#carton inspection system

Text

#carton inspection system#variable data printing#print inspection system#Variable data inkjet printing machines#Data Printing Retrofit#Digital Inkjet Printing Technology

1 note

·

View note

Text

Pretzel

Steve Harrington runs an animal shelter with his friend and fellow veterinary Robin.

They have a joke between them: they often have to take in poor unfortunate abandoned pets, and they used to name them after the last thing Steve ate. All started years ago, when Robin came in with a rescued parrot and asked Steve how they should name it, who distractedly answered “Montecristo,” pointing at the half sandwich on his desk. Montecristo has been the shelter mascot since then and Robin, after laughing out loud for a good minute, declared the tradition set up.

He finds a carton box this day on the clinic door, and there are Pretzel, Brownie and Caesar (salad), Steve’s lunch he just ate in the cafeteria at the corner. They are so tiny they can easily rest in Steve’s hands, they have to be bottle fed every four hours for some day until they can eat alone, and the red Pretzel is the real incarnation of the very Satan.

This fluffy demon is able to eat the entire prescription book on Robin’s desk, he learned how to open his cage at night and he plots new pranks everyday, bribing his sibling with the delicious treats Steve hides in his drawers.

The kitty is on a shelf, adjusting his bottom to the distance, and then…

“Robin! The demon jumped on my head! Come and catch him!”

Robin runs in the room, laughing out loud. She takes the furious, hissing kitty and returns him in the cage, locking it with the complicated system of chains, sticks and duct tape they invented to keep him in.

“It’s funny, he seems to attack only you,” Robin laughed, checking the scratches on Steve’s neck.

“He hated me. I bottle fed him and he hates me,” whimpers Steve.

“Welcome to parenting,” Robin laughed again, disinfecting him.

A few days later, Pretzel is missing.

“Where is the little demon? The cage is closed!” Rambled Robin, inspected the shelf.

The little demon has been secretly and patiently breaking the bottom of the cage, ripping the wood and the plastic until he can fit in the hole and disappear.

“He can be everywhere! We left the door open when we cleaned before!” Robin was worried and angry with herself, they need to have a thousand eyes with all these little rascals inside…

They turn everything but the cat isn’t there. Steve walked a hundred times the street back and forth, calling him, but without success. He asked their neighboring shops if they saw a little ginger cat that probably would try to kill them if they tried to catch him.

The only one he can’t advise is the mechanic shop three doors down at the other side of the street.

Steve has already seen the blonde, handsome mechanic, most of the time covered in car grease and a stupid sexy overall he leaves open on his chest, but he has neves spoken to him. He just stared at him most of the time, and at this moment the shop seems closed.

Steve and Robin wait and search all day for little Pretzel, but at a certain moment Robin has to clock out and go home, Steve stays for some paperworks.

An instant before, the bells on the door ring and Steve snorts.

“Robin, what did you forget this time?”

“I’m not Robin and maybe I have something you want back”.

Steve raises his eyes and remains mouth wide open for a while.

The blonde, hot mechanic he likes to stare at is here in front of him, only this time he is perfectly cleaned and combed and his hair isn't covered in dark oil. Steve can smell the colony from his desk.

The mechanic opens his jacket and shows a little ball of red fur, sleeping and purring against his chest. Steve has never seen Pretzel sleeping so peacefully and surely he has never heard him purring.

The blonde man raises the cat to his face and rubs his face to the content kitty (when Steve tried to do it, he almost lost an eye), and the kitty seems to really smile at the blonde while mocking Steve with the corner of his eye.

“Hey princess!” Call the mechanic again. “Is he the kitty you were searching for? Mary from the cafe said something”.

Steve blinks and shakes, then nods.

“Yes, of course, he is! Thank you!”

“What’s his name?”

“Well, he is Pretzel…”

“Oh, really? I really, really love pretzels…” answered the mechanic, rubbing the cat more to him. “Is the little Pretzel available for adoption?”

Steve is fascinated by the hot man playing with the kitty, but he has to shake his head.

“Not now, Pretzel has a condition we need to treat. But when he will be ok, we can consider your offer”, he says, raising his hands to take the animal. He has to get near the mechanic, inside his personal space, and blushes and shivers when they touch each other.

“Well, can I contribute to his treatments?” Insists the blonde.

“Well, it’s all covered really…”

“At least can I buy you a drink? I’m Billy, by the way”.

Steve puts Pretzel down in another cage, really hoping he could stay there for at least a night. He turns his back to Billy so he can’t see him blushing furiously.

“Well, okay…” he whispered, shivering a little and excited.

The drink rapidly becomes a sandwich and an ice cream, and a ride on Billy's vintage Camaro.

“Do you like it?” Says Billy. “I can take you for a ride, if you want”.

The next morning, Robin finds Steve already at his desk in the early morning.

“Steve? Are you here so early? You look tired! Did you find Pretzel?”

Steve nodded.

“Steve? Are you wearing the same clothes of yesterday?”

“Oh, don’t be silly, Robin!”

The doorbell rings and Robin goes to speak with a man with a carton box. She returned putting the box with a mallard duck on the desk.

“Look what people throw away nowadays… Well, Steve, did you have breakfast?”

Steve blushes and shakes his head slowly, lowering his eyes.

Robin is puzzled. “Well, we have to name that little one, what is the last thing you ate?”

Steve blushed even more, sinking in his chair.

“Billy. Her name is Billy”.

#stranger things#writing#billy hargrove#steve harrington#harringrove#veterinary#kitty cat#red cat#mechanic Billy

103 notes

·

View notes

Text

Residential Roofing - What You Need to Know

alt="Residential asphalt shingle roofing system installation"

Prevent having your residential roofing system improperly installed or assembled with poor-quality material. Knowing how components of a residential roofing system are made and installed will help you acquire the best quality residential roof and its installation in the Atlanta metro area.

newimageroofingatlanta.com gathered the following residential roof anatomy, manufacturing, and installation information to help you when selecting a roofing system, its components, and the roof installer for your Atlanta, Georgia, home.

Residential Sloped Roofing System

A residential sloped roof is a protective shield for your home, safeguarding you from the elements while increasing your home’s structural integrity. An essential component of the roofing system is the shingle (a key component that enhances your home’s aesthetic appeal and contributes to the durability and longevity of its roof). Consider the following anatomy of a residential sloped roof:

1. Roof Deck – A sloped roof’s foundation is its deck, typically made of plywood or oriented strand board (OSB). It provides a sturdy base for the installation of roofing materials and ensures structural stability.

2. Underlayment – Beneath the roofing shingles lies the underlayment, a water-resistant barrier shielding the roof deck from moisture and helps prevent leaks. Common underlayment types include asphalt-saturated felt and synthetic materials like synthetic underlayment or rubberized asphalt.

3. Roofing Shingles – Roofing shingles are the visible layer of a residential sloped roof, providing protection and enhancing the overall aesthetics. There are various shingle types available, like asphalt shingles, wood shingles, metal shingles, and clay or concrete tiles. Among these, asphalt shingles are the most commonly used due to their affordability, durability, and ease of installation (specially cut or formed shingles are produced for the ridge and hips).

Asphalt Shingle Manufacturing Process

While asphalt shingle manufacturing and technology have evolved over the years, their basic composition has remained the same. Consider the following asphalt shingle manufacturing process:

Raw Materials – Asphalt shingle production begins with high-quality material selection. Fiberglass or organic mats serve as a shingle’s core, while asphalt acts as a waterproofing agent. Mineral granules are then applied for surface protection and UV resistance, and additives are incorporated to enhance the shingle’s fire resistance and flexibility.

