#atex load cell

Text

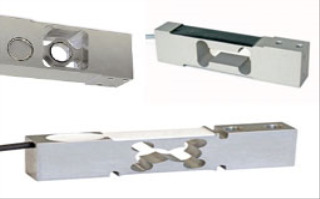

Thames Side produces Atex Load Cells expertly and in a range of styles. Due to our extensive experience over the years in the distribution of load cells, we are regarded as one of the most trustworthy names in the industry. Please contact us if you need any additional details on the Atex load cell.

0 notes

Text

Thames Side excels in crafting Atex load cells, known for their precision and diversity. With our rich experience, we're a trusted source for Atex load cell solutions. For more information, reach out to us.

0 notes

Text

Top Atex Load Cell Producer - Thames Side

Thames Side skillfully manufactures a premium range of Atex Load Cells. Because of our extensive expertise and many years of supply, we are regarded as one of the most trustworthy names in the load cell industry. Contact us if you would like more information about the Atex load cell.

0 notes

Text

Best Atex Load Cell Constructor In Market - Thames Side

The best ATEX load cells are made by Thames Side. Our ATEX-certified loadcells can be used in Zones 0, 1, and 2 for Gas (1G, 2G, and 3G), as well as Zones 20, 21, and 22 for Dust (1D, 2D, and 3D).

0 notes

Text

T66 Bending Beam Load Cell | 9560915555 | Weighbridge Load Cell – Kanta King

The T66 high precision stainless steel bending beam is a world class load cell and widely used in industrial weighing applications. It has OIML approval (which is ideal in legal-for-trade applications) and it can withstand harsh manufacturing environments due to its fully welded and hermetically sealed design (IP68 & IP69K). The T85 also has Model approval from Legal Metrology Department, Government of India.

Available in a 4-wire or 6-wire (with sense wires) configuration, it has OIML approval to 3000 divisions (Class C3) or 6000 divisions (C6) and ATEX, PESO approval for use in hazardous areas where an explosion risk exists. Its certification for dust zones 20, 21 and 22 does not require the use of safety barriers.

More Info:

Call: +91 9560915555

#Load cell#load cell#kanta king load cell#beam load cells#single point load cell#silo weighing system

0 notes

Text

Everything You Need to Know About Load Cells and Their Technology

In the dynamic industrial world, load cells are one of the most ubiquitous components that cannot be overlooked. Wondering what load cells are? Well, they fall under the umbrella of transducers or electro-mechanic sensors that helps convert force into electrical output. The cell functions to measure weight or force and it has an effective design that depends on the electricity flow and material deformation. Load cells are versatile devices offering accurate performance across diverse applications. All commercial and industrial processes use load cells as an effective way to measure weights and forces across systems.

Load Cell Technology

There are different types of load cells. While the resistive load cells work on the principle of piezo-resistivity, the capacitive load cells function on the principle of the change of the capacitance. Typically, capacitance is a system’s ability to hold a certain amount of charge when the voltage is applied to it. Also, load cell designs can also be differentiated as per the type of output signals generated (hydraulic, pneumatic, electric) or according to the way how they detect weight (compression, bending, tension, shear, etc).

Load cells find their uses in geotechnical fields. They are typically used to monitor deep sea foundations in excavation bracing like struts, anchors or tiebacks, soldier pile, and retaining walls. Load cells can also be used to keep tabs on tunnels and shafts. Working on the classic principle of Wheatstone bridge, load cells need the application of voltage to opposite nodes.

How do load cells work?

Load cells involve the use of geotechnical instruments and they can’t wok without being paired up with sensors. One of these sensors is the strain gauge. Strain gauges are fundamentally thin elastic materials made up of stainless steel. They are fixed inside the load cells and they have a specific resistance directly proportional to its width and length. When the force is applied on the load cell, it stretches or bends causing the strain gauge to move and when the cross-section and length of the strain gauge alters, its electrical resistivity also gets changed, thereby changing the overall output voltage.

