#brickforce

Text

Cavity Walls In New Buildings In South Africa

SANS 10400-XA (Energy Usage in Buildings)

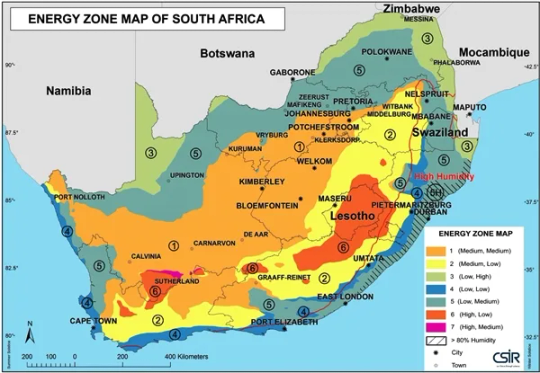

The 2021 SANS 10400-XA revision requires the construction of cavity walls in place of 230 mm solid brick external walls. This energy-saving change is applicable in all the energy zones in South Africa except in zones 3, 5 and 5H.

How wise this course of action is considering the lack of skills in the building trade will have to be seen!

What is a cavity wall?

A cavity wall consists of two skins separated by a hollow space (cavity). The advantage is that a cavity wall gives better thermal insulation than a solid wall. The space between the two leaves of cavity walls reduces heat transmission into the building from outside.

The following are the advantages of cavity walls when compared to solid walls.

- This type of wall gives better thermal insulation than solid walls.

- The hollow space between leaves prevents moisture penetration through the wall from the outside. This prevents dampness internally.

- They also act as good sound insulators.

- These walls also prevent efflorescence from occurring.

Construction of cavity walls

The construction of these walls is technically more difficult than for solid 230 mm walls.

- The cavity between the two masonry leaves should be a minimum of 50 mm. The gap must be consistent from the bottom of the wall to the top.

- Below the DPC level, the bricklayer must fill up the wall cavity with concrete or mortar before installing the DPC.

- The bricklayer then installs the DPC at slab level to step down from the slab-level interior wall across the cavity to the outer wall and weep holes. Its purpose is to drain away any water in the cavity towards the weep holes to discharge it outside.

- Weep holes must be provided in the external leaf above the Damp Proof Course (DPC) at every 4th brick horizontally.

- The bricklayer must build in wall ties at every 5th course of brickwork vertically and space them horizontally at every second brick to tie the two leaves of brickwork together.

- Mortar dropping down in the cavity can stop water from draining away. The bricklayer should leave some bricks out temporarily at the DPC level to clear mortar droppings at the end of each day’s work.

- The normal method of preventing mortar droppings from falling to the base of the cavity is to use a cloth-rapped batten (38 x 38 mm) or specially sized 50 x 38 mm planed to 45 mm. The bricklayer places the batten on the wall ties while building the wall. The bricklayer raises the batten, using wire tied to its ends and then positions it on the next row of ties.

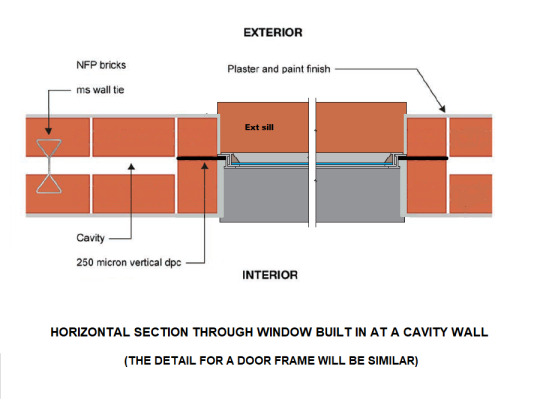

- Furthermore, the bricklayer should install a vertical DPC on the sides of doors and windows when closing off the cavity wall. This is to prevent water from driving to the inner face.

- In addition, the bricklayer should install a layer of DPC and weep holes in the cavity above exposed doors and windows similar to the DPC at floor level. This is to prevent moisture from penetrating the inner leaf.

- At the roof line, the bricklayer should fill or brick up the cavity for two or three courses below the roofline to stiffen and distribute the load over both leaves. He should also build in roof ties at this level to tie down the roof trusses or beams.

- No wide brick force can be used to span both leaves and cavities of brickwork. A 90 mm width of brickforce will need to be used on every 5th layer of brickwork on both leaves up to window or door height and every course above that until the cavity is closed at roof height.

My Concerns with the new requirements

The Western Cape Province has already been following this practice for many years. Cavity walls are also better for damp prevention than solid walls. The introduction of cavity walls nationally is to satisfy regulatory requirements for building energy efficiency.

However, such sweeping changes to the construction of brick buildings in other areas of the country may have serious consequences because of skills shortages. They may lead or may have led to substandard work because of the lack of sufficient skills and training of bricklayers and their supervisors!

The newer generation of bricklayers and builders never adhered fully to the requirements of the building regulations before with the construction of solid 230 mm walls! Most of them have had no experience with building cavity walls either!

I have listed some of the issues I have seen on building sites below:

- In my experience, the bricklayers in the building trade never used collar jointing of the solid brick walls leading to weakened wall structures.

- The bricklayers seldom place the DPC on a half layer of mortar on the brickwork. Instead, they place the DPC directly on the brickwork. This often led to moisture intrusion in the structure at the DPC level.

- Generally, no bricklayer has installed DPC on the sides or above the door and window openings to prevent moisture intrusion through the wall at the windows and doors inland from the coastal areas.

- Few bricklayers build in the correct number of layers of brickforce reinforcing above windows and doors.

- Often, the bricklayers tooth the brickwork of the internal walls to external walls and corners instead of stepping back the brickwork as required.

- The mixing of large amounts of mortar resulting in the retempering (adding additional water) of mortar is a common practice. This causes weakened mortar and brickwork.

Most of the issues result from a lack of knowledge and training. This includes not only the bricklayers but also the supervisors!

So how do we get the bricklayers to build the more technical cavity walls correctly?

- One way is to train the supervisors who in turn can train the bricklayers!

- Various brick associations and training schools offer bricklaying training. The various training associations and schools may be open to do on-site training.

- Both the supervisors and the bricklayers can learn from videos that show how to build cavity walls. They all have cellphones on which they can view the videos.

- Articles by the Clay Brick Association can update supervisors and bricklayers with the technicalities of building a cavity wall.

Let us hope the above happens so that new homeowners will have properly constructed homes!

Conclusion

With the correct training, newly built cavity walls will provide the thermal benefit required by the new revision of SANS 10400-XA. In addition, the construction of cavity walls will minimise moisture intrusion into new buildings if constructed properly. They also provide sound insulation benefits.

Read the full article

#cavitywall#Homebuyersinspection#homeinspection#Homeinspector#houseinspections#maintenanceinspection#propertyInspection

0 notes

Photo

Ready for movie night. #theincredibles #theincredibles2 #legostoreslovenija #LEGO #legostore #disney #pixar #legofamily #instalego #welovelego #brickstagram #legogram #legolife #legomania #legophoto #legoworld #legopicture #legostagram #legophotography #brickforce #brickverse #brickleague #bricknation #brickcentral #brickinsider #bricknations #bricknetwork #bricknerd #collectable #minifigures (at Ljubljana, Slovenia) https://www.instagram.com/p/Bp_okSTnFBB/?utm_source=ig_tumblr_share&igshid=xyckqk02mb0t

#theincredibles#theincredibles2#legostoreslovenija#lego#legostore#disney#pixar#legofamily#instalego#welovelego#brickstagram#legogram#legolife#legomania#legophoto#legoworld#legopicture#legostagram#legophotography#brickforce#brickverse#brickleague#bricknation#brickcentral#brickinsider#bricknations#bricknetwork#bricknerd#collectable#minifigures

1 note

·

View note

Video

youtube

(通过 https://www.youtube.com/watch?v=EK4Sn7lYOks)

Full automatic brick force mesh machine made by jiaoyang machine company 2017

It's full automatic and welding speed is about 80 times/min.

Daily production: 900 coils ( 8 hours)

What's more, the brickforce mesh coils will be automatic unloading within 2 seconds.

0 notes

Text

Brick-Force best Game!

1 note

·

View note

Quote

I'd rather drag my testicles through 5 miles of broken glass and sandpaper than to play this game for another 15 minutes

02 | Steem Gam Revewer

1 note

·

View note

Text

New Season Confirmed for 2014!

Yep, you heard right, Brick Soldiers!

A new Season has been confirmed for the year 2014.That's all that we can reveal for now, but stay tuned. More info will hit the airwaves next year.

5 notes

·

View notes

Photo

Lego history. The fire department is always ready to fight against the fire and of course to rescue cats! #LEGO #legohistory #legofiretruck #legofiredepartment #6389 ##legofamily #instalego #welovelego #brickstagram #legogram #legolife #legomania #legophoto #legoworld #legopicture #legostagram #legophotography #brickforce #brickverse #brickleague #bricknation #brickcentral #brickinsider #bricknations #bricknetwork #bricknerd #collectable (at Ljubljana, Slovenia) https://www.instagram.com/p/BpoX81hna4B/?utm_source=ig_tumblr_share&igshid=1dedrprl0hpjm

#lego#legohistory#legofiretruck#legofiredepartment#6389#legofamily#instalego#welovelego#brickstagram#legogram#legolife#legomania#legophoto#legoworld#legopicture#legostagram#legophotography#brickforce#brickverse#brickleague#bricknation#brickcentral#brickinsider#bricknations#bricknetwork#bricknerd#collectable

1 note

·

View note

Photo

Something special made for a special friend. <3

Epoxy clay on a wooden base.

I really love the Brickforce posters, specially the Sniper's. The design is so clean and refreshing, not to mention that a game, that could be a lovechild of Minecraft & TF2 is totally my style!

Go to my blog for WIP Pictures and details:

http://chocodecadence.livejournal.com/76817.html

#Epoxy Sculpt#Clay#Brickforce#It's like#Minecraft#but with guns#and I love it!#figurine#handmade#F2P#Infernum#Sniper

11 notes

·

View notes

Photo

New update! =)

0 notes

Video

youtube

Here it is, the official release trailer for the global launch of Season 3 - Bricksaga. We hope you have fun, folks!

3 notes

·

View notes

Photo

My new map, but is not finished.

1 note

·

View note

Video

youtube

Have you seen the Brick-by-Brick Special for Bricksaga? Here's a sneak peek of some of the stuff we have planned for Brick-Force's next major season.

1 note

·

View note

Photo

Reinterpreting a surface... #LEGO #engraving #ninjago #legostoreslovenija #legofamily #instalego #welovelego #brickstagram #legogram #legolife #legomania #legophoto #legoworld #legopicture #legostagram #legophotography #brickforce #brickverse #brickleague #bricknation #brickcentral #brickinsider #bricknations #bricknetwork #bricknerd #collectable #minifigures (at Ljubljana, Slovenia)

#legostagram#brickforce#instalego#brickleague#engraving#legomania#ninjago#legolife#welovelego#brickstagram#legofamily#brickcentral#brickinsider#brickverse#bricknetwork#minifigures#bricknation#legostoreslovenija#bricknerd#legogram#legophoto#legoworld#lego#bricknations#collectable#legopicture#legophotography

1 note

·

View note