#best process gas blowers manufacturer in india

Text

Best Combustion air blowers Manufacturer & Supplier in Delhi

For negative suction, the pumps are ideally suited for processes requiring medium such as degassing, exhausting, and pneumatic conveying. Pumps with secondary cooling (MHV series) develop vacuum up to 8000 mmHg. The operation is completely dry. (Can also be used as a Truck Blower Application).

Capacity: Upto 38000 M3 / Hr., Pressure: Upto 80%

Visit Now: https://swamatics.com/ProductDetails.aspx?prod=Vacuum%20Pumps%20with%20Secondary%20Suction/Air%20Injection

#condencer exhausters#Mechanical vacuum boosters#truck blowers#air blower exporter#vacuum pump manufacturer#bio gas blowers#Turbo Blower#bio gas compressors#Roots blower#Roots blower manufacturer#Positive displacement blowers#best process gas blowers manufacturer in india#Best Air Blowers Manufacturer in Delhi#best process gas blowers#Twin lobe blowers#Mechanical vacuum re compressor#Aeration blowers#Combustion air blowers#Oxidation blowers#Dry screw vacuum pumps

0 notes

Text

#best air blowers manufacturer in delhi#best process gas blowers manufacturer in india#best process gas boosters manufacturer in india

0 notes

Text

2024 - Top Quality Centrifugal Fans and Blowers Manufacturers in India

Centrifugal Fans and Blowers Manufacturers in India

Teral-Aerotech is a Top Centrifugal Fans and Blowers Manufacturers in India, offering a wide range of high-quality ventilation products. Their centrifugal blowers are engineered for high efficiency and low noise, making them suitable for various industrial and commercial applications. The company prides itself on its mission to develop, manufacture, and market top-notch ventilation products, with a focus on reliability, quality, and customer satisfaction.

Centrifugal Fans and Blowers

Centrifugal Fans and Blowers Manufacturers in India, Teral-Aerotech's centrifugal blower fans are precision designed to deliver efficient air movement and increase air or gas pressure. They offer a variety of fan types, including Double Inlet Double Width (DIDW) and Single Inlet fans, with features such as forward curved or backward curved impellers.

Teral

These fans are suitable for a wide range of applications, including general ventilation, pressurization, and various industrial processes, thanks to their high volume air displacement capabilities. The company's commitment to excellence is evident in its emphasis on trust, customer satisfaction, and continuous product development. They also prioritize timely delivery and aim to be the most reliable company for quality, availability, and delivery reliability.

Centrifugal Fans and Blowers

With a strong focus on customer relationships and community engagement, Teral-Aerotech is dedicated to providing the right products with the right performance characteristics, delivered at the right time. Their wide range of centrifugal blowers and fans, coupled with a commitment to quality and customer satisfaction, positions them as a leading manufacturer in the industry.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.blowers-fans.com/centrifugal-fan-blowers.html

Address : PLOT NO.188-89,ECOTECH EXTENSIONS-1, KASANA GREATER NOIDA-201301,(NEAR ASIAN PAINT) UTTAR PRADESH,INDIA

1 note

·

View note

Text

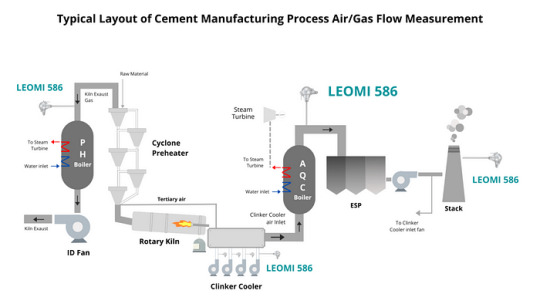

ADVANCEMENT IN AIR & PROCESS GAS FLOW MONITORING IN CEMENT PLANTS FOR PROCESS OPTIMIZATION

One of the essential foundational industries for the growth of infrastructure and building is the cement industry; in 2021, the globe produced about 4.4 billion tons of cement. China is the world’s largest cement producer, with over 55% of the global capacity; India comes in second, with over 7% of the global capacity.

Following the COVID-19 epidemic, there was an abrupt increase in demand for both urban and rural infrastructure expansions worldwide, primarily in developing nations. Long-term demand for cement products will result from initiatives like India’s Smart City project, which will push current cement plants to greatly upgrade their technological capabilities in order to optimize energy and cost.

Among all industrial sectors, the cement industry is one of the ones that uses the most energy. Between 40% and 60% of industrial expenses are attributed to energy use. In addition, the cement sector accounts for 5% to 8% of global emissions of CO2 produced by humans. Today’s cement plant operators will prioritize efficiency and optimization due to the rising demand, which will primarily rely on the precise and repeatable measurement of several process parameters like temperature, pressure, flow rate and level, etc.

In the cement industry, process gas flows are typically calculated using temperature and pressure in relation to the speed and power consumption of fans and blowers. However, this is an assumption that creates significant uncertainty regarding the real gas flow rate and energy consumption of prime mover, such as fans and blowers.

The following processes require the best possible control over air and process gas flow monitoring in order to improve cement quality overall, efficiency, and cost optimization:

1. PREHEATER PROCESS EXHAUST GAS FLOW RATE MEASUREMENT:

Before the raw mix is put into the rotary kiln in a cement production facility, it is heated in cyclone preheaters, which also remove water and carbon dioxide from the mixture. The stability of the calcining temperature and the quality of the cement clinker in the kiln are directly impacted by the caliber of the preheater in a cement plant. The ID Fan downstream can be fine-tuned for optimal management of the O2 content of the kiln off gas by measuring the exhaust gas flow rate in the downcomer.

The measurement of exhaust gas flow is often difficult because of the duct’s enormous diameter, the high concentration of dust, and the high temperatures (between 350 and 400 degrees Celsius). Velocity is typically measured momentarily using a Pitot tube with large uncertainty for cross-checking, which hinders effective process management.

