#bulkhead repair services

Note

Do you have any breakdown head-canons to share? I'd love to hear them

Of course I do:3 he's one of my silly fellas. I have headcanons for EVERYONE. Probably. Maybe. (I'm going with tfp Breakdown<3)

He's like the most normal guy on the Nemesis. However, he's so used to Knock Out's brand on insane that he is unfazed by the rest of the nuts jobs there for the most part. He knows how to stay in his lane and keep his head low.

I like the idea that he's into making stuff. I read a fic once where he made little sculptures and that's kind of stuck with me. He's probably not really good at it but he likes messin around with it.

He's very handy. Soundwave runs a tight-ship on the Nemesis and isn't keen on people Starscream messing around with things but Breakdown's proven to be useful and has been granted a limited permission to take care of any repairs.

That being said, I like to think Breakdown is Soundwave's unofficial favorite co-worker. He trusts him to do his job, keep it professional, not to try and start a coup d'etat. The ideal co-worker. Soundwave was actually probably a little saddened by Breakdown's death. One less functional co-worker.

He's not a trained medic nor nurse. Breakdown knows basic first aid which is better than nearly everyone else on the Nemesis but it's only because he's watched Knock Out repair him enough. Knock Out still prefers to do Breakdown's repairs himself but sometimes Breakdown feels guilty about coming back with injuries all the time and tries to take care of them himself. Knock Out can usually tell if he has attempted self-repair.

He's got a softness to him, especially with the vehicons and Knock Out. I like to think in his free time, if Knock Out is busy, he hangs with the vehicons. They trade stories, play stupid games, just kind of chill? He's a great boss to them.

He doesn't care all that much about racing, but he likes to watch Knock Out race and they have an open comm link so they can trade shitty jokes and bad puns back and forth. Breakdown can do this for hours if he's got a comfy spot to rest and ideally some energon to sip on.

Breakdown loves a good fight, even just sparring but can't really get that from Knock Out or the vehicons and certainly not Starscream. He always jumps at the opportunity to fight Bulkhead and doesn't want to closely examine what the hell that means. No introspection allowed there.

Breakdown is pretty selfless? Something something love language acts of service something something. He likes to treat Knock Out, is more than happy to pamper him but not so much the inverse. He feels...uncomfortable when he is the center of that type of attention. It's not...bad? but its...weird. He can acknowledge that it feels good to have someone take care of him but he can't get over the mental hurdle that he should be the one to do that for others, he doesn't need pampering, he doesn't deserve it. Again, not introspection to be found here.

He's not much into music, but he has a guilt pleasure of listening to audio books. Knock Out managed to snag him a bunch of earth novels and...he rather likes them. He'll listen to them on shift. He primarily likes adventure/action books but...the occasional romcom..is...not so..bad...and if he pictures himself and uh someone else there. Well, no one needs to know about that. Especially Knock Out.

31 notes

·

View notes

Note

I think I can imagine what the platonic love languages of each bot from team prime would be; (without watching the show /hj)

Optimus: his love language would probably be Acts of Service, like he would sometimes make his team mates their morning energon just how they like it when he's the first one up. or maybe words of affirmation, just expressing his feelings through words.

Ratchet: his would definitely be Words of Affirmation, I don't really think that Acts of Service/Gifting and physical touch and quality time would suit him best tbh. If he thinks one of his teammates did a good job, he'd tell them that, straight forward.

Bumblebee: with your head canon bout him being crafty from being a repair bot, I'd say his would be Gift Giving. he creates things he'd think his teammates would enjoy; like giving bulkhead paints and custom paint brushes for him to use. he's observant and therefore knows what aspects to think of and include in his gifts

Bulkhead: my best guess for him is that his would be Quality Time, this stems from the fact he's very close with his family back on cybertron, I'm not sure if this is canon or not but let's just say it's a head canon if it's not. so, he'd see what he can do to spend time individually or as a group with the others. he makes sures that they do something that bot will like or something that fits them all.

Prowl: with how stand offish he seems to be, I'd think that he would use words of affirmation (like ratchet) to express his gratitude towards his teammates. and if he got close to one, then it would switch to physical touch. he would give a small touch on the arm or even a hug if the situation calls for it. hell, maybe even a handshake idk much about physical touch in general lmao. but he would show his affection through carefully chosen words.

awwh that is cute.

Yeah Optimus would defo be doing that as his love language; You want something but you don't have money? Bam, now you have like 3 of that thing. He has quite a lot of savings from the time he was still a high-ranking Prime and not a repair bot. Although i think Bee would be the first one to wake up and make the oil for everyone, Bossbot is free to buy any treats and stuff for everyone tho.

Ratchet is defo more straight forward; if you did something stupid or need affirmation/comfort, he'll straight up tell you. No need to waste time dancing around the topic. He's surprisingly good at comfort, even if he's grumpy all the time, if the situation needs it, he will show his soft-caring side.

Bumblebee is defo one for physical contact, he'll give out hugs like candy on halloween. He's not very good at comfort via words so it's the least he can do. He's also keen on giving gifts, be it servo-made or bought. He's not as good as Bulkhead at painting but he has some talent- on their 1st christmas he painted a picture of Team Prime+Sari with a word "Family". That painting is still hanging of the wall in the main room.

Bulkhead is all about spending time with the ones he cares about. While he's shy with strangers, he's pretty open with stuff with his friends. That being said, he will occasionally throw a compliment or two. If you've earned it, you might even get a cool painting.

Prowl is the secluded type, not really good at socializing. What he is good at tho is being an unpaid therapist listening to his friend's troubles and helping them emotionally/mentally. He'll tell you how he sees you in all honesty and comfort you with words. If you have a problem or need to vent, Prowl is the bot to go to. Once he gets comfortable enough with someone, he will offer a hug or a shoulder to lean on.

In addition: Sari would be about gift giving and physical affection, similar to Bee. She'll coax her dad or any other empoyee taking care of her atm and get stuff for her beloved robots. She'll hang out and give hugs to anyone feeling down.

#tfa#maccadam#ask box#tfa bumblebee#tfa prowl#tfa optimus prime#tfa bulkhead#tfa ratchet#tfa headcanons

32 notes

·

View notes

Text

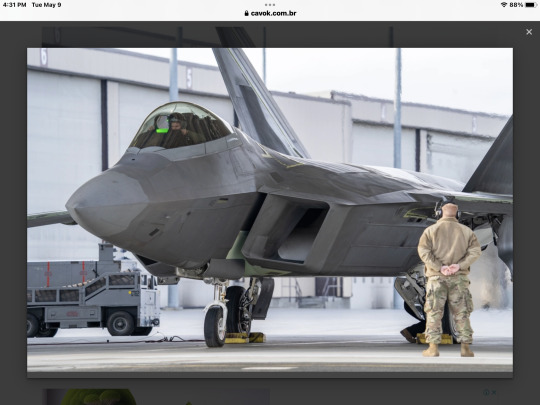

F-22 Raptor returns to the skies, 5 years after serious damage caused by unsuccessful takeoff

Fernando Valduga By Fernando Valduga 05/09/2021 - 08:00 in Military

A U.S. Air Force F-22 Raptor returned to flight on May 4, five years after suffering major damage due to an unsuccessful takeoff on April 13, 2018.

