#automatic heat shrink wrapping machine

Text

Are Shrink wrapping machines easy to operate?

Shrink wrapping machines have become an integral tool in various industries, providing a secure and professional packaging solution for a wide range of products. But one common question arises: Are shrink wrapping machines easy to operate?

Types of Shrink Wrapping Machines

Shrink wrapping machines come in various types, each designed for specific applications and varying levels of user interaction:

Manual Shrink Wrapping Machines: These are the simplest and most cost-effective options. They require the operator to manually place the product in the shrink wrap, seal the wrap, and apply heat.

Semi-Automatic Shrink Wrapping Machines: These machines provide a balance between manual and automatic operations. The operator still needs to place the product and initiate the wrapping process, but the machine handles the sealing and shrinking.

Fully Automatic Shrink Wrapping Machines: They automatically feed, wrap, seal, and shrink the products. While these machines are the most complex, they are equipped with user-friendly interfaces, programmable settings, and advanced sensors.

Factors Affecting Ease of Operation

Several factors contribute to the ease of operating shrink wrapping machines:

User Interface: Modern shrink wrapping machines often feature intuitive touchscreens and control panels that guide the operator through the wrapping process.

Training and Support: The availability of comprehensive training programs and user manuals significantly impacts how easy it is to operate a shrink wrapping machine.

Maintenance and Troubleshooting: Machines designed with easy-access components and clear maintenance instructions are easier to keep in optimal working condition.

Customization and Flexibility: Machines that can handle a variety of product sizes and shapes without requiring complex adjustments are generally easier to operate.

0 notes

Text

ZONESUN is a manufacturer of sealing machines, with a wide variety of types including manual, semi-automatic, and fully automatic. These machines are used in a wide range of applications, such as sealing bags, boxes, tubes, and strapping. The sealing methods include heat sealing and shrink wrapping. Moreover, ZONESUN can connect the sealing machine with labeling machines, filling machines, capping machines, and boxing machines to form a complete set of packaging equipment, making your production easier.

0 notes

Text

Best Kinds of Sealers

If your vacuum sealer has a detachable drip tray you presumably can take it out and give it a great wash. You’ll additionally need to make sure you give the machine, together with the heat seal, a good wipe down and use an antibacterial spray to avoid the unfolding of micro organism. Some machines even have a separate design, which means you possibly can raise the lid off to clean too, which is handy for cleansing. These vacuum sealers are available in several different bar widths to cater for bigger bulk luggage in addition to small pouches. You can use bag warmth sealing machines for an excellent variety of purposes. They can be used to seal a broad range of packaging products from food, pharmaceutical, hardware, and other materials – all into thermoplastic bags - vacuum packager.

The best vacuum sealer is a nifty gadget that may help lengthen the shelf life of your food. The sealing process can help hold produce contemporary for as much as five times longer than commonplace storage strategies, depending on the sort of food and the place you retail it. So you’ll soon discover that you throw much less away, not only doing your bit for planet Earth, but saving precious money on wasted food too. These vacuum sealers are available in several different bar widths to cater for bigger bulk luggage in addition to small pouches. With fixed sealing the inner layer is sealed with no defect to the backing material. Our best specialized functions including the very high automated steady sealers. Based on its overwhelmingly constructive critiques, the Vacuum Sealer is our high choice - automatic shrink wrap machine.

If the world of food vacuum storage is new to you, there's a couple of questions you might wish to ask yourself earlier than investing in a model new gadget. We try to pair the standard merchandise with essentially the most sustainable supplies and methods. We are a company that offers with the provision of high quality services at competitive prices. These sizes will swimsuit most tasks however bespoke widths can be made to order. In our experience a lot of the business hand heat sealing machine models in the marketplace are unsuitable for repeat or high volume sealing. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

Bisleri Plant Manufacturer, Bisleri Plant - kceindia.com

Bisleri Plant Manufacturer : kceindia.com is Bisleri Plant Manufacturer, Bisleri Plant Supplier, and Bisleri Plant Exporter in Navi Mumbai, India. Call Now.

Packaging Machineries, Packaging Machinery, Wrapping Machines, Wrapping Machine, Wrap Machine, Sealing Machine, Sealing Machines, Sealing Machinery, Auto Impale Sealing Machine, Foot Operated Direct Heat Sealer, Continuous Pouch Sealing Machine, Shrink Tunnel Machine, Shrink Wrapping Machines, Carton Sealer Machine, Carton Sealing Machine, Carton Taping Machine, Pallet Stretch Wrappling Machine, Stretch Wrapping Machine, Flow Pack Wrapping Machine, Horizonatal Flow Pack Wrapping Machine, Piston Filler, Cup Filler Machine, Form Fill and Seal Machine, Form Fill Seal Machine, Auger Filler, Vertical Flow Pack Machine, Cut and Wrap Machine, Chocolate Cutting Machine, Enrober, Enrober Cooling Tunnel, Packaging Automation, Pouch Sealing Machine, Food Processing Equipments, Packaging Equipments, Air Pillow Making Machines, Auger Filler, Automatic Packaging Machine, Biscuit Packaging Machinery, Biscuit Packing Machines, Bunch Wrapping Machines, Bunch Wrapping Machines, Center Seal Flow Wrapping Machines, Centre Seal Pouch Machines, Chocolate Cutting Machines, Chocolate Packing Machines, Chocolate Wrapping Machinery, Complete Packing Line, Continuous Pouch Sealing Machine, Cup Sealing Machines, Cut And Wrap Machine, Flow Pack Wrapping Machine, Flow Wrap Machinery, Flow Wrap Machines, Flow Wrapping Machine, Form Fill Seal Machines, Four Side Seal Flow Wrapping Machines, Granules Packing Machines, Horizontal Flow Pack Wrapping Machine, Ice Cream Wrapping Machines, Jelly Packing Machines, Liquid Sealing Machines, Liquid Wrapping Machines, Masalas Packaging Machine, Packaging Automation, Packaging Machinery, Packaging Machines, Pickling Plant, Pillow Pack Flow Wrapping Machines, Pillow Pack Machines, Piston Filler, Plastic Bag Sealing and Packaging Machines, Pouch Sealing Machine, Pvc Seaming Machines, Sealing Machinery, Shampoo Wrapping Machines, Soap Banding Machines, Soap Wrapping Machines, Vertical Flow Pack Machine Cup Filler, Wrapping Machinery, Vasai, karjan , khopoli, neral, lonavala, khandala, igatpuri, bhivandi, shahapur , nasik , shirdi, titwala, bhor , sinner, shirdi, Ahamadnagar, kholapur, sangli, ichalkarangi, Ahamadnagar, solapur, jejuri, Baramati, ratnagiri, roha, Talasari, wada,palghar, dahanu , nagpur, nanded, latur, Alibag, pen , vashi , cbd belapur

