#beryllium copper rod

Text

Beryllium Copper Rod | Beryllium Copper Properties | Copper Rod

Discover the exceptional properties of Beryllium Copper Rod through our comprehensive guide. Learn more about its unique characteristics and advantages for various industrial applications. Our website offers extensive information on Beryllium Copper Properties and its various uses. Browse our Copper Rod selection and find the perfect fit for your project needs.

#beryllium copper#beryllium copper rod suppliers#beryllium copper rod#beryllium copper bar#beryllium copper round bar#beryllium copper alloy

0 notes

Text

Cybertronian Drinks and Food

So wanted to try and make a little interactive thing for y'all to send in as request. I'm sure you guys have seen this piece I've made for some of the Energon and Minerals the Transformers consume. Send in to my ask box

So I'm giving you guys the power to send in different things from this list to be made into energon drink art. Or edibles of a sort.

Energon and Fuels

Dark Energon

Synthetic Energon

Tox-En

Red Energon

engex

High grade

Energon wine

Energon Z

Natural Energon

Pure energon

Biofuel

super energon

Energon rod

EnerGULP

Diesel

unleaded petrol

95-octane

E10

E85 - flex-fuel

Jet A and Jet A1 Jet B

JET-A, JP5, JP8

LH2/LOX

RP-1/LOX

kerosene

LSFO

Oil

Minerals, Crystal's and Chemicals

Petroleum

Hydrogen

Copper

Aluminium

Titanium

Lead

Tin

Nickel

Gold

Zinc

Magnesium

Cobalt

Tungsten

Platinum

Chromium

Silver

Manganese

Sodium

Beryllium

Vanadium

Molybdenum

Palladium

Uranium

Zirconium

Bismuth

Cadmium

Mercury

Hafnium

Lanthanum

Niobium

Rhodium

Scandium

Tantalum

Yttrium

Cerium

Plutonium

Lithium

Neptunium

Meitnerium

Seaborgium

Dubnium

Francium

Gallium

Indium

Potassium

Rubidium

Strontium

Thallium

Barium

Calcium

Cesium

Calcite

Pyrite

Copper

Quartz

Benitoite

Diamond

Fluorite

Galena

Garnet

Gold

Oxide

Sulfides

Gypsum

Halite

Phosphates

Sulfates

Carbonates

Iron

__________

Let me know if you would like to be added to tag list (tagged for every fic)

Taglist

@angelxcvxc

@saturnhas82moons

@kgonbeiden

@murkyponds

@autobot79

@buddee

@bubblyjoonjoon

@chaihena

@pyreemo

@lovenotcomputed

@mskenway97

@delectableworm

@cheesecaketyrant

@ladyofnegativity

@desertrosesmetaldune

@stellasfallow

@coffee-or-hot-cocoa

@shinseiokami

@tea-loving-frog

@aquaioart

@daniel-meyer-03

@pupap123

@dannyaleksis

@averysillylittlefellow

@wosemoose1

#transformers#transformers idw#mtmte#transformers lost light#transformers prime#world building#transformers worldbuilding

170 notes

·

View notes

Text

Kushal Metal is a metal distributor based in the India we specializes in providing alloys, including beryllium copper. We offer beryllium copper in various forms, including sheets, rods, and wire. Choose our trusted supply for premium Beryllium Copper today.

0 notes

Text

Beryllium copper rods are extremely useful tools for a variety of applications. They have a unique set of properties that makes them ideal for applications such as electrical conductivity and heat transfer. These rods are also known for their high strength-to-weight ratio and corrosion resistance, making them an excellent choice for a wide range of industrial uses. Beryllium copper rods are available in a variety of shapes and sizes, giving engineers and technicians the ability to find the perfect solution for their project. Beryllium copper rods are used in various industrial applications for their unique properties. It is heavily resistant to corrosion and does not require frequent maintenance. The rods are more malleable than other materials, making them easy to shape into the desired form. Additionally, it can be produced with a variety of finishes and textures.

0 notes

Video

youtube

High Hardness Beryllium Copper Rod sheet C17200 C17300 C17510Beryllium B...