Environmental Conditions

The load cell may face versatile environmental conditions. However, you must ensure to protect it from the exterior environment to make sure it has an efficient performance for the intended usage timeline. A few load cells are in potted form and their cavities get filled with resin material or epoxy to cover the anodic components. The protection helps guard the circuit system from humidity and outside damage while dissipating heat.

A few load cells also exhibit hermetic seals to enable environmental protection. Fully welded seals provide a robust and airtight enclosure that helps the load cell to stand up during challenging environments.

You may find FM and ATEX certificates for certain load cell types that indicate it is safe to use the equipment in dangerous or explosive environments.

Conclusion

You must ensure that the load cell gets properly installed and aligned to make the most of its performance. You can follow the manufacturer’s recommendations to get the best results from the reliable device and ensure long-lasting usage.

Source: https://packagingmachinesaustralia.blogspot.com/2022/08/everything-you-need-to-know-about-load.html

0 notes

Text

It’s All About Straatman BV

Straatman BV is a leading manufacturer of quick release mooring and towing equipment. For more than 35 years, all their quick release hooks are engineered, manufactured and tested in their own factory, located in the Netherlands. Thanks to their facilities and the highly skilled workers they employ, they consistently deliver products of the highest quality to their global customers in several kind of industries. Rubber Fender

Quick release hooks:

Straatman BV delivers quick release mooring systems worldwide for terminals, jetties, Buoys, FPSOs and FSRUs. Their mooring systems are high-quality products, to ensure the safe mooring of vessels carrying oil, gas and LNG. All quick release hooks are tested on their calibrated testing machine and all standard test certificates will be issued as part of the user manual. The systems are easy to use and support an efficient and safe port environment

All hooks are available in single and multiple assemblies and can be equipped with all kind of options, for example:

Remote release: All quick release hooks can be equipped with an electric or electric-hydraulic mechanism. Floating Fenders

Load monitoring: For a continuous measurement of the load, the quick release mooring and towing hooks can be equipped with load cells

Remote control: The remote release option can be integrated in a remote-control system.

Explosion proof: The quick release hooks are often used and located in a hazardous area. In these specific situations, all electrical parts are available in an explosion proof version. Each component will be supplied with an explosion proof certificate, in accordance with ATEX/IECEx. Port Bollard

Integrated capstans: The quick release hooks can be equipped with an integrated capstan that can be provided with several features.

Solar power system: Straatman BV developed a sustainable power supply system based on solar panels, to power the capstan which is integrated in the quick release mooring hook. It’s the perfect solution in a situation where a regular power supply system is not preferred or even impossible.

View More: Trelleborg Marine

0 notes

Text

Freight Brokers & Broker Agents

What the Difference between a Freight Broker and a Broker Agent? And even which way is the best way to go?

These are common questions from the ones interested in this industry. Let's try to shed some light regarding these questions.

1 . A freight broker (also called a lorry broker) is fully self-employed and is required to obtain his or her specialist. He or she will do his or her own invoicing to customers and will pay for the motor carriers. Essentially, the truck broker is performing a complete business.

2 . A broker agent works for another freight loans broker and does not need to obtain a broker authority. The agent works in the authority of his or her broker and is not responsible for invoicing and freight quote paying the trucks.

There are pros and cons to each option.

First, a fully self-employed broker is required to get his or her authority but he or she retains hundred percent of the profit on each load. Further, the freight broker is completely responsible for invoicing the customer and making collections as well as paying the powerplant carriers. Having sufficient capital and good cash management competencies are an absolute necessity. Since time is required to run an entire online business, the broker has relatively less time to search for new customers and find lorries.

Second, a broker agent is not required to get his or her broker power and, therefore , this option is less costly. But the broker agent divides his or her commission on each load with whomever the work under. Almost all agent's time is spent searching for new customers and finding vans.

Third, most brokers are seeking experienced agents. There are a few who will allow new inexperienced agents but these freight brokers are far in addition to few in between. If an agent is new or inexperienced, the very broker normally does not want to spend a lot of time training or "hand-holding".

