#automotive injection

Explore tagged Tumblr posts

Text

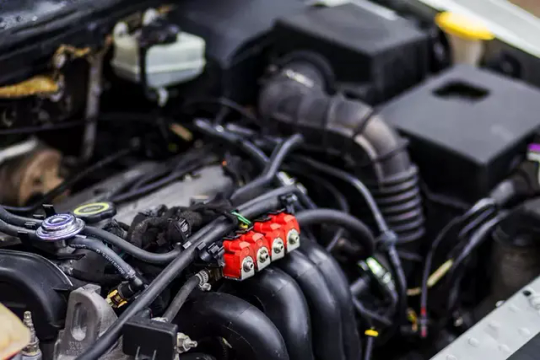

Fuel Injection: SPFI, MPFI, GDI & Dual Fuel—Quick Breakdown

Fuel injection systems efficiently deliver fuel to an engine for combustion. Here’s a brief overview of the different types:

1️⃣ SPFI (Single-Point Fuel Injection):

Uses one injector in the throttle body. Simple and cheap but less efficient than multi-point systems.

2️⃣ MPFI (Multi-Point Fuel Injection):

Injectors near each cylinder’s intake valve improve fuel atomization and efficiency.

• Sequential MPFI: Sprays fuel precisely before valve opens.

• Batch MPFI: Injectors fire simultaneously in groups.

3️⃣ GDI (Gasoline Direct Injection):

Injects fuel directly into the combustion chamber for better power and fuel efficiency, but may cause carbon buildup on valves.

4️⃣ Dual Fuel Injection:

Combines Port Fuel Injection (PFI) with Direct Injection (DI) for optimal performance, balancing emissions and power.

23 notes

·

View notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

Looking for durable, lightweight, and high-performance parts for your ride? Our Automotive Plastic Parts are crafted from advanced engineering plastics to deliver strength without the extra weight, helping your vehicle run more efficiently.

Built to handle high temperatures and resist corrosion, these parts are perfect for tough spots like engine bays. Thanks to precise molding, they fit perfectly and install easily, saving you time and hassle.

Plus, they’re designed to take hits and wear without breaking down, keeping your car safe and reliable on every drive. With sleek surface finishes and a variety of colors and textures, they also add a touch of style to your vehicle.

Best of all? They’re eco-friendly and recyclable, so you can feel good about your choice. Whether it’s bumpers, dashboards, or door panels, these plastic parts offer lasting quality and performance—rain or shine.

Upgrade your car with parts that combine innovation, durability, and sustainability. Your vehicle deserves it.

#china automotive plastic parts#automotiveplasticparts#chinaautomotiveplasticparts#automotive plastic parts manufacturer china#injection molding car parts

0 notes

Text

Injection Mould for Automotive Parts

Mould Type Compression mould Mould Steel P20 / S50C / S45 Mould Cavity

Single cavity / Multiple cavities / Multiple cavities with interchangeable inserts

0 notes

Text

OPM Plastics is one of the top-rated plastic molded components manufacturers in Pune which is known for its high-quality injection-molded components customized as per the requirements of the customers.

#plastic injection molding products manufacturers India#plastic molded components manufacturers in Pune#automotive plastic injection molding companies#automotive plastic injection molding manufacturers in Pune

0 notes

Text

In the fast-paced world of automotive manufacturing, seamless integration of components is important. Our Auto Lamp Mould ensures that the molded parts seamlessly integrate into the larger framework of the automobile, contributing to the overall structural integrity and aesthetic appeal. This seamless integration is not just a convenience but a necessity in the quest for automotive.

Materials and Durability:

Recognizing the demanding nature of automotive manufacturing, our molds are built to withstand the rigors of continuous use. The durability of our molds translates to longevity and cost-effectiveness for our clients.

Customization: We understand that each automotive manufacturer may have unique requirements. Our molds can be customized to meet specific design criteria, ensuring that the final product aligns seamlessly with the client's vision.