0 notes

Text

The industry mainly adopts purification methods such as clarification,

Aluminum ingot for remelting-5kg, 20kg (≤99. The task of aluminum ingot casting is to improve the utilization rate of low-grade aluminum liquid and remove impurities as much as possible. However, the actual aluminum produced has a higher grade of 99.85%A).7%. Possible compounds are Fe(CO)5, Ni(CO)4, TiF3, TiF4 and GaF3. If the collection efficiency of the trough cover is increased, it will affect the quality of aluminum to a certain extent. In addition, due to the erosion of the operating tool and the cathode steel rod, the iron is also in balance. The industry mainly adopts purification methods such as clarification, flux, and gas, and some also try directional solidification and filtration methods for purification.668×0-8Ω·m. After the flux is finished, take out the iron cage and rest for 5~0min. Those with less influence are indium, lead, zinc, cadmium, tin, beryllium and iron.996% Al pure aluminum (aluminum wire φ2mm, hard-drawn), the resistivity is 2.3% of total revenue.80%Al):

The impurity elements from the flux are mostly phosphorus, accounting for about 20% of the total phosphorus, and the remaining silicon, iron, titanium and vanadium are very few. Since the increased phosphorus content in the electrolyte will affect the current efficiency, and the increased amount of vanadium in aluminum will reduce the electrical conductivity of aluminum, it can be expected that improving the collection efficiency of the tank cover will bring about the quality of the original aluminum and better production effects damage. The solubility of the gas in the aluminum liquid increases with increasing temperature. In addition to alumina bringing impurities to the electrolytic cell, carbon anodes and flux cryolite also bring a lot of impurities. Aluminum ingot casting process

Aluminum-dross slag-inspection weight-ingredients-furnace-scouring-casting-alloy ingot-casting alloy ingot-finished product inspection-finished product inspection-storageThe aluminum liquid drawn from the electrolytic cell contains various impurities, so it needs to be purified before casting. The impurities brought by the carbon anode are mainly iron and silicon, as is cryolite. The aluminum liquid sucked from the electrolytic cell must be purified to remove some impurities, and then cast into a commercial aluminum ingot (99. . In this case, the collection efficiency of the trough cover does not matter. Flux purification.Fluent purification is to use the flux added to the aluminum liquid to form a large number of fine droplets, so that the oxides in the aluminum liquid are moistened, adsorbed and dissolved by these droplets, forming new droplets to the surface, and forming scum to be removed after cooling. If there is an impurity element in pure aluminum, the resistivity increases.6%, and zinc 9. Balance of impurity elements in aluminum

In the industrial alumina produced from bauxite by the Bayer method, the content of impurities is greatly reduced relative to reducer copper tube factory the raw material bauxite.999%Al);Round ingot--30~60kg (for drawing).. Impurities in primary aluminum can be divided into the following three categories: the former categories are metal elements such as iron, silicon, copper, calcium, magnesium, titanium, vanadium, boron, nickel, zinc, gallium, tin, lead, phosphorus, etc.

1 note

·

View note

Photo

Beryllium Copper Alloy - Busby Metals carries the largest inventory globally of copper beryllium alloy, in a variety of forms including rod, bar, wire, tube, strip and plate forms. With applications in demanding fields such as aerospace, automotive design, industrial machining, and petroleum drilling, copper beryllium demonstrates its superior strength in numerous ways.

0 notes

Text

How To Control Beryllium Copper Heating Time ?

The beryllium copper heating time encompasses both the heating and heat preservation (soaking) times. Short heating times, high heating rates, and uniform heating are needed to minimise ingot oxidation and energy consumption. It is essential to add up and take into account the heating temperature, the type of alloy, and the ingot’s dimensions in order to calculate the beryllium copper heating time.

The beryllium copper should be heated quickly and for the proper amount of time. Heat conduction is quick, the furnace temperature is high, and the temperature increases quickly. High-temperature heating has many advantages, especially for metals and alloys with excellent thermal conductivity. For some metals, however, the ingot will merely result in the overburn of coarse grains. The primary purpose of the soaking procedure is to prevent an excessive temperature difference between the ingot’s various components. Generally speaking, the temperature differential cannot be greater than 15-20 degrees Celsius; consequently, the better the ingot’s temperature uniformity, the better. Uneven heating will result in issues like cracks, waves, sickle curves, uneven thickness, and challenging biting when hot rolling. When the ingot size is big, the beryllium copper heating time should be appropriately prolonged, or the heating furnace temperature should be appropriately raised.

The beryllium copper heating components are more intricate. Therefore, during the actual production process, we must always remember the beryllium copper heating principle, accurately and flexibly apply the beryllium copper heating techniques, and constantly enhance the beryllium copper processing quality and power.