2. CLINKER COOLER AIR FAN FLOW RATE MEASUREMENT:

A crucial component of the clinker manufacturing line, the clinker cooler provides hot air for the rotary kiln and preheater system as well as aids in cooling and transporting the hot clinkers that are discharged from the kiln. It is essential for decreasing the amount of coal and power used, raising the temperature of secondary and tertiary air, and enhancing the rate of heat recovery since it is the first piece of equipment where high-temperature clinker releases heat.

Two ways that a good clinker cooler can assist cement plants in reducing energy consumption are by increasing the cooling efficiency and lowering the power consumption of the clinker cooler itself, and by increasing the heat recovery rate, which can lower the amount of coal used in the rotary kiln and preheating systems. In order to achieve cooling efficiency and energy savings with a higher cooling rate concerning feed rate adjustment, clinker cooler grate air fan effective management is essential. For a clinker cooler to operate as efficiently as possible, continuous cooling air flow rate measurement is crucial.

Because of the high concentration of clinker dust and high abrasion rate, measuring a cooler air fan is a difficult operation. Strong flow sensors that are resistant to severe abrasion are required. This application’s flow solution is currently restricted, and its life expectancy is only 1–6 months.

3. AQC BOILER & PHP PROCESS GAS OUTLET FLOW MEASUREMENT:

The heat produced by the rotary kiln preheater (PH) and the hot gases from the AQC exhaust are used to create power in waste heat recovery (WHR) power plants, which are situated in cement factories. Waste heat recovery systems (WHRS) use steam turbines to recover heat energy from hot waste gas that is sent to boilers for power generation (in this case, electricity) and after quenching chambers (in this case, clinker cooler and preheater boilers in rotary kilns. Usually, this waste heat can be used for power generation applications to meet the cement plant’s 20–30% power need, which results in a significant reduction in the overall cost of production.

Effective management of pH and AQC A flow measurement device that is appropriate for high temperatures and abrasion resistance design is required by the boiler in order to ensure an accurate and dependable gas flow rate at the intake or output.

4. PRIMARY AIR FAN FLOW MEASUREMENT IN POWER GENERATION BOILERS:

In addition to AQC & PH Waste heat recovery boilers, a captive coal power plant is erected in the cement plant to provide additional electricity needs. It’s critical to keep an eye on the boiler’s primary airflow in order to maintain the ideal stoichiometric air-to-fuel ratio and achieve effective combustion. It is necessary to have a primary air flow measurement that is accurate, dependable, and low-maintenance. It should also have a minimal pressure drop.

5. PROCESS & FLUE GAS FLOW MEASUREMENT IN EXHAUST STACK:

For the purpose of maintaining control over emission criteria, the pollution control authority must monitor the exhaust process flue gas from the boiler and clinker cooler. In order to achieve high thermal efficiency, enhance ESP performance, minimize emissions of dangerous pollutants, and provide helpful information on optimizing mass balance, this requires accurate and dependable flow measurement technologies.

6. COMPRESSED AIR MEASUREMENT FOR UTILITY CONTROL AND CONSERVATION:

AN ACCURATE AIR & GAS FLOW MEASUREMENT IN CEMENT PRODUCTION HELPS IN:

Reducing Blower (ID/FD Fan) power consumption i.e., energy saving

Controlling the accurate and repeatable operation of kiln & improving clinker production quality

Improves energy efficiency of Clinker cooler fan & energy conservation

MAJOR CHALLENGES IN EXISTING FLOW MEASUREMENT SOLUTIONS FOR THE ABOVE APPLICATIONS:

High-pressure drop means energy loss

Lower turn-down ratio implies limited operational range and leakage insensitive.

Lower accuracy & measurement resolution implies limited efficiency & performance analysis

Clogging and high wear factor

High cost of installation & needs frequent maintenance.

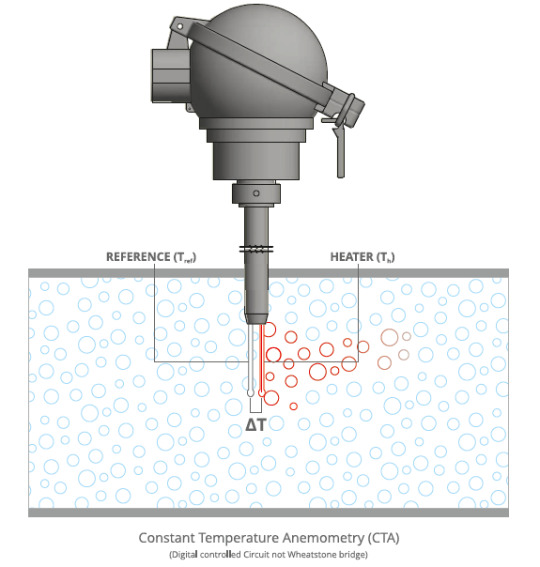

OVERCOMING ABOVE CHALLENGES BY ADVANCE PROVEN CALORIMETRIC (HEAT DISSIPATION) TECHNOLOGY:

The technology of Insertion Thermal Mass (Heat Dissipation) Flow Meters is advancing these days to overcome the drawbacks of the traditional pitot tube or annbar differential pressure-based flow measurement methods now in use.

NSERTION THERMAL MASS FLOWMETER:

WORKING PRINCIPLE:

The fundamental principle of thermal dispersion from a heated element to the ambient medium (such as air or gases) underlies the operation of thermal mass (calorimetric) flow meters. The velocity, density (temperature and pressure), and properties of the medium all have an impact on this. The mass flow and temperature differential, ∆T, determine how much energy is required.

ADVANTAGES OF INSERTION THERMAL MASS FLOW METERING TECHNOLOGY AGAINST CONVENTIONAL FLOW METERING:

Pipe sizes suitable 15mm to 10 metres

Easy Installation, orientation & rugged design with customized sensor material design

Working temperature upto 40⁰⁰C & 16barg or higher can be achieved

Better accuracy < ±2%RD of mass flow rate

Highest turn down ratio 100:1 or better, too sensitive throughout flow ranges.