Mat Preparation – The selected mat material (fiberglass or organic), undergoes a manufacturing process to reinforce its strength and durability. Fiberglass mats are made by weaving glass fibers together, while organic mats are typically composed of recycled felt paper.

Coating and Drying – The prepared mat is then coated with asphalt (front and back), using a saturation process to ensure consistent coverage. The coated mat passes through a drying oven, which allows the asphalt to rapidly cure and stabilize.

Granule Application – Once dried, the coated mat proceeds to the granule application process. A layer of ceramic-coated mineral granules is evenly distributed on the top surface of the shingle, providing color, texture, and protection against weathering elements. The granules are embedded into the asphalt surface to enhance adhesion and durability.

Cutting and Shaping – After granule application, the asphalt-coated mat is cut into individual shingles. This process can be done manually or using automated machinery, depending on the production scale.

Packaging and Distribution – Finished roofing shingles are carefully inspected for quality and packed into bundles or cartons. They are then shipped to distributors, contractors, and suppliers for installation on residential roofs.

Note: Read more about roofing shingle production and options by visiting this roof shingle manufacturer.

Residential Sloped Roof Installation

Installing a residential shingle roofing system requires careful planning, proper preparation, and skilled execution. Here is a step-by-step overview of the typical installation process:

Preparation and Safety – Before beginning any work, safety must be prioritized. This includes wearing appropriate personal protective equipment (PPE) like:

Hard hat

Gloves

Goggles

Non-slip footwear

Harness

The area around the home should be cleared of any obstacles, and precautions should be taken to protect landscaping and outdoor features or furniture.

Removal of Existing Roofing Materials (Tear-off) – If there is an existing roof, the first step is to remove the old roofing materials. This may involve stripping off old shingles, underlayment, and flashing. Care should be taken to dispose of the old materials properly.

Inspection and Repair – Once the roof is cleared, a thorough inspection should be conducted to identify any damaged roof decking, sheathing, or structural issues. Any necessary repairs or replacements should be completed before installing a new roofing system.

Underlayment Installation – Install the underlayment, which acts as a moisture barrier and provides an additional protective layer. Asphalt-saturated felt or synthetic underlayment is commonly used. The underlayment should be rolled out horizontally, starting from the bottom edge of the roof and overlapping each subsequent row by a few inches (to ensure proper watershed).

Flashing Installation – Flashing is used to prevent water penetration at vulnerable areas like:

Valleys

Chimneys

Skylights

Roof intersections

Flashing is typically made of metal or a flexible waterproof material. Flashing should be installed before the shingles, ensuring proper coverage, sealing, and drainage.

Starter Shingle Placement – These shingles have a specialized adhesive strip and are installed along the roof’s eaves. These specialized shingles provide a secure foundation for the rest of the shingles and help prevent wind uplift.

Shingle Installation – The chosen shingles are installed from the bottom up, working in rows. Each shingle is nailed or stapled into place using appropriate roofing fasteners. It is crucial to follow the manufacturer’s guidelines regarding nail placement, spacing, and shingle overlap (for best product performance).

Ventilation and Ridge Cap Installation – Roof vents or ridge vents are installed to ensure proper attic ventilation preventing moisture buildup, allow air circulation, and help regulate temperature and humidity. The ridge cap, a specialized shingle designed for the roof’s peak, is then installed, overlapping the adjacent shingles and providing a solid, finished look.

Cleanup and Final Inspection – Once the roof’s shingles are installed, the work area should be thoroughly cleaned, removing all debris or loose material. A final inspection should be conducted to ensure the roof is properly installed, all shingles are secure, and there are no visible issues or gaps.

Note: The specific installation process may vary depending on factors like the shingle type, roof design, and local building codes. It is recommended to consult with a professional roofing contractor for a precise installation or replacement tailored to your specific roof and location requirements. A well-installed residential shingle roofing system provides long-lasting protection, durability, and aesthetic appeal to your home.

Residential Asphalt Shingle Roofing

In this article, you discovered the composition of a residential roofing system, asphalt shingle manufacturing, and how residential sloped roofs are installed.

Understanding how residential roofing systems are built, manufactured, and installed will help you choose the best materials for your home’s roof.

Not knowing how to recognize quality roofing material or identify the steps in a roof replacement or installation will leave you vulnerable to unscrupulous and unprofessional roofers trying to take advantage of your need.

Sources:

energy.gov/eere/buildings/articles/cool-asphalt-shingles

gccds.msstate.edu/research/altconstruction/roof/roof.pdf

owenscorning.com

To see the original version of this article, visit https://www.newimageroofingatlanta.com/residential-roofing-what-you-need-to-know/

#Residential Roofing Atlanta#Roofing Contractors Atlanta GA#Roofer Atlanta GA#Residential Roofing Systems Atlanta#Shingle Roof#Asphalt Shingles

2 notes

·

View notes

Text

Food Packaging Equipment Market Poised to Achieve $25.37 Billion

Meticulous Research® - a leading market research company, published a research report titled “Food Packaging Equipment Market by Type (Form-fill-seal Equipment, Cartoning Equipment, Filling & Dosing Equipment, Wrapping & Bundling Equipment, Case Packing Equipment), Application, and Geography - Global Forecasts to 2029”.

The Food Packaging Equipment Market is poised for substantial growth, with an anticipated CAGR of 6% from 2022, projecting to reach $25.37 billion by 2029. In terms of volume, the market is expected to expand at a CAGR of 8% during the same period, reaching 12,131.3 thousand units by 2029. This growth is primarily driven by the increasing integration of automated technologies, machinery flexibility, and the rising demand for hygienic food packaging. Additionally, food manufacturers are increasingly inclined towards using efficient packaging products.

Emerging economies experiencing a surge in the packaged food industry and the use of packaging as a tool for product differentiation present significant growth opportunities for market players. However, challenges persist, including the high cost of advanced packaging solutions and stringent environmental regulations. Recycling complexities of multilayer films and a scarcity of skilled personnel further impede market growth.

The global food packaging equipment market is segmented based on type, application, and geography, with an in-depth analysis of industry competitors and country-level market assessment. The types of equipment include form-fill-seal, cartoning, filling & dosing, wrapping & bundling, case packing, labeling & coding, inspecting, detecting, and checking weighing machines, among others.

In 2022, form-fill-seal equipment is expected to dominate the market, particularly due to the speed and versatility it offers, streamlining packaging processes. This segment includes both vertical and horizontal form-fill-seal equipment, with the former accounting for a larger share due to its suitability for automated assembly-line packaging systems.

Application-wise, segments such as meat, poultry, and seafood are anticipated to hold significant market shares, driven by increased consumption of processed and frozen products. Geographically, Asia-Pacific is expected to lead the market, owing to rising packaged food applications and a high concentration of local packaging equipment manufacturers.

Download Free Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=5249

The key players profiled in the food packaging equipment market are Syntegon Technology GmbH (Germany), Coesia S.P.A (Italy), GEA Group Aktiengesellschaft (Germany), MULTIVAC Group (Germany), IMA Group (U.S.), Krones AG (Germany), Tetra Laval Group (Switzerland), OPTIMA Packaging Group GmbH (Germany), ARPAC LLC (U.S.), Ishida Co. Ltd (Japan), Omori Machinery Co. Ltd. (Japan), and TNA Solutions Pty Ltd. (Australia).

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of type, application, and geography?

What is the historical market size for global food packaging equipment across the globe?