On the ageing characteristic curve, the relative maximum strength value will be visible when ageing at a temperature greater than 340 degrees Celsius. If the quantity of cold working remains constant, the strength corresponding to this maximum strength will diminish as the ageing temperature rises. If the ageing temperature is set and the rate of cold deformation is increased, the relative maximum strength value will slightly increase and the time of presentation will also be shortened. This results in a shorter ageing time to achieve the corresponding strength value. The ageing hardening of beryllium bronze only creates a meta-stable sedimentary phase below 330 degrees Celsius; above 330 degrees Celsius, it can create an equilibrium sedimentary phase or a meta-stable phase, with the latter being centred on the grain boundaries.

To prevent under and over-ageing, the temperature of beryllium copper during the ageing process needs to be carefully regulated. Under-ageing can also be made up for by ageing to achieve the necessary mechanical function, but once over-ageing begins, it is difficult to reverse without repeated solution heat treatment. Of course, the necessary functions can also be achieved by maximising the interaction between cold work, underaging, and averaging. For instance, when the strength is less than the maximum value asked, cold work and under- or over-ageing (lowering temperature, extending the time, or increasing temperature, shortening the time) are used to achieve the mechanical function of beryllium bronze that is desired.

Read More :

The Casting Shortening Rate Of Beryllium Copper Rod Is Small: Beryllium copper rods are used in the atmosphere, in seawater, in freshwater, and in steam for steam boilers and maritime ship components. Copper beryllium which contains phosphorus has mechanical properties and can be used in high-precision machine tools as polishing and elastic components.

C17200 Can Be Used As High Air Tightness Casting: It has been used for approximately 6,000 years. C17200 has excellent mechanical and technological properties, and it can be welded and brazed without sparks during impact.

0 notes

Text

Beryllium Copper Market With Emerging Trends And Revenue Estimation By 2027

Data Lab Forecast, one of the world’s prominent market research firms has released a new report on Beryllium Copper Market. The report is full of crucial insights on the market which will help the clients in making correct business decisions. This research will help both existing and new aspirants for Beryllium Copper Market to figure out and study market requirements, market size, market share, growth and competition. This market report offers an overall scope of the market which includes future supply and demand scenarios, changing market trends, high growth opportunities, and in-depth analysis of the future prospects of the market.

The recently published Beryllium Copper market report helps readers in understanding the factors that will impel the industry growth in the forthcoming years, as well as the challenges and threats that are likely to obstruct the progression. The study maps out the various regions where business has thrived while highlighting the potential areas for expansion. Beryllium Copper data documented in the study includes market share, market size, application spectrum, market trends, supply chain, and revenue graph.

For More Information, Get a Sample PDF @ https://www.datalabforecast.com/request-sample/84661-beryllium-copper-market

Beryllium Copper Market with 100+ market data Tables, Pie Chat, Graphs & Figures spread through Pages and easy to understand detailed analysis. The information is gathered based on modern floats and requests identified with the administrations and items.

Competitive Landscape:

Leading players operating in the global Beryllium Copper Market include Key Manufacturers Analysis: Materion, NGK, ULBA, NBM Metals, IBC Advanced Alloys, Belmont Metals, CNMNC, FHBI, Jinfeng Metal, Lanfeng Non-ferrous Metal, Yinke, Shenyang Kehang Metal.

Detailed Segmentation:

Global Beryllium Copper Market, By Product Type:

⇛ Rod, Bar, Wire, Tube, Plate, Strip, Forgings.

Global Beryllium Copper Market, By End User:

⇛ Plastic Molds & Tooling, Electronic Springs & Connectors, Oil & Gas Equipment Components.

Data Lab Forecast, understand the economic impact on Beryllium Copper markets. Using our holistic market research methodology, we are focused on aiding your business sustain and grow during COVID-19 pandemics. With deep expertise across various industries-no matter how large or small- and with a team of highly experienced and dedicated analysts, we will offer you an impact analysis of coronavirus outbreak across industries to help you prepare for the future.

We are currently offering Quarter-end Discount to all our high potential clients and would really like you to avail the benefits and leverage your analysis based on our report.

Avail 30-50% Discount on various license type on immediate purchase (Use Corporate email ID to Get Higher Priority) @ https://www.datalabforecast.com/request-discount/84661-beryllium-copper-market

Beryllium Copper Market

10 Key Benefits of Beryllium Copper Market Research Report:

• It helps businesses strengthen their position.

• It minimises any investment risk.

• It identifies potential threats and opportunities.

• It helps to discover yours and your competitor’s strengths and weaknesses.

• It facilitates strategic planning.

• It helps in spotting emerging trends.

• It assists businesses to stay ahead of the competition.

• It provides revenue projections.

• It focuses on customer needs and demands.

