#Horizontal form fill seal (HFFS)

Text

#Pouch filling#Automatic packaging#Vertical form fill seal (VFFS)#Horizontal form fill seal (HFFS)#Multih uch packaging materials#Pouch packaging designs#Pouch packaging industry#Pouch packaging equipmen#ead weigher#Auger filler#Rotary packing machine#Bagging machine#Packaging automation#Pouch sealing#Sachet packing#pouch packing machine#buy pouch packing machine#pouch packing machine seller#pouch packing machine manufecturer#automatic packing machine#FFS packing machine#chips packing machine#namkeen packing machine#snacks packing machine

2 notes

·

View notes

Text

HFFS Machines | T-110 | Packaging Machines | Nichrome Africa

Automatic horizontal form fill sealing HFSS machine T-110 offers convenient packaging solutions products like Powders for Pharma, coffee & Masala, Free flowing powders like ORS, granular products like sugar & rice, Snacks, fruits, nuts, Viscous products like cosmetics, hair dye, paste, ghee & shampoo, Free flowing liquids like milk, Lassi, liquors & wines.

#HFFS Machines#horizontal packaging machine#powder filling machine#liquid packaging machine#tea packaging machine#innovative packaging solutions#integrated packaging solutions#Vertical Form Fill Seal Machines

0 notes

Text

NICHROME KETCHUP PACKING SOLUTIONS ARE A NOTCH UP

Globally, and across industries, pouch filling machines are a popular choice for viscous condiments packing and viscous ready to eat foods like tomato ketchup. Tomato ketchup packing is usually done in two ways—in tear away or standee pouches, or in High Density Polyethylene (HDPE) bottles.

In either case, the tomato ketchup packaging needs to be robust and leak-proof. Hence the need for superior quality packing machinery. Pouches are flexible, lightweight bags that offer many advantages over traditional packaging such as metal cans or glass bottle packing.

Types of Ketchup Packing

There are two major types of liquid pouch filling machines: vertical form fill seal (VFFS) and horizontal form fill seal (HFFS) packing machines. The filled and sealed bag is cut away. As is evident in many tomato sauce/ketchup brands, the top seal on the first bag becomes the bottom of the next bag, and the process repeats. The cut pouch falls to a collection system, typically a belt conveyor that brings the pouch to the next packaging step.

Ketchup packing is generally referred to as ‘flexible packaging’ or ‘sachet packing’ as opposed to ‘bottle and jar packing’ which is rigid.

Flexible packaging offers several advantages: it uses less material, needs less energy during formation, and produces less greenhouse gases during manufacturing. Being lightweight & unbreakable, it is economical to pack, store, and transport.

Nichrome Ketchup Packaging

There are many pouch filling machine manufacturers offering multiple packaging machines for diverse applications. If you are looking for a ketchup pouch packing machine manufacturer--Nichrome is your best bet.

Four decades of experience worldwide, intensive inhouse R&D, state-of-art manufacturing, technology tie-ups with global majors, thousands of successful installations, strong nation-wide service network – few pouch filling machine manufacturers can match the knowhow, capabilities, and record of accomplishment of Nichrome.

HFFS for Ketchup Packing

Whether your ask is for HFFS or multitrack packing machine (for 4 side seal pouches up to 100 gm); pick fill seal machines; bottling line or standee pouch/ DOYPACK pouch packing-- explore Nichrome's offerings for packing tomato paste/ketchup. Nichrome offers special sealing technology for viscous liquids on its multitrack machines.

Cost-effectiveness

Nichrome is dedicated to offering the most advanced packaging technology for food, pharma, and other relevant industries. Nichrome can deliver top quality at competitive prices with its own R&D centre, manufacturing, and testing facilities.

High ROI

Nichrome proactively supports customers from consultation and customized packaging machine development to the production of the packaging machine, backing it up with extensive after-sales service. Some hallmarks of Nichrome’s packaging solutions are high production rates, optimum accuracy, and consistent pouch quality as per the client’s requirements.

T-110

In its T-110 ketchup packaging machine, Nichrome offers an efficient integrated system for ketchup filling and packaging that covers a turntable, UV sterilisation chamber, automatic liquid filling machine, cap feeding elevator, rotary capping machine, induction sealer, labelling machine, date & batch coding system, and packing table. SKUs range from 100 ml to 20 litres. Applications include a wide range of packing solutions for food & liquids such as ketchup.

T-140

Nichrome's HFFS packaging machines bring you next generation, linear technology from Europe. The series is versatile and can be used for packing a wide range of powders, grains, snacks, liquids, and viscous products like ketchup using different fillers. The series also offers a range of pouch formats with superior pouch aesthetics.

T-170

Nichrome’s HFFS packaging machines, especially the T-170 are PLC based with touch screen interface. The compact and versatile design offers both single and perforated chain of pouches with quick and easy changeover. Well-designed duplex modules are available for higher outputs.

Nichrome is a leading manufacturer of form-fill-seal packaging machines in India. A pioneer of flexible packaging in India, Nichrome brings four decades of experience and innovation to the table.

Nichrome’s offerings include a wide range of VFFS and HFFS packaging machines. Horizontal form fill seal machines are traditionally more flexible and versatile than vertical form fill seal ones, although the latest VFFS packaging systems are more adaptable to different products, pouch types & sizes, film types than earlier versions.

Pick and Fill Seal

Nichrome’s Pick-Fill-Seal machine provides the combined benefits of variety, productivity, and specialty packaging for ready-to-eat foods. Using versatile rotary technology, the horizontal packaging machine conveniently packs a wide variety of ready-to-eat foods in eye-catching innovative shapes while maintaining freshness of the products.