To recap, as a broker agent, you don't need your broker capacity. You work under the authority of another truck broker. Someone can begin as either a freight broker or broker agent after which it switch to the other. The two fundamental differences are the scope of the projects and responsibilities and the fact that the broker agent does not need most of their authority.

Regardless of whether you work as a freight broker or representative agent, you may work out of your home. And you will meet and work with prospects and carriers over the entire country.

All you need to get started is:

The best computer with a high-speed internet connection,

Preferably two telephone lines (one could be either a cell phone or internet telephone),

A good fax machines,

Proper education and the drive and determination to succeed.

For together brokers and agents, good, comprehensive training or on-the-job feel is absolutely essential.

Here are a few topics you can expect to learn when you take difficulty broker or broker agent training:

How to use the Load Boards

Finding shippers

How to search for trucks

How to talk to shippers and dispatchers

How to pre-qualify your motor carrier

How to calculate rates

Stage-by-stage procedures for booking a load

How to get set-up with your motor carrier's

How to monitor and track your loads

How to set-up plus manage your information flow

Atex Freight Broker Training, Inc is going to train agents only if the agent has a broker to work with.

Author Bio:

John is the sole owner and president for Atex Freight Broker Training, Inc. He trains individuals across the telephone and Internet, live in El Paso, Texas or that has a home study program to become fully self-employed freight brokers. Chris is a certified public accountant by profession with over 30 years' experience using the services of small business startups.

0 notes

Text

Thames Side are the leading manufacturer and supplier of weighing equipment, complies with the ATEX equipment directive 2014/34/EU. Contact us now to discuss your requirements for atex load cell.

0 notes

Text

Atex Load Cell Producer - Thames Side

Thames Side manufactures Atex Load Cells with competence and a wide range. We are considered as one of the most reliable brands in the delivery of load cells due to our considerable experience over the years. For further information about the Atex load cell, please contact us.

0 notes

Text

Flow meter enhances chlorination system performance for municipal water department

The water municipality at a mid-size city in the western region of the U.S. serving a population of about 180,000 people needed to address a chlorine disinfection system problem at one of its water treatment plants. The city’s engineers take great pride in providing their community with a safe source of drinking water and gave this issue the highest priority.

In order to provide a reliable, safe source of clean drinking water, all municipal system operators rely on a disinfection system to kill germs. There are several different methods of disinfection treatment, such as chlorine (Cl2), UV, and ozone. Chlorine remains a popular disinfectant around the world. Where chlorine is in use, accurate measurement of the gas is essential for successful disinfection and for safety purposes.

Problem

At one of the city’s water treatment plants, the chlorinator system’s flow measurement lacked suitable turndown capability (measuring range) and was not repeatable at lower flow rates, and total monthly chlorine usage was not consistent (Figure 1). This poor control over the amount of chlorine being dispensed resulted in either excessive, wasteful chlorine use, or potentially hazardous and expensive re-treatment. Adding too much chlorine affects water taste (swimming pool), wastes expensive chlorine gas and adds the cost of extra residual chlorine removal. With too little chlorine added, the disinfection treatment process is incomplete, and the water requires costly additional alternative treatment or re-treatment.

The city’s system had been initially designed with simple site-gauge rotameters. Later, for automated control purposes, differential pressure (dP) type orifice plate flow meters were added into the system. The city’s engineers soon discovered the orifice plate dP meters could not be relied upon to measure accurately under flow conditions where little pressure differential was available, and the limited flow range could not support the changing dose rates with changes in water demand.

The treatment plant needed a better gas flow meter solution that would be appropriate for service in a 1-inch diameter pipe at a flow rate of 150 lb/day to 2000 lb/day [68 kg/day to 907 kg/day]. The operating temperature was 60°F to 100°F [16°C to 38°C] at a pressure of 0 psig to 10 psig [0 bar(g) to 0.7 bar(g)]. The flow meter would be used to measure chlorine and no other gases and would be installed in a location where inadequate straight-pipe run was present and added to the accuracy challenge for any velocity-based instrument. The flow velocities also resulted in measurement required in the transitional zone where the gas flow profile was transitioning from laminar to turbulent. Mass flow provided an additional advantage of allowing a simple, direct means of reconciling monthly throughput compared against the change in weight of the chlorine gas containers that were installed on load cell technology scales.