• It helps to evaluate the success of a business against benchmarks.

Top-down and bottom-up approaches were used to validate the size of the global Beryllium Copper market and estimate the size of various other dependent submarkets. Major players in the market were identified through secondary sources secondary sources, directories and databases. Secondary research included the study of the annual and financial reports of top market players, whereas primary research included extensive interviews with the key opinion leaders such as CEOs, directors, and marketing executives. The percentage splits, shares, and breakdowns of the product markets were determined using secondary sources and verified through primary sources.

Do You Have Any Query Or Specific Requirement? Drop Your Query Here @ https://www.datalabforecast.com/request-enquiry/84661-beryllium-copper-market

Business Opportunities in Following Regions and Countries:

Like any other research material, the report has covered key geographical regions such as Europe, Japan, United States, India, Southeast Asia and Europe. Researchers have given their opinion or insights of Beryllium Copper value, product sales, and industry share besides availability opportunities to expand in those regions. As far as the sub-regions, North America, Canada, Medico, Australia, Asia-Pacific, India, South Korea, China, Singapore, Indonesia, Japan, Rest of Asia-Pacific, Germany, United Kingdom, France, Spain, Italy, Rest of Europe, Russia, Central & South America, Middle East & Africa are included.

Major Points Covered in TOC:

Overview: Along with a broad overview of the global Beryllium Copper market, this section gives an overview of the report to give an idea about the nature and contents of the research study.

Analysis on Strategies of Leading Players: Market players can use this analysis to gain competitive advantage over their competitors in the Beryllium Copper market.

Study on Key Market Trends: This section of the report offers deeper analysis of latest and future trends of the Beryllium Copper market.

Market Forecasts: Buyers of the report will have access to accurate and validated estimates of the total market size in terms of value and volume. The report also provides consumption, production, sales, and other forecasts for the Beryllium Copper market.

Regional Growth Analysis: All major regions and countries have been covered in the report. The regional analysis will help market players to tap into unexplored regional markets, prepare specific strategies for target regions, and compare the growth of all regional Beryllium Copper markets.

Buy Now This Premium Report to Grow your Business@ https://www.datalabforecast.com/buy-now/?id=84661-beryllium-copper-market&license_type=su

Years Considered to Estimate the Beryllium Copper Market Size:

History Year: 2015-2019

Base Year: 2020

Estimated Year: 2021

Forecast Year: 2021-2028

Why Choose Data Lab Forecast?

• Deliver updated information on the current industry trends

• Available 24/7 to facilitate clients with unbiased solutions

• Embrace digital technologies to offer accurate business ideas

• Exhaustive supply chain augmentation analysis

• Provide reports strictly according to the requirements of the clients

Thank you for reading our report. To know more about customization options, please get in touch with us. Our team will ensure the report is tailored to suit your requirements.

About Us

Transforming Information into Insights

We pride ourselves in being a niche market intelligence and strategic consulting and reporting firm driven towards resulting in a powerful impact on businesses across the globe. Our accuracy estimation and forecasting models have earned recognition across majority of the business forum.

We source online reports from some of the best publishers and keep updating our collection to offer you direct online access to the world’s most comprehensive and recent database with skilled perceptions on global industries, products, establishments and trends. We at ‘Data Lab Forecast’, wish to assist our clients to strategize and formulate business policies, and achieve formidable growth in their respective market domain. Data Lab Forecast is a one-stop solution provider right from data collection, outsourcing of data, to investment advice, business modelling, and strategic planning. The company reinforces client’s insight on factors such as strategies, future estimations, growth or fall forecasting, opportunity analysis, and consumer surveys, among others.

Contact:

Henry K

Data Lab Forecast

86 Van Wagenen Avenue, Jersey,

New Jersey 07306, United States

Phone: +1 917-725-5253

Email: [email protected]

Website: https://www.datalabforecast.com/

Follow Us on: LinkedIN | Twitter |

0 notes

Text

https://www.kushalmetal.net/beryllium-copper

Beryllium Copper Supplier - Kushal Metal

Kushal Metal is a metal distributor based in the India we specializes in providing alloys, including beryllium copper. We offer beryllium copper in various forms, including sheets, rods, and wire. Choose our trusted supply for premium Beryllium Copper today.

0 notes

Text

20L Pail Mould-We Are Right To Choose

In order to make good cooling system to keep less cycle time, we suggest to make beryllium copper on the paint pail mould.Regardless of how strangely your wine may behave, you are not the first person to experience the problem.When you face something like this, do not feel bad, and do not discard the wine.Paint pail mould size control and fitness ensure the high quality of product, especially for square Paint Pail Mould.