0 notes

Text

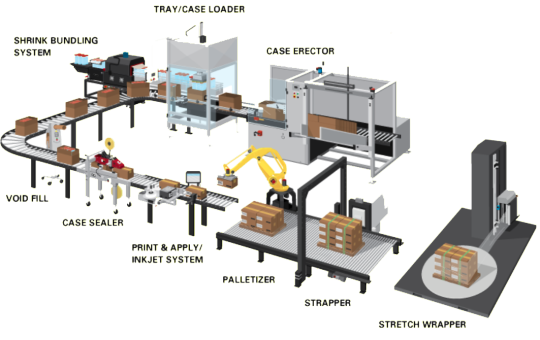

Packaging Automation

Packaging automation can be a powerful tool for businesses that need to ship large quantities of products quickly. If you would like to increase productivity and shorten the time it takes to deliver products to customers, automated packaging systems and processes might be the answer.

With so many options available, you may be wondering which solution is the best for your operations. Don’t worry, we’ve got you covered!

We will define packaging automation, explore different types available and look at some of the key advantages and frequently asked questions related to packaging automation.

Packaging automation entails introducing automated equipment and machinery into your packing operation to accelerate the packing process.

This helps to assure consistency, avoid material waste, and save money overall. It also enables you to reallocate valuable resources to high-value jobs or in the most efficient method for your operation. Most areas of the packaging process can be improved by introducing automated packaging systems; from picking and packing to conveying and wrapping, there are packaging machines for it all.

What are the different types of packaging automation?

Erecting boxes, taping cartons, and wrapping pallets for shipment can all be automated.

We distinguish between semi-automated and automated packing methods:

A semi-automated packing process combines both human involvement with elements of automation. For example, an operator can start the process, but an automatic packing system will finish it. If you want to use automation but have a restricted budget, this is usually the most cost-effective option.

An automated packing process is pre-programmed from start to end. It can handle everything from picking products, and packaging to palletizing for shipping. This option is a good solution for operations where demand is high or that predict significant grow.

We distinguish between the following automation solutions, based on the product you’re using:

Box automation – including solutions, such as case and box erectors, fully and semi-automated auto boxing machines as well as void reduction systems.

Tape automation – e.g., semi, and fully automatic tape dispensers, in-line taping machines and carton sealers.

Bag automation – e.g., automated bagging machines and bulk bagging equipment.

Protective automation – including semi and fully automated void fill machines, air cushioning and air pillow machines.

Paper automation – e.g., paper wrapping equipment, paper void fill machines and paper cushioning systems.

Strapping automation – solutions such as: semi and fully automated strapping machines, friction welders, battery powered strapping tools and banding tables.

Stretch automation – e.g., fully, and semi-automatic pallet wrappers, vertical and horizonal stretch wrapping machines and rotating arm stretch wrap machines.

Shrink automation – e.g., shrink-wrapping machines, heat shrink tunnels, heat sealers, impulse heat sealers and vacuum packing machines.

Auxiliary equipment – solutions, such as: automated labelling equipment, case stackers, sorters, palletizers, and conveyor systems.

Packaging automation offers many benefits. It can help you to:

-Boost productivity, allowing you to pack more cases in less time.

-Save space, using fewer packaging SKUs and, therefore, saving storage space before cases are packed (less packaging stored on site), as well as cubage, which saves transport space.

-Lower operating costs, resulting in savings on labor, storage, transportation, packing materials, and productivity.

-Streamline workflow, ensuring your packaging process runs as smoothly as possible.

-Reduce volume handling, relieving operational strain and helping better manage spikes in demand.

-Assure pack optimization and consistency, ensuring that the appropriate quantity and type of packaging is used every time.

-Minimize material waste, making sure you only use the right amount of material required to protect your product during transit and avoiding overpacking.

-Reduce transport and fuel costs, enabling you to pack more products onto a pallet. This will also help reduce your carbon footprint, as less fuel means fewer CO2 emissions.

-Ensure customer satisfaction, providing smart, beautifully packaged products that arrive with your customers damage-free.

-Future-proof for growth and demand, increasing your capacity and helping control costs as your business grows.

How do I automate my packing process?

