#calibrate instruments

Explore tagged Tumblr posts

Text

#temperature measurement equipment#temperature measurement devices#calibration solutions#calibrate instruments

0 notes

Text

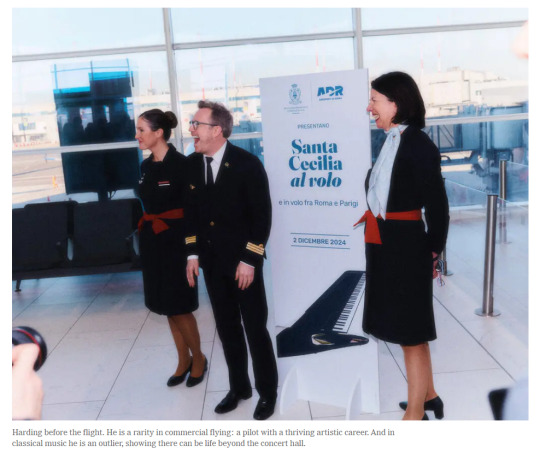

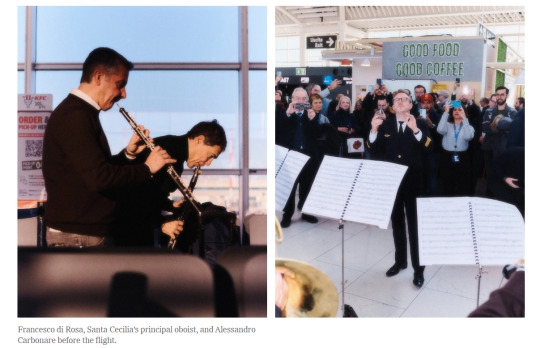

On a stormy day more than 34,000 feet above Paris, Air France Flight 1205 prepared to make its descent. Flight attendants began checking seat backs and tray tables, and passengers groggily emerged from naps. Then a voice from the cockpit came over the intercom, offering an update on the weather (cloudy and 54 degrees) and the remaining flight time (about 30 minutes). “Thank you for choosing Air France,” said Daniel Harding, the flight’s first officer. “And remember: Rehearsal is at 6 p.m.” The cabin erupted into whistles and cheers. Harding, 49, an Air France pilot, also happens to be one of the world’s top orchestral conductors. And on this December day, he was flying his ensemble, the esteemed Orchestra dell’Accademia Nazionale di Santa Cecilia, from its home base in Rome to Paris for the start of a European tour. (A few dozen unknowing members of the public were also aboard.)

from The Flying Maestro: A Top Conductor Moonlights as an Air France Pilot, written by Javier C. Hernández for The New York Times, January 9th 2025. Photos by Benjamin Melapris.

#dude is lowkey living my dreams aka being able to tamper with instruments and heavy calibre machines#(my concert organist brother-in-law is kinda like this too but instead of planes he teaches latin and ancient scripts lol)#now how do i tag this... lets seee#conductor#photos#classical music#stories#pilot#*#reading excerpts

2 notes

·

View notes

Text

Imaging Solutions

#Metrology equipment#Metrology tools#Tool maker microscope#Calibration in metrology#Metrology and measuring instruments#Metrology measuring instruments#Optical comparator in metrology#Metrology tools semiconductor#Metrology machines#Metrology and measuring instruments in India#Calibration in metrology in Gurugram#Dimensional Measurement Instruments Suppliers in Gurugram#star wars#succession#super mario

4 notes

·

View notes

Text

Ensure accuracy, safety, and compliance with expert Instrument Calibration Services in Houston by Industrial Scale & Measurement. Reliable results, every time. Get more information :https://scaleandmeasure.com/calibration-services/

0 notes

Text

Tuning a NASA Instrument: Calibrating MASTER

NASA’s Ames Research Center in Silicon Valley houses a unique laboratory: the Airborne Sensor Facility (ASF). The engineers at the ASF are responsible for building, maintaining, and operating numerous instruments that get deployed on research aircraft, but one of their most important roles is instrument calibration. Think of calibration like tuning a piano between performances: […] from NASA https://ift.tt/ytip0Sf

0 notes

Text

Why Factory Verified Calibration Services Matter: Choosing the Right Calibration Company

As pioneers in the test and measurement sector, Arabcal LLC defines the standard for precision and dependability. Through our calibration solutions, you receive factory-level accuracy for your equipment. Experience the advantage of working with experts who have led the way in measurement excellence for decades.

