#bulletproof cars manufacturers

Text

#Bulletproof Cars in India#Bulletproof Luxury Cars In India#bulletproof cars manufacturers#Bulletproof car manufacturers in India#bulletproof vehicle manufacturers in India

2 notes

·

View notes

Text

Shield Armoring has set the standard in the design and development of Luxury Armored Vehicles Bulletproof BMW. Visit : https://shieldarmoring.com"

#Bulletproof Cars in India#Bulletproof Luxury Cars In India#bulletproof cars manufacturers#Bulletproof car manufacturers in India#bulletproof vehicle manufacturers in India#Top Armored Cars Company in India#bulletproof luxury cars#Armored Vehicle Manufacturers In India#top armored car manufacturers#Armored Vehicle Company#top armored car companies

1 note

·

View note

Text

Artan Armored - Reliable and Safe Transportation Solutions

In today's world, the need for secure and reliable transportation solutions has become increasingly important. This is especially true for individuals and organizations that deal with high-value goods and individuals who need to be transported safely from one place to another. That's why Artan Armored has been providing top-notch armored personnel carrier (APC) services to its clients for many years.

Artan Armored is a leading provider of armored vehicles, offering a wide range of APCs to meet the needs of different clients. Our APCs are built with the latest technology and materials, providing superior protection against various threats, including bullets, fire, and explosions. They are designed to offer maximum security and comfort to the passengers, making them the perfect choice for individuals and organizations looking for safe and secure transportation solutions.

Booking an APC with Artan Armored is a simple and straightforward process. You can book your vehicle through our website, where you'll find a range of APCs to choose from. You can select the vehicle that best suits your needs and make your booking online, with just a few clicks. Our team of experts will be available to assist you every step of the way, from choosing the right APC to arranging your transportation.

At Artan Armored, we understand the importance of timely and reliable transportation services. That's why we have a team of experienced and highly-skilled drivers who are trained to handle any situation that may arise during transportation. Our drivers are equipped with the latest navigation systems, ensuring that your journey is smooth, efficient, and safe.

Artan Armored also takes great care to ensure that our APCs are well-maintained and in top condition. Our vehicles undergo regular inspections and maintenance, ensuring that they are always ready for use when you need them. We also have a team of mechanics on hand to address any issues that may arise during your journey, ensuring that you reach your destination safely and on time.

In conclusion, if you're looking for a reliable and safe transportation solution, look no further than Artan Armored. Our APCs are designed to offer maximum protection and comfort to the passengers, making them the perfect choice for individuals and organizations looking for secure and efficient transportation services. Book your APC today through our website, and let us help you get to your destination safely and on time.

0 notes

Text

On 28 February, 1997, Larry Phillip Jr. and Emil Mătăsăreanu entered the North Hollywood Bank of America, Los Angeles, California. They were armed with two Norinco Type 56 S rifles that they had converted into fully automatic, a fully automatic Norinco Type 56 S-1, a semi automatic HK-91, a fully automatic Bushmaster (M16) XM15 Dissipator and approximately 3,300 rounds of ammunition.

The two men were also somewhat prepared for the aftermath as they were wearing bulletproof vests and homemade body armor. They also manufactured a bomb and placed it in their car to destroy any evidence. The two men had prepared for this moment, even monitoring police transmission to estimate how long it would take them to arrive to the bank once called.

However, they hadn't prepared for the scenario which unfolded. As they were entering the bank, two LAPD officers spotted them and called for backup. Phillips and Mătăsăreanu forced the patrons and staff to the ground as they ordered the manager to open the safe; they left with $303,305.

Outside, a number of officers had positioned themselves behind their cars with their weapons drawn and facing toward the bank doors. When Phillips and Mătăsăreanu exited with their loot, they engaged in gunfire with the officers, whose arsenal and armor could not compare to that of the bank robbers.

A number of officers and civilians were harmed in the gunfire which lasted approximately eight minutes before Mătăsăreanu jumped into their white sedan in an attempt to make a getaway, urging Phillips to do the same. Instead, Phillips retrieved a HK-91 from the trunk of the car and continued to fire at the surrounding officers.

After suppressing the officers, Phillips made his way to the passenger side of the car but was stopped when a shotgun blast penetrated his wrist. He responded by backing away from the car and ensuing in more gunfire. The SWAT team, who were more prepared, arrived 18 minutes after the initial gunshots.