There are many ways to automate your packing process. You can automate almost any part of it, but if you need pointers of where to start, you will need to review your packing operation first. This will help you identify any bottlenecks or processes that could be improved or automated.

Some of the common bottlenecks include:

Picking accuracy – miss-picks can be a sign that something is not working or that demand is outstripping capacity.

Packing times – have packing times met targets? Are packers taking longer to process orders? During high-pressure times, packing times can be a bottleneck if processes aren’t efficient and packing materials aren’t easy.

Shipping lead times – do your lead times keep increasing and getting longer? This can be in response to high demand, but it can also suggest that processes need to change.

Damages – are customers reporting an increase in damages? This can be an indicator that packing isn’t being completed properly or that the packing materials being used aren’t sufficient.

How to choose the right packaging machine equipment?

The type of automation solution you need will depend on your products, processes, productivity goals and space in your warehouse. You will also need to factor in your budget.

What will packaging automation cost me?

Packaging automation can be an investment, depending on the solution you’re looking at. There may be a large upfront cost to purchase an automated packaging system, but the money you will save elsewhere in your operation will counterbalance this overall.

Not every system requires an initial outlay – many are available for rental or can be purchased through finance agreements. A free trial is available on many machines, which gives you the opportunity to test if the solution is right for your business. Plus, there are some cost-effective automation options out there.

How do I calculate return on investment (ROI) for packaging automation?

The ROI for packaging automation is calculated by comparing the costs associated with implementing automation to the benefits it brings, including cost savings and increased productivity.

When calculating the cost of automation for your business, there are several factors to consider, including your initial investment, equipment costs, installation setup fees, staff training, and any projected long-term costs, such as maintenance and repair. Then, think about how much money you can save each year with packaging automation. This can include reducing labor costs, increasing productivity and throughput, reducing material waste, as well as improving product quality and consistency.

How do I futureproof the investment in packaging automation?

When you invest in packaging automation, it is important to make strategic decisions and put processes in place to keep your packaging automated system running smoothly and up to date with the latest technologies and industry developments. Consider things such as regular and preventative maintenance, staff training, periodic calibration, and testing of equipment as well as spare parts inventory.

At Quick Pak Inc, we work closely with our customers on a case-by-case basis to find the best automated packaging solutions for their requirements.

We can offer a wide choice of automated packaging solutions to fit various demands and budgets, whether you need a pallet wrapper, shrink equipment, labeling and marking, carton sealer, case erector, or anything in between.

Contact us today at 813 242 6995 or [email protected]

#packaging automation#less packaging#pack faster#better packaging#pricing news#quickpakinc#stretch film pricing#stretch film#resin pricing#free pallet wrapper#coreless film#youtube#quick pak inc#free machine

0 notes

Text

Mastering Packaging Efficiency: Unveiling the Power of Shrink Wrapper Machines

In the realm of product packaging, the utilization of advanced technology has become a cornerstone of efficiency. Among these innovations, shrink wrapper machines stand out as an essential tool for businesses aiming to optimize their packaging processes.

Understanding Shrink Wrapper Machines

Shrink wrapping involves the packaging of products using a plastic film that shrinks when heat is applied, conforming to the shape of the product. Shrink wrapper machines automate this process, streamlining packaging operations across various industries.

1. Increased Efficiency

Shrink wrapper machines significantly enhance productivity by automating the packaging process. They can wrap products rapidly and consistently, reducing manual labor and increasing output.

2. Versatile Applications

These machines cater to various industries, including food and beverage, pharmaceuticals, cosmetics, and more. They accommodate different product shapes and sizes, ensuring flexibility in packaging.

3. Enhanced Product Presentation

The tight, secure packaging provided by shrink wrapper machines not only protects products from damage but also enhances their visual appeal. This professional presentation can positively influence consumer perception.

4. Cost Efficiency

Despite the initial investment, shrink wrapper machines offer long-term cost savings. They decrease material wastage, reduce labor costs, and improve overall operational efficiency.

5. Environmental Sustainability

Shrink wrapping often uses recyclable materials, promoting eco-friendliness. Additionally, the reduction in packaging material usage contributes to a more sustainable packaging process.

How Shrink Wrapper Machines Work

Shrink wrapper machines function by enclosing products in shrink film, which is then heated to shrink tightly around the product. The process involves:

Film Dispensing: The shrink film is unwound from a roll and guided around the product.

Sealing: The film is sealed around the product using heat or adhesives.

Shrinking: Heat is applied to the film, causing it to shrink and conform to the product's shape.

Cooling: The film cools and solidifies, creating a secure and tamper-evident package.

Advantages of Shrink Wrapping

Tamper-Resistance: The tightly sealed film provides tamper-proof packaging, ensuring product integrity.

Customization: Shrink wrapping allows for branding and labeling, offering an opportunity for custom designs and promotional messages.

Protection: It safeguards products from dust, moisture, and external damage during transportation and storage.

Choosing the Right Shrink Wrapper Machine

Consider factors such as the type of products to be wrapped, production volume, speed requirements, and available space when selecting a shrink wrapper machine. Different models—such as L-bar sealers, continuous motion wrappers, or automatic wrappers—offer varying features suitable for distinct needs.

Conclusion

Shrink wrapper machines are pivotal in optimizing packaging efficiency across industries. Their ability to streamline processes, improve product presentation, reduce costs, and support sustainability makes them indispensable tools for modern businesses. By harnessing the power of these machines, companies can enhance their packaging operations, ensuring consistent and high-quality product delivery to their consumers.