Explore the Exceptional Benefits of Arabcal LLC Certified Calibration Solutions

Comprehensive Maintenance Checks: Our Factory Verified Calibration goes beyond standard calibrations, incorporating additional preventative maintenance checks across the full range of instrument operation. Keeping your equipment in top shape, optimizing performance throughout the plan.

Firmware and Software Upgrades: Stay ahead of the curve with regular firmware and software updates for your instruments. Experience the latest features and enhancements, ensuring your equipment operates at its full potential.

What is the difference between Factory-Verified & OEM Compliant Calibration?

In the accuracy-focused field of calibration, recognizing the differences between service types is essential to maintain peak instrument performance. Arabcal LLC, a frontrunner in calibration solutions, provides two specialized services: Factory-Certified Calibration and OEM-Standard Calibration.

High-Quality and Accurate & Accredited Calibration Service

We are proud of our team of expert Calibration Specialists and Customer Support Engineers, whose exceptional knowledge ensures reliable servicing of a broad spectrum of test and measurement instruments.

You can trust that each instrument is calibrated with thorough attention to detail, adhering to strict certification and accreditation standards set by independent recognized bodies and aligned with NIST traceability guidelines, guaranteeing consistent precision, accuracy, and dependability.

With Arabcal LLC, you can have complete confidence that your critical equipment is handled by experts who are committed to delivering precision, dependability, and consistent accuracy.

Tailored Solutions for Your Specific Needs

Every engineering and manufacturing operation is unique, and we recognize that. That’s why we don’t believe in a one-size-fits-all approach. Our committed team of Calibration Experts, Material Coordinators, and Customer Support Engineers works collaboratively with you to understand your specific needs, challenges, and objectives. We then craft tailored service solutions that align seamlessly with your goals, empowering you to concentrate on innovation and optimizing production performance.

Trusted Partnership Approach

At Arabcal LLC, we view ourselves not merely as service providers but as dedicated partners in your success. Our focus on fostering long-term partnerships ensures you can depend on us for not only exceptional service but also continuous support and teamwork. Together, we’ll navigate challenges and drive your operational goals forward.

Arabcal LLC: Setting the Standard for Precision Calibration Services in QatarIn conclusion, when it comes to precision, reliability, and customized calibration solutions, Arabcal LLC stands out among the leading calibration companies in Qatar. With a commitment to excellence, advanced technology, and a customer-first approach, Arabcal delivers factory-verified and OEM-compliant calibration services that meet the highest industry standards. Their expert team ensures your equipment performs at its best, making Arabcal LLC the trusted partner for businesses seeking accuracy, compliance, and long-term operational success in Qatar’s growing industrial landscape.

#instrument and equipment supplier in uae#calibration#iso 17025 accredited calibration company in uae#calibration lab#qatar

0 notes

Text

#Calibration Service Dubai#Equipment Calibration Dubai#Instrument Calibration UAE#Temperature Calibration Services UAE

0 notes

Text

Understanding Calibration Services: Beginner’s Guide

In a world where precision and accuracy matter more than ever, calibration services play a crucial role in ensuring the reliability of measurements across industries. Whether you're running a laboratory, a manufacturing plant, or a research facility, having your instruments properly calibrated can make all the difference. If you're new to this concept, don’t worry — this guide is here to help you understand the basics of calibration services, especially if you're looking for Calibration Services in Jaipur.

What Are Calibration Services?

Calibration is the process of comparing the measurements of an instrument to a known standard and making adjustments if necessary. Think of it like tuning a guitar. Over time, strings can get out of tune, and you need to adjust them so they sound just right. Similarly, measuring instruments can drift from their original accuracy, and calibration helps bring them back to their correct values.

Calibration services ensure that tools and instruments — whether they're weighing scales, pressure gauges, temperature sensors, or lab equipment — give precise and consistent results.

Why Is Calibration Important?

You might wonder why calibration is such a big deal. Here are a few key reasons:

Accuracy: Regular calibration ensures your equipment provides accurate readings, which is especially important in fields like pharmaceuticals, electronics, and research.