What are the market forecasts and estimates for the period 2022–2029?

What are the major drivers, restraints, opportunities, and challenges in the global food packaging equipment market?

Who are the major players in the market, and what are their market shares?

How is the competitive landscape for the global food packaging equipment market?

What are the recent developments in the global food packaging equipment market?

What are the different strategies adopted by the major players in the market?

What are the key geographic trends, and which are the high-growth countries?

Who are the local emerging players in the global food packaging equipment market, and how do they compete with other players?

Contact us :

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Food Packaging Equipment Market#Food Packaging Equipment#Packaging Equipment#Food and Beverage Package Machines#Food Packaging Machine#Food Packaging

0 notes

Text

Gufic Biosciences Walk-In Drive in Indore

Gufic Biosciences Limited is excited to announce a walk-in drive for various positions in Production, Engineering, QC Chemical, and Microbiology. The drive will be held on 9th June 2024 in Indore. This is an excellent opportunity for professionals with relevant experience and qualifications in the pharmaceutical industry to join one of the world's leading lyophilized injectable plants. Immediate joiners will be given preference.

About Gufic Biosciences: Gufic Biosciences Limited is a global leader in the pharmaceutical industry, renowned for its innovative injectable formulations. Located in Indore, the company is dedicated to excellence in the production of high-quality pharmaceutical products. This walk-in drive aims to recruit talented professionals for multiple departments to support their expanding operations.

Walk-In Drive Details:

Date: 9th June 2024 (Sunday)

Time: 10:00 AM - 5:30 PM

Venue: The Red Maple Jhoomer Ghat, Rasalpura, Rau, Indore-453 446 (M.P.)

Open Positions: Gufic Biosciences is hiring for various roles across different departments. Here are the details:

Production Roles:

Designations: Jr. Technician, Technician, Officer

Qualifications: Diploma, ITI, B.Pharm, B.Sc

Experience: 1-8 years

Responsibilities: Vial Washing, Autoclave, GMP Washer, Filling & Sealing, Vial Collection, Terminal Sterilizer, Visual Inspection, X-ray, Packing, Blister, Cartonator

Engineering Roles:

Designations: Operators, Documentation Engineer, EHS Supervisor

Qualifications: Diploma, ITI

Experience: 1-7 years

Responsibilities: HVAC, Lyophilizer, Fitter, Refrigeration, Water System, EHS

Quality Assurance (QA) Roles:

Designations: Officer, Sr. Officer, Executive

Qualifications: B.Pharm, M.Pharm, M.Sc

Experience: 1-7 years

Responsibilities: Validation & Qualification, Lab QA, IPQA, QMS

QC Chemical & Microbiology Roles:

Designations: Officer, Sr. Officer

Qualifications: M.Sc, B.Sc, B.Pharm, M.Pharm

Experience: 1-5 years

Responsibilities: Analyst AMV, PV, RM/PM/FP, Stability, MLT, BET, Assay, EM, Media Preparation, Culture Identification

Candidate Requirements:

Experience: Minimum 1-8 years of relevant experience in the pharmaceutical industry.

Qualifications: Diploma, ITI, B.Pharm, B.Sc, M.Pharm, M.Sc

Note: Prior working experience in injectable formulation is preferred.

How to Prepare for the Walk-In Drive: Candidates are requested to bring the following documents:

Updated resume

Photocopies of educational certificates

Relevant experience certificates

Passport size photographs

Alternatively, Please share your resume on [email protected]

Immediate joiner would be given preference

[caption id="attachment_79820" align="aligncenter" width="930"] Gufic Biosciences Limited Recruitment - Job vacancies[/caption]

0 notes

Text

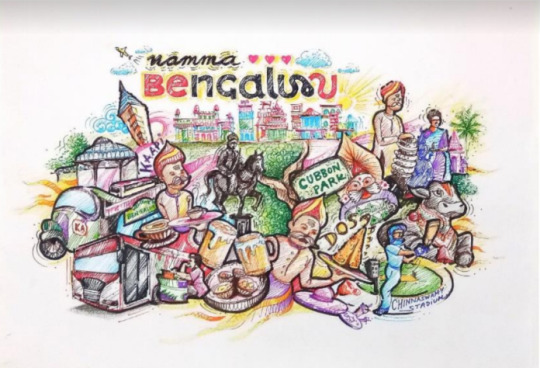

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025

at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision

Events Private Limited. "India is poised to become the world's third-largest economy

within the next five years, and we acknowledge that specific sectors as well as regions of

the country have played a crucial role in driving this growth. It is essential that we feature

them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.

Venue

The Bangalore International Exhibition Centre (BIEC) enhances its 77,000 square meters of covered space with aesthetically and functionally designed exhibition halls, along with vast open areas ideal for showcasing large and heavy machinery. The venue is conveniently linked via the Green Metro Line and is just a 45-minute drive from the airport and a 30-minute drive from the city centre.

Organizer

ReEnvision carries forward the legacy of its group companies that have launched or co-organized India’s most successful events in the printing and packaging sector including India Label Show, Pack Plus and PAMEX. ReEnvision Events Private Limited is a sister organization of Print-Packaging.com Private Limited.

"We are preparing to open bookings for the Show and anticipate a tremendous response from the industry,” concludes Anil Arora.

0 notes

Text

Revolutionizing Packaging: Continuous Cartoning Machines in India for Automatic Crown Capping Lines

Packaging automation, continuous cartoning machines have emerged as indispensable assets for manufacturers, particularly in India, where efficiency and reliability are paramount. Paired with automatic crown capping lines, these advanced systems offer seamless integration and unparalleled efficiency in the packaging process. This comprehensive guide explores the benefits and applications of continuous cartoning machines in India, specifically in conjunction with automatic crown capping lines.

Understanding Continuous Cartoning Machines in India:

Continuous cartoning machines are sophisticated packaging solutions designed to automate the cartoning process, efficiently packaging products into cartons with precision and speed. In India, where the demand for fast-paced production is ever-growing, continuous cartoning machines have become indispensable for manufacturers across various industries. These machines excel in handling a wide range of products, from pharmaceuticals and food items to cosmetics and household goods, making them versatile assets for packaging operations of all scales.

The Advantages of Automatic Crown Capping Lines:

Automatic crown capping lines are another innovative solution that complements the efficiency of continuous cartoning machines in India. These lines automate the capping process, ensuring consistent and secure closure of bottles with crown caps. With features such as automatic cap feeding, precise capping torque control, and integrated quality inspection systems, automatic crown capping lines offer unmatched reliability and accuracy, minimizing errors and maximizing throughput in the production line.

Enhancing Efficiency with Continuous Cartoning Machines and Automatic Crown Capping Lines:

When combined, continuous cartoning machines and automatic crown capping lines create a seamless packaging process that enhances efficiency and productivity. By automating key aspects of the packaging line, these systems reduce the need for manual labor, minimize downtime, and increase throughput, allowing manufacturers to meet growing demand without sacrificing quality. Moreover, the integration of continuous cartoning machines and automatic crown capping lines ensures consistency and precision in the packaging process, resulting in superior product presentation and customer satisfaction.

Applications and Industries Benefiting from Integrated Packaging Solutions:

The versatility of continuous cartoning machines and automatic crown capping lines makes them ideal for a wide range of applications and industries in India. From pharmaceutical companies packaging medications and supplements to beverage manufacturers capping bottles of soft drinks and beer, these integrated packaging solutions cater to diverse needs with ease. Additionally, industries such as cosmetics, food, and household goods also benefit from the efficiency and reliability of continuous cartoning machines and automatic crown capping line, ensuring smooth and efficient packaging operations.