By now, the tyres of the sedan had been shot out and Mătăsăreanu and Phillips were separated. Phillips continued to fire at authorities and was shot in the hand, causing him to drop the gun. He picked the pistol up and shot himself under the chin; as his body slumped down, he was shot in the back of the neck.

Mătăsăreanu on the other hand, attempted to carjack a car just a few blocks from where Phillips had died. Unable to start the car, Mătăsăreanu took cover and shot at authorities. Noticing his legs were unprotected by armor, authorities shot at him from underneath the car, shooting him over 20 times. Mătăsăreanu died on the ground due to the trauma.

Mătăsăreanu and Phillips had fired approximately 1,100 rounds in what became infamously known as the North Hollywood Shootout. The shootout was aired live on television.

58 notes

·

View notes

Note

Seeing comments of a hydrologic failure on George’s car (im not watching so literally taking it from on here) what is wrong with Mercedes usually bulletproof reliability this year? Definitely think they’ve had to cut costs in the manufacturing department due to cost cap. Think I’m not watching anything else f1 related this year

He had steering rack issues when he was testing for them the other week and now suddenly he has complete failure, on top of an engine blow up and a front brake issue this season while their other car has had no mechanical issues at all?

I mean fuck me, his Williams luck has come back with a vengeance this season. There’s something dodgy going on with Merc to suddenly have this level on unreliability…

3 notes

·

View notes

Text

'No logo': Beef between Italian government and Fiat 500 maker turns personal

Audrey Hepburn and Gregory Peck frolicked around Rome in it. Pope Francis chose it over a bulletproof limousine. Italian PM Giorgia Meloni enjoyed a ride in it at the G7 in Puglia just last week.

Now, the iconic Fiat 500 is being used to make a point.

In its latest video advertisement, Stellantis — a Netherlands-based Franco-Italian multinational that designs and manufactures cars under 14…

View On WordPress

0 notes

Text

I was pondering how I'd do my vehicles, if I were some supervillain or Metal Gear Solid bigwig character.

If I were some sort of private military company owning, private island having supervillain or private citizen, I think my designs for a P.M. Vehicle would have the following principles.

1.) Timeless Engineering. Though it would be made with 2024 sentiments in mind, we haven't really made a whole lot of improvements with things like car engine technology or materials in a while. Some things, like the wheel, are pretty much maxed out in their tech tree. So. Every part would be custom engineered and custom manufactured to be more or less futureproof. We can already burn almost all of a fuel in the engines we have. The sort of engine technology that makes bulletproof consumer engines. Whether it's internal combustion, chemical fuel cell, or pure electric. We virtually can't get any more giddy-up-and-go from gasoline or diesel fuel than we already do, and even if we had a pure hydrogen tank, there's a finite limit to what an engine is capable of. We are nearly at that level. So, making reasonable guesstimates and assuming things can't improve much beyond it is reasonable to imagine the model will be about as good 1 or 100 years from now as today. The standards will be based on "end of the tech tree" according to conventional physics and materials science, today.

2.) Ageless Product. The materials selected mean you can manufacture thousands of the thing and keep them in storage without worry about vermin like insects and mice or the natural breakdown of the cable insulation or degredation of the light bulbs causing the thing to be shit. What computerized components there are would be made as close to tiny chips as possible and easily manufactured or replaced, and modularly supportable. As close to a pure dumb analog machine as possible, save the layer of interface for things like fire control systems, communications and some creature comfort amenities. These things need to be able to sit in warehouses by the SEA and not be any worse for wear despite potential rain and tidal floods. Something you can make an enormous cheap surplus of and count on them not being eaten by things that skitter in the dark or eaten by mold and fungus. If it couldn't do this with every single component, it's not worth having that component on the vehicle.

3.) Light and Zippy. Firepower and mobility are the parts of the triangle cared for. Armor is nice, but weighs one down. Better to not be seen or hit, better to be able to evade.

4.) Locally sourceable. If a war occurs and you can't acquire parts and materials due to their scarcity, you don't have a model, you have a dud. The materials you have access to have to come reasonably from wherever you are, be it silica sand from the dirt, or aluminum, or iron. But no rare earths, even if they would make for superior components. The power of said vehicle comes not from its material supremacy, but its engineering and principles. And being able to make more or replacements for cheap and reliably is better than being able to make one that can be easily destroyed and then irreplaceable. Being made of such materials also means broken parts can be melted and recycled without much worry or care about toxicity.