Sometimes we may make little thick on some areas to enhance pail strength,but we need to think that unven wall thickness will cause uneven injection and unequal cooling.Unique paint pail mould construction to ensure container mold durable and easy maintenance.While we can make our lid fit well with 20L pail mould, this is good knowledge and technology.

Because as we know, during the edge of the 20L pail mould, there is a undercut, so, we should let the undercut out before fall.If you’re still looking for the good 20L pail mould maker in China, we can be your another good choice!The 20L Pail Mould includes a core movable along a molding axis, a stripper ring movable a limited distance along one set of guide rods with axes parallel to the molding axis.

0 notes

Text

Beryllium copper rods are extremely useful tools for a variety of applications. They have a unique set of properties that makes them ideal for applications such as electrical conductivity and heat transfer. These rods are also known for their high strength-to-weight ratio and corrosion resistance, making them an excellent choice for a wide range of industrial uses. Beryllium copper rods are available in a variety of shapes and sizes, giving engineers and technicians the ability to find the perfect solution for their project. Beryllium copper rods are used in various industrial applications for their unique properties. It is heavily resistant to corrosion and does not require frequent maintenance. The rods are more malleable than other materials, making them easy to shape into the desired form. Additionally, it can be produced with a variety of finishes and textures.

0 notes

Video

youtube

Beryllium Copper Rod bar plates sheet strip C17200 C17300 C17500 C17510 ...

0 notes

Text

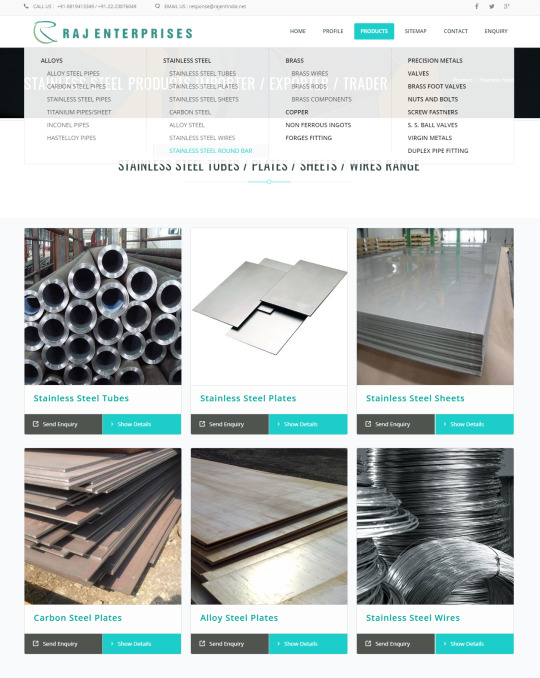

Stainless Steel Plates, Stainless Steel Tubes, Stainless Steel Wires, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India.

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes

Text

Connector material material knowledge

When talking about the connector, it must be inseparable from the material of the connector. Different materials can bring different product performance. At the same time, the material of the connector can affect the price of the product, so understand the connector. Knowledge of material materials is necessary. The following Konnra Electronics engineers have compiled some of the materials of the connector materials. The following is a summary. Let's read them together.

As shown in Figure 1, the connector insulator is commonly used

Usually: PBT, nylon, ABS, PC, LCP and other materials are shown in Table 1, but in principle, materials with better flame resistance are used.

A.PBT material:

Generally used PBT material plus 20-30% glass fiber, with anti-cracking, anti-shock, anti-electricity, good wear resistance, low friction coefficient, good self-lubricating effect, good oil and chemical resistance. It has good dielectric strength under high temperature and high humidity. The shrinkage rate is between 0.6% and 3.0%, and the temperature resistance is about 230 °C. Good formability and flame resistance. It is a commonly used compound for connector products.

B.NYLON66, NYLON6T, PC, LCP material:

The shrinkage rate is 1.0%-0.3%, the temperature resistance is higher than PBT, the temperature is 260°C-280°C for NYLON66, the temperature is 280°C-300°C for NYLON6T, and the temperature is 290°C-320°C for LCP. However, it has a large water absorption, and is generally used for products with high temperature resistance and less PITCH (such as SMD, housing, PLCC, etc.)

C. ABS material:

It has good impact toughness, oil resistance, wear resistance, easy molding, good hardness, good rigidity and temperature resistance of about 100 °C. It is generally used in auxiliary products in connectors.