Future Trends and Innovations in Packaging Automation:

As technology continues to advance, the future of packaging automation holds even more promise for continuous cartoning machines and automatic crown capping lines. Innovations such as artificial intelligence, machine learning, and robotics are revolutionizing the packaging industry, enabling even greater levels of efficiency, flexibility, and customization. By staying abreast of these trends and embracing emerging technologies, manufacturers in India can future-proof their operations and maintain a competitive edge in an evolving market landscape.

0 notes

Text

Because their ancestors were frequent victims of sky-dwelling predators, modern chickens often fear open spaces. Farmers can make pastures more suitable for hens with trees and brush cover.

Do Happy Hens Chicken🐓 🐓 🐓 Make Better Eggs🥚🥚🥚?

Some Farmers are Betting that Consumers Would Pay More for Eggs If They Knew the Chickens That Made Them Were Healthy and Well-treated. The Hard Part is Figuring Out Where Your Eggs Come From.

— By Rachel Fobar | February 16, 2024 | Photographs By Michael George

On open-pasture farms around the country, egg-laying hens seem to have it made: an open door offers access into fresh air beyond.

But ultimately, “access to pasture” means just that—the barn door is open, says Kestrel Burcham, a policy director at the Cornucopia Institute, a nonprofit consumer watchdog group. “It doesn't necessarily mean they're actually using it.”

Many chickens fear open spaces, which leave them vulnerable to predators from above. Unless these open spaces are well-designed with trees, brush cover, or even solar panels, “pasture-raised” hens may never experience the pasture. Still, when it comes to chicken welfare, pasture-raised sets the highest standards, and the label indicates the hens can spend most of their day outside—if they want.

Thanks to tree cover, hens on this farm in Western Kentucky venture further from the coop.

To get the “free range” label, hens must have outdoor access for at least half of their lives, but like “pasture raised,” there are few requirements for what that outdoor space should look like—it could be concrete rather than grass, for example. And “cage-free” means only that hens aren’t in cages, but they may be kept indoors 24 hours a day. If a carton of eggs has none of these labels, the hens likely lived in battery cages, usually all-wire, communal enclosures in which each bird has 67 to 86 square inches.

“Egg cartons are the most confusing of any livestock products,” Burcham says. (Confused at the grocery store? Here’s how to decode your egg label.)

Take “all-natural.” That label can be applied to chickens that were raised in farms that use battery cages, so long as the product was “minimally processed” in a way that doesn’t “fundamentally alter the product,” according to the U.S. Department of Agriculture (USDA). Typically that means there are no colors or artificial ingredients added. The words “farm fresh” on an egg carton have no specific meaning at all.

Photographer Michael George has spent more than two years capturing images of U.S. farmers who are trying to raise happier, pasture-raised hens. It’s been an eye-opening experience “learning how regulations with good intentions can often outpace science,” he says. But it’s been encouraging to see how farmers “are putting in significant time and money to keep tweaking the system to find what is truly most healthy for the birds,” he says. “There’s also an earnest sense of care the farmers have for their flocks.”

What Does “Pasture-Raised” Mean?

The USDA, which jointly regulates egg production with the U.S. Food and Drug Administration, requires that “pasture-raised” animals “had continuous, free access to the out-of-doors for a significant portion of their lives.” The USDA doesn’t inspect facilities to ensure compliance, but farms are required to submit documents proving they provide pasture access.

“There are penalties if you make false labeling claims,” Burcham says. Consumers can file complaints about farms that misrepresent their outdoor access, and farms can be vulnerable to lawsuits. In 2021, PETA filed a class-action lawsuit on behalf of consumers around the country against egg company Vital Farms, alleging that the company’s marketing led them to believe the company’s practices were more humane than they are. Vital Farms says it has always been transparent about its practices and that it has been independently audited. The lawsuit is ongoing.

On this farm in Upstate New York, farmer Glenn Zimmerman and his two daughters walk amongst their flock.

Left: Unlike many store-bought eggs, those from pasture-raised hens usually have yolks that are firmer and more orange in color. “If you don't have a good environment for them, they won't produce like they should,” says farmer Vernon Martin. Right: Martin believes consumers are willing to pay more for fresher eggs that come from healthier—and happier—hens.

Separate from the USDA’s “pasture-raised” label, egg producers may choose to seek a “pasture-raised” label from Certified Humane, a voluntary animal welfare certification program run by the nonprofit Humane Farm Animal Care, which independently audits farms to ensure they meet specific welfare standards. Certified Humane’s “pasture-raised” label requires that farms have 2.5 acres for every thousand birds, and hens generally must be outdoors year-round.

Starting in 2025, the USDA also will require new welfare standards for livestock products labeled “organic,” which include minimum outdoor space criteria, requirements that the outdoor space be at least 75 percent soil, and preventative health care such as sufficient nutrition and parasite prevention programs. Current organic standards require organic feed, no “unnecessary” antibiotics, and living conditions that accommodate an animal’s natural behaviors.

‘Pretty Smart Birds’

Modern domestic chickens are thought to be descendants of the Southeast Asian red junglefowl, which were preyed upon by sky-dwelling predators like raptors. Fearing open spaces, these wild ancestors evolved to seek sheltered habitats, including shrubs and vegetation, forests, and mangroves.

Studies suggest that today’s domesticated chickens show the same preferences. In environments dense with sorghum plants or olive trees, birds were more likely to explore and use the pasture available to them, according to one study. The same was true for chickens in habitats with human-made cover, including netting and straw huts. Even indoors, studies have shown that chickens prefer to hang out under painted Plexiglas panels in their pens, where they were more likely to preen and rest.

A good pasture setting consists of space, grass and vegetation, and, inside the coop, nesting boxes rather than battery cages for hens to lay their eggs, says Lewis Bollard, director for Open Philanthropy's farm animal welfare program.

Handsome Brook Farms, a network of small, organic farms that sells eggs from pasture-raised hens to supermarkets like Safeway and Sprouts, requires that farms have at least 108 square feet per chicken, half of which is covered by vegetation, and that they provide enrichment for the animals. (Handsome Brook, too, was the defendant in a 2016 lawsuit alleging some of its “pasture raised” eggs didn’t meet criteria for the label. An out-of-court settlement in 2018 required third-party audits of the company’s egg purchases and farm practices for 18 months.)

Ultimately, “Access to Pasture” means just that—the barn door is open, says Kestrel Burcham, a policy director at the Cornucopia Institute, a nonprofit consumer watchdog group. “It doesn't necessarily mean they're actually using it.”

Allie Haggarty and Aubrey Thompson are flock supervisors with Handsome Brook Farms, a network of small, organic farms. They visit the farms every week to ensure the hens are healthy and farmers are supported.

On Vernon Martin's farm in New York, an agroforestry technician looks at a young black locust tree that was planted the previous fall. Since Martin has planted more than 400 trees around his chicken barn, he's noticed the chickens will venture out more often.

Vernon Martin, owner of Crystal Spring Farm in New York, sells eggs through Handsome Brook. When he first built his chicken barn, there were no trees within a hundred feet of it. To encourage his chickens to go outside, he planted about 350 saplings, and a year later, he replanted some 10-foot trees. Gradually, as the trees have grown, he’s noticed the chickens venturing out more and more. They’re “pretty smart birds,” he says.