5.) Endlessly repairable. Whether it's to give patch jobs or complete replacements, the easy access and modularity of the design means it was built to be repaired under combat conditions in a field, if you have the parts handy. And as doctrine, one should always have parts they can deploy to the field for repairs. These things should be cleanable and fixable with a minimum of chemical cleaners and absolutely no rare proprietary specialty substances. Consumer tools should suffice. It should be cheap and fixable, or it shouldn't be employed as a light vehicle.

6.) Individuality. It's a weapons platform that relies on speed, firepower and numbers. And if every person can drive and repair it and operate the systems alone, you multiply your combat effectiveness. These are weapons platforms, not sports cars. Riders should be able to get up and get out of them at a moments notice to avoid incoming attacks, even if sacrificing the vehicle to something like infrared chasing missiles.

7.) EMP and Electrical Disruption Hardened. All cables and all computer systems would be insulated from disruption by electronic warfare, by nature of the cables and their containment. By virtue of its design, it should be immune to targeted electronic disruption.

8.) Finally, FIREPOWER.

Use your imagination! You've got a field of these high mobility, cheap, enduring, repairable transports, where the complete loss of one results in a maximum of one casualty instead of 4-5, or even up to 12 in the event of a catastrophic armored personnel carrier failure. What do you give the troops?

0 notes

Text

There is no person who does not seek to have security and safety today, more so in various locations where instability poses a massive risk. Zida Security has put its mind to coming up with the latest models of cars after studying all the challenges likely. We have dedicated ourselves to the manufacture ofhigh-quality armored cars specifically for the African region to provide the best protection so that our customers can have a secure journey wherever they go in whatever situation arises.

0 notes

Text

China invents super-strong impact-resistant material: it eats soft, but does not eat hard, and can withstand violent impacts

In the exploration of materials science, the Chinese research team once again made a breakthrough, LinZhi science and technology ACF successfully developed a kind of super-strong impact-resistant material called ACF. This material with its unique "eat soft, but not hard" characteristics, as well as a series of impressive data support, showing a huge advantage in the field of security protection.

Technical Principle and Characteristics of ACF Material

ACF material, full name ACF artificial cartilage material, is a new type of polymer energy-absorbing material developed based on the principle of bionics, which imitates the function and structure of articular cartilage. The material realizes efficient absorption and dispersion of impact energy on the micro-nanometer scale, and has excellent impact resistance.

The uniqueness of ACF material lies in the ingenious design of its internal structure. By introducing nanoscale reinforcing particles, ACF material improves the mechanical properties and toughness of the material. When subjected to high velocity and high energy impacts, these nano-reinforced particles respond quickly by interacting with the polymer matrix to form a large number of tiny deformation regions, thus effectively absorbing and dispersing the impact energy.

Advantages of ACF material and data support

Super impact resistance: ACF material can absorb up to 97.1% of the impact energy, which is far more than traditional materials. According to authoritative experimental data show that the 15mm thickness of the ACF protective gear impact resistance of up to 50 joules, equivalent to 5Kg hammer at a speed of 4.5M / s hit the iron plate to produce 11 tons of instantaneous impact peak.

Excellent shock absorbing performance: ACF material also performs well in shock absorbing performance. Under the impact energy of 50J, the energy release time of ACF material is 20ms, and the maximum peak impact force is 5000N, which is far lower than that of EVA material of 20000 N. This means that ACF material can better prolong the dispersion and absorption of the impact force when it is subjected to the impact, so as to reduce the peak force and reduce the instantaneous destructive force.

Wide range of application prospects: ACF material's "soft but not hard" characteristics make it in a number of fields with a wide range of application prospects. In the field of daily human body protection, often used for shoes, shoe insoles, fall pants, fall caps in the field of juniper protection, ACF materials can be used for the manufacture of explosion-proof shields, bulletproof vests, helmets and other personal protective equipment; in the field of aviation and aerospace, it can be used for the structural components of aircraft and rockets; in the field of electronic protection, is used to protect the chip sealing, vibration isolation; in the field of automotive manufacturing, ACF materials can be used for body and chassis and other key anti-collision, vibration, sealing components. In the field of automobile manufacturing, ACF materials can be used for key anti-collision, vibration damping and sealing parts such as car body and chassis.

Environmentally friendly and healthy: ACF materials are made of healthy and environmentally friendly materials, which are non-toxic and harmless, and will not cause any harm to the user's health. This advantage makes ACF materials have great application potential in medical devices, wheelchairs and other fields.

