#resin pricing

Text

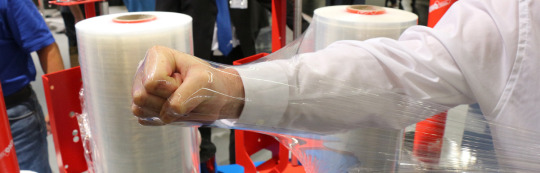

Why Use High Performance Stretch Film

In the world of logistics and supply chain management, efficiency is the name of the game. But pallet wrap might not be the first thing that comes to mind when you are thinking about how to optimize your operation. Enter high performance stretch film…

The right stretch film can often be the key to unlocking improvements. However, the challenge lies in finding the delicate balance between reducing the thickness of your pallet wrap and maintaining adequate load containment.

High performance stretch film is an innovative category of pallet wrap that has a much lower thickness than traditional film but provides a high level of performance. Traditionally, thicker stretch films were considered essential to provide sufficient strength and stability for wrapping pallets. However, advances in technology have paved the way for thinner performance films.

High performance pallet wrap enables businesses to wrap more pallets with less film without sacrificing effective load containment.

One of the primary advantages of reducing thickness in stretch wrap is the potential for significant cost savings. Thinner films, when applied to pallets in the right way, can reduce the overall amount of material required to wrap a pallet. In turn, this helps cut the amount of money you spend on purchasing stretch films.

With the right application process, it can also reduce the number of wraps around the pallet. This speeds up the wrapping process and reduces the time taken to wrap each pallet.

Using a high-performance stretch film with a lower thickness can positively impact your sustainability goals. Compared to a conventional film, using a high-performance pallet wrap can remove tons of plastic from a supply chain.

Whilst cost savings and sustainability are compelling reasons to explore using a high-performance film, ensuring that load containment is not compromised is critical. The primary purpose of stretch wrap is to secure and protect palletized loads during transportation and storage.

Striking the right balance between thickness reduction and load containment is imperative in reducing product damage, maintaining pallet integrity in the supply chain, and reducing incidents of health and safety breaches.

This is why pairing the right high-performance film with the right application method is important. The type of pallet wrapping machine used to apply material plays a pivotal role in achieving the delicate balance required for effective thickness reduction.

Call us at 813 242 6995 or [email protected] to discuss and test our range of high-performance stretch films.

#stretch film pricing#pricing news#stretch film#resin pricing#coreless film#quickpakinc#free pallet wrapper#quick pak inc#free machine#high performance stretch film#amtopp#loadstar pallet wrap

2 notes

·

View notes

Text

2 am shenanigans, baked a bunch of shrinking plastic Rollos last night and coated them with UV resin.

Not as nice looking as the machine made riddle acrylic pin but first tries are never perfect right away

Hand for scale for the tiniest Rollo

#twisted wonderland#rollo flamme#twst shitpost#burnt my finger getting him out of the oven then proceeded to dip that same finger in the uv resin#a small price to pay for a bunch of tiny rollos#waiting to get pin parts I ordered to make actual rollo pins#also made a really tiny luo binghe but he shrinked beyond recognition

158 notes

·

View notes

Text

me checking f4f's twitter every day like

#n0t seri0us#tbh when I first saw the specs and compared them against the other okami figures I was like#'oh no'#I know the price is going to be revealed tomorrow#but I've been examining the pictures released to try and guess an estimate and. well.#let's just say that the word 'resin' does not fill me with confidence#neither did seeing him next to a human and being like. ah. large.#and also. 7kg weight.#I Do Not Think That This Gentleman WIll Be In My Price Range. At All

7 notes

·

View notes

Text

not the most amazing pictures on the planet, but i'm going to be tabling a big convention for the first time ever in a few weeks and all my acrylic stuff is finally here from the manufacturer!