No pressure drop saves energy (pressure) loss

Versatile & Cleanable sensors (auto-purging) design

Can be used with too low upstream straight length with special installation procedure

Low cost of ownership against other flow technology

CONCLUSION:

The main components of a cement plant are large ducts with blowers (FD & ID Fans). Conventional flow measurement uses differential pressure sensors as primary elements, such as average pitot tubes, orifices, and aerofoils, which are prone to clogging, insensitive to changes in flow velocity, and result in significant pressure drops with lower accuracy. It has now been shown that using differential pressure sensors against the latest development in heat dissipation technique — insertion thermal mass flow — is generally uneconomical when compared to inserting thermal mass flow (heat dissipation technique) metering.

Current research is being done to develop more materials that are compatible with hot gas that has high abrasion and heavy dust concentration. These materials will meet the majority of application needs in cement plants, with the exception of a few that have temperature restrictions up to 500°C. Conventional technologies continue to dominate the industry, with operating temperatures remaining above 50⁰⁰C. I hope this will assist operators of cement plants in seeing the advantages of utilizing modern technologies in place of traditional flow measurement.

AUTHOR:

Mr.Manish S Patel, A Chartered Mechanical Engineer with more than 24 years rich experience in process industries especially in flow measurement with a wide range of applications.

Request to kindly write us your queries related to the flow measurement applications would be happy to assist at our best. For more information contact us.

0 notes

Text

2023 - Top Quality Centrifugal Blower Manufacturers

Centrifugal Blower Manufacturers

Centrifugal blowers play a pivotal role in numerous industries by providing efficient air movement solutions for various applications. These powerful mechanical devices are designed to generate a continuous flow of air or gas, making them indispensable in settings where ventilation, cooling, and material handling are essential. From manufacturing plants and chemical facilities to HVAC systems and wastewater treatment plants, centrifugal blowers are used to maintain optimal working conditions and enhance production processes.

Centrifugal Blower

At Centrifugal Blower Manufacturers, AMCS Cooling Systems stands out as one of the best centrifugal blower manufacturers in the industry. With a reputation for quality and reliability, they offer a wide range of centrifugal blowers designed to meet the specific needs of different industrial sectors. Their centrifugal blowers are known for their durability, energy efficiency, and low maintenance requirements, making them a top choice for businesses looking to optimize their operations while reducing operating costs.

Airmake Cooling

AMCS Cooling Systems' commitment to innovation and customer satisfaction is evident in their technology and custom-engineered solutions. These centrifugal blowers are engineered to deliver consistent and precise airflow, ensuring that industries maintain the desired environmental conditions and achieve their productivity goals. In an era of sustainability and energy conservation, Centrifugal Blower Manufacturers AMCS Cooling Systems' products are designed with eco-friendly features, reducing carbon footprint and energy consumption.

Centrifugal Blower

If you want to know more about our Centrifugal Blower how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.airmakecooling.com/centrifugal-blower.html

Address - PLOT NO. 49 UDYOG KENDRA - II, ECHOTECH-III Noida - 201306 (U.P.), (India)

Twitter - https://twitter.com/make_air

#manufacturer#centrifugal blower suppliers#amcs#air filter#high quality#exhaust blower manufacturers in noida#air quality

0 notes

Text

Are there the most efficient the best gas blowers made for process in India?

Manufacturers and suppliers of blowers for the process are located India. But able to provide some general tips on how to find reliable manufacturers and suppliers in the region:

Directories online: Web directories are well-known platforms where manufacturers and suppliers display their products and services. Look for manufacturers of gas blowers situated at Delhi NCR on these platforms.

Business Directory: Check local directories of businesses that are offline as well as online to find listings of equipment suppliers for industrial use and their distributors inside Delhi NCR.

Trade shows and exhibitions: Being a part of trade fairs and trade shows that are held within Delhi NCR can provide. You have the chance to interact with manufacturers and suppliers in person.

Networks: Connect with industry professionals, colleagues, and other contacts who might have details about reliable manufacturers and suppliers in the region.

Industry Organizations: Industries organizations that focus on manufacturing, engineering, or industrial equipment might include directories or information for companies from Delhi NCR.

Contact: In case you've got specific requirements for blowers that are used for processing gases. You should talk to an expert in industrial equipment who can help you find suitable manufacturers and suppliers.

Website search: Full online search that includes relevant keywords such as "process gas blower manufacturers Delhi NCR" to find potential suppliers.

When evaluating manufacturers and suppliers, consider factors such as the quality of the product and reputation, along with price, customer reviews, and after-sales support. It is suggested to request estimates from several suppliers to enable you to test their offerings and make a well-informed decision.

Take note that the information you find here might not be up-to-date with the latest advancements or updates. Always verify this information with the manufacturer as well as the suppliers directly. Additionally, you should gather a variety of sources of information before making a business decision.

Trilobe Rotary Piston for sale at a bargain price in India

Swamatics is the best and most trusted Trilobe Rotary piston manufacturer and supplier company. Which provides air blower gas blowers, compressors, and Acoustic enclosures at a reasonable cost for Delhi. The most cost-effective and efficient for conveying, fluidizing, and mixing powdered or granular materials, as well as the air aeration of liquids the circulation.

Capacities that go up to capacities of up to CMH and pressures as high as 1.1 kg/cm2.

The blowers made explicitly for high suction pressures use mechanical seals, pressurized oil, and various design changes.

Swamatics are among the Best Air Blowers. The Manufacturer and supplier Company offers compressed air blowers, gas burners, and Acoustic enclosures for sale at a lower cost in Delhi. Swam offers a complete Turn Key service starting from the very first concept engineering and design all the way up to production testing installation, commissioning, and even commissioning.

We offer our customers an extensive selection of Rotary Twin Lobe Roots Blowers. They are manufactured by a tried and tested volumetric method that claims that the volume produced is proportional to the speed of rotation. Also, it is free of oil as well as gas that is free of contamination. The product is made up of two trilobe Rotary piston that are identical, or twins, that move towards opposite sides. It is available from 20m3/hr up to 30000 m3/hr. The pressure range in sizes ranges from 1,000 mmWC (0.1kg/cm2) to 10,000 mmWG (1.0kg/cm2).