The machine is sturdy and compact, easy to clean and maintain. An advanced variant of packaging technology innovated by Nichrome enables two or three different fillers to dispense multiple types of ingredients in the same pouch.

Bottle Filling Machine

Nichrome’s Automatic Bottle Filling system is designed to handle many different types of products, from water to tomato ketchup. From products with thin watery consistency to highly viscous products like ketchup, Nichrome’s liquid food packaging system can handle them all.

Nichrome’s liquid filling machine also handles a versatile SKU range with fast changeover and no change of parts. It is equally efficient packing in glass, HDPE and PP bottles or metal tins.

Conclusion

It could be a small variation in a pouch format or customization of an existing machine; a pro-actively developed filling system or consultancy & system design for a complete packaging plant - -Nichrome has the expertise, capabilities and innovation to transform productivity and enrich customer relationships in endless ways. Call Nichrome to discuss your unique requirements and let us amaze you with our products and services.

#ketchup filling#pouch filling machines#tomato ketchup packaging#vertical form fill seal (VFFS)#horizontal form fill seal (HFFS) packing machines#pouch filling machine manufacturers#ketchup pouch packing machine manufacturer#pick fill seal machines#bottling line#ketchup packaging machine#Automatic Bottle Filling system#liquid filling machine

0 notes

Text

Perfecting Powder Packaging with Nichrome

The packaging of powders is not an easy task as different powders come with their own unique characteristics. Some can be free-flowing, while others can be clumpy. Some can cause a dusty environment as in the case of flour. Powders like agrochemicals can become explosive when exposed to certain gases or electric sparks. Changeovers of products can also lead to issues of cross-contamination.

Hence, the powder packaging machines used to package these powders have a crucial role to play. Packaging tends to be the last stage of the manufacturing process. These machines pack the product in packaging that ensures its protection and safety until it reaches the consumer. Any problem in the packaging stage results in the entire process quality and throughput being adversely affected.

With convenience products gaining widespread popularity, it is reasonable to expect a larger variety of products and different packaging formats for products such as spice blends, instant coffee, drink mixes, protein powders, and sweeteners among many others.

Another facet to consider is the fact that different customers have different demands. Some may have limited floor space on their premises, while others may want multiple pouch formats and SKU sizes. Some clients look for versatility - in order to pack a variety of products with the same machine. Some packaging setups might do just sachet packaging while others carry out bulk packaging. Some might have a preference for Horizontal-Form-Fill-Seal (HFFS) machines, while others might prefer Vertical-Form-Fill-Seal (VFFS) technology.

Some of the issues faced by powder filling machines are:

Powder Flow

The powder flow is an important factor. Powder filling machines are configured for powders that may be clumpy. This is of considerable importance when we consider small packaging formats and dosing systems that rely on gravity to fill the cups.

Weight Control

The filling process is done on the basis of volume because of which, there can be a difference in the actual weight packed. In order to fill a consistent weight of the products, the dosing system should have very good control of the volume of the product being moved.

Leakage of the Pack

The pack needs to be sealed without letting powder stick between the two sides of the packaging. This is usually the case when the product is dusty and does not settle before the shutting of the sealing jars.

Hygiene

Hygienic packaging is imperative in the case of powders as they need packaging machines that prevent contamination. The packaging needs to be done taking into account containment, prevention of contamination, and cleaning.

Powder Packaging with Nichrome

Nichrome offers an automated powder packaging solution for pretty much any packaging requirement or challenge. As a renowned fully automatic packing machine manufacturer and an accomplished supplier of integrated packaging solutions, Nichrome’s packaging technology expertise and knowledge of various industries and applications are unparalleled.

Nichrome’s offerings include a diverse range of spice packaging machines, shrink packing machines, coffee packaging machines, tea packaging machines, and blister packaging machines among other powder filling machines. Nichrome also has the expertise to customise its solutions for specific requirements.

Nichrome’s offerings for powder packaging include:

Vertical-Form-Fill-Seal (VFFS) Machines

Excel 400 Plus Servo Auger: This adaptable machine can be easily integrated into upstream or downstream machines and systems. It can pack in a number of pouch formats. Its optimum bagger speed is 80 pouches/min which depends on the pack size and bulk density.

Sprint 250 Plus Servo Auger: Nichrome’s Sprint 250 Plus Servo Auger has a speed of up to 120 pouches/min, high accuracy and high efficiency for the flexible packaging of a diverse range of powders in addition to snacks and grains. It can pack pouch quantities up to 2 Kgs.

Maxima 200/400: The Maxima 200/400 has a compact design and a small footprint for the production of a single or perforated chain of pouches. It has a PLC-based control system and an optional interface with PC and Data processors. The Maxima series is particularly preferred for powder packaging.

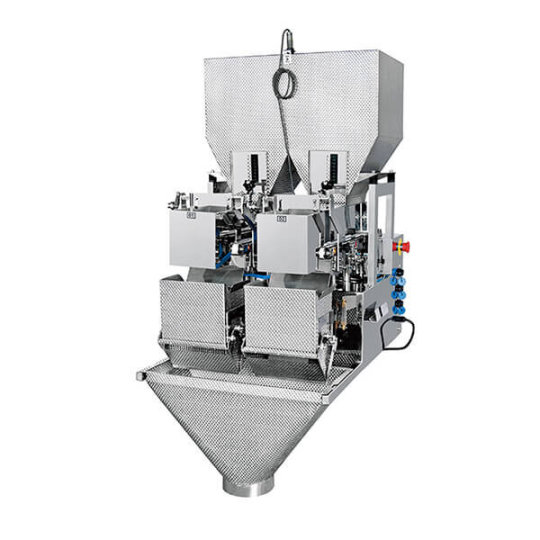

Horizontal-Form-Fill-Seal (HFFS) Machines

T Series: The T Series HFFS packaging machines from Totpack, Spain offer cutting-edge linear technology in a compact design. They can pack in a range of pouch formats with attractive and aesthetic pouch designs. Properly integrated duplex modules allow for higher outputs.