#i also have some prints hand-drawn paintmarker illustrations and other bits and bobs#i do resin crafting so some of that's gonna be there too#for anyone wondering why those two keychains and the bill pin are in the shame corner... they were the first things i produced#and i had been uing a different maufacturer which frankly stunk#so they're gonna be super heavily reduced pricewise so i can get rid of 'em#anyway super excited it's a pretty large convention and i'm still shocked i got in#also i need to fill out that keychain board lmao... i'll probably list prices there

21 notes

·

View notes

Text

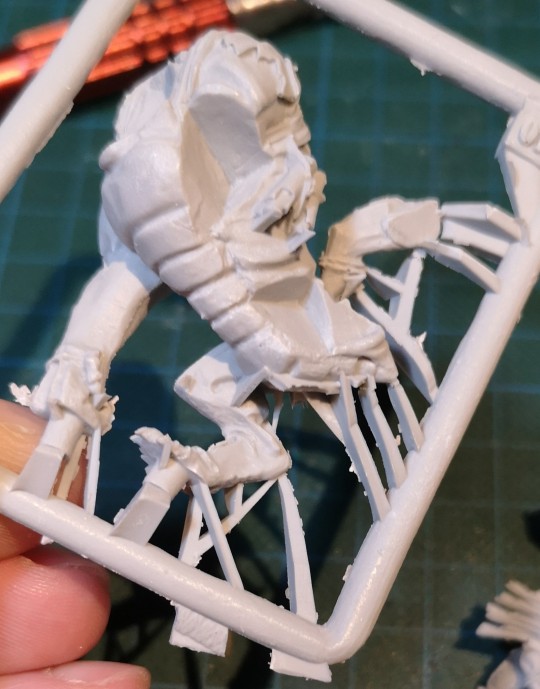

Bruh...

#Finecast resin#Just make connection points where ever boys#Don't worry we'll just sculpt it back ourselves or something it's fine#Don't put too much effort into it#No one plays T'au let alone Kroot anyways so fuck it#Paid full price for this sucker too hèhè -_-#If I didn't love kroot so much I'd put it in a bottom drawer and forget about it#Also my first post I guess in weeks if not months#Guess I'm back-ish?!

7 notes

·

View notes

Text

dice polishing . . . . . . . . hard

#i finally got the supplies together to polish a set of raw dice i bought years back#but after spending 2 hours on a single D6#i i get why sharp edge dice are priced like that sdkfjhg#like cool news is it's super super smooth to the touch and the edges are Crisp™#and when you put it on the table it reflects the face that's facing the light onto the surface#but there's still a bunch of microscratches that has me like#awe :(#also i had been hoping i could get it smooth enough that the interior would be clearer#and you could see the glitter more clearly#but it turns out the resin is just kind of foggy in general#ala fake moonstone consistency#which is nice but awe :(#alas . . . . . it's premade dice for me . . . . . . .#i say as if i don't have like 75 sets of dice already#(this is not an exaggeration. i love dice.)

10 notes

·

View notes

Note

te way you draw furrys reminds me of beastars

oh yeah that’s definitely one of my main inspirations for drawing furries! i tend to prefer more human-like furries when it comes to bodies? like i think super animallistic furries are cool also, but for me personally i quite like the look of “animal head on human body” ie egyptian gods or like you said beastars. if i ever got a suit made i would probably just get a head and tail and foot+hand paws because of that.

#peachsoda asks#ive been looking at fursuit head commission prices and theyre SO EXPENSIVE???#i know the creators put a lot of work in and that’s why#but omg theyre so expensive im never gonna be able to afford one 😭#i might try making one but i’ll probably still buy like a resin head base or something#especially since i want something that matches more my style and the resin heads tend to be more#realistic#and i guess my style is more in that direction#anyways i desperately want to get a fursuit head of shiba inu reigen i think it would be so silly and cute

2 notes

·

View notes

Text

Thousands of hobbyists and you treat every confession like it's from one or two people. SMH MBears upping her second pre order $200 and not being transparent " tee hee fun box opening extras " instead of " I want more profit " is the criticism. And it IS her Cul0r style and her blatant matched piss yellow and light blue resin tones to Cul0r proving her only merit is replacing Cul0r since Harv won't work with a liar. Cul0r can cast with Miro or Resin S0ul and still charge $$$. Honestly how many non white hobbyists bought an Elle? Because I haven't seen one POC bragging about getting one. In 50.