With only 186 Raptors in the entire U.S. Air Force inventory, placing only one of the formidable fighters back into operations represents a significant achievement for the 3ª Wing at Joint Elmendorf-Richardson Base, Alaska, where the F-22 is assigned.

“There are few F-22s in the inventory,” said Chief Master Sgt. Adam Willeford, the senior leader of the 3º Aircraft Maintenance Squadron, in a press release. "Each aircraft in the fleet is highly valuable for the success of the mission, so returning it to operational status is a great victory for the team."

An Accident Investigation Board blamed the 2018 accident on incorrect takeoff and landing data, an inadequate flight summary and the pilot prematurely retracting the landing gear. The pilot was taking off from Naval Air Station Fallon, Nevada, for a TOPGUN graduation exercise when the accident occurred. The pilot ran with the aircraft - lifting his nose - at 120 knots and, when the aircraft indicated that its wheels were coming off the ground, the pilot retracted the landing gear. Immediately after the collection of the landing gear, the aircraft "sit down" on the runway with the doors completely closed.

The Raptor slid about 2,000 meters on the track before stopping, at which time the unharmed pilot left the cabin. The investigation board later found that the pilot should have reached a higher speed before the rotation, but that the aviators of the F-22 community tended to trust too much that the high thrust of the jet could “overcome deviations from [takeoff and landing data]. This perception led to a decrease in the emphasis on takeoff data".

The board did not specify the exact cost of the accident, but the recovery process was extensive, with the fighter having to be partially rebuilt to return to service. The maintainers started dismantling the jet and dispatching it back to Alaska aboard a C-5 Galaxy transport jet - only the disassembly took a month.

"We took away everything that was damaged and everything that did not fit dimensionally," said Sergeant Ethan Rentz, team leader of the 3ª Aircraft Maintenance Unit (AMU), in a 2021 press release. “We removed the wings and vertical stabilizers and the entire belly of the F-22 because these panels were damaged and burned. We couldn't let these panels shaking or breaking during transportation."

When the aircraft returned to Alaska, the U.S. Air Force first had to determine whether it was worth restoring it. The simulations suggested yes, said Tech. Sergeant Kevin Fitch, another team leader of the 3ª AMU. In January 2020, the Raptor was mounted on stands in a hangar and stripped of its wire harnesses, supports and bulkheads.

“It went to the bones of the fuselage at that point,” Fitch said in a statement.

Contractors, engineers and structural specialists took 16 months to replace the entire bottom of the aircraft, the fuselage stations and more than 40 wiring harnesses. It was not until June 2021 that the active aviators finally got involved in the reconstruction. Fitch maintained inventory lists and spreadsheets to track the large number of spare parts needed for the damaged jet.

“Sgt. Fitch took it out of the blue,” Rentz said in the statement. "He is operating at the master or senior sergeant level because he is not only dealing with team leader tasks, he is coordinating several different workshops and agencies. He is essentially commanding a squadron of one-man aircraft."

The collection of parts was the biggest challenge for the repair of the Raptor, since the jet and its spare parts are no longer manufactured. The recovery process could have taken even longer if another F-22 had not fallen at Eglin Air Base in Florida in 2022, when its landing gear broke. The maintainers of the 90ª Aircraft Maintenance Unit based in JBER traveled to Eglin to cannibalize parts of the downed Raptor, including the leading edge, two flaps and a seat.

Although cannibalization prolongs the recovery time of Eglin's F-22, it helped JBER's Raptor return to service earlier - ensuring that at least one jet is flying.

On May 4, Lieutenant Colonel Philip Johnson, a functional verification flight pilot assigned to the 514º Flight Test Squadron at Hill Air Base, Utah, performed an F-22 test flight.

“They did a great job on the plane,” he said in the press release. "Some minor maintenance notes were found during the surtida, but they will be handled by maintenance. It's good to start flying operationally again."

The return of F-22 to operational status is one of the many small miracles that military aircraft maintainers perform regularly. USAF maintainers restored an A-10 “Warthog” four years after landing in Michigan, while Navy sailors once brought back an EA-18G Growler that had been considered unrecoverable five years after suffering a collision in the air.

“Five months ago, he had no struts, no wings, no flight controls, no hydraulic system, no stabilizers,” Fitch said in December 2021. “Seeing progress and doing something out of the ordinary was really gratifying. ... It will be very satisfying when you fly.

Tags: Military AviationF-22 RaptorUSAF - United States Air Force / U.S. Air Force

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Daytona Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work around the world of aviation.

Related news

MILITARY

Angolan L-39 jets will receive U.S. engines

05/09/2023 - 16:30

SAAB

IMAGES: F-39 Gripen production line is inaugurated in Brazil

09/05/2023 - 15:26

MILITARY

Important milestone for Boeing's new T-7A training aircraft is now postponed to 2027

09/05/2023 - 14:00

DEMONSTRATION SQUADS

Snowbirds jets will receive a major avianics update

09/05/2023 - 11:00

A ROCAF F-16 armed with AGM-84 Harpoon anti-ship missiles, as well as AMRAAMs and Sidewinders. (Photo: CHIANG YING-YING/AP)

ARMAMENTOS

US offers "grace" missiles valued at $500 million to Taiwan

05/09/2023 - 06:00

MILITARY

U.S. Navy orders more CMV-22B Osprey aircraft

05/08/2023 - 16:00

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Digital Tchê Web Creation

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Digital Tchê Web Creation

3 notes

·

View notes

Text

Best Pier Construction Services

We endeavour to prefabricate and modularise on our tasks wherever attainable. Our latest work has included prefabricated modules, girders, and trusses, all absolutely assembled in our own facility in Teesside. We measure our performance in all areas of service against security, high quality, programme delivery, applied valued engineering end result, and commercial. A professional evaluation is among the most important issues you can do to stop damage that water can cause. If harm has already occurred, it can be professionally repaired as well. Vacuum excavation provides a safer, decrease risk excavation alternative to more traditional excavation strategies - Ship Assist.

Our marine construction create your dream dock or pier today. Get a completely custom structure made for your property with every specification built to meet your needs. No job is too big or too small for the team. We can design, build, and install any size or height pier, large piers, marina piers, and more of any size. Bring in your own design or let us create something from your vision. We can also renovate existing docks, ramps, or piers to better suit your needs - Santa Rosa Island Barge Service.

Our licensed and insured team is ready to build the perfect structure for you. Expect competitive prices and on-time turnaround with the highest quality on the finished project. Our docks are constructed for strength and stability from the start. We offer construction and repair of marine piers as well as associated structures (bulkheads, dolphins and fendering. Additionally, we have extensive experience with loading/unloading mechanical, piping and structural systems employed with marine construction and services.