Multilane Machines

Multilane Stickpack with Multi Head Servo Auger: This versatile machine can pack free-flowing powders like milk powder, coffee powder, salt, sugar, tea etc in single-serve stickpacks which are mainly used by food chains and the travel and hospitality industries.Conclusion

There aren’t many packaging machine manufacturers that can match Nichrome’s range of automated powder packaging machines. The powder filling machines in Nichrome’s repertoire are high-speed and high-performance ones. They offer high accuracy, durability and dependability in performance for years together. These versatile machines are easier to clean and maintain and allow for easy changeovers.

Contact Nichrome if you need a packaging machine manufacturer with unparalleled expertise in powder packaging.

Visit https://bangladesh.nichrome.com to learn more!

#powder packaging machines#sachet packaging#bulk packaging#v#Horizontal-Form-Fill-Seal (HFFS) machines#Vertical-Form-Fill-Seal (VFFS)#powder filling machines#automated powder packaging solution#fully automatic packing machine#integrated packaging solutions#spice packaging machines#shrink packing machines#coffee packaging machines#tea packaging machines#blister packaging machines#packaging machine manufacturers#automated powder packaging machines

0 notes

Text

How Bag Filling Machines Enhance Productivity and Accuracy?

Bag filling machines revolutionize packaging processes by enhancing productivity and accuracy. These automated systems streamline production, significantly reducing manual labor and time requirements. By precisely measuring and dispensing product quantities, they ensure consistent fill weights and packaging quality, minimizing waste and maximizing efficiency. With advanced features such as programmable settings and multi-head weighing systems, bag-filling machines optimize throughput while maintaining accuracy. This results in increased output rates, improved operational efficiency, and higher levels of customer satisfaction, making them indispensable assets in modern manufacturing facilities.

Understanding the Functionality of Bag Filling Machines

Bag filling machine are essential equipment in various industries for efficiently filling bags with products such as powders, granules, and liquids. These machines automate the filling process, improving efficiency and accuracy while minimizing labor costs. Understanding how bag-filling machines work is crucial for optimizing production processes and achieving consistent results.

Exploring the Types of Bag Filling Machines

Bag filling machines come in various types, each designed for specific applications and production requirements. Common types include vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and open-mouth bagging machines. Each type offers unique features and advantages, allowing businesses to choose the most suitable option based on their packaging needs and product characteristics.

Advantages of Automated Bag Filling Machines

Automated bag filling machines offer numerous advantages over manual filling methods. By automating the filling process, these machines increase production rates, reduce labor costs, and minimize the risk of human error. Additionally, automated bag filling machines ensure consistent fill weights and packaging quality, enhancing overall efficiency and customer satisfaction.

Factors to Consider When Choosing a Bag Filling Machine

Several factors should be considered when selecting a bag filling machine for your business. These include production volume, product characteristics, bag type and size, and required fill accuracy. By carefully evaluating these factors and consulting with a reputable supplier, businesses can choose a bag filling machine that meets their specific needs and production goals.

Innovative Features in Modern Bag Filling Machines

Modern bag filling machines incorporate innovative features and technologies to enhance performance and versatility. These features may include touch-screen controls, programmable settings, multi-head weighing systems, and advanced sealing mechanisms. By leveraging these innovations, businesses can optimize their packaging processes, improve efficiency, and stay competitive in the market.

Applications of Bag Filling Machines Across Industries

Bag filling machines find applications across a wide range of industries, including food and beverage, agriculture, pharmaceuticals, chemicals, and more. Whether filling bags with coffee beans, rice, pet food, or industrial chemicals, bag filling machines play a critical role in streamlining packaging operations and ensuring product quality and consistency.

Future Trends in Bag Filling Machine Technology

The future of bag filling machines is marked by continued innovation and advancement in technology. Key trends include the integration of artificial intelligence (AI) and machine learning algorithms for predictive maintenance and optimization, as well as the development of eco-friendly packaging solutions and energy-efficient machine designs. By staying abreast of these trends, businesses can future-proof their packaging operations and maintain a competitive edge in the market.

Conclusion

Bag filling machines stand as indispensable tools in modern packaging operations, offering unparalleled benefits in productivity and accuracy. By automating the filling process and employing advanced technologies, these machines optimize production efficiency while ensuring precise measurement and consistency. The result is increased throughput, reduced labor costs, and enhanced product quality, ultimately driving overall profitability and customer satisfaction. With their ability to streamline operations and deliver reliable performance, bag filling machines continue to be vital assets in the manufacturing industry.

0 notes

Text

Pouch Filling Machines Are Reshaping Industries

In the dynamic landscape of industrial production, pouch filling machines have emerged as transformative catalysts, reshaping the very foundations of various industries. These cutting-edge machines represent the pinnacle of efficiency, precision, and innovation, revolutionizing the packaging process with their seamless ability to fill and seal pouches with unparalleled speed and accuracy. From the food and beverage sector to pharmaceuticals, these technological marvels have become indispensable, streamlining operations and ensuring product integrity. The integration of advanced features, such as customizable filling options and automated controls, not only enhances productivity but also contributes to sustainability goals. As industries embrace the future of manufacturing, pouch filling machines stand at the forefront, embodying a paradigm shift that promises to elevate efficiency, reduce waste, and redefine the standards of excellence in production.