Figure 1: Water treatment plant chlorine tanks.

After consulting with the application engineering team at Fluid Components International (FCI), the engineers at the water department selected the Model ST100L thermal dispersion gas mass flow meter with built-in Vortab® flow conditioner (Figure 2). The Model ST100L is an in-line, spool piece flow meter that combines best-in-class transmitter/electronics and superior sensor design to provide a truly state-of-the-art gas flow meter for industrial process and plant applications in line sizes up to 2 inches [50 mm].

Figure 2: Installed ST100L Flow Meter with Vortab Flow Conditioner Solution.

FCI’s model ST100L constant power technology thermal flow meter (Figure 3) was installed in the water system’s chlorine gas inlet line to the chlorinator panel. To ensure maximum corrosion resistance and longest service life in the highly corrosive chlorine gas environment, the ST100L’s entire sensor assembly, including flow elements, flow body and Vortab flow conditioner elements, are fabricated entirely of Hastelloy C-276.

FCI’s gas flow meters are typically calibrated in FCI’s NIST traceable flow laboratory using the actual gas to be measured and at the installation’s actual temperature and pressure conditions. However, chlorine gas presents safety concerns during the calibration process which renders that process unfeasible. It has also been thoroughly established that air equivalency calibrations for chlorine gas are inaccurate, unrepeatable and simply, inadequate. FCI solves this problem by combining a lab-based equivalency basic calibration with an on-site, in-situ calibration adjustment against the site’s rotameters, all performed by an FCI field service technician. This achieved the highly accurate and repeatable measurement needed by the client. The on-site calibration matching proved to be the best solution because the total flow readings from the FCI Model ST100L and the weigh scale comparison were now consistently aligned.

Figure 3: Thermal dispersion constant power principle of operation.

The in-line configuration ST100L meter measures air/gas flow from 0.25 SFPS to 1000 SFPS (0,07 NMPS to 305 NMPS), with turndowns of 100:1 and with accuracy of ± 0.75 percent of reading, ± 0.5 percent of full scale. To match present and future DCS, PLC or SCADA needs, users can select from multiple output options including triple 4-20 mA analog, frequency/pulse, or certified digital bus communications of HART®, Foundation Fieldbus, PROFIBUS PA and Modbus RS485.

The ST100L flow meter also features a best-in-class graphical, multivariable, backlit LCD readout, which provides operators with a continuous display of all process measurements, alarm status and service diagnostics. Its four-button user keyboard is activated through the glass, which means the user never needs to remove lids or open up the unit at the installation site. The instrument also includes a USB port for PC interface and an ethernet port for service needs.

The ST100L meter is designed to ensure the longest service life in even the most rugged industrial applications and installations. The enclosure is NEMA4X/IP67 rated and features four separate conduit ports to isolate all wiring. Additional pedigrees include global agency approval for hazardous environments (ATEX, IECEx, FM, FMc, Inmetro, NEPSI and EAC/TR CU) and SIL compliance. The electronics/transmitter is available for installation as either integral with the flow element or remotable (up to 1000 feet [300 meters]).

The integral Vortab flow conditioner ensured optimal installation performance by overcoming the limited piping straight run and the flow range occurring in the transitional flow region. Vortab uniquely eliminates both swirl and velocity profile distortions produced by process equipment obstructions and/or inadequate straight run of pipe and ducting, as well as temperature and media stratification that can be present at the low flow rates where FCI meters perform and with the lowest pressure drop of all flow conditioner alternatives.

Conclusion

The ST100L flow meters have been installed in the chlorine gas inlet lines, achieving consistent accurate and repeatable flow measurement results. The site is achieving the desired disinfection results with proper chlorine dosing at significant cost savings due to reduced chlorine use, avoiding re-treatment and lessened residual chlorine removal processes.