Safety: Incorrect readings in sensitive environments, such as chemical labs or medical settings, can be dangerous. Calibration minimizes that risk.

Compliance: Many industries must meet strict regulatory standards. Calibration ensures your instruments stay compliant with ISO, NABL, or other quality frameworks.

Cost Efficiency: Uncalibrated instruments can lead to product defects or process errors, costing time and money. Calibration helps reduce these costly mistakes.

Types of Calibration Services

When we talk about Calibration Services in Jaipur, it's important to know the different kinds available:

1. Instrument Calibration Services in Jaipur

This involves checking and adjusting tools like multimeters, pressure gauges, and torque wrenches used in industries ranging from automotive to aerospace. These services help businesses maintain accurate results and high-quality output.

2. Laboratory Instrument Calibration in Jaipur

Labs require extremely precise instruments. This type of service focuses on devices like spectrophotometers, pipettes, balances, and temperature chambers. Proper calibration ensures these instruments give trustworthy data — which is critical in research and development and Laboratory Instrument Calibration in Jaipur is Important for work and precise data.

How Calibration Services Work

The process typically involves a few essential steps:

Initial Assessment: The instrument is evaluated to see if it functions within acceptable limits.

Comparison with Standards: The instrument is tested against certified reference standards, often traceable to national or international bodies.

Adjustment (if required): If the device is not accurate, technicians adjust it.

Documentation: A calibration certificate is issued, showing the test results and confirming compliance.

In Jaipur, many certified labs offer these services using advanced tools and experienced professionals. Look for NABL-accredited providers for the most reliable outcomes.

When Should You Calibrate Your Instruments?

There’s no one-size-fits-all answer. However, regular intervals such as every 6 to 12 months are common in most industries. Other signs that you may need calibration include:

Sudden changes in readings

After a repair or mechanical shock

Post-installation of new equipment

Before critical measurements

Choosing the Right Calibration Partner in Jaipur

When searching for Calibration Services in Jaipur, it’s essential to pick a provider that understands your industry needs and follows international standards. Ask about:

NABL or ISO certification

Turnaround time

On-site vs. in-lab calibration

Calibration scope and documentation provided

A reliable partner not only performs the service but also guides you on how to maintain your instruments in optimal condition.

Final Thoughts

Calibration might sound technical, but it’s simply about ensuring your instruments work correctly and reliably. Whether you’re managing a research lab or running a factory, investing in Instrument Calibration Services in Jaipur helps you achieve better accuracy, efficiency, and safety.

And if you’re in the scientific or industrial field, regular Laboratory Instrument Calibration in Jaipur isn’t just good practice — it’s essential. With trusted calibration service providers available locally, maintaining precision has never been more accessible.

Ready to get started? Ensure your equipment is in top shape by choosing expert Calibration Services in Jaipur that you can rely on. Your data, processes, and results depend on it

Also Read: NABL Calibration Services: Ensuring Accuracy and Compliance in Testing

#Laboratory Instrument Calibration in Jaipur#Instrument Calibration Services in jaipur#Calibration Services in jaipur

0 notes

Text

The Impact of Temperature on Pipetting Accuracy

Pipetting is an essential laboratory process, and depends heavily on precision instruments like micropipettes. Whether you're using an automatic micropipette for high-throughput experiments or a manual micropipette for delicate tasks, maintaining accuracy is essential. However, one often-overlooked factor that can significantly influence pipetting accuracy is temperature.

Let’s explore how temperature affects pipetting accuracy and how you can mitigate these challenges for reliable results.

How Does Temperature Affect Pipetting Accuracy?

Thermal Expansion of Liquids and Instruments Temperature fluctuations directly impact liquid density and volume. For instance, warmer liquids expand, which can lead to inaccurate volume measurements. This is particularly important when working with nanoliter dispensing or small volumes where even minor variations can cause significant errors. The mechanics of micropipettes, including pipette calibration standards, are also influenced by temperature. Plastic components in an auto micropipette or graduated micropipette may expand or contract, affecting their calibration.

Vapor Pressure Changes High temperatures can increase the vapor pressure of volatile liquids, making precise liquid handling more challenging. In such cases, using specialized micropipette tips designed for volatile substances can help.