Durability and Stability: ACF materials have excellent abrasion resistance and compression resistance, and are able to withstand long periods of use and frequent movement, maintaining stable performance and extending service life. This feature makes ACF materials perform well in occasions that require long-time operation and heavy pressure.

III. Conclusion

The successful development of ACF materials marks an important progress in the field of impact protection material science in China. This super-strong impact-resistant material shows great advantages with its unique characteristic of "eating soft but not eating hard", excellent impact resistance and shock absorption performance, and a wide range of application prospects. For industrial production and civil life to bring more safety and comfort.

400-6543-699

www.acf.com

0 notes

Text

Exploring the Versatility of Polycarbonate: Applications, Manufacturing, and Advantages of Polycarbonate (2023-2034)

Polycarbonate is a common polymer which finds applications from automotive to consumer goods. In this blog, we'll dive into the fascinating world of polycarbonates. We'll explore its unique properties, its manufacturing process, and its range of applications that make it popular in the world of polymers. The global Polycarbonate market is likely to flourish at a moderate CAGR of 4.32% by the year 2034.

Here are some of the main topics we'll cover in this blog:

The Properties: Get to know the details of polycarbonate's remarkable properties like toughness, clarity, and heat resistance.

Applications: Explore the applications of polycarbonate, from lifesaving medical devices to everyday consumer products.

Introduction

Polycarbonate (PC) stands out as a high-performance thermoplastic polymer. Its molecular structure comprises organic functional groups connected by carbonate groups (–O–(C=O)–O–), granting it a distinctive array of properties. Due to its remarkable compatibility with certain polymers, polycarbonate finds extensive use in blends like PC/ABS, PC/PET, and PC/PMMA. This versatile material is employed in various applications, including compact discs, safety helmets, bulletproof glass, car headlamp lenses, baby feeding bottles, roofing, glazing, and more. With its exceptional toughness, transparency, and thermoplastic nature, polycarbonate remains a sought-after choice across industries, offering a balance of strength, durability, and optical clarity. Its ability to withstand impact, coupled with its transparent quality, renders it indispensable in safety-critical applications like protective gear and automotive components. Moreover, its versatility allows for diverse applications, ranging from consumer products to architectural solutions. Its properties include:

Transparency: PC boasts high transparency, facilitating superior light transmission. It is commonly utilized in applications necessitating optical clarity, like eyeglass lenses and transparent protective shields.

Impact resistance: A standout characteristic of PC is its outstanding resistance to impact. It is virtually indestructible, making it ideal for safety-critical applications such as bulletproof glass, safety goggles, and automotive headlight lenses.

Heat resistance: PC can endure high temperatures without melting or distorting. Its elevated glass transition temperature renders it suitable for applications requiring exposure to heat, such as microwave-safe cookware and LED light covers.

Lightweight: Despite its strength, PC is relatively lightweight. This property makes it favored for weight reduction in industries such as aerospace and automotive.

UV resistance: PC exhibits good resistance to ultraviolet (UV) radiation, making it suitable for applications like greenhouse panels or protective covers for outdoor equipment.

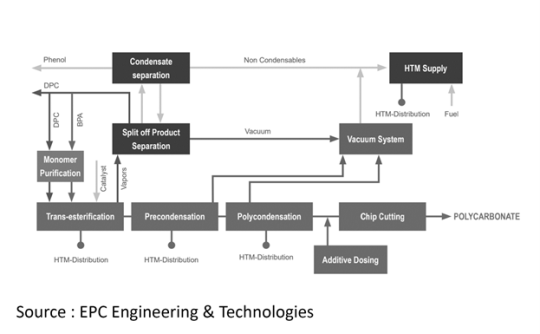

Manufacturing Process

VARIPLANT Process is the main process used to produce Polycarbonate. This process initiates Bisphenol A (BPA) and Diphenyl carbonate (DPC) melting which are then introduced into a raw material melt mixing tank. To ensure high-purity monomer essential for polycarbonate production, purification methods like filtration and impurity removal through stripping are applied. The pre-heated raw materials are then delivered in liquid form into the transesterification reactor. During the initial reaction phase, the raw material melt is combined with catalysts and heated to the specified transesterification temperature, adjusting a specific pre-conversion rate. As monomer and polymer chains develop, phenol begins to separate. Upon completion of transesterification, the produced oligomers are continuously discharged and directed to the prepolycondensation I reactor for the subsequent reaction phase.