Consistency in Performance:

Consistency is the hallmark of our Auto Lamp Mould. Our manufacturing processes are engineered to provide consistent performance no matter which mold is used. This level of reliability is essential for automotive manufacturers seeking to maintain high standards in their production lines.

Quality Assurance:

Quality assurance is woven into the fabric of our manufacturing philosophy. Rigorous testing protocols are employed at every stage of production to ensure that each Auto Lamp Mould meets the predefined quality benchmarks. This commitment to quality assurance is a testament to our dedication to delivering products that meet our clients' expectations.

Technological Integration:

In an era where technological advancements drive innovation, our Auto Lamp Mould stands at the intersection of tradition and modernity. While rooted in proven manufacturing practices, our molds also integrate technological advancements to enhance efficiency and precision. This harmonious blend ensures that our products remain relevant in the ever-evolving landscape of automotive manufacturing.

Customer Satisfaction:

The satisfaction of our customers measures the success of our Auto Lamp Mould. We take pride in forging lasting partnerships with automotive manufacturers who rely on our molds to enhance their production processes. Our commitment to customer satisfaction extends beyond the sale of a product; it encompasses ongoing support, collaboration, and a shared vision of excellence in automotive manufacturing.

#auto lamp mould#car body moulds#automotive plastic injection mold#automotive plastic injection moulding#automotive plastic mould#auto mould#Auto Lamp Mould

0 notes

Text

check out this cool piece of plastic! a diffuser for two bulbs to provide the backlight for three hvac dials on a 2005 honda civic

0 notes

Text

#Automotive Fuel Injection Pump Market size#Automotive Fuel Injection Pump Market report#Automotive Fuel Injection Pump Market forecast

0 notes

Text

Automotive Fuel Injection System Market Drivers: Impact of Emission Norms & Fuel Efficiency Demands Globally

The automotive industry is continuously evolving with technological advancements aimed at enhancing vehicle efficiency, performance, and sustainability. One of the critical innovations driving this transformation is the Automotive Fuel Injection System Market. This system is integral to optimizing fuel combustion, reducing emissions, and improving engine efficiency. With rising concerns over fuel economy and stringent emission norms, the demand for fuel injection systems is soaring.

Stringent Emission Regulations and Environmental Concerns Governments worldwide are implementing stricter emission norms to combat climate change and air pollution. Regulatory bodies such as the Environmental Protection Agency (EPA) in the U.S. and the European Environment Agency (EEA) are enforcing stringent standards to minimize carbon emissions from automobiles. Fuel injection systems help in optimizing fuel-air mixture, leading to complete combustion and reduced pollutants. As a result, automakers are investing in advanced fuel injection technologies to comply with these evolving regulations, significantly propelling the market’s growth.

Rising Demand for Fuel-Efficient Vehicles With fluctuating fuel prices and growing environmental awareness, consumers are increasingly prioritizing fuel-efficient vehicles. Fuel injection systems contribute to improved mileage and reduced fuel wastage, making them an essential component in modern automobiles. The integration of direct injection systems and common rail fuel injection in diesel engines further enhances fuel efficiency. As a result, automakers are compelled to incorporate advanced fuel injection technologies, driving market expansion.

Advancements in Automotive TechnologyThe advent of electronic fuel injection (EFI) and gasoline direct injection (GDI) systems has revolutionized the automobile sector. These technologies offer precise fuel control, enhancing engine performance, durability, and throttle response. Additionally, innovations like turbocharged direct injection (TDI) and multi-point fuel injection (MPFI) are becoming standard in modern vehicles. These advancements contribute to greater efficiency, making them a major driver for the fuel injection system market.

Growing Adoption of Hybrid and Electric Vehicles (HEVs and PHEVs)While electric vehicles (EVs) are gaining momentum, hybrid vehicles that use both combustion engines and electric power are witnessing significant demand. Fuel injection systems in hybrid vehicles ensure optimal fuel efficiency and reduced carbon footprint. The transition towards plug-in hybrid electric vehicles (PHEVs), which still rely on internal combustion engines, sustains the demand for fuel injection technologies, positively influencing market growth.