~Anonymous

12 notes

·

View notes

Text

Co op is so fun

6 notes

·

View notes

Text

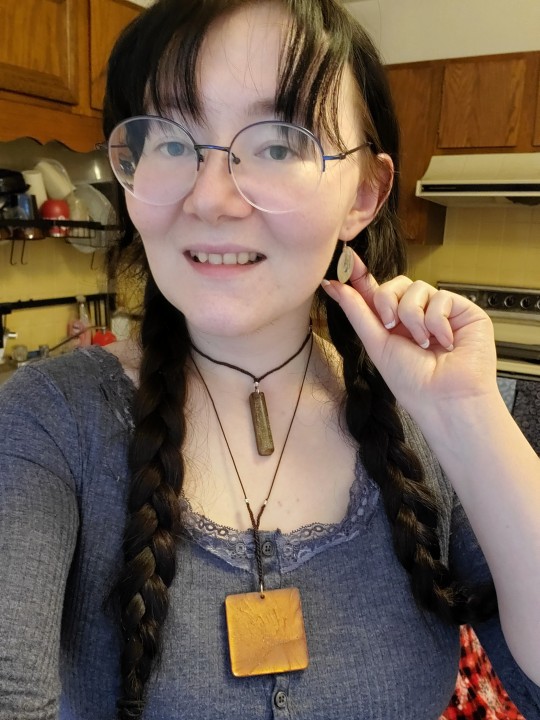

My sister makes epoxy jewelry, has started selling on etsy

These necklaces are made w snakeskins she collected. She sells chains w them but i hate metals on skin, so i crocheted cord instead. Also got bonus pendants w flowers in them, made those into earrings

#she also does pencil n charcoal hyperrealistic art#am i advertising for my sister? ye#she is willing to negotiate prices if you msg her#etsy shop#resin epoxy#jewelry#my face ? idk#selfie

1 note

·

View note

Text

Benefits of Chipboard for Packaging

Chipboard cardboard is a cost-effective packaging solution for businesses. Demand for cost-effective, reliable, and eco-friendly packaging material is constantly growing. Let us take a quick look at the advantages of this increasingly popular product.

Thanks to the simplicity of the manufacturing process, chipboard cardboard is cheaper to produce than traditional corrugated card. As well as this significant saving in production costs, the thickness of chipboard also means it is cheaper to transport as it takes up less space than corrugated card or other packaging products that contain a considerable proportion of air.

This lack of air also means that, when you are storing the chipboard, it takes up far less space. Also, as it is a solid sheet rather than a corrugated one, there is a much smaller risk of it being damaged or crushed when being stored before use.

Since chipboard is much thinner than corrugated materials, it is far easier to cut and fold to the desired dimensions.

Corrugated card does tend to puncture easily, leaving the contents of the package vulnerable to damage. The density of chipboard cardboard gives it a greater strength and provides a packaging material that is less susceptible to damage. This makes it ideal for use in food packaging and other areas that need a robust, easy to fold carton.

There are few products that are as green as chipboard. Made from recycled paper and cardboard, the energy needed to produce the finished product is far less than other packaging materials.

The advantages of chipboard have seen it become favored throughout the retail and food sectors and this popularity continues to grow. Call us at 813 242 6995 or reach out to [email protected] to see if chipboard is right for you.