2, the common defects of injection molding and its causes

Common molding defects are as follows: plastic parts have black spots or black liquid, the surface is not smooth, flashing, plastic forming is incomplete, bubble or charred,shape, stitching line or plastic parts are tightened in the mold and so on. . The main reason is divided into three parts: the factors of the injection molding machine, the factors of the mold, and the factors of the rubber compound.

3, Connector contact composition and performance

Bonding material: metal joint material for plugs, generally in principle brass, but the number of insertions and removals is extremely high, and the long life of phosphor bronze, beryllium copper, etc. can be used for the following industry copper Introduction of types and sexuality

1. Brass - Alloy of copper and zinc, the total color varies with the content of zinc.

A. Brass - 25~35% zinc, suitable for normal temperature processing.

B. Brass - 35% ~ 45% tin, the most suitable for normal temperature processing, the copper plate sold in the market, copper rods belong to it.

2. Bronze - An alloy of copper and tin whose color varies with the tin content.

Generally speaking, a copper alloy other than brass is called bronze.

Phosphor Bronze - Phosphorus is added to bronze, which has anti-friction properties. However, if phosphorus is too much, casting is difficult. The composition is 8 to 12% of tin and 0.5 to 1.5% of phosphorus.

The contacts can be made of any of several alloys, depending on the type of contact, the frequency of insertion and removal, and the electrical and environmental conditions under which the connector operates. Some commonly used materials and their applications are as follows:

Brass - Although brass is a material with good electrical conductivity, it is easily deformed and fatigued after repeated bending. It is usually used as a fixed contact in an inexpensive connector or as a metal part in a connector. Connectors with brass contacts should not be used where excellent flexibility is required. Of course, due to the low cost, brass can still be used as a contact in many places.

Phosphor Bronze - Phosphor bronze has a higher hardness than brass and maintains long-term elasticity. It is often used as a material for contacts that operate at temperatures below 300 °C. For most connectors with low insertion frequency or normal bending of the contacts, the use of phosphor bronze guarantees good reliability.

Bronze bronze - Bronze bronze has much better mechanical properties than brass or phosphor bronze. The beryllium bronze part can be shaped and hardened after annealing, and can actually maintain its shape forever. It is also the most resistant to mechanical fatigue. In applications where insertion and removal are frequent and where high reliability is required, beryllium bronze is recommended.

4, copper plate partial plating

Surface processing (electroplating) of the bonded body: In order to prevent corrosion and oxidation, the surface of the bonded body is smoothed and the mechanical properties of the raw material are generally subjected to electroplating processing and various plating characteristics.

(1). The gold plating thickness is 30 μ", and the Ni plating thickness in the gold plating area is 50 to 80 μ".

(2). The gold plating thickness is 3μ", and the gold plating area is 30~50μ thick.

(3) Other:

Size: Acceptance according to the size of the order item.

Exterior:

A. Unplated surface: no oil, flat strip, non-deformable, bent or stretched.

B. Electroplating surface: smooth gloss, fine particles, no pollution and deformation.

C. Baking: Freezing -55±3°C* 30' Room temperature 10'~15'→105±2°C* 30'→room temperature 10'~15.

D. Heat resistance: 85 ± 2 ° C * 2 hours.

(4). Copper plated tin

A. Salt spray testing is subject to agreement between the parties.

B. The baking test is as follows (a 0.3 item) and the tin is up to 90%.

C. Direct tin is more than 90%.

D. Heat resistance: 85 ± 2 ° C * 2 hours.

E. Copper plated copper plated with a thickness of 30~50μ".

F. tin to lead ratio of Sn / PB90: 10 or 95: 5

G. Tin plating thickness is subject to order requirements.

5, electrical performance

A. Voltage and current rating: Voltage rating involves spacing, while current rating involves contact area and tip area, which should be used according to specifications.

B. Contact resistance: When the connector is properly engaged, a current of 0.1A DC is applied between each terminal and the PIN. The contact impedance resistance is as shown in the attached table, but if the current circuit is used, it is tested with a current of 1KHZ and 1mA. The test involves the pressing portion between the wire and the joint.

C. Insulation resistance: The voltage between the terminals and the terminal and the grounding point between the terminals and the grounding point shall be as shown in the attached table.

D. Withstand voltage terminals between each other and between the terminals and grounding points, as shown in the attached table, the voltage time test should be free of abnormalities.

6, mechanical properties

(1) Insertion force: The insertion force obtained by inserting the combined speed of 25 mm to ±3 mm/min shall conform to the specifications of the insertion force.