Expanding Automotive Industry and Rising Vehicle ProductionThe global rise in vehicle production, especially in emerging economies like China, India, and Brazil, is fueling the demand for advanced fuel injection systems. The increasing purchasing power of consumers, coupled with urbanization and infrastructure development, is driving the sales of automobiles. Consequently, automakers are adopting cutting-edge fuel injection technologies to improve vehicle efficiency and meet regulatory standards, further propelling market expansion. Conclusion The automotive fuel injection system market is experiencing robust growth due to factors such as stringent emission norms, fuel efficiency demands, technological advancements, hybrid vehicle adoption, and increased vehicle production. As the industry progresses toward sustainability and enhanced performance, fuel injection systems will remain a crucial component in modern automobiles. Automakers and suppliers investing in innovative fuel injection technologies will gain a competitive edge in this dynamic market.

0 notes

Text

3D Printing Service

Verso3D offers a wide range of 3D printing services for several industrial applications and sectors. Whether you need parts, prototypes, or custom products, 3D printing services can help throughout the product development and production phase.

Verso3D majorly deals with –

Automobile Plastics

Medical Products

Rubber Components

What Is 3D Printing Solutions?

3D printing is the process of producing a three-dimensional object from any digital file.

In short, if you have a prototype design with perfect measurement data, you can create any component you desire. In this process, the object is created by laying down very fine layers of materials as per the digital design provided.

The major benefit of using 3D printing over the traditional production method is that you save a lot of raw materials, especially when designing a complex component. We use the Figure 4 Standalone 3D Printer for ultra-fast and affordable prototyping

#3d printing service#3d printing automotive parts#3d printing plastic injection molding#3d printing rubber service#best 3d printing service in chennai#printing services#reverse engineering in 3d printing#best 3d printer for jewelry casting#3d printing shops in chennai

0 notes

Text

Motoarele cu Hidrogen: Viitorul Curseor Durabile și Performante

Sporturile cu motor se află într-o continuă transformare, iar presiunea de a deveni mai durabile crește pe zi ce trece. Pe lângă vehiculele electrice, o altă soluție promițătoare prinde contur: motoarele cu combustie pe bază de hidrogen (H2 ICE). Acestea nu doar că ar putea reduce emisiile de carbon, dar promit și performanțe spectaculoase pe circuit. Hidrogenul – O Sursă de Energie cu Potențial…

#alternative fuel#automotive performance#AVL Racetech#combustibil alternativ#combustie hidrogen#emisii zero#H2 ICE#hidrogen în motorsport#hydrogen combustion#hydrogen engines#hydrogen motorsport#injecție apă#motoare hidrogen#motorsport technology#performanță-auto#tehnologie motorsport#water injection#zero emissions

0 notes

Text

BMW 530i (chassis code E32), mid ‘70’s.

Link to vid: https://youtu.be/tXvWcH5uKCo?si=WKtdUK1qIBpjZfrl

youtube

https://www.autoevolution.com/news/real-drivers-drive-real-cars-the-story-of-a-babied-1977-bmw-530i-video-84222.html

#bmw classic#bmw motorsport#bmw 5 series#bmw cars#bmw#auto show#auto news#automotive#automobile#performance#fuel injection#Youtube

1 note

·

View note

Text

Our Automotive Interior Injection Plastic Part Molding solutions are engineered to meet the high standards of today’s automotive industry. Designed for precision, durability, and seamless integration, these components play a vital role in enhancing both the functionality and appearance of modern vehicle interiors.

Manufactured using high-performance thermoplastics, our Automotive Interior Injection Plastic Part Molding products offer exceptional dimensional stability, heat resistance, and impact strength. Whether it’s dashboard panels, air vent housings, console trims, or door panel inserts, each part is molded with superior accuracy to ensure a perfect fit and finish—every time.