Main image caption: ST100L Flow Meter with Vortab Flow Conditioner.

source http://sustainabilitymatters.net.au/content/water/article/flow-meter-enhances-chlorination-system-performance-for-municipal-water-department-250585611

from WordPress https://davidkent.home.blog/2021/08/31/flow-meter-enhances-chlorination-system-performance-for-municipal-water-department/

0 notes

Text

T85-T Stainless Steel Shear Beam is a High Accuracy Load Cell

The T85-T stainless steel shear beam is a high accuracy load cell for industrial weighing applications, but primarily for platform scales due to its low height and blind loading hole, which introduces the load into the shear beam in the most optimum way. It has OIML C3 approval (which is ideal in legal-for-trade platforms) and it can withstand harsh working environments due to its fully welded and hermetically sealed design (IP68 & IP69K). The T85-T also has Model approval from Legal Metrology Department, Government of India.

It is suitable for a wide range of applications, thanks to its OIML approval to 3000 divisions (Class C3) and ATEX, PESO approval for use in hazardous areas where an explosion risk exists. For gas zones 20, 21 and 22 it has ATEX certification that does not require the use of safety barriers.

More Info:

Call: +91 9560915555

#Load Cell#beam load cells#kanta king load cell#single point load cell#silo weighing system#load cell#business

0 notes

Text

Rugged Laptops versus Rugged Tablets: Which is ideal?

Rugged Laptops versus Rugged Tablets: Which is ideal?

Picking the privilege rugged gadget for your work is a dubious choice. Rugged laptops and tablets are both endorsed to military-grade principles (MIL-STD-810G) and work in the harshest conditions. They can support drops, vibrations, stuns, and fluid spills. While picking a rugged gadget, you need to consider what you need the gear to do. In the event that your activity requests from you to take loads of photographs in the field, at that point you need a rugged tablet.

Rugged Laptops:

Rugged laptops are worked from extreme materials that let them work in situations where a regular laptop would fall flat. Rugged laptops give unwavering quality, usefulness, insurance, and top notch execution to a scope of callings, including military staff and different employments subject to alterable conditions.

One of a kind Features:

A large portion of the rugged laptops are outfitted with the accompanying highlights:

•Operates in extreme temperatures (- 30 degrees Celsius to 50 degrees Celsius)

•Can withstand dampness and downpour

•MIL-STD-810G ensured

•Drop and Shock safe (1.2m to 1.5m)

•Sunlight meaningful presentation (600 - 1000 nits)

•Long battery life

•Optional vehicle docking station

Rugged laptops are ideal for individuals who work from their vehicles and require all the usefulness of a run of the mill laptop. They are appropriate for vehicle introduces on account of the vehicle mounting dock alternatives and in light of the fact that they will keep on working in the hot and uneven condition of a vehicle.

Rugged laptops are more intense than tablets and make it simpler to finish office work in light of their bigger screens and implicit consoles.

Rugged Tablets:

Rugged tablets are designed to a similar military measures and can finish huge numbers of indistinguishable occupations from a rugged laptop. The principle distinction with a rugged tablet is that it is increasingly lightweight and versatile, which furnishes the client with more prominent adaptability in the field. A rugged tablet is ideal for employments that need lightweight innovation in a hurry.

Rugged laptops can weigh between 3 to 4.5kgs while rugged tablets weigh around 1 - 1.5kg. Some rugged tablets have a worked in standardized tag scanner. This trademark is incredible for distribution center or strategic employments that require a gadget that won't break on the off chance that it comes to pass for from racks or hardware. You have an enormous scope size choice with rugged tablets from 5-inch cell phone evaluated gadgets to 10-inch tablets.

There are likewise numerous rugged tablets that are endorsed as being Intrinsically Safe. This implies they can be utilized in risky territories with Atex zone order, important for any work environments in the oil and gas industry.

The line inside rugged tablets and rugged tablets is clouded now in view of 2-in-1 gadgets like the Panasonic FZ G1, which has a separable console, giving you the best of the two universes.