1 note

·

View note

Text

Acoustic Enclosures

Envirotech, a renowned manufacturer of Acoustic Enclosures in India, leads the industry with its exceptional expertise. Our primary focus revolves around designing, manufacturing, and installing acoustic enclosures for a diverse range of noise sources, including turbines, compressors, air blowers, glass crusher machines, fin presses, power plants, and various industrial processes. We take pride in providing comprehensive design services for acoustic enclosures to address specific noise challenges faced by our clients. Our designs effectively cater to all types of industrial noises emitted during the production process.

Our meticulously engineered acoustic enclosures are specifically designed to minimize noise emissions into the surrounding environment. We strictly adhere to the noise level standards set by industrial application CPCB norms and ISO 14001 standards, ensuring optimal performance and compliance.

Whether your requirements involve DG sets ranging from 5kVA to 2000kVA, we are fully equipped to offer the best protection against noise-related issues through custom-built enclosures. Our acoustic enclosures find extensive applications in industries such as automotive and home appliances, especially for noise testing purposes. We provide a diverse range of products that cater to various sizes, shapes, and budgets. Our solutions have undergone thorough testing, proving to be both cost-effective and reliable.

Envirotech Acoustic Enclosure offers an extensive selection of enclosures suitable for diverse purposes. Whether you need to control acoustic levels for a home theater system, an office, or a data center, we have the perfect enclosure to meet your specific needs. Our enclosures are crafted using high-quality materials and are competitively priced, ensuring exceptional value for our customers.

Our specialized product, the Envirotech Acoustic Enclosure, effectively mitigates the noise and vibration generated by industrial machinery. It utilizes innovative technology that enables industries to operate their equipment without causing disturbances to the surrounding environment. Customized to fit specific equipment and applications, this enclosure incorporates sound-absorbing materials that can reduce noise levels by an impressive 99%. The Envirotech Acoustic Enclosure not only offers a cost-effective and reliable solution but also enhances operational efficiency, productivity, and employee well-being while significantly reducing noise pollution.

In addition to creating a safe working environment by minimizing the risk of hearing damage and other health-related issues, our Soundproof Enclosure also helps companies meet regulatory compliance standards. Its versatility extends across various industries, including power generation, manufacturing, and oil and gas, making it a valuable asset for businesses striving for regulatory adherence and noise control.

0 notes

Text

Things you need to know about Fluid Bed Dryer.

VJ Instruments has introduced the Fluid Bed dryer Processor, Fbd Fluid bed dryer, and Rapid dryer. VJ Instruments are one of the most trusted Fluidized-bed dryer manufacturing company in India. Dryers are used in a variety of industries, such as the food processing, pharmaceutical, paper, pollution control, and agricultural sectors.VJ Instruments can provide important information about the different technologies available and what makes the most sense for your specific need.

Fluid Bed Dryer

A fluid bed dryer is a revolutionary dryer. including fluid bed granulation machine is ideal for production. a truly versatile for Pharmaceuticals, Dyestuff, Food, Chemical, Bulk Drugs, and Polymer Industries. Fluid Bed Dryers are designed to Uniform drying of the material at low temperatures. fluid bed dryers have established themselves as dependable and multi-functional processors. a fluid-bed system is a machine in which a continuous flow of “wet” powder, granular, or flakes material is conveyed over a perforated bed. Hot drying air is blown through the holes of a perforated plate.

What You Need in a Fluid Bed Dryer

When you’re looking to invest in a fluid bed dryer system, keep in mind all the features that are important to you, and don’t compromise.

Ø Heat transfer with minimal energy consumption: energy efficient

Ø Manufactured from stainless steel, carbon steel, or nickel alloy

Ø Customized for your individual needs

Ø Low maintenance

Ø Multi-functional: capable of heating, drying, cooling, coating, and more

Ø Adaptable to continuous or batch processing

Ø Vibration to aid in processing

Key Benefits Of Fluid Bed Dryer :

ü High Specific Drying Capacity

ü High Operational Safety

ü High Hygienic Standard

ü High-Temperature Stability

ü Optimal Energy Efficiency

FBD Fluid Bed Dryer

FBD Fluid Bed dyer is a top choice for fast and uniform drying of a multitude of products. The FBD is widely used in pharmaceutical, chemical, food, and allied industries to reduce the moisture/solvent content of particulate materials. The smart system combines best-in-class features with an intelligent automation platform to deliver reliable, safe, and sustainable performance over decades. A fluidized bed dryer (FBD) is well known and widely used equipment in the granulation area of pharmaceutical manufacturing.

Advantages Of FBD

Ø Excellent gas-particle constant results in strong heat and mass transfer rates, resulting in high moisture removal rates.

Ø Lower initial and ongoing cost

Ø Stability and easy to use

Disadvantages of FBD

Ø Considerable pressure drops are caused by the necessity to suspend the entire bed in gas, resulting in high energy usage.

Ø When organic solvents must be eliminated, this is not the best equipment to use.

Ø For certain types of fluidized bed dryers, product quality is non-uniform.

Rapid Dryer

This instrument is used for Drying sand samples for determining Moisture percentage, Clay percentage, and Fineness number.

The Rapid Dryer works fast and gently. Bulk materials whether organic, inorganic, chemical, pharmaceutical, coarse, fine, crystalline, fibrous, or leafy – will be dried in a single pass without hot spots and they are loosened and mixed at the same time. Glass components, such as pipettes, ceramics, plastics, textiles, wood, or metal (such as test sieves) can be dried with superb results using this equipment.

Drying in the Rapid Dryer makes use of the fluidized bed process, a technique similar to the one used in large industrial dryers. Ambient air is drawn in through a filter. A blower moves the air around the motor and across heating elements and ultimately forces it through the perforated plate and into the detachable drying container. The solid particles are blown upward and agitated and thus kept separate one from another so that their surfaces cannot stick together. The air stream extracts moisture from the particles and then exits through the filter bag in the cover of the drying container.