One of the key advantages of Automotive Interior Injection Plastic Part Molding is its ability to deliver consistent quality at high volumes. Using advanced injection molding technology, we can replicate complex geometries and fine surface textures with minimal variation. This ensures that every component meets OEM standards for aesthetics, strength, and longevity.

Our molding process also allows for integration of design features such as clips, vents, and mounting points directly into the part, reducing assembly time and overall production costs. In addition, materials can be customized for UV stability, scratch resistance, and color matching, allowing you to create a truly premium vehicle interior experience.

Backed by strict quality control and a commitment to innovation, our Automotive Interior Injection Plastic Part Molding is trusted by leading automotive manufacturers and Tier 1 suppliers around the world.

Choose our Automotive Interior Injection Plastic Part Molding solutions to elevate your automotive interior components—where precision meets performance.

#china automotive plastic parts#automotiveplasticparts#automotive plastic parts manufacturer china#injection molding car parts#automotive plastic molding#plastic auto body parts#chinaautomotiveplasticparts#automotive plastic parts#automotiveindustry

0 notes

Text

The plastics market in the United States is experiencing robust growth, driven by several key factors. Firstly, the increasing demand for lightweight and durable materials in various industries, such as automotive and packaging, has propelled the plastics market forward. Moreover, the versatility of plastics in design and functionality enhances their appeal, contributing to heightened adoption across diverse applications. Additionally, the escalating need for sustainable and eco-friendly solutions has spurred innovation in bio-based and recycled plastics, creating new avenues for market expansion.

#United States Plastics Market Report by Type (Polyethylene#Polypropylene#Polyvinyl Chloride#and Others)#Application (Injection Molding#Blow Molding#Roto Molding#Compression Molding#Casting#Thermoforming#Extrusion#Calendering#End User (Packaging#Automotive#Infrastructure and Construction#Consumer Goods#and Region 2024-2032

0 notes

Text

Automotive Plastic Injection Molding Companies in India

The automotive industry in India has been evolving continuously, and plastic injection molding has become an integral part of vehicle manufacturing because of several benefits like fuel efficiency, lightweight components, and cost-effectiveness. As the automotive industry has been witnessing advancements in technological tools, more skilled workers, and an increase in demand for customized plastic products, we can observe substantial growth in the industry. As India is growing to be the hub for automotive production, there are many injection molding companies in India that are delivering plastic products for vehicles to serve both global and local markets.

We have curated a list of automotive plastic injection molding companies that are known for their expertise, experience, and premium work.

1. Supreme Moulders

Established in 1987, Supreme Moulders is one of the best automotive plastic injection molding companies that has been delivering high-quality products for many years. Located in Delhi, this company is utilizing gas injection technology along with fully electric presses to manufacture precise and lightweight auto components and healthcare devices.

2. OPM Plastics

Headquartered in Pune, OPM Plastics is recognized as one of the most trusted automotive plastic injection molding manufacturers in Pune which has a strong presence in the market. Being in the industry for more than 60 years, this company is known for its precision, detail-oriented work in injection molding. It has a big manufacturing plant of 80000 SqFt with different rooms for different purposes like molding, assembly area, storage, mold storage room, tool room, utility area, and dispatch zones. With the utilization of its highly equipped big manufacturing units, this company can complete bulk orders in minimal possible time.

3.Primex Plastics Pvt Ltd.:

Primex Plastics Pvt Ltd. was founded in 1991 in Bangalore. The main industries served by this company are automotive, household goods, and electronics. With a 25000 SqMtr operational facility, this company can take big orders and complete them with precision. Renowned for its high-quality and customized solutions, this company is making a good place in the industry of automotive plastic injection molding.

4. Lumax Auto Technologies Ltd.:

Another trusted name in the automotive plastic injection molding industry is Lumax Auto Technologies, which has been providing amazing products for many years. The plastic division of this company is known for a variety of plastic injection-molded products like engine covers, HVAC components, and other important parts. The key strengths of this company are the use of advanced simulation tools for mold flow analysis and a strong hold over plastic components utilized in both 2-wheeler and 4-wheeler segments.