One of a kind Features:

•Touchscreen LCDs with Anti-intelligent covering

•Typically the touchscreens work in wet climate and with gloves on

•MIL-STD-810G ensured - drop and shockproof

•Camera abilities

•Lightweight (1.5kg)

Rugged Tablets inclusion:

Rugged tablets spread the accompanying zones:

•Transport and coordination’s

•Airline administrators

•Scientists

•Field administrators

•Tradespeople and any individual who works on building destinations.

#rugged laptops#panasonic toughbook for sale#panasonic toughbook cf 20#rugged computing solutions#ruggedized tablet#rugged accessories#panasonic toughpad fz b2#getac computers notebooks and tablets#rugged tablet in UAE

0 notes

Text

Things to Know about Pressure Vacuum Vents

The uses and importance of Pressure Vacuum Vents are enormous. These pressure vacuum vents are mostly installed on top of vent pipes from the underground or the aboveground fuel storage tank. This vent cap and the internal wire screen are mainly designed to protect tank vent lines against any intrusion or blockage from water, insects or debris. A closed poppet in valve opens at predetermined pressure or the vacuum is set to allow tank to vent.

Key Features of Tank Vents

Here follow some remarkable features of the tank vent, that you should know;

The setting of pressure vacuum vent is made at 2.5” to 6” water column pressure settings. And -6” to -10” water column vacuum is set to suit the factor preset and it is tested too

It is tested to ensure that there is no leakages problems happen even during the sever environment existing

This features the corrosion- resistant construction. The duratuff composite body will assure long service life of the pressure Vacuum Vents

This vent can be easily installed. This is also available in 2” and 3” threaded version. This makes the installation easy and simple too

The complies with NFPA 30 requirements will imply venting gasoline vapors upwards

The manifold vent pipes will produce single pressure vacuum vent line. This will control maximum vapor leak rate

It features high maximum flow rate

The leak rate is monitored by multiple pressure vacuum vents that is installed on single site.

This is easy to maintain and there is no special tool required for it. Moreover, a removable snap fit top will allow easy maintenance

The 100- mesh stainless steel wire screens will help to prevent debris and insects entering the tank vent lines. Moreover the added screen installed at base will prevent debris from intruding from vent stack

The removable hex threaded bushing designed for easy installation on NPT threaded risers. This will allow easy access to lower screen

It features ATEX approve for the flame arrestor applications

The top and body is made of polypropylene materials. The base features anodized aluminium and poppet features anodized aluminium. The screen features stainless steel mesh and gasket is made of closed cell foam

To know more about the tank Vents, here follow;

These vacuum vents are factor set and they feature the specifications that pallet assemblies in housings open with particular pressure and the level of vacuum is sensed

The setting points for vents are achieved by loading of weight or loading spring or pallet assemblies on the basis of setting required

The vapour space pressure of tank will work opposite to force applicable to the pallet assemblies and it reseals automatically

This tank vent will help to maintain atmospheric pressure.

The other types of tank vent accessories will include flame arrestors, which are installed within vent pipe on flammable liquid storage tanks

This flame arrestor is designed to allow air flow through series of parallel plates, which break up flame flowing through vent

0 notes

Text

Things to Know about Pressure Vacuum Vents

The uses and importance of Pressure Vacuum Vents are enormous. These pressure vacuum vents are mostly installed on top of vent pipes from the underground or the aboveground fuel storage tank. This vent cap and the internal wire screen are mainly designed to protect tank vent lines against any intrusion or blockage from water, insects or debris. A closed poppet in valve opens at predetermined pressure or the vacuum is set to allow tank to vent.