Operator-Related Factors Human body heat can subtly affect the pipette price you pay in terms of accuracy. For example, holding the micropipette for extended periods might warm it up, leading to slight deviations in the dispensed volume. Understanding this interaction can help you choose the right types of micropipette for your tasks.

Best Practices for Mitigating Temperature Effects

Use Temperature-Adapted Tools Modern micropipette technology includes tools designed to minimize temperature effects. Investing in an automated micropipette or a well-calibrated micropipette pipette ensures consistent performance.

Pre-Equilibrate the Pipette and Liquid Allow both your automatic micropipette and the liquid to equilibrate to room temperature before beginning your work. This reduces discrepancies caused by temperature differences.

Calibrate Regularly Regular pipette calibration ensures your instrument remains accurate despite environmental changes. Calibration services often account for temperature variations when setting pipette calibration standards.

Choose the Right Tools Selecting the right pipette, whether it’s a micropipette pipette, an auto micropipette, or a graduated micropipette, for your specific application is crucial. For high-precision tasks, consider a pipette with nanoliter dispensing capabilities.

Monitor Environmental Conditions Maintain a stable lab environment to minimize temperature fluctuations. Using precision instruments in a controlled setting ensures more consistent results.

Why It Matters

Accurate pipetting is essential in fields like molecular biology, drug development, and clinical diagnostics. Inaccuracies, even if minor, can lead to failed experiments, increased costs, and unreliable results. By accounting for temperature effects and investing in reliable tools like automatic micropipettes or glass micropipettes, you ensure better reproducibility and efficiency.

Final Thoughts

Temperature plays a subtle but significant role in pipetting accuracy. Understanding its impact can help you make informed decisions, whether you're choosing a new micropipette pipette, comparing micropipette cost, or learning about the mechanics of micropipettes. Regular calibration, proper usage, and investing in advanced micropipette technology can mitigate temperature-related challenges, enabling accurate and reliable liquid handling every time.

Whether you're handling nanoliters or milliliters, accuracy is non-negotiable. Choose the right pipettor at the right pipettor price, calibrate regularly, and always consider environmental factors like temperature to achieve the best results in your work.

#micropipette#pipette calibration standards#types of micropipette#liquid handling#liquid handling instruments#pipettes#micropipette pipette

1 note

·

View note

Text

Calibration technician (M/F/D)

Ready for a professional adventure with us?

WHAT TO EXPECT AT TECHFIRM

Exciting projects that showcase your exceptional expertise.

Opportunities for professional development in a collaborative and innovative environment.

A warm and stimulating team atmosphere.

Voir l'offre (en anglais).

1 note

·

View note

Text

2 notes

·

View notes

Text

Coating Thickness Gauge

#Metrology equipment#Metrology tools#Tool maker microscope#Calibration in metrology#Metrology and measuring instruments#Metrology measuring instruments#Optical comparator in metrology#Metrology tools semiconductor#Metrology machines#Metrology and measuring instruments in India#Calibration in metrology in Gurugram#Dimensional Measurement Instruments Suppliers in Gurugram#succession#star wars#super mario

2 notes

·

View notes

Text

Annual instrument calibration ensures accurate measurements, reduces waste, prevents production delays, and maintains compliance. Trust Industrial Scale & Measurement for reliable calibration services.

Get more information visit: https://scaleandmeasure.com/calibration-services/

0 notes

Text

How Accurate Calibration Services Enhance Marine Safety?

In the maritime industry, accurate instrument calibration is crucial for safety, compliance, and efficiency. Instruments can drift out of calibration due to environmental factors, risking navigational errors and undetected hazards. Regular calibration ensures precise data from gas detection systems and navigation equipment, minimizing risks. It enhances safety, ensures regulatory compliance, boosts operational efficiency, and saves costs by preventing expensive repairs. Invest in reliable calibration services to protect your crew and optimize your maritime operations. Contact Blessed Marine Automation for top-notch marine services!

#marine services#instrument calibration#equipement calibration#marine engineering#calibration services

0 notes

Text

The Role of Precision Dimensional Instruments in Modern Product Inspection

Precision is crucial for industries to produce components with the correct shape and size. Dimensional measurement instruments are tools used to accurately assess parameters such as length, diameter, circumference, and other two-dimensional and three-dimensional metrics. These measurements are essential for manufacturing sectors to ensure the precise creation of each part.