0 notes

Video

2023 year best supplier for Bse 4525 fql450 L L Sealer Automatic Shrink Wrapping Machine

Bse 4525+fql450 L L Sealer Automatic Shrink Wrapping Machine - Buy Automatic Shrink Wrapping Machine,Heat Shrink Tube Machine,Shrink Wrapping Machine Product

0 notes

Text

Best Automatic L Sealer Machine Manufactuer in India

L Sealer Machine Manufacturer in India

Ace Packaging Solution is a leading manufacturer, supplier and exporter of L-sealer machines in India. With years of experience in the packaging industry, we take pride in offering high-quality and reliable L-sealer machines that are designed to meet the diverse needs of our customers. Our machines are built using cutting-edge technology and premium-grade materials, ensuring their durability and performance.

What is an L-Sealer Machine?

An L-sealer machine, also known as a sleeve wrapper, is a packaging device used to wrap and seal products in a protective film or shrink wrap. The machine consists of two main components: a sealing bar in the shape of the letter "L" and a heat source. When in operation, the L-sealer wraps a plastic film around the product and uses heat to seal the edges of the film, creating a tightly enclosed package around the item. Subsequently, the packaged product can be sent through a heat tunnel or heat shrink chamber to apply uniform heat and shrink the film, providing a secure and tamper-evident package.

Applications of L-Sealer Machines:

L-sealer machines are versatile and find applications across various industries, including:

Food Industry: L-sealers are widely used for packaging food items such as fresh produce, frozen meals, baked goods, and confectionery. The airtight seal provided by the machine helps extend the shelf life of the products and preserves their quality.

Pharmaceuticals and Healthcare: In the pharmaceutical industry, L-sealers are employed to package medicines, medical devices, and other healthcare products securely. The tamper-evident packaging ensures the integrity of the products.

Cosmetics: L-sealers package cosmetics and personal care items, protecting them from external contaminants and maintaining their visual appeal.

Electronics: Delicate electronic components and devices benefit from L-sealer machine packaging, as it shields them from dust, moisture, and physical damage during transit.

Textiles and Apparel: L-sealers are used to package clothing and textiles, providing a clean and professional presentation for retail display.

Benefits of L-Sealer Machines:

Efficiency and Speed: L-sealer machines automate the packaging process, significantly increasing the speed at which products are wrapped and sealed. This boost in efficiency can lead to higher productivity and lower labor costs for businesses.

Versatility: These machines can handle a wide range of products, regardless of their size, shape, or orientation. As long as the item can fit within the sealing area, the L-sealer can enclose it effortlessly.

Cost-Effectiveness: Investing in an L-sealer machine can be cost-effective in the long run, especially for businesses with high-volume packaging needs. The reduced reliance on manual labor and the ability to use cost-efficient packaging materials contribute to cost savings.

Product Protection: L-sealers provide a secure and tight seal around products, protecting them from external elements, such as dirt, moisture, and tampering, during storage and transportation.

Enhanced Aesthetics: The neatly sealed and professionally packaged products improve the overall presentation, which can positively impact a brand's image and attract potential customers.

Environmental Benefits: Many L-sealer machines use recyclable and eco-friendly packaging materials, promoting sustainable packaging practices and reducing the environmental impact.

In Conclusion:

L-sealer machines are a boon for businesses seeking to enhance their packaging processes. From efficient and consistent sealing to improved product presentation, the benefits of L-sealer machines are hard to ignore. Whether it's the food industry, pharmaceuticals, electronics, or other sectors, the versatility and effectiveness of L-sealers make them a valuable asset for any business aiming to optimize its packaging operations and excel in a competitive marketplace.

We value your interest in L-sealer machines and would be delighted to provide you with further details and address any inquiries you may have!

Website - https://www.shrinkpackagingmachines.in/

Email - [email protected]

Contact No. - +91-9810264335

#Automatic l sealer machine manufacturer in India#l sealer machine manufacturer in India#Best L sealer machine manufacturer in India#L sealer machine manufactuer in India#L sealer machine manufacturer in Ghaziabad#L sealer machine manfuacturer in Delhi NCR#L Sealer machine supplier in India#L sealer machine supplier in Ghaziabad#best packaging machines supplier in India#Best packaging machines manufacturer in Ghaziabad#Shrink packaging machines#ace packaging solutions

1 note

·

View note

Text

How Does Shrinkwrap Machinery Work?

How Does Shrinkwrap Machinery Work?

Shrinkwrap machines work by creating a sleeve, or envelope, of loose shrink film around a product, from a continuous plastic roll. Heat is then applied to shrink the individual sleeve or envelope firmly around the product. If the film is properly applied by a shrinkwrap machine then the resultant packaged product will have an outer wrap which conforms tightly around the product itself. The film is strong, thin, and clear, and will provide both tamper evidence and enhanced optical display properties, both of which are essential for retail distribution.Get more news about Auto Shrink Wrap Machine,you can vist our website!

This process is available to all businesses, whether the demand is low level, or whether required by large scale organisations that have continuous production requirements. Accordingly Shrink wrapping can be fulfilled by machinery that is very simple, such as a manual heat gun, or it can be through specialist packaging machinery. Kempner is here to offer exactly the right advice, because for all businesses, the right shrink wrap machine is vital to efficiency, allowing as many products to be wrapped in as short an amount of time as possible.

The type of shrink wrapping machinery you need for your business will depend upon understanding your current, or proposed, wrapping process and what you goals are. You will need to think about the wrapping process: how

quickly packs are produced prior to the wrapping process, what range of sizes are required, and how many packs are to be wrapped in a given time.