Advantages

flØ Drying periods of just a few minutes.

Ø Glass container for visual monitoring of the drying process.

Ø Simple operation thanks to a quick-clamping cover with bayonet catch.

Ø Versatile with a choice of drying chambers and exhaust air filters.

Ø Gentle drying even of temperature-sensitive substances.

0 notes

Photo

Industrial Exhaust Fan Manufacturers In India | Sonika Engineers

Industrial exhaust fans are used in many industries to help remove heat from industrial processes. They can be mounted on walls or ceilings, and some models even come equipped with lights that turn them into attractive decorative pieces. An industrial exhaust fan is a device that pulls air through a filter and pushes it out again. This helps to cool down the room. A fan may use either electricity or natural gas to power its motor. Sonika Engineers offer a wild range of Industrial blowers. As an industrial exhaust fan manufacturers in India, we make centrifugal blowers in a wide capacity range. We make range of Industrial blowers for pollution control. Our custom industrial fan is a great choice for any business looking to increase their productivity. Buy efficient industrial exhaust fan from the best exhaust fan manufacturers in india. Industrial Exhaust Fan Design – The design of an industrial exhaust fan varies according to the manufacturer. Some have blades that spin clockwise while others spin counter-clockwise. There are also fans that are designed to blow air upward or downward depending on where they are placed. There are many different types of motors that can be used depending on the type of fan. Some common types include centrifugal, axial-flow, and mixed flow. Fans are usually rated based on their CFM (cubic feet per minute) output. Airflow – Airflow is the movement of air through a space. In industrial settings, airflow is used to move fumes from areas where they are generated to other locations where they can be safely handled. Industrial fans are designed to create this flow of air. They are often powered by electricity, but may also be driven by compressed air or steam.

0 notes

Text

Best Trubo and Air gas blower manufacturer in India

http://www.swamatics.com/

1 note

·

View note

Text

Tri Lobe Roots Blowers

Swamtics, India's leading root blower manufacturer introduces the new Tri lobe root blowers. Tri-lobe technology means that the blowers have the tips of the lobes exposed at 120 degrees around the rotor instead of 180 degrees as in a Bi-lobe blower. This provides a stiffer rotor assembly, which means less deflection under any load. Best process gas blowers, these blowers are designed with specific industry demands in mind for continuous operation, rugged design, reduced noise, reduced pulsation and vibration, longer bearing life, and minimal maintenance. These blowers are designed for continuous duty. Full package units ship with all essential accessories and electric motor, ready to install, plug and play. Tri lobe rotary piston, A Swam Tri-Lobe blower is supplied with integrated safety and monitoring equipment, such as a safety valve and pressure gauge. best process gas blowers manufacturer in india

Swamtics, Tri-Lobe Blowers / Compressors are positive displacement units, the pumping capacity of which is determined by size, operating speed and pressure conditions. best process gas boosters, It employs two three-lobe impellers mounted on parallel shafts, rotating in opposite directions within a casing closed at the ends by side plates. As the impellers rotate, air is drawn into one side of the casing and blown out the opposite side against existing pressures. Air Blowers Manufacturer, The differential pressure developed, therefore, depends on the resistance of the connected system.

Blowers, being the positive displacement type, do not develop pressure within the housing, but the discharge pressure depends on the resistance / back pressure of the system. Best Air Blowers Manufacturer, Effective sealing of the compressor inlet area from the discharge area is achieved through the use of a very small operating space, eliminating the need for internal lobe lubrication. Pair of precision machined, hardened and ground alloy steel timing gears maintains clearances between impellers during rotation.

The air, thus delivered, is 100% OIL FREE. The pumping capacity of a lobe compressor, operating at constant speed, remains relatively independent of variations in inlet and discharge pressure. These blowers are constant volume machines, delivering a fixed discharge against the back pressure of the system. Therefore, it is essential to ensure that minimal restrictions are placed on the piping, inlet and discharge. Properly sized pipes and large radius bends ensure minimal line losses resulting in higher efficiency and low energy consumption. A sudden change in pipe cross section should also be avoided. To change the capacity, it is necessary to change the speed or vent some of the air to the atmosphere. best process gas boosters manufacturer in india

Air should not be recirculated from discharge to suction as it may cause the triple lube fan to overheat. Never attempt to control compressor capacity by means of butterfly valves in the inlet or discharge piping. Condenser exhausters, This increases the power load on the engine and can seriously damage the compressor. There is an increase in the discharge air temperature due to the heat of compression. vacuum pump manufacturer.

Features

· Anti-friction bearings

· Three-lobe rotor design, suitable for both pressure service and vacuum service

· Fail-safe labyrinth seal

· Splash-lubricated, hardened and ground alloy steel timing gears

· Improved volumetric efficiency and reduced operating temperatures

· Dynamically balanced rotor shaft assembly

· Low-noise, low-pulsation three-lobe blower construction

· 100% oil-free air delivery, Turbo Blowers

· Superior product designed and guaranteed from the factory

· Standard Orientation - Right Angle Flow

· Low-noise, low-pulsation three-lobe blower construction

· Extended shaft design for cold operation

· Rigid one-piece IC housing and end plates

· Large inlet and outlet connections for minimal loss

Hardened alloy steel shafts ground to close tolerances

#turbo blowers#best process gas boosters manufacturer in india#best process gas blowers manufacturer in india

0 notes

Text

Best Turbo Blowers Manufacturer & Supplier in Delhi

Swamatics is the Best High efficiency Turbo Blowers are most advanced single stage centrifugal machine based on high speed focused specialized technology oil less operation.

Capacity: Upto 15000 CFM .