By employing elevated temperatures and reduced vacuum conditions, mid-size chain length molecules are formed. Following the prepolycondensation I reactor (PP I), and depending on the plant's production rate design, the system can be configured with one, two, or three polycondensation lines in parallel. This allows for the simultaneous production of up to three distinct product grades. The product from PP I is then transferred to the prepolycondensation II reactor for further chain growth, and subsequently to the final polycondensation reactors. The final polycondensation reactor plays a crucial role in achieving the desired polymer chain length, thereby attaining the targeted properties of the Polycarbonate. Both the horizontal prepolycondensation II stage and the final reactor are equipped with a disc-ring agitator, ensuring significant surface area for efficient mass transfer and chemical reactions.

Applications of Polycarbonate

Electricals & Electronics

Polycarbonate and their blends find application in various appliances like refrigerators, air conditioners, coffee machines, and washing machines. Their utilization enables design flexibility due to a diverse range of mechanical properties, enhancing product durability and aesthetic appeal.

Automotive

Polycarbonate (PC), known for its lightweight and transparent nature, contributes to eye-catching vehicle designs and enhances efficiency by reducing weight without compromising durability or aerodynamics. Its exceptional heat resistance makes it ideal for light housing, headlamp bezels, and lenses. PC blends offer optimal rigidity and excellent creep resistance, making them suitable for both interior and exterior car body parts.

Construction

PC serves as a viable substitute for glass in diverse glazing applications including agricultural structures, industrial and public buildings, facades, security windows, shelters, and skylights. Its attributes of high impact strength, transparency, UV light resistance, and weatherability make it an ideal choice for such purposes.

Consumer goods

Polycarbonate's minimal birefringence, low internal stress, and precise dimensional accuracy make it ideal for CD/DVD manufacturing. Its exceptional transparency enables innovative designs for everyday items like safety goggles, ophthalmic lenses, and large-volume water bottles. Additionally, its optical clarity lends itself to applications such as shatterproof sunglasses, face shields, and bulletproof windows.

Market Outlook:

The automotive sector serves as the primary driver for the global Polycarbonate market, with its utilization in lightweight exterior and interior parts. Polycarbonate's unique properties enable sleek designs while reducing component weight by up to half, particularly in applications like automotive glazing, panoramic roof panels, and backlights. Additionally, its high impact resistance extends its usage to electronic devices, meeting the demand for durable and technologically advanced gadgets. The growing consumer preference for stylish automotive designs and innovative electronics further propels the demand for Polycarbonate, positioning it as a pivotal material in driving industry innovation and meeting evolving market demands. The global Polycarbonate market is anticipated to reach approximately 8.5 million tonnes by 2034.

Polycarbonate Major Manufacturers

Significant companies in the Global Polycarbonate market are Covestro AG, SABIC, Mitsubishi Engineering-Plastics Corporation, Lotte Chemical Corporation, LG Chem, Formosa Chemicals & Fibre Corp., Teijin Limited, Chi Mei Corporation, Idemitsu Kosan Co. Ltd. (Japan), Zhongsha (Tianjin) Petrochemical, SABIC-Sinopc JV, SHELL-CNOOC, LG Dow polycarbonate, Lutianhua Zhonglan New Materials, Wanhua Chemical, and Others.

Polycarbonate market restraints

The Polycarbonate market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Polycarbonate production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Polycarbonate manufacturers.

Environmental Concerns: The production process of Polycarbonate involves the use of chemicals and solvents that can have environmental implications. Stringent environmental regulations aimed at reducing emissions and waste disposal pose challenges for Polycarbonate manufacturers in terms of compliance and operational costs.

Competitive Pressure: The Polycarbonate market faces competition from alternative materials such as acrylics, polyethylene terephthalate (PET), and polystyrene (PS). These materials may offer similar properties at lower costs, posing a threat to Polycarbonate's market share.

Conclusion:

The global Polycarbonate demand, closely tied to Electrical and Electronics, Automotive, and Construction industries, has experienced strong growth in the past few years. Polycarboante’s distinct characteristics, including lightweight nature, high resilience, and resistance to chemicals, suggest an anticipated expansion of the Polycarbonate market in the forecast period. With urbanization activities on the rise, increasing demand for modern electronic devices, and heightened vehicle sales projected, there is expected to be a surge in demand for Polycarbonate by the year2034.

0 notes

Text

#Bulletproof Cars in India#Bulletproof Luxury Cars In India#bulletproof cars manufacturers#Bulletproof car manufacturers in India#bulletproof vehicle manufacturers in India#Top Armored Cars Company in India#bulletproof luxury cars#Armored Vehicle Manufacturers In India#top armored car manufacturers#Armored Vehicle Company#top armored car companies

0 notes

Text

Is Silicon Carbide a Ceramic

Is Silicon Carbide a Ceramic?