Whatever the need, there will nearly always be a shrink wrapping machine designed to meet the application. If you would like to discuss individual requirements then Kempner can help you understand which packaging

machine and shrinkwrap film options may be best suited to your needs. The ways in which shrink wrapping machines operate can vary in type in a number significant ways. In simple terms the choice is between Manual, Semi-Automatic and Fully Automatic, but within each of these broader categories there are various options to choose. Below are some of the available options:

Side Sealer

A side sealer is the quickest and most versatile way of packaging large volumes of products. They wrap products in a continuous tube of film, sealing one side of the package then separating individual units downstream through a cross seal. Side sealers usually come in one of two configurations: two belts or three belts. A two belt sealer is more compact (only slightly bigger than an L-sealer) and eliminates one of the indeed belts to make the end seal before the side seal.

They are best when you need to wrap longer products but cannot afford to expand production line lengths. Three belt sealers are slightly larger than two belt sealers and have the added advantage of precisely spacing the products before entering the wrapping area.

0 notes

Text

Maximizing Efficiency with Steam Shrink Tunnel: A Comprehensive Guide

In today's fast-paced industrial world, maximizing efficiency is crucial to maintaining a competitive edge. One area where this is particularly important is in the packaging process. One of the most effective ways to increase efficiency in this area is by using steam shrink tunnels. These machines use steam to shrink-wrap products quickly and effectively, saving time and reducing waste. Siddhivinayak Engineering is a leading Manufacturer and Exporter of Steam Shrink Tunnel and Electric Shrink Tunnel. We have a unique range of Shrink Sleeve Label Applicator Machine including Heat Shrink Tunnel, Shrink Wrapping Tunnel, Heat Shrink Packaging machines, and more.

What is a Steam Shrink Tunnel?

A Steam Shrink Tunnel is a machine that uses steam to shrink-wrap products. These machines are commonly used in the packaging industry to package a wide range of products, including food items, beverages, and pharmaceuticals. Steam shrink tunnels work by exposing the product to steam, which causes the shrink film to shrink and conform to the shape of the product. The end result is a tightly wrapped package that is both secure and visually appealing.

How steam shrink tunnels work

Steam shrink tunnels work by exposing the product to steam, which causes the shrink film to shrink and conform to the shape of the product. The steam is typically generated by a boiler, which heats the water to create steam. The steam is then directed into the shrink tunnel, where it comes into contact with the product. The Shrink Wrapping Tunnel shrinks as the film is wrapped around the product and then passed through the tunnel, where it is exposed to steam.

Tips for maximizing efficiency with Steam Shrink Tunnel-

There are several tips you can follow to maximize efficiency when using a steam shrink tunnel. One of the most important tips is to choose the right shrink film for your products. This can help to reduce waste and ensure that your products are wrapped securely and professionally.

Another tip is to ensure that the machine is calibrated correctly and operating at the correct temperature. This can help to ensure that the Heat Shrink Tunnel film shrinks evenly and that your products are wrapped tightly and securely.

Finally, it's important to train your employees on how to properly operate the machine. This helps ensure that the machine is used efficiently and that your products are wrapped consistently and professionally.

Benefits of using a steam shrink tunnel-

One of the most significant benefits is increased efficiency

Another benefit of using a steam shrink tunnel is improved product appearance

Steam shrink tunnels require less energy

Steam shrink tunnels are faster than traditional heat tunnels.

The use of steam in the shrink tunnel ensures uniform shrinkage of the film or sleeve

We are a leading Steam Shrink Tunnel Manufacturer in India. We offer a variety of High-Speed Steam Shrink Tunnel, Automatic Single Head Steam Shrink Tunnel, Automatic Dual Head Steam Shrink Tunnel, Automatic Double Head Bottle Steam Shrink Tunnel, Automatic Neck Steam Shrink Tunnel, and Heat Shrink Packaging Machine. These machines can wrap products quickly and effectively, reducing waste and improving product appearance. By following the tips outlined in this guide and working with a reputable supplier or manufacturer, you can maximize efficiency and streamline your packaging process.

