give you useful tips & flavor text, in addition, it keeps track as to how many of said enemy you've killed (including the times they've killed your Helldivers)/how many items you've collected), it also tracks the random notes you find out on the field, listing it as "Questionable Material").

2c. Armor-Smith Cybernetics (Commons, Rares & STREAMLINED REQUEST PROCESS Required) - The Armory is now further enhanced with the usage of highly advanced patriotic-robotics & precise liberty-based algorithms (Allows for Weapon & Armor Customization, Armor requires the usage of Requisition Slips in order to unlock color variations, in order to give some extra uses for RS, same could apply for weapon customization sorta similar to MGSV, where weapons cost GMP in order to deploy except for the really low level versions, which in the case of HD2, it would be the weapon that had the preset attachments, additionally, this means your death is gonna cost more than just a life, so be weary of that, but so it isnt as expensive, maybe the application of each attachment is about... 100 or 250 RS each).

2d. Super Sonar Dish (Commons, Rares, Supers & NUCLEAR RADAR Required) - The Nuclear Radar is now retrofitted with the Super Sonar Dish, allowing for better reads on the battlefield (The radar will now display items you've run past, such as if you ran past a Common or Rare Sample, the Radar will now track it. In addition, as an added bonus, you are given an alert a minute prior to whenever a geological or meteorological event is about to occur. Something else to note is that if you complete a Radar Station Objective, this further enhances the Super Sonar Dish).

3. Medical Spray Tower (Unlocked at Level 10) - A tower full of Stim-Based Spray is deployed and will periodically heal nearby Helldivers that are within range of it, although unlike Stims, it cannot heal serious wounds and does not provide the temporary regeneration a Stim provides (It is highly unknown what it does to bugs and cannot bring people back from the dead).

4. "Buddy" (Unlocked at Level 20 - Costs 25K Requisition Slips) - This patriotic rover is capable of helping you with tasks that your otherwise heroic teammates are unable to help you with! (It helps specifically for opening buddy doors but it will constantly blare loud patriotic music, thus alerting enemies to your position at a constant, can be deactivated with the BACKPACK button).

5. The ability to deactivate backpack related items using the backpack button, so for example, being able to put away the ballistic shield without needing to have a two handed weapon, or maybe deactivating the Shield Backpack to Recharge it to full capacity.

6. Different Super Earth Structure Designs Related to Planet's Composition & Planetary Events - As to what this means, is... well, we shouldnt assume that a planet is constantly dealing with shitty conditions without some method to protecting themselves from it(such as Meteorites, Volcanic Activity, Tremors, and Ion Storms), they definitely would have had something to defend themselves or make living on the planet much more tolerable. Additionally, some more varied SE Designs related to the planet's habitat would be nice compared to the same old Super Earth Generated Structure Number Something Something.

6a. In addition, maybe unique new missions relating to whatever the shitstorm the planet deals with? So lets take the Tein Kwan Event for example, it was simply a "Oh, heres a new planet unlocked, liberate it and you get exo-mechs!", which, while neat, I feel like it could have been made more interesting if it was done akin to the TCS Dispersal Event where you need to activate an Asteroid Defense System (that the automatons took out at various factories across the planet) in order to actually protect the planet, so maybe something like this:

"The production of the Exo-Patriots have halted after Automatons hit the ADS of Tein Kwan, liberate this planet and crush the Automaton Presence so the production of the mechs may resume."

Main Event Mission:

Reactivate A.D.S - Your mission is to land in one of the many exo-patriot facilities and reactivate the defense systems. Eradicate the automaton infestation that is keeping managed democracy in their shackles! Doing so will resume production of the facility and allow for the workers to be safe.

Planet World Gen Details: Evidence of much "smaller" but destroyed ADS in certain spots of a planet. Automaton AA Guns acting as a means to protect Outposts from oncoming Meteorites.

...More ideas to be added later when i remember about them.

2 notes

·

View notes

Text

Gemini is an open-source robotics platform for R&D, education, and personal development, with a smart design and a high price-performance ratio. Gemini combines the concepts of AGV and AMR robotics, based on a two-wheeled Differential Velocity Mechanism, and integrates more than 10 sensors such as laser radar, depth camera, ultrasonic array, microphone array, monocular array, etc., as well as rich computing power from the NVIDIA. The rich ROS/ROS2 software packages and simulation environment for beginner developers allow users to easily develop robot systems, positional guidance systems, and other systems. Users can easily develop robotic systems, positioning and navigation, audio-visual, machine learning, storage, and logistics functions.

2 notes

·

View notes