Silicon carbide is an advanced ceramic material, known for being strong, durable and versatile. It can withstand high temperatures, corrosion and chemicals without suffering damage or degradation.

Foamed SiC is an extremely versatile material used in metallurgy, mining, transportation, machinery and national defense applications. Notably it possesses superior chemical resistance as well as being electrically heated for heating. Foamed SiC ceramics feature uniform three-dimensional network structures for optimal use.

Hardness

Silicon carbide (SiC) is an inorganic chemical compound composed of silicon and carbon. Found naturally as the mineral moissanite, SiC has been mass produced since 1893 as a powder and crystal form for use as an abrasive. By sintering grains together they can form very hard ceramics with applications in car brakes and bulletproof vests requiring high endurance.

Silicon Carbide is a refractory material with superior mechanical properties, high thermal conductivity, low thermal expansion and superior corrosion resistance that is well suited for use in high temperature environments. Furthermore, it exhibits low neutron cross sections as a radiation shield and thus is suitable for nuclear reactor applications.

Tungsten carbide abrasives have long been used as an industrial machining abrasive material due to their resilience, making them popular choices in several industrial machining processes such as honing, grinding, water-jet cutting and sandblasting. Furthermore, their durability makes them indispensable in modern lapidary due to their relatively low costs; additionally they rank third hardest on Mohs scale behind diamond and boron carbide.

SiC is an incredible material for use as a semiconductor. Doped with elements like boron and aluminum to form a p-type semiconductor or nitrogen and phosphorus for an n-type semiconductor configuration, its versatility as an electrical material expands dramatically when coupled with these other attributes.

Corrosion Resistance

Silicon carbide ceramics offer unparalleled corrosion resistance among advanced ceramics, and have the strength to withstand high temperatures without degrading in strength. They're suitable for acid, alkali and oxidative environments; additionally they can withstand acid rain, alkaline conditions as well as complex environments like coal slag.

Corrosion of SiC is determined by both its structure and chemical composition. SiC crystallizes in an interlocked structure covalently bonded together with four silicon and four carbon atoms covalently linked into primary coordination tetrahedra; further, this configuration contains polytypes with different stacking sequences which create distinct properties and behaviors in its various forms.

Tetrahedral units feature corner-sharing interactions among themselves to form a honeycomb structure and allow atomic cores to move independently while still maintaining structural integrity - this allows SiC to be manufactured into an infinite variety of shapes and dimensions while still remaining strong and secure.

Silicon carbide's ability to withstand extreme conditions makes it a popular engineering ceramic material. Used in mechanical applications like pumps, bearings and seals as well as thermal shock resistance better than most materials, silicon carbide makes an excellent abrasive material with high thermal conductivity making it suitable for furnace linings and heat shields.

Thermal Conductivity

Silicon carbide (SiC) is a nonoxide ceramic used in numerous demanding industrial applications, from abrasives as grit for grinding wheels and cutting tools, refractories lining industrial furnaces, ceramic components like wear-resistant parts for pumps and rocket engines, wear-resistant parts in aircraft engine components, semiconductor substrates and semiconductor material substrates - it's no secret why SiC ranks third hardest among known substances after Boron carbide and Diamond!

Silicon Carbide, with a Mohs hardness rating of 9, is an exceptionally strong and scratch resistant material that is found naturally as the gem moissanite or manufactured commercially via chemical reactions between silica and carbon in electric resistance furnaces at high temperatures.

Pure silicon carbide monocrystals exhibit a thermal conductivity of 490 W/(m K). Polycrystalline SiC has much lower conductivity due to random orientation of grain boundaries, lattice impurities within grains, and secondary phases with poorer conductivity at their grain interfaces [1.]

Dopants such as boron and aluminum can be added to silicon carbide in order to modify its molecular structure, creating either a p-type or an n-type semiconductor. N-type semiconductors are more often used for electronic applications due to being more energy-efficient; gallium nitride has 10x higher voltage resistance. Doping silicon carbide with these dopants allows it to function at higher voltage levels while remaining reliable over its lifespan.

Strength

Silicon carbide is one of the strongest materials known to man, boasting ten times greater strength than steel and higher hardness than diamond. Furthermore, it serves as an excellent conductor of heat and electricity while remaining corrosion-proof.