#stretch film pricing#chipboard#sheets#corrugated#packaging#resin pricing#pricing news#quickpakinc#coreless film#stretch film#free pallet wrapper#minimalism#quick pak inc#free machine#packing#youtube

2 notes

·

View notes

Text

#Bigger Printing Jl. Baja Raya No. 7 Perumnas 2 Karawaci#Tangerang. Info Order 0877-7850-5584#cetak gantungan kunci akrilik terdekat#BEST PRICE#Wa./Call. 0877-7850-5584#Cetak Gantungan Kunci Foto#KLIK https://wa.me/6287778505584#Gantungan Kunci Nct#Gantungan Kunci Resin#Gantungan Kunci Kulit#Tempat Cetak Gantungan Kunci Tangerang#Jasa Cetak Gantungan Kunci

2 notes

·

View notes

Text

Unsaturated Polyester Resin Prices Trend, Monitor, News & Forecast | ChemAnalyst

Unsaturated polyester resin prices have undergone fluctuations influenced by various factors, including global market dynamics, industrial demand, and production costs. Understanding these price movements requires a comprehensive analysis of supply and demand dynamics, regulatory changes, and macroeconomic indicators.

One of the primary drivers affecting unsaturated polyester resin prices is the balance between supply and demand within the chemical and composite materials industries. Unsaturated polyester resin, a versatile material used in the production of fiberglass-reinforced plastics, composites, and construction materials, is essential in various sectors. Disruptions in the supply chain, such as fluctuations in raw material availability, transportation costs, or production capacity, can impact the availability and cost of unsaturated polyester resin, thereby influencing its market price.

Industrial demand plays a crucial role in determining unsaturated polyester resin prices. Industries such as construction, automotive, marine, and aerospace are major consumers of unsaturated polyester resin, utilizing it in applications such as laminates, coatings, and structural components. Fluctuations in demand from these sectors, influenced by factors such as economic conditions, infrastructure projects, and technological advancements, can lead to price volatility for unsaturated polyester resin.

Get Real-Time Unsaturated Polyester Resin Prices: https://www.chemanalyst.com/Pricing-data/unsaturated-polyester-resin-1563

Raw material costs significantly influence unsaturated polyester resin prices. The price of raw materials such as styrene, maleic anhydride, and phthalic anhydride, which are used in unsaturated polyester resin production, can fluctuate due to changes in global supply and demand dynamics, petroleum prices, and currency fluctuations. Any substantial increase in raw material costs can translate into higher production costs for unsaturated polyester resin manufacturers, thereby exerting upward pressure on prices.

Macroeconomic indicators, such as GDP growth, construction activity, and manufacturing output, can indirectly impact unsaturated polyester resin prices by affecting overall industrial activity and consumer spending. Economic downturns or slowdowns in major manufacturing sectors may lead to decreased demand and downward pressure on prices. Conversely, robust economic growth and increased infrastructure spending can support higher prices for unsaturated polyester resin by stimulating demand for construction materials and composite products.

Regulatory changes and quality standards also play a role in shaping unsaturated polyester resin prices. Government regulations on environmental standards, product specifications, and safety requirements can impact production costs and market access for unsaturated polyester resin manufacturers. Compliance with these regulations may require investments in technology and process improvements, which could influence pricing dynamics.

Looking ahead, several factors are expected to continue influencing unsaturated polyester resin prices. Continued growth in sectors such as construction, transportation, and renewable energy, coupled with increasing demand for lightweight and durable materials, is likely to drive sustained demand for unsaturated polyester resin. Moreover, advancements in composite manufacturing technologies and the development of new applications could lead to changes in market dynamics and price levels for unsaturated polyester resin.

In conclusion, unsaturated polyester resin prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, regulatory changes, and macroeconomic indicators. Stakeholders in the chemical, construction, and manufacturing industries must closely monitor these factors to anticipate price movements and make informed decisions. As industries evolve and sustainability concerns become more prominent, navigating the dynamic landscape of unsaturated polyester resin pricing will remain a key challenge for industry participants.