Call Now +91-120469 6222

#condencer exhausters#Mechanical vacuum boosters#truck blowers#air blower exporter#vacuum pump manufacturer#bio gas blowers#Turbo Blower#bio gas compressors#Roots blower#Roots blower manufacturer#Positive displacement blowers#best process gas blowers manufacturer in india#Best Air Blowers Manufacturer in Delhi#best process gas blowers#Twin lobe blowers

0 notes

Text

0 notes

Text

Alumina Bricks - Refractory Material

Refractories are non-metallic materials that have chemical and physical properties that can withstand high temperatures without changing their physical and chemical properties. Due to their high resistance to heat and thermal shock, this can be used as a lining material inside the kilns and furnaces which will prevent damages to the steel structures and reduce the heat loss from the furnace/kiln, Refractories are mainly used in Iron & Steel, Cement, Power, Aluminium, petroleum and other high-temperature process industries. Refractories are pivotal to this energy-saving process due to their inherent low heat conductivity as well as advantages derived from ease of placement and the strength of the materials.

Calderys is a globally leading manufacturer of refractory that provides customized refractory solutions such as Shaped & unshaped refractory of both dense and insulation, Ready Shape blocks (PCPF blocks), high alumina cement, isostatically pressed continuous casting refractories and many similar products to widely diversified industries which include Iron & Steelmaking, Cement, Petrochemicals, Boilers & Incinerators, Foundry, Aluminium, DRI, etc.

To make the shopping experience more convenient Calderys have developed 'Caldezone', their very own online portal with all their products so the clients can check their specifications, get the best price and buy refractory products online according to their requirement.

Alumina Bricks are a multi-industrial refractory product that is produced with select bauxite chamotte as the main raw material, formed with an advanced process with strict quality control. These bricks are used in all kinds of industrial furnaces and high-temperature areas to enhance the productivity of furnaces.

Petrochemical & Refinery Industry

Petrochemicals are procured from various chemical compounds, mainly hydrocarbons. These chemical compounds are derived from crude oil and natural gas. There are various fractions produced by the distillation of crude oil. Among which petroleum gases, naphtha, gas oil, and kerosene are the main feedstocks for the petrochemical industry.

Petrochemicals play a vital role in directing our basic needs in the fields of food and water security, shelter, clothing and textiles, health care, social and physical infrastructure, information, communication and entertainment, directly & indirectly.

Usage of Alumina bricks in Petrochemical Industry

The main parts of the furnace are the control system-thermostat and electrical controls, the gas valve, burners, heat exchanger, blower, and duct and ventilation system. These furnaces are required to be built in a way that they should retain the produced heat as much as possible. Here comes the role of refractories, Alumina bricks.

Get the best Alumina bricks for Petrochemical Industry on Calderys' Caldezone

AC BW are medium alumina bricks with standard and customized dimensions. These have the basic application at the fired heaters-bridge wall area. These refractory bricks have a high density, high purity, high strength and high chemical inertness towards alkali attack.

AC RF are medium alumina bricks with standard and customized dimensions. These have a basic application in the radiant floor area and fire heaters floor. These special fireclay bricks are manufactured by using special grade refractory materials of various particle sizes and have optimum strength, volume stability at operating temperature, chemically inert, thermal spalling resistance with excellent refractoriness.

AC HP are high alumina bricks with standard and customized dimensions. These have a basic application in the SRU-reaction chamber main cylinder-Hot Face. These low iron and special dense high alumina refractory bricks have high chemical purity, high Hot load strength and controlled porosity and are designed for service temperature up to 1700 deg C.

Cement Industry

India ranks second in terms of the world's largest producer of cement. There is a huge potential for development in the infrastructure and construction sector in India. Being one of the most essential requirements of every project in this industry, quality cement will always have higher demands in the market.

Cement manufacturing is a complex process. It begins with mining, grinding raw materials which are then heated to a sintering temperature as high as more than a thousand degrees Celsius in a cement kiln.

Usage of Alumina bricks in the Cement Industry

The cement kiln, which is a thermally insulated chamber, a type of huge oven, requires to produce temperatures sufficient to complete the processes such as hardening, drying, or chemical changes. These kilns are required to be built in a way that they should retain the produced heat as much as possible. For this purpose, refractory alumina bricks are used.

Get the best Alumina bricks for Cement Industry on Calderys' Caldezone

AC 40 are medium alumina bricks with standard and customized dimensions. These have a basic application in the Preheating Zone. These bricks are manufactured in the high precision press and fired at extremely controlled and high precision kilns. They have optimum strength, medium temperature abrasion resistance and high thermal stability. Other applications of this product are in Non Ferrous-lead, Aluminium-as back and Hot face and other metallurgical industry, boilers and waste incinerators, foundry ladle back up lining, pizza oven and general purpose oven and baking furnace.

AC 30 are alumina bricks with standard and customized dimensions. These have a basic application in the upper cyclones-riser ducts. These bricks are produced with quality raw materials in the high-precision press and fired in extremely controlled and precision kilns. These are excellent back up lining materials for foundry ladle, tundish back up. They have optimum strength, medium temperature abrasion resistance and high thermal stability to be used in other areas such as non ferrous-lead, aluminium-as back and hot face and other metallurgical industries, boilers and waste incinerators, foundry ladle-back up lining and pizza oven.

Power-Waste-to-Energy (WtE)

WtE, Waste to Energy technologies that process non-renewable waste to produce sustainable energy while reducing the environmental & health damages can be classified into municipal solid waste, process waste, medical waste, & agricultural Waste. WtE technology is an energy recovery process that converts chemicals from waste residues into practical forms of energy like electricity, heat or steam. The thermal conversion techniques lead the market among all the WtE technologies.

Usage of Alumina bricks in the Power-Waste-to-Energy (WtE) industry

A steam power plant consists of a boiler, steam turbine, generator, and other auxiliaries require to generate steam at high pressure and high temperature. The steam turbine converts the heat energy of steam into mechanical energy and then the generator converts the mechanical energy into electric power. For this process to be completed smoothly the boiler has to be built to hold the high temperature, which is made possible with the help of alumina refractory bricks.