At Red Hen Roost, a 73-acre corn farm in New York that also sells through Handsome Brook, some hens are waiting at the barn doors first thing in the morning, owner Luke Nolt says. On his pasture, hens can wander in the shade of pines, willows, flowering pears, and crabapple trees. Thousands of hens follow him as he performs his daily checks, he says, and one white hen was particularly friendly, sometimes hopping up on his shoulder as he walked.

Better Treatment, Better Business?

Higher welfare standards don’t only benefit the hens. They may also be beneficial for farm owners. In one 2008 study, giving hens access to cover panels boosted egg production by two percent and provided an estimated $3 million in revenue the participating poultry company.

In New York, Martin checks on his 15,000 birds twice a day, making sure the barns have proper ventilation and that it’s at a comfortable temperature, between 65 and 70 degrees.

When one of his flocks was sick, he noticed the yolks were pale and yellow rather than their usual orange color. “If you don't have a good environment for them, they won't produce like they should,” he says.

He believes consumers are willing to pay more for fresher eggs that come from healthier—and happier—hens.

That’s true, Bollard says, except for one problem: “A lot of consumers have no idea where their eggs come from.”

Usually, “consumers assume that the regular eggs on the shelf came from hens outside,” he says. And because pasture-raised eggs tend to cost more, customers might avoid them. Part of the problem is that supermarkets tend to mark up free-range and pasture-raised eggs more than conventional eggs, Bollard says.

On their farm in western Kentucky, Rhoda and Dave Zimmerman collect eggs and place them into pallets. As the eggs come down the conveyor belt, they pick out feathers, check for damaged shells, and do quality control.

Kentucky farmer Jeremy Schlabach, who sells his eggs through Handsome Brook, shows off one of his pasture-raised hens.

Glenn Zimmerman's daughter embraces two hens on their farm in upstate New York. “There’s an odd perception that birds are not as complex or sentient as mammals, which isn't accurate,” Burcham says. In reality, chickens are smart, often friendly animals.

Some grocery stores have recently made commitments to phase out caged eggs by 2025. Stores like Whole Foods, Sprouts, Costco, and Target are either entirely cage-free or well on their way. “When chickens behave naturally, they naturally lay great eggs,” Whole Foods says on its website.

The Animal Welfare Act, the federal law that regulates the treatment of animals in research, exhibition, and transport, doesn’t cover livestock, which means it’s often up to farmers and consumers to demand better welfare, Burcham says.

“There’s an odd perception that birds are not as complex or sentient as mammals, which isn't accurate,” Burcham says. “They're a very dynamic species and I wish people paid more attention to what makes birds special.”

#Chickens 🐓🐓🐓#Happy Chickens 🐓🐓🐓#Better & Health Eggs 🥚🥚🥚#Farmers#Consumers#Rachel Fobar#Pasture-Raised#Smart Birds 🐓🐓🐓#Better Treatment#Better Business#National Geographic

0 notes

Text

Innovations in Packaging Machinery and Gluing Solutions

Innovations in Packaging Machinery and Gluing Solutions

....................................................................................

Innovations in Packaging Machinery and Gluing Solutions

Gluing Machines

&

Order price below 5,000$

Top products in Packaging Machines

(01) Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine

Introduction

In the ever-evolving world of manufacturing and production, efficiency and precision are key. COLORDOWELL's Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine emerges as a reliable and innovative solution for a variety of industries. From food and beverage to medical and apparel, this gluing machine proves to be a versatile asset with its user-friendly design and top-notch features.

Easy to Operate

One of the standout features of the COLORDOWELL Gluing Machine is its user-friendly design. With a straightforward manual feeding system and easy operation, even those new to the manufacturing process can quickly adapt. This ensures a seamless integration into different production setups, making it an ideal choice for various businesses.

Diverse Applications

The gluing machine's adaptability is truly impressive. It caters to a wide range of industries including food, beverage, commodity, medical, chemical, machinery & hardware, apparel, and textiles. Whether you're working with cartons, cans, bottles, barrels, bags, film, pouches, or cases, this machine handles it all. This versatility makes it a valuable asset for businesses with diverse production needs.

Sturdy Construction

Crafted from high-quality stainless steel, the machine guarantees durability and longevity. The robust build ensures stability during operation, and its compact dimensions (1060390430mm) make it suitable for various workshop sizes. The 65 KG weight adds to the stability without compromising on portability.

Water-base Glue Technology

The use of water-based glue technology not only contributes to a more environmentally friendly operation but also ensures a secure and efficient bonding process. This feature aligns with modern sustainability standards, making it an appealing choice for eco-conscious businesses.

Semi-Automatic Operation

The semi-automatic grade and electric-driven type of the gluing machine strike a balance between manual control and automated precision. This ensures that operators have control over the process while benefiting from the efficiency and consistency provided by automation.

Conclusion

In the competitive landscape of manufacturing, COLORDOWELL's Stainless Steel Gluing Machine stands out as a reliable and versatile choice. Its ease of use, diverse applications, sturdy construction, and eco-friendly glue technology make it a game-changer for businesses looking to enhance their production processes. With a one-year warranty on core components, investing in this machine not only ensures immediate benefits but also long-term reliability. Upgrade your production capabilities with the COLORDOWELL Gluing Machine and experience a new level of efficiency in your operations.

Quick Details

Applicable Industries : Manufacturing Plant, Machinery Repair Shops, Restaurant, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 65 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type : Cartons, CANS, Bottles, Barrel, Bags, Film, Pouch, case

Packaging Material : Plastic, Paper, Metal, Glass

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1060*390*430mm

Product name : Gluing Machine

Glue type : Water-base Glue

Feeding way : Manul Feeding

Max. gluing width : 700mm

Buy Now & Read More

(02) High quality manual corrugated gluing machine paper gluing machine gluing machines

Introduction

In the dynamic landscape of manufacturing machinery, the Allraise OR-2000 emerges as a standout solution, particularly in the realm of gluing machines designed for food packaging. This semi-automatic gluing machine is a testament to efficiency, boasting high productivity and precision in its operations.

Versatility for Various Industries

The Allraise OR-2000 is a versatile gluing machine that finds applications across diverse industries, including hotels, garment shops, manufacturing plants, food and beverage factories, and more. Its adaptability makes it a valuable asset for businesses involved in packaging and production.

Robust Construction for Longevity

Crafted in Henan, China, the OR-2000 embodies robust construction, weighing 400 KG and guaranteeing durability for extended usage. The high-quality materials and meticulous engineering ensure that this machine stands the test of time in demanding industrial environments.

Intelligent Control with PLC Technology

At its core, the Allraise OR-2000 is equipped with a PLC (Programmable Logic Controller) system, providing intelligent control over its operations. This not only enhances the precision of gluing but also contributes to the overall efficiency of the packaging process.

Semi-Automatic for User-Friendly Operation

Designed with user convenience in mind, the OR-2000 operates on a semi-automatic mode. This ensures that operators have control and flexibility in managing the gluing process while benefiting from the efficiency and speed that automation brings.

Reliable Performance with 1-Year Warranty

Allraise stands behind the quality of the OR-2000 by offering a 1-year warranty on its core components. This commitment to customer satisfaction reflects the brand's confidence in the reliability and performance of their product.

Carefully Packaged for Safe Delivery

The packaging of the Allraise OR-2000 is a testament to the brand's dedication to customer satisfaction. Housed in a robust wooden case, the machine is securely protected during transit, ensuring that it reaches customers in pristine condition.