Transforming Packaging Efficiency

In the dynamic landscape of modern packaging, pouch filling machine stand out as technological marvels. This section delves into the foundational aspects of these machines, exploring their role in revolutionizing the packaging industry. From their inception to their current state-of-the-art designs, we'll uncover the evolution that has led to enhanced efficiency, precision, and versatility in pouch filling processes.

Types of Pouch Filling Machines

This detailed exploration delves into the diverse array of pouch filling machines available in the market. From vertical form-fill-seal VFFS machines to horizontal form-fill-seal HFFS machines, and rotary pouch fillers to pre-made pouch fillers, each type has its unique features and applications. By understanding the distinctions between these varieties, businesses can make informed decisions to meet their specific packaging needs.

Mechanics and Technology Behind Pouch Filling Machines

Uncover the engineering brilliance behind pouch filling machines in this section. From the intricate mechanics that ensure precise filling to the incorporation of cutting-edge technologies like servo-driven systems and automation, we'll explore how these machines operate seamlessly. A closer look at the inner workings sheds light on the factors that contribute to reliability, speed, and consistency in pouch filling processes.

Versatility of Pouch Filling Machines

Pouch filling machines find applications across a spectrum of industries, from food and beverage to pharmaceuticals and beyond. This section delves into the versatile nature of these machines, showcasing how they adapt to different product types, viscosities, and packaging requirements. Case studies and examples will illustrate the widespread impact and relevance of pouch filling machines in diverse manufacturing sectors.

Advantages of Pouch Filling Machines

Explore the tangible benefits that businesses gain by integrating pouch filling machines into their packaging lines. From increased production speed and reduced labor costs to the sustainability advantages of flexible packaging, this section highlights how these machines contribute to a more efficient, eco-friendly, and cost-effective packaging process.

Navigating the Complexities of Pouch Filling

No technology is without its challenges. This segment addresses common issues faced in pouch filling processes, such as product waste, machine downtime, and maintenance complexities. By providing insights into troubleshooting and preventative measures, businesses can optimize the performance of their pouch filling machines and overcome potential hurdles.

Innovations Shaping the Future of Pouch Filling Machines

As technology continues to advance, so do pouch filling machines. This concluding section explores the latest innovations and trends shaping the future of pouch filling technology. From the integration of artificial intelligence to advancements in material science, we'll uncover the exciting developments that promise to further elevate the efficiency and capabilities of pouch filling machines in the years to come.

Conclusion

In conclusion, pouch filling machines stand as indispensable contributors to the modern packaging landscape, embodying a perfect amalgamation of efficiency, versatility, and technological prowess. Through this exploration, we have witnessed the evolution of these machines from humble beginnings to sophisticated, automated systems that redefine packaging processes across industries.

1 note

·

View note

Text

Flow Pack Machine Industry and the Rise of Food Delivery Services

The Flow Pack Machine Industry demonstrates robust growth potential, with an estimated market size of US$ 4.8 billion in 2022. Projections indicate that this market is on a path of continuous expansion, with anticipated revenues reaching US$ 6.8 billion by 2032. This growth trajectory is underpinned by a notable compound annual growth rate (CAGR) of 3.4% from 2022 to 2032.

One of the driving factors behind this growth is the increasing adoption of automatic machines across diverse industries, including food and beverage, personal care, and more. As these industries seek to enhance efficiency and streamline their packaging processes, the demand for flow pack machines is expected to rise steadily. The study also points to a substantial absolute incremental opportunity of US$ 1.9 billion that the Flow Pack Machine Industry is set to create by 2032, signifying the market's considerable growth potential.

Buy this Exclusive Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-15590

The flow pack machine industry plays a vital role in the packaging sector, offering efficient and versatile packaging solutions. Here is an analysis of the flow pack machine industry, focusing on its key aspects:

Market Overview: The flow pack machine, also known as horizontal form-fill-seal (HFFS) machines, is designed to package products in a continuous motion. These machines are used for a wide range of applications, from food and beverages to pharmaceuticals and personal care products.

Key Drivers:

Efficiency: Flow pack machines offer high-speed packaging with minimal downtime, making them an attractive option for industries seeking improved efficiency in production and packaging.

Diverse Applications: The versatility of flow pack machines allows them to be used for various product types, shapes, and sizes, contributing to their widespread adoption.

Cost-Effective: These machines are cost-effective solutions for high-volume production, reducing labor costs and enhancing packaging consistency.

Automation: The growing trend of automation in manufacturing and packaging processes drives the demand for flow pack machines.

Challenges:

Competition: The flow pack machine industry faces competition from alternative packaging solutions, including pouch packaging and tray sealing machines.

Customization: Meeting specific customer requirements for unique packaging designs and materials can be challenging.

Regulatory Compliance: Industries such as pharmaceuticals and food need to adhere to strict regulatory standards, which can affect the design and operation of flow pack machines.

Trends:

Sustainability: The industry is focusing on sustainable packaging materials and practices, including reducing packaging waste and using recyclable materials.

Smart Packaging: Integration of smart technologies and sensors in flow pack machines to enhance product tracking and quality control.

Flexibility: Manufacturers are developing flexible flow pack machines that can adapt to different product shapes and sizes.

Global Market: The Flow Pack Machine Industry is global in scope, with key players located in various regions, serving a wide range of industries with diverse packaging needs.

Outlook: The flow pack machine industry is expected to maintain steady growth, primarily driven by its efficiency, versatility, and cost-effectiveness. As industries seek to enhance their packaging processes, flow pack machines are well-positioned to meet these demands. However, addressing competition, customization, and regulatory compliance challenges will be essential for industry players to stay competitive and innovative.