Get the best Alumina bricks for Power-Waste-to-Energy (WtE) Industry on Calderys' Caldezone

AC 60 are medium alumina bricks with standard and customized dimensions. These have a basic application in the Secondary Cooling Chambers. These medium density, low porosity bricks are manufactured in the high precision press and fired in extremely controlled and high precision tunnel kilns. These refractory bricks have high refractoriness, high strength, good abrasion resistance, and high thermal stability to be used in other areas such as non ferrous-lead, aluminium-as back and hot face and other metallurgical industries, cement, boilers and waste incinerators, foundry ladle-back up lining and pizza oven and general purpose oven and baking furnace.

Steel Making

Steelmaking consists primarily of a two-step process. In the primary steelmaking step, liquid iron is converted into steel by the basic oxygen furnace (BOF) process, or by melting scrap steel or direct reduced iron (DRI) in an electric arc furnace. Secondary steelmaking is a refining process in which impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium, and vanadium are added to produce the steel required.

Usage of Alumina bricks in the Steel Making industry

Steel is primarily produced using one of two methods, a blast furnace or an electric arc furnace. The modern steelmaking process also requires good quality furnaces to keep the high temperatures. Alumina bricks are an excellent refractory solution to built quality furnaces.

Get the best Alumina bricks for the Steel Making industry on Calderys' Caldezone

AC 70 are high alumina bricks with standard and customized dimensions. It is being used as a backup layer in the furnace refractory lining. These bricks are manufactured in the high precision press and fired in extremely controlled and high precision tunnel kilns. These refractory bricks have high refractoriness, high strength, good abrasion resistance, high thermal stability and optimum load bearing capacity to be used in other areas such as non ferrous-lead, aluminium-as back and hot face and other metallurgical industries, cement, boilers and waste incinerators, foundry ladle-back up lining and pizza oven and general purpose oven and baking furnace.

Iron Making

Iron is one of the key industries in the Indian economy. We have been making iron for centuries. It has been the fuel to the industrial revolution of modern industrialized economies. Be it construction, vehicles, engines or machines, iron is the basic requirement in everything.

Usage of Alumina bricks in the Iron Making industry

In the blast furnace where the iron ore is mixed with coke and heated to form an iron-rich clinker, a very high level of temperature is required in the complete process. This blast furnace is required to be built with the best refractory solutions. Aluminium bricks are one of the most important parts of these blast furnaces.

Get the best Alumina bricks for the Iron Making industry on Calderys' Caldezone

AC 70 M is a mullite-based brick that is being manufactured in the high precision press and fired in extremely controlled and high precision tunnel kilns. These refractory bricks are being used as backup layer of blast furnace due to its high refractoriness, high MOR, high strength, good abrasion resistance, high thermal stability and optimum load-bearing capacity

Reheating Furnace

Reheating furnaces are used in many industries where their classification is based on the method of heating, method of charging the reheating furnace, the movement of steel stock in the reheating furnace, the heat recovery methods.

Usage of Alumina bricks in the Reheating Furnace industry

The reheating furnaces that are used in hot rolling mills is a continuous process where feedstock is charged at the furnace entrance, heated in the furnace, and discharged at the furnace exit to get the required product. For the high level of combustion optimization, high refractoriness is required in the furnace. The alumina bricks provide the best refractory solution for blast furnaces.

Get the best Alumina bricks for the Reheating Furnace industry on Calderys' Caldezone

AC 60 are medium alumina bricks with standard and customized dimensions. These medium density, low porosity bricks are manufactured in the high precision press and fired in extremely controlled and high precision tunnel kilns. These refractory bricks have high refractoriness, high strength, good abrasion resistance, and high thermal stability to be used in other areas such as non ferrous-lead, aluminium-as back and hot face and other metallurgical industries, cement, boilers and waste incinerators, foundry ladle-back up lining and pizza oven and general purpose oven and baking furnace.

Aluminium

Aluminium is the second most used metal in the world after steel. It is also the fastest growing metal in terms of usage. India is the fourth largest producer of aluminium in the world contributing a significant quantum of aluminium in the global market.

Usage of Alumina bricks in the Aluminium industry

To extract the alumina, or aluminium oxide from the bauxite through refining, the alumina mixture requires to be calcined first in a kiln or furnace. Alumina bricks work as the best refractory product for these furnaces.

Get the best Alumina bricks for the Aluminium industry on Calderys' Caldezone

AC 70 are high alumina bricks that are commonly used in the furnace which can be supplied in standard and customized dimensions. These refractory bricks have high refractoriness, high strength, good abrasion resistance, high thermal stability and optimum load-bearing capacity which helps in better life of the refractory for alumina furnace.

AC 85 P is a phosphate bonded brick that is commonly used in Aluminum Melting and holding furnaces. Due to the non-wettability nature and high MOR value, these bricks are most suitable for the melting holding furnace hearth and bottom lower wall lining.

Calderys is a wholly-owned subsidiary of Imerys, the world leader in mineral-based specialities for industry. For any type of Refractory solutions requirement, you can visit their online product library

on http://www.caldezone.com/

or contact the company's corporate office at:

Calderys India Refractories Ltd

6th Floor, Fidvi Tower, Opp. Saraf

Chambers, Mount Road, Sadar, Nagpur -440001, Maharashtra, India

Telephone 0712 - 2811600 / 7391052888

Email ID: [email protected]

1 note

·

View note

Text

Best Quality Centrifugal Blower Manufacturers

Centrifugal Blower Manufacturers

Centrifugal blowers play a pivotal role across diverse industries, facilitating the efficient movement of air and gases. These robust machines are engineered to produce substantial air volumes at varying pressures, making them indispensable for a wide array of applications, including ventilation, cooling, combustion, and material handling. Among the multitude of manufacturers in this field, AMCS Cooling Systems distinguishes itself as a premier provider of centrifugal blowers tailored to industrial needs.