We focuses on the marine construction market along the with an emphasis on serving both public and private clients. Utilizing a highly competitive price structure, we complete projects with an emphasis on the highest quality of work, along with safety being our number one priority. For more information, please visit our site https://www.Pacificmaritimegroup.com/

0 notes

Text

Don't Get Stuck in a Sticky Situation: Why Pro Mudding and Taping from Rapid Repair Services is the Perfect Finish for Your Edmonton Drywall

The drywall is hung, the bones of your Edmonton renovation are taking shape. But before you can paint and decorate, there's a crucial step: mudding and taping. This seemingly simple process can be a messy and time-consuming endeavor. Here's why calling in the pros at Rapid Repair Services is the perfect solution:

A Flawless Finish: From Seams to Smoothness

Mudding and taping are all about achieving a seamless, invisible finish. Rapid Repair Services' skilled technicians have the experience and technique to ensure those drywall seams completely disappear. They'll expertly apply and smooth the joint compound, leaving a perfectly flat and even surface, ready for painting.

Avoiding the DIY Disaster Zone: Save Time, Money, and Sanity

Uneven mud application, visible tape lines, and a project that takes longer than anticipated – these are all common pitfalls of DIY mudding and taping. Rapid Repair Services gets the job done right the first time, minimizing disruption to your daily life and saving you the time, money, and frustration of potential mishaps.

The Expertise to Tackle Any Challenge

Not all drywall joints are created equal. Corners, inside angles, and bulkheads require specialized techniques. The professionals at Rapid Repair Services have the knowledge and tools to handle any drywall joint, ensuring a flawless finish throughout your entire project.

A Keen Eye for Perfection: Preventing Future Problems

Improper mudding and taping can lead to cracking, peeling paint, and even visible tape lines down the road. Rapid Repair Services' trained professionals can identify potential issues and apply the right techniques to prevent these problems before they start, ensuring a long-lasting, beautiful finish.

Rapid Repair Services: Your Edmonton Mudding and Taping Specialists

Located right here in Edmonton, Rapid Repair Services offers exceptional service and top-notch craftsmanship for all your mudding and taping needs. Whether you have a small project or a whole-home renovation, they have the expertise to handle the job efficiently and effectively.

Invest in Quality and Beauty

Mudding and taping are the foundation for a professional-looking paint job. By hiring Rapid Repair Services, you're investing in a smooth, flawless finish that will enhance the overall aesthetics of your Edmonton home for years to come.

Contact Rapid Repair Services Today!

Don't let the mudding and taping stage of your Edmonton renovation project become a sticky situation. Contact Rapid Repair Services today for a free consultation and quote. They'll assess your project and ensure your drywall joints are flawlessly finished, allowing you to move forward with your dream space with confidence.

#drywall installation#drywall contractor#drywall repair#home repair#business#repair#commercial#handyman services

0 notes

Text

Ultrasonic Thickness Measurement Services for Ships - IRS Class Approved Service Supplier in Fujairah | AIMMS Group

Introduction:

AIMMS Group is a leading provider of Ultrasonic Thickness Measurement Services for Ships, offering reliable and accurate inspections for vessels in Fujairah. As an IRS Class approved service supplier, we pride ourselves on delivering exceptional quality and complying with the highest industry standards. Our team of skilled IRS Class UTG Technicians ensures precise measurements and assessments to maintain the structural integrity of ships. With AIMMS Group, you can trust in our expertise and commitment to providing top-notch ultrasonic thickness measurement services in Fujairah.

Ultrasonic Thickness Measurement Services for Ships:

At AIMMS Group, we specialize in Ultrasonic Thickness Gauging (UTG) for ships, catering to various vessel types and sizes. Our comprehensive range of services includes:

Hull Thickness Assessment: Our skilled IRS Class UTG Technicians utilize advanced ultrasonic technology to measure the thickness of a ship's hull, identifying any potential areas of concern such as corrosion, erosion, or material degradation. This assessment is crucial for maintaining the structural integrity of the vessel.

Tank and Pipe Thickness Evaluation: We conduct thorough UTG inspections of tanks and pipes onboard ships to determine their thickness levels accurately. This evaluation helps in identifying potential leaks, weak spots, or material degradation, ensuring the safety and efficiency of the vessel's systems.

Structural Integrity Analysis: Our team assesses the overall structural integrity of ships using ultrasonic thickness measurements. By analyzing critical areas such as bulkheads, decks, and superstructures, we identify any signs of deterioration, enabling timely maintenance and repairs.

IRS Class Approved Service Supplier in Fujairah:

As an IRS Class approved service supplier, AIMMS Group adheres to the stringent guidelines set by the Indian Register of Shipping (IRS). This recognition demonstrates our commitment to delivering services of the highest quality and complying with international standards. Our expertise and experience enable us to provide reliable and accurate ultrasonic thickness measurement services for ships in Fujairah.

IRS Class UTG Technicians:

Our team of highly skilled IRS Class UTG Technicians possesses the necessary qualifications and certifications to perform ultrasonic thickness measurements with precision and efficiency. They undergo rigorous training and stay updated with the latest industry practices and technological advancements. With their expertise, we ensure accurate results and dependable assessments for our clients in Fujairah.

Conclusion:

When it comes to Ultrasonic Thickness Measurement Services for Ships in Fujairah, AIMMS Group is your trusted partner. As an IRS Class approved service supplier, we offer comprehensive inspections performed by our skilled IRS Class UTG Technicians. With our commitment to quality, accuracy, and adherence to international standards, we provide reliable assessments that help maintain the structural integrity of ships. Contact AIMMS Group today for top-notch ultrasonic thickness measurement services in Fujairah.

AIMMS GROUP

Address: 604, 3S Business Center,

Butina, Al Sharq Street,

Rolla, Sharjah, UAE

Call: +971 656 222 90

Mail: [email protected]

Website: https://aimmsgroup.com/

1 note

·

View note

Text

How to Choose the Right Avionics Repair Service

Avionics plays a central role in modern aircraft. It is vital that pilots and other organizations in the aeronautics sector keep these components in top working order. There are many companies that can repair avionics today. You can easily choose the best repair service by reviewing the key characteristics of each company.

One important thing to consider is the level of expertise that each company has in different areas of avionics repairs. Some companies are experts in repairing old aircraft. Some aircraft maintenance company specialize in the repair of newer electronic equipment.

A company that is specialized in the repair of your aircraft will be better equipped to serve you. Many companies specialize in the repair of electronics from specific manufacturers. They can complete repairs on your equipment faster and more efficiently with this specialized knowledge.

Another important aspect to consider is the company's experience. In the aeronautics field, experience can make all the difference. Experienced mechanics are able to provide more reliable services because they have the additional knowledge and experience that customers can rely on.

There are many ways to measure the level of experience of each repair company. One company might have a skilled mechanic with many years of experience, but the staff may not be as experienced. Before you give your business to a mechanic, make sure you check their experience.