Dimensional measurement devices come in various forms depending on their functionality and design. Common types include manual tools, air gauging instruments, optical devices, and coordinate measuring machines (CMMs). In this article, we’ll explore 5 commonly used dimensional inspection instruments that play a key role in enhancing product quality across industries, available through Arabcal LLC.

Top 5 Types of Dimensional Measurement Instruments

Vernier Caliper

Micrometer

Dial Indicator

Coordinate Measuring Machine (CMM)

Height Gauge

1. Vernier Caliper

Vernier calipers are high-precision tools used to measure linear dimensions such as length, depth, and diameter. They are especially effective for accurately determining both internal and external diameters, and are also commonly used for depth measurements. Based on application needs, Vernier calipers come in two variants – one with a dial gauge and the other with a digital (LCD) display. During measurement, the readings are shown either on the dial or the digital screen. These calipers feature two scales: the primary (main) scale, which indicates whole numbers, and the Vernier scale, which provides precise decimal readings.

2. Micrometer

A micrometer is a highly accurate measuring tool used to determine the thickness and diameter of a workpiece. It features a C-shaped frame with a movable component known as the spindle, and relies on finely calibrated screws to deliver exact measurements. One end is called the spindle, while the opposite side is referred to as the anvil. The item to be measured is positioned between these two parts, and the spindle is adjusted until it securely holds the object in place. Once properly set, the measurement can be read either from a digital screen or an analog scale.

3. Dial Indicator

A dial indicator, also referred to as a dial gauge, is a precision measuring instrument used to detect minute distances, dimensional deviations, and angular shifts. It operates through a rack and pinion mechanism that translates the movement of the probe tip (contact point) into rotational motion, causing the dial needle to move clockwise as the tip is pressed into the housing. Dial indicators are commonly employed to check tolerances, clearances, and discrepancies in machined components, offering accuracy up to one-thousandth of an inch. Their high sensitivity enables them to identify even the slightest surface irregularities.

4. Coordinate Measuring Machine

A coordinate measuring machine (CMM) is a precision instrument used to evaluate the physical and geometric properties of an object. It determines dimensions such as height, width, and depth by applying principles of coordinate geometry. By pinpointing specific locations on the surface, the machine uses a probe to capture the object’s physical characteristics. This probe moves along three axes—X, Y, and Z—to collect data points essential for calculating accurate measurements. Depending on their specific applications, CMMs are available in different configurations, including bridge type, cantilever, and horizontal arm models.

5. Height Gauge

A height gauge is an accurate vertical measuring instrument used to determine the height of an object from a defined reference surface. It can measure vertical distances or elevations of various items, typically up to 1800 mm. Height gauges can assess both internal and external heights relative to a base reference plane. The main parts of this device include the base, sliding beam, measurement face, slider, and locking screw. The item to be measured is positioned against the measuring surface and base, and the corresponding measurement is displayed on a digital readout.

Precision Measurement Solutions by Arabcal LLC

To guarantee that products are produced according to exact specifications and precise dimensions, dimensional measurement instruments play a vital role. Arabcal LLC, a leading test and measurement instruments supplier in Qatar, offers a wide range of measuring tools designed to enhance product safety and ensure quality and structural integrity. Whether you need to measure internal features, external surfaces, or complex shapes, these instruments provide highly accurate results. For more detailed information or to request a quote, feel free to contact Arabcal LLC — your trusted partner for precision measurement solutions across all industries in Qatar.

#instrument and equipment supplier in uae#biomedical test equipment#calibration#iso 17025 accredited calibration company in uae#pressure and temperature chart recorder in uae

0 notes

Text

Ensure Accuracy with Precision Calibration Lab’s Electro-Technical Instrument Calibration

At Precision Calibration Lab, we specialize in Electro Technical Instrument Calibration to ensure your devices deliver accurate and reliable measurements. From voltmeters to oscilloscopes, our state-of-the-art facility is equipped to handle a wide range of instruments. Our expert technicians follow stringent standards to calibrate your equipment, reducing errors and ensuring precision. Trust us to enhance the performance and compliance of your electro-technical instruments, so you can focus on what matters most—accuracy and efficiency in every operation.

#electro technical instrument calibration#PrecisionCalibration#InstrumentCalibration#AccurateMeasurements#CalibrationServices

0 notes