Conclusion

In conclusion, the Allraise OR-2000 stands out as a high-quality, semi-automatic gluing machine that excels in the precision packaging of food products. Its versatility, durability, intelligent control, and user-friendly operation make it a valuable investment for businesses seeking to enhance their productivity in the packaging process. Backed by Allraise's commitment to quality and a 1-year warranty, the OR-2000 is a reliable choice for those looking to elevate their packaging operations to new heights.

Quick Details

Applicable Industries : Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : PLC

Place of Origin : Henan, China

Weight : 400 KG

Warranty : 1 Year

Key Selling Points : High Productivity

Type : Gluing Machine

Application : Food

Packaging Type : case

Automatic Grade : Semi-automatic

Driven Type : Manual

Voltage : 220V

Brand Name : Allraise

Model : OR-2000

Packaging and delivery

Packaging Details,

1. Automatic PVC Card Foil Printer Hologram Signature Panel Printing Machine Holographic Images Hot Stamping Machine Price is packed in a strong wooden case.

2. As the customers' reasonable requires

Selling Units : Single item

Single package size : 127X122X183 cm

Single gross weight : 590.000 kg

Buy Now & Read More

(03) Fast Speed semi automatic Paper Box Cardboard Carton Cold Gluing Machines

Introduction

In the competitive world of printing, efficiency and precision are paramount, and the Befitter Cold Gluing Machine emerges as a true game-changer. This semi-automatic wonder is designed to revolutionize your printing process, offering a seamless experience with its cutting-edge features and user-friendly interface.

Unmatched Performance

The Befitter Cold Gluing Machine is engineered for excellence, making it an ideal choice for machinery repair shops, home use, retail, printing shops, and advertising companies alike. Its robust motor, a core component backed by a 1-year warranty, ensures durability and consistent performance. With a max gluing width of 380mm and an impressive max speed of 0-26m/min, this machine is built to handle a wide range of printing applications with precision and speed.

Easy to Operate

One of the key selling points of the Befitter Cold Gluing Machine is its user-friendly design. The machine's interface is intuitive and easy to operate, allowing users to seamlessly integrate it into their workflow. Whether you are a seasoned professional or a novice, the learning curve is minimal, ensuring that you can start maximizing your productivity from day one.

Versatile Application

The machine's versatility shines through in its application. Perfect for printing, it effortlessly handles various materials and projects with ease. The cold glue technology employed by the machine ensures a clean and efficient gluing process, catering to the diverse needs of the printing industry.

Compact and Durable

Weighing in at just 32kg and with dimensions of 600x410x360mm, the Befitter Cold Gluing Machine is compact and space-efficient. Its sturdy build and wooden packaging guarantee that it arrives in pristine condition, ready to be deployed for your printing requirements. The 1-year warranty provides peace of mind, showcasing the manufacturer's confidence in the machine's longevity.

Enhanced Support and Technical Assistance

Post-purchase, Befitter stands by its product with video technical support during the after-warranty period. This commitment ensures that you have continuous access to assistance and guidance, further solidifying the trust in your investment.

Conclusion

In the world of printing, the Befitter Cold Gluing Machine stands out as a reliable, efficient, and easy-to-operate solution. Its impressive features, coupled with the backing of a 1-year warranty and ongoing technical support, make it a smart investment for businesses looking to elevate their printing processes. Upgrade your operations with the Befitter Cold Gluing Machine and experience a new era of efficiency in the world of printing.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : 1pc/ wooden case

Selling Units : Single item

Single package size : 60X41X36 cm

Single gross weight : 40.000 kg

Buy Now & Read More

(04) Rjs Sheet Glue Machine Paper Gluing Machine with heating

Introduction

I recently purchased the Rjs Sheet Glue Machine from COLORDOWELL for my manufacturing plant, and I am extremely satisfied with its performance. This semi-automatic gluing machine has proven to be a valuable addition to our production process, and here's why:

Versatile Application

The Rjs Sheet Glue Machine caters to a wide range of industries, making it a versatile choice for manufacturing plants, machinery repair shops, restaurants, printing shops, advertising companies, and more. Its adaptability across various sectors, including food, beverage, commodity, medical, chemical, machinery and hardware, apparel, and textiles, makes it a worthwhile investment for businesses with diverse needs.

Ease of Operation

One of the key selling points of this machine is its user-friendly interface. The easy-to-operate design simplifies the gluing process, ensuring that our team can efficiently use it without extensive training. The manual feeding feature adds an extra layer of control, allowing for precise application of glue on different materials.

Sturdy Construction

The build quality of the Rjs Sheet Glue Machine is impressive. Crafted with durability in mind, the machine boasts a robust motor as its core component, ensuring reliable and consistent performance. The machine's solid structure, weighing 65 KG, is a testament to its durability, providing stability during operation.

Adaptable Glue Type

The water-based glue used by the machine is a thoughtful choice, considering environmental concerns and safety standards. This feature aligns with our commitment to sustainable practices, making the Rjs Sheet Glue Machine an eco-friendly option.

Size and Dimensions

The compact size of the machine, with dimensions of 1060390430mm, makes it suitable for various production environments. It efficiently fits into our workspace without occupying excessive floor space.

Packaging and Delivery

The machine arrived in perfect condition, securely packaged in a wooden case. COLORDOWELL ensures that each unit is well-protected during transit, and the packaging details, including dimensions (105X52X90 cm) and gross weight (120.000 kg), reflect their commitment to delivering products in top-notch condition.

Warranty and Support

The 1-year warranty on core components, especially the motor, provides peace of mind. While we haven't encountered any issues, knowing that we have support in case of unexpected situations adds an extra layer of confidence in our purchase.

Conclusion

In conclusion, the Rjs Sheet Glue Machine from COLORDOWELL has exceeded our expectations. Its versatility, user-friendly design, and durability make it an excellent choice for businesses looking for a reliable and efficient gluing solution. I highly recommend this machine for anyone in need of a semi-automatic gluing machine with exceptional performance.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : Wooden case

Selling Units : Single item

Single package size : 105X52X90 cm

Single gross weight : 120.000 kg

Buy Now & Read More

(05) A4 A3 automatic rubber machine fully automatic hot glue book Perfect glue binder book Binding machine

Introduction

In the fast-paced world of manufacturing and printing, efficiency is key. COLORDOWELL, a leading name in machinery innovation, has once again raised the bar with their A4 A3 Automatic Rubber Machine – a fully automatic hot glue book binder that promises to revolutionize bookbinding processes. Let's delve into the details of this impressive piece of equipment.

Unmatched Performance

Boasting a weight of 130 KG, the COLORDOWELL hot glue book binder is a robust machine designed for seamless operation. Its 1 Year warranty on core components, including the engine and bearing, reflects the manufacturer's confidence in the product's durability. The binding width of 320mm, binding thickness of 50mm, and a remarkable binding speed of 200 books per hour make it a standout choice for manufacturing plants, printing shops, and advertising companies.

Innovative Technology

The Automatic Grade feature ensures a hassle-free operation, making it incredibly easy to operate. With an electric-driven type and a voltage requirement of 220V, this machine aligns with modern technological standards, ensuring a smooth and reliable performance in diverse applications, from machinery and hardware to apparel.

Space-Efficient Design

Measuring at 1090mm480mm950mm, the compact design of this machine makes it ideal for various working environments. The manufacturer, COLORDOWELL, has crafted a perfect balance between functionality and space efficiency, ensuring that it seamlessly integrates into any workspace.

Quality Packaging

The attention to detail doesn't stop at the machine itself. COLORDOWELL understands the importance of secure transportation. The packaging, whether it's a carton case or wooden case, is designed to withstand the rigors of shipping, reflecting their commitment to delivering a pristine product to your doorstep.