Silicon carbide material can be produced in various forms depending on its final use, with sintered silicon carbide being one of the more prevalent options. Sintered silicon carbide is an easily produced self-bonded material created using hot pressing, microwave sintering, pressureless sintering and reaction sintering processes; ceramic powder may also be combined with silicon nitride for production of nitride bonded silicon carbide (NBSC), an option commonly seen in tools, cutting equipment and bulletproof armor applications.

Nitride-bonded silicon carbide (NBC) is created by bonding SiC ceramic powder with nitrides such as Ti and Zr to produce a durable yet lightweight material that can withstand ballistic threats. NBC is often chosen for high-end products like bulletproof vests and aircraft parts due to its durability against ballistic threats; additionally it's popularly used as an abrasive wheel material and grinding stone material, being especially suitable for extremely high temperatures and pressures; moreover it is preferred for use in grinding stones due to its durability as well as cost effectiveness; press blocks can then be joined together using welding techniques allowing this material's versatility being used as part of various products like kiln shelves or furnace linings as well as being cut using waterjet cutting technologies to produce components of high quality components from this durable material.

0 notes

Text

Hope you're having a great day. The number one concern people have when I talk to them about automated parking is how reliable is your system? Is this thing going to break a lot? Are you going to be out there to fix it? Are we going to be taken care of?

I just want to make sure my tenants are up and running and don't have to worry about this. So this is probably the most important thing we focus on with all of our systems. It's important to note that we are an integrated provider, so we do everything for you. We're one point of contact from design, manufacturing, installation, service.

So really, we don't want to be on site a lot, doing a lot of service. We really want to focus our efforts on design, maintenance and installation, making sure these systems run, and not being out there a lot, servicing them. So if you look at our different systems, the mechanical, hydraulic car stacker, these have been in the market for many years.

They're super bulletproof and reliable. They can be in all kinds of weather. Indoor, outdoor, inclement weather, snowing, don't require a roof. We'll be out there during the year to maintain them. Basically make sure the connections are there, it has fluid, everything's working well, doesn't actually require a lot of maintenance with those.

For our puzzle system, there's more aspects of that. To really have a reliable puzzle system, it starts with the equipment. And this system has been installed in over 100 installations. We've refined it, many different iterations. We've swapped out parts for the best quality, long lasting parts in there as well, so it'll run. Our design engineer has over 25 years in the business. He's designed hundreds of these systems, maybe thousands.

And the reason why that's important is he can look at a design and say, are the motors lined up right? Is this traversing right, is this too close to the wall? Is this going to work? So we know when it's installed, before it's installed, that it's going to work. Number three is really the installation. That's one of the things we saw in this industry that's really lacking.

And it starts with the steel erection has to be

designed plumb, level, true and square. If it's not,

the system will scrape and it will lead to service issues.

Next is the electrical installation and then the commissioning the

project. So our service people are involved with those three critical

points to sign off on them before they inherit it.

And then lastly, we have our remote connect system, so we can remote

into your system. We'll get alerts if there're any issues we can troubleshoot

remotely. Most of the time, we can solve it in minutes without

coming on site. So greater system uptime,

greater customer experience. If we have to send somebody out there, we will.

https://lnkd.in/gt-ErFRK

#the automated parking company#automated parking systems#puzzle parking#puzzle parking system company#agv parking system#puzzle parking system#puzzle parking system cost#puzzle parking system price#puzzle parking systems#agv parking

0 notes

Text

Most (And Least) Reliable Small Cars

Used car prices have soared in 2023 for several reasons, including the limited supply of fairly new models and the demand for cleaner used cars for sale for use in low-emission zones.

That means it’s more important than ever to choose your second-hand car wisely, and reliability is a crucial factor in keeping costs down – especially if you’re buying an older car that’s no longer covered by the manufacturer’s warranty.

A dependable model shouldn’t land you with anything other than routine servicing and maintenance bills for the foreseeable future. However, if you pick a car that’s prone to faults, you could end up facing a constant barrage of expensive repair bills.

To help used car buyers select the best models aged from six to 20 years old, WhatCar? asked nearly 25,000 car owners to tell them how reliable their cars had been over the previous 24 months. This data forms their annual What Car? Reliability Survey which is compiled in association with MotorEasy.

The most reliable small cars

1. 2015-2020 Honda Jazz

Reliability rating 100%

The third-generation Jazz offers the low running costs you’d expect of a small car and the space and practicality of a mini MPV. On top of that, it’s very unlikely to let you down because it’s extremely robust. In fact, not a single older Jazz suffered any faults at all, according to the owners who completed our survey.