People with extensive experience run the best companies in this field. This experience gives mechanics the ability to repair your equipment efficiently. This knowledge also gives mechanics the expertise to repair equipment made specifically by manufacturers.

The size of a repair company can be a useful indicator. Because of their small operations, some companies can only serve the needs of pilots. Some are capable of serving the needs of large airlines. Established airlines have the resources and knowledge to repair Honeywell avionics.

Major repairs to aircraft are more complicated and require a large amount of money. To avoid major accidents following major repairs, it is important to follow the FAA's exact guidelines. It can adversely impact the aircraft's structural strength and balance. This can affect the plane's overall weight and performance, lowering its airworthiness. Before the craft can be used, they recommend a variety of tests to ensure safety. Minor repairs are repairs that cannot be classified as major repairs. They involve fewer technical complications and costs, and don't affect the craft in any way.

They are not only classified according to their general functionality, but also the broad classification of repairs for aircraft. These types of repairs include fixing external injuries to an aircraft's body. These injuries can cause damage to the bulkheads, formers, and skin. They are often caused by lightning strikes, bird strikes, friction with ground equipment, and other factors.

There is also the Component Repair service, which repairs internal components of aircrafts. Each component is disassembled individually before being serviced or tested. The CMM (Component Manufacturer’s Maintenance Manual) is almost always followed when performing component repair services. Repairs to the aircraft's hydraulic, pneumatic or fuel systems are called system repairs. Engine repairs and avionics repair are two other options for aircraft repairs. There are many options for repair but one thing remains constant: the safety and airworthiness of the craft once the maintenance workers have completed the work.

0 notes

Text

Empire Nautical is the Best Place to Buy Boat Floating Docks in Florida

Empire Nautical Offers The Best Floating Docks For Sale In Miami, Fort Lauderdale Hollywood, Jupiter Florida. Get a Wide Range Of Floating Dock Products For All Marine Needs. Contact Empire Nautical And Get Custom-Built Solutions For Your Floating Dock Project.

Empire Nautical Is Your One-Stop Shop For Everything Related To Commercial Or Residential Wooden Floating Docks In Florida. We Carry All Of The Flotation, Hardware And Lumber You Need For Your Next Project. In Addition, We Offer Design And Construction Services. If You’re Building Yourself, We Can Provide Complete Design Support, Product Supply And Helpful Advice To Make Sure Your Next Float Is Built To Meet Your Specifications.

Empire Nautical Selling Jetski Dock And Waverunner Floating Dock In Florida With a Wide Range Of Floating Dock Products For All Marine Needs. Request a Quote Now!

Services Available:

Details & Washes

Floating Docks & Bulkheads

Bottom Painting & Scraping

Vinyl Wrap, Decals & Names

Electronics Sales & Set Up

Transport & Hauling

Cosmetic Repair & Restoration

Mechanical

Our Service Locations:

West Palm Beach,

Fort Myers,

Fort Lauderdale,

Oceanside,

Jacksonville,

Tallahassee

Whether You’re Looking To Upgrade Your Existing Floating Dock Or Design a New One, Call Empire Nautical At (561) 295-9166. Our Dock Specialists Can Help You Get Started On Your Design.

0 notes

Text

Near MeEvery plastering task we begin, we consummate with excellency and pride.

<iframe width="560" height="315" src="https://www.youtube.com/embed/SPBLlBA2Q_w" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

From the original quotation to the job site training and product covering, our skills volition transcend your expectations

and meet industry standards . Our experience and expertness in the industry volition secure that the plaster is done properly

and that our work standards will impress.

Plastering For Homes - Smooth Walls For A Smooth Finish

Until you have a fresh painted wall, you do not see imperfectnesses or uneveness .

<iframe width="560" height="315" src="https://www.youtube.com/embed/Vmd2wlvKegM" title="YouTube video player" frameborder="0" allow="accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture" allowfullscreen></iframe>

Choosing a plasterer who deeds

not but chop-chop but skillfully can be a challenge . Many plasterers do get lazy and volition take shorter cuts or they do not keep up to date with the Australian guidlines.

We see this a lot when we are doing overhaul jobs.

If you are after the best local plasterer team ? You have come to the mighty home.

The Plastering services we provide are:

1 . Gyprock installs

2 . Plasterboard Installation

3 . Cornices including Decorative

4 . P50 Shadow Lines

5 . Suspended Ceilings

6 . Office Tile Ceilings

7 . Bulkheads and Pelmets

8 . Sound Proofing Solutions

9 . Partition Stud Walls

10 . Professional Plastering

Modern Or Minimalist Or Statement and Heritage

Which appeals to you?

We surpass in restoration and ornamental plastering skills, as it takes a highest grade of experience to create a flawless ornamental outcome

So if you care a square cornice style or a stunning cornice style and ceiling with tail lines, then we are the right nonpareils for you.

A talented plasterer can get a smoothen wind up on the broader wall or ceiling . Thus, the palisade volition take a seamless look after house painting.<br />

<a href='https://plasteringnearme919.blogspot.com/2022/11/plastering-near-me.html'>https://plasteringnearme919.blogspot.com/2022/11/plastering-near-me.html</a><br />

<a href='https://coastplastering.com.au/'>Plasterers </a><br />

<a href='https://qldinteriorlinings.com.au/'>Plasterers </a><br />

<a href='https://brisbaneplasterpro.com.au/'>Plasterers </a><br />

<a href='https://plasteringcentral.com.au/'>Plasterers </a><br />

<a href='https://persianrugrepairwarnersprings722.blogspot.com/2022/11/persian-rug-repair-garden-grove_0784126926.html'>https://persianrugrepairwarnersprings722.blogspot.com/2022/11/persian-rug-repair-garden-grove_0784126926.html</a><br />

<a href='https://persianrugrepairdelmar482.blogspot.com/2022/10/persian-rug-repair-del-mar.html'>https://persianrugrepairdelmar482.blogspot.com/2022/10/persian-rug-repair-del-mar.html</a><br />

<a href='https://littlestpersimmon.tumblr.com/post/684619384191336448/the-prince-of-fortune/'>https://littlestpersimmon.tumblr.com/post/684619384191336448/the-prince-of-fortune</a><br />

<a href='https://howdoigetdivorcedinjamaica544.blogspot.com/'>https://howdoigetdivorcedinjamaica544.blogspot.com/</a><br />

<a href='https://employeeretentioncreditforhot303.blogspot.com/2022/11/employee-retention-credit-for-hotels.html'>https://employeeretentioncreditforhot303.blogspot.com/2022/11/employee-retention-credit-for-hotels.html</a><br />

<br />

0 notes

Text

Atw Acquires Custom Truck Body Manufacturer Dakota Our Bodies North American Trailer Sellers Affiliation

When you receive a Trebor custom semi truck accent, corresponding to a tool box, headache rack, or flatbed, you're totally anticipating to put it through its paces. A custom device box, for instance, might be uncovered to the elements and endure heavy use. A flatbed will literally be carrying your paycheck on its again and can never slack off. A custom headache rack or bulkhead might custom truck manufacturers sustain an influence or two if your load ever strikes. Only aluminum can face up to all of those eventualities and nonetheless be able to go the subsequent day. It doesn't turn out to be brittle in the cold, does not rust, and, with a good polish, can replicate the blazing solar as you barrel down the highway.