Global Presence

With a showroom presence in Kazakhstan and Uzbekistan, COLORDOWELL has made its mark on the international stage. This signifies their commitment to providing cutting-edge machinery solutions to a global clientele.

Conclusion

In conclusion, the COLORDOWELL A4 A3 Automatic Rubber Machine is more than just a hot glue book binder; it's a testament to the future of efficient bookbinding. Whether you are running a manufacturing plant, a printing shop, or an advertising company, this machine promises to elevate your productivity to new heights. With its impressive specifications, innovative technology, and global presence, it's no surprise that COLORDOWELL stands at the forefront of the industry. Choose efficiency, choose innovation – choose COLORDOWELL.

Quick Details

Applicable Industries : Manufacturing Plant, Printing Shops, Advertising Company

Showroom Location : Kazakhstan, Uzbekistan

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Engine, Bearing

Place of Origin : Zhejiang, China

Weight : 130 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Machinery & Hardware, APPAREL

Packaging Type : Cartons

Packaging Material : Paper

Automatic Grade : Automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1090mm*480mm*950mm

Binding width : 320mm

Binding thickness : 50mm

Binding speed : 200 books/hour

Packaging and delivery

Packaging Details : Carton case or wooden case

Selling Units : Single item

Single package size : 115X61X103 cm

Single gross weight : 160.000 kg

Buy Now & Read More

.....................................................................................

Smeartra Amb

(Affiliated Marketing Business)

Affiliated marketer

This my blogs

Read MORE

...........................................................................................................

{Although the majority of the products are in stock, we were unable to include all of them on the website.}

Click here link and read more or buy more productsResource : Packaging Machines Buy Now & Read More

0 notes

Text

Proofreading software for pharmacy

What is Proofreading?

Proofreading, at its core, is the art of meticulously examining content to catch errors, ensuring it's polished and error-free. It's like being the vigilant guardian of written documents, preventing embarrassing typos, and ensuring clarity.

The role of pharmaceutical artwork proofreading is pivotal in maintaining the integrity of pharmaceutical products. Whether through the meticulous eyes of a human proofreader or the efficiency of automated systems, the goal remains the same precision that safeguards both regulatory compliance and patient well-being. As we navigate the future, the synergy of human and machine capabilities promises a new era of accuracy in pharma artwork proofreading.

1. Pre-press Proofreading: Pre-press proofreading is a crucial step in the production of printed materials in the pharmaceutical industry. It involves a thorough review of content, graphics, and layout before mass production to ensure accuracy and prevent errors.

2. FDA Guidelines: The FDA, or U.S. Food and Drug Administration, establishes guidelines and standards for the pharmaceutical industry. Companies must adhere to these guidelines to ensure the safety, efficacy, and quality of drugs and medical products throughout their development and manufacturing processes.

3. Incoming Material Inspection: Incoming material inspection is a quality control process where raw materials or components for pharmaceutical manufacturing are carefully examined upon arrival. This step ensures that materials meet specified quality standards and are suitable for use in the production process, preventing the use of substandard or contaminated materials.

4. Manufacturing Practices in Pharma: Good Manufacturing Practices (GMP) are regulations and standards that ensure consistent production and quality of pharmaceutical products. Adhering to GMP is essential for manufacturers to meet regulatory requirements and produce safe and effective drugs. GMP covers aspects such as facility cleanliness, equipment calibration, process validation, and personnel training.

What is Manual Proofreading?

In the not-so-distant past, proofreading was a manual affair. Manual proofreading involved eagle-eyed individuals poring over documents, hunting for elusive mistakes. It was a labour-intensive process, akin to searching for a needle in a haystack.

Manual proofreading has been the backbone of quality assurance in the pharmaceutical industry. However, it comes with its own set of challenges, including time-consuming processes and resource-intensive workflows.

What is Automated Proofreading?

Fast forward to today, and we have the marvel of the automatic proofreader or electronic proofreader. Imagine a digital assistant with a magnifying glass scanning documents at lightning speed. The role of automation in pharma artwork proofreading has revolutionised the game, bringing efficiency and accuracy to new heights. Automation has emerged as a game-changer in pharma artwork proofreading.

Automatic proofreader refers to the use of technology, such as software and algorithms, to identify and correct errors in written content. This method relies on computer programmes that are designed to analyse and do global vision print inspection.

Automation introduces speed into the pharma artwork proofreading process, enabling the swift analysis of large volumes of artwork. An automated proofreading machine will ensure that every piece of artwork is evaluated with the same level of scrutiny, eliminating the variability inherent in manual processes.

ipvProofCheck is a cutting-edge solution that revolutionises the identification process through pixel-to-pixel comparison for carton, leaflet, and label analysis. The system sorts deviations using advanced algorithms that give an unmatched level of accuracy and make it clear whether a deviation is accepted, not accepted, or still needs to be handled. This system stands out as a 21CFR Part 11-compliant solution, adhering to stringent regulatory standards.

Embedded within ipvProofCheck is an in-built algorithm designed for efficient proofreading of documents. It is capable of identifying nuanced issues such as character shifts, colour changes, and the absence or presence of characters. The system's pixel-to-pixel comparison methodology enables it to capture even minute discrepancies.

Similarly, ipvPSA ensures quality control in labs. It is microscopic particle size analyser with a wide range of benefits.

Stock Keeping Unit (SKU)

Stock-keeping Keeping Unit refers to a unique identifier assigned to each distinct product or variant in inventory management. In the pharmaceutical industry, SKUs are assigned to different drug formulations, strengths, and packaging configurations. Automation aids in SKU management during artwork proofreading by ensuring that the correct SKU information is accurately reflected in the artwork. This helps prevent packaging errors and ensures that the right product information is associated with the corresponding SKU. Automated systems can cross-verify SKU details, reducing the likelihood of discrepancies.

AstraZeneca

AstraZeneca is a multinational pharmaceutical company known for developing and manufacturing a wide range of pharmaceutical products, including vaccines such as those for COVID-19. In the context of AstraZeneca and pharmaceutical artwork proofreading, automation can enhance efficiency and accuracy.

Automated proofreading tools can assist in reviewing and validating the content of packaging materials, ensuring that they align with AstraZeneca's branding guidelines, regulatory requirements, and specific product information.

Good Manufacturing Practices (GMP)

Good Manufacturing Practices are essential in the pharmaceutical industry to ensure the quality, safety, and efficacy of medicinal products. GMP guidelines provide a framework for manufacturing processes, including artwork creation and proofreading. Automation can play a crucial role in adhering to GMP standards during artwork proofreading.

Automated systems can help in maintaining consistency, accuracy, and compliance with regulatory requirements. They can streamline the proofreading process, reducing the risk of errors and ensuring that the final artwork aligns with GMP standards.

Manual vs. Automated Proofreading

Let's pit the old against the new in a friendly face-off: manual vs. automated proofreading. While manual proofreading relies on human scrutiny and intuition, automated proofreading is all about algorithms and artificial intelligence. It's not a battle of superiority but a collaboration for perfection.

Manual Proofreading

Manual proofreading has been the stalwart guardian of written content for generations. It involves the meticulous scrutiny of documents by human eyes and intellect. The process is akin to a skilled artisan crafting a masterpiece, with each word and punctuation mark receiving personal attention.

Advantages of Manual Proofreading

1. Personalised Attention: The human touch adds a level of understanding and nuance that machines may struggle to grasp. Manual proofreaders can interpret context, ensuring that the intended meaning is preserved.