Top of Form

Read more info: https://www.futuremarketinsights.com/reports/flow-pack-machine-market

0 notes

Text

What is the cost of a automatic packaging machine?

The cost of an automatic packaging machine varies depending on the type of machine, the features it has, and the manufacturer. In general, automatic packaging machines range in price from a few thousand dollars to several hundred thousand dollars.

Here are some factors that can affect the cost of an automatic packaging machine:

Type of machine: There are many different types of automatic packaging machines, each with its own set of features and capabilities. The type of machine you need will depend on the products you are packaging and the volume of your production.

Features: The features of an automatic packaging machine can also affect its price. For example, machines with more automation features, such as load cell weighing and robotic arms, will typically be more expensive than machines with simpler features.

Manufacturer: The manufacturer of an automatic packaging machine can also affect its price. Machines from well-known manufacturers, such as Bosch and Krones, will typically be more expensive than machines from lesser-known manufacturers.

Here are some examples of the cost of different types of automatic packaging machines:

Horizontal form-fill-seal (HFFS) machine: HFFS machines are used to package products in bags or pouches. They typically range in price from $5,000 to $100,000.

Vertical form-fill-seal (VFFS) machine: VFFS machines are used to package products in bottles, jars, or cartons. They typically range in price from $10,000 to $200,000.

Case packing machine: Case packing machines are used to pack products into cases. They typically range in price from $25,000 to $500,000.

Checkout the Auto Coater Features

If you are considering purchasing an automatic packaging machine, it is important to compare the prices of different machines and to factor in the features you need. You should also get quotes from several manufacturers before making a decision.

Also, you can check Aseptic Isolator System

0 notes

Text

Horizontal Packing Machine SBMHD-240S

Horizontal Packing Machine SBMHD-240S

The SBMHD-240S doypack horizontal packing machine makes, fills & seals Doypack, Doypack with zippers, larger Flatpacks, mold-cut shaped stand up pouches, and stand up spout pouches for liquids.Get more news about professional horizontal packing machine,you can vist our website!

The SBMHD-240S Horizontal Packing Machine is kind of the horizontal form, fill and seal (HFFS) machine, which makes ,fills and seals pouches in one automatic process.These high-performance machines eliminate the need for pre-made bags by using laminated roll stock film to create a large variety of pouch styles and reduce material cost dramatically. As opposed to purchasing pre-made pouches, cost savings of up to 30% may be incurred by producing a finished product in these machines.

The SBMHD-240S doypack packing machine makes, fills & seals Doypack, Doypack with zippers, larger Flatpacks, mold-cut shaped stand up pouches, and stand up spout pouches for liquids. This high performer delivers pouches of premium quality of seals and appearance.

The SBMHD Series doypack horizontal packing machines feature a transmission system, which enables for multiple independent axis movements.

This technology substitutes the traditional and standard single cam shaft, and therefore has significantly fewer mechanical parts. The control is provided by means of an intuitive touch screen HMI, facilitating format change-over and adaptability to multiple formats. This is made possible by the servo technology, which enables independent movements of machine parts.

The SBMHD Series doypack packing machines produce pouches with excellent seals, equal to the quality of premade pouches. Moreover, these machines produce pouches with a huge number of designs and shapes for a better product differentiation on the shelf.

Pouch width automatic correction system, allows for a productivity up to 10% higher than mechanical HFFS doypack packing machines.

Accessibility for easier maintenance facilitated by the touch screen. Which includes instructions manuals, electronic and pneumatic diagrams.

Little maintenance is required because the SBMHD series machines possess fewer mechanical parts. And its Sanitary construction simplifies the machine.

0 notes

Text

Available Different types of Flow Pack Machines

A Flow Pack Machine, also known as a horizontal form-fill-seal machine (HFFS), is a packaging machine used in the food, pharmaceutical, and other industries to wrap products in a flexible film or laminate. The machine forms a tube of film, fills it with the product, and seals the edges of the film to create a package.

#flow pack machine#Powder packing machine#multihead weigher#tea bag machine#vffs packaging#pouch packing Machine#packing machine

0 notes

Text

POUCH PACKAGING MACHINES

Around the world and across industries, Automatic pouch-filling machines are becoming increasingly popular for industrial packaging. Pouches are flexible, lightweight bags that offer many advantages over traditional packagings such as metal cans or glass bottles.

Pouch-filling machines are typical of two types: Vertical Form Fill Seal (VFFS) and Horizontal Form Fill Seal (HFFS), with FFS being the preferred technology.

Let's see how FFS packaging machines work.

The vertical seal filling machine is a kind of vertical structure bag-making and filling machine. Mainly used for industrial packaging and processing, it provides a more convenient and efficient automatic packaging method, saving time, material waste, and cost.

Understanding the main components of a VFFS pouch-filling machine will explain how these machines work:

Film take-up system: This system consists of an unwinding roller and a tensioner. The film roll (usually laminated PE, PET, or aluminum foil) is placed on the unwinding roller, usually located at the back of the machine. Using servomotors and a tensioner, the film is tightly and precisely unrolled and pulled into the system.

Printer (optional): The film goes through a printer where the date, batch code, etc. will be printed on the film.

Pouch Former: After printing, the film is moved to form the pouch. The process overlaps the edges of the film and shapes the bag. Vertical and bottom sealing is done with sealing jaws.

Filling and Sealing Machine: Filling is done by connecting the bagging machine to a multi-head weigher and other filling machines such as a screw or volumetric filler. The two machines are electronically synchronized so that once the bag is ready, the product is automatically inserted. Once the product falls into the bag, the top is sealed. Sealing jaws compress 2 pieces of overlapping material and weld them together, often by heating, to form a side or center seal.