This is why Trebor Manufacturing can offer a free quote for the setup you truly require to make your job environment friendly, secure, and gratifying. And what’s extra, your custom semi truck accessories come prepared to install and use immediately. Take the custom flatbed, for instance, with winches, reflectors and straps already put in. Located in Elwood, Indiana, Warner Bodies manufactures a range of service truck our bodies, together with Select II and Select Pro service truck bodies custom truck manufacturers, platform bodies, hauler our bodies, fireplace / rescue our bodies, and extra. Our options include the biggest working kitchen house in the trade, low service counters, premium finishes and cabs that present consolation and adaptability for your staff. Every meals truck constructed by us is seamlessly tailored to particular menus, whether or not BBQ, Italian, Mexican, or Asian-inspired.

However, there's nonetheless a considerable difference between standard physique and custom physique lead occasions. Standardization was first pioneered within the automotive trade by Henry T. Ford. Today, truck body manufacturers offer standard models of service, utility, platform, gooseneck, dump our bodies and extra to select from. When every different manufacturer was bogged down in steel, JOMAC was advancing the business and serving clients with aluminum truck our bodies custom-designed and manufactured to their specs and their work.

They offer food trucks and concession trailers build-out and repairs. Sun Country's experienced technicians can deal with anything from a fundamental service body set up, to a few of the most extremely personalized truck bodies on the street right now for the commerce trade you need. We try to exceed our clients' expectations, and we will do our best to make sure you are at all times satisfied.

Our vans can be utilized in several industries, together with heavy civil construction, combination provide, rentals, tools dealership. Hercules Manufacturing Company is the premier truck physique manufacturing firm in Henderson, KY. Our firm has been in business since 1902, but our merchandise are something however old fashioned. We're continually upgrading our expertise to scale back the weight of our truck our bodies and increase our shoppers' gasoline financial savings. You'll appreciate our progressive designs and cutting-edge products. Hercules Manufacturing Company is a high truck physique manufacturing company in the Henderson, KY area. No matter where you are headed, our top-of-the-line truck bodies can get your inventory there safely.

Consult with us and we will advise you on the optimum truck configuration for your particular wants. Located in Edmonton, Alberta, Advance Manufacturing produces a spread of merchandise, including service truck bodies, truck slip-ins, truck decks, and more. Located in Houston, Texas, RKI manufactures a spread of service truck our bodies custom truck manufacturers, truck boxes, cranes and winches. RKI products are bought by way of their network of Authorized RKI Distributors. About TriVan Truck Body

We are a leading manufacturer and distributor who has been designing and constructing work truck bodies with excellent craftsmanship for more than 65 years. You can depend upon us for secure, durable truck bodies; skilled set up; and all the elements, gear, equipment and companies you need to get the job accomplished. Kenworth Truck Company is the manufacturer of The World's Best® heavy and medium duty trucks.

0 notes

Text

Which Air Conditioners Are Best?

When deciding which air conditioner to buy, consider the which air conditioners are best. If you live in a hot climate, you should buy a unit that is specifically designed for that climate. If you live in a cooler climate, you might want a smaller model that cools the rooms in your home without being intrusive. Also, consider the energy efficiency of the unit. Some models use less energy than others, which is important if your electricity bill is high.

Goodman Central Air Conditioners

Goodman is one of the few companies in the world that offers self-diagnostics systems in their air conditioners. These systems are a great way to save money on air conditioning maintenance and repair costs. These systems connect to the control board of the air conditioner and can provide diagnostic information for repairs and troubleshooting. These systems can also identify issues like high/low pressure or cycling.

The Goodman central air conditioner range offers several different models to choose from, and many of them have innovative features. These include variable-speed inverter compressors, improved coil designs, and the CoolCloud HVAC app. The line-up includes affordable single-stage air conditioners as well as more sophisticated variable-speed models.

Mitsubishi Electric

If you're in the market for an air conditioning system, Mitsubishi Electric is a great choice. Their air conditioners come in various sizes, from mini to large, split to ducted, and they can suit both residential and commercial needs. While Mitsubishi is not as well-known as their car-making counterpart, you can rest assured that their air conditioners are up to the task.

They don't feature Wi-Fi connectivity, but they do offer whisper-quiet operation, which is ideal for home use. The cooling capacity of these units ranges from 12 to 22 kilowatts, which is more than enough to keep your house comfortable year-round.

Daikin

When it comes to energy efficiency, Daikin air conditioners are one of the best options for your home. They are capable of cutting summer cooling costs and may qualify for cost-saving rebates. They also have the same high-quality design features as their value counterparts, such as a high SEER rating and a smart thermostat. Plus, they are very quiet.

One of the best features of Daikin air conditioners is their ability to adapt to existing duct systems. This means that you can retrofit an older model if you want to reduce energy costs. And, if you need to save space, Daikin offers space-saving bulkhead units. These are whisper quiet and sit flush to the ceiling.

Senville

With a number of advantages, Senville air conditioners have become the best choice for those looking for a high quality, reliable air conditioning unit. Their advanced features include energy-saving features and remote controls via Alexa or apps. They are also highly dependable and require minimal maintenance. They also come with a five-year warranty.

Whether you're looking for a single-zone unit or a multi-zone air conditioner, the Senville SENL-* range is sure to fit your needs. The SENL-* line offers a variety of BTU ratings and sizes, as well as a number of other features that make them perfect for your home.

Live Well Air Conditioning provides quality air conditioners and installation services. Our goal is to provide air conditioning systems that will give our clients excellent air quality and comfort.

#installation air conditioner cost#installing air conditioner cost#which air conditioners are best#local aircon service#how much air conditioner installation#air conditioning installation companies near me#air conditioning installation companies#air conditioning installation and service#air conditioner service and installation#air conditioner installation and service#air conditioner installation service near me#air conditioner removal and installation#local aircon installer

0 notes

Video

E & LS 202 by Jim J.