(2). Pull out force: pull out at a speed of 25 mm ± 3 mm / min. The pull-out force of the pull-out should be in accordance with the specifications of the pull-out force.

(3) Durability: The following requirements shall be met after the insertion of the 30 owing at the speed of (10 ow/minute) and then the test.

Answer: The contact impedance is within two digits of the initial value.

B: The pull-out force should meet the specification value.

(4). Terminal holding force: Pull the terminal out of the HSG at a speed of 5 mm ± 3 mm / min. The pulling force should meet the tensile force specification.

(5). PIN retention: The PIN is pushed out of BASE at a speed of 5 mm ± 3 mm / min, and the thrust should be in accordance with the thrust specification.

(6). Terminal riveting force: Pull the terminal out of the WIRE at a speed of 5 mm ± 3 mm / min. The pulling force should meet the riveting specification value.

7, environmental performance

(1) Temperature rise of the terminal: After applying the maximum rated current of AC to the thermal equilibrium for any joint, the temperature rise value should be 30 °C or less.

(2). Vibration resistance: In the energized state of DC 0.1A, the test is carried out under the conditions of amplitude 1.5m / m and frequency 10Hz-55Hz / Min, and the X, Y and Z axes are 3 times each time and 2 hours after each axis. The following requirements:

Answer: The contact impedance should be within two of the initial value;

B: discontinuous conduction time is below 1 microsecond;

C: The appearance should be free from abnormalities.

(3). Impact resistance: Under the condition of DC 0.1A, the test is carried out under the acceleration condition of 50g and the X, Y and Z axes are 3 times. After the test, the following requirements should be met. a: I discontinuous conduction time is 1 microsecond. Below, b: the appearance should be no abnormality.

(4). Tin-like property: immersed in a tin bath of 230±50°C for 3±1 seconds from the terminal of the terminal, and immersed in a tin bath of 230±50°C for more than 95%.

(5) High temperature resistance: after being placed in a temperature and temperature bath of 85±2 °C for 96 hours, it should be abnormal and the contact resistance should be within twice of the initial value.

(6) Solder heat resistance: from the terminal body of 1.2 mm at the reference surface, 5 ± 1 second in the tin bath with immersion self-esteem 260 ± 50 °C, the insulator should be free from abnormal state such as crack deformation, and the terminal strength should be within the specification. .

(7) Moisture resistance: 96-inch in a constant temperature and humidity chamber with a temperature of 85±2°C and a humidity of 90%~95%. The test within 30 minutes after wiping the droplets should meet the following requirements:

A. The contact impedance should be within the initial two digits;

B. The insulation resistance should be above 10MΩ;

C. The appearance should be free of irregularities;

D. Should meet the requirements of withstand voltage.

(8) Salt spray test: Place the sample at 35±2°C, and the ratio of 5±1% of salt spray, 16 hours ON, 8 hours OFF for one cycle, 3 cycles after washing with water, should meet the following Requirements, one: the contact impedance should be less than twice the initial value, C: no cracks or obvious corrosion.

(9) Vulcanization gas test: After the sample is placed at 40±2° C. and the vulcanization gas with a concentration of 50±5 ppm is used for 24 hours, the contact resistance should be within twice the initial value.

8, copper conductor related detection items

(1) Wire diameter tolerance:

When 0.10 mm ≦d ≦ 0.40 mm, the tolerance is ±0.004 mm;

0.40 mm

(2). Maximum outer diameter and minimum outer diameter difference (F)

When 0.10 mm ≦d ≦ 0.40 mm, the allowable difference ̊F<0.004 mm;

0.40 mm

(3) Elongation (soft state): the total length of the taken line is 20mm

0.10 mm ≦d ≦ 0.25 mm, elongation ≧ 12%; 0.25 mm

- Elongation = (breaking time -20) / 20

9, copper conductor related performance

The most commonly used conductor in wire and cable is copper, which has comprehensive properties such as high electrical and thermal conductivity, high ductility, good strength, and can be alloyed with other metals or coated with other metals. .

Copper conductors used at temperatures up to 300 °F (or 400 °F for a short time) are coated with tin, tin-lead or pure lead and have a coating thickness of 40 to 70 micro-inch. In addition to being used to minimize oxidation, these coatings also increase solderability and corrosion protection.

Copper wires that are used continuously (or at a short time of 500 °F) at temperatures up to 400 °F are plated with a minimum of 40 micro-inch silver, which is well exposed to higher temperatures. The silver plating layer is more conductive than the tin plating layer when the frequency is sufficiently high and the skin effect becomes high.