Centrifugal blowers serve as a linchpin in industrial environments where precise air circulation and regulation are imperative. They find application in diverse sectors such as HVAC (Heating, Ventilation, and Air Conditioning), chemical production, petrochemical facilities, food processing, and wastewater treatment. In HVAC systems, centrifugal blowers play a vital role in maintaining optimal indoor air quality and temperature, ensuring comfort for occupants.

Airmake Cooling

AMCS Cooling Systems, renowned centrifugal blower manufacturers, have garnered acclaim owing to their unwavering commitment to quality and innovation. They offer a comprehensive range of centrifugal blowers meticulously designed to meet specific industry demands. These products are celebrated for their robustness, energy efficiency, and cost-effective maintenance, making them a prudent choice for enterprises.

At the core of AMCS Cooling Systems' centrifugal blowers technology to guarantee consistent and dependable performance. Their emphasis on eco-friendliness aligns seamlessly with the growing sustainability trend in industrial operations. By selecting AMCS Cooling Systems as your centrifugal blower manufacturer, you not only gain access to top-tier products but also contribute to a greener and more energy-efficient future for your industry. Centrifugal blowers assume an indispensable role in diverse industrial scenarios, and AMCS Cooling Systems has emerged as a trusted beacon in this domain. Their unwavering commitment to quality, efficiency, and environmental stewardship positions them as the quintessential choice for enterprises seeking reliable solutions for air and gas handling.

If you want to know more please visit :-https://www.airmakecooling.com/centrifugal-blower.html

Address - PLOT NO. 49 UDYOG KENDRA - II, ECHOTECH-III Noida - 201306 (U.P.), (India)

Twitter - https://twitter.com/make_air

0 notes

Text

Fabric Bag Dust Collector | Fabric Bag Dust Collector Manufacturer in India | Fabric Bag Dust Collector Supplier in India | Fabric Bag Dust Collector Price in India | Fabric Bag Dust Collector in India

Fabric Bag Dust Collectors, normally referred to as Bag Filters, Baghouse, are maximum usually used dirt collectors for massive dirt process applications. Bag filters use long cylindrical tubes of woven fabric material or non-woven felt fabric material bags of 05 - 12 inches diameter (130 - 300 mm), and 6.5 - 10 feet (2M - 3M) or more in length, open from one cease.

Some of the clear-out bag tubes are housed inside the dirt collector frame forming a matrix of rows, in reference to the total filter-out fabric area needed for the designed ability of a dirt collector. The high extent centrifugal blowers of designed pressure create required suction for Dust Collector from the source.

Working of Fabric Bag Dust Collector

Dust-laden air is drawn into the dust collector through the inlet due to suction created via exhaust fan and passes through material luggage. Heavier dirt particles fall into the hopper because of a loss of momentum. Finer dust gets deposited on the inner surface of material baggage and easy air passes across the outer surface of filter-out bags after which exit into atmosphere through the outlet. Baggage is wiped clean through the motorized shaking arrangement. When a motor is switched OFF, the shaking cycle receives activated automatically and baggage is shaken for the preset timer. Dust launched from filter out luggage slides downward into the hopper for in addition collection into the dustbin.

Features of Fabric Bag Dust Collector

· Low maintenance and replacement of fabric, bags is easy and quick

· Assures longer life of bags

· Fabric bags are normally of cotton woven satin cloth. However, other materials can be supplied to suit individual application

Motorized Shaking Fabric Bag Dust Collector

Motorized Shaking fabric Bag dust Collector or a shaker dust collector also referred to as shaker fabric filter out refers to a dirt collector using a shaker cleaning device to remove the collected dust particles from the floor of the filter out media via mechanically shaking the clear-out luggage with the help of a motor. This may be accomplished by way of two approaches either manually or through the use of a motor driving an eccentric which in turn has been linked to the filter out bags.

Applications of Motorized Shaking Fabric Bag Dust Collector

· Woodworking Dust Collection

· Sand Blasting Machines

· Shot Blasting Machines

· Metal Grinding

· Pharmaceutical

· Paper Core Grinding

· Grinding or Buffing Applications

Reverse Pulse Jet Fabric Bag Dust Collector

In reverse pulse jet fabric bag dirt collector, individual luggage is supported with the aid of a steel cage within the cloth bag that is mounted onto a mobile plate at the pinnacle of the bag clear out. Dirty gas enters from the bottom of the bag filter and flows from outside to in the bags. The metal cage prevents fall apart of the bag filter out.

Application of Reverse Pulse Jet Fabric Bag Dust Collector

· Woodworking Dust

· Sand Blasting

· Shot and grit blasting

· Ceramics

· Pharmaceuticals

· Chemicals

· Activated Carbon

· Food Processing

· Rubber

Reverse Pulse Jet Pleated Filter Dust Collector

Reverse Pulse Jet Pleated filter a dust Collector is a unit of dirt collector that is maximum typically utilized in industries or factories. An excessive stress blasting of air is done to put off dust from the Pleated filter bag. The blasted air enters from the top of the Pleated filter bag tube, quickly stopping the go with the flow of grimy air. The unexpected surprise of air causes a wave of expansion to journey down the pleated clear-out bag.

Applications of Reverse Pulse Jet Pleated Filter Dust Collector

· Sand Blasting, shot, or grit blasting machines

· Metalizing spray Booth

· Powder Coating Booth

· Pharmaceuticals

· Cement

· Powder & Coating

· Metals & Minerals

· Chemicals

· Steel & Power

Fabric Bag Dust Collector Manufacturer in India

We are the leading Fabric Bag Dust Collector manufacturer in India. Blast Room is the best supplier and exporter of Pleated Filter Bag Dust Collector, sand blasting machine, grit blasting machine, shot blasting machine, Dust Collector, abrasive media, thermal spray gun, sand blasting nozzles, sand blasting cabinets, etc.

Shot Blasting Machine | Sand Blasting Machine | Portable Sand Blasting Machine | Sand Blasting Cabinet

#Fabric Bag Dust Collector Supplier in India#Fabric Bag Dust Collector Manufacturer#Fabric Bag Dust Collector Price in India

0 notes