2. 2011-2020 Toyota Yaris

Reliability rating 98.6%

Toyota has a rock-solid reputation for building dependable cars – it’s been in the top three brands in our newer car reliability survey for the past six years, so it’s a great choice if you want a car that won’t let you down. Just 5% of the cars we were told about had a problem and the only area concerned was the suspension.

3. 2010-2017 Suzuki Swift

Reliability rating 98.1%

The Swift might not be the most popular small car, but it’s got a lot going for it, including great driving manners, a reasonable amount of space and a high rating for safety. Like other Suzuki models, it’s also bulletproof, even as it ages. Only 6% of the Swifts in our survey developed a fault, and the battery was the only component affected.

The least reliable small cars

3. 2010-2016 Nissan Micra

Reliability rating 66.4%

The Micra suffers more than its fair share of problems, according to owners, who told us 47% of their cars had gone wrong in the previous 24 months. The most common gripe was about the suspension, affecting 29% of faulty cars, followed by the engine’s electrical systems (18% of faults). Problems rendered 50% of cars undrivable and kept a similar proportion in the garage for up to a week. Cars were often costly to put right.

2. 2002-2008 Ford Fiesta

Reliability rating 65.5%

The Fiesta is cheap to buy and fun to drive, but it’s no joy to live with if you get one that suffers a string of costly faults. And that is a possibility because owners told us that 46% of their cars had suffered an issue. The most frequent trouble spot was the suspension, affecting 18% of broken cars, but there were also issues with the air-con, bodywork, exhaust and gearbox. Two-thirds of faulty cars could still be driven, and 45% were out of the workshop in less than a week, but some repair bills were pricey.

1. 2010-2016 Citroën C3

Reliability rating 53.0%

A wide range of issues affected the C3s we were told about, but the most frequent were with the air-con and braking system. They rendered more than 50% of cars undrivable and kept 40% of them in the garage for more than a week.

Find a quality used car for sale in Stellenbosch at great prices.

.

.

.

.

Article shared from https://pre-ownedsmarts.postach.io/post/most-and-least-reliable-small-cars

0 notes

Text

All the tut-tutting over how the cybertruck’s door skins can stop bullets (what caliber and range was that even tested at?) and how it’s unsafe for crashes is quite easily some of the stupidest hand-wringing I’ve seen in a second. A bunch of bullet pinpoints do not equal the force required to actually showcase side impact crumple zones, but even if they did the door skins of a car are not what actually absorbs being hit by a car!

The door skin in your average automobile is made out of relatively thin metal that’s easy to shape and manufacture. A RAV4 slamming into you doesn’t care that your door skins are soft and not bulletproof.

What actually absorbs most of the impact is the actual frame below the surface of the door, and even more than that is the actual body of the car below that.

Elons Gimmick machine is more of a death trap for having electronically actuated doors than stopping bullets, but other car companies do that too so it’s not as fun of a dunk I guess.

0 notes

Text

Top 10 Best Armored Cars For Heads Of State

youtube

Top 10 the Best Bulletproof cars

Bulletproof cars ensure the safe transport of world leaders and top dignitaries, and there is nothing to stop a rich person from buying one.

📌 People also ask:

✔️ Which is the best bulletproof car?

✔️ What is the strongest bullet proof car in the world?

✔️ Can a car be 100% bulletproof?

✔️ Are luxury cars bulletproof?

📌 Related searches:

✔️ top 10 bulletproof cars in the world

✔️ best armored vehicles military

✔️ bulletproof car name

✔️ best bulletproof suv

✔️ bentley bentayga armoured

The fortification level of highly customized security-grade cars is astounding. Vehicles must be built to withstand specific types of attacks in order to be certified. Instead of crash tests, automobile manufacturers must submit the car to ballistic testing. The car must be secure enough to shield dummy passengers from damage. Ballistic situations range from gunfire, machine gun fire, and grenade bombs.

#RollsRoyce#RollsRoycePhantomSeriesII#Bentley#BentleyArnageR#Audi#AudiA8LSecurity#Aurus#AurusSenat#Toyota#ToyotaCenturyRoyal#Cadillac#CadillacOne#DS7CrossbackÉlysée#Mercedes#MercedesMaybach#MercedesS600PullmanGuard#RangeRover#RangeRoverAbioSentinel#MercedesS680Guard#Youtube

1 note

·

View note