Via Flickr:

Escanaba and Lake Superior 202 DS4-1000 switches woodchip cars at the Pressed Board Factory at Ontonagan, MI. Canon EOS 2000 Canon 28~80mm lens Fujifilm 400 OVERVIEW The Escanaba & Lake Superior Railroad (E&LS) is a privately owned shortline railroad company operating in Northeastern Wisconsin and the Upper Peninsula of Michigan. Under current ownership, the E&LS has expanded from the original core line of 65 miles that was purchased in 1978, to over 235 miles of operating railroad in 2005. The E.&L.S.R.R. is headquartered in Wells, MI, with an additional office located in Green Bay, WI. The 208 mile mainline of the E&LS stretches from Ontonagon, MI on the shores of Lake Superior to Green Bay, WI. In addition to the mainline, two key branches are the 6-mile Stiles Junction, WI to Oconto Falls, WI line and the 21-mile Crivitz, WI to Marinette, WI/Menominee, MI line. Other lines owned by the E&LS include Channing, MI to Republic, MI, and Channing to Wells. The E&LS operates on trackage rights over the Canadian National Railroad from North Escanaba, MI to Pembine, WI. The E&LS connects with the Canadian National at Green Bay, North Escanaba, Pembine, and Iron Mountain, MI. FREIGHT SERVICE The E.&L.S.R.R. provides a minimum of 5 day per week service over the mainline from Ontonagon to Green Bay, and customizes service to meet shipper requirements in Oconto Falls and Marinette/Menominee. Seven road locomotives and 3 switch locomotives provide the power for operations over the system. The E&LS owns and/or leases a substantial car fleet that includes: 781 boxcars, 77 bulkhead flatcars, 4 gondolas, and 15 RBL’s for a total of 877 rail freight cars. CUSTOMER BASE The E.&L.S.R.R. is privileged to serve a multitude of paper, forest products, and other manufacturing companies in Michigan and Wisconsin. The commodities transported by the E&LS include: medium corrugated or pulpboard, scrap paper, woodpulp, pulpwood logs, oriented strand board, lumber, wood bark, canned goods, steel, scrap metal, aggregate, chemicals, and agricultural items such as corn, grains, feed, and fertilizers. MARKETING AND ANCILLARY SERVICES Maintaining existing business as well as adding new customers have been the guiding principles for the ongoing marketing efforts of the E.&L.S.R.R. In conjunction with reliable and competitively priced rail service, the E&LS works with customer’s everyday to insure that their freight transportation requirements are met successfully. From customer service personnel to the operating department, the E&LS builds lasting business relationships in order to meet the challenges of moving freight by rail for shippers in Michigan and Wisconsin. Other services and assistance offered by the E&LS include: · Industrial development and site planning · State DOT finance programs for industrial spur track construction · Truck transloading · Contract car repairs for private and railroad owned car fleets · Railcar Storage

0 notes

Photo

Progress made on a salvaged F-35’s, repurposed for training aids

Published July 8, 2022

By Todd Cromar 75th Air Base Wing Public Affairs

HILL AIR FORCE BASE, Utah -- Airmen here are currently involved in transforming a salvaged F-35A fuselage and F-35B cockpit into sectional training aids. Significant progress is being made on the two condemned aircraft, which were both involved in mishaps during the last several years, then scrapped after being considered unrepairable.

This innovative idea originated with Airmen in the 372nd Training Squadron, Det. 3, at Hill Air Force Base, and Dan Santos, F-35 Joint Program Office, who worked closely together to determine the feasibility and approvals needed to salvage the aircraft parts for training.

“After receiving the F-35A jet last year, the aircraft has been decontaminated and made safe, as well as the engine removed,” said Master Sgt. Andrew Wilkow, 372nd TRS. “We found that except for the nose section, nearly all the components and systems inside the F-35A fuselage were in surprisingly good condition and ideal for usability as training aids.”

Wilkow was then able to arrange the assistance and volunteer cooperation of a well-known civilian saw manufacturing company, to have the entire fuselage completely sawed in half, lengthwise, as a product demonstration.

“We looked at possibly tearing down each individual system in order to create its own individual aid,” continued Wilkow. “But found that, because of the way the bulkheads are designed, it would be better to leave the fuselage essentially in tack, but in two halves, then do training instruction on multiple systems, in their original respective location within the jet.”

The plan is to permanently mount each complete half-fuselage section on stands, at actual real world height, giving trainees the opportunity to remove exterior panels and practice maintenance on all components and systems in their normal orientation and position.

309th Aircraft Maintenance Group engineers will be designing the permanent stand fixtures, then 388th Maintenance Group machinists will work with them to fabricate and build the fixtures.

“We were able to work with the Aircraft Battle Damage Repair section in the Ogden Air Logistics Complex to use some of the materials they have in stock, which we will then backfill from the 388th materiel order, allowing us to move forward with the training facility without long delays waiting on material.”

A nose section was acquired from a condemned Marine Corps F-35B aircraft as well, but it had several exterior panels missing, which required Wilkow to work with the advanced composite program office on base to fabricate replacements.

A canopy deemed unserviceable and unfit for flight was also obtained, which appears new, and will replace the original canopy destroyed in the aircraft accident.

In order to support the aircraft sections, a permanent training classroom is being prepared to house the training aids by converting and remodeling a large un-used garage bay located in the 372nd training building.

“Until now, maintenance training has been accomplished using operational aircraft,” said Tech. Sgt. Dennis Corcoran, 372nd TRS. “Obviously, this is a significant challenge because often units are unable to support training evolutions, simply due to operational commitments or the real-world need for jets to be immediately returned to flying status, in order to maintain the squadron’s readiness requirements.”

The creation of this indoor training facility will allow for F-35 maintainers to receive “anytime” instruction on an entire F-35 in a climate-controlled environment, while also saving on wear and tear of the service’s operational aircraft.

“I believe creating training aids from salvage aircraft, which the Air Force already owns and were destined to be scrapped, benefits everyone involved and the Air Force as a whole,” said Wilkow.

Wilkow added he is “grateful” for the support this “non-traditional project” has received from leadership, and the cooperation demonstrated by units and organizations across different commands involved in the project.

0 notes

Text

Incredibly USAF is rebuilding Raptor after belly landing in 2018

The F-22 is expected to return to service in early 2022, almost four years after an unsuccessful takeoff.

Fernando Valduga By Fernando Valduga 12/23/2021 - 08:23 in Aeronautical Accidents, Military

Members of the 3rd Aircraft Maintenance Squadron rebuild the tail of the U.S. Air Force F-22 Raptor (number AF-07-146) at Joint Base Elmendorf-Richardson, Alaska. (Photo: U.S. Air Force)

Members of the 3rd Aircraft Maintenance Squadron rebuild the tail of the U.S. Air Force F-22 Raptor (number AF-07-146) at Joint Base Elmendorf-Richardson, Alaska. (Photo: U.S. Air Force)

The U.S. Air Force (USAF) is close to completing repairs to an F-22 Raptor that was damaged immediately after aborting a takeoff and landing on the runway of Fallon, Nevada Air Station, in April 2018.

The successful restoration effort is due to the crew chiefs of the aircraft at Joint Base Elmendorf-Richardson (JBER), who became part of a unique team in charge of rebuilding the Raptor.

USAF Chief Technology Sergeant Kevin Fitch and team Sergeant Ethan Rentz, chiefs of crew of the 3rd F-22 Aircraft Maintenance Unit, are now approaching the end of a year-old process that began shortly after the F-22 tail accident number AF-07-146.

Jet was damaged after aborting takeoff and landing on the track in Fallon, Nevada.