2. Contextual Awareness: Humans bring a wealth of contextual understanding to the table. This is particularly crucial in pharmaceutical artwork, where precision and clarity are paramount.

3. Emotional Intelligence: Understanding the emotion behind the words is uniquely human. Manual proofreading can discern the tone and intent, ensuring that the content resonates appropriately.

Challenges of Manual Proofreading

1. Time-Consuming: Manual proofreading is a time-intensive process. In industries like pharma, where time is often of the essence, this can be a limiting factor.

2. Prone to Human Error: Despite the best efforts, humans are fallible. Fatigue or distractions can lead to oversights, and the margin for error exists.

Automated Proofreading

Enter the era of automated proofreading, where algorithms and artificial intelligence take centre stage. Automation brings speed, efficiency, and a different kind of accuracy to the proofreading process.

Advantages of Automated Proofreading

1. Speed and Efficiency: Automation can scan through large volumes of content at a speed that humans can't match. This is a significant advantage in industries like pharma, where time is often critical.

2. Consistency: Machines are consistent in their approach. They don't get tired, ensuring that every instance of proofreading is approached with the same level of scrutiny.

3. Scalability: Automated systems can handle vast amounts of data simultaneously, making them scalable for the demands of the pharmaceutical industry.

Challenges of Automated Proofreading

1. Lack of Contextual Understanding: While algorithms excel in pattern recognition, they might struggle with the nuanced understanding of context that a human brain possesses.

2. Inability to Detect Certain Errors: Some errors, especially those related to context or subtle language nuances, may elude automated systems.

#proofreading software#software for pharma proofreading#proofreading software for pharmacy#proofreading software for pharma industry#proofreading software for pharma#proofreading software for pharmaceutical industry#proofreading software for pharmaceutical

0 notes

Text

Morayfield Termite Control

Morayfield’s warm climate attracts pests that can cause serious damage to your property. These include Termites, Mosquitoes and Flies.

Many older homes in Morayfield are made of timber, and a termite attack can have disastrous results. Termite inspections and treatment are very important. The best place to start is with Palace Pest Control, they know where to look for the little guys! To know more about Termite Control Morayfield, visit the Bug Out Pest Solutions website or call 0426263320.

Termites are a very destructive wood-eating pest that can cause significant damage to your home. They enter homes through soil and eat the structural timbers within them. Termites can be prevented by maintaining a proper moisture level in soil around the house, keeping firewood away from the house, and installing concrete foundation blocks and retaining walls.

During the spring, swarmers (winged reproductives) fly out of mature termite colonies and look for a new habitat. They are usually found in rotting or damp wood components of your home, tree stumps and root sections, fence posts, and firewood piles. Termite species differ in size, but all termites have a caste system that includes workers, soldiers, and nymphs (immature reproductives). Queens and kings are the sexually mature members of the colony.

Mosquitoes are blood-feeding insects that cause a lot of discomfort with their itchy bites. They also spread diseases and viruses in humans and animals.

The best control measures for mosquitoes are source reduction and the use of insect surface sprays. Ensure that fly screens on doors and windows are in place and regularly wash and clean them. Wear light coloured clothes and use an insect repellent that contains picaridin or diethyltoulamide (DEET).

Remove all sources of water where mosquitoes can breed. Regularly empty and scrub, overturn or cover tyres, wheelbarrows, trailers, garden containers, bird baths, flower pot saucers, pet drinking bowls, vases and children’s toys.

Flies are common pests in urban and rural areas. These insects are often attracted to garbage receptacles, compost piles, excrement and rotting organic materials. They also breed in poultry ranches and swine facilities.

Female flies can lay hundreds of eggs, and larvae can hatch within four days. They grow up to 12 mm in just a few days, and are then ready to pupate.

To control flies, all trash containers should have tight-fitting lids and be kept dry. Similarly, manure should be buried under inorganic wastes to deteriorate its capacity for fly breeding, and all poultry facilities should be fully enclosed. Pesticide bait formulations may be used to reduce fly populations.

Silverfish (Lepisma saccharinum) are insects that feed on starch, cellulose and certain glues in book bindings and wallpaper. They are easily identified by the tiny skin casts that they leave behind on items as they move across them. They are often introduced into buildings in cardboard cartons of books and papers. They breed in wall voids, in subflooring and cellars and even in shake roofs.

To control them, vacuum carpets and floors regularly, keep food in one part of the house and use dehumidifiers in humid areas. You can also try running sticky traps in areas they frequent like basements and cupboards or dusts that are toxic to them such as boric acid, diatomaceous earth and Japanese cedar essential oil.

In early summer, scarab beetles lay eggs that hatch into grubs that munch on grass roots. They can cause serious damage in yards, gardens and sporting ovals. The grubs grow until mid- to late fall and then move deeper into the soil where they spend the winter. The next spring, they emerge as adult beetles and the cycle starts again.

Preventive products containing imidacloprid, thiamethoxam or clothianidin will reduce 75-100% of grubs when applied in June or July and watered-in immediately. Curative products containing carbaryl, trichlorfon or zeta-cypermethrin kill grubs on contact and should be used during the late summer or fall. Your pest control technician will recommend the best option for your situation.

Both rats and mice are rodents that can cause structural damage to your home. They are nocturnal and feed on garbage, seeds and other plant materials. They can also gnaw on wires and wood and are known fire hazards. They can enter the home through gaps and openings. A mouse can squirm through a hole that’s one-quarter inch in size, while a rat requires a larger gap.

To prevent a rat infestation, contact your local pest control company to remove the rodents from your property. The company’s entomologist can help you identify the rodents, as well as recommend other preventative measures. The staff can also monitor and treat sanitary sewers for rat activity in the area. To know more about Termite Control Morayfield, visit the Bug Out Pest Solutions website or call 0426263320.

#pest control services#pest control#pest control brisbane#termite control brisbane#cockroach control solutions#termite control solutions#termite inspection#cockroach control solutions in brisbane#cockroach termination services#bug control services#pest control Kippa Ring#pest control morayfield#Termite control Morayfield#Termite inspection Morayfield

0 notes

Text

Edible Oil Bottle Filling Line Machine in Bahrain

Edible Oil Bottle Filling Line Machine in Bahrain

Shiv Shakti Machtech is a well-known designer and manufacturer of turnkey packaging solutions. Shiv Shakti Machtech has gained a thorough understanding of liquid filling techniques through continual client involvement.

"An Edible Oil Bottle Filling Line, a specialized production system, is designed for efficiently and accurately filling bottles with edible oil. This automated process ensures precise measurements, cleanliness, and a high level of productivity in the packaging of edible oils.

How an Edible Oil Bottle Filling Line Works

Bottle Feeding: Empty bottles are fed onto the conveyor system and moved to the filling station.

Filling: At the filling station, the filling machine dispenses the precise amount of edible oil into each bottle. This is typically done through a nozzle that enters the bottle's opening.

Capping: After filling, caps or closures are applied to the bottles, ensuring a secure seal.

Labeling: At the labeling machine, bottles receive labels that provide essential product information and branding.

Quality Control: At quality control stations, sensors and cameras inspect filled bottles for proper filling levels and seal integrity.

Packaging: The packaging process involves placing filled and labeled bottles into cartons or cases according to the desired packaging configuration.

Final Inspection: The packaged products undergo a final inspection to ensure they meet quality standards.

We Provide Edible Oil Bottle Filling Line Machine in Bahrain Including Manama, Al Qadam, Hamad Town, Jidhafs, Al Hidd, Riffa, Mahazza, Murqoban, Samaheej.