Copper or copper-clad steel conductors are used to increase strength, but the use of these materials is always at the expense of conductivity. For example, cadmium copper, a copper alloy containing 0.5-1.0% cadmium, has a tensile strength of 150% of copper, but the electrical conductivity is only about 80% of copper. In addition, the tensile strength of the copper-clad steel wire is 150-200% of copper, but the electrical conductivity is usually only 30-40% of copper.

Aluminum alloy is lighter than copper conductors of the same specification, but its electrical conductivity is only about 60% of copper. In addition, when exposed to air, aluminum forms a surface oxide that can form an undesirable high resistance connection. Therefore, the conductors in wire and cable are often made of copper. According to the current industry, there are roughly the following types of conductors: solid conductors, stranded conductors, and braided conductors.

A. Solid conductor - . The use of solid (single strand) conductors with little wire and cable deflection is advantageous in that it is less expensive than equivalent stranded wires and is usually used for wires and cables with solid conductors. Small instrument, backplane wiring or any similar mounting line for fixed equipment.

B. Stranded conductors - Stranded conductors are used in most wire and cable to provide better flexibility and longer flex life. From a practical point of view, stranded conductors have a longer life than solid conductors. . If there is a small V-shaped crack or similar damage, it will break as soon as it is bent a few times. However, in the same operation, only a few conductors of the stranded conductor are scored or damaged, and the remaining damaged strands still provide an appropriate service life.

C. Braided Conductors - - Flat or round (tubular) braided conductors are also sometimes used in certain applications where they are more suitable than round solid or stranded cables. The braided conductor is rarely insulated because the insulating layer prevents high deflection and the ability to slightly stretch the length due to the axial pushing and pulling of the cable.

10, wire and cable insulation

The insulation of wire and cable can be divided into two basic categories - thermoset and thermoplastic, but there are so many kinds of compounds, mixtures and mixtures in each category, so that the available insulation materials are almost unlimited. Most insulating materials consist of a compound made of a synthetic rubber polymer (thermosetting) and a compound made of a synthetic material to provide special physical and electrical properties.

(1) Thermosetting insulating materials:

Thermoset materials are characterized by mechanical stresses that can be stretched, compressed, or otherwise deformed (within reasonable limits), and when this mechanical stress is removed, can "bounce back" to the original state and shape. Since thermoset insulating materials are not susceptible to thermal softening, they do not melt, flow or deform during the added thermal and electrical overloads, which cause internal heating.

(2). Thermoplastic insulation

Thermoplastic insulation is known for its excellent electrical properties and low cost. Thermoplastics are widely used as insulating materials due to their good electrical properties due to their very thin insulation thickness, especially in high voltage cables. In addition, a cable having a thin insulating layer is generally smaller in size than a cable made of a thermosetting insulating material having the same electrical properties.

Several modified thermoplastic insulating materials can be formulated with a variety of basic thermoplastic materials. Sometimes the main change is color, but most thermoplastics have different grades to meet specific temperature, strength and environmental resistance requirements. Naturally, these materials are thermoformed, thermally softened and flowed under mechanical pressure, and then retained in their deformed shape and state after cooling and/or removal of mechanical strain.

Polyvinyl chloride insulation is widely used in wire and cable because of its high dielectric strength and mechanical strength, high flexibility and flame retardancy, water resistance, oil resistance and wear resistance. They also have low cost and convenience.

#connector#connectors#connector_manufacturer#connectors_manufacturer#connector_supplier#connector_factory

0 notes

Text

Teknologi MotoGP Apa Saja yang Bro Sudah Tahu ?

Teknologi MotoGP Apa Saja yang Bro Sudah Tahu ?

Assalamu’alaikum wa rochmatullohi wa barokatuh

Semoga Allah menyelamatkan kita semua di mana pun kita berada

Untuk saat ini pagelaran balap motor motogp memang masih menjadi yang tertinggi dalam hal teknologi. Meskipun iwf menganggap motor-motor yang berlaga pada balapan motogp memang dibuat tidak cerdas, akan tetapi dalam hal yang lain seperti material, aerodinamika dan lain sebagainya…

View On WordPress

#aluminium twin spar#beryllium copper#camshaft#carbon fibre#clutch#connecting rod#crankshaft#cylinder#desmodromic#diamond like carbon#DLC#floating#frame#hollow stem#inline-4 engine#mesin#monocouqe#piston#piston speed#pistong ring#pneumatic#reinfornced#seamless gearbox#seating valve#silinder#superbike#titanium#trust steel#tungsten carbide#v4 engine

0 notes