Key Features of Tank Vents

Here follow some remarkable features of the tank vent, that you should know;

• The setting of pressure vacuum vent is made at 2.5” to 6” water column pressure settings. And -6” to -10” water column vacuum is set to suit the factor preset and it is tested too

• It is tested to ensure that there is no leakages problems happen even during the sever environment existing

• This features the corrosion- resistant construction. The duratuff composite body will assure long service life of the pressure Vacuum Vents

• This vent can be easily installed. This is also available in 2” and 3” threaded version. This makes the installation easy and simple too

• The complies with NFPA 30 requirements will imply venting gasoline vapors upwards

• The manifold vent pipes will produce single pressure vacuum vent line. This will control maximum vapor leak rate

• It features high maximum flow rate

• The leak rate is monitored by multiple pressure vacuum vents that is installed on single site.

• This is easy to maintain and there is no special tool required for it. Moreover, a removable snap fit top will allow easy maintenance

• The 100- mesh stainless steel wire screens will help to prevent debris and insects entering the tank vent lines. Moreover the added screen installed at base will prevent debris from intruding from vent stack

• The removable hex threaded bushing designed for easy installation on NPT threaded risers. This will allow easy access to lower screen

• It features ATEX approve for the flame arrestor applications

• The top and body is made of polypropylene materials. The base features anodized aluminium and poppet features anodized aluminium. The screen features stainless steel mesh and gasket is made of closed cell foam

To know more about the tank Vents, here follow;

• These vacuum vents are factor set and they feature the specifications that pallet assemblies in housings open with particular pressure and the level of vacuum is sensed

• The setting points for vents are achieved by loading of weight or loading spring or pallet assemblies on the basis of setting required

• The vapour space pressure of tank will work opposite to force applicable to the pallet assemblies and it reseals automatically

• This tank vent will help to maintain atmospheric pressure.

• The other types of tank vent accessories will include flame arrestors, which are installed within vent pipe on flammable liquid storage tanks

• This flame arrestor is designed to allow air flow through series of parallel plates, which break up flame flowing through vent

0 notes

Text

R10 LOAD CELL – MASTER K VIỆT NAM

Vui lòng liên hệ với chúng tôi– chúng tôi sẽ liên hệ lại với khách hàng bằng điện thoại hoặc email.

Lưu ý: Tham khảo ý kiến của nhân viên INO sẽ giúp bạn tiết kiệm được thời gian và chi phí khi cần mua sắm. Với sự tư vấn của chúng tôi, bạn sẽ không gặp khó khăn khi tìm hiểu về đặc tính của sản phẩm cần mua.

R10 LOAD CELL

R10 load cell & mouting kit

This type of stainless steel low profile compression load cell is particularly suitable for silos weighing.

Various models of mounting kits are available for a fast and simple integration under silos’ feet, machine, hopper…

R10 compression load cell characteristics:

Measuring capacity (weighing) from 1 to 100 tons

IP68 Protection rating

Accuracy up to ± 0.05%.

Grain of spherical supports for centering the load on the load cell.

R10 compression load cell options:

Compression mounting kit

Compression mouting kit with anti-lifting device

ATEX version (explosive zone)

R10 load cell electrical characteristics:

Supply voltage range: 1 to 15 V

Compensated temperature range: -10 … +50 C°

Protection rating: IP68 according EN 60529

Temperature range: -20 … +60 C°

Material : Stainless steel

Cable length : 10m

Load cell net weight: 1,5 (≤ 15 t)/4 (30 t et 50 t-S)/10 (≥ 50 t) kg

The R10 load cell & mounting kit can be connected to weight indicator.

Resource & Download

Datasheet

Lưu ý: Nếu một thiết bị nào đó không được liệt kê ở đây, điều đó không có nghĩa rằng chúng tôi không hỗ trợ được bạn về thiết bị đó. Hãy liên hệ với chúng tôi để biết danh sách đầy đủ về thiết bị mà chúng tôi có thể hỗ trợ và cung cấp.

INO: Bán, Báo giá, tư vấn mua sắm và cung cấp, tư vấn sản phẩm thay thế; tương đương, hướng dẫn sử dụng, giá…VNĐ, …USD [email protected] | 02873000184 | R10 LOAD CELL – MASTER K VIỆT NAM.

Calibrator http://www.calibrator.vn/khac-do-luong-kiem-tra/r10-load-cell-master-k-viet-nam/

0 notes