Cutting off the bag: The filled and sealed bag is cut off. This top seal on the first bag becomes the bottom of the next bag and the process repeats. The cut bag falls into a collection system, typically a belt conveyor, which feeds the bag into the next packaging step.

Control box: There is a control box on the side of the vertical mold-filling machine. It contains all the electrical parts inside. PLC, contactor, servo motors, pneumatic cylinder, solenoid valves, PLC expansion mode, low-pressure electrical parts. The HMI facilitates the operation and control of the machine.

There are many bag-filling machine manufacturers that offer multiple machines for different applications. Whether you are looking for an oil pouch packing machine or looking for a reliable milk pouch packing machine manufacturer; whether you want to pack powder, liquid, viscous or granular products in flexible bags – smart pack is your best choice.

With four decades of worldwide experience, intensive in-house research and development, state-of-the-art manufacturing, technological ties with global majors, thousands of successful installations, and a strong nationwide service network - few bag-filling machine manufacturers can match the know-how, capabilities, and track record of Smartpack.

0 notes

Text

Omron – Rapid shift towards automation in Indian packaging machine manufacturing

There has been a rapid shift toward automation in the packaging machinery manufacturing industry in India in the last two years as the demand for speed and efficiency has grown in the Covid-19 pandemic, Sameer Gandhi, managing director of Omron Automation India, told Packaging South Asia during the recent Automation Expo 2022 in Mumbai.

Omron works very closely with some of India’s leading packaging machine manufacturers, especially in the vertical form fill seal (VFFS) and horizontal form fill and seal (HFFS) segments.

“Post-Covid, the demand for packaged goods has increased, and the consumer is looking for better quality. Customers are concerned about the environmental impact of packaging, which has greatly boosted some of our technologies – for instance, perfect sealing. What perfect sealing does is that it makes sure all the packs are produced, and the sealing is perfect, as the name suggests. Many companies are experimenting with eco-friendly packaging, and that is where the role of perfect sealing comes in. Because compostable materials can be a little challenging to seal, the sealing controls need to be much more precise for these laminates,” says Sameer Gandhi.

Zero-touch

Gandhi says that the acceptance of robotics in machine manufacturing has increased. “Covid made manufacturers realize that people will not always be available. This gave a boost to the adoption of movements such as zero touch. We have done projects involving high-speed pick and place where complete lines have been automated by multiple robots, and these projects were accelerated due to the pandemic’s impact on labor availability,” he adds.

Omron Automation India, a private limited company, is a part of the Japan-based Omron Automation. It offers automation solutions for the automotive, digital, infrastructure, and packaging industries. Globally, Omron employs around 30,000 people and generates a revenue of nearly US$ 6 billion (Rs 48,000 crore). The company aims to bring innovation to manufacturing sites through innovative- automation with ‘integrated,’ ‘intelligent’ and ‘interactive’ concepts and a wide product range encompassing panel components, smart sensors, vision technologies, PLCs, servos, drives, robots, cobots, and machine safety solutions (ILOR+S) technology.

Apart from machine manufacturers, Omron works closely with end users and brand owners to offer quality inspection systems and end-of-line solutions.

Human-machine collaboration

Speaking about some future trends, Gandhi says that we will see more machine-human collaborations. “Initially, it was just the humans. Then came the machines. And then came a phase when the talk was that machines will replace humans. That has not materialized, and we have moved past that phase. Of course, simple tasks on the shop floor will increasingly be done by machines. But the trend now is more collaborative work between humans and machines. Cobots are one such example. Even in quality inspection and track and trace segments, there will be more man-machine collaborations,” he says.

Indian machine manufacturers are increasingly confident

The future looks very bright for the Indian packaging machine manufacturers, Gandhi says, adding there has been a clear trend of manufacturers moving up the value chain. “There has been a move from making slower machines to faster ones. From making simpler machines to more complex machines. This evolution will continue to take place in the Indian packaging machine manufacturing space. And because of this, there is a lot more confidence in the Indian packaging machine manufacturing industry,” he says.

“Because of this growing confidence, many Indian companies are looking to export their machines to developed markets such as the EU and the US. We are seeing more and more companies participating in global exhibitions. This shows that the machine manufacturers have a solid business plan,” Gandhi says.

SF Vision 2030

Omron has announced its long-term business vision for India. Based on its global vision for the industrial automation business – ‘Enriching the Future for People, Industries and the Globe by Innovative Automation’ – the company aims to translate this in the country by working with customers and partners to solve the issues of the manufacturing industry.

The Shaping the Future 2030 (SF 2030) vision is cognizant of the fast-changing, dynamic, diversified, and complex world of manufacturing led by Industry 4.0 and digitization. The company believes that with its unique automation capabilities based on human-machine harmony, it will be able to contribute to the creation of sustainable and innovative factories coexisting with the environment and well-being of people.

Gandhi says providing solutions to make the factory floor more efficient, safe, and flexible has long been one of Omron’s core competencies. “In recent years, we’ve worked to automate manufacturing by integrating high-speed and high-precision control application technologies, making full use of IoT and AI to create intelligent equipment and production lines, and achieving interactive harmonization between people and machines,” he says.

“These strategies will help Omron shape the future of how India makes things by contributing significantly towards solving the challenges impacting the adoption of automation in the manufacturing sector, such as the lack of skilled resources and misconceptions around automation technologies replacing humans on the shop floor. The next decade promises to be exciting as a combination of India’s rising manufacturing growth trajectory and Omron’s focus on anticipating and resolving new and existing issues,” Gandhi concludes.

0 notes

Text

Don’t think twice; Nichrome packing systems are great for rice!

In most of Asia, particularly India and Bangladesh, the staple food is rice. Food grains like rice, provide much needed healthy nutrients like carbohydrates, proteins, fats, vitamins, and minerals.