Fortunately, the pilot was unharmed, although the aircraft suffered substantial damage. As the aircraft belongs to the 3rd Wing, a JBER team went to the cout site to disassemble the jet, load it on a cargo aircraft and transport it home.

Rentz was among the group that dismantled the F-22 in Nevada and prepared it for transportation.

“We had to fit it into a C-5 Galaxy aircraft, so we removed everything that was damaged and everything that did not fit dimensionally,” Rentz said. “We removed the wings and vertical stabilizers and the entire belly of the F-22 because these panels were damaged and burned. We couldn't have these panels hitting or breaking during traffic."

The disassembly took about a month. Then the jet was transported to JBER for a complete analysis to assess whether or not

“Everything worked out in the simulations, so the aircraft was placed in our hangar in January 2020 and placed on supports,” Fitch said. "That's when the complete disassembly began - the harnesses, the struts and the bulkhead. We went to the 'bones' of the fuselage at that point.

“Contrays, engineers and structure personnel spent about 16 months replacing almost the entire bottom of the aircraft, the fuselage stations and more than 40 harnesses,” Fitch continued. “Our active guys didn’t start helping with the reconstruction until June this year.”

Fitch has created inventory lists and order tracking spreadsheets to keep organized the myriad of parts needed for aircraft reconstruction.

“Sergeant Fitch learned this out of nowhere,” Rentz said. “He is operating at a master's or senior sergeant-master level because he is not only dealing with team leader tasks, he is coordinating with several different stores and agencies. He is essentially commanding a one-man aircraft squadron."

As the ordered parts arrive, Rentz and Fitch classify, continue to label and organize them to ensure that the reconstruction occurs smoothly.

“At the moment, the biggest challenge is to acquire parts because the F-22 is no longer manufactured,” Fitch said. “Some of the pieces will not be available until the summer or fall of 2022, so we will probably end up “canning” (in literal translation) those of aircraft that will be down for a while.”

Canning, is a colloquial term for cannibalization, which refers to removing usable parts from one aircraft for use in another, depending on the repair status of the aircraft and the schedule for new manufactured parts to be completed. This method returns the aircraft to combat capacity status earlier because it reduces the waiting time for the manufacture of new parts.

With pieces arriving throughout the year, Rentz compared the reconstruction of the F-22 with the completion of a puzzle. Although they have some parts to complete the sections of the aircraft, the intention is not to undo these repairs when other parts arrive to complete the necessary repairs behind the previously built section.

With constant progress being made in reconstruction, the functional verification flight for tail number AF-07-146 is now projected for March 2022. If the schedule doesn't be late, Rentz and Fitch will be here to see the jet fly once again.

“Sergeant Fitch and Sergeant Rentz were obvious choices for our F-22 subject matter experts to lead the team with Lockheed Martin and engineers in rebuilding the crashed aircraft,” said U.S. Air Force Master Sergeant. Steven Banda, head of the section of the 90th Aircraft Maintenance Unit. “Both are qualified maintainers with the technical knowledge to put that aircraft back into combat. They performed unique modifications and atypical maintenance tasks.”

As the F-22s are no longer manufactured, returning this jet to mission status and ready for combat is important not only for the capabilities of the 3rd Wing, but also for the entire United States Air Force.

“It is very important to put this jet back on the flight,” Fitch said. “Five months ago, he had no supports, no wings, no flight controls, no hydraulic system, no stabilizers. Seeing progress and doing something out of the ordinary has been very rewarding.”

After being part of the team that dismantled the crashed aircraft and now part of the reconstruction team, Rentz saw and did what only a handful of team leaders can do.

"It will be very rewarding when he flies," he said. “Several agencies, with all their efforts, are fulfilling the Air Force's vision of putting this jet back into operation.”

Fernando Valduga

Cavok Brazil - Digital Tchê Web Creation

24 notes

·

View notes

Text

Battleship USS West Virginia underway in the Pacific, circa 1944. Severely damaged by Japanese torpedoes at Pearl Harbor, USS West Virginia returned to service in October 1944. When the Japanese surrendered on September 2, 1945, she was in Tokyo Bay, a symbol of the resilience of the United States Navy. By all accounts, she shouldn’t have been there. She had suffered damage beyond any expectations her designers had. But she was an American warship, a fulfillment of Alfred T. Mahan’s ideas of power projected around the world. Her salvage and repair were a feat of engineering and determination. A phoenix rises from the ashes, but USS West Virginia (BB-48) rose from the waters of Pearl Harbor to contribute to the defeat of the Japanese empire.

Pearl Harbor was shallow, and on December 7, 1941, West Virginia was moored outboard of USS Tennessee (BB-43) at Ford Island in 40 feet of water. As the Japanese attack began, West Virginia, her port side laid bare, became an easy target for enemy torpedoes. The first two struck simultaneously, at 7:55 a.m, as General Quarters sounded. Men poured from hatchways as she began to list. A third explosion rocked the battlewagon. Spotter planes atop main turrets were aflame when a massive explosion on USS Arizona (BB-39) sent chunks of steel flying into the air. Moored nearby, pieces as large as five inches rained down on West Virginia. Gun crews fired on approaching enemy aircraft, adding to the cacophony of the first day of a new war.

Torpedoes ripped into her hull below the waterline and bombs fell from enemy aircraft, one causing the sections of the superstructure to collapse. As fires broke out, the ship’s damage control parties fruitlessly attempted to extinguish them. All hands not severely wounded were at work, fighting fires, manning guns, or assisting with damage control. Up on the bridge, the ship’s commanding officer, Captain Mervyn S. Bennion, had been mortally wounded in the abdomen by an explosion. Mess Attendant second class Doris Miller helped pull sailors through oil and water, up to higher decks not awash as West Virginia began to settle on the bottom. Miller assisted with moving the wounded Bennion, and even though he’d had no instruction in the weapon’s use, manned a machine gun, firing at incoming Japanese planes.

Eventually the order to abandon ship was given. As the wounded were loaded into whaleboats and other small craft, others either crossed over to Tennessee, or dove into the oil-covered water, swimming to Ford Island. When the crew was finally accounted for, there were two officers, including her commanding officer Bennion, and 106 enlisted men killed. Numerous others were wounded, and some would need months to recover from the attack. West Virginia, known by her crews as “Wee Vee” would need much longer.