0 notes

Text

buy Flow Wrapping Machine

buy Flow Wrapping Machine Automatic High-Speed Heat Shrink Able Packaging Machinery(Downward film) RecommendationsThis high speed auto wrapping machine is produced according to Japanese Techniques with their developed technique and rich experience,and all electrical elements are imported.This machine can be easily operated,of good quality and stable performance.the speed can be frequency varied but not classed.PLC is equipped to control the unit to reduce failure points. Circulated high efficiency air and auto temperature control at high efficiency area of heated contract furnace ensure contracting quality. Performance characteristicsThe color touch screen control system, driven by three servo motors, is easy to operate, high stability and high packaging efficiency. Low failure rate; long bag, speed and temperature can be adjusted independently, easy to operate and accurate. Cut-proof safety clutch device, does not damage the packaging. High sensitivity photoelectric eye color mark tracking, mathematically input the sealing position, so that the sealing position is more accurate. Temperature independent PID control, better suitable for all kinds of coating materials. Location stop function, no sticking knife, no waste of film. The transmission system is simple, reliable and easy to maintain. Cut to the product automatic inversion, restart directly after boot convenient operation. Adding waste recycling device makes packaging more beautiful and saves about 20%-30% material than traditional folding film packaging machine. It can be equipped with a typewriter or a jet printer without manual use. With motor brake control, the equipment is responsive. High efficient double temperature zone, high efficient hot air circulation, automatic temperature control, ensure the quality of shrinkage. Application scopeSkin package for grouped food and drinks,bowl noodles,milk tea,mosquito coils,wallpaper,exercisebooks,filters,electrical switches,a variety of stationery,industry parts,commodities and cosmetics,etc. Main technical parametersMax Flim size鈮?90mm Model120150180210 Packing sizeL:Bag lengthL:60mm-320mmL:100mm-450mmL:150mm-530mmL:180mm-600mm W:Object widthw:10mm-200mmw:10mm-200mmw:10mm-200mmw:10mm-200mm H:HeightH:5mm-35mmH:35mm-70mmH:75mm-100mmH:80mm-130mm Packing speed30-150(Package / min)30-150(Package / min)30-135(Package / min)30-100(Package / min) Flim typePVC;POF;Isothermal shrink film Power consumptionPackaging machine: 4.5kw:; shrinkage furnace: 15.5KW Power supplyHost:220V,50HZ/60HZ;Shrinking machine:380V锛?0HZ/60HZ Envelop dimensions5000x1170x1500mm Shrinking machine2600x600x1700mm WeightHost:1000KGShrinking machine:600KG According to the different requirements of packaging and packaging, the specific technical parameters will be changed. The technical parameters confirmed by both sides shall prevail. Machine videos:聽buy Flow Wrapping Machine website:http://www.sz-polytech.com/flow-wrapping-machine/

0 notes

Text

Wrapping Machine

Heat Shrink wrapping machine suitable for gift’s confectionery, bottle, cosmetics etc. It’s a high speed of sealing machine and high equipment sealing. The complete process is visible & is furnish with L- sealer shaped. The automatic process of shrinkable pouch complete with web- sealer. We are provide very high quality of heat-sealing machine and branded shrink machine - shrink packing machine.

0 notes

Text

Water Plant, Manufacturer in India

Manufacturer, Supplier, and Exporter of Reverse Osmosis Plants, RO Plants, Industrial, RO Water Plants, Commercial RO Plant, Reverse Osmosis System in Navi Mumbai, India.

Packaging Machineries, Packaging Machinery, Wrapping Machines, Wrapping Machine, Wrap Machine, Sealing Machine, Sealing Machines, Sealing Machinery, Auto Impale Sealing Machine, Foot Operated Direct Heat Sealer, Continuous Pouch Sealing Machine, Shrink Tunnel Machine, Shrink Wrapping Machines, Carton Sealer Machine, Carton Sealing Machine, Carton Taping Machine, Pallet Stretch Wrappling Machine, Stretch Wrapping Machine, Flow Pack Wrapping Machine, Horizonatal Flow Pack Wrapping Machine, Piston Filler, Cup Filler Machine, Form Fill and Seal Machine, Form Fill Seal Machine, Auger Filler, Vertical Flow Pack Machine, Cut and Wrap Machine, Chocolate Cutting Machine, Enrober, Enrober Cooling Tunnel, Packaging Automation, Pouch Sealing Machine, Food Processing Equipments, Packaging Equipments, Air Pillow Making Machines, Auger Filler, Automatic Packaging Machine, Biscuit Packaging Machinery, Biscuit Packing Machines, Bunch Wrapping Machines, Bunch Wrapping Machines, Center Seal Flow Wrapping Machines, Centre Seal Pouch Machines, Chocolate Cutting Machines, Chocolate Packing Machines, Chocolate Wrapping Machinery, Complete Packing Line, Continuous Pouch Sealing Machine, Cup Sealing Machines, Cut And Wrap Machine, Flow Pack Wrapping Machine, Flow Wrap Machinery, Flow Wrap Machines, Flow Wrapping Machine, Form Fill Seal Machines, Four Side Seal Flow Wrapping Machines, Granules Packing Machines, Horizontal Flow Pack Wrapping Machine, Ice Cream Wrapping Machines, Jelly Packing Machines, Liquid Sealing Machines, Liquid Wrapping Machines, Masalas Packaging Machine, Packaging Automation, Packaging Machinery, Packaging Machines, Pickling Plant, Pillow Pack Flow Wrapping Machines, Pillow Pack Machines, Piston Filler, Plastic Bag Sealing and Packaging Machines, Pouch Sealing Machine, Pvc Seaming Machines, Sealing Machinery, Shampoo Wrapping Machines, Soap Banding Machines, Soap Wrapping Machines, Vertical Flow Pack Machine Cup Filler, Wrapping Machinery, Vasai, karjan , khopoli, neral, lonavala, khandala, igatpuri, bhivandi, shahapur , nasik , shirdi, titwala, bhor , sinner, shirdi, Ahamadnagar, kholapur, sangli, ichalkarangi, Ahamadnagar, solapur, jejuri, Baramati, ratnagiri, roha, Talasari, wada,palghar, dahanu , nagpur, nanded, latur, Alibag, pen , vashi , cbd belapur.

0 notes

Text

Types of Packaging Machines You Should Know

Packaging Machines can be costly, but they often pay for themselves with increased production and efficiency. When coupled with a preventative maintenance plan, they reduce downtime and expensive repairs.

Humans can be inconsistent, overfilling containers or damaging packages. This can cost businesses thousands of dollars in lost productivity. Automation eliminates these issues and produces consistent results. It also frees up staff to reassign to more valuable duties. Thus quality packaging machines are important to grow a business.

Let's discuss some popular packaging machine types these modern days.