5. Plastic Moulders Ltd.

Located in Chennai, Plastic Moulders Ltd. has strategically chosen its location on the auto manufacturing belt of South India. It supplies high-grade molded plastic components for interior and under-the-hood applications. It is in close proximity to major auto manufacturers, including Ford and Hyundai. Its key strengths are high production lines with robotic arms, consistent quality, and fast delivery time.

How OPM Helps:

Modern vehicle production means lightweight automotive parts with reduced costs and enhanced durability. All of them can be achieved through just one process, plastic injection molding. OPM Plastics is one of the top-rated plastic molded components manufacturers in Pune which is known for its high-quality injection-molded components customized as per the requirements of the customers.

Recognized for its automotive plastic injection molding in India, OPM Plastics Ltd uses high-strength, lightweight polymers so the durability of vehicle parts can be enhanced without any compromise in its structure. With its expertise in engineering-grade plastics, this company ensures that every product must meet the standards of safety and performance. This company utilizes automated production processes to minimize defects and enhance repeatability for mass production of plastic components.

Being one of the best plastic injection molding products manufacturers India, this company utilizes advanced molding technology to achieve accuracy in every component manufactured. This company has a team of experienced professionals who follow sustainable practices to provide energy-efficient manufacturing with customized solutions. Whether it is about enhanced impact resistance, aesthetic finishing, or temperature tolerance, its experts know how to integrate specialized plastic components perfectly.

Conclusion:

The Indian automotive industry is changing and growing every year. Because of this evolution, we can see an increase in the need for high-quality, eco-friendly, and creative plastic components. Numerous plastic injection molding companies in India are delivering premium services in the automotive sector, and OPM Plastics is one of the most recommended plastic injection molding companies in Pune, which is known for its reliable solutions.

Get in touch with OPM Plastics today if you are looking to create magic in the automotive sector!

#plastic injection molding products manufacturers India#plastic molded components manufacturers in Pune#automotive plastic injection molding companies#automotive plastic injection molding manufacturers in Pune

0 notes

Text

Characteristics of Automotive Component Molds

Automotive component molds are intricate tools at the heart of the automotive manufacturing industry, characterized by several key attributes:

Precision Engineering: Known for their exceptional accuracy, these molds replicate complex geometric shapes and details with precision, ensuring that produced components match design specifications in terms of dimensions and appearance.

Durability and Strength: Fabricated from high-performance materials such as specialty steels or aluminum alloys, they maintain stability and durability under high pressure and temperature conditions involved in processes like injection molding or stamping.

Temperature Resistance: Mold designs accommodate extreme temperatures associated with the material processing, ranging from cold stamping to hot plastic injection, without compromising their structural integrity.

Surface Finish: High-quality molds produce parts with a smooth surface finish, reducing post-processing requirements and enhancing the overall aesthetics and performance of the components.

Design Flexibility: Modern mold design software and manufacturing technologies allow for rapid prototyping and design modifications to adapt to evolving market demands.

Repeatability: The precision of molds ensures consistency across components, which is critical for safety and performance in automotive applications.

Ease of Maintenance and Repair: Molds designed for ease of disassembly and maintenance reduce downtime and increase production efficiency.

Cost-Effectiveness: Despite high initial investments, high-quality molds reduce costs over time by minimizing waste and improving production rates.

Environmental Adaptability: Mold materials and designs consider environmental factors such as corrosion resistance and chemical resistance to perform reliably in various production settings.

Quick Response to Market Changes: The ability to quickly change molds allows production lines to swiftly adapt to new product demands, maintaining market competitiveness.

These characteristics make automotive component molds indispensable in producing high-quality parts that meet the rigorous demands of the automotive industry, ensuring safety, performance, and efficiency in vehicle production.

#car part mold#automotive injection molding#Automotive Plastic Mould#Automotive Plastic Injection Mold

0 notes