Get Real-Time Unsaturated Polyester Resin Prices: https://www.chemanalyst.com/Pricing-data/unsaturated-polyester-resin-1563

ChemAnalyst

GmbH — S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49–221–6505–8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Epoxy Resin Prices Trend, Monitor, News & Forecast | ChemAnalyst

Epoxy Resin Prices: During the Quarter Ending December 2023

North America:

In the North American region, the Epoxy Resin market witnessed a bearish trend during the fourth quarter of 2023, influenced by multiple factors affecting market dynamics and prices.

A significant contributor to this trend was a decrease in demand, particularly within the construction industry, leading to reduced buying interest among end-users. Despite manufacturers maintaining consistently high production levels in anticipation of future demand, the market experienced an abundance of Epoxy Resin supply, exerting downward pressure on pricing.

Focusing on the United States, the primary focal point, Epoxy Resin prices notably decreased by 16% compared to the previous quarter, driven by the combination of low demand and ample supply. Additionally, a significant 28% decrease in prices was observed compared to the same quarter of the previous year.

The latest recorded price for Epoxy Resin Liquid (EEW 176-183) DEL Texas in the USA at the end of December 2023 was USD 4217/MT. These pricing trends in the USA were profoundly influenced by low demand, surplus supply, and a discernible downward trajectory.

Get Real Time Prices of Epoxy Resin: https://www.chemanalyst.com/Pricing-data/epoxy-resin-79

APAC:

In the Asia-Pacific (APAC) region during Q4 2023, the Epoxy Resin market displayed a bearish trend influenced by several significant factors impacting prices. Notably, there was a noteworthy surplus in Epoxy Resin supply attributed to a simultaneous reduction in the price of upstream Crude Oil, contributing to a bearish market scenario in China and Japan.

While demand remained stable in India, fostering a bullish market situation, Japan experienced substantial price variations with a 3% decrease compared to the previous quarter. Overall, the APAC region encountered price fluctuations in Epoxy Resin, driven by factors such as abundant supply, stable demand, and the absence of reported plant shutdowns.

Europe:

Europe's Epoxy Resin market faced notable challenges in Q4 2023, characterized by a bearish sentiment. Weakened overall demand from downstream industries like paints and coatings, supply chain disruptions in countries like Germany and Belgium, and a bearish pricing strategy adopted by manufacturers contributed to this sentiment.

Despite ample product availability, the market found some support in anticipated economic improvements and increased demand from the construction sector. The quarter ended with the latest price of USD 3367/MT for Epoxy Resin Liquid FD Hamburg in Germany, reflecting a significant 31% decrease compared to the same quarter of the previous year and a 15% decrease compared to the previous quarter. Overall, Europe's Epoxy Resin market grappled with challenges, balancing low demand and supply chain disruptions with glimpses of optimism in economic activities and increased demand in specific sectors.

Get Real Time Prices of Epoxy Resin: https://www.chemanalyst.com/Pricing-data/epoxy-resin-79

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

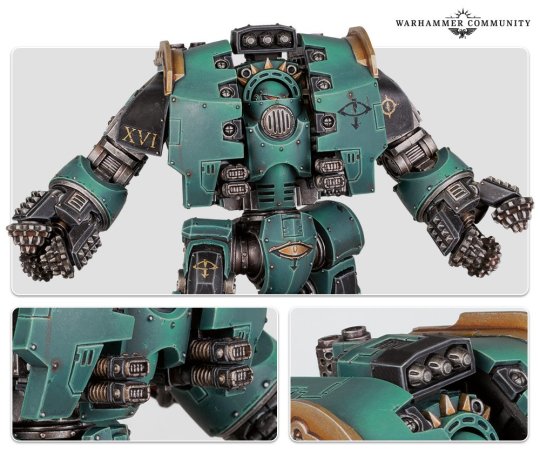

Stomp stomp stomp SMASH!!

Rogal Dorn better reinforce those walls cause OH lawd he coming!

#All it needs is some spikes and it'll be perfect for my Black Legion#Especially with the son's of Horus iconography on it#What an absolute unit#In resin it was a bit too pricey but hopefully it'll be better priced now#Also those details are crisp af!

19 notes

·

View notes