Stretch Wrapping Machines

A stretch wrap machine places a load of goods on the wrapper plate then mechanically rotates the pallet and pulls film around it in a predetermined cross-spiral pattern that maximizes the containment force. Machines come in two basic styles: turntable or rotary tower. Both styles are available in semi and fully automatic models.

Unlike human hand wrapping, machine applied stretch wrap is consistent and produces superior load containment. Most important, the wrap is tighter and uses less film.

Poorly wrapped loads can shift during transit and fall apart. This costs companies money in lost productivity and waste. It also takes time and resources to repair or replace damaged products, clean up the mess and put other (paid) production on hold. A good stretch wrap machine can eliminate this problem and reduce overall expenditures at the packaging line. It is worth the investment. A well-operated machine can increase output by up to 300% compared to a manually wrapped pallet.

Hot Tunnel Machines

Heat tunnels work by applying heat to shrink a plastic film around the product. This creates a tightly sealed package that is less vulnerable to damage and tampering. This machine is ideal for packaging food products, board games, and more.

There are several types of heat tunnels on the market. Steam tunnels use live steam for heating, and they offer the least aggressive heat of the three types. They are also great for round and hourglass packages, which require gentle heat for even shrinkage.

Radiant tunnels use infrared radiation to heat the packaging. They are the most effective at shrinking tamper-evident seal bands and other tamper-proof materials. The machine is durable, and it can handle a high volume of products per minute. It is also easy to use and clean. It is available in a variety of sizes to accommodate different production lines. The tunnel can also be customized to fit the specific needs of the business.

Blister Pack Machines

Blister pack machines produce a hollow plastic container for pharmaceuticals. They use thermoforming processes to create the package’s final shape, which include pressure forming and vacuum forming. The plastic sheet is first guided through a preheating station, which heats it slightly above the glass transition temperature. This softens the plastic and allows it to be shaped by a die that imprints its desired profile.

Once the formed blisters have been printed with batch numbers, dates, and other important information, they are sealed together using a special foil-seal coating. This binds the blister to the aluminum foil, creating an airtight seal.

The C80R is a high-performance machine with a compact design. It is ideal for small-to-medium production batches, and it can be used in conjunction with cartoners or wallet machines. It also offers several benefits, including a balcony-style configuration that improves accessibility for the operator. It also works with most types of blister and foil materials, including PVC, PP, and Aclar.

Folding Machines

Folding machines work by using a series of rollers to process a sheet of paper. There are two types of folding machines: flat pile and continuous feed. The first type uses a flat feeder that puts individual sheets on the machine’s table, and the second uses a belt or a table with air-controlled suction wheels to transport them through the process.

Unlike bending, metal folding has high precision and accuracy because the machine’s clamping axis is referenced against CNC-controlled backstops nested in the support table. The iconic swing-beam folding arm then bends the flange to the desired angle with flat tooling, which prevents scratching or sliding on the workpiece.

A programmable folding machine can help you save money by reducing your postage costs and allowing your team to work more efficiently. It can also make it easier to organize your company’s mail and documents, and eliminate conference room letter parties. This type of equipment is ideal for large-scale mailings.

You can also read – how packaging machinery can save your business time and money.

0 notes

Photo

Stretch Hood Film and Shrink Hood Film

What Is Stretch Hooder Film? Introduced back in the 1980s, the stretch hooder type of film and method of palletizing products offers a range of different benefits with respect to distribution chain performance, reliability, operating costs, speed, and sustainability. Stretch hooder film or hooder film is a type of tubular film sealed one end; while the other end of the film is open and designed to stretch over your palletized load. It involves applying a gusseted, stretchable polyethylene hood to a pallet via a specialized piece of equipment or machinery.

How Is Stretch Hooder Film Applied? The "hood" on stretch hooder film is created from gusseted tubing, and the total height of the pallet load is automatically measured as the pallet enters the machine — making sure the exact amount of film used is precisely dispensed and appropriate for the job. Each film application is strategically cut to the proper length, sealed with heat on the top end, and then collected on four 'fingers' of the highly specialized application equipment.

The fingers are engineered to stretch the film horizontally until the dimensions of the film are just larger than the dimensions of the load. Afterwards, the fingers will draw the stretch hood film over the pallet, unrolling it as it goes.

By alternating the unrolling rate, a degree of vertical directional stretch is gained to provide a superior hold for the pallet. Once it reaches the bottom of the pallet, the fingers will release the film, and the film is then securely wrapped under the bottom of the pallet.

Benefits of Stretch Hooder Film.

Exceptional, proven performance across several industries.

Transparence allows the ease of identifying errors and damage.

Higher elastic recovery for secure packaging.

Outstanding potential stretch performance up to and more than 100%.

Vertical stretch potential for optimized load stability.

Much stronger than standard corrugated packaging solutions.

Higher resistance to tearing and puncturing.

Excellent sealing.

Heat Shrink Hooder Film: As the oldest type of pallet packaging with polyethylene film, heat shrink hooding was originally introduced back in the 1960s. Until the invention of newer technology, heat shrink hooding was the primary solution for providing pallet load protection and optimal stability. Heat shrink hooding film utilizes equipment that implements gusseted tubing that is sealed and cut to create a bag.

This oversized bag is then applied over the desired pallet and heat is used to shrink the plastic. The most common sources of heat for shrink hooding are liquid propane gas or natural gas, but other innovative methods are used, such as electrical heaters and infrared heaters You can choose from a vast range of different types of heat shrink hooding equipment.

Benefits of Shrink Hooder Film.

Proven, reliable performance across multiple industries.

Cost-effective solutions for specific customizations.

Decreased level of permeability.

Increased 6-sided protection from environmental elements.

Higher resistance to tears and punctures.

Outstanding sealing.

Wide operability range of temperatures.

Bolstered load stability over virtually all flexible applications.

Benefits of Stretch Hood Film vs Shrink Hooder Film

Stretch hood film offers the ability to re-align the hood and continue hooding in the event the product isn't perfectly aligned on the pallet. In contrast, you would need to stop the entire line to correct the fault with a shrink hooder you, would have to stop the entire line to correct the problem with shrink hooder film.

Shrink hooder film is especially ideal for products that are sensitive to elastic packaging stacking, such as mirrors and glass products. Yet, your ability to quickly see the contents of a shrink hood wrapped pallet may be hampered because the shrinking process causes the film to become hazy or milky.

For more information and pricing on both films call 813 242 6995 or [email protected]

0 notes

Text

Streamlining Packaging Processes with Automated Shrink Wrapper Machines

In the world of modern packaging, efficiency is key. Manufacturers and businesses are continually seeking ways to streamline their packaging processes to save time, reduce costs, and improve overall productivity. One technology that has proven invaluable in this quest is the automated shrink wrapper machine. This piece of equipment has revolutionized packaging, making it faster, more efficient, and cost-effective.

In this blog, we'll delve into the world of automated shrink wrapper machines, exploring how they work and the many advantages they offer to businesses of all sizes.

Understanding Shrink Wrapper Machines

Shrink wrapper machines are devices designed to wrap a variety of products in shrink film, a material that, when heated, shrinks tightly around the product it encases. These machines have been in use for decades, initially operated manually. However, modern manufacturing and packaging needs have led to significant advancements in the technology. Automated shrink wrapper machines are now the industry standard for high-speed, precision packaging.

How Do Automated Shrink Wrapper Machines Work?

Automated shrink wrapper machines operate through a series of well-coordinated steps. Here's an overview of the process:

Product Feeding: Products to be wrapped are loaded onto a conveyor belt or feeding system. Depending on the machine's design, products can be loaded manually or automatically.

Sealing and Cutting: The shrink film is dispensed from a roll and cut to the appropriate length. The machine then seals the film around the product's leading edge.

Shrinking: The sealed product passes through a heat tunnel. The heat activates the film's properties, causing it to shrink tightly around the product.

Cooling and Final Product: After passing through the heat tunnel, the product is cooled quickly, and the shrink film solidifies, creating a snug, protective wrap.

Discharge: The wrapped product is discharged from the machine for storage, further processing, or distribution.

Advantages of Automated Shrink Wrapper Machines

Speed and Efficiency: Automated shrink wrapper machines are incredibly fast. They can wrap numerous products per minute, far outpacing manual methods.

Consistency: Automation ensures that each product is wrapped consistently, with the right amount of tension and film to provide a professional appearance.

Cost Reduction: Although the initial investment in an automated shrink wrapper machine can be significant, it's offset by long-term cost savings. Automation reduces labor costs, minimizes material waste, and speeds up the packaging process, allowing businesses to handle higher volumes efficiently.

Versatility: These machines can wrap a wide range of products, from food items to consumer goods to industrial parts, making them suitable for diverse industries.

Product Protection: Shrink film provides an effective barrier against dust, moisture, and tampering, ensuring that products remain in pristine condition.

Enhanced Aesthetics: The tight, transparent wrap enhances the visual appeal of products, making them more attractive to customers.

Reduced Environmental Impact: Modern shrink films are often recyclable, contributing to sustainable packaging practices.

Choosing the Right Automated Shrink Wrapper Machine

Selecting the appropriate shrink wrapper machine for your business involves considering several factors:

Product Type: Choose a machine that can effectively wrap your specific products. Consider their size, shape, and material.

Production Volume: Determine the machine's throughput and compare it to your production needs.

Space: Make sure you have sufficient space for the machine and its components, including the heat tunnel.

Budget: While automated shrink wrapper machines can provide substantial cost savings, they do require an initial investment. Weigh this against your budget.

Film Type: Different shrink films are available, including polyolefin and PVC. Consider the film type that best suits your products and the machine you choose.

Machine Features: Investigate the features of different machines, such as automatic film changeovers, touchscreen controls, and the ability to handle multipacks.

Maintenance and Support: Ensure that you have access to maintenance and technical support to keep your machine running smoothly.

Case Studies: Success with Automated Shrink Wrapper Machines

Food Industry: A bakery that manually wrapped thousands of loaves of bread each day was able to double its production with an automated shrink wrapper machine. This increase in output helped the bakery meet growing demand and significantly reduced labor costs.

Manufacturing: An automotive parts manufacturer adopted automated shrink wrapper machines for their products. This not only saved time and money but also improved the cleanliness and organization of their products during transport.

Pharmaceuticals: Pharmaceutical companies have implemented automated shrink wrapper machines to package medication bottles. The machines ensure airtight and tamper-evident seals, critical for pharmaceutical safety.

Conclusion

Automated shrink wrapper machines are a testament to how technology is continuously improving packaging processes across various industries. These machines offer speed, precision, cost savings, and enhanced product protection. When selecting the right machine for your business, carefully consider factors such as your product type, production volume, space, budget, film type, machine features, and support options. As the packaging industry continues to evolve, automated shrink wrapper machines remain a key component in ensuring efficiency and productivity. Whether you're in the food industry, manufacturing, pharmaceuticals, or any other sector, the adoption of these machines can significantly benefit your business.

0 notes