Most foodgrains are annual crops. But they are consumed daily. This stresses the need for rice packing machines and rice bag packing machines to avoid losses due to attacks by insects & rodents, pilferage, microbial infestation, high humidity, and heat while the product is stored. Fully automatic rice packing systems are necessary to mitigate the above risks globally.

Nichrome’s fully automatic rice packing machines and airtight food packaging systems feature pouch sealing machines and pouch packing machines. Theyare the epitome of excellence. We offer a wide array of pouch packing machines and have been acclaimed as the leading airtight food packaging machine supplier in Bangladesh.

Bangladesh Market

According to a recent study, the rice packaging machine market in Bangladesh is growing at a CAGR of 4.1% and is expected to cross US$1.2 billion by 2028. If you are looking for a reliable airtight food packaging machine supplier in Bangladesh, then Nichrome is your first choice.

Automated rice-filling systems

Fully automatic rice packing machines are designed to weigh, fill, seal, fold, convey, shape, and palletize rice bags with high efficiency and intelligence.

The machines are made with stainless steel and feature:

Microcomputer chip for control

Programmable logic controller (PLC) touchscreen

Tracking & detection of defective pouches

Output speeds exceeding 80 bags per minute

Nichrome Machines Excel

Nichrome offers a range of fully automatic rice packing and pouch sealing machines, including rice bag packing machines, and other airtight food packaging machines that keep the contents fresh, and contamination free. They extend the shelf-life of the product. Nichrome’s Excel Plus Electronic Weigh Filler is an airtight food packaging machine that can be used for filling rice and other foodgrains.

The machine is equipped with:

Control engineering

Human-machine interface (HMI)

Print mark scanners

Servo motor driven bag length control system

Adjustable stroke of cross sealing jaws for optimum performance

The machine can pack rice in different bag styles such as back seal, 3-side seal, and 4-side seal bags. The output speed of the rice pouch filling machine ranges from 20-80 bags per minute. Nichrome offers an extensive range of vertical form fill seal machines (VFFS) and horizontal form fill seal machines (HFFS) for automatic, high-speed packaging of grains, pulses, and seeds.

We also offer filling and packaging machines for other food products like sugar, maize, millets, and ready to eat foods. Over the years, Nichrome has emerged as the trusted go-to supplier for fully automated filling and food packaging machinery in Bangladesh.

Efficiency & Precision

Nichrome’s automatic rice packaging machines are designed to handle various pouch or bag rice sizes and textures with precision, ensuring that each grain of rice is packed efficiently. Nichrome’s automatic rice packing machines are equipped with accurate pouch sealing mechanisms, ensuring that the rice is securely sealed.

Our pouch sealing machines create an airtight environment that shields the rice from moisture, contaminants, and oxidation, thereby preserving the inherent goodness of the product.

Reliability

Nichrome is a reliable fully automatic rice packaging machine supplier in Bangladesh, committed to provide high-quality air-tight food packaging systems, combined with exceptional customer support.

Our airtight food packaging machines are equipped with cutting-edge technology and offer innovative rice packaging solutions that follow stringent quality norms.

Conclusion

Packaging for foodgrains, cereals and sugar is vital for storage, handling, display, and preservation of the product. As these are essential commodities and staples of our daily diet, packaging must fulfill all its functions at the lowest possible cost to minimize losses and bring down the retail price.

Nichrome is your one stop shop for a wide range of fully automated rice packaging solutions. We promise safety, speed, accuracy, and efficiency for enhanced profitability and assured ROI. Call us today to know more about our stellar machines and we assure you that you will not be disappointed.

#filling and packaging machine#rice bag packing machine#pouch sealing machine#airtight food packaging#vertical form fill seal machine

0 notes

Text

For Net linear Scales and Flow wrapper Contact us

Plan IT Packaging specializes in delivering high-quality end-to-end packaging system solutions to businesses ranging from small to Fortune 500. Our goal is to be known as THE automated packaging solution supplier in North America. As your partner, our mission is to assist you in being more productive and lucrative by packaging your items swiftly and effectively while staying within your budget. Plan IT Packaging provides cutting-edge packaging equipment from start to finish, including flow wrappers (Flow wrapper , flow pack, flow wrap machine), pre-made pouch machines (stand-up machine / doy pack machine), vertical form fill & seal (VFFS), horizontal form fill & seal (HFFS), stick pack machine, sachet machine, thermoforming, tray sealers, multi-head weigher (Net linear Scales ), shrink wrapping, bundling machine, and end of line solution.

Every aspect of your packaging solution is crucial. We make the packaging process easier for you by providing full-service automated packaging solutions. Find out what it's like to collaborate with us. We will come to your company for an on-site consultation anywhere in North America after your free 30-minute automated packaging planning call. Our automated packaging specialists will observe your production procedures, current equipment, and physical work environment during an on-site consultation. The outcomes of this visit are crucial in choosing which packaging options are ideal for your business. This on-site meeting is free of charge, however it will provide basic information on how a turnkey automated packaging system might help your company. Every company that is contemplating automated packaging systems has different requirements.

We will examine the unique demands of your company in order to adopt the best packaging solution for you. We at Plan It Packaging fully anticipate your company to face its own set of problems in order to get the greatest benefits from automated packaging. These challenges excite us, and we are ready to meet them. We begin developing the plan for your ideal automated packaging system only after a comprehensive consultation and in-depth examination of your company's demands. Before any equipment arrives, we present all of our results, conclusions, designs, and plans for your approval. We value our cooperation with your company, therefore we make sure your bespoke automated packaging plan is complete and mutually acceptable before moving further. Visit us online at http://www.planitpackaging.com/

0 notes

Text

Flow Wrap Packaging Market Demands, Analysis, Size, Trends, Revenue by 2032

The Flow Wrap Packaging Market is a segment of the packaging industry that specializes in the production of flexible packaging solutions designed for wrapping and sealing products with a flow wrap technique. Flow wrap packaging, also known as horizontal form-fill-seal (HFFS) packaging, is widely used for various consumer goods and food products. Here's an overview of the Flow Wrap Packaging Market:

Market Significance:

The Flow Wrap Packaging Market plays a crucial role in packaging a wide range of products efficiently and cost-effectively.

It caters to industries such as food and beverages, pharmaceuticals, personal care, and household products.

Key Features of Flow Wrap Packaging:

Versatility: Flow wrap packaging can accommodate products of various shapes and sizes, making it suitable for a broad range of items.

Sealing: The packaging process includes sealing the product from all sides, providing tamper-evident and airtight packaging.

Customization: Flow wrap machines can be adjusted to create different packaging formats, including pillow packs and gusseted bags.

Efficiency: It is a high-speed packaging method, making it suitable for mass production.

Get Sample Copy: https://www.futuremarketinsights.com/reports/sample/rep-gb-4755

Types of Products Packaged:

Flow wrap packaging is used for products such as snack bars, cookies, candies, fresh produce, frozen foods, medical devices, and more.

End-Use Industries:

Flow wrap packaging serves a wide range of industries, including food and beverages, pharmaceuticals, cosmetics, personal care, and non-food items.

Materials Used:

Common packaging materials include plastic films (such as polyethylene and polypropylene), laminates, and specialty films for barrier properties.

Sustainable and eco-friendly materials are gaining popularity in response to environmental concerns.

Benefits of Flow Wrap Packaging:

Product Protection: Flow wrap packaging provides excellent protection against moisture, contaminants, and physical damage.

Shelf Appeal: Transparent film options allow consumers to see the product, enhancing its visual appeal.

Efficiency: High-speed packaging lines are cost-effective for large-scale production.

Sustainability Focus:

As with other packaging segments, the Flow Wrap Packaging Market is increasingly focusing on sustainable practices and materials to reduce environmental impact.

Regulatory Compliance:

Packaging materials and processes must adhere to regulatory standards, especially in the food and pharmaceutical industries.

Technological Advancements:

Continuous innovation in packaging machinery and materials drives improvements in efficiency, automation, and sustainability.

Global Reach: - The market for flow wrap packaging is global, with manufacturers and users located worldwide.

Impact of COVID-19: - The pandemic influenced packaging preferences, with a shift towards convenient and single-serve packaging formats, which flow wrap packaging can accommodate.

The Flow Wrap Packaging Market is an integral part of the packaging industry, providing efficient and versatile solutions for packaging a wide array of products. Its adaptability to various industries and products, coupled with its speed and efficiency, makes it a crucial packaging method for both manufacturers and consumers.

For more info: https://www.futuremarketinsights.com/reports/flow-wrap-packaging-market

0 notes

Text

Global HFFS Bagging Machines Market Outlook Analysis 2021, Global Demand, Industry Share, Business Growth , Challenges, Opportunities, and Application forecast till 2027

Global HFFS Bagging Machines Market

The HFFS bagging machines are known as horizontal form-fill-seal bagging machines or flow wrapping machines which are used in applications where product orientation, breakage is critical. Also, these machines are used for packaging of cereal bars, medical items, and food & confectionery products.

Market Drivers

The growing consumer demand for a wide range of packaged products is expected to boost the global HFFS bagging machines market growth during this forecast timeline. Furthermore, the rise in per capita income of individuals as well as the increase in preference for small portions and single-serve-bag sizes, is further anticipated to drive the demand for HFFS bagging machines during this forecast period. The manufacturers of consumer packaged goods require flexible packaging machines which are compatible with various products and have a low footprint due to ever increase in product lines. It acts as an important driving factor and supports the market growth. Moreover, the increase in demand for HFFS bagging machines in various end use industries including pharmaceutical and personal care will fuel the market growth.

Get Sample Copy of this Report @ https://qualiketresearch.com/request-sample/HFFS-Bagging-Machines-Market/request-sample

Market Restraints

Low versatility in terms of packaging material is the major challenging factor which expected to hamper the global HFFS bagging machines market growth. Also, they are uneconomical for low density products which may limit the growth of global HFFS bagging machines market over the forecast period.

Market Segmentation

The Global HFFS Bagging Machines Market is segmented into type such as 3-side Sealed, 4-side Sealed, and Others. Further, market is divided on the basis of application such as Pharmaceutical & personal Care, Food & Beverages, Chemical Products, and Others.

Also, the Global HFFS Bagging Machines Market is segmented into five regions such as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa.

Market Key Players

Various key players are discussed in this report such as Winpak Ltd., Rees Machinery Group, HDG Verpackungsmaschinen GmbH, Sacmi Imola S. C., Mega Plast GmbH, Arpac LLC, Mespack SL, Busch Machinery, Inc., PFM Group, Viking Masek Global Packaging, etc.

Market Taxonomy

By Type

3-side Sealed

4-side Sealed

Others

By Application

Pharmaceutical & personal Care

Food & Beverages

Chemical Products

Others

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Browse Full Research Report @ https://qualiketresearch.com/reports-details/HFFS-Bagging-Machines-Market

About Us

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers. QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition.

#HFFS Bagging Machines Market size#HFFS Bagging Machines Market Share#HFFS Bagging Machines Market Trend#HFFS Bagging Machines Market Growth#HFFS Bagging Machines Market Application

0 notes