The damage inflicted in a matter of minutes took over two years to repair. To say the Japanese attack on Pearl Harbor on December 7, 1941, left West Virginia crippled is understating the true extent of the damage. In an official report of ships damage at Pearl Harbor, West Virginia hardly sounds worth repairing:

“West Virginia sank at her berth as a result of four or five aircraft torpedo hits and at least two bomb hits. The vessel rests on a hard bottom with all spaces flooded up to two or three feet below the main deck. Most of the damage from torpedoes is in the midship area, which is badly wrecked both below water and above water. A large bomb passed through the foretop and the boat deck and apparently exploded near the port side on the main or second deck. This explosion caused considerable wreckage and a terrific powder and oil fire, which burned out the whole area and extended to the foremast structure up to and including the bridge. A second bomb hit the top of turret III and passed through the 6-inch top. The nature of the penetration indicated defective material. This bomb did not explode but caused damage to the slide of the left gun. Recently another torpedo hole, and parts of the torpedo, have been located aft under the counter. The steering engine room appears to be wrecked and the rudder is lying on the bottom.” Her salvation was due to the actions of one man, which resulted in West Virginia remaining upright at her moorings, unlike USS Oklahoma (BB-37), which capsized. Lieutenant Commander John S. Harper, the damage control officer aboard West Virginia, quickly initiated counterflooding, keeping the battlewagon upright. As a result, West Virginia was found to be drawing 50 feet 6 inches forward, and 40 feet 10 inches aft, compared to her usual draft of approximately 30 feet. The midship area was considerably damaged, and the oil fire, which had burned for 30 hours, caused extensive damage to the upper works. The hull crinkled as the ship settled on the bottom, and one torpedo had knocked the rudder off. Despite the damage, the decision was made to salvage the ravaged ship, modernize her, and return her to service. Salvage was undertaken in several stages. Patches had to be placed on holes in the hull by divers. These patches were made as cofferdams, which were large wooden structures braced with steel and attached to the ship by divers. Special concrete that would harden in water was then poured into sections around the cofferdams, sealing the bottoms and making them watertight. With the major holes patched, 800,000 gallons of fuel oil, all projectiles and other supplies were removed from the ship to reduce weight. As water was pumped out of the ship, salvage crews began to work through compartments, removing the remains of 66 trapped sailors. Marks on a bulkhead in one compartment indicated three sailors survived there for 16 days. With access to food and water, they held on until the breathable air ran out.The work was done in earnest, performed by naval and civilian personnel and a skeleton crew of sailors and marines which remained attached to West Virginia. Specialists from various companies arrived in Pearl Harbor to break down and repair equipment such as electrical panels and the steam-driven turbine engines which powered West Virginia. Seventy tons of fresh meat had been aboard Wee Vee when she sank, all of which the crew removed via 10 gallon cans. Crews took care to wear rescue breathing apparatus or monitor the air quality as they cleaned compartments. Those containing large stores of paper were some of the most hazardous to empty, as the decaying paper gave off noxious gasses.

On May 17, 1942, West Virginia was once again floated. The first step in her recovery was done, and she was moved to Drydock #1 at Pearl on June 9. Her draft had improved to 33 feet, just barely allowing her to enter the drydock. There, repairs were made to the hull to make it watertight once again. Machinery and other equipment were removed and either repaired at Pearl or marked for later installation stateside. The oil residue left behind had to be removed from surfaces. At the time of the attack, West Virginia still had her original cage masts, both of which were removed in Pearl. Some guns were repaired so the ship could defend itself on the trip home. Crew spaces were cleaned up and returned to a usable state, and while the enlisted galley had burned, the officer’s galley was repaired and put to use for the entire crew. The ship was safely floated again after just three months, but work on the ship continued pier side until April 1943. On April 30, after more than a year of work on temporary repairs, West Virginia was stabilized, repaired, and ready to make the journey to Bremerton, Washington, for final repairs and outfitting.

In early July 1944, over two and a half years after the attack at Pearl Harbor, West Virginia began her sea trials from Puget Sound Navy Yard, Bremerton, Washington. She had been at the yard in Washington for over a year undergoing permanent repairs and modernization. The ship that took to the seas in July 1944 looked nothing like the old battlewagon that had been a target of the Japanese attack. Equipped with updated radar and fire-control equipment, she was ready to unleash the power of her 16-inch main battery on the enemy who had sidelined her years before.

Her first opportunity to exact her toll on Japanese forces came on October 19, 1944, as Wee Vee bombarded targets in Leyte, Philippines, flying the same flag which had been hoisted on that fateful Sunday in December. The next day, she covered landing forces there, providing fire as needed. What might be her crowning achievement came on October 25, when she participated in the battle of Surigao Strait. In what was to be the last engagement of battleships in history, West Virginia opened fire on an enemy ship, firing 16 salvos from her main battery. When the smoke cleared, the target was discovered to be the Japanese battleship Yamashiro, which sank in minutes. Though West Virginia’s captain let the crew claim credit, the damage had been inflicted by five battleships, plus cruisers, firing on the Japanese ship and making it a group effort which sank her.

After her triumphant engagement at Surigao, West Virginia continued her tear across the Pacific, supporting the landings at Mindoro, Luzon, Iwo Jima, and finally, Okinawa. After spending years in dry docks and shipyards, West Virginia put in 223 days in battle, where she shot down eight would-be Kamikazes and assisted with 12 others. Her number came up on April 1, 1945, when one successful Japanese pilot plowed his aircraft into Wee Vee, killing four sailors and wounding 23. But after Pearl, one enemy aircraft was akin to a mosquito bite, and she stayed in the action. On August 31, 1945, West Virginia steamed into Tokyo Bay. A Japanese harbor pilot had come aboard to navigate the battlewagon to her berth. Five members of the ship’s crew, all musicians, were transferred to USS Missouri (BB-63) to augment the band which would play at the official surrender ceremony.As the Japanese delegation boarded Missouri on September 2, West Virginia lay in harbor some distance away. She was the only survivor of the Pearl Harbor attack present in Tokyo Bay that morning. (The cruiser USS Detroit (CL-8), had also been present at Pearl, but received no damage.) As the most important ceremony of the war got underway, West Virginia had no role in the somber occasion. She lay silently, ghastly in the distance, a triumphant reminder of how Japan had gambled and lost.

38 notes

·

View notes

Text

Empire Nautical is the Best Place to Buy Boat Floating Docks in Florida

Empire Nautical offers the best floating docks for sale in Miami, Fort Lauderdale Hollywood, Jupiter Florida. Get a wide range of floating dock products for all marine needs. Contact Empire Nautical and get custom-built solutions for your floating dock project.

Empire Nautical is your one-stop shop for everything related to commercial or residential Wooden Floating Docks in Florida. We carry all of the flotation, hardware and lumber you need for your next project. In addition, we offer design and construction services. If you’re building yourself, we can provide complete design support, product supply and helpful advice to make sure your next float is built to meet your specifications.

Empire Nautical selling Jets ki dock and Waverunner floating dock in Florida with a wide range of floating dock products for all marine needs. Request a quote now!

Services Available:

· Details & Washes

· Floating Docks & Bulkheads

· Bottom Painting & Scraping

· Vinyl Wrap, Decals & Names

· Electronics Sales & Set Up

· Transport & Hauling

· Cosmetic Repair & Restoration

· Mechanical

Our Service Locations:

· West Palm Beach,

· Fort Myers,

· Fort Lauderdale,

· Oceanside,

· Jacksonville,

· Tallahassee

Whether you’re looking to upgrade your existing floating dock or design a new one, call Empire Nautical at (561) 295-9166. Our Dock Specialists can help you